Page 1

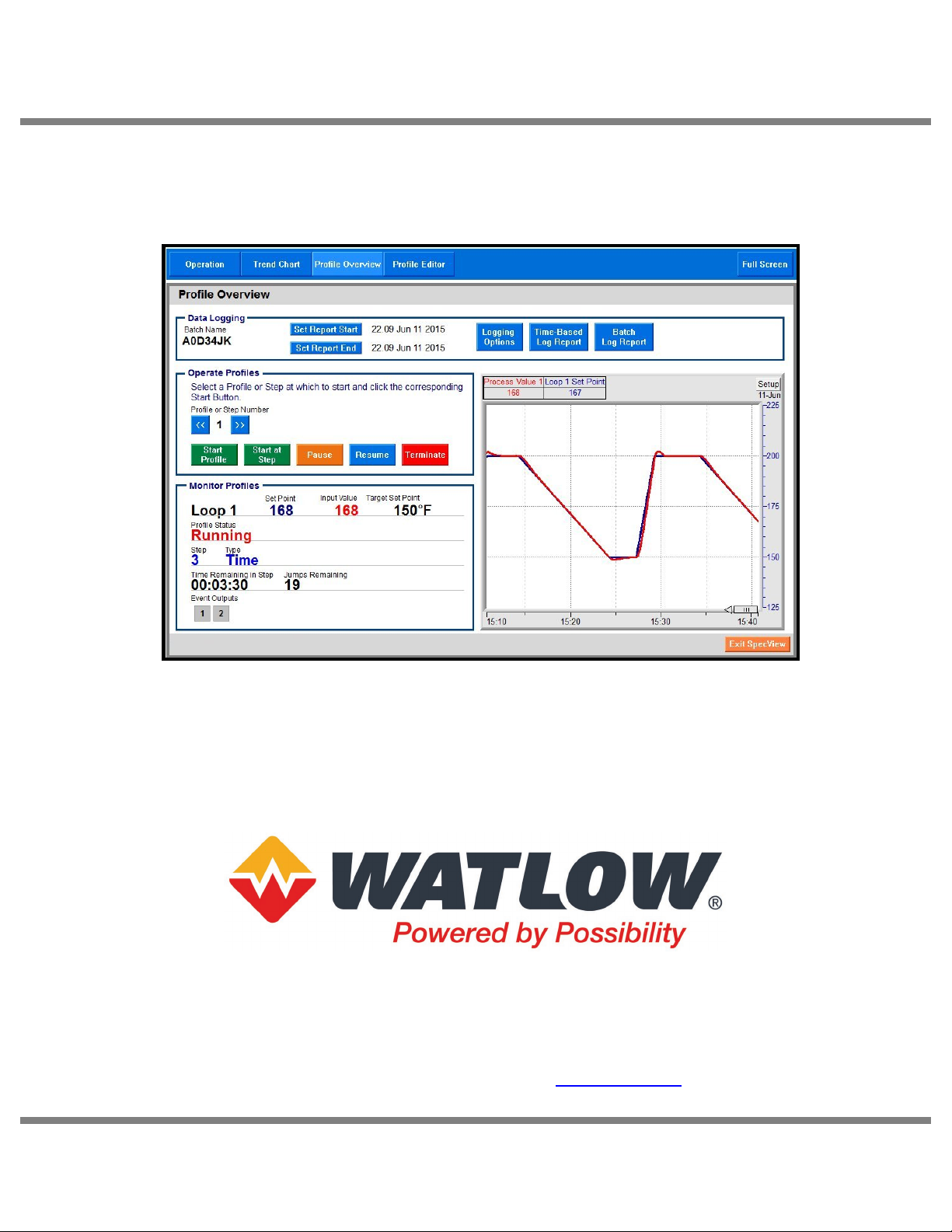

Using Watlow® Products with SpecView

Addendum to SpecView Manual

SCADA Software

Phone: +1 (507) 454-5300, Fax: +1 (507) 452-4507 http://www.watlow.com

1241 Bundy Boulevard, Winona, Minnesota USA 55987

Document 10-38238 Rev. A ©2019 Watlow Electric Manufacturing, Inc. All rights reserved.

July 2019

Page 2

TC

Table of Contents

Chapter 1: Introduction .................................................................................. 3

Additional Resources ................................................................................. 3

Chapter 2: About Setting up Communications ............................................ 3

Instrument Templates and Protocols .......................................................... 3

Automatic and Manual Configuration ......................................................... 4

Naming Instruments ................................................................................... 5

Saving Settings in Non-Volatile Memory .................................................... 5

Using F4T Controllers and D4T Data Loggers ........................................... 5

Using EZ-ZONE Controllers with Standard Bus ......................................... 6

Using EZ-ZONE Controllers with Modbus® ................................................ 6

Chapter 3: Setup Procedures ...................................................................... 11

Automatically Detect an F4T or D4T ........................................................ 11

Automatically Detect a New Standard Bus, 485 or 232 Network .............. 14

Manually Set up or Modify an EZ-ZONE Standard Bus Network ............. 17

Manually Set up or Modify a Modbus® RTU, 485 or 232 Network ............ 20

Manually Set up or Modify a Modbus® TCP Network ............................... 24

Adjust the Displayed Decimals ................................................................. 27

Chapter 4: Instrument Reference ................................................................ 29

F4T and D4T Instruments ........................................................................ 29

EZ-ZONE Standard Bus Instruments ....................................................... 30

EZ-ZONE Standard Bus Instrument Views .............................................. 39

EZ-ZONE Modbus® Instruments .............................................................. 43

Watlow Assembly Instruments ................................................................. 46

Generic Modbus Instruments ................................................................... 46

Part Number: 2060-2136 (replaces 0600-0056-0015)

WATLOW®, ASPYRE®, EZ-ZONE® and INTUITION® are registered trademarks of Watlow Electric Manufacturing,

Incorporated

Modbus® is a registered trademark of Schneider Automation, Incorporated.

Using Watlow Products with SpecView 2 Addendum to SpecView Manual

Page 3

Chapter 1: Introduction

2

1

SpecView is a powerful and easy-to-use Supervisory Control and Data Acquisition (SCADA) software

package. The purpose of this addendum is to quickly get you up and running using SpecView with

Watlow controllers. Chapter 2 provides a brief explanation of concepts that may not be familiar to first

time users of SpecView. Basic familiarity with these concepts is assumed in Chapter 3 which provides

procedures for getting Watlow controllers communicating with SpecView. Chapter 4 provides detailed

information regarding addressing and describes features specific to Watlow controllers.

This addendum supports SpecView version 3.

Additional Resources

In addition to this addendum the following resources are available for learning about SpecView and

other products available from Watlow:

• SpecView User Manual—available on the SpecView installation disk and at Watlow.com

navigate to Resources and Support, Technical Library: User Manuals and search on Keyword:

SpecView.

• SpecView Secrets Video Tutorials—available at Watlow.com navigate to Resources and Support,

Technical Library: Tutorials and Training and search on Keyword: SpecView.

• SpecView Frequently Asked Questions—available at Watlow.com navigate to Resources and

Support, Technical Library: Tutorials and Training and search on Keyword: SpecView.

• SpecView Software Download—the latest version of SpecView is always available at

Watlow.com navigate to Resources and Support, Technical Library: Software and Demos and

search on Keyword: SpecView.

• SpecView Software Field Upgrade Order Form—guides you through the process of adding

features to a copy of SpecView you already own. Get the form at Watlow.com navigate to

Resources and Support, Technical Library: Software and Demos and search on Keyword:

SpecView.

Chapter 2: About Setting up Communications

The following sections provide information to help you understand how to set up communications

between SpecView and Watlow controllers.

Instrument Templates and Protocols

SpecView includes support for hundreds of different devices. The protocol drivers and instrument

templates included with SpecView tell it how to communicate with specific devices. You will need to

choose the appropriate templates whenever you want to automatically or manually set up

communications between SpecView and a device.

Using Watlow Products with SpecView 3 Addendum to SpecView Manual

Page 4

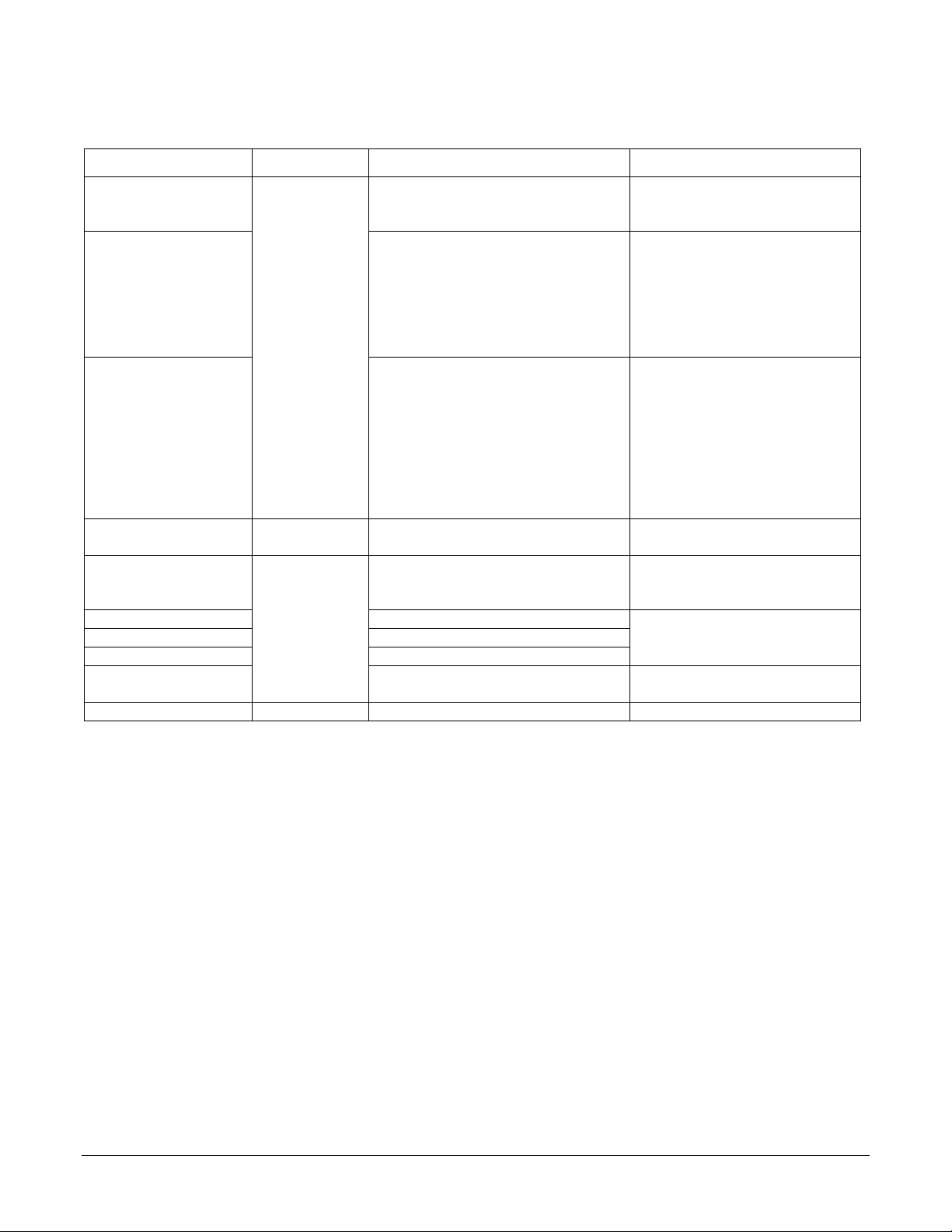

There are many instrument templates grouped by communication protocol and product family that

Support for F4T and D4T

outputs in the flex modules

Support for basic operation

profiles.

Supports reads and writes to

Instruments on page 46.

Watlow EZ-ZONE

Standard Bus

EZ-ZONE PM, EZ-ZONE RM,

EZ-ZONE ST

Allows saving profiles as

Programmer ordering option.

Anafaze 16 Loop

16CLS, CLS216, 16MLS, MLS316

Anafaze 32 Loop

32MLS, MLS332

Anafaze 8 Loop

4CLS, CLS204, 8CLS, CLS208

CLS204, CLS208, CLS216,

MLS316, MLS332

Ramp/Soak Profile

programming and operation

Anafaze/AB

ANAFAZE

32MLS

Proprietary Anafaze protocol

support Watlow products. The table below lists these template groups, protocols and the Watlow models

supported by each.

