Page 1

Page 2

Proven Capabilities

®

hermocouple wire and thermocouple extension wire

ince 1914, SERV-RITE

S

from Watlow

All SERV-RITE wire is manufactured under rigid quality control. It is

manufactured under ISO 9001 quality standards. Some wire can even be

shipped next day for your convenience.

All testing has National Institute of Standards Technology (NIST), formally

National Bureau of Standards (NBS), traceability. Unless otherwise specified, all

SERV-RITE thermocouple wire and extension wire are supplied to meet

standard tolerances of ASTM E 230. Special tolerances are also available.

®

have been known for premimum performance and reliability.

t

Watlow provides:

• Same day shipment on hundreds of stock items

• Temperature range capability from -328 to 2200°F

(-200 to 1205°C)

• Superior products and technical support delivered

worldwide

• State-of-the-art, in-house laboratory services including;

calibration, end-to-end uniformity testing, drift testing, base

metal, platinum and standard platinum resistance

thermometer (SPRT) standards with traceability to NIST

• NIST certifications of conformance and calibration

• Multitude of overbraids, wraps and insulations available,

including electrical noise shields and wraps

• Full range of resistance temperature detector (RTD) wire

(not listed in this publication)

• ASTM E 230 tolerances from ±0.9°F (±0.5°C)

