Page 1

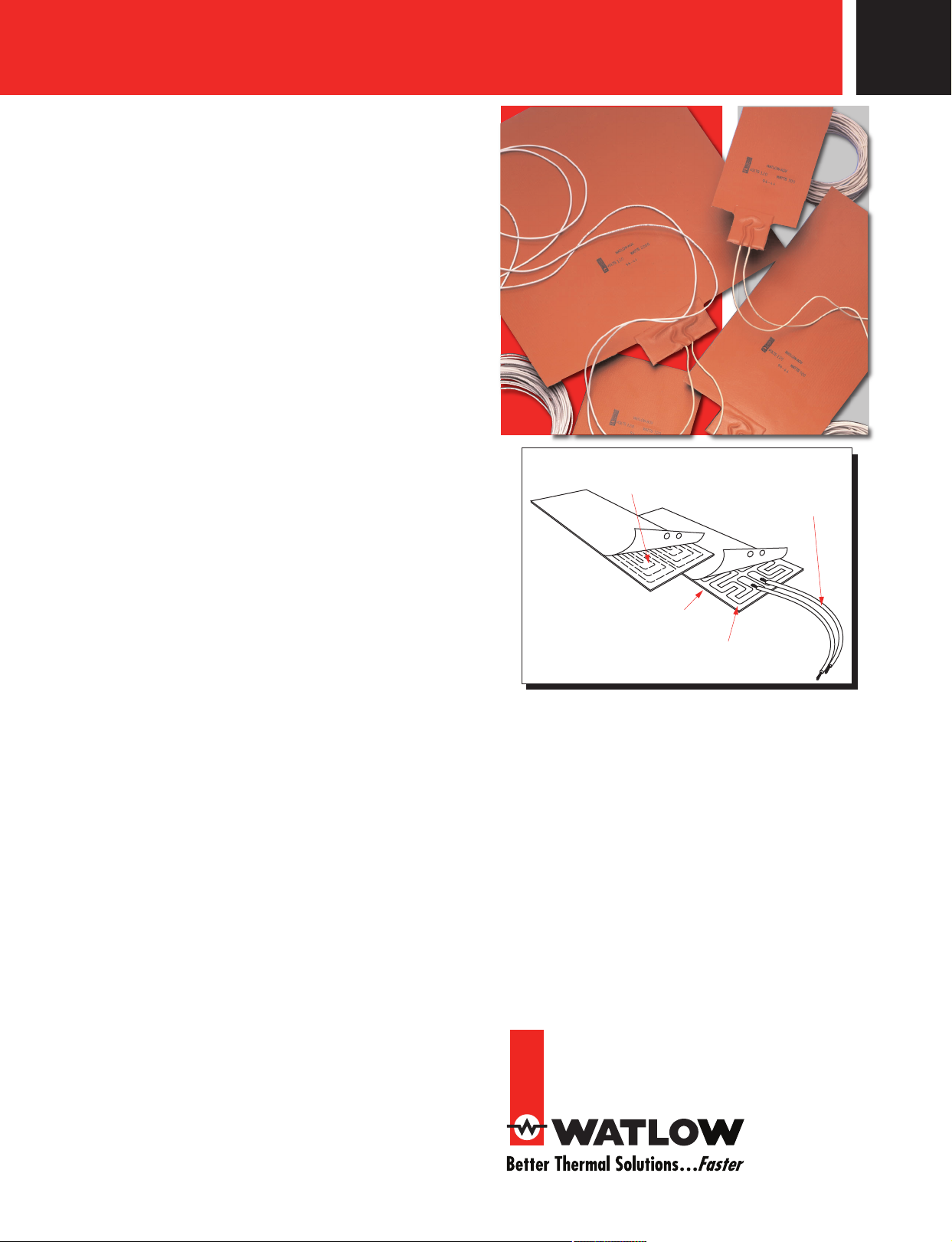

Silicone Rubber Heaters

®

Improve Heat Transfer,

Speed Warm Ups and

Decrease Wattage

Requirements

Rugged, yet thin, lightweight and flexible —the use of

®

Watlow

imagination. With these heaters, heat can be placed where

it is needed. In the application process these heaters

improve heat transfer, speed warm ups and decrease

wattage requirements.

Fiberglass-reinforced silicone rubber gives the heater

dimensional stability without sacrificing flexibility. Because

very little material separates the element from the part, heat

transfer is rapid and efficient. The heaters are constructed

with a wire-wound element or an etched foil element.

The heater construction creates a very thin heater allowing

it to fit applications where space is limited.

