Page 1

SERV-RITE®Wire

Product Description

Thermocouple

and Extension

Wire

RTD Lead Wire

Single pairs of thermocouple conductors are available using a variety of

insulation materials. Matched pairs with duplex insulation are color coded

according to ANSI MC 96.1-1982 requirements. The operating temperature

rating for thermocouple and extension wire is up to 2600°F (1427°C).

Nickel or tin plated 2, 3 and 4-wire copper conductor constructions are

available in a variety of gauge sizes. All types are twisted to achieve maximum

reduction of electromagnetic interferences, are available with PVC, FEP, PFA

or fiberglass insulations and are color coded according to ANSI requirements.

Page

153

188

WATLOW

SERV-RITE

®

Wire

®

151

Page 2

SERV-RITE®Wire

General Information

Thermocouple and Extension Wire

Color Codes

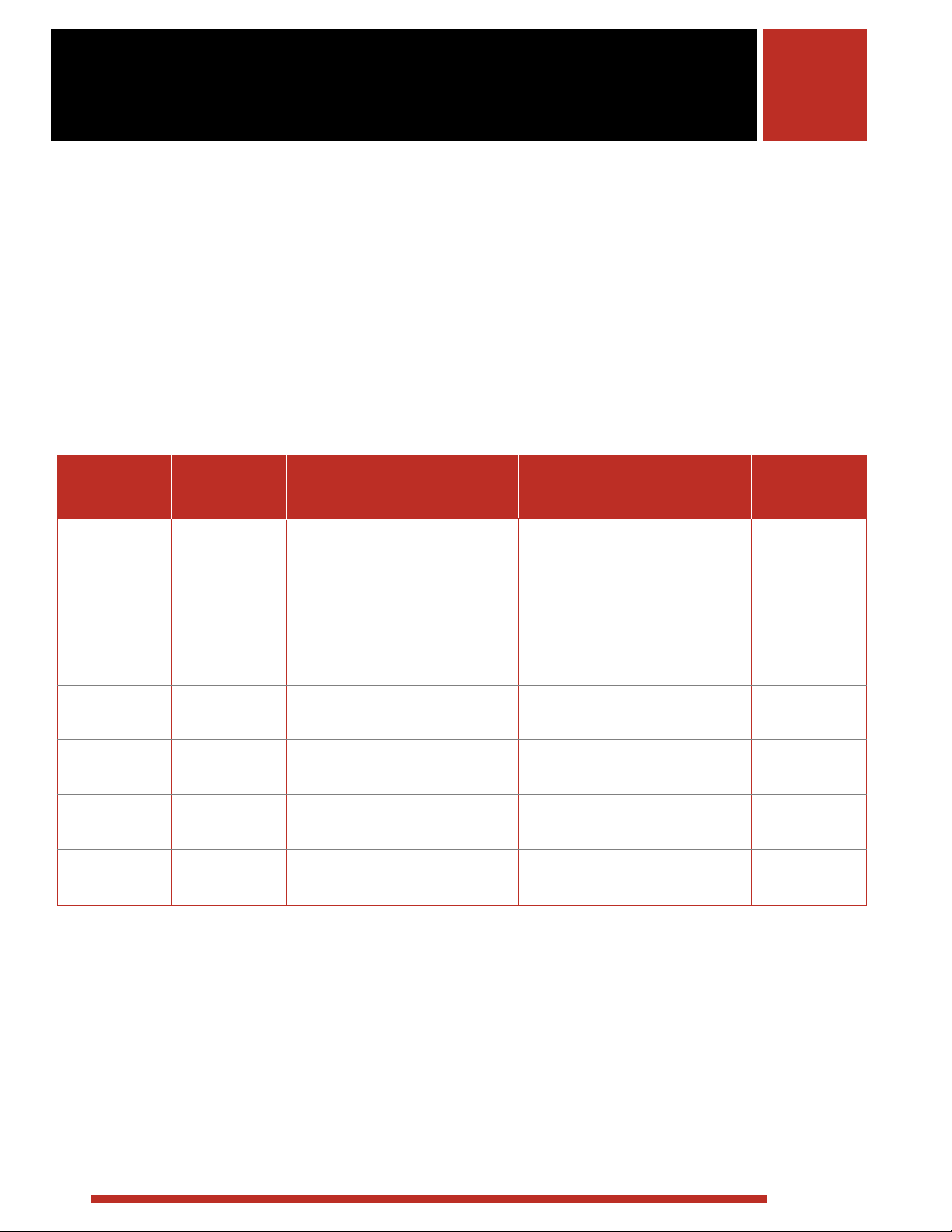

United States and International Color Coding

Standard ASTM E 230 color coding (United States) is

used on all insulated thermocouple wire and extension

wire when insulation type permits. In color coding, the

right is reserved to include a tracer to identify the ASTM E

230 type. Thermocouple grade wire normally has a brown

overall jacket. For Types R and S, the color codes

correlate to the compensating cable normally used.

Thermocouple and Extension Wire Color Codes

Overall/Positive (+)/Negative (-)

ASTM ASTM

T/C E 230 E 230 BS DIN JIS IEC

Type T/C Extension 1843 43710 C1610-1981 584-3

E (overall) Brown Purple Brown Black Purple Violet

EP +Purple +Purple +Brown +Red +Red +Violet

EN Red- -Red -Blue -Black -White -White

J (overall) Brown Black Black Blue Yellow Black

JP +White +White +Yellow +Red +Red +Black

JN -Red -Red -Blue -Blue -White -White

K (overall) Brown Yellow Red Green Blue Green

KP +Yellow +Yellow +Brown +Red +Red +Green

KN -Red -Red -Blue -Green -White -White

N (overall) Brown Orange ————

NP +Orange +Orange ————

NN -Red -Red ————

R (overall) — Green Green — Black Orange

RP — +Black +White — +Red +Orange

RN — -Red -Blue — -White -White

S (overall) — Green Green White Black Orange

SP — +Black +White +Red +Red +Orange

SN — -Red -Blue -White -White -White

T (overall) Brown Blue Blue Brown Brown Brown

TP +Blue +Blue +White +Red +Red +Brown

TN -Red -Red -Blue -Brown -White -White

Various national and international standard agencies have

adopted color codes for identifiying thermocouples which

generally

differ from those specified in ASTM E 230. The

overall extension color code is also used to identify

connectors to specific thermocouple types.

UK Germany Japan

152

WATLOW

®

Page 3

SERV-RITE®Wire

Thermocouple Wire

Manufactured to Exact Specifications

Since 1914, SERV-RITE®thermocouple wire and

thermocouple extension wire have been recognized for

premium performance and reliability. All stock and

custom wire is manufactured in Watlow’s plant where

materials, manufacturing equipment and quality controls

are carefully selected to ensure superior uniformity.

Watlow offers popular wires as well as custom

manufactured wire using alloys and insulation types

to meet specific application demands.

All SERV-RITE thermocouple wire and thermocouple

extension wire is manufactured under rigid quality

controls following ISO 9001 standards. In addition, all

electromotive force (EMF) versus temperature calibration

procedures follow one or more of the following standards:

• ASTM E 207

• ASTM E 220

• AMS 2750

All testing has NIST traceability. Unless otherwise

specified, all SERV-RITE thermocouple wire and

extension wire are supplied to meet standard tolerances

of ASTM E 230. Special tolerances are also available.

Performance Capabilities

• Compliance with recognized agency tolerances

• Insulation temperature ranges from -328 to 2600°F

(-200 to 1427°C)