Template Group Protocol(s) Supported Watlow Models Notes

Watlow F4T & D4T

Watlow Modbus

Watlow Assembly

Watlow F4

Programmer

®

Modbus

Modbus

Standard Bus

Modbus

RTU

®

TCP

®

RTU

F4T with INTUITION

D4T with INTUITION®

®

ASPYRE

EZ-ZONE

EZ-ZONE ST, SERIES 96, 97, SD

MICRODIN, POWER SERIES,

986, 987, 988, 989

SERIES F4 Ramping

F4T with INTUITION

D4T with INTUITION

EZ-ZONE PM, EZ-ZONE RM

SERIES F4 Ramping

Power Controllers

®

PM, EZ-ZONE RM,

®

functions and inputs and

parameters in EZ-ZONE

products. See

Modbus

. Limited support for

43

programming SERIES F4

16 or 32 contiguous floatingpoint values. Intended to

minimize update time for

measurements when used

with the user-configurable

communication assemblies.

Watlow Assembly

See

Recommended for EZ-ZONE.

recipes. Requires Series F4

Standard firmware option only

EZ-ZONE

®

Instruments on page

Anafaze Ramp/Soak

Using Instruments from More than one Group or Protocol

The templates in the groups listed above that support Modbus® RTU on serial communications ports are

compatible with each other. Similarly the templates that support Modbus® TCP used over Ethernet are

compatible with each other. SpecView allows protocol-compatible templates to be used on the same

port, but you will need to help SpecView by instructing it when to do so. When there are controllers

connected to the same port that require instrument templates from different groups, you will scan once

for each of those groups to automatically detect the various devices.

If your configuration requires communicating with controllers supported by different protocols via serial

communications ports, each protocol must have its own network connected to SpecView via a separate

communications port. Support for multiple communication ports is an ordering option for SpecView,

and is field upgradeable.

Automatic and Manual Configuration

SpecView can automatically detect and set up communications with controllers. However, in some cases

it may be necessary to manually configure SpecView. This method is particularly useful if you want to

create screens and configure SpecView prior to receiving your controllers. Projects that were created

automatically can be updated by testing the communications network for new controllers. It is also

Using Watlow Products with SpecView 4 Addendum to SpecView Manual

Page 5

possible to manually add or remove controllers from any configuration whether it was created

automatically or manually. This addendum contains procedures for automatically and manually

configuring communications for the various networking options supporting Watlow controllers.

SpecView can automatically detect F4T and D4T data loggers controllers using Modbus® TCP or

Modbus® RTU and EZ-ZONE controllers using the Standard Bus protocol. When using Modbus® with

EZ-ZONE controllers create the configuration manually.

Naming Instruments

It is useful to name instruments such that you can easily relate what you see on the screen in SpecView

to your equipment and processes. You might want to use a name that:

• Indicates the controller’s function in the process

• Indicates the controller’s location in the panel

• Includes network information such as port and address

When you create a project or add instruments to one by automatically detecting controllers, SpecView

prompts you to name the instruments as it adds them. You must name any instruments that you add

manually. You can change an instrument’s name whenever you like. However, changing an instrument’s

name makes logged data associated with the old name inaccessible going forward; it is best to name

instruments up front.

Saving Settings in Non-Volatile Memory

Some Watlow controllers protect their non-volatile memory from being worn out prematurely due to

excessive use that may occur when communicating with devices such as a PLC that send the same

settings to a controller many times a second. In these controllers, the settings received via

communications can be held in volatile memory that is cleared when the controller is turned off. Since

SpecView will typically send parameter settings to a controller only when you edit a parameter on the

screen, for your convenience you can set the controller to routinely save the parameter settings that

come through communications in non-volatile memory. That way the values you set are saved even

when the controller is powered down. Consult the controller manual for the appropriate parameter,

typically called, “Non-Volatile Save”.

Using F4T Controllers and D4T Data Loggers

The instruments in the Watlow F4T & D4T group support standard and optional features in in F4Ts and

D4Ts as well as the flex modules those devices are set to expect. For details see F4T Instruments on

page 29.

Automatic Detection of F4Ts and D4Ts

When automatically detecting a network with the Watlow F4T & D4T group, SpecView reads the part

number of the F4T or D4T and adds the appropriate instruments for features including control loops,

cascade loops, profiles and alarms. Additionally, an instrument is added for each flex module the F4T or

D4T is configured to expect.

Additional Instruments Available with the Watlow F4T Driver

Because F4Ts and D3Ts offer many additional functions such as math, logic, timers and counters that

may not all be used in the application, other instruments may be manually added to a configuration to

gain access to the values and settings associated with these features.

Using Watlow Products with SpecView 5 Addendum to SpecView Manual

Page 6

Using EZ-ZONE Controllers with Standard Bus

When automatically detecting a Standard Bus network with the Watlow EZ-ZONE Standard Bus driver,

SpecView reads each device’s part number and adds the appropriate instruments. For the details see EZ-

ZONE Standard Bus Instruments on page 30.

Note! Run the 32-bit version of SpecView for compatibility with the Watlow EZ-ZONE Standard Bus

driver. This driver is not supported by the 64-bit version of SpecView.

Using EZ-ZONE Controllers with Modbus®

To configure SpecView to communicate with EZ-ZONE products via Modbus® you will select and add

appropriate instruments manually. For each instrument you must determine the correct address string.

The address string depends on the type of network and its configuration. You will add as many copies of

the instrument as needed to allow access to the desired controller features. For example, to access all

four analog inputs in an EZ-ZONE RM Control Module, you will add four EZ-ZONE Analog Input

instruments.

SpecView Instruments Supporting EZ-ZONE Devices via Modbus®

The tables in this section list the instruments that may be used with each EZ-ZONE product. Additional

tables in the EZ-ZONE Modbus® Instruments section on page 43 list each parameter included in these

instruments. Review the supported parameters carefully and determine whether they allow you to

develop a project that meets your requirements. Standard Bus communications provides access to many

more EZ-ZONE controller parameters.

Simplified Address Strings in SpecView Version 3

In previous versions of SpecView the “address string” included the controller address, number of

decimal places to display and the register offset. As of version 3 these are now entered in separate fields

in SpecView which makes setting up instruments more straight forward.

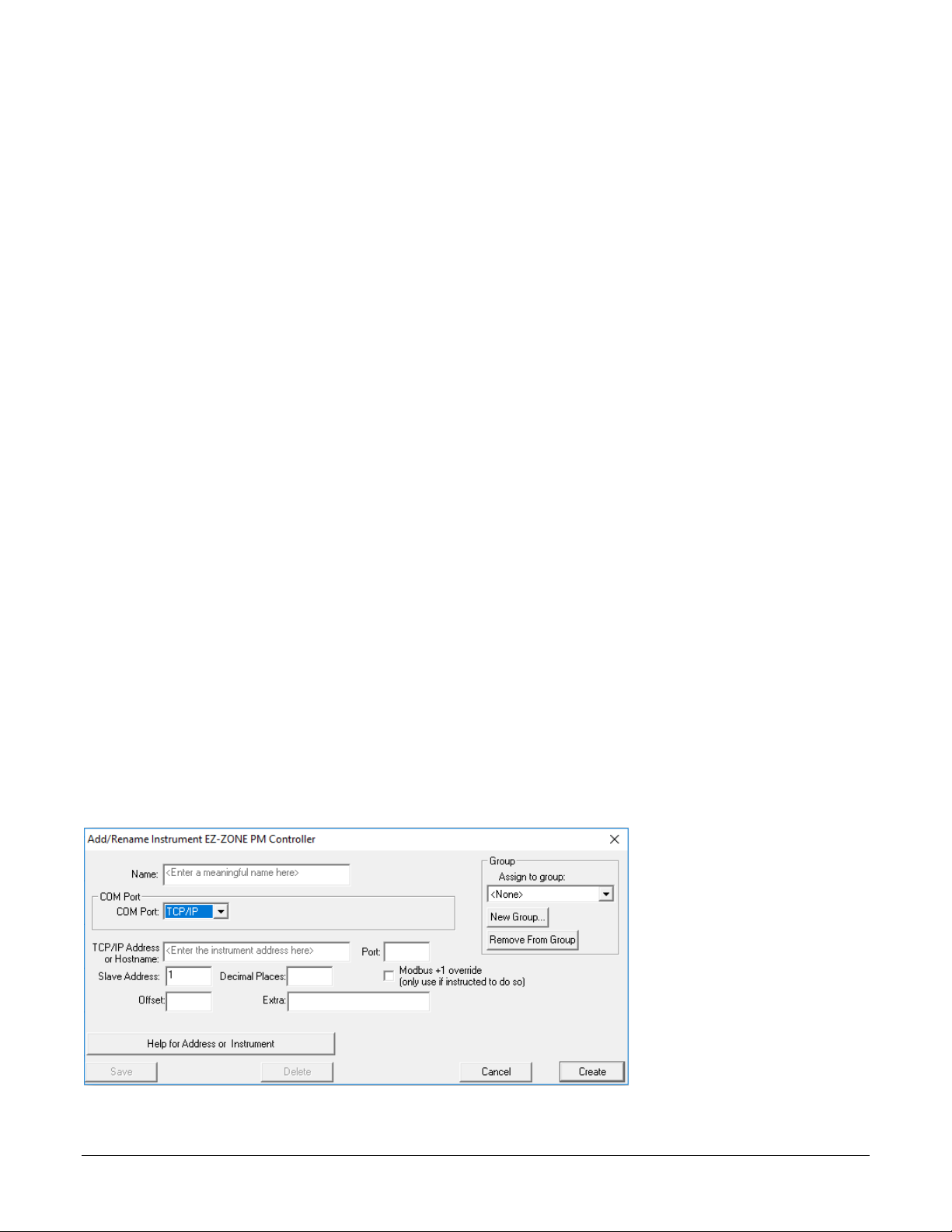

Controller or Gateway Slave Address

For Modbus® TCP each controller or gateway is identified by its TCP/IP Address. EZ-ZONE controllers

and gateways will respond to any valid setting (1 to 247) for the Slave Address. It is not necessary to set

each device to a unique Modbus® address, but each must have a unique and appropriate IP address. See

the figure below.

Using Watlow Products with SpecView 6 Addendum to SpecView Manual

Page 7

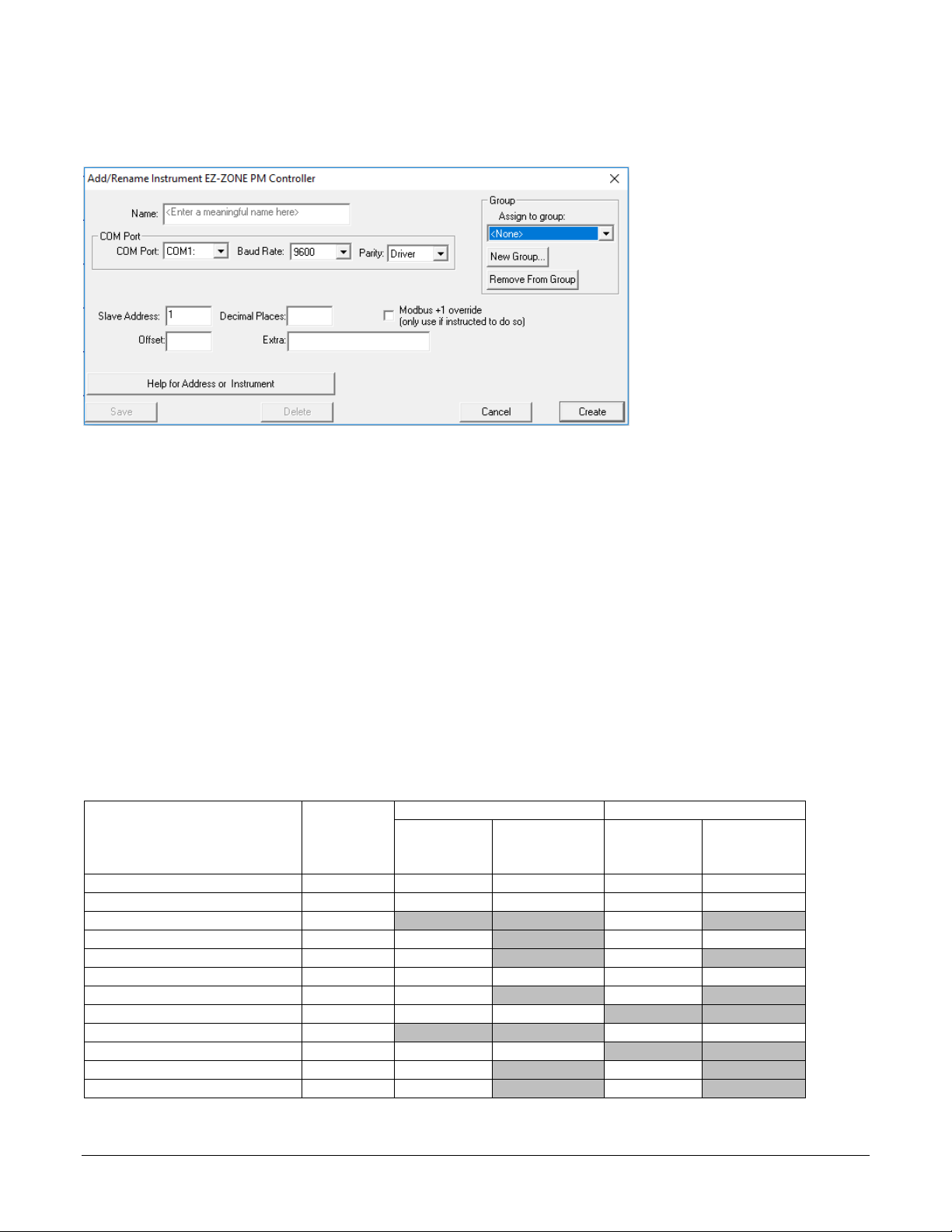

For Modbus® RTU specify the controller or gateway’s Modbus® Slave Address (1 to 247). This is set in