Performance Capabilities

• Operating temperatures up to 500°F (260°C)

• Watt densities up to 80 W/in

• Wire-wound element thickness — 0.055 in. (1.4 mm)

• Etched foil element — 0.022 in. (0.56 mm)

• UR

Features and Benefits

Designed to the exact shape and size needed

• Conforms to your component and/or equipment

More than 80 designs available immediately from stock

• Reduces downtime

Constructed with wire-wound or etched foil elements

• Delivers a thin, lightweight heater

• Provides the desired flexibility for many dynamic

• Delivers low mass and easily repeatable distributed

Moisture- and chemical-resistant silicone rubber material

• Provides longer heater life

Vulcanizing adhesives or fasteners

• Allows heaters to be easily bonded to the part

silicone rubber heaters is limited only by the

2

(12.5 W/cm2), dependent

upon application temperature

®

, cUR®, VDE and CE recognitions are available on

many designs up to 428°F (220°C)

applications

watt densities

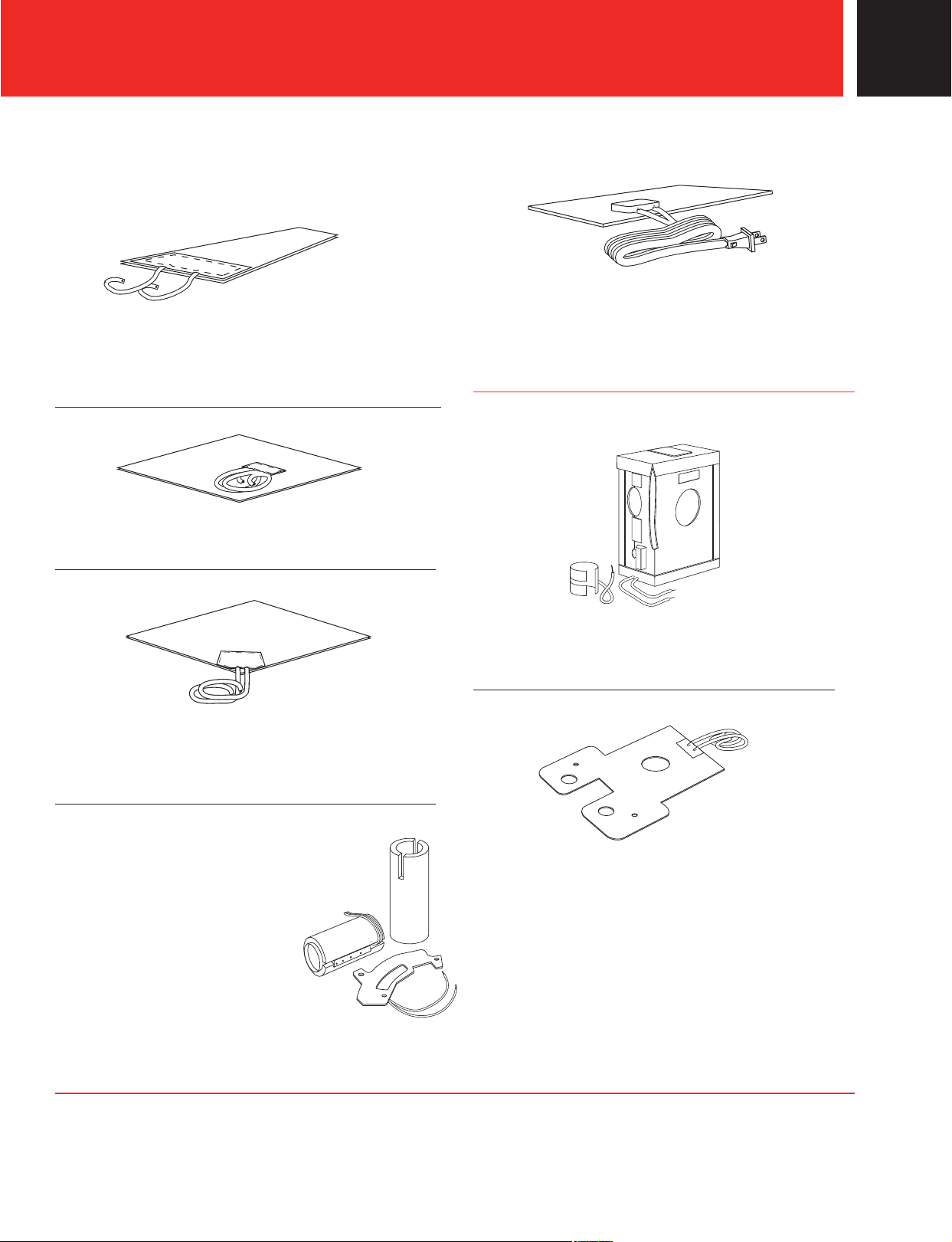

0.055 in. (1.4 mm)