or ±0.4 percent

• ISO 17025 accredited lab

Features and Benefits

Type E, J, K, N and T

thermocouple wire

• Fits virtually all applications

Type EX, JX, KX, NX, TX

extension wire

• Matches thermocouple type

Compensation extension wire for

Type R and S thermocouples

• Permits fine tuning of

temperature measuring circuit

Solid or stranded wire

construction

• Meets specific application

requirements

Wide selection of insulation types

• Meets temperature, chemical,

moisture and abrasion resistance

objectives

Color coding

• Allows compliance with United

States, United Kingdom, Germany,

Japan and IEC standards

Select metallic overbraids and

wraps

• Provides enhanced abrasion

resistance

Stock RTD lead wire

• Meets virtually all industrial RTD

applications

Page 3

SERV-RITE Wire and Cable

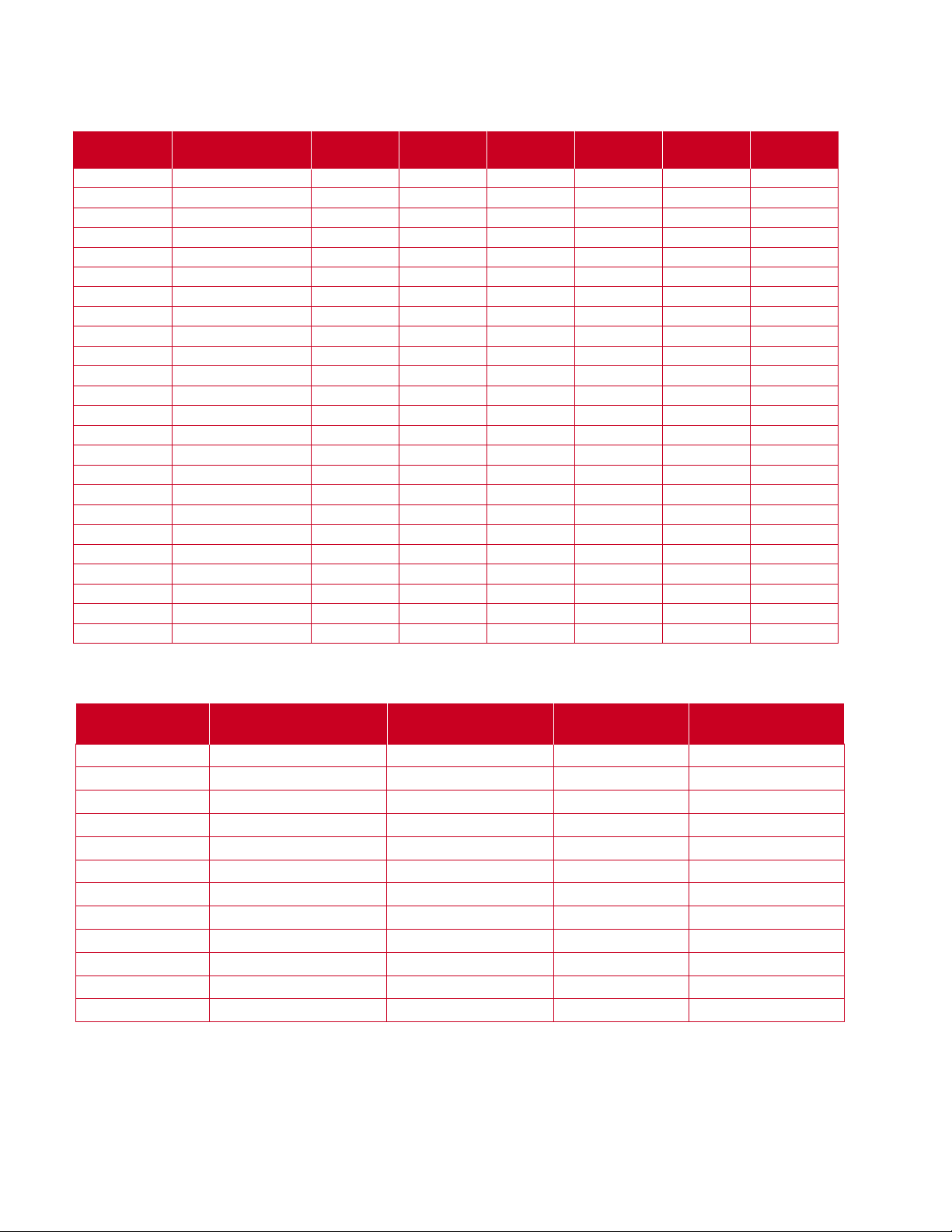

Nominal Resistance for Thermocouple Alloys in Ohms per Double Feet at 68°F (20°C)

B and S

Gauge

2 0.258 (6.5) 0.011 0.006 0.009 0.012

4 0.204 (5.2) 0.017 0.009 0.014 0.019

6 0.162 (4.1) 0.028 0.014 0.023 0.030

8 0.129 (3.3) 0.044 0.023 0.036 0.048

10 0.102 (2.6) 0.070 0.036 0.058 0.077

12 0.081 (2.1) 0.111 0.057 0.092 0.123 0.006 0.048

14 0.064 (1.6) 0.177 0.091 0.147 0.195 0.010 0.076

16 0.051 (1.3) 0.281 0.145 0.233 0.310 0.016 0.120

18 0.040 (1.0) 0.453 0.234 0.376 0.500 0.025 0.194

20 0.032 (0.8) 0.709 0.367 0.589 0.783 0.040 0.304

22 0.025 (0.7) 1.129 0.584 0.937 1.245 0.063 0.483

24 0.020 (0.5) 1.795 0.928 1.490 1.980 0.100 0.768

26 0.016 (0.4) 2.853 1.476 2.369 3.148 0.159 1.221

28 0.013 (0.3) 4.537 2.347 3.767 5.006 0.253 1.942

30 0.010 (0.3) 7.214 3.731 5.990 7.960 0.402 3.088

32 0.008 (0.2) 11.470 5.933 9.524 12.656 0.639 4.910

34 0.006 (0.2) 18.239 9.434 15.145 20.126 1.016 7.808

36 0.005 (0.1) 29.000 15.000 24.080 32.000 1.615 12.415

14 Stranded 0.076 (1.9) 0.161 0.083 0.134 0.178 0.009 0.069

16 Stranded 0.060 (1.5) 0.256 0.133 0.213 0.283 0.014 0.110

18 Stranded 0.048 (1.2) 0.408 0.211 0.338 0.450 0.023 0.174

20 Stranded 0.038 (1.0) 0.648 0.335 0.538 0.715 0.036 0.277

22 Stranded 0.030 (0.8) 1.031 0.533 0.856 1.137 0.057 0.441

24 Stranded 0.024 (0.6) 1.639 0.848 1.361 1.808 0.091 0.701

Diameter

in. (mm) E J K N RX, SX T

Conductor Size

B and S

Gauge

14 0.064 (1.6) 0.076 (1.9) 7 22

16 0.051 (1.3) 0.060 (1.5) 7 24

18 0.040 (1.0) 0.048 (1.2) 7 26

20 0.032 (0.8) 0.038 (1.0) 7 28

22 0.025 (0.6) 0.030 (0.8) 7 30

24 0.020 (0.5) 0.024 (0.6) 7 32

26 0.016 (0.4)

28 0.013 (0.3)

30 0.010 (0.3)

32 0.008 (0.2)

34 0.006 (0.2)

36 0.005 (0.1)

Solid Diameter

in. (mm)

Stranded Diameter

in. (mm) Number of Strands Stranding Gauge

1

Page 4

y

Thermocouple Calibration Types

ANSI Popular Generic Maximum Useful (whichever is greater)

Code Conductor and Trade Names Temperature Ranges* Standard Special

p

p

Limits of Error

E

J

K

N

EP

EN

JP

JN

KP

KN

NP

NN

Chromel

Constantan

Iron

Constantan

Chromel

Alumel

Nicrosil

Nisil

®

®

®

T/C grade

-328 to 1652°F (-200 to 900°C)

Extension grade

32 to 392°F (0 to 200°C)

T/C grade

32 to 1382°F (0 to 750°C)

Extension grade

32 to 392°F (0 to 200°C)

T/C grade

-328 to 2282°F (-200 to 1250°C)