Data Map 1 via RUI Only1

Data Map 22

First

Address

First

Address

EZ-ZONE Alarm

1 to 2

1480

50

1450

60

EZ-ZONE Analog Input

1 to 2

360

160

360

90

EZ-ZONE Control Loop

1

N/A

N/A

1750

N/A

EZ-ZONE Communications

1

2418

N/A

2060

20

EZ-ZONE Current

1

1120

N/A

1240

N/A

EZ-ZONE Digital I/O

1 to 6

880

30

940

30

EZ-ZONE Limit

1

680

N/A

720

N/A

EZ-ZONE Profile (Map 1)**

1 to 4

6070

500

N/A

N/A

EZ-ZONE Profile (Map 2)**

1 to 4

N/A

N/A

4000

1000

EZ-ZONE Profile (ST Map 1)

1 to 4

2870

800

N/A

N/A

EZ-ZONE Profile Operation

1

2720

N/A

3800

N/A

EZ-ZONE Set Points

1

2160

N/A

1890

N/A

the controller or gateway’s Setup Communications menu. Each controller or gateway on the network

must have a unique Modbus® address. See the figure below.

Decimal Places

Specify zero (0) to display whole numbers for parameters such as process variable and set point. Specify

one (1) to display these parameters with tenths precision, two (2) to display hundredths and so on. Valid

settings range from zero (0) to four (4).

Register Address Offset

The register address offset is the sum of the First Instance Address for the specific EZ-ZONE product,

any applicable Instance Offsets and the Gateway Offset, if any. The Gateway Offset is set by the user

when the RUI Gateway or RM Access Module gateway is configured. The First Instance Address and

Instance Offsets depend on the controller’s data map setting and are supplied in the tables below for

each instrument and product.

Gateway Offset

Be careful not to set up instruments that attempt to read Modbus® registers that are mapped over by the

configuration of the gateway.

Register Addresses and Offsets for EZ-ZONE ST

Instrument Instances

Instance

Instance

Offset

Instance

Instance

Offset

1

Supported only via EZ-ZONE RUI Gateway.

2

Available with firmware version 4.0 or later.

Using Watlow Products with SpecView 7 Addendum to SpecView Manual

Page 8

Register Addresses and Offsets for EZ-ZONE PM

Data Map 1

Data Map 2

First

Address

First

Address

EZ-ZONE Alarm

1 to 4

1480

50

1880

60

EZ-ZONE Analog Input

1 to 2

360

80

360

90

EZ-ZONE Communications

1 or 2

2490

20

2970

20

EZ-ZONE Control Loop

1 to 2

1880

70

2360

70

EZ-ZONE Current

1

1120

N/A

1360

N/A

EZ-ZONE Digital I/O

1 to 12

880

30

1000

30

EZ-ZONE Limit

1

680

N/A

720

N/A

EZ-ZONE Profile (Map 1)

1 to 4

2570

500

N/A

N/A

EZ-ZONE Profile (Map 2)

1 to 4

N/A

N/A

4500

1000

EZ-ZONE Profile Operation

1

2520

N/A

4340

N/A

EZ-ZONE Set Points

1 to 2

2160

80

2640

80

First

Address1

EZ-ZONE Alarm

1480

EZ-ZONE Analog Input

360

EZ-ZONE Control Loop

1880

EZ-ZONE Set Points

2160

First

Address1

EZ-ZONE Alarm

1480

EZ-ZONE Analog Input

360

EZ-ZONE Limit

680

First

Address

EZ-ZONE Alarm

1 to 8

1740

60

EZ-ZONE Analog Input

1 to 4

360

90

EZ-ZONE Communications

1

2830

N/A

EZ-ZONE Control Loop

1 to 4

2220

70

EZ-ZONE Current

1 to 4

1380

50

EZ-ZONE Digital I/O

1 to 12

1020

30

EZ-ZONE Limit

1 to 4

720

30

EZ-ZONE Profile (Map 2)

1 to 25

5440

1000

EZ-ZONE Profile Operation

1

5280

N/A

EZ-ZONE Set Points

1 to 4

2500

80

EZ-ZONE Sub Routine

1 to 15

30440

860

Instrument Instances

Instance

Instance

Offset

Register Addresses for EZ-ZONE Express Controller

Instrument

1

PM Express has only one instance each.

Instance

Instance

Instance

Offset

Register Addresses for EZ-ZONE Express Limit

Instrument

1

PM Express has only one instance each.

Instance

Register Addresses and Offsets for EZ-ZONE RMC Modules

Instrument Instances

Instance

Instance

Offset

Using Watlow Products with SpecView 8 Addendum to SpecView Manual

Page 9

Register Addresses and Offsets for EZ-ZONE RME Modules

First

Address

EZ-ZONE Alarms

1 to 8

1440

60

EZ-ZONE Communications

1

2170

N/A

EZ-ZONE Digital I/O

1 to 24

360

30

First

Address

EZ-ZONE Alarms

1 to 24

2660

60

EZ-ZONE Analog Input

1 to 16

380

90

EZ-ZONE Communications

1

6510

N/A

EZ-ZONE Control Loop

1 to 16

4100

70

EZ-ZONE Digital I/O

1 to 12

1820

30

EZ-ZONE Set Points

1 to 16

5220

80

First

Address

EZ-ZONE Alarms

1 to 16

2530

60

EZ-ZONE Analog Input

1 to 12

410

90

EZ-ZONE Communications

1

3500

N/A

EZ-ZONE Digital I/O

1 to 12

1850

30

EZ-ZONE Limit

1 to 12

1490

30

First

Address

EZ-ZONE Alarms

1 to 16

2500

60

EZ-ZONE Analog Input

1 to 16

380

90

EZ-ZONE Communications

1

3470

N/A

EZ-ZONE Digital I/O

1 to 12

1820

30

Instrument Instances

Instance

Instance

Offset

Register Addresses and Offsets for EZ-ZONE RMH Modules

Instrument Instances

Instance

Instance

Offset

Register Addresses and Offsets for EZ-ZONE RML Modules

Instrument Instances

Instance

Instance

Offset

Register Addresses and Offsets for EZ-ZONE RMS Modules

Instrument Instances

Instance

Instance

Offset

Address Example 1: Analog Input 1 in an EZ-ZONE ST via Modbus® RTU

For an EZ-ZONE ST communicating with SpecView directly (no gateway) via Modbus® RTU, use the

First Instance Address for the EZ-ZONE Analog Input, 360 to read analog input 1. If the controller’s

address on the 485 network is 2, set the following properties for the instrument:

• Slave Address: 2

• Offset: 360

Note that we must use data map 2 because data map 1 is not supported by SpecView for EZ-ZONE STs

without a gateway.

Address Example 2: Analog Input 2 in an EZ-ZONE ST via Modbus® RTU

For an EZ-ZONE Analog Input instrument supporting analog input 2 in the ST controller from example

1, set the following properties for the instrument:

• Slave Address: 2

• Offset: 450

Using Watlow Products with SpecView 9 Addendum to SpecView Manual

Page 10

The offset is 450 because 360 is the address for the first analog input and you add the offset, 90, to reach

• EZ-ZONE PM Controller

• EZ-ZONE ST Controller

• EZ-ZONE ST Profiling

the second input.

Address Example 3: EZ-ZONE PM Controllers via an EZ-ZONE RUI Gateway with Modbus® TCP

Consider three EZ-ZONE PM controllers configured for data map 2 and connected to an EZ-ZONE RUI

Gateway with the local/remote gateway offsets set to 0, 4000 and 8000 respectively. To determine the

register address offset for an EZ-ZONE Set Points instrument to support the second control loop in the

third EZ-ZONE PM, locate the First Instance Address and the Instance Offset. These are 2640 and 80

respectively. Add these together for second control loop and add the gateway offset for the third

controller: 2640 + 80 + 8000 = 10720. So the register address offset is 10720. Set the following

properties for this instrument:

• TCP/IP Address or Hostname: 10.3.37.105

• Slave Address: 1

• Offset: 10720

Keep in mind that with Modbus® TCP the EZ-ZONE PM will respond to any slave address.

EZ-ZONE Modbus® Profile Instruments

The instruments supporting programming profiles include 10 steps each. Therefore, the instance offsets

indicated above are ten times the instance offsets indicated for the steps in the controller manuals.

Old EZ-ZONE Modbus® Instruments

The following instruments are included in the Watlow Modbus® instrument group, but are no longer

described in this document. They are not maintained or tested for use with later versions. They are

provided for backwards compatibility only.

• EZ-ZONE PM Limit

• EZ-ZONE PM Profiling

Note: These instruments support data map 1 only.

• EZ-ZONE Gateway ST Controller

• EZ-ZONE Gateway ST Profiling

Using ASPYRE Power Controllers with Modbus®

Connect a 485 port on the PC to port 2 on the ASPYRE power controller via RS-485 Modbus RTU. To

configure SpecView to communicate with ASPYRE products via Modbus® RTU from the Watlow

Modbus group in the New Instruments list select and add one ASPYRE DT instrument manually per

power controller. Configure communications with each instrument with the information listed below.

• COM Port: the serial port to on the PC which the ASPYRE power controller is connected

• Baud Rate: per the setting of the ASPYRE RS-485 port to which the PC is connected

• EZ-ZONE PM Profiling

• Parity: Driver

• Slave Address: the address of the ASPYRE power controller on the 485 network (also known as

station address)

• Decimal Places: 0

• Modbus +1 override: not selected

• Offset: leave blank

• Extra: leave blank

Using Watlow Products with SpecView 10 Addendum to SpecView Manual

Page 11

To create a configuration automatically:

1) For each F4T / D4T:

3

Chapter 3: Setup Procedures

The following sections provide procedures for establishing communications between SpecView and

Watlow controllers.

Automatically Detect an F4T or D4T

The following procedure guides you through the process of configuring SpecView to communicate with

Watlow F4T controllers and D4T data loggers via Modbus® TCP or Modbus® RTU. It is assumed that

the controllers are connected correctly via Ethernet or one or more of the computer’s serial

communications ports. To add a controller to an existing configuration, see Manually Set up or Modify a

Modbus® RTU, 485 or 232 Network on page 20 or Manually Set up or Modify a Modbus® TCP Network

on page 24.