• Tolerances from ±0.5°C or ±0.4 percent

• NIST calibration certificates

• ISO 17025 Accredited Lab

Features and Benefits

Type E, J, K, N, S and T thermocouple wire

• Fit virtually all applications

Compensation extension wire

• Permits fine tuning of temperature measuring circuits

Solid or stranded wire

• Meets specific application requirements

Wide selection of insulation types

• Meets temperature, chemical, moisture and abrasion

resistance objectives

Color coding

• Complies with United States, United Kingdom,

German, Japanese and IEC standards

Metallic overbraids and wraps

• Enhance abrasion resistance

Stock RTD lead wire

• Meets virtually all industrial RTD applications

WATLOW

®

153

Page 4

SERV-RITE Wire

SHIPMENT

STOCKED FOR

SAME DAY

Thermocouple Wire

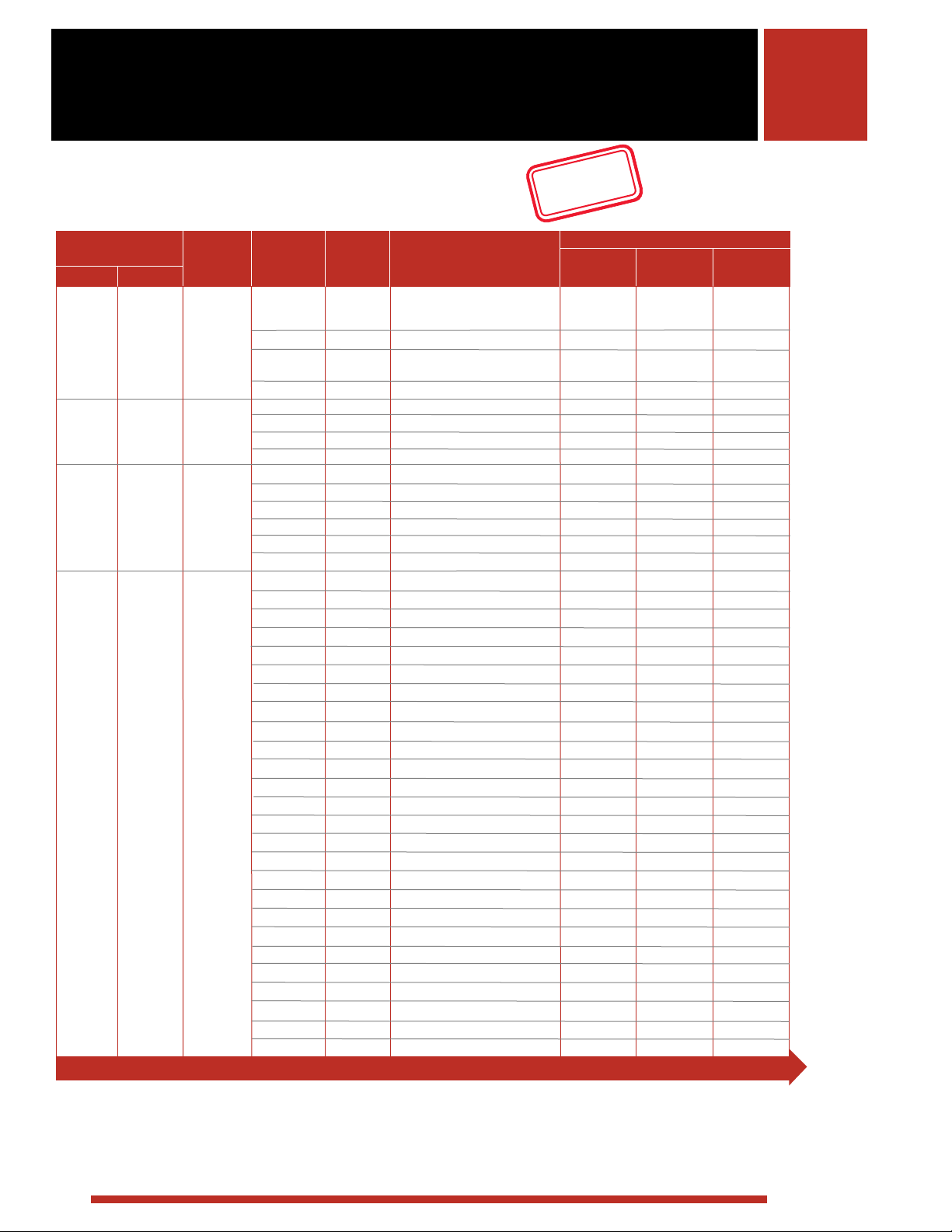

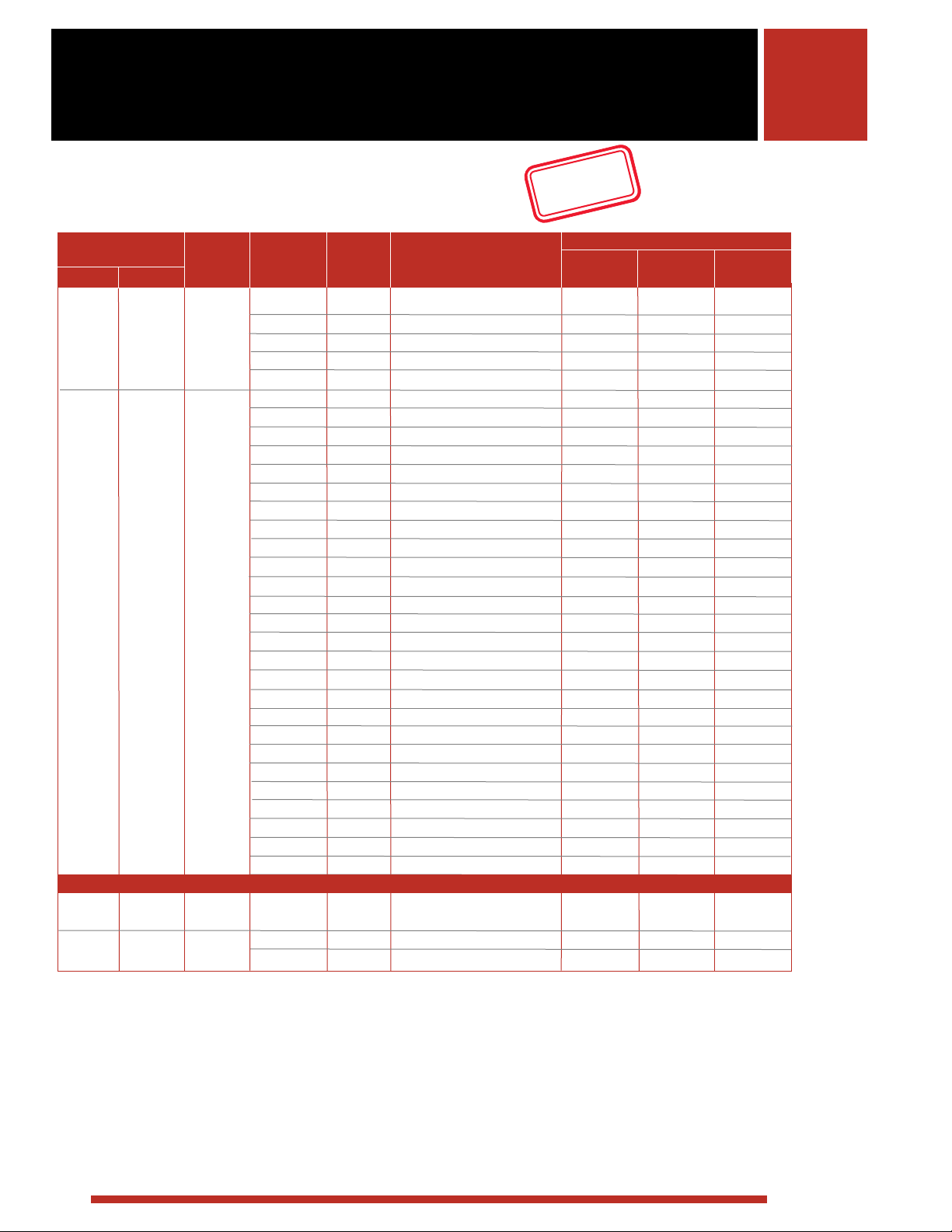

Stock Wire Products by Temperature

Thermocouple Wire Physical Properties

Max. Opr. Temp. Part Limits of Abrasion Moisture Chemical

°

F °C Insulation Number Error Description Resistance Resistance Resistance

K20-1-350 Standard Brd. C. Fbr./Brd. C. Fbr. Good Fair Good

2600 1427 Ceramic K20-1-355 Standard Brd. C. Fbr./Brd. C. Fbr. Good Fair Good

K20-2-350 Special Brd.C. Fbr./Brd. C. Fbr. Good Fair Good

K20-2-355 Special Brd. C. Fbr./Brd. C. Fbr. Good Fair Good

K20-1-301 Standard Brd. Sil./Brd.Sil. (heavy build) Fair Fair Good

2000 1093 Vitreous K20-1-365 Standard Brd. Sil./Brd.Sil. Fair Fair Good

Silica K20-2-301 Special Brd. Sil/Brd.Sil. (heavy build) Fair Fair Good

K20-2-365 Special Brd. Sil./Brd.Sil. Fair Fair Good

J20-1-321 Standard Brd. HT Gls./Brd. HT Gls. Good Good Good

High J20-2-314 Special Brd. HT Gls./TW Good Good Good

1652 900 Temp. J20-2-321 Special Brd. HT Gls./Brd. HT Gls. Good Good Good

Fiberglass K20-1-321 Standard Brd. HT Gls./Brd. HT Gls. Good Good Good

K20-2-314 Special Brd. HT Gls./TW Good Good Good

K20-2-321 Special Brd. HT Gls./Brd. HT Gls. Good Good Good

E20-1-304 Standard Brd. Gls./Brd. Gls. Fair Good Good

J20-1-304 Standard Brd. Gls./Brd. Gls. Fair Good Good

J20-1-S-304 Standard Brd. Gls./Brd. Gls. Fair Good Good

J20-2-304 Special Brd. Gls./Brd. Gls. Fair Good Good

J20-3-304 Standard Brd. Gls./Brd. Gls. Fair Good Good

J20-3-S-304 Standard Brd. Gls./Brd. Gls./SS Brd. Fair Good Good

J24-1-304 Standard Brd. Gls./Brd. Gls. Fair Good Good

J24-2-304 Special Brd. Gls./Brd. Gls. Fair Good Good

J24-3-304 Standard Brd. Gls./Brd. Gls. Fair Good Good

J28-2-305 Special Wrp. Dbl. Gls./Brd. Gls. Fair Good Good

1000 538 Standard J30-1-305 Standard Wrp. Dbl. Gls./Brd. Gls. Fair Good Good

Fiberglass J30-2-305 Special Wrp. Dbl. Gls./Brd. Gls. Fair Good Good

K20-1-304 Standard Brd. Gls./Brd. Gls. Fair Good Good

K20-1-S-304 Standard Brd. Gls./Brd. Gls. Fair Good Good

K20-2-304 Special Brd. Gls./Brd. Gls. Fair Good Good

K20-3-304 Standard Brd. Gls./Brd. Gls. Fair Good Good

K20-3-S-304 Standard Brd. Gls./Brd. Gls./SS Brd. Fair Good Good

K24-1-304 Standard Brd. Gls./Brd. Gls. Fair Good Good

K24-2-304 Special Brd. Gls./Brd. Gls. Fair Good Good

K24-3-304 Standard Brd. Gls./Brd. Gls. Fair Good Good

K28-2-305 Special Wrp. Dbl. Gls./Brd. Gls. Fair Good Good

K30-1-305 Standard Wrp. Dbl. Gls./Brd. Gls. Fair Good Good

K30-2-305 Special Wrp. Dbl. Gls./Brd. Gls. Fair Good Good

S20-5-304* Standard Brd. Gls./Brd. Gls. Fair Good Good

T20-1-304 Standard Brd. Gls./Brd. Gls. Fair Good Good

T24-1-304 Standard Brd. Gls./Brd. Gls. Fair Good Good

*Note: The recommended operating temperature is limited to the extension grade alloy recommended temperature of 400°F (204°C).

(heavy build)

(heavy build)

CONTINUED

154

WATLOW

®

Page 5

SERV-RITE Wire

SHIPMENT

STOCKED FOR

SAME DAY

Thermocouple Wire

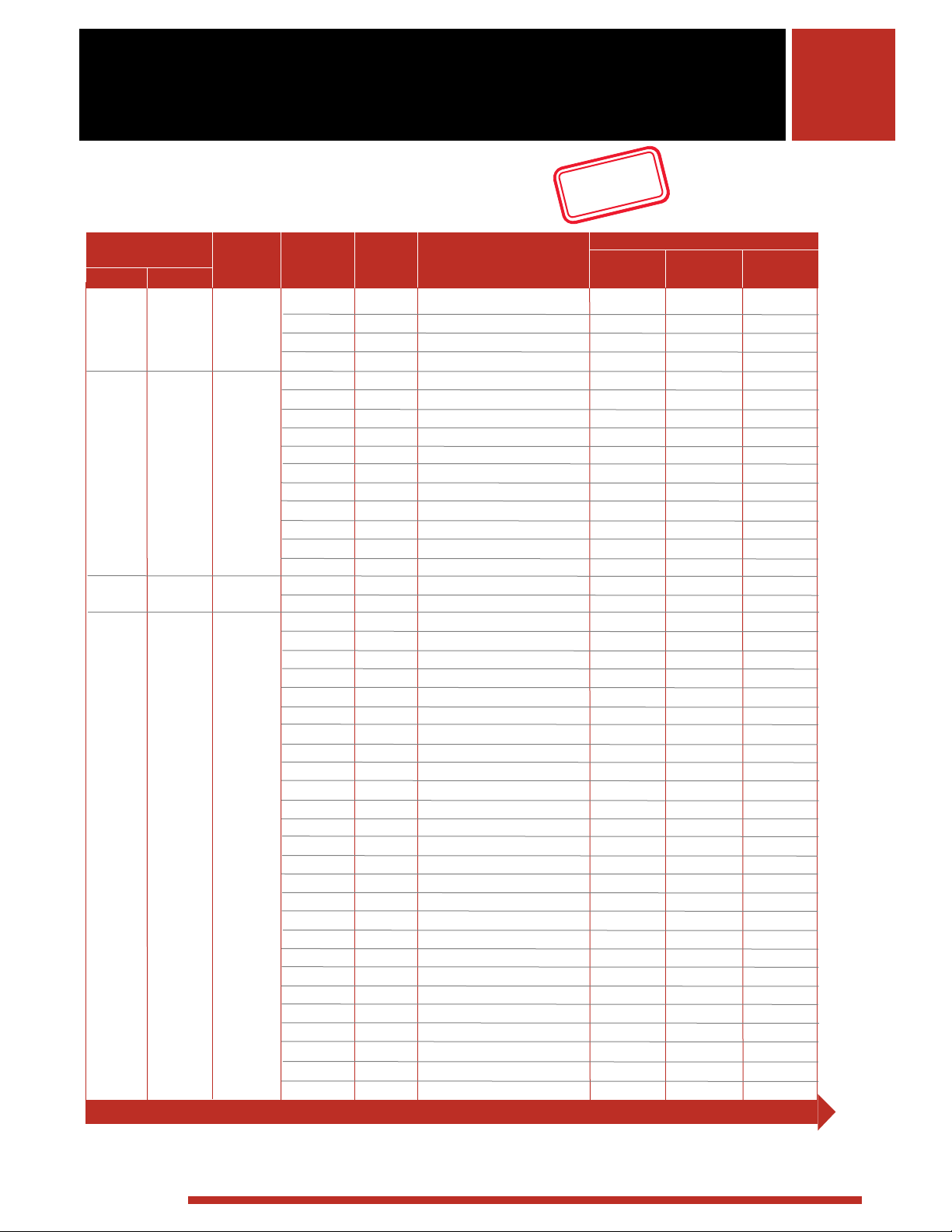

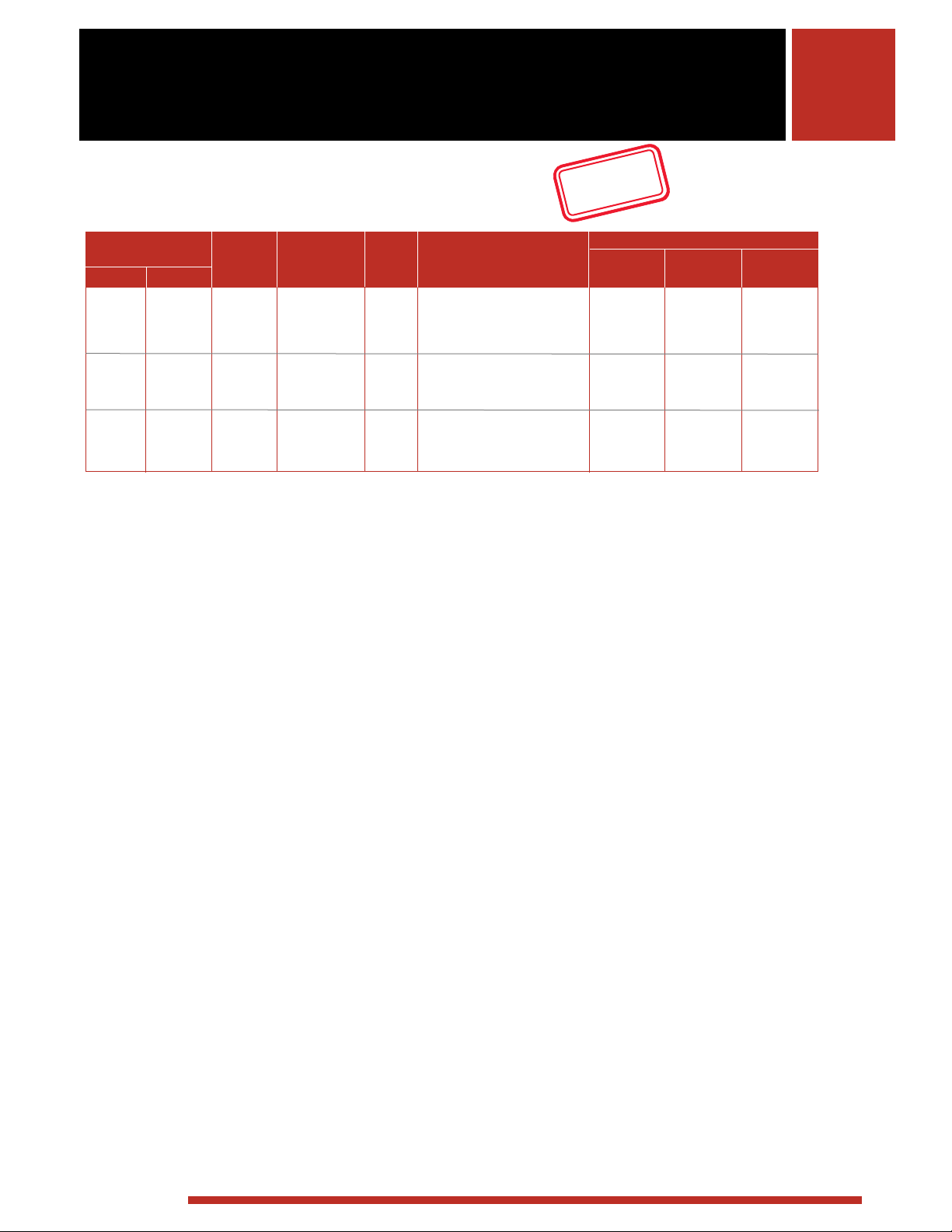

Stock Wire Products by Temperature (Continued)