Extension grade

32 to 392°F (0 to 200°C)

T/C grade

32 to 2282°F (0 to 1250°C)

Extension grade

32 to 392°F (0 to 200°C)

Above 32°F (0°C)

±3.0°F (1.7°C) or 0.5%

Below 32°F (0°C)

±3.0°F (1.7°C) or 1.0%

±4.0°F (2.2°C) or 0.75% ±2.0°F (1.1°C) or 0.4%

Above 32°F (0°C)

±4.0°F (2.2°C) or 0.75%

Below 32°F (0°C)

±4.0°F (2.2°C) or 2.0%

Above 32°F (0°C)

±4.0°F (2.2°C) or 0.75%

±1.8°F (1.0°C) or 0.4%

±2.0°F (1.1°C) or 0.4%

±2.0°F (1.1°C) or 0.4%

RP

R**

RN

SP

S**

SN

TP

T

TN

* Note: Conductor gauge size may limit upper temperature ranges. Contact a Watlow representative for additional information.

**Note: Compensating alloys used for extension wire applications.

Copper

#11 Alloy

Copper

#11 Alloy

Copper

Constantan

Extension grade

32 to 392°F (0 to 200°C)

Extension grade

32 to 392°F (0 to 200°C)

T/C grade

-328 to 662°F (-200 to 350°C)

Extension grade

32 to 212°F (0 to 100°C)

±9.0°F (±5.0°C) ±1.1°F (0.6°C) or 0.1%

±9.0°F (±5.0°C) ±1.1°F (0.6°C) or 0.1%

Above 32°F (0°C)

±1.8°F (1.0°C) or 0.75%

Below 32°F (0°C)

±1.8°F (1.0°C) or 1.5%

±1.1°F (0.6°C) or 0.4%

2

Page 5

International Color Codes

ANSI/ASTM ANSI/ASTM 1843 43710 C1610-1981 584-3 Common

T/C Exten. (Britian) (Germany) (Japan) (Europe) Uses

BS DIN JIS IEC

Suitable for use in

oxidizing or inert

atmosphere. Limited use

in vacuum or reducing

atmosphere. Suitable for

sub zero.

Reducing vacuum, inert.

Limited use in oxidizing

above 1004°F (540°C).

Not recommended for

sub zero.

Suitable for use in

oxidizing or inert

atmosphere. Limited use

in vacuum or reducing.

Suitable for sub zero.

Alternative to Type K.

More stable at high

temperatures.

Suitable for use in

oxidizing or inert

atmosphere. Do not

insert in metal tubes.

Beware of contamination

at high temperatures.

Suitable for use in

oxidizing or inert

atmosphere. Do not

insert in metal tubes.

Beware of contamination

at high temperatures.

Mild oxidizing, reducing

vacuum or inert. Good

where moisture is

present. Low

temperature and

cryogenic applications.

3

Page 6

Braided Insulations

Insulation

Series Number

301

302

303

304

305

306

307

309

311

313

314

315

321

350

355

365

Insulations

Primary Secondary

itreous Silica Vitreous Silica

V

Double Glass Glass

namel Glass

E

lass Glass

G

Double Glass Wrap Glass

lass Glass (no impregnation)

G

TFE Glass

lass Glass

G

Glass Glass (low temp. impregnation)

eavy Glass Heavy Glass

H

Glass Twisted

lass Twisted

G

Glass Glass

eramic Fiber Ceramic Fiber

C

Ceramic Fiber Ceramic Fiber

itreous Silica Vitreous Silica

V

Temperature Range

Continuous Single Reading

°F (°C) °F (°C) Abrasion Moisture Chemical

1800 (982) 2000 (1093) F F G

900 (482) 1000 (538) G G G

900 (482) 1000 (538) F G G

900 (482) 1000 (538) F G G

900 (482) 1000 (538) F G G

900 (482) 1000 (538) F F G

900 (482) 1000 (538) G E E

1300 (704) 1600 (871) G F G

1300 (704) 1600 (871) F F G

900 (482) 1000 (538) G G G

1300 (704) 1600 (871) G G G

900 (482) 1000 (538) G G G

1300 (704) 1600 (871) G G G

2200 (1204) 2600 (1427) G F G

2200 (1204) 2600 (1427) G F G

1800 (982) 2000 (1093) F F G

Tape and Extruded Insulations

Insulation

Insulation Construction

Series Number

Single Shield Jacket

502 PVC PVC 221 (105) 221 (105) G E G

505 PVC Ripcord 221 (105) 221 (105) G E G

506 FEP FEP (<26 AWG) 400 (204) 500 (260) E E E

507 FEP FEP 400 (204) 500 (260) E E E

508 TFE Tape TFE Tape 500 (260) 600 (316) G E E

509 FEP Shield FEP 400 (204) 500 (260) E E E

510 PVC Shield PVC 221 (105) 221 (105) G E G

511 Polyimide Tape Twisted 600 (316) 800 (427) E E E

512 Polyimide Tape Polyimide Tape 600 (316) 800 (427) E E E

514 Tefzel

515 Tefzel

®

®

Shield Tefzel

Tefzel

®

®

516 PFA PFA 500 (260) 550 (288) G E E

517 PFA Shield PFA 500 (260) 550 (288) G E E

Temperature Range

Continuous Single Reading

°F (°C) °F (°C)