Modbus® RTU:

• Set all controllers to

the same baud rate

• Set each controller to a

unique Modbus

Modbus® TCP:

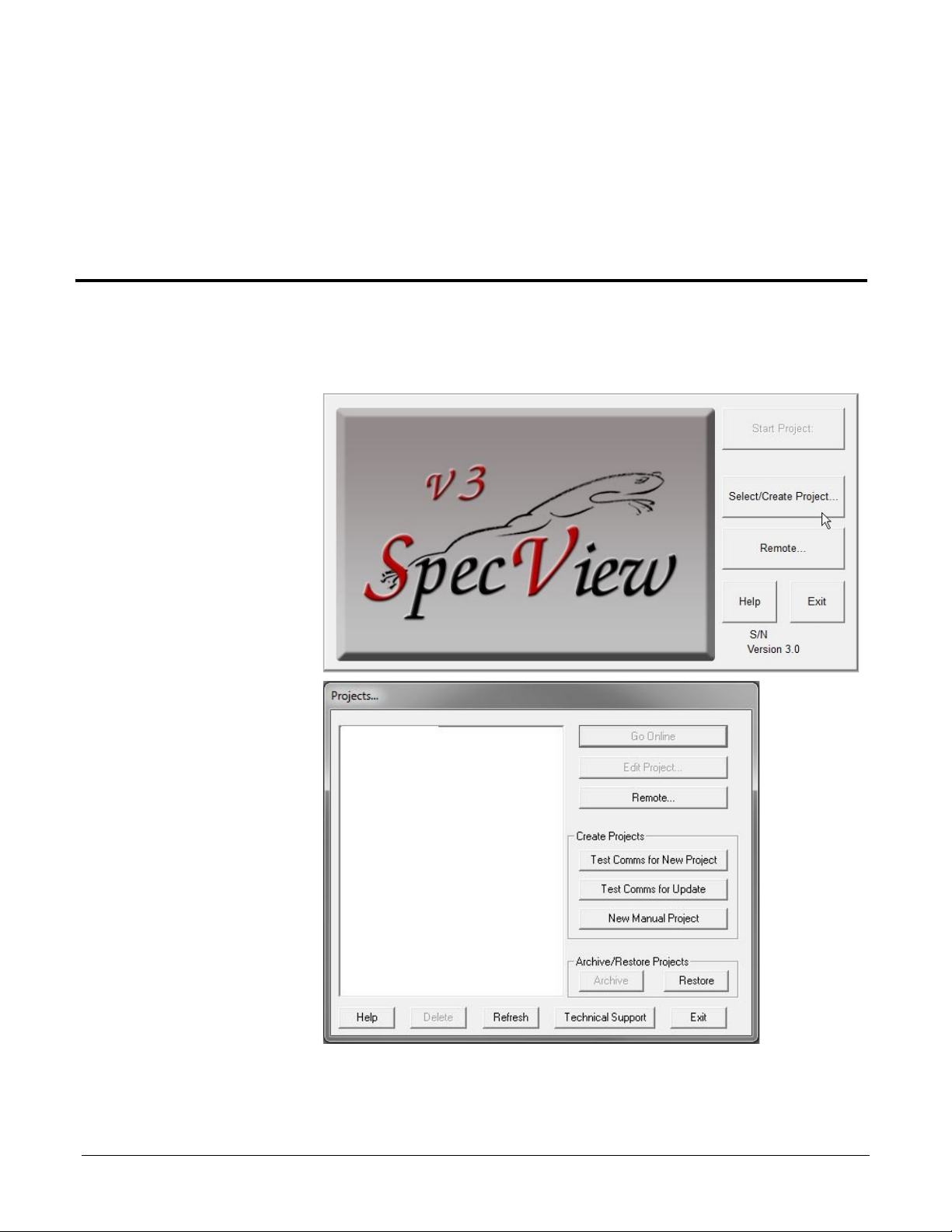

2) Launch SpecView

Address

• Set Parity to None.

• Set Modbus Word

Order to Low High

• Modbus Data Map: 1

• Set each controller to a

unique IP address.

• Make sure Modbus

TCP is enabled.

and click through

any informational

dialogs.

3) At the splash screen,

click Select/Create

Project…

Using Watlow Products with SpecView 11 Addendum to SpecView Manual

Page 12

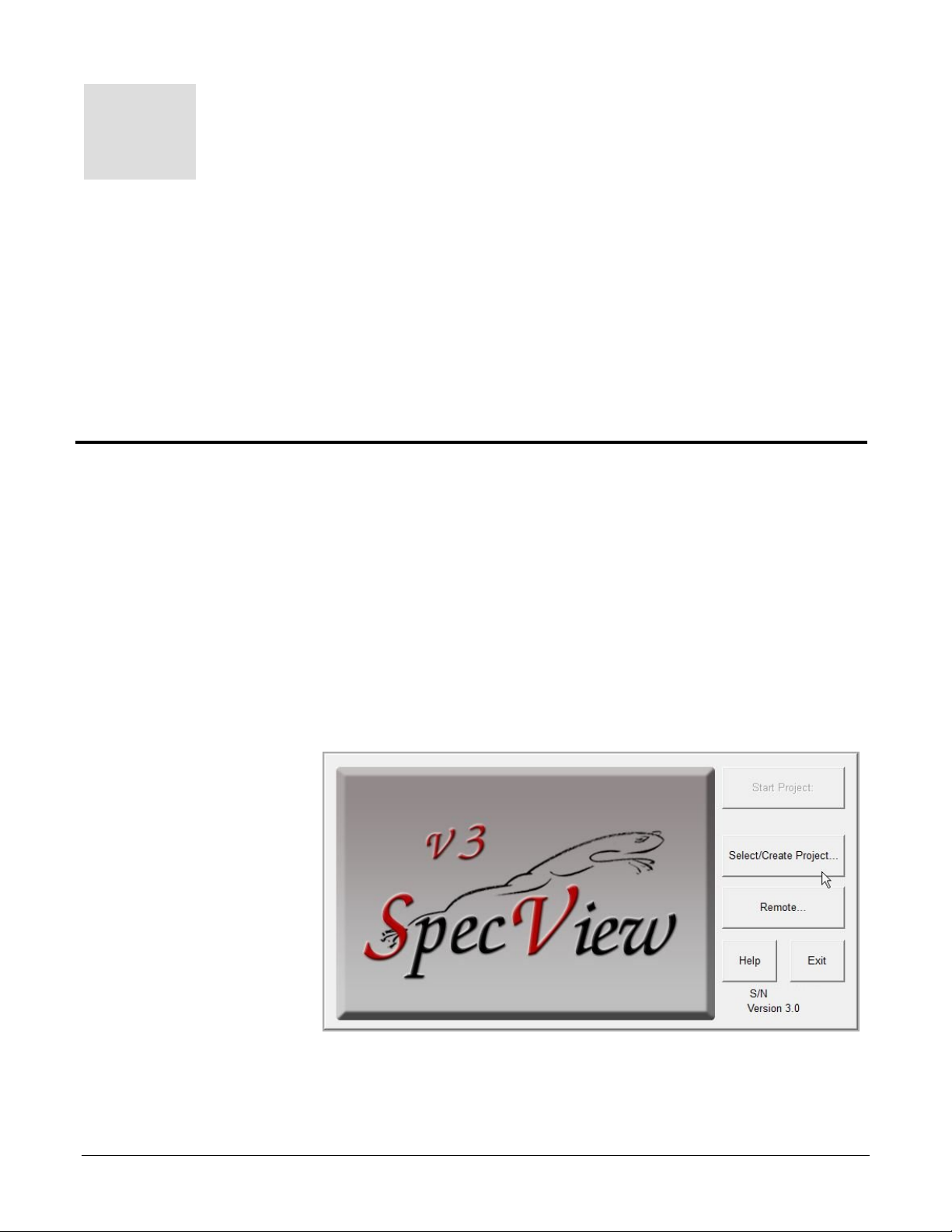

4) In the Projects

dialog click Test

5) Enter a name for the

7) For the Port to

Comms for New

Project.

project.

6) Click OK.

which the

controllers are

attached, under

Protocol choose the

Watlow F4T & D4T

template group.

8) For TCP/IP enter

Begin and End

addresses to limit

the range of

addresses scanned.

9) Click Start Scan.

Using Watlow Products with SpecView 12 Addendum to SpecView Manual

Page 13

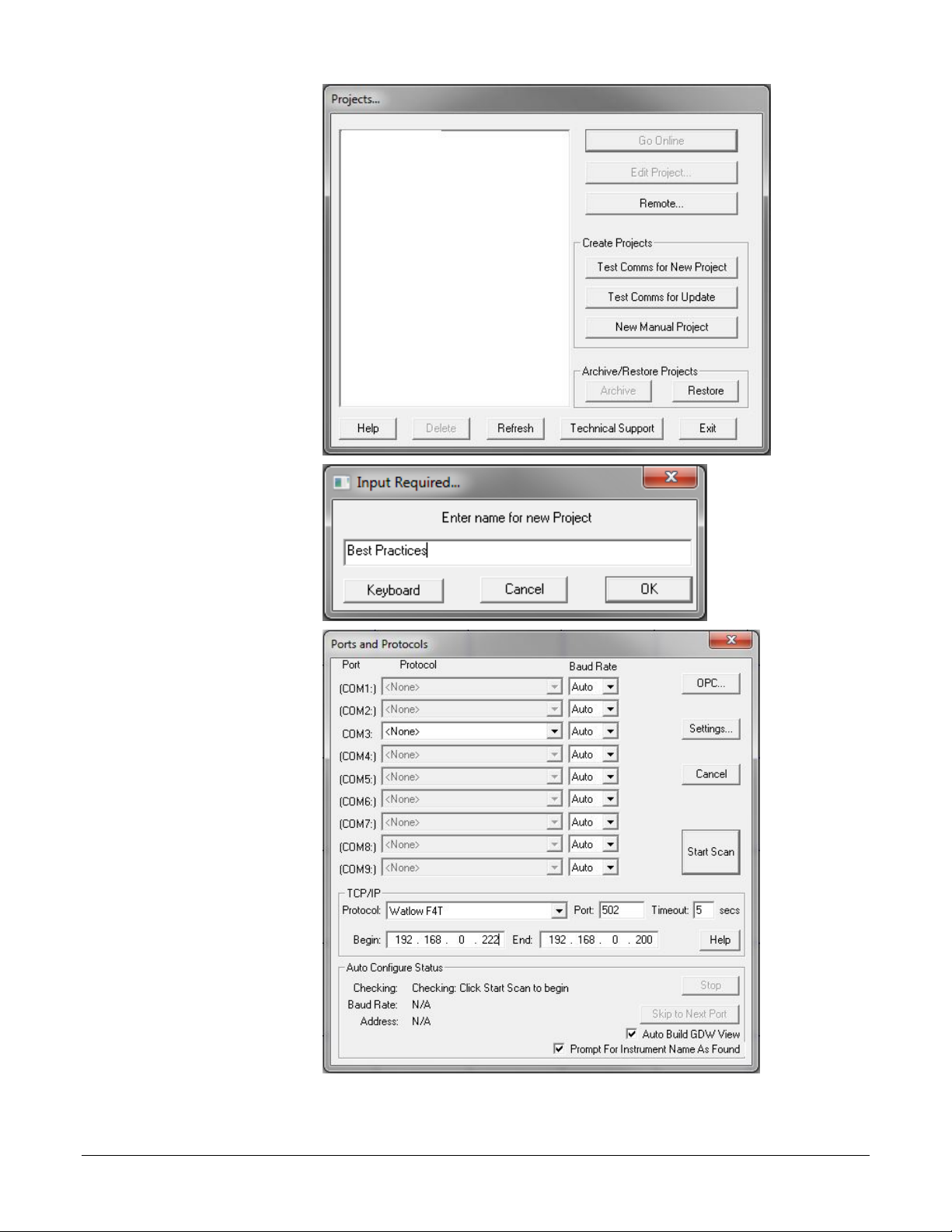

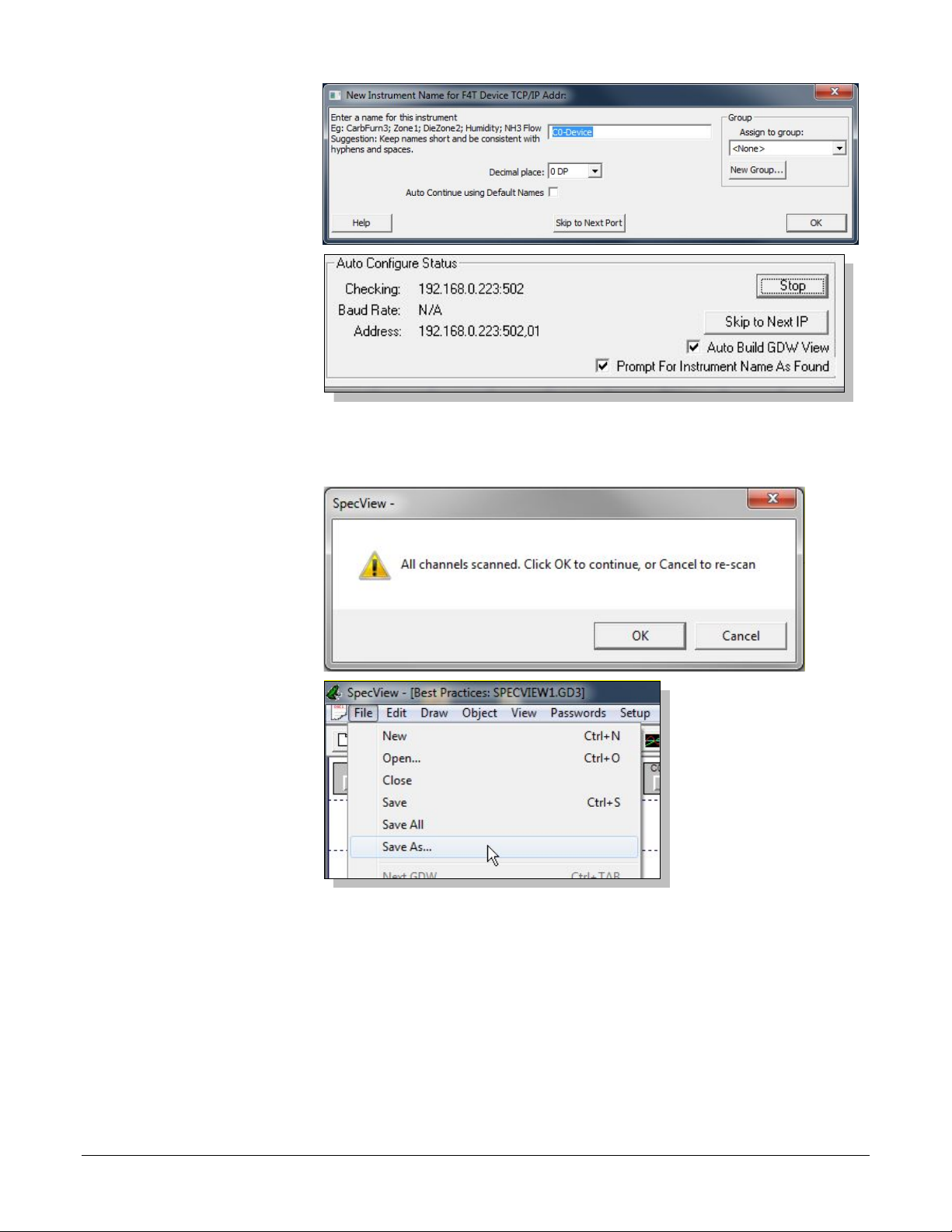

10) For each instrument

SpecView detects,

11) Once SpecView has

12) To scan another

14) To save the GDW:

enter a name and set

Decimal Places or

click OK to accept

the default settings.