Thermocouple Wire Physical Properties

Max. Opr. Temp. Part Limits of Abrasion Moisture Chemical

°

F °C Insulation Number Error Description Resistance Resistance Resistance

J20-1-512 Standard Tp. P-mide/Tp. P-mide Excellent Excellent Excellent

J20-3-512 Standard Tp. P-mide/Tp. P-mide Excellent Excellent Excellent

800 427 Polyimide J24-2-511 Special Tp. P-mide/TW Excellent Excellent Excellent

Tape K20-3-512 Standard Tp. P-mide/Tp. P-mide Excellent Excellent Excellent

J20-1-508 Standard Tp. TFE/Tp. TFE Good Excellent Excellent

J20-2-508 Special Tp. TFE/Tp. TFE Good Excellent Excellent

J24-1-508 Standard Tp. TFE/Tp. TFE Good Excellent Excellent

J24-2-508 Special Tp. TFE/Tp. TFE Good Excellent Excellent

K20-1-508 Standard Tp. TFE/Tp. TFE Good Excellent Excellent

600 316 TFE Tape K20-2-508 Special Tp. TFE/Tp. TFE Good Excellent Excellent

K24-1-508 Standard Tp. TFE/Tp. TFE Good Excellent Excellent

K24-2-508 Special Tp. TFE/Tp. TFE Good Excellent Excellent

T20-2-508 Special Tp. TFE/Tp. TFE Good Excellent Excellent

T24-1-508 Standard Tp. TFE/Tp. TFE Good Excellent Excellent

T24-2-508 Special Tp. TFE/Tp. TFE Good Excellent Excellent

550 288 PFA J24-3-516 Standard PFA/PFA Good Excellent Excellent

K24-2-516 Special PFA/PFA Good Excellent Excellent

E20-1-507 Standard FEP/FEP Excellent Excellent Excellent

J16-5-509* Standard FEP/TWS/FEP Excellent Excellent Excellent

J20-1-507 Standard FEP/FEP Excellent Excellent Excellent

J20-1-509 Standard FEP/TWS/FEP Excellent Excellent Excellent

J20-2-507 Special FEP/FEP Excellent Excellent Excellent

J20-3-507 Standard FEP/FEP Excellent Excellent Excellent

J20-5-507* Standard FEP/FEP Excellent Excellent Excellent

J20-5-509* Standard FEP/TWS/FEP Excellent Excellent Excellent

J24-1-507 Standard FEP/FEP Excellent Excellent Excellent

500 260 FEP J24-2-507 Special FEP/FEP Excellent Excellent Excellent

J24-3-507 Standard FEP/FEP Excellent Excellent Excellent

J30-2-506 Special FEP/FEP Excellent Excellent Excellent

K16-5-509* Standard FEP/TWS/FEP Excellent Excellent Excellent

K20-1-507 Standard FEP/FEP Excellent Excellent Excellent

K20-1-509 Standard FEP/TWS/FEP Excellent Excellent Excellent

K20-2-507 Special FEP/FEP Excellent Excellent Excellent

K20-2-509 Special FEP/TWS/FEP Excellent Excellent Excellent

K20-3-507 Standard FEP/FEP Excellent Excellent Excellent

K20-5-507* Standard FEP/FEP Excellent Excellent Excellent

K20-5-509* Standard FEP/TWS/FEP Excellent Excellent Excellent

K24-1-507 Standard FEP/FEP Excellent Excellent Excellent

K24-2-507 Special FEP/FEP Excellent Excellent Excellent

K24-3-507 Standard FEP/FEP Excellent Excellent Excellent

K30-2-506 Special FEP/FEP Excellent Excellent Excellent

S20-5-507* Standard FEP/FEP Excellent Excellent Excellent

T20-1-507 Standard FEP/FEP Excellent Excellent Excellent

CONTINUED

*Note: The recommended operating temperature is limited to the extension grade alloy recommended temperature of 400°F (204°C).

WATLOW

®

155

Page 6

SERV-RITE Wire

SHIPMENT

STOCKED FOR

SAME DAY

Thermocouple Wire

Stock Wire Products by Temperature (Continued)

Thermocouple Wire Physical Properties

Max. Opr. Temp. Part Limits of Abrasion Moisture Chemical

°

F °C Insulation Number Error Description Resistance Resistance Resistance

500 260 FEP T20-1-509 Standard FEP/TWS/FEP Excellent Excellent Excellent

T20-2-507 Special FEP/FEP Excellent Excellent Excellent

T20-3-507 Standard FEP/FEP Excellent Excellent Excellent

T24-2-507 Special FEP/FEP Excellent Excellent Excellent

T30-2-506 Special FEP/FEP Excellent Excellent Excellent

E20-5-502* Standard PVC/PVC Good Excellent Good

E20-5-510* Standard PVC/TWS/PVC Good Excellent Good

J16-5-502* Standard PVC/PVC Good Excellent Good

J16-5-510* Standard PVC/TWS/PVC Good Excellent Good

J20-5-502* Standard PVC/PVC Good Excellent Good

J20-5-510* Standard PVC/TWS/PVC Good Excellent Good

J20-7-502* Standard PVC/PVC Good Excellent Good

J20-7-510* Standard PVC/TWS/PVC Good Excellent Good

J24-1-505 Standard PVC/Ripcord Good Excellent Good

J24-2-505 Special PVC/Ripcord Good Excellent Good

K16-5-502* Standard PVC/PVC Good Excellent Good

221 105 PVC K16-5-510* Standard PVC/TWS/PVC Good Excellent Good

K20-5-502* Standard PVC/PVC Good Excellent Good

K20-5-510* Standard PVC/TWS/PVC Good Excellent Good

K20-7-502* Standard PVC/PVC Good Excellent Good

K20-7-510* Standard PVC/TWS/PVC Good Excellent Good

K24-1-505 Standard PVC/Ripcord Good Excellent Good

K24-2-505 Special PVC/Ripcord Good Excellent Good

S20-5-502* Standard PVC/PVC Good Excellent Good

S20-5-510* Standard PVC/TWS/PVC Good Excellent Good

T16-5-510* Standard PVC/TWS/PVC Good Excellent Good

T20-5-502* Standard PVC/PVC Good Excellent Good

T20-5-510* Standard PVC/TWS/PVC Good Excellent Good

T20-7-502* Standard PVC/PVC Good Excellent Good

T24-1-505 Standard PVC/Ripcord Good Excellent Good

T24-2-505 Special PVC/Ripcord Good Excellent Good

RTD Lead Wire

1000 538 Standard RT3-24-8-705 N/A Brd. Gls./TW/Brd. Gls. Fair Good Good

Fiberglass

500 260 FEP RT3-22-8-704 N/A FEP/TW/FEP Excellent Excellent Excellent

221 105 PVC RT3-22-4-701 N/A PVC/TW/PVC Good Excellent Good

*Note: The recommended operating temperature is limited to the extension grade alloy recommended temperature of 400°F (204°C).

156

WATLOW

®

Page 7

SERV-RITE Wire

SHIPMENT

STOCKED FOR

SAME DAY

Thermocouple Wire

Heat Treat Thermocouple Wire

Thermocouple Wire Physical Properties

Max. Opr. Temp. Part Limits of Abrasion Moisture Chemical

°

F °C Insulation Number Error Description Resistance Resistance Resistance

1800 982 High Temp.

Fiberglass

2200 1204 Vitreous

Silica

2200 1204 Ceramic

Legend

Brd. = Braided

Gls. = Fiberglass

TWS. = Twisted and shielded

HT = High temperature

Tp. = Taped

P-mide = Polyimide

Cbl. = Cable

TW. = Twisted

Wrp. = Wrapped

K20-2-321-CAL

K-20-2-301-CAL

K20-2-350-CAL

Special Brd. HT Gls./Brd. HT Gls. Good Good Good

Calculated from 200-1800°F

(93-982°C), every 200°F (93°C)

Special Brd. Vit. Sil./Brd. Sil. Fair Fair Good

Calculated from 200-2200°F

(93-1204°C), every 200°F (93°C)

Special Brd. C. Fbr./Brd. C. Fbr. Good Fair Good

from 200-2200°F

(93-1204°C), every 200°F (93°C)

Dbl. = Double

Cot. = Cotton

C.Fbr = Ceramic fiber

Sil. = Vitreous silica

Pr. = Pair

Std. = Standard

Spc. = Special

WATLOW

®

157

Page 8

SERV-RITE Wire

Thermocouple Wire

Ordering Information

How to Order

Include the following information when ordering

SERV-RITE thermocouple and extension wire:

Calibration

• E, J, K, N, S or T

Gauge size

• AWG gauge

Solid or stranded conductors

• Stranded conductors are seven strand constructions.

If other configurations are required, please contact the

factory.

Thermocouple or extension grade

• Determine if it will be used for the actual sensor or only

to “extend” the signal at lower temperatures.

Standard or special limits of error

• This will determine the accuracy of the sensor. Limits

of error are determined by testing at a pre-defined

Watlow standard test point. To guarantee limits of error

at other temperature points, please contact the factory

to arrange special testing.

Insulation on singles and duplex

• The insulation material used is usually chosen to fit the

environment where the sensor will be used.

Color coding

• Unless specified, all color coding is to ASTM E

230 standards.

Spool lengths

• Spool length requirements should be specified.

Watlow strives to maintain a policy of shipping 1,000

foot spools. However, if not specified, random lengths

may be shipped. If special packaging is required,

please contact the factory.

Variation in quantity

• Watlow follows the industry standard of shipping and

invoicing at plus or minus ten percent of the cost for

any ordered item. If requirements dictate anything other

than plus or minus ten percent, contact the factory for

potential additional charges.

Overbraid options

• Options for overbraid are shown below.

Overbraid selection code

• S–Stainless steel wire braid

C–Tinned copper wire braid

N–Alloy 600 wire braid

Options are listed on each page. Special requirements

and testing are available at additional cost. Contact the

factory for details. These include:

Shielding

• Some constructions are available with shielding

possibilities.

Calibration Tests

• If calibration is required, please specify temperatures.

Certificate of Compliance

• These may be provided for various specifications.

When ordering, please provide specification

requirements.

Special Requirements

• Please contact the factory for any requirements not

listed above.

Availability

Stock constructions: Many constructions are available

for same day shipment

Stock constructions with options: Shipment is usually

within five working days or less

Stock constructions requiring calibration or other

laboratory services: Shipment is usually within five

working days or less

158

WATLOW

®

Page 9

SERV-RITE Wire

Thermocouple Wire

Technical Data

How to Select Wire to Meet Requirements

The following information will explain some of the

nomenclature associated with thermocouple wire and

thermocouple extension wire. By reading this information,

orders can be placed quickly and accurately.

Thermocouple Wire or Thermocouple

Extension Wire

There are some significant differences between wire used

to actually measure temperature and wire used to carry a

millivoltage signal to an instrument.

The most obvious difference is the color-code used to

identify the wire itself. In most instances, thermocouple

grade wire is identified by its overall brown color.

Exceptions in the SERV-RITE wire product line are the

very high temperature yarns such as

SERIES 301 and 350.

not used if there is no overall covering, as in SERV-RITE

wire SERIES 505, 511 and 314.

The functional differences between the two wires are that

thermocouple “extension” wire is not calibrated above

400°F (204°C). The temperature rating of the insulations

used on some extension grade wire exceeds 400°F

(204°C) temperature to allow the wire to survive

occasional contact with hot parts or furnace walls.

Terms used in the tables of this section:

Single Conductor Insulation

Identifies insulation type used on individual thermoelements.

Certain part numbers use a combination of insulations.

When there is a combination, insulations are listed in

order of application.