Abrasion Moisture Chemical

302 (150) 392 (200) E E E

302 (150) 392 (200) E E E

F = Fair, G = Good, E = Excellent

4

Page 7

Ordering Information*

Code Number

③③

ANSI

Calibration

B and S

Gauge

Conductor

Type/

Tolerance

⑤⑤④④

Metallic

Overbraids

(Optional)

⑥⑥⑦⑦⑧⑧

Insulation

Series

⑨⑨②②①①

⑩⑩

Color

Codes

⑪⑪

①①

E = Type E

J = Type J

K = Type K

N = Type N

S = Type S

T = Type T

Note:

Color coding will be to ANSI standards, unless specified.

②②③③

14 -36

④④

1 =

Thermocouple grade, solid wire, standard tolerance

2 =

Thermocouple grade, solid wire, special tolerance

3 =

Thermocouple grade, stranded wire, standard tolerance

4 =

Thermocouple grade, stranded wire, special tolerance

5 =

Extension grade, solid wire, standard tolerance

6 =

Extension grade, solid wire, special tolerance

7 =

Extension grade, stranded wire, standard tolerance

8 =

Extension grade, stranded wire, special tolerance

Note:

Stranded conductors will be seven strand constructions. Contact

a Watlow representative for other configurations.

ANSI Calibration

B and S Gauge

Conductor Type/Tolerance

⑤⑤

S= Stainless steel

N=

Alloy 600

C=

Tinned copper

⑥⑥

⑧⑧

⑦⑦

Refer to insulation chart on page 4.

⑨⑨⑩⑩⑪⑪

Blank =

BSC =

DIN =

JIS =

IEC =

* Product normally shipped in 1,000 foot spools. Contact a Watlow

ANSI/ASTM E230 (formally ANSI MC96.1)

BS 1843

DIN 43710

JIS C 1610-1981

IEC 584-3

representative for special packaging.

Metallic Overbraids (optional)

Insulation Series

Color Codes

Watlow®and SERV-RITE®are registered trademarks of Watlow Electric Manufacturing Company

Teflon®and Tefzel®are registered trademarks of E.I. duPont de Nemours & Company.

Chromel®and Alumel®are registered trademarks of Hoskins Manufacturing Company.

5

Page 8

Find out more about Watlow and how we can

provide thermal solutions for your company:

Phone: 1-800-WATLOW2 (1-800-928-5692)

E-mail: inquiry@watlow.com

Web site: www.watlow.com

Watlow Products and Technical

Support Delivered Worldwide

North American Technical Support &

Sales Offices

North America 1-800-WATLOW2

(1-800-928-5692)

Asian Technical Support &

Sales Offices

Australia +61 3 9335 6449

China +86 21 3381 0188

Japan +81 3 3518 6630

Korea +82 2 2628 5770

Malaysia +60 3 8076 8745

Singapore +65 6773 9488

Taiwan +886 7 288 5168

European Technical Support &

Sales Offices

France +33 1 41 32 79 70

Germany +49 (0) 72 53 / 94 00-0

Italy +39 024588841

Spain +34 91 675 12 92

United Kingdom +44 (0) 115 964 0777

Latin American Technical Support &

Sales Office

Mexico +52 442 217 6235

About Watlow

Watlow designs and manufactures industrial heaters,

temperature sensors, controllers and system

assemblies – all of the components of a thermal

system. Designing and manufacturing the complete

thermal system allows Watlow to recommend,

develop and deliver the optimum thermal solution for

our customers’ equipment and process heat

requirements.

Watlow manufactures thermal systems for a broad

range of industries including but not limited to:

semiconductor processing, photovoltaics, diesel

emmisions, aerospace, medical equipment and

foodservice equipment. Watlow customers receive

the highest level of technical engineering combined

with exceptional customer service.

Since 1922, Watlow has grown in product capability,

market experience and global reach. We hold more

than 200 patents and employ 2,000 employees

working in 12 manufacturing facilities in the United

States, Mexico, Europe and Asia. We also have sales

offices in 15 countries around the world. Our

company has grown at an exponential rate, but our

commitment remains the same – to provide our

customers with superior products and services for

their individual needs.

©2009

Your Authorized Watlow Distributor is:

© 2010 Watlow Electric Manufacturing Company

RIC-WB-1110

RIC-

Loading...

Loading...