scanned all the

addresses with F4T

controllers and D4T

data loggers, click

Stop or, if there are

more ports to scan,

click Skip to Next

Port or Skip to

Next IP.

template group,

click Cancel and

repeat from step 7

above for the next

template group.

13) Click OK.

• From the File menu,

choose Save As.

• Enter a File name for

the GDW.

• Click Save.

Using Watlow Products with SpecView 13 Addendum to SpecView Manual

Page 14

Automatically Detect a New Standard Bus, 485 or 232

To create a project automatically:

3) Launch SpecView.

5) In the Projects

Network

The following procedure guides you through the process of configuring SpecView to communicate with

Watlow controllers via Standard Bus, 232 and 485 serial communications. It is assumed that the

controllers are connected correctly to one or more of the computer’s serial communications ports. To

add a controller to an existing configuration, see Manually Set up or Modify an EZ-ZONE Standard Bus

Network on page 17 or Manually Set up or Modify a Modbus® RTU, 485 or 232 Network on page 20.

1) Set all controllers to the same baud rate. (Not necessary for Standard Bus.)

2) Set each controller to a unique address or zone number.

Note! Use the 32-bit

version of

SpecView with the

Watlow EZ-ZONE

Standard Bus driver.

4) At the splash screen,

click Select/Create

Project…

dialog click Test

Comms for New

Project.

Using Watlow Products with SpecView 14 Addendum to SpecView Manual

Page 15

6) Enter a name for the

project.

8) For the Port to

10) For each instrument

7) Click OK.

which the

controllers are

attached, choose the

appropriate template

group driver in

Protocol. See the

table below.

9) Click Start Scan.

SpecView detects,

enter a name and set

Decimal Places or

click OK to accept

the default settings.

Using Watlow Products with SpecView 15 Addendum to SpecView Manual

Page 16

For this Controller… Choose this Template

Watlow EZ-ZONE

Standard Bus

SERIES 96, 97, SD

986, 987, 988, 989

For the SERIES F4 Profiling controller, scan twice,

page 20.

16CLS, 16MLS,

CLS216, MLS316

CLS200 and MLS300 Standard and Ramp/Soak

20.

32MLS, MLS332

Anafaze 32 Loop

32MLS (Anafaze protocol)

Anafaze/AB

11) If another template

13) To save the GDW:

Group for Protocol…

Notes

EZ-ZONE PM, RM or ST

MICRODIN,

POWER SERIES,

SERIES F4 Ramping

8CLS, CLS208

4CLS, CLS204

1

Scan with the Watlow F4 Programmer driver only if the F4 programmer option is enabled in the SpecView key.

Watlow Modbus

Watlow Modbus

Watlow F4 Programmer

Anafaze 16 Loop

Anafaze 8 Loop

once with each template group. Add the F4 Cascade

instrument manually if desired. See

1

or Modify a Modbus

firmware options. For controllers with Ramp/Soak to

add the Anafaze Profile Status and the desired

Anafaze Profile instruments. See

Modify a Modbus

®

RTU, 485 or 232 Network on

®

RTU, 485 or 232 Network on page

Manually Set up

Manually Set up or

group must be

scanned, click

Cancel and repeat

this procedure from

step 8 for the next

template group.

12) Click OK.

• From the File menu,

choose Save As.

• Enter a File name for

the GDW.

• Click Save.

Using Watlow Products with SpecView 16 Addendum to SpecView Manual

Page 17

Manually Set up or Modify an EZ-ZONE Standard Bus

To create a manual project:

1) Launch SpecView.

4) Enter a name for the

Network

The following procedures guide you through the process of manually creating a configuration for a

Standard Bus network and adding devices to this configuration. Use this procedure when the EZ-ZONE

controllers are not available to detect automatically.

Note! Use the 32-bit

version of SpecView

with the Watlow EZZONE Standard Bus

driver.

2) At the splash screen,

click Select/Create

Project…

3) Click New Manual

Project.

project.

5) Click OK.

Using Watlow Products with SpecView 17 Addendum to SpecView Manual

Page 18

To add one or more instruments to a project:

1) Open the Graphical

Display Window in

3) In New Instruments

EZ-ZONE PM

Watlow EZ-ZONE Standard Bus

See the PM table on page 31.

EZ-ZONE PM Express Controller2

Watlow EZ-ZONE Standard Bus

PM Express Controller

z

EZ-ZONE PM Express Limit1

Watlow EZ-ZONE Standard Bus

PM Express Limit_

z

EZ-ZONE RMA Access Module

Watlow EZ-ZONE Standard Bus

See the RMA table on page 31.

EZ-ZONE RMC Control Module

Watlow EZ-ZONE Standard Bus

See the RMC table on page 32.

EZ-ZONE RMH High-Density

Control Module

EZ-ZONE RML High-Density Limit

Module

EZ-ZONE RMS High-Density

Scanner Module

EZ-ZONE RME Expansion Module

Watlow EZ-ZONE Standard Bus

See the RME table on page 37.

See the Function Block table on page

38.

ST Controller

z

ST Profiling3

z

the edit mode if it is

not already open.

2) Click the Templates

button.

List click to

expand Watlow EZ-

ZONE Standard

Bus.

4) Select the instrument

you want to add. (See

the table below.)

5) Click Create Inst.

For This Controller… From this Template Group…

EZ-ZONE RM Function Blocks Watlow EZ-ZONE Standard Bus

EZ-ZONE ST Watlow EZ-ZONE Standard Bus

1

Replace “z” in the address with the zone number (also known as the standard bus address).

2

For PM model numbers of the form PMxxxxx-AAAABxx.

3

Add these instruments for a controller that includes the ramp and soak or profiling option.

Add These

Instruments…

Watlow EZ-ZONE Standard Bus See the RMH on page 34.

Watlow EZ-ZONE Standard Bus See the RML table on page 35.

Watlow EZ-ZONE Standard Bus See the RMS table on page 36.

With

Address...

1

Using Watlow Products with SpecView 18 Addendum to SpecView Manual

Page 19

6) In the Add/Rename

Instrument dialog

12) To add an instrument view

13) To add a variable to the

14) To save the GDW:

type a Name for the

instrument.

7) Select the COM Port.

8) Enter the Address.

See the table above.

9) Click Create.

10) Repeat from step 4 for

each instrument to be

added.

11) Close the New Instruments

List.

to the GDW, drag the

instrument from the list to

the GDW.

GDW:

• Open the Variables list

• Expand the instrument

by clicking .

• Drag the parameter from

the list to the GDW.

• From the File menu,

choose Save.

• Enter a File name for

the GDW.

• Click Save.

Using Watlow Products with SpecView 19 Addendum to SpecView Manual

Page 20

Manually Set up or Modify a Modbus® RTU, 485 or 232

To create a new project manually:

1) Launch SpecView.

4) Enter a name for the

Network

The following procedures guide you through the process of manually creating a configuration for a

Modbus® RTU, 485 or 232 network and adding devices to this configuration. Use this procedure when

the controllers are not available to detect automatically, when you want to add a new controller to an

existing configuration and for creating configurations that communicate with EZ-ZONE controllers via

Modbus® RTU.

2) At the splash screen,

click Select/Create

Project…

3) Click New Manual

Project.

project.

5) Click OK.

Using Watlow Products with SpecView 20 Addendum to SpecView Manual

Page 21

To add one or more instruments to a project:

1) Open the Project in

the edit (on-line)

3) In New Instruments

6) In the Add/Rename

mode if it is not

already open.

2) Click the Templates

button.

List click to

expand the group that

includes the

instrument you want

to add. See the table

below.

4) Select the instrument

you want to add.

5) Click Create Inst.

Instrument dialog

type a Name for the

instrument.

7) Select the Port.

8) Set the Baud Rate.

9) Enter the Slave

Address set in the

controller.

10) Enter the Decimal

Places.

11) For EZ-ZONE

controllers enter the

Offset. See Using EZ-

ZONE Controllers

with Modbus® on

page 6.

Using Watlow Products with SpecView 21 Addendum to SpecView Manual

Page 22

For This Controller…

F4T or D4T

Watlow F4T & D4T

See F4T Instruments on page 29.

ASPYRE DT (See Using ASPYRE Power

Controllers with Modbus® on page 10

EZ-ZONE PM

EZ-ZONE PM Express Controller

EZ-ZONE PM Express Limit

EZ-ZONE RM

EZ-ZONE ST

MICRODIN

Watlow Modbus

MicroDin

SERIES 96

Watlow Modbus

Series 96

SERIES 97

Watlow Modbus

SERIES 97 Limit

SERIES SD Controller

SERIES SD Profiling1

SERIES SD Limit

Watlow Modbus

SERIES SD Limit

986, 987, 988, 989

Watlow Modbus

Watlow 988

POWER SERIES

Watlow Modbus

Watlow Power Series

Watlow F4

F4 Cascade

Watlow F4 Programmer

Watlow F4 Program2

Any

Generic Modbus

See Generic Modbus Instruments on page 46.

16CLS, 16MLS,

CLS216, MLS316

MLS CPU

Yes

MLS(16)Ch (1 per loop)

Yes

n (n = loop)

MLS CPU

Yes

MLS(32)Ch (1 per loop)

Yes

n (n = loop)

8CLS, CLS208

4CLS, CLS204

MLS CPU

Yes

CLS(8)Ch (1 per loop)

Yes

n (n = loop)

Anafaze Profile Status1

Yes

Anafaze Profile A to

as desired to program) 1

12) For Anafaze

13) Click Create.

ASPYRE DT Watlow Modbus

From this Template

Group…

Add These Instruments…

Watlow Modbus

Watlow Assembly

SERIES SD Watlow Modbus

SERIES F4 Ramping

1

Add this instrument for a controller that includes the ramp and soak or profiling option.

2

Add the Watlow F4 Program instrument only if the F4 programmer option is enabled in the SpecView key.

For This

Controller…

From this Template

Group…

Anafaze 16 Loop

Watlow Modbus

Add These Instruments…

See SpecView Instruments Supporting EZ-ZONE

Devices via Modbus

See Watlow Assembly Instruments on page 46.

Modbus +1

Override option

®

on page 6.

With Offset…

32MLS, MLS332 Anafaze 32 Loop

CLS204, CLS208,

CLS216, MLS316,

MLS332

1

Add these instruments for a controller that includes the ramp and soak or profiling option.

instruments only:

• Check Modbus +1

• Enter the Offset, if

required.

14) Repeat from step 3 as

needed to add

additional

instruments.

Anafaze 8 Loop

Anafaze Ramp/Soak

Anafaze Profile Q (as many

Yes

Using Watlow Products with SpecView 22 Addendum to SpecView Manual

Page 23

15) Close the New

Instruments List.

16) To add an instrument

17) To add a variable to the

18) To save the GDW:

view to the GDW,

click-and-drag the

instrument from the

list to the GDW.

GDW:

• Open the Variables list

• Expand the instrument

by clicking .