Duplex Conductor Insulation

Lists the overall insulation when one is used. Constructions

which have no overall insulation use this area to describe

the duplexing method—i.e. twisting, “ripcord”, etc.

Of course, the overall color code is

those used in the

Temperature Rating

Most constructions are rated for both continuous use

and for single reading applications. Continuous use

temperature is considered to be the highest temperature a

particular construction will survive indefinitely. The single

reading temperature is the highest temperature at which

the construction will perform and continue to produce an

accurate reading. However, after exposure to the single

reading temperature, the wire will exhibit less flexibility

and/or abrasion resistance. Therefore, it is not likely that

the wire could be removed from the application and

then reused.

ASTM E 230 Color Code

Generally, SERV-RITE wire has color codes wherever

possible. Exceptions are high temperature yarn

constructions such as the SERIES 301 and 350. Color

coding of the SERIES 511 and 512 is accomplished by

including a colored thread or “tracer” under the tape.

Physical Properties

Abrasion Resistance is rated fair, good, or excellent and

is based on the wall thickness of the construction and

how well it survives with other insulations of similar

thicknesses. The 511 SERIES receives an excellent rating

because the thin wall of polyimide tape will survive better

than almost any other insulation applied in the same wall

thickness. The “absolute” abrasion resistance of a

construction will depend not only on the type of insulation,

but on thickness at which it is applied.

Moisture Resistance ratings are given for wire in the

“as received” condition. In the case of fiberglass insulated

wire, moisture resistance is achieved by using

impregnations or spirally applied tapes called moisture

barriers. The impregnations and/or tapes will burn off

at temperatures below the upper useful operating

temperatures of the fiberglass. The thermoplastic

insulations (PVC and fluoroplastics) and polyimide

insulated constructions will maintain their moisture

resistance up to their “continuous” temperature rating.

Chemical Resistance ratings are applied as they relate

to most common chemicals. These ratings apply to

insulation types and not necessarily to the type of

impregnation used. Contact the factory for specific

applications.

WATLOW

®

159

Page 10

SERV-RITE Wire

Thermocouple Wire

Technical Data (Continued)

Metallic Overbraids and Wraps

Although standard SERV-RITE wire products are

designed to yield a high degree of abrasion resistance,

it is sometimes necessary to add an additional metallic

covering to further enhance this property. Following are

available overbraids and wraps.

Stainless Steel Wire Braid (S)

This most popular over-braid uses 300 series stainless steel

and is available on virtually all standard SERV-RITE wire

offerings. It is an economical method to extend the life of

thermocouple and extension wire. Several of Watlow’s

standard wire items are available from stock with a

stainless overbraid. Non-stock items are available as a

special order.

Alloy 600 Wire Braid (N)

Most commonly specified on high temperature SERV-RITE

wire yarn insulations, the Inconel®braid offers a higher

operating temperature than the series 300 stainless steel

overbraid. When this braid is specified on SERV-RITE

SERIES 350, the performance of the material is only

surpassed by metal-sheathed cables. Consult the factory

for availability on specific wire items.

Tinned Copper Wire Overbraid (C)

When there is a possibility of electrical interference in the

area of the thermocouple installation, it may be necessary

to shield the wire from electrical “noise.” Several Watlow

standard products use aluminized tapes as an intrinsic

shield. If shielding is needed on other constructions, a

tinned copper shield can be specified as a special order.

160

WATLOW

®

Page 11

SERV-RITE Wire

Thermocouple Wire

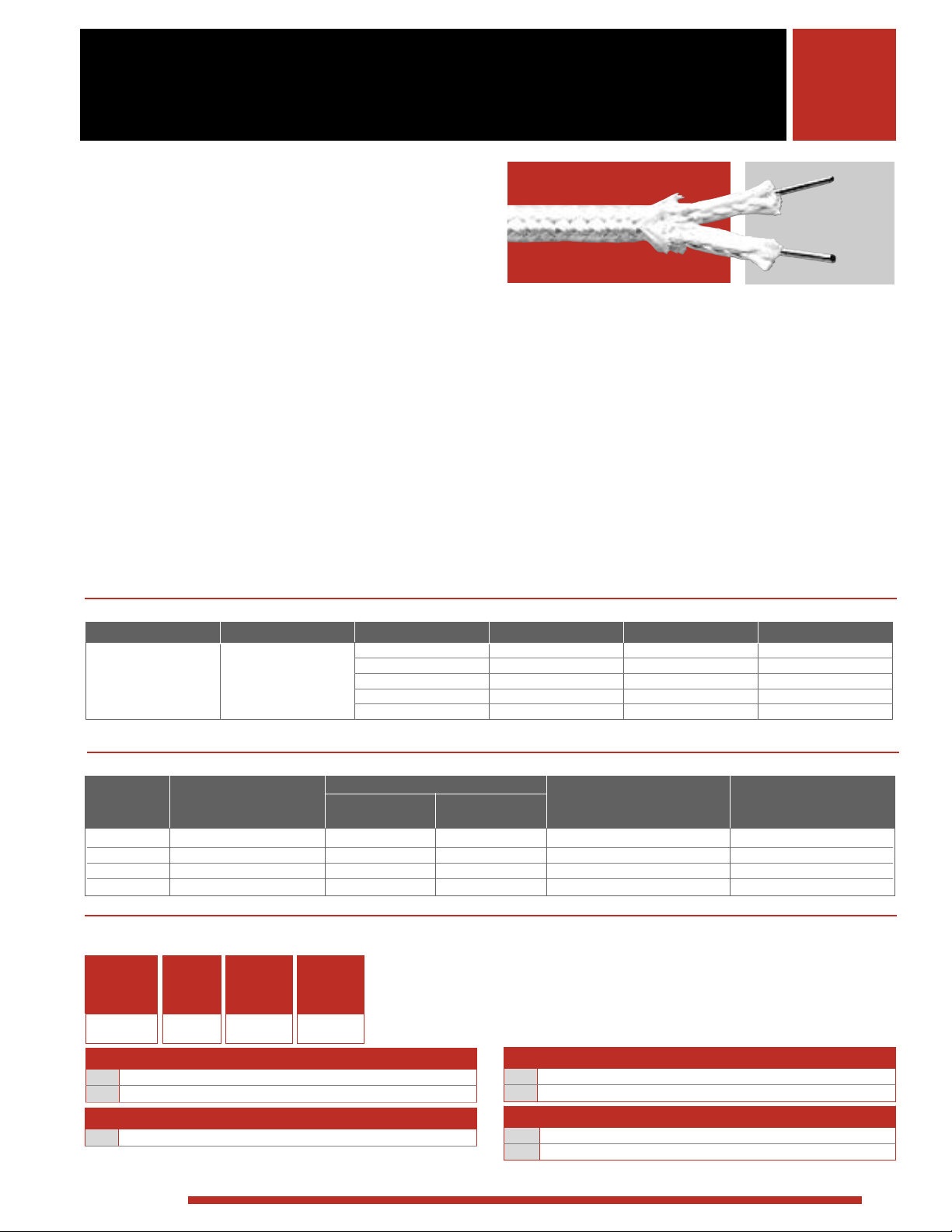

High-Temperature Vitreous Silica Braided

Thermocouple Wire SERIES 301 and 365

Both the SERIES 301 and 365 use vitreous silica yarn

as the insulation on both the conductors and duplex.

This yarn retains its flexibility after exposure to high

temperatures. Because this insulation has no binders or

impregnations, it may “flower” when stripped.

The vitreous silica yarn’s greater purity performs better

at high temperatures than other fibrous glass products.

Testing indicates that “contamination” will compromise

this material’s upper use temperature. For this reason,

our standard offering is supplied without color coding or

impregnations. The SERIES 365 construction is a

cost-effective, medium insulation build of the popular

heavy duty SERIES 301 construction.

For higher temperatures consider SERIES 350.

Performance Capabilities

• Continuous temperature rating: 1800°F (982°C)

• Vitreous silica braided yarn insulation

• Available with an optional metallic overbraid for

additional abrasion resistance

Popular Constructions

Grade AWG Wire Type Insulation Limits of Error Type K

Solid Heavy Standard K20-1-301

Thermocouple 20

* Calibrated from 200 to 2200°F (93 to 1204°C), every 200°F (93°C). Only available in this construction.

Note: Bolded products are stocked.

Solid Heavy Special K20-2-301

Solid Heavy Special K20-2-301-CAL*

Solid Medium Standard K20-1-365

Solid Medium Special K20-2-365

Applications

• Heat treating

• Oven and furnace

• Survey and load

Specifications

Continuous use temperature

• 1800°F (980°C)

Single use temperature

• 2000°F (1093°C)

Resistance properties

• Moisture: Fair

• Chemical: Good

• Abrasion: Fair

Wire Specifications

AWG

20

18

16

20

a

SERIES 301,2SERIES 365

Nominal Conductor Size

in. (mm)

a

a

a

2

0.032 (0.813) 0.018 (0.457) 0.015 (0.381) 0.098 x 0.154 (2.49 x 3.91) 15 (22.4)

0.040 (1.020) 0.018 (0.457) 0.015 (0.381) 0.110 x 0.180 (2.79 x 4.57) 19 (28.3)

0.051 (1.290) 0.016 (0.406) 0.015 (0.381) 0.118 x 0.198 (3.00 x 5.03) 25 (37.3)

0.032 (0.813) 0.015 (0.381) 0.012 (0.305) 0.090 x 0.140 (2.29 x 3.56) 13 (19.4)

Ordering Information

Part Number

③③⑤⑤④④

ASTM E

230

Calibration

①①

K=

Type K

N=

Type N

③③

②②

20 =

20 gauge solid

WATLOW

AWG

®

Conductor

Type/

Tolerance

ASTM E 230 Calibration

AWG

⑥⑥

⑦⑦②②①①

Insulation

Type

Nominal Insulation Thickness

Conductor

in. (mm)

Overall

in. (mm)

⑤⑤⑥⑥

Note: Minimum order sizes apply for non-stock constructions.

Nominal Overall

Size

in. (mm)

④④

1=

Thermocouple grade, solid wire, standard tolerance

2=

Thermocouple grade, solid wire, special tolerance

⑦⑦

301=

Heavy build

365=

Medium build

Conductor/Type Tolerance

Insulation Type

Approximate

Shipping Weight

lbs/1000 ft (kg/km)

161

Page 12

SERV-RITE Wire

Thermocouple Wire

Fiberglass Braided Thermocouple and

Extension Wire SERIES 304

The uniform quality and availability of the SERIES 304

make it the ideal wire for general applications requiring

moderate abrasion and moisture resistance, wide

temperature capabilities and economy.

Each conductor is covered with a color coded glass

braid. This braid is impregnated to enhance abrasion

resistance and reduce fraying. The insulated single

conductors are laid parallel and covered with another

layer of woven glass. A final impregnation is then applied

to the glass.

For higher temperatures, consider SERIES 321.

Performance Capabilities

• Continuous temperature rating: 900°F (482°C)

• Fiberglass braided yarn insulation

• Available with an optional metallic overbraid for

additional abrasion resistance

Applications

• Heat treating

• Oven

• General use

Specifications

Continuous use temperature

• 900°F (482°C)

Single use temperature

• 1000°F (540°C)

Resin retained to 400°F (204°C)

Resistance properties

• Moisture: Good

• Chemical: Good

• Abrasion: Fair

Popular Constructions

Grade AWG Wire Type Limits of Error Type K Type J Type T Type E

Solid Standard K20-1-304* J20-1-304* T20-1-304 E20-1-304

20

Thermocouple

24

Extension 20 Solid Standard

* These constructions stocked with a stainless steel overbraid (order overbraid by adding “-S” in front of construction type (i.e. K20-1-S-304).

Note: Bolded products are stocked.

Solid Special K20-2-304 J20-2-304 T20-2-304 E20-2-304

Stranded Standard K20-3-304* J20-3-304* T20-3-304 E20-3-304

Solid Standard K24-1-304 J24-1-304 T24-1-304

Solid Special K24-2-304 J24-2-304 T24-2-304

Stranded Standard K24-3-304 J24-3-304

Wire Specifications

Nominal Insulation Thickness

AWG

24 0.020 (1.508) 0.005 (0.127) 0.006 (0.152) 0.045 x 0.072 (1.14 x 1.83) 7 (10.4)

24 S* (7/32) 0.024 (1.610) 0.005 (0.127) 0.006 (0.152) 0.048 x 0.080 (1.22 x 2.03) 8 (11.9)

20 0.032 (1.813) 0.005 (0.127) 0.006 (0.152) 0.056 x 0.096 (1.42 x 2.44) 9 (13.4)

20 S* (7/28) 0.038 (1.965) 0.006 (0.152) 0.006 (0.152) 0.064 x 0.112 (1.63 x 2.84) 10 (14.9)

* “S” denotes stranded wire: e.g., “20 S (7/28)” is seven strands of 28 gauge wire to make a 20 gauge stranded conductor.