hick Heater with

T

Wire-Wound Element

0.022 in. (0.6 mm) Thick Heater

with Etched Foil Element

Element Vulcanized

Between Two Layers of

Silicone Rubber/Fiberglass

Teflon®or Silicone

eads Available

L

Typical Applications

• Freeze protection and condensation prevention for many

types of instrumentation and equipment

• Medical equipment such as blood analyzers and test

tube heaters

• Computer peripherals such as laser printers

• Curing of plastic laminates

• Photo processing equipment

• Semiconductor processing equipment

Mounting Methods

• Pressure Sensitive Adhesive Surface (PSAS)

• Silicone contact cement kit

• Field applied adhesive

• Mechanical fasteners

• Factory bonding

©2001, 2011 Watlow Electric Manufacturing Company, all rights reserved.

COL-SRH-0311

Page 2

Termination Styles

Watlow offers many types of leads and terminations.

Leads can project from any position along the perimeter

f the unit. They will be centered on the short side width

o

of rectangular heaters unless otherwise specified.

®

eflon

T

L

U

®

180 CSA

1

Extended Capability Termination Style

HPN Cord and Plug Set

eads Shown Exiting End of

L

eater, Centered on Short Side

H

Watlow’s leads are 12 in. (305 mm) long, white, Teflon

®

insulated, flexible, plated copper UL®1180 CSA wire. They

are rated for 392°F (200°C)/300V. The lead connections

on or at the heater are insulated with a cap of sheath

material, vulcanized to the heater body.

®

Teflon

Teflon

Leads

eads Shown Exiting Middle

L

of Heater

®

Type E (MIL-W-16878) and Teflon®UL®1199 rated for

392°F (200°C)/600V are also available.

Silicone Insulated Leads

Leads Shown Exiting

Corner of Heater

For a better moisture seal, specify UL

®

silicone insulated lead

wires. This lead type is rated for 302°F (150°C)/ 600V. Any

lead length is available. Note: Silicone rubber heaters are not

designed to be waterproof. Excess exposure to moisture may

facilitate premature heater failure.

Molded Leads are Shown Exiting Edge of Heater.

apped Leads are also Available

C

For removable heaters, a 6 ft (1.8 m) HPN cord and plug set

provides convenience. It is rated for 194°F (90°C)/ 300V. HPN

cord without a plug is also available in any length.

Extended Capability Options

Formed Heaters

Many three-dimensional shapes, such as cylinders,

cones and boxes, can be factory formed. Semi-rigid

shapes can be self-gripping to the part. Special

tooling may be required for some designs.

Holes, Cutouts and Notches

Option

Thermal Insulation

To increase the heating efficiency of

your application, silicone rubber

heaters can be thermally insulated

with silicone sponge rubber, bonded to

one side in the following thicknesses:

1

⁄16,1⁄8,1⁄4,3⁄8 or1⁄2 in. (1.6, 3.2, 6, 9.5 or

Watlow can provide flexible heaters with special holes,

cutouts and notches in nearly any position required for

your design. The resistance element can be brought to

1

within

⁄8 in. (3.2 mm) of all edges. Standard spacing is

1

⁄4 in. (6 mm) from all edges.

13 mm)

An aluminized surface can be added

to the back of the heater to reduce

radiated heat losses. This aluminized

surface, called “low loss treatment,”

adds very little to the unit thickness

and maintains a very clean appearance.

Watlow®is a registered trademark of Watlow Electric Manufacturing Company.

Teflon®is a registered trademark of E.I. duPont de Nemours & Company.

UR®and cUR®are registered trademarks of Underwriter’s Laboratories, Inc.

To be automatically connected to the nearest North American Technical Sales Office:

1-800-WATLOW2 • www.watlow.com • inquiry@watlow.com

International Technical Sales Offices: Australia, +61 3 9335 6449 • China, +86 21 3381 0188 • France, +33 1 41 32 79 70

Germany, +49 (0) 72 53 / 94 00-0 • Italy, +39 024588841 • Japan, +81 3 3518 6630 • Korea, +82 2 2628 5770

Malaysia, +60 3 8076 8745 • Mexico, +52 442 217 6235 • Singapore, +65 6773 9488 • Spain, +34 91 675 12 92

Taiwan, +886 7 288 5168 • United Kingdom, +44 (0) 115 964 0777

Loading...

Loading...