• Click-and-drag the

parameter from the list

to the GDW.

• From the File menu,

choose Save.

• Enter a File name for

the GDW.

• Click Save.

Using Watlow Products with SpecView 23 Addendum to SpecView Manual

Page 24

Manually Set up or Modify a Modbus® TCP Network

To create a new project manually:

1) Launch SpecView.

3) Click New Manual

4) Enter a name for the

The following procedures guide you through the process of manually configuring SpecView to

communicate with F4T and EZ-ZONE controllers via Modbus® TCP and adding instruments to the

project.

2) At the splash screen,

click Select/Create

Project…

Project.

configuration

5) Click OK.

Using Watlow Products with SpecView 24 Addendum to SpecView Manual

Page 25

To add one or more instruments to a project:

1) Open the Project in

the edit (on-line)

3) In New Instruments

F4T

Watlow F4T

See F4T Instruments on page 29.

EZ-ZONE PM

EZ-ZONE PM Express Controller

EZ-ZONE PM Express Limit

EZ-ZONE RM

EZ-ZONE ST

Any

Generic Modbus

See Generic Modbus Instruments on page 46.

6) In the Add/Rename

mode if it is not

already open.

2) Click the Templates

button.

List click to

expand the group that

includes the

instrument you want

to add. See the table

below.

4) Select the instrument

you want to add.

Locate them in the

sections referenced

below.

5) Click Create Inst.

For This Controller…

Instrument dialog for

COM Port select

TCP/IP.

7) In the TCP/IP

Address field enter

the IP Address.

8) In Decimal Places

enter the number of

decimals to show.

From this Template

Group…

Watlow Modbus

Add These Instruments…

See Using EZ-ZONE Controllers with Modbus on

page 6.

With Address

and Offset…

Using Watlow Products with SpecView 25 Addendum to SpecView Manual

Page 26

9) In Offset enter the

necessary address

13) To add instrument views

14) To add a variable to the

15) To save the GDW:

offset, if any. See the

section referenced in

the table above.

10) Click Create.

11) Repeat from step 3 as

needed to add additional

instruments.

12) Close the New Instruments

List.

to the GDW, for each:

• In the Variables list

select the instrument.

• Click Add Item.

GDW:

• Expand the instrument

by clicking .

• Click-and-drag the

parameter from the list

to the GDW.

• From the File menu,

choose Save As.

• Enter a File name for

the GDW.

• Click Save.

Using Watlow Products with SpecView 26 Addendum to SpecView Manual

Page 27

Adjust the Displayed Decimals

To make the number of decimal places displayed in SpecView match the controller display:

1) Set the decimal

controller.

EZ-ZONE ST, PM, RM

Any

N/A

dEC

0 to 3

MICRODIN

Any

Decimal Point

(No Display)

0 or 1

Thermocouple, RTD

Decimal Pt 1

dEC1

0 or 1

Process

Decimal Pt 1

dEC1

0 to 3

SERIES 97

Any

Decimal 1

dEC1

0 or 1

SERIES SD Controller

SERIES SD Limit

Thermocouple, RTD

See Note (1)

dEC

0 or 1

Process (mA, mV, V)

See Note (2)

dEC

0 to 3

POWER SERIES

Not available

Decimal 1

Decimal 2

Input 1 DecPlaces

Input 3 DecPlaces

Input 1 DecPlaces

Input 3 DecPlaces

CLS, MLS,

CLS200, MLS300

Thermocouple, RTD

Precision

Disp Format

1

Linear

Precision

Disp Format

0 to 4

The following procedure describes how to adjust the number of decimal places displayed in SpecView.

Note this procedure does not apply to EZ-ZONE controllers communicating with SpecView by Watlow

EZ-ZONE Standard Bus because with that protocol the decimal places are automatically displayed

according to the controller setting.

When communicating with F4T or EZ-ZONE controllers via Modbus® the Decimal Places setting in

SpecView determines the precision with which numbers are displayed; it does not shift the decimal

placement relative to the digits. For older Watlow controllers it is necessary to set the Decimal Places

setting according to the controller setting so that numbers are scaled correctly and not off by orders of

magnitude.

setting in the

controller as desired.

(See the table for

details about each

For This Controller… For Sensor Type…

Parameter in

SpecView…

Parameter in

Controller…

Available

Decimals

SERIES 96

986, 987, 988, 989 Any

Thermocouple, RTD,

Wet Bulb-Dry Bulb

SERIES F4 Ramping

Process

Notes:

For a SERIES SD with a thermocouple or RTD set the Decimals (Ctlr Temp Display Only) parameter, the

(1)

Decimals (SpecView and Ctlr Prcs Display) parameter and SpecView for the same number of decimals.

(2) For a SERIES SD with a process input (mA, mV or V) set the Decimals (SpecView and Ctlr Prcs Display)

parameter and SpecView for the same number of decimals.

Input 2 DecPlaces

Input 2 DecPlaces

dEC1 0 to 3

Choose

Decimal

Choose

Decimal

0 or 1

0 to 3

Using Watlow Products with SpecView 27 Addendum to SpecView Manual

Page 28

2) Open the project and

from the File menu

6) Set the Decimal

Set…

For…

0

Whole Numbers

1

Tenths

2

Hundredths

3

Thousandths

4

Ten-thousandths

8) To save the GDW:

choose Edit Mode

(go offline).

3) Click to open the

Variables list.

4) Select the instrument.

5) Click Properties.

Places as desired:

7) Click Save.

• From the File menu,

choose Save.

Note: The possible decimal settings may depend on other controller settings such as the sensor type.

Not all parameters are affected by the decimal places setting.

Using Watlow Products with SpecView 28 Addendum to SpecView Manual

Page 29

Chapter 4: Instrument

4

Reference

This chapter describes the instruments and instrument views supporting Watlow products.

F4T and D4T Instruments

The following sections list the instruments that support F4T controllers and D4T data loggers.

Automatic Detection with the Watlow F4T & D4T Instrument Group

When automatically detecting a network with the Watlow F4T & D4T instrument group, SpecView

reads each controller’s part number and adds the appropriate instruments. When adding instruments

manually, refer to the table below which correlates F4T and D4T configuration codes with the

instruments that support the corresponding features. The table also lists the Offset setting, if required, for

each instrument.

For part numbers matching… Add… Instrument Name (Description) Offset

F4Txxxxxxxxxxxx

F4Txxx(D, E or F)xxxxxxxx

F4Txxx(B, C, E or F)xxxxxxxx F4T Special OP Function (used for compressor control) 1

F4TxxxxxxxxUxxx

U = (1, 2, 3, 4, 7, 8, 9, B or C)

F4TxxxxxxxxUxxx

U = (2, 3, 4, 8, 9 or C)

F4Txxxxxxxx(3, 4 or 9)xxx

F4Txxxxxxxx4xxx

F4TxxxxxxxxUxxx

U = (6, 7, 8, 9, A. B or C)

F4Txxxxxxxx(A, B or C)xxx F4T Cascade Loop (setup and monitor cascade loop 2) 2

F4T Device (real time clock, global and diagnostic settings)

F4T Alarms (14) (alarm settings for alarms 1 to 14)

F4T Profile Editor

F4T Profile Engine (monitor and operate ramp-soak profiles)

F4T Profile List (name and start command for each profile)

F4T Control Loop (setup and monitor control loop 1) 1

F4T Control Loop (setup and monitor control loop 2)

F4T Control Loop (setup and monitor control loop 3)

F4T Control Loop (setup and monitor control loop 4)

F4T Cascade Loop (setup and monitor cascade loop 1) 1

2

3

4

D4Txxxxxxxxxxxx

Flex modules which the F4T or

D4T is configured to expect

*The offset for a flex module instrument is simply the slot number in which the module is expected.

Using Watlow Products with SpecView 29 Addendum to SpecView Manual

D4T Device (real time clock, global and diagnostic settings)

D4T Alarms (14) (alarm settings for alarms 1 to 14)

FMxx-xxxx-xxxx... (corresponding to the module configuration

code)

*

Page 30

Additional Instruments Available in the Watlow F4T & D4T Instrument Group

The table below lists the other instruments that may be manually added to a configuration to gain access

to additional values and settings in F4T controllers and D4T data loggers.

Instrument Names Description Offset1

F4T Alarm / D4T Alarm One alarm function block 1 to 14

F4T Alarms (14) / D4T Alarms (14) 14 alarm function blocks 1

F4T Compare / D4T Compare One compare function block 1 to 16

F4T Counter / D4T Counter One counter function block 1 to 16

F4T Limit One limit function block 1 to 6

F4T Linearization / D4T Linearization One linearization function block 1 to 8

F4T Logic / D4T Logic One logic function block 1 to 24

F4T Math / D4T Math One math function block 1 to 24

F4T Process Value / D4T Process Value One process value function block 1 to 8

F4T Special OP Functions/ D4T Special OP Functions One special output function block 1 to 4

F4T Timer / D4T Timer One timer function block 1 to 16

F4T Variable / D4T Variable One variable function block 1 to 24

F4T Variables (24)/ D4T Variables (24) 24 variable function blocks

Notes

1

With the exception of Variables (24) and Alarms (14) instruments which support variables 1 to 24 and alarms 1

to 14 respectively, each of these instruments supports a single function block. Set the address offset in the

instrument properties to the function block number you want. For example, for Counter 2, set the offset to 2.

EZ-ZONE Standard Bus Instruments

The tables in this section list the part number options for EZ-ZONE controllers correlating them with the

instruments that support the corresponding features. The tables also list the format of the addresses for

each instrument which are entered when configuring SpecView manually.

Addresses for Standard Bus EZ-ZONE Instruments

The addresses entered into SpecView for each instrument are the zone number (also known as standard

bus address) and, for some instruments, an offset. The tables indicate which instruments require the

offset.

Standard Bus instrument addresses consist of:

• “z” the Zone number or Standard Bus address (1 to 9, A, B, C, D, E, F, H or J)

• ; a semicolon when an offset is required

• the offset or instance number required for some instruments

Note: For the individual Function Block instruments the offset is shown as “o” in the Address column.

In place of the “o” enter the instance number of the function block. For example, for Alarm 7 in an RM

at zone 5 the Address is, “5;7”.

Using Watlow Products with SpecView 30 Addendum to SpecView Manual

Page 31

EZ-ZONE PM Standard Bus Instruments

diagnostic)

This table describes the instruments supporting the EZ-ZONE PM controllers and limits including the

PM Express models.

Model

PM

For part numbers

matching…

PMxxxxx-xxxxVxx

(V = A, C, D or F)

PMxUxxx-xxxxVxx

(U = C, R, B, J, N, E or S)

(V = A, C, D or F)

PMxxxxx-x(C or J)xxVxx

(V = A, C, D or F)

PMxxxxx-x(L or M)xxVxx

(V = A, C, D or F)

PMxxxxx-x(R or P)xxVxx

(V = A, C, D or F)

PMxxxxx-xTxxVxx

(V = A, C, D or F)

Add… Instrument Name

(Description)

PM Zone (alarm, digital input,

output, global and diagnostic)

Control-Loop (setup and

monitor loop 1)

Control-Loop (setup and

monitor loop 2)

Address1 Named2

z Cn-EZ-z Zone

z;1 Cn-EZ-z Ctlr-1

z;2 Cn-EZ-z Ctlr-2

Integrated Limit z Cn-EZ-z Limit

Auxiliary Input z;2 Cn-EZ-z AI-2

Single Current Input

z;1 Cn-EZ-z CT-1

PMxxxxx-xxxx(C or F)xx PM Function Blocks z Cn-EZ-z FB

PMxUxxx-xxxxVxx

(U = L, M or D)

(V = A, C, D or F)

PMxUxxx-xxxxxxx

(U = R, B, N or E)

Stand Alone and RM Limit

(not in PM with a control loop)

PM Profiling (program and

operate ramp-soak profiles)

z;1 Cn-EZ-z Limit-1

z Cn-EZ-z Prof

PMxCxxx-xxxx(B or E)xx PM Express Controller z Cn-EZ-z Ctlr

PMxLxxx-xxxx(B or E)xx PM Express Limit_ z Cn-EZ-z Limit

PMxTxxx-xxxxxxx PM Timer z Cn-EZ-z Timer

Notes

1

Replace “z” in the address with the zone number (also known as Standard Bus address).

2

Instrument names are shown as automatically detected by SpecView where “n” is replaced by the port number

and “z” is replaced by the zone number (also known as Standard Bus address).

EZ-ZONE RMA Standard Bus Instruments

This table describes the instruments supporting EZ-ZONE RM Access Modules.