Nominal Conductor Size

in. (mm)

Conductor

in. (mm)

Overall

in. (mm)

Nominal Overall

Size

in. (mm)

Approximate

Shipping Weight

lbs/1000 ft (kg/km)

162

WATLOW

®

Page 13

SERV-RITE Wire

Thermocouple Wire

Fiberglass Braided Thermocouple and Extension

Wire SERIES 304

Ordering Information

Part Number

ASTM E

230

Calibration

③③

AWG

(Continued)

④④

Conductor

Type/

Tolerance

⑤⑤

⑤⑤⑥⑥

3

⑦⑦②②①①

0

4

①①

E=Type E

J=

Type J

K=

Type K

N=

Type N

S=

Type S

T=

Type T

③③②②

24 =

24 gauge solid or 24 gauge stranded (7/32)

20 =

20 gauge solid or 20 gauge stranded (7/28)

ASTM E 230 Calibration

AWG

④④

1=

Thermocouple grade, solid wire, standard tolerance

2=

Thermocouple grade, solid wire, special tolerance

3=

Thermocouple grade, stranded wire, standard tolerance

4=

Thermocouple grade, stranded wire, special tolerance

5=

Extension grade, solid wire, standard tolerance

6=

Extension grade, solid wire, special tolerance

7=

Extension grade, stranded wire, standard tolerance

8=

Extension grade, stranded wire, special tolerance

Note: Minimum order sizes apply for non-stock constructions.

Conductor Type/Tolerance

WATLOW

®

163

Page 14

SERV-RITE Wire

Thermocouple Wire

Fiberglass Wrapped Thermocouple and

Extension Wire SERIES 305

SERIES 305 is specifically constructed for light duty

applications where size is a critical factor. Single

conductors are insulated using a specialized yarn

wrapped around the conductors in layers. Yarn is then

impregnated to add abrasion resistance and enhance

electrical properties. The insulated single conductors are

then laid parallel and covered with a layer of braided

glass. A final impregnation is applied to the braid.

For higher temperature applications, use SERIES 321.

Performance Capabilities

• Continuous temperature rating: 900°F (482°C)

• Fiberglass braided yarn insulation

• Yarn wrapped conductors for superior coverage on

small gauge wires

• Available with an optional metallic overbraid for

additional abrasion resistance

Applications

• Heat treating

• Oven

• General use

Specifications

Continuous use temperature

• 900°F (482°C)

Single use temperature

• 1000°F (540°C)

Resin retained to 400°F (204°C)

Resistance properties

• Moisture: Good

• Chemical: Good

• Abrasion: Fair

Popular Constructions

Grade AWG Wire Type Limits of Error Type K Type J

Solid Standard K24-1-305 J24-1-305

Solid Special K24-2-305 J24-2-305

Solid Standard K28-1-305 J28-1-305

Solid Special K28-2-305 J28-2-305

Solid Standard K30-1-305 J30-1-305

Solid Special K30-2-305 J30-2-305

Thermocouple

Note: Bolded products are stocked.

24

28

30

Wire Specifications

Nominal Insulation Thickness

AWG

30 0.010 (0.254) 0.005 (0.127) 0.008 (0.203) 0.036 x 0.056 (0.914 x 1.42) 3 (4.5)

28 0.013 (0.320) 0.005 (0.127) 0.008 (0.203) 0.040 x 0.062 (1.02 x 1.57) 3 (4.5)

24 0.020 (0.508) 0.005 (0.127) 0.006 (0.152) 0.042 x 0.072 (1.07 x 1.83) 7 (10.4)

24 S* (7/32) 0.024 (0.610) 0.005 (0.127) 0.006 (0.152) 0.048 x 0.080 (1.22 x 2.03) 8 (11.9)

20 0.032 (0.813) 0.005 (0.127) 0.006 (0.152) 0.054 x 0.096 (1.37 x 2.44) 9 (13.4)

20 S* (7/28) 0.038 (0.965) 0.005 (0.127) 0.006 (0.152) 0.060 x 0.108 (1.52 x 2.74) 10 (14.9)

* “S” denotes stranded wire: e.g., “24 S (7/32)” is seven strands of 32 gauge wire to make a 24 gauge stranded conductor.

Nominal Conductor Size

in. (mm)

Conductor

in. (mm)

Overall

in. (mm)

Nominal Overall

Size

in. (mm)

Approximate

Shipping Weight

lbs/1000 ft (kg/km)

164

WATLOW

®

Page 15

SERV-RITE Wire

Thermocouple Wire

Fiberglass Wrapped Thermocouple and

Extension Wire SERIES 305

Ordering Information

Part Number

ASTM E

230

Calibration

③③

AWG

④④

Conductor

Type/

Tolerance

(Continued)

⑤⑤

⑤⑤

3

⑥⑥

0

⑦⑦②②①①

5

①①

E=

Type E

J=

Type J

K=

Type K

N=

Type N

S=

Type S

T=

Type T

③③

②②

30 =

30 gauge solid

28 =

28 gauge solid

24 =

24 gauge solid or 24 gauge stranded (7/32)

20 =

20 gauge solid or 20 gauge stranded (7/28)

ASTM E 230 Calibration

AWG

④④

1=

Thermocouple grade, solid wire, standard tolerance

2=

Thermocouple grade, solid wire, special tolerance

3=

Thermocouple grade, stranded wire, standard tolerance

4=

Thermocouple grade, stranded wire, special tolerance

5=

Extension grade, solid wire, standard tolerance

6=

Extension grade, solid wire, special tolerance

7=

Extension grade, stranded wire, standard tolerance

8=

Extension grade, stranded wire, special tolerance

Note: Minimum order sizes apply for non-stock constructions.

Conductor Type/Tolerance

WATLOW

®

165

Page 16

SERV-RITE Wire

Thermocouple Wire

High-Temperature Fiberglass Twisted

Thermocouple Wire SERIES 314

The SERIES 314 is an economical construction for

general, high temperature applications. The braided high

temperature yarn is applied in a unique manner that

allows SERIES 314 to be competitively priced with other

fiberglass constructions. It produces a finished wire that

performs at temperatures to 1600°F (870°C).

The conductors are insulated with braided, high strength

fiberglass and impregnated to improve abrasion

resistance. The impregnation is tinted to impart color

coding to primary insulations. The insulated single

conductors are then twisted together to yield a

construction flexible enough for almost any application.

Performance Capabilities

• Continuous temperature rating: 1300°F (705°C)

• Fiberglass braided yarn insulation

• Twisted design has no jacket

• Available with an optional metallic overbraid for

additional abrasion resistance

Applications

• Heat treating

• Aluminum stress relieving

• Steel annealing

Specifications

Continuous use temperature

• 1300°F (705°C)

Single use temperature

• 1600°F (870°C)

Resin retained to 400°F (204°C)

Resistance properties

• Moisture: Good

• Chemical: Good

• Abrasion: Good

Popular Constructions

Grade AWG Wire Type Limits of Error Type K Type J

Thermocouple

20

24

Note: Bolded products are stocked.

Solid Standard K20-1-314 J20-1-314

Solid Special K20-2-314 J20-2-314

Solid Standard K24-1-314 J24-1-314

Solid Special K24-2-314 J24-2-314

Wire Specifications

Nominal Conductor

AWG

24 0.020 (0.508) 0.015 (0.381) 0.100 (2.54) 6 (8.9)

20 0.032 (0.965) 0.015 (0.381) 0.124 (3.15) 10 (14.9)

18 0.040 (1.02) 0.018 (0.457) 0.152 (3.56) 16 (23.8)

16 0.051 (1.29) 0.018 (0.457) 0.174 (4.42) 21 (31.3)

Nominal Conductor Size

in. (mm)

Insulation Thickness

in. (mm)

Nominal Overall

Size

in. (mm)

Approximate

Shipping Weight

lbs/1000 ft (kg/km)

Ordering Information

Part Number

ASTM E

230

Calibration

①①

J=

Type J

K=

Type K

③③②②

24 =

24 gauge solid

20 =

20 gauge solid

16 =

16 gauge solid

②②①①

AWG

③③

④④

Conductor

Type/

Tolerance

⑤⑤

⑤⑤⑥⑥

3

ASTM E 230 Calibration

AWG

⑦⑦

1

4

④④

1=

Thermocouple grade, solid wire, standard tolerance

2=

Thermocouple grade, solid wire, special tolerance

Note: Minimum order sizes apply for non-stock constructions.

Conductor Type/Tolerance

166

WATLOW

®

Page 17

SERV-RITE Wire

Thermocouple Wire

High-Temperature Braided Fiberglass

Thermocouple Wire SERIES 321

The addition of color coding and impregnation to the

high temperature fiberglass make this wire the next logical

step for systems which exceed temperature capabilities of

the standard glass insulated series.

Each conductor is covered with a color coded, high

temperature fiberglass braid. This braid is then

impregnated to enhance abrasion resistance and

reduce fraying. The insulated conductors are laid

parallel and covered with another braid of high

temperature fiberglass and impregnation.

Performance Capabilities

• Continuous temperature rating: 1300°F (705°C)

• Heavy fiberglass braided yarn insulation

• Twisted design has no jacket

• Available with an optional metallic overbraid for

additional abrasion resistance

Applications

• Heat treating

• Aluminum and steel

Specifications

Continuous use temperature

• 1300°F (705°C)

Single use temperature

• 1600°F (870°C)

Resin retained to 400°F (204°C)

Resistance properties

• Moisture: Good

• Chemical: Good

• Abrasion: Good

Popular Constructions

Grade AWG Wire Type Limits of Error Type K Type J

Thermocouple

20

24

* Calibrated from 200 to 2200°F (93 to 1204°C), every 200°F (93°C). Only available in this construction.

Bolded products are stocked.

Solid Standard K20-1-321 J20-1-321

Solid Special K20-2-321 J20-2-321

Solid Special J20-2-321-CAL*

Solid Standard K24-1-321 J24-1-321

Solid Special K24-2-321 J24-2-321

Wire Specifications

Nominal Insulation Thickness

AWG

24 0.020 (0.508) 0.015 (0.381) 0.010 (0.254) 0.072 x 0.120 (1.83 x 3.05) 10 (14.9)

20 0.032 (0.965) 0.015 (0.381) 0.010 (0.254) 0.082 x 0.140 (2.08 x 3.56) 13 (19.4)

18 0.040 (1.02) 0.015 (0.381) 0.010 (0.254) 0.090 x 0.156 (2.29 x 3.96) 18 (26.8)

Nominal Conductor Size

in. (mm)

Conductor

in. (mm)

Overall

in. (mm)

Nominal Overall

Size

in. (mm)

Approximate

Shipping Weight

lbs/1000 ft (kg/km)

Ordering Information

Part Number

ASTM E

230

Calibration

①①

J=

Type J

K=

Type K

N=

Type N

③③②②

24 =

24 gauge solid

20 =

20 gauge solid

②②①①

AWG

③③

④④

Conductor

Type/

Tolerance

⑤⑤

⑤⑤

3

ASTM E 230 Calibration

AWG

⑥⑥

2

⑦⑦

1

④④

1=

Thermocouple grade, solid wire, standard tolerance

2=

Thermocouple grade, solid wire, special tolerance

Note: Minimum order sizes apply for non-stock constructions.