Model

For part numbers

matching…

RMAx-xxxx-xxxx

RMA

RMAx-xYxx-xxxx

(Y = 2, 3, 5, or 6)

RMAx-xxxD-xxxx

Notes

1

Replace “z” in the address with the zone number (also known as Standard Bus address).

2

Instrument names are shown as automatically detected by SpecView where “n” is replaced by the port number

and “z” is replaced by the zone number (also known as Standard Bus address).

Add… Instrument Name

(Description)

RMA Zone (global and

Address1 Named2

z Cn-EZ-z Zone

RMA Gateway z Cn-EZ-z GW

RM Data Logging

z Cn-EZ-z Log

Using Watlow Products with SpecView 31 Addendum to SpecView Manual

Page 32

EZ-ZONE RMC Standard Bus Instruments

This table describes the instruments supporting EZ-ZONE RM Control Modules.

Model

RMC

For part numbers

matching…

RMCxxxxxxxxxxxx

RMCxxxxxxxxxxxx RMC Outputs 1 to 8 z Cn-EZ-z Out

RMCxxxxxxxxxxxx RM Function Blocks4 z Cn-EZ-z FB

RMCYxxxxxxxxxxx

(Y = 1, 2, 3 or 4)

RMCxx(1 or 2)xxxxxxxxx

RMCxxxx(1 or 2)xxxxxxx

RMCxxxxxx(1 or 2)xxxxx

RMC(5 or 6)xxxxxxxxxxx

RMCxx(5 or 6)xxxxxxxxx

RMCxxxx(5 or 6)xxxxxxx

RMCxxxxxx(5 or 6)xxxxx

RMC7xxxxxxxxxxx

RMCxx7xxxxxxxxx

RMCxxxx7xxxxxxx

RMCxxxxxx7xxxxx

RMCxx(R or P)xxxxxxxxx

RMCxxxx(R or P)xxxxxxx

RMCxxxxxx(R or P)xxxxx

RMCxxxxxxxCxxxx Digital I/O 07 to 12 z Cn-EZ-z DIO 07-12

RMC(3 or 4)xxxxxxxxxxx

RMC(3 or 4)xxxxxxxxxxx

RMC(3 or 4)xxxxxxxxxxx

Add… Instrument Name

(Description)

RM Zone (alarms, actions

globals and diagnostics)

Control-Loop (setup and

monitor control loop 1)

Control-Loop (setup and

monitor control loop 2)

Control-Loop (setup and

monitor control loop 3)

Control-Loop (setup and

monitor control loop 4)

Stand Alone and RM Limit

(set up and monitor limit 1)

Stand Alone and RM Limit

(set up and monitor limit 2)

Stand Alone and RM Limit

(set up and monitor limit 3)

Stand Alone and RM Limit

(set up and monitor limit 4)

Single Current Input (set up

and monitor current input 1)

Single Current Input (set up

and monitor current input 2)

Single Current Input (set up

and monitor current input 3)

Single Current Input (set up

and monitor current input 4)

Auxiliary Input (set up and

monitor analog input 2)

Auxiliary Input (set up and

monitor analog input 3)

Auxiliary Input (set up and

monitor analog input 4)

RMC Profile Operation (setup

and operate ramp and soak)

RMC Profiles 1 to 5 (program

profiles steps 1 to 50)

RMC Profiles 6 to 10

(program steps 51 to 100)

3

Address1 Named2

z Cn-EZ-z Zone

z;1 Cn-EZ-z Ctlr-1

z;2 Cn-EZ-z Ctlr-2

z;3 Cn-EZ-z Ctlr-3

z;4 Cn-EZ-z Ctlr-4

z;1 Cn-EZ-z Lim-1

z;2 Cn-EZ-z Lim-2

z;3 Cn-EZ-z Lim-3

z;4 Cn-EZ-z Lim-4

z;1 Cn-EZ-z CT-1

z;2 Cn-EZ-z CT-2

z;3 Cn-EZ-z CT-3

z;4 Cn-EZ-z CT-4

z;2 Cn-EZ-z AI-2

z;3 Cn-EZ-z AI-3

z;4 Cn-EZ-z AI-4

z Cn-EZ-z Prof Ops

z Cn-EZ-z Prof 1-5

z Cn-EZ-z Prof 6-10

Using Watlow Products with SpecView 32 Addendum to SpecView Manual

Page 33

Model

(program steps 101 to 150)

(sub routine steps 51 to 100)

150)

For part numbers

matching…

RMC(3 or 4)xxxxxxxxxxx

Add… Instrument Name

(Description)

RMC Profiles 11 to 15

Address1 Named2

z Cn-EZ-z Prof 11-15

RMC Profiles 16 to 20

(program steps 151 to 200)

RMC Profiles 21 to 25

(program steps 201 to 250)

RMC Sub Routines 1 to 5

(sub routine steps 1 to 50)

RMC Sub Routines 6 to 10

z Cn-EZ-z Prof 16-20

z Cn-EZ-z Prof 21-25

z Cn-EZ-z SR-1-5

z Cn-EZ-z SR-6-10

RMC

(cont.)

RMC(3 or 4)xxxxxxxxxxx

RMC(3 or 4)xxxxxxxxxxx

RMC(3 or 4)xxxxxxxxxxx

RMC(3 or 4)xxxxxxxxxxx

RMC Sub Routines 11 to 15

RMC(3 or 4)xxxxxxxxxxx

(sub routine steps 101 to

z Cn-EZ-z SR-11-15

Notes

1

Replace “z” in the address with the zone number (also known as Standard Bus address).

2

Instrument names are shown as automatically detected by SpecView where “n” is replaced by the port number

and “z” is replaced by the zone number (also known as Standard Bus address).

3

The RM Zone instrument includes eight instances of alarms. Several types of EZ-ZONE RM modules support

more alarm instances. Add a Function Block: Alarm instrument manually for each additional instance you want to

access.

4

The RM Function Block instrument includes four or eight instances of each type of function block. Several types

of EZ-ZONE RM modules support more function block instances than that. To access these additional instances,

add an individual function block instrument for each block you want to access.

Using Watlow Products with SpecView 33 Addendum to SpecView Manual

Page 34

EZ-ZONE RMH Standard Bus Instruments

This table describes the instruments supporting EZ-ZONE RM High-Density Control Modules.

Model

RMH

For part numbers

matching…

RMHx-xxxx-xxxx

RMHx-(1 or 2)xxx-xxxx

RMHx-x(1 or 2)xx-xxxx

RMHx-xx(1 or 2)x-xxxx

Add… Instrument Name

(Description)

RM Zone (alarms, actions

globals and diagnostics)

3

Address1 Named2

z Cn-EZ-z Zone

RM Function Blocks4 z Cn-EZ-z FB

Control-Loop (setup and

monitor control loop 1)

Control-Loop (loop 2)

z;1 Cn-EZ-z Ctlr-1

z;2 Cn-EZ-z Ctlr-2

Control-Loop (loop 3) z;3 Cn-EZ-z Ctlr-3

Control-Loop (loop 4) z;4 Cn-EZ-z Ctlr-4

Control-Loop (loop 5) z;5 Cn-EZ-z Ctlr-5

Control-Loop (loop 6) z;6 Cn-EZ-z Ctlr-6

Control-Loop (loop 7) z;7 Cn-EZ-z Ctlr-7

Control-Loop (loop 8) z;8 Cn-EZ-z Ctlr-8

Control-Loop (loop 9) z;9 Cn-EZ-z Ctlr-9

Control-Loop (loop 10) z;10 Cn-EZ-z Ctlr-10

Control-Loop (loop 11) z;11 Cn-EZ-z Ctlr-11

Control-Loop (loop 12) z;12 Cn-EZ-z Ctlr-12

Control-Loop (loop 13) z;13 Cn-EZ-z Ctlr-13

Control-Loop (loop 14) z;14 Cn-EZ-z Ctlr-14

RMHx-xxx(1 or 2)-xxxx

Control-Loop (loop 15) z;15 Cn-EZ-z Ctlr-15

Control-Loop (loop 16) z;16 Cn-EZ-z Ctlr-16

RMHx-xxCx-xxxx Digital I/O 01 to 06 z Cn-EZ-z DIO 01-06

RMHx-xx(J, F or L)x-xxxx RM Outputs 1 to 4 z Cn-EZ-z Out 01-04

RMHx-xxxC-xxxx Digital I/O 07 to 12 z Cn-EZ-z DIO 07-12

RMHx-xxx(J, F or L)-xxxx RM Outputs 7 to 10 z Cn-EZ-z Out 07-10

Notes

1

Replace “z” in the address with the zone number (also known as Standard Bus address).

2

Instrument names are shown as automatically detected by SpecView where “n” is replaced by the port number

and “z” is replaced by the zone number (also known as Standard Bus address).

3

The RM Zone instrument includes eight instances of alarms. Several types of EZ-ZONE RM modules support

more alarm instances. Add a Function Block: Alarm instrument manually for each additional instance you want to

access.

4

The RM Function Block instrument includes four or eight instances of each type of function block. Several types

of EZ-ZONE RM modules support more function block instances than that. To access these additional instances,

add an individual function block instrument for each block you want to access.

Using Watlow Products with SpecView 34 Addendum to SpecView Manual

Page 35

EZ-ZONE RML Standard Bus Instruments

This table describes the instruments supporting EZ-ZONE RM High-Density Limit Modules.

Model

RML

For part numbers

matching…

RMLx-xxxx-xxxx

RMLx-x(5 or 6)xx-xxxx

RMLx-xx(5 or 6)x-xxxx

RMLx-xxCx-xxxx

Add… Instrument Name

(Description)

RM Zone (alarms, actions

globals and diagnostics)

3

Address1 Named2

Z Cn-EZ-z Zone

RM Function Blocks4 Z Cn-EZ-z FB

Stand Alone and RM Limit

(set up and monitor limit 1)

Stand Alone and RM Limit

(set up and monitor limit 2)

Stand Alone and RM Limit

(set up and monitor limit 3)

Stand Alone and RM Limit

(set up and monitor limit 4)

Stand Alone and RM Limit

(set up and monitor limit 1)

Stand Alone and RM Limit

(set up and monitor limit 2)

Stand Alone and RM Limit

(set up and monitor limit 3)

Stand Alone and RM Limit

(set up and monitor limit 4)

Stand Alone and RM Limit

(set up and monitor limit 1)

Stand Alone and RM Limit

(set up and monitor limit 2)

Stand Alone and RM Limit

(set up and monitor limit 3)

Stand Alone and RM Limit

(set up and monitor limit 4)

Digital I/O 01 to 06

z;1 Cn-EZ-z Lim-1

z;2 Cn-EZ-z Lim-2

z;3 Cn-EZ-z Lim-3

z;4 Cn-EZ-z Lim-4

z;5 Cn-EZ-z Lim-5

z;6 Cn-EZ-z Lim-6

z;7 Cn-EZ-z Lim-7

z;8 Cn-EZ-z Lim-8

z;9 Cn-EZ-z Lim-9

z;10 Cn-EZ-z Lim-10

z;11 Cn-EZ-z Lim-11

z;12 Cn-EZ-z Lim-12

z Cn-EZ-z DIO 01-06

RMLx-xxJx-xxxx

RMLx-xxxx-xxxx

RM Outputs 1 to 4

Digital I/O 07 to 12

z Cn-EZ-z Out 01-04

z Cn-EZ-z DIO 07-12

Notes

1

Replace “z” in the address with the zone number (also known as Standard Bus address).

2

Instrument names are shown as automatically detected by SpecView where “n” is replaced by the port number

and “z” is replaced by the zone number (also known as Standard Bus address).

3

The RM Zone instrument includes eight instances of alarms. Several types of EZ-ZONE RM modules support

more alarm instances. Add a Function Block: Alarm instrument manually for each additional instance you want to

access.

4

The RM Function Block instrument includes four or eight instances of each type of function block. Several types

of EZ-ZONE RM modules support more function block instances than that. To access these additional instances,

add an individual function block instrument for each block you want to access.

Using Watlow Products with SpecView 35 Addendum to SpecView Manual

Page 36

EZ-ZONE RMS Standard Bus Instruments

This table describes the instruments supporting EZ-ZONE RM High-Density Scanner Modules.

Model

RMS

For part numbers

matching…

RMSx-xxxx-xxxx

RMSx-x(R or P)xx-xxxx

RMSx-xx(R or P)x-xxxx

RMSx-xxx(R or P)-xxxx

RMSx-xxCx-xxxx

Add… Instrument Name

(Description)

RM Zone (alarms, actions

globals and diagnostics)

2

Address1 Named2

z Cn-EZ-z Zone

RM Function Blocks3 z Cn-EZ-z FB

Auxiliary Input (input 1) z;1 Cn-EZ-z AI-1

Auxiliary Input (input 2) z;2 Cn-EZ-z AI-2

Auxiliary Input (input 3)

Auxiliary Input (input 4)

Auxiliary Input (input 5)

Auxiliary Input (input 6)

Auxiliary Input (input 7)

Auxiliary Input (input 8)

Auxiliary Input (input 9)

Auxiliary Input (input 10)

Auxiliary Input (input 11)

Auxiliary Input (input 12)

Auxiliary Input (input 13)

Auxiliary Input (input 14)

Auxiliary Input (input 15)

Auxiliary Input (input 16)

Digital I/O 01 to 06

z;3 Cn-EZ-z AI-3

z;4 Cn-EZ-z AI-4

z;5 Cn-EZ-z AI-5

z;6 Cn-EZ-z AI-6

z;7 Cn-EZ-z AI-7

z;8 Cn-EZ-z AI-8

z;9 Cn-EZ-z AI-9

z;10 Cn-EZ-z AI-10

z;11 Cn-EZ-z AI-11

z;12 Cn-EZ-z AI-12

z;13 Cn-EZ-z AI-13

z;14 Cn-EZ-z AI-14

z;15 Cn-EZ-z AI-15

z;16 Cn-EZ-z AI-16

z Cn-EZ-z DIO 01-06

RMSx-xx(J, F or L)x-xxxx RM Outputs 1 to 4 z Cn-EZ-z Out 01-04

RMSx-xxx(C or B)-xxxx

Digital I/O 07 to 12

z Cn-EZ-z DIO 07-12

RMSx-xxx(J, F or L)-xxxx RM Outputs 7 to 10 z Cn-EZ-z Out 07-10

Notes

1

Replace “z” in the address with the zone number (also known as Standard Bus address).

2

Instrument names are shown as automatically detected by SpecView where “n” is replaced by the port number

and “z” is replaced by the zone number (also known as Standard Bus address).

3

The RM Zone instrument includes eight instances of alarms. Several types of EZ-ZONE RM modules support

more alarm instances. Add a Function Block: Alarm instrument manually for each additional instance you want to

access.

4

The RM Function Block instrument includes four or eight instances of each type of function block. Several types

of EZ-ZONE RM modules support more function block instances than that. To access these additional instances,

add an individual function block instrument for each block you want to access.

Using Watlow Products with SpecView 36 Addendum to SpecView Manual

Page 37

EZ-ZONE RME Standard Bus Instruments

This table describes the instruments supporting EZ-ZONE RM Expansion Modules.

Model

RME

For part numbers

matching…

RMEx-xxxx-xxxx

RMEx-xxxx-xxxx RM Function Blocks3 z Cn-EZ-z FB

RMEx-Cxxx-xxxx Digital I/O 01 to 06 z Cn-EZ-z DIO 01-06

RMEx-Txxx-xxxx

RMEx-Vxxx-xxxx

(V = J, K, F or L)

RMEx-xCxx-xxxx Digital I/O 07 to 12 z Cn-EZ-z DIO 07-12

RMEx-xTxx-xxxx

RMEx-xVxx-xxxx

(V = J, K, F or L)

Add… Instrument Name

(Description)

RM Zone (alarms, actions

globals and diagnostics)

Single Current Input (set up

and monitor current input 1)

Single Current Input (set up

and monitor current input 2)

Single Current Input (set up

and monitor current input 3)

Single Current Input (set up

and monitor current input 4)

RM Outputs 1 to 4 z Cn-EZ-z Out 01-04

Single Current Input (set up

and monitor current input 5)

Single Current Input (set up

and monitor current input 6)

Single Current Input (set up

and monitor current input 7)

Single Current Input (set up

and monitor current input 8)

RM Outputs 7 to 10 z Cn-EZ-z Out 07-10

2

Address1 Named2

z Cn-EZ-z Zone

z;1 Cn-EZ-z CT-1

z;2 Cn-EZ-z CT-2

z;3 Cn-EZ-z CT-3

z;4 Cn-EZ-z CT-4

z;5 Cn-EZ-z CT-5

z;6 Cn-EZ-z CT-6

z;7 Cn-EZ-z CT-7

z;8 Cn-EZ-z CT-8

RMEx-xxCx-xxxx Digital I/O 13 to 18 z Cn-EZ-z DIO 13-18

RMEx-xxTx-xxxx

RMEx-xxVx-xxxx

(V = J, K, F or L)

RMEx-xxxC-xxxx

Single Current Input (set up

and monitor current input 9)

Single Current Input (set up

and monitor current input 10)

Single Current Input (set up

and monitor current input 11)

Single Current Input (set up

and monitor current input 12)

RM Outputs 13 to 16 Z Cn-EZ-z Out 13-16

Digital I/O 19 to 24

z;9 Cn-EZ-z CT-9

z;10 Cn-EZ-z CT-10

z;11 Cn-EZ-z CT-11

z;12 Cn-EZ-z CT-12

z Cn-EZ-z DIO 19-24

Using Watlow Products with SpecView 37 Addendum to SpecView Manual

Page 38

Model

and monitor current input 13)

(set up

For part numbers

matching…

Add… Instrument Name

(Description)

Single Current Input (set up

Address1 Named2

z;13 Cn-EZ-z CT-13

RME

RMEx-xxxT-xxxx

Single Current Input (set up

and monitor current input 14)

Single Current Input

and monitor current input 15)

Single Current Input (set up

and monitor current input 16)

z;14 Cn-EZ-z CT-14

z;15 Cn-EZ-z CT-15

z;16 Cn-EZ-z CT-16

RMEx-xxx(F or L)-xxxx RM Outputs 19 to 22 z Cn-EZ-z Out 19-22

Notes

1

Replace “z” in the address with the zone number (also known as Standard Bus address).

2

Instrument names are shown as automatically detected by SpecView where “n” is replaced by the port number

and “z” is replaced by the zone number (also known as Standard Bus address).

3

The RM Zone instrument includes eight instances of alarms. Several types of EZ-ZONE RM modules support

more alarm instances. Add a Function Block: Alarm instrument manually for each additional instance you want to

access.

4

The RM Function Block instrument includes four or eight instances of each type of function block. Several types

of EZ-ZONE RM modules support more function block instances than that. To access these additional instances,

add an individual function block instrument for each block you want to access.

EZ-ZONE RM Standard Bus Individual Function Block Instruments

This table describes the instruments supporting function blocks in EZ-ZONE RM Modules. These

instruments are not automatically added to configurations. The RM Function Block instrument includes

four or eight instances of each type of function block. Several types of EZ-ZONE RM modules support

more function block instances than that. To access these additional instances, add the appropriate

function block specific instrument for each instance you want to access.

Model

For part numbers

matching…

Add… Instrument Name

Function Block: Action

Address1 Named

z;o EZ Act-

Function Block: Alarm z;o EZ Alm-

Function Block: Compare z;o EZ Cmp-

Function Block: Counter z;o EZ Ctr-

RM

RMYx-xxxx-xxxx

(Y = E, H, L or S)

or

RMCxxxxxxxxxxxx

Function Block: Linearization z;o EZ Lnr-

Function Block: Logic z;o EZ Lgc-

Function Block: Math z;o EZ Math-

Function Block: Special

Output

Function Block: Timer

Function Block: Variable

z;o EZ SOF-

z;o EZ Tmr-

z;o EZ Var-

Notes

1

An address for an individual function block instrument consists of the zone number (shown as “z”) and the

instance number separated by a semicolon. For example, the address string for Logic block number 8 in an RM

module with address 5 is 5;8.

Using Watlow Products with SpecView 38 Addendum to SpecView Manual

Page 39

EZ-ZONE ST Standard Bus Instruments

This table describes the instruments supporting EZ-ZONE ST Controllers.

Model

ST

Notes

1

Replace “z” in the address with the zone number (also known as Standard Bus address).

2

Instrument names are shown as automatically detected by SpecView where “n” is replaced by the port number

and “z” is replaced by the zone number (also known as Standard Bus address).

For part numbers

matching…

STxx-xxxx-xxxx

STxx-xxxx-xPxx

Add… Instrument Name

(Description)

ST Controller (setup and

monitor control loop and limit)

ST Profiling (program and

operate ramp-soak profiles)

Address1 Named2

z Cn-EZ-z Ctlr

z Cn-EZ-z Prof

EZ-ZONE Standard Bus Instrument Views

The following sections describe the instrument views that are available for use when EZ-ZONE

controllers are connected to SpecView via a Standard Bus network.

Failed Sensor Indication

When the area that normally displays a process value on an instrument view is covered by a red

rectangle, the instrument is indicating that the sensor has failed.

Failed sensor indication

CAUTION: This feature may not be available for all instruments, so take

the appropriate precautions to insure fail-safe system operation.

EZ-ZONE PM Standard Bus Instruments

EZ-ZONE PM controllers, limit controller and integrated controller are supported by the PM Zone,

Control Loop, Integrated Limit, Stand Alone and RM Limit, Auxiliary Input, Single Current Input, PM

Function Blocks, PM Profiling, PM Express Controller and PM Express Limit_ instruments. The

corresponding instrument views are illustrated below.

PM Zone

Using Watlow Products with SpecView 39 Addendum to SpecView Manual

Page 40

Control Loop and PM Express Controller

Integrated Limit, Stand Alone and RM Limit and PM Express Limit_

Auxiliary Input

Single Current Input

PM Function Blocks

PM Profiling

Using Watlow Products with SpecView 40 Addendum to SpecView Manual

Page 41

EZ-ZONE RM Standard Bus Instruments

EZ-ZONE RM control systems are supported by a wide variety of instruments. The PM Timer, RMA

Zone, RMA Gateway, RM Data Logging, RMC Outputs 1 to 8, RM Function Blocks, as well as eight

instruments for programming profiles and sub routines in RM control modules and four instruments for

configuring outputs are supported with the simple parameter button instrument view.

Parameter Button instrument View.

The RM Zone, Control Loop, Stand Alone and RM Limit, Auxiliary Input, Single Current Input and RMC

Profile Operation instruments and a sample of the four Digital I/O instruments are illustrated below.

RM Zone

Control Loop

Stand Alone and RM Limit

Auxiliary Input

Using Watlow Products with SpecView 41 Addendum to SpecView Manual

Page 42

Single Current Input

RMC Profile Operation

Digital I/O

EZ-ZONE ST Standard Bus Instruments

The EZ-ZONE ST is supported by the ST Controller and ST Profiling instruments. The corresponding

instrument views are illustrated below.

ST Controller

ST Profiling

Using Watlow Products with SpecView 42 Addendum to SpecView Manual

Page 43

EZ-ZONE Modbus® Instruments

High Set Point

Low Set Point

Error Status

Heat Prop Band

Dead Band

Cool Power

Autotune Request

Reading RMS

Error

Input State

Open Loop Working SP

Watlow recommends using Standard Bus communications between SpecView and EZ-ZONE products

because there are many advantages including automatic detection. However, there are situations where it

may be preferable to use Modbus® RTU or Modbus® TCP. For these cases the following instruments are

offered. The tables below list the parameters supported by these instruments.

EZ-ZONE Alarm

State

Clear Request

Silence Request

EZ-ZONE Analog Input

Input Value

Cal Offset

Clear Latch

EZ-ZONE Communications

Display Units

Non-volatile Save

EZ-ZONE Control Loop

Control Mode

Control Mode Active

Cool Prop Band

Time Integral

Time Derivative

EZ-ZONE Current

Read

Heater Error

High Set Point

Low Set Point

EZ-ZONE Digital I/O

Output State

Direction

EZ-ZONE Limit

State

Status

Low Set Point

High Set Point

Clear Request

EZ-ZONE Set Points

Clsd-Loop Set Point

Open Loop Set Point

Clsd-Loop Working SP

Heat Hysteresis

Cool Hysteresis

Heat Power

Output Power

TRU-TUNE+ Enable

Autotune Status

Using Watlow Products with SpecView 43 Addendum to SpecView Manual

Idle Set Point

Ramp Working SP

Ramp Target SP

Page 44

EZ-ZONE Profile Operation

Control Mode 1

Target Set Point 1

Hours

Wait For Process Enable 1

Wait For Process Enable 3

Wait for Process Instance

Wait Event 4

Guaranteed Soak Enable 2

Subroutine Step

End Type

Event 4

Event 8

Profile State

Profile Start

Profile Action Request

Active Step

Current File

Active Step Type

Target SP Loop 1

Target SP Loop 2

Target SP Loop 3

Target SP Loop 4

Produced SP Loop 1

Produced SP Loop 2

Produced SP Loop 3

Produced SP Loop 4

Step Time Remaining

Event 1

Event 2

Event 3

Event 4

Event 5

Event 6

Event 7

Event 8