Conductor Type/Tolerance

WATLOW

®

167

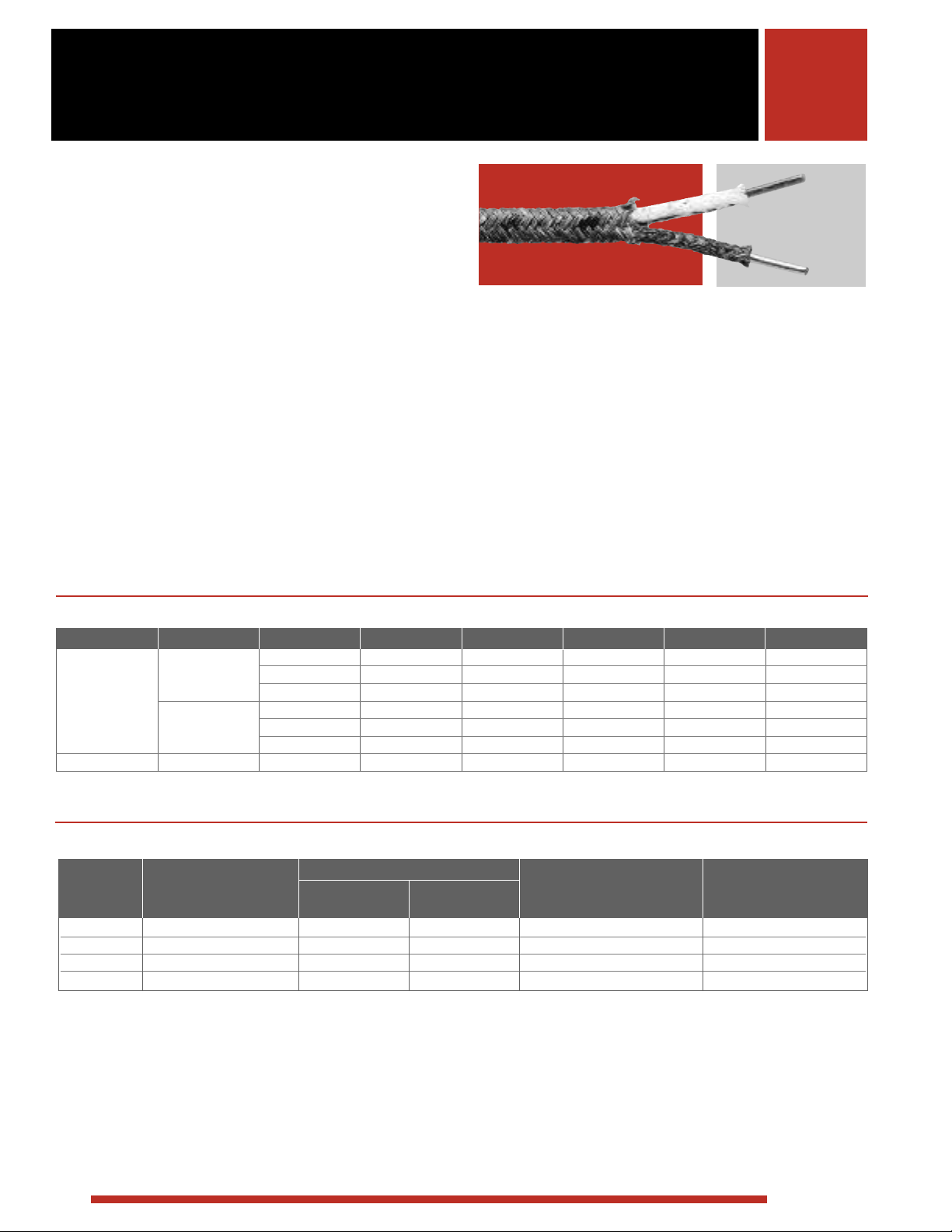

Page 18

SERV-RITE Wire

Thermocouple Wire

High-Temperature Ceramic Fiber

Thermocouple Wire SERIES 350 and 355

The SERIES 350 uses the ultimate high-temperature

flexible insulating system. The ceramic fiber yarn’s upper

temperature limit often exceeds the melting point of the

material it insulates. Because this insulation has no

binders or impregnations, it may “flower” when stripped.

When an application requires flexible insulation, while

pushing Type K or Type N to extreme limits, ceramic fiber

insulation is the only choice.

Watlow supplies standard SERIES 350 without color

coding or impregnations to minimize contaminating the

pure ceramic fiber yarn. Because this insulation has no

binders or impregnations, it may “flower” when stripped.

Laboratory testing indicates impregnation can decrease

the upper use temperature by as much as 1000°F

(540°C).

The SERIES 355 construction is a cost-effective, medium

insulation build of the popular SERIES 350 heavy-duty

construction.

If application temperatures exceed SERIES 350

construction, specify XACTPAK®mineral-insulated,

metal-sheathed cable.

Applications

• Heat treating

• Oven and furnace survey

• Load thermocouple

Specifications

Continuous use temperature

• 2200°F (1205°C)

Single use temperature

• 2600°F (1430°C)

Resistance properties

• Moisture: Fair

• Chemical: Good

• Abrasion: Good

Performance Capabilities

• Continuous temperature rating: 1205°C (2200°F)

• Ceramic fiber braided yarn insulation

• Available with an optional metallic overbraid for

additional abrasion resistance

Popular Constructions

Grade AWG Wire Type Insulation Limits of Error Type K

Solid Heavy Standard K20-1-350

Solid Heavy Special K20-2-350

Thermocouple 20

* Calibrated from 200 to 2200°F (93 to 1204°C), every 200°F (93°C). Only available in this construction.

Bolded products are stocked.

Solid Heavy Special K20-2-350-CAL*

Solid Medium Standard K20-1-355

Solid Medium Special K20-2-355

Wire Specifications

AWG

24

20

16

14

24

20

16

a

SERIES 350, 2SERIES 355

Nominal Conductor Size

in. (mm)

a

a

a

a

2

2

2

0.020 (0.508) 0.016 (0.406) 0.016 (0.406) 0.088 x 0.132 (2.24 x 3.35) 13 (19.4)

0.032 (0.965) 0.016 (0.406) 0.016 (0.406) 0.100 x 0.154 (2.54 x 3.91) 16 (23.8)

0.051 (1.29) 0.016 (0.406) 0.016 (0.406) 0.119 x 0.192 (3.02 x 4.88) 32 (47.7)

0.064 (1.63) 0.016 (0.406) 0.016 (0.406) 0.132 x 0.218 (3.35 x 5.54) 44 (65.6)

0.020 (0.508) 0.012 (0.305) 0.016 (0.406) 0.078 x 0.116 (1.98 x 2.95) 13 (19.4)

0.032 (0.965) 0.012 (0.305) 0.016 (0.406) 0.090 x 0.138 (2.29 x 3.50) 16 (23.8)

0.051 (1.29) 0.012 (0.305) 0.016 (0.406) 0.111 x 0.176 (2.82 x 4.47) 32 (47.7)

168

Nominal Insulation Thickness

Conductor

in. (mm)

Overall

in. (mm)

Nominal Overall

Size

in. (mm)

Approximate

Shipping Weight

lbs/1000 ft (kg/km)

WATLOW

®

Page 19

SERV-RITE Wire

Thermocouple Wire

High-Temperature Ceramic Fiber

Thermocouple Wire SERIES 350 and 355

Ordering Information

Part Number

ASTM E

230

Calibration

③③

AWG

④④⑥⑥

Conductor

Type/

Tolerance

⑤⑤

⑦⑦②②①①

Insulation

Type

(Continued)

①①

K=

N=

③③

②②

24 =

20 =

16 =

14 =

Type K

Type N

20 gauge solid

20 gauge solid

16 gauge solid

14 gauge solid

ASTM E 230 Calibration

AWG

④④

1=

Thermocouple grade, solid wire, standard tolerance

2=

Thermocouple grade, solid wire, special tolerance

⑤⑤⑥⑥

⑦⑦

350=

Heavy build

355=

Medium build

Note: Minimum order sizes apply for non-stock constructions.

Conductor/Type Tolerance

Insulation Type

WATLOW

®

169

Page 20

SERV-RITE Wire

Thermocouple Wire

Polyvinyl Chloride (PVC) Insulated Extension

Wire SERIES 502

SERIES 502 is an economical wire that has PVC for the

primary and duplex insulation.

The primary and duplex insulation is PVC. It yields a

construction that is inexpensive and performs

continuously at temperatures up to 220°F (105°C).

SERIES 502 is often used in conduit and wiring trays

where its flexibility allows for easy installation. It can be

easily stripped using hand tools or mechanical methods.

Performance Capabilities

• Continuous temperature rating: 220°F (105°C)

• Flexible PVC plastic insulation

• Available with an optional metallic overbraid for

additional abrasion resistance

Popular Constructions

Grade AWG Wire Type Limits of Error Type K Type J Type T Type E Type S

16

Extension

Note: Bolded products are stocked.

20

24

Solid Standard K16-5-502 J16-5-502

Stranded Standard K16-7-502 J16-7-502

Solid Standard K20-5-502 J20-5-502 T20-5-502 E20-5-502 S20-5-502

Stranded Standard K20-7-502 J20-7-502 T20-7-502

Solid Standard K24-5-502 J24-5-502 T24-5-502

Stranded Standard K24-7-502 J24-7-502 T24-7-502

Applications

• General use extension wire

Specifications

Continuous use temperature

• 220°F (105°C)

Single use temperature

• 220°F (105°C)

Resistance properties

• Moisture: Excellent

• Chemical: Excellent

• Abrasion: Excellent

Wire Specifications

Nominal Insulation Thickness

AWG

24 0.020 (0.508) 0.015 (0.381) 0.015 (0.381) 0.080 x 0.130 (2.03 x 3.30) 10 (14.9)

24 S* (7/32) 0.024 (0.610) 0.015 (0.381) 0.015 (0.381) 0.084 x 0.138 (2.13 x 3.51) 11 (16.4)

20 0.032 (0.813) 0.015 (0.381) 0.015 (0.381) 0.092 x 0.154 (2.34 x 3.91) 14 (20.9)

20 S* (7/28) 0.038 (0.965) 0.015 (0.381) 0.015 (0.381) 0.098 x 0.166 (2.49 x 4.22) 16 (23.8)

16 0.051 (1.29) 0.020 (0.508) 0.020 (0.508) 0.131 x 0.222 (3.33 x 5.64) 28 (41.7)

16 S* (7/24) 0.060 (1.52) 0.020 (0.508) 0.020 (0.508) 0.140 x 0.240 (3.56 x 6.10) 30 (44.7)

* “S” denotes stranded wire: e.g., “24 S (7/32)” is seven strands of 32 gauge wire to make a 24 gauge stranded conductor.

Nominal Conductor Size

in. (mm)

Conductor

in. (mm)

Overall

in. (mm)

Nominal Overall

Size

in. (mm)

Approximate

Shipping Weight

lbs/1000 ft (kg/km)

170

WATLOW

®

Page 21

SERV-RITE Wire

Thermocouple Wire

PVC Insulated Extension Wire SERIES 502 (Continued)

Ordering Information

Part Number

①①

ASTM E

230

Calibration

③③

AWG

④④

Conductor

Type/

Tolerance

⑤⑤

⑤⑤⑥⑥

5

⑦⑦②②

0

2

①①

E=

Type E

J=

Type J

K=

Type K

N=

Type N

S=

Type S

T=

Type T

③③②②

24 =

24 gauge solid or 24 gauge stranded (7/28)

20 =

20 gauge solid or 20 gauge stranded (7/28)

16 =

16 gauge solid or 16 gauge stranded (7/24)

ASTM E 230 Calibration

AWG

④④

5=

Extension grade, solid wire, standard tolerance

6=

Extension grade, solid wire, special tolerance

7=

Extension grade, stranded wire, standard tolerance

8=

Extension grade, stranded wire, special tolerance

Note: Minimum order sizes apply for non-stock constructions.

Conductor Type/Tolerance

WATLOW

®

171

Page 22

SERV-RITE Wire

Thermocouple Wire

PVC Insulated “RIPCORD” SERIES 505

The SERIES 505 is the most economical wire produced.

Unlike some competitive “ripcord” type constructions

which use only a stripe to establish polarity, SERIES 505

single conductors are fully color coded. The conductors

are individually insulated with the proper colored PVC and

fused into “ripcord” using a proprietary process.

Insulated conductors can be easily separated by hand

once the bond between conductors has been slit. As with

other PVC insulated products, SERIES 505 lends itself

well to both manual and mechanical stripping methods.

Performance Capabilities

• Continuous temperature rating: 220°F (105°C)

• Flexible PVC plastic insulation

• “Ripcord” peelable construction

• Available with an optional metallic overbraid for

additional abrasion resistance

Applications

• Laboratory

• Test stand

• Automotive

Specifications

Continuous use temperature

• 220°F (105°C)

Single use temperature

• 220°F (105°C)

Resistance properties

• Moisture: Excellent

• Chemical: Good

• Abrasion: Good

Popular Constructions

Grade AWG Wire Type Limits of Error Type K Type J Type T

Thermocouple 24

Note: Bolded products are stocked.

Solid Standard

Solid Special

K24-1-505 J24-1-505 T24-1-505

K24-2-505 J24-2-505 T24-2-505

Wire Specifications

Nominal Conductor

AWG

26 0.016 (0.406) 0.015 (0.381) 0.046 x 0.088 (1.17 x 2.24) 4 (6.0)

24 0.020 (0.508) 0.015 (0.381) 0.050 x 0.096 (1.27 x 2.44) 5 (7.5)

Nominal Conductor Size

in. (mm)

Insulation Thickness

in. (mm)

Nominal Overall

Size

in. (mm)

Approximate

Shipping Weight

lbs/1000 ft (kg/km)

Ordering Information

Part Number

ASTM E

230

Calibration

①①

J=

Type J

K=

Type K

T=

Type T

③③②②

26 =

26 gauge solid

24 =

24 gauge solid or 24 gauge stranded (7/32)

20 =

20 gauge solid or 20 gauge stranded (7/28)

③③

AWG

④④⑦⑦②②①①

Conductor

Type/

Tolerance

⑤⑤

⑤⑤

5

ASTM E 230 Calibration

AWG

⑥⑥

0

5

④④

1=

Thermocouple grade, solid wire, standard tolerance

2=

Thermocouple grade, solid wire, special tolerance

3=

Thermocouple grade, stranded wire, standard tolerance

4=

Thermocouple grade, stranded wire, special tolerance

Note: Minimum order sizes apply for non-stock constructions.

Conductor Type/Tolerance

172

WATLOW

®

Page 23

SERV-RITE Wire

Thermocouple Wire

Small Gauge

Fluorinated Ethylene Propylene

(FEP) Insulated SERIES 506

The SERIES 506 is the smallest standard insulated wire

construction. The thin FEP

duplex insulation yields a construction that can operate

safely at temperatures far beyond common PVC and

nylon insulations.

The SERIES 506 is fully color coded for easy installation.

Its small size allows use in high density circuits.

Response time is minimized by small diameter

conductors. For larger diameter gauge sizes than

#28, specify SERIES 507.

Performance Capabilities

• Continuous temperature rating: 400°F (204°C)

• Flexible FEP plastic insulation

• Thin insulation wall for a compact construction

• Available with an optional metallic overbraid for

additional abrasion resistance

wall on both primary and

Applications

• Laboratory

• Test stand

• Industrial equipment testing

Specifications

Continuous use temperature

• 400°F (204°C)

Single use temperature

• 500°F (260°C)

Resistance properties

• Moisture: Excellent

• Chemical: Excellent

• Abrasion: Excellent

Popular Constructions

Grade AWG Wire Type Limits of Error Type K Type J Type T

28 Solid Special

Thermocouple

Note: Bolded products are stocked.

30 Solid Special

36 Solid Special

K28-2-506 J28-2-506 T28-2-506

K30-2-506 J30-2-506 T30-2-506

K36-2-506 J36-2-506 T36-2-506

Wire Specifications

Nominal Insulation Thickness

AWG

36 0.005 (0.127) 0.005 (0.127) 0.005 (0.127) 0.025 x 0.040 (0.635 x 1.02) 2 (3.0)

32 0.008 (0.203) 0.005 (0.127) 0.005 (0.127) 0.028 x 0.046 (0.711 x 1.17) 2 (3.0)

30 0.010 (0.254) 0.005 (0.127) 0.005 (0.127) 0.030 x 0.050 (0.762 x 1.27) 3 (4.5)

28 0.013 (0.330) 0.005 (0.127) 0.005 (0.127) 0.033 x 0.056 (0.838 x 1.42) 3 (4.5)

Nominal Conductor Size

in. (mm)

Conductor

in. (mm)

Overall

in. (mm)

Nominal Overall

Size

in. (mm)

Approximate

Shipping Weight

lbs/1000 ft (kg/km)

Ordering Information

Part Number

ASTM E

230

Calibration

①①

E=

Type E

J=

Type J

K=

Type K

N=

Type N

S=

Type S

T=

Type T

WATLOW

③③

②②①①

AWG

®

④④

Conductor

Type/

Tolerance

⑤⑤

⑤⑤⑥⑥

5

ASTM E 230 Calibration

⑦⑦

0

6

③③②②

36 =

36 gauge solid

30 =

30 gauge solid

28 =

28 gauge solid

④④

1=

Thermocouple grade, solid wire, standard tolerance

2=

Thermocouple grade, solid wire, special tolerance

Note: Minimum order sizes apply for non-stock constructions.

Conductor Type/Tolerance

AWG

173

Page 24

SERV-RITE Wire

Thermocouple Wire

FEP Insulated Thermocouple and

Extension Wire SERIES 507

The SERIES 507 is the most economical fluoroplastic

insulated wire. Individual conductors are coated with a

layer of color coded FEP. The insulated conductors are

then parallel duplexed with an additional layer of color

coded FEP. The finished construction has a continuous

temperature rating of 400°F (204°C). Abrasion, moisture

and chemical resistance exceed most other insulations.

This construction is widely used when pulling long

lengths of wire through conduit. FEP’s low friction

coefficient and abrasion resistance are suited for

these applications.

For higher abrasion resistance consider SERIES 514

Tefzel®insulated constructions.

For higher temperatures specify SERIES 508.

Performance Capabilities

• Continuous temperature rating: 400°F (204°C)

• Flexible FEP plastic insulation

• Available with an optional metallic overbraid for

additional abrasion resistance

Applications

• General use extension wire

Specifications

Continuous use temperature

• 400°F (204°C)

Single use temperature

• 500°F (260°C)

Resistance properties

• Moisture: Excellent

• Chemical: Excellent

• Abrasion: Excellent

Popular Constructions

Grade AWG Wire Type Limits of Error Type K Type J Type T Type E Type S

Extension

Thermocouple

Note: Bolded products are stocked.

20 Solid Standard K20-5-507 J20-5-507 T20-5-507 E20-5-507 S20-5-507

24 Solid Standard S24-5-507

Solid Standard K20-1-507 J20-1-507 T20-1-507 E20-1-507

20

24

Stranded Standard K20-3-507 J20-3-507 T20-3-507 E20-3-507

Solid Special K20-2-507 J20-2-507 T20-2-507 E20-2-507

Solid Standard K24-1-507 J24-1-507 T24-1-507 E24-1-507

Stranded Standard K24-3-507 J24-3-507 T24-3-507 E24-3-507

Solid Special K24-2-507 J24-2-507 T24-2-507 E24-2-507

Wire Specifications

Nominal Insulation Thickness

AWG

24 0.020 (0.508) 0.008 (0.203) 0.010 (0.254) 0.056 x 0.096 (1.42 x 2.44) 8 (11.9)

24 S* (7/32) 0.024 (0.610) 0.008 (0.203) 0.010 (0.254) 0.060 x 0.104 (1.52 x 2.64) 9 (13.4)

22 0.025 (0.635) 0.008 (0.203) 0.010 (0.254) 0.061 x 0.106 (1.55 x 2.69) 10 (14.9)

22 S* (7/30) 0.030 (0.762) 0.008 (0.203) 0.010 (0.254) 0.066 x 0.116 (1.68 x 2.95) 11 (16.4)

20 0.032 (0.813) 0.008 (0.203) 0.010 (0.254) 0.068 x 0.120 (1.73 x 3.05) 12 (17.9)

20 S* (7/28) 0.038 (0.965) 0.008 (0.203) 0.010 (0.254) 0.074 x 0.132 (1.88 x 3.35) 14 (20.9)

18 0.040 (1.02) 0.008 (0.203) 0.010 (0.254) 0.076 x 0.136 (1.93 x 3.45) 18 (26.8)

18 S* (7/26) 0.048 (1.22) 0.008 (0.203) 0.010 (0.254) 0.084 x 0.152 (2.13 x 3.86) 20 (29.8)

* “S” denotes stranded wire: e.g., “24 S (7/32)” is seven strands of 32 gauge wire to make a 24 gauge stranded conductor.

Nominal Conductor Size

in. (mm)

Conductor

in. (mm)

Overall

in. (mm)

Nominal Overall

Size

in. (mm)

Approximate

Shipping Weight

lbs/1000 ft (kg/km)

174

WATLOW

®

Page 25

SERV-RITE Wire

Thermocouple Wire

FEP Insulated Thermocouple and Extension

Wire SERIES 507

Ordering Information

Part Number

③③

ASTM E

230

Calibration

②②①①

AWG

(Continued)

④④

Conductor

Type/

Tolerance

⑤⑤

⑤⑤⑥⑥

5

0

⑦⑦

7

①①

E=

Type E

J=

Type J

K=

Type K

N=

Type N

S=

Type S

T=

Type T

③③②②

24 =

24 gauge solid or 24 gauge stranded (7/32)

22 =

22 gauge solid or 22 gauge stranded (7/30)

20 =

20 gauge solid or 20 gauge stranded (7/28)

ASTM E 230 Calibration

AWG

④④

1=

Thermocouple grade, solid wire, standard tolerance

2=

Thermocouple grade, solid wire, special tolerance

3=

Thermocouple grade, stranded wire, standard tolerance

4=

Thermocouple grade, stranded wire, special tolerance

5=

Extension grade, solid wire, standard tolerance

6=

Extension grade, solid wire, special tolerance

7=

Extension grade, stranded wire, standard tolerance

8=

Extension grade, stranded wire, special tolerance

Note: Minimum order sizes apply for non-stock constructions.

Conductor Type/Tolerance

WATLOW

®

175

Page 26

SERV-RITE Wire

Thermocouple Wire

TFE Insulated SERIES 508

The primary and duplex insulation of SERIES 508 is fused

TFE tape which is spirally applied to the conductor and

heated. This process, called sintering, forms the tape

into a homogeneous layer. When sintered, the tape

exhibits all of the advantages of extruded TFE insulation,

while eliminating the concentricity problems associated

with TFE extrusions.

The SERIES 508 is fully color coded and capable of

continuous operation in excess of 500°F (260°C).

Because the fusing process causes the duplex tape to

fuse with the primary insulation, SERIES 508 is not

recommended for applications where it is necessary

to remove the outer tape while leaving the primary

insulation intact.

Performance Capabilities

• Continuous temperature rating: 500°F (260°C)

• Fused TFE tape insulation

• Available with an optional metallic overbraid for

additional abrasion resistance

Applications

• Aircraft

• Petroleum processing

Specifications

Continuous use temperature

• 500°F (260°C)

Single use temperature

• 600°F (315°C)

Resistance properties

• Moisture: Excellent

• Chemical: Excellent

• Abrasion: Good

Popular Constructions

Grade AWG Wire Type Limits of Error Type K Type J Type T Type E

Solid Standard K20-1-508 J20-1-508 T20-1-508 E20-1-508

20

Thermocouple

24

Note: Bolded products are stocked.

Stranded Standard K20-3-508 20-3-508 T20-3-508 E20-3-508

Solid Special K20-2-508 J20-2-508 T20-2-508 E20-2-508

Solid Standard K24-1-508 J24-1-508 T24-1-508 E24-1-508

Stranded Standard K24-3-508 J24-3-508 T24-3-508 E24-3-508

Solid Special K24-2-508 J24-2-508 T24-2-508 E24-2-508

Wire Specifications

Nominal Insulation Thickness

AWG

26 0.016 (0.406) 0.006 (0.152) 0.008 (0.203) 0.044 x 0.072 (1.12 x 1.83) 4 (6.0)

24 0.020 (0.508) 0.006 (0.152) 0.008 (0.203) 0.047 x 0.077 (1.19 x 1.95) 5 (7.5)

24 S* (7/32) 0.024 (0.610) 0.006 (0.152) 0.008 (0.203) 0.049 x 0.084 (1.24 x 2.13) 6 (8.9)

20 0.032 (0.813) 0.006 (0.152) 0.008 (0.203) 0.061 x 0.106 (1.55 x 2.69) 11 (16.4)

20 S* (7/28) 0.038 (0.965) 0.006 (0.152) 0.008 (0.203) 0.064 x 0.112 (1.63 x 2.84) 12 (17.9)

18 0.040 (1.02) 0.006 (0.152) 0.008 (0.203) 0.068 x 0.120 (1.73 x 3.05) 16 (23.8)

18 S* (7/26) 0.048 (1.22) 0.006 (0.152) 0.008 (0.203) 0.076 x 0.136 (1.93 x 3.45) 18 (26.8)

* “S” denotes stranded wire: e.g., “24 S (7/32)” is seven strands of 32 gauge wire to make a 24 gauge stranded conductor.

Nominal Conductor Size

in. (mm)

Conductor

in. (mm)

Overall

in. (mm)

Nominal Overall

Size

in. (mm)

Approximate

Shipping Weight

lbs/1000 ft (kg/km)

176

WATLOW

®

Page 27

SERV-RITE Wire

Thermocouple Wire

TFE Insulated SERIES 508 (Continued)

Ordering Information

Part Number

ASTM E

230

Calibration

②②①①

AWG

③③

④④

Conductor

Type/

Tolerance

⑤⑤

⑤⑤⑥⑥

5

0

⑦⑦

8

①①

E=

Type E

J=

Type J

K=

Type K

N=

Type N

S=

Type S

T=

Type T

③③

②②

26 =

26 gauge solid

24 =

24 gauge solid or 24 gauge stranded (7/32)

20 =

20 gauge solid or 20 gauge stranded (7/28)

ASTM E 230 Calibration

AWG

④④

1=

Thermocouple grade, solid wire, standard tolerance

2=

Thermocouple grade, solid wire, special tolerance

3=

Thermocouple grade, stranded wire, standard tolerance

4=

Thermocouple grade, stranded wire, special tolerance

Note: Minimum order sizes apply for non-stock constructions.

Conductor Type/Tolerance

WATLOW

®

177

Page 28

SERV-RITE Wire

Thermocouple Wire

FEP Insulated and Shielded Thermocouple

and Extension Wire SERIES 509

The SERIES 509 was developed specially for use with

microprocessor-based systems.

The conductors are insulated with color coded FEP. They

are then twisted with a copper drain wire. An aluminized

polyester tape is wrapped around the conductors and

drain wire and then FEP is applied.

The finished construction can withstand temperatures in

excess of 400°F (204°C). Twisted conductors minimize

electromagnetic interference (EMI) and the shield tape

eliminates most problems associated with AC “noise” in

the sensing circuit.

Performance Capabilities

• Continuous temperature rating: 400°F (204°C)

• Flexible FEP plastic insulation

• Twisted and shielded construction to reduce electrical

noise interference

• Available with an optional metallic overbraid for

additional abrasion resistance

Applications

• General use extension wire

Specifications

Continuous use temperature

• 400°F (204°C)

Single use temperature

• 500°F (260°C)

Resistance properties

• Moisture: Excellent

• Chemical: Excellent

• Abrasion: Excellent

Popular Constructions

Grade AWG Wire Type Limits of Error Type K Type J Type T Type E Type S

16

Extension

20

20

Thermocouple

24

Note: Bolded products are stocked.

Solid Standard K16-5-509 J16-5-509

Stranded Standard K16-7-509 J16-7-509

Solid Standard K20-5-509 J20-5-509 T20-5-509 E20-5-509 S20-5-509

Stranded Standard K20-7-509 J20-7-509 T20-7-509

Solid Standard K20-1-509 J20-1-509 T20-1-509

Solid Special K20-2-509 J20-2-509 T20-2-509

Solid Standard K24-1-509 J24-1-509 T24-1-509

Stranded Standard K24-3-509 J24-3-509 T24-3-509

Wire Specifications

Nominal Insulation Thickness

AWG

24 0.020 (0.508) 0.008 (0.203) 0.012 (0.305) 0.104 (2.64) 12 (17.9)

24 S* (7/32) 0.024 (0.610) 0.008 (0.203) 0.012 (0.305) 0.112 (2.84) 13 (19.4)

20 0.032 (0.813) 0.008 (0.203) 0.012 (0.305) 0.128 (3.25) 18 (26.8)

20 S* (7/28) 0.038 (0.965) 0.008 (0.203) 0.012 (0.305) 0.140 (3.56) 20 (29.8)

18 0.040 (1.02) 0.008 (0.203) 0.015 (0.381) 0.152 (3.86) 25 (37.3)

18 S* (7/26) 0.048 (1.22) 0.008 (0.203) 0.015 (0.381) 0.168 (4.27) 27 (40.2)

16 0.051 (1.29) 0.008 (0.203) 0.015 (0.381) 0.174 (4.42) 33 (49.2)

16 S* (7/24) 0.060 (1.52) 0.008 (0.203) 0.015 (0.381) 0.192 (4.88) 35 (52.2)

* “S” denotes stranded wire: e.g., “24 S (7/32)” is seven strands of 32 gauge wire to make a 24 gauge stranded conductor.

Nominal Conductor Size

in. (mm)

Conductor

in. (mm)

Overall

in. (mm)

Nominal Overall

Size

in. (mm)

Approximate

Shipping Weight

lbs/1000 ft (kg/km)

178

WATLOW

®

Page 29

SERV-RITE Wire

Thermocouple Wire

FEP Insulated and Shielded Thermocouple

and Extension Wire SERIES 509

Ordering Information

Part Number

ASTM E

230

Calibration

③③

AWG

④④

Conductor

Type/

Tolerance

⑤⑤

⑤⑤⑥⑥

5

(Continued)

⑦⑦②②①①

0

9

①①

E=

Type E

J=

Type J

K=

Type K

N=

Type N

S=

Type S

T=

Type T

③③②②

24 =

24 gauge solid or 24 gauge stranded (7/32)

20 =

20 gauge solid or 20 gauge stranded (7/28)

16 =

16 gauge solid or 16 gauge stranded (7/24)

ASTM E 230 Calibration

AWG

④④

1=

Thermocouple grade, solid wire, standard tolerance

2=

Thermocouple grade, solid wire, special tolerance

3=

Thermocouple grade, stranded wire, standard tolerance

4=

Thermocouple grade, stranded wire, special tolerance

5=

Extension grade, solid wire, standard tolerance

6=

Extension grade, solid wire, special tolerance

7=

Extension grade, stranded wire, standard tolerance

8=

Extension grade, stranded wire, special tolerance

Note: Minimum order sizes apply for non-stock constructions.

Conductor Type/Tolerance

WATLOW

®

179

Page 30

SERV-RITE Wire

Thermocouple Wire

PVC Insulated and Shielded Thermocouple

and Extension Wire SERIES 510

The SERIES 510 is a PVC insulated, twisted and shielded

construction for systems sensitive to induced voltages

and “noise.”

The conductors are insulated with color coded PVC and

then twisted with a copper drain wire. An aluminized

polyester tape is wrapped around the two conductors

and drain wires to impart 100 percent shielding. Then,

another layer of PVC is applied.

The twisting eliminates most EMI while the shield tape

minimizes AC “noise” in the sensing circuit.

Performance Capabilities

• Continuous temperature rating: 220°F (105°C)

• Flexible PVC plastic insulation

• Twisted and shielded construction to reduce electrical

noise interference

• Available with an optional metallic overbraid for

additional abrasion resistance

Applications

• General use extension wire

Specifications

Continuous use temperature

• 220°F (105°C)

Single use temperature

• 220°F (105°C)

Resistance properties

• Moisture: Excellent

• Chemical: Good

• Abrasion: Good

Popular Constructions

Grade AWG Wire Type Limits of Error Type K Type J Type T Type E Type S

16

Extension

Note: Bolded products are stocked.

20

24

Solid Standard K16-5-510 J16-5-510 T16-5-510

Stranded Standard K16-7-510 J16-7-510 T16-7-510

Solid Standard K20-5-510 J20-5-510 T20-5-510 E20-5-510 S20-5-510

Stranded Standard K20-7-510 J20-7-510 T20-7-510

Solid Standard K24-5-510 J24-5-510 T24-5-510

Stranded Standard K24-7-510 J24-7-510 T24-7-510

Wire Specifications

Nominal Insulation Thickness

AWG

24 0.020 (0.508) 0.015 (0.381) 0.020 (0.508) 0.140 (3.56) 13 (19.4)

24 S* (7/32) 0.024 (0.610) 0.015 (0.381) 0.020 (0.508) 0.148 (3.76) 14 (20.9)

20 0.032 (0.813) 0.015 (0.381) 0.020 (0.508) 0.164 (4.17) 22 (32.8)

20 S* (7/28) 0.038 (0.965) 0.015 (0.381) 0.020 (0.508) 0.176 (4.47) 24 (35.8)

18 0.040 (1.02) 0.020 (0.508) 0.020 (0.508) 0.200 (5.08) 30 (44.7)

18 S* (7/26) 0.048 (1.22) 0.020 (0.508) 0.020 (0.508) 0.216 (5.49) 32 (47.7)

16 0.051 (1.29) 0.020 (0.508) 0.020 (0.508) 0.222 (5.64) 39 (58.1)

16 S* (7/24) 0.060 (1.52) 0.020 (0.508) 0.020 (0.508) 0.240 (6.10) 41 (61.1)

* “S” denotes stranded wire: e.g., “24 S (7/32)” is seven strands of 32 gauge wire to make a 24 gauge stranded conductor.

Nominal Conductor Size

in. (mm)

Conductor

in. (mm)

Overall

in. (mm)

Nominal Overall

Size

in. (mm)

Approximate

Shipping Weight

lbs/1000 ft (kg/km)

180

WATLOW

®

Page 31

SERV-RITE Wire

Thermocouple Wire

PVC Insulated and Shielded Thermocouple

and Extension Wire SERIES 510

Ordering Information

Part Number

ASTM E

230

Calibration

③③

AWG

④④

Conductor

Type/

Tolerance

⑤⑤

⑤⑤⑥⑥

5

(Continued)

⑦⑦②②①①

1

0

①①

E=

Type E

J=

Type J

K=

Type K

N=

Type N

S=

Type S

T=

Type T

③③②②

24 =

24 gauge solid or 24 gauge stranded (7/32)

20 =

20 gauge solid or 20 gauge stranded (7/28)

16 =

16 gauge solid or 16 gauge stranded (7/24)

ASTM E 230 Calibration

AWG

④④

1=

Thermocouple grade, solid wire, standard tolerance

2=

Thermocouple grade, solid wire, special tolerance

3=

Thermocouple grade, stranded wire, standard tolerance

4=

Thermocouple grade, stranded wire, special tolerance

5=

Extension grade, solid wire, standard tolerance

6=

Extension grade, solid wire, special tolerance

7=

Extension grade, stranded wire, standard tolerance

8=

Extension grade, stranded wire, special tolerance

Note: Minimum order sizes apply for non-stock constructions.

Conductor Type/Tolerance

WATLOW

®

181

Page 32

SERV-RITE Wire

Thermocouple Wire

Polyimide Insulated and Twisted SERIES 511

SERIES 511 is the most economical polyimide taped

construction. Polyimide film applied to the conductors is

considered to be the ultimate “soft” insulation. The tape

maintains its strength at temperatures up to 600°F

(315°C). The FEP laminate serves as a moisture barrier

and allows the tape to fuse with itself. The finished

construction will not unravel when cut.

SERIES 511 conductors are wrapped with the polyimide

tape which is fused to itself. Each conductor is color

coded with a colored thread under the tape. The

insulated conductors are twisted into a duplex

construction to eliminate the overall duplex insulation

and minimize cost.

Performance Capabilities

• Continuous temperature rating: 600°F (315°C)

• Polyimide fused tape insulation

• Twisted design has no outer jacket

• Colored tracer used to indicate calibration type

• Available with an optional metallic overbraid for

additional abrasion resistance

Applications

• Aerospace

• Petrochemical

• Plastics

Specifications

Continuous use temperature

• 600°F (315°C)

Single use temperature

• 800°F (430°C)

Resistance properties

• Moisture: Excellent

• Chemical: Excellent

• Abrasion: Excellent

Popular Constructions

Grade AWG Wire Type Limits of Error Type K Type J

Thermocouple

Note: Bolded products are stocked.

20

24

Solid Standard

Solid Special

Solid Standard

Solid Special

K20-1-511 J20-1-511

K20-2-511 J20-2-511

K24-1-511 J24-1-511

K24-2-511 J24-2-511

Wire Specifications

Nominal Conductor

AWG

30 0.010 (0.254) 0.004 (0.102) 0.040 (1.02) 3 (4.5)

24 0.020 (0.508) 0.005 (0.127) 0.060 (1.52) 4 (6.0)

24 S* (7/32) 0.024 (0.610) 0.005 (0.127) 0.068 (1.73) 5 (7.5)

20 0.032 (0.813) 0.005 (0.127) 0.084 (2.13) 8 (11.9)

20 S* (7/28) 0.038 (0.965) 0.005 (0.127) 0.094 (2.39) 9 (13.4)

Note: FEP laminate melts at approximately 260°C (500°F).

* “S” denotes stranded wire: e.g., “24 S (7/32)” is seven strands of 32 gauge wire to make a 24 gauge stranded conductor.

Nominal Conductor Size

in. (mm)

Insulation Thickness

in. (mm)

Nominal Overall

Size

in (mm)

Approximate

Shipping Weight

lbs/1000 ft (kg/km)

182

WATLOW

®

Page 33

SERV-RITE Wire

Thermocouple Wire

Polyimide Insulated and Twisted SERIES 511

(Continued)

Ordering Information

Part Number

ASTM E

230

Calibration

②②①①

AWG

③③

④④

Conductor

Type/

Tolerance

⑤⑤

⑤⑤⑥⑥

5

⑦⑦

1

1

①①

J=

Type J

K=

Type K

T=

Type T

③③②②

30 =

30 gauge solid

24 =

24 gauge solid or 24 gauge stranded (7/32)

20 =

20 gauge solid or 20 gauge stranded (7/28)

16 =

16 gauge solid

ASTM E 230 Calibration

AWG

④④

1=

Thermocouple grade, solid wire, standard tolerance

2=

Thermocouple grade, solid wire, special tolerance

3=

Thermocouple grade, stranded wire, standard tolerance

4=

Thermocouple grade, stranded wire, special tolerance

Note: Minimum order sizes apply for non-stock constructions.

Conductor Type/Tolerance

WATLOW

®

183

Page 34

SERV-RITE Wire

Thermocouple Wire

Polyimide Insulated SERIES 512

The SERIES 512 is a heavier duty version of SERIES 511

construction, using the same polyimide insulation. Color

coding is accomplished using the same colored thread

“tracers.” The SERIES 512 has a duplex insulation of

polyimide tape. The extra wall of tape yields a

construction with increased abrasion resistance.

For higher temperature requirements, choose one of our

fiberglass insulated wires.

For improved abrasion resistance, and easier color

identification of conductors, specify SERIES 513 when

contacting the factory.

Performance Capabilities

• Continuous temperature rating: 600°F (315°C)

• Polyimide fused tape insulation

• Colored tracer used to indicate calibration type

• Available with an optional metallic overbraid for

additional abrasion resistance

Applications

• Aerospace

• Petrochemical

• Plastics

Specifications

Continuous use temperature

• 600°F (315°C)

Single use temperature

• 800°F (430°C)

Resistance properties

• Moisture: Excellent

• Chemical: Excellent

• Abrasion: Excellent

Popular Constructions

Grade AWG Wire Type Limits of Error Type K Type J