Page 1

0600-0042-0000 Rev. B

March 2004

Installation Manual

ISO 9001

CUS

ER

TISF

CTI

Series N7

Time and Temperature

Controller

Made in the U.S.A.

$15.00

1241 Bundy Boulevard., Winona, Minnesota USA 55987

Phone: +1 (507) 454-5300, Fax: +1 (507) 452-4507 http://www.watlow.com

TOTAL

CUS

TOMER

SATISF

ACTI

3 Year Warranty

ISO 9001

Registered Company

Winona, Minnesota USA

ON

Page 2

Safety Information

We use note, caution and warning symbols throughout this book to draw your

attention to important operational and safety information.

A “NOTE” marks a short message to alert you to an important detail.

A “CAUTION” safety alert appears with information that is important for protecting your equipment and performance. Be especially careful to read and follow all cautions that apply to your application.

A“WARNING” safety alert appears with information that is important for protecting you, others and equipment from damage. Pay very close attention to

all warnings that apply to your application.

The safety alert symbol, ç(an exclamation point in a triangle) precedes a

general CAUTION or WARNING statement.

The electrical hazard symbol, Ó(a lightning bolt in a triangle) precedes an

electric shock hazard CAUTION or WARNING safety statement.

Warranty

The Series N7 is manufactured by ISO 9001-registered processes and is

backed by a three-year warranty.

Return Material Authorization (RMA)

1. Call Watlow Customer Service, (507) 454-5300, for a Return Material

Authorization (RMA) number before returning any item for repair. We need

this information:

•Ship to address • Bill-to address

•Contact name • Phone number

•Method of return shipment • Your P.O. number

•Detailed description of the problem • Any special instructions

•Name and phone number of person returning the product.

2. Prior approval and an RMA number, from the Customer Service

Department, is needed when returning any unused product for credit. Make

sure the RMA number is on the outside of the carton, and on all paperwork

returned. Ship on a Freight Prepaid basis.

3. After we receive your return, we will examine it and determine the cause

for your action.

4. In cases of manufacturing defect, we will enter a repair order, replacement

order or issue credit for material returned.

5. To return products that are not defective, goods must be be in new condition, in the original boxes and they must be returned within 120 days of

receipt. A 20% restocking charge is applied for all returned stock controls and

accessories.

6. If the unit is unrepairable, it will be returned to you with a letter of explanation. Repair costs will not exceed 50 percent of the original cost.

7. Watlow reserves the right to charge for no trouble found (NTF) returns,

not to exceed 20% of the original net price.

The Series N7 User’s Manual is copyrighted by Watlow Winona, Inc., © March

2004 with all rights reserved.

ç

CAUTION or

WARNING

Ó

Electrical

Shock Hazard

CAUTION or WARNING

Page 3

Watlow Series N7 ■ 3 ■ Table of Contents

TC

Table of Contents

Chapter 1: Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Chapter 2: Install and Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Install or Replace the Relay/High-Voltage Output Module . . . .24

Install or Replace the Ethernet Module . . . . . . . . . . . . . . . . . .25

Page 4

Chapter 1: Overview ■ 4 ■ Watlow Series N7

Overview

1

Series N7 Controller

Watlow’s Series N7 temperature controller provides ample flexibility for use in a broad range of

applications. The Series N7 delivers up to four zones

of on-off or PID control, that can be sensed with thermocouples (types J, K and E), 2-wire RTDs and 3wire RTDs. Voltage or process inputs are also available.

The Series N7 offers a wide variety of outputs.

The base model has six switched dc outputs, with a

nominal output voltage of 5V and a maximum current of 30 mA. Two additional switched dc outputs

can be added, for a total of eight possible outputs. An

optional high-voltage board provides up to six highvoltage outputs, in place of the switched dc outputs.

The base output module has two solid-state

relays; an option of four additional solid-state relays

is available. The solid-state relays have a maximum

operating current of 0.4 amps. Other available

options offer either two or four electromechanical

relays, or four no-arc relays. The electromechanical

relays and no-arc relays each have a maximum operating current of 8 amps. The maximum operating

voltage for all high-voltage options is 250VÅ (ac).

Because the Series N7 can operate different types

of equipment, it can replace other controllers, which

simplifies inventory and manufacturing, and reduces

your supplier base. The Series N7 can operate under

many rigorous environmental conditions with an

80°C (176°F) ambient rating and a superior immunity to electrical interference.

The controller is tested to UL and CE standards.

Features and Benefits

Custom Firmware

• Allows you to customize multiple applications in

one controller.

Custom Overlay

• Customize your interface with up to 32 keys and

32 indicator lights.

Multiple Inputs and Outputs

• Enough inputs and outputs to run most applications.

• Up to four loops of control, control temperatures

and times.

• Machine functions.

Communications

• Capable of flash downloading firmware, and of

Modbus and PC communications.

Ethernet Communications Add-on Board

• NAFEM Protocol and development of additional

memory

Mounting Options

• The Series N7 mounts either vertically or horizontally to fit your equipment.

Page 5

Watlow Series N7 ■ 5 ■ Chapter 2: Install and Wire

Install and Wire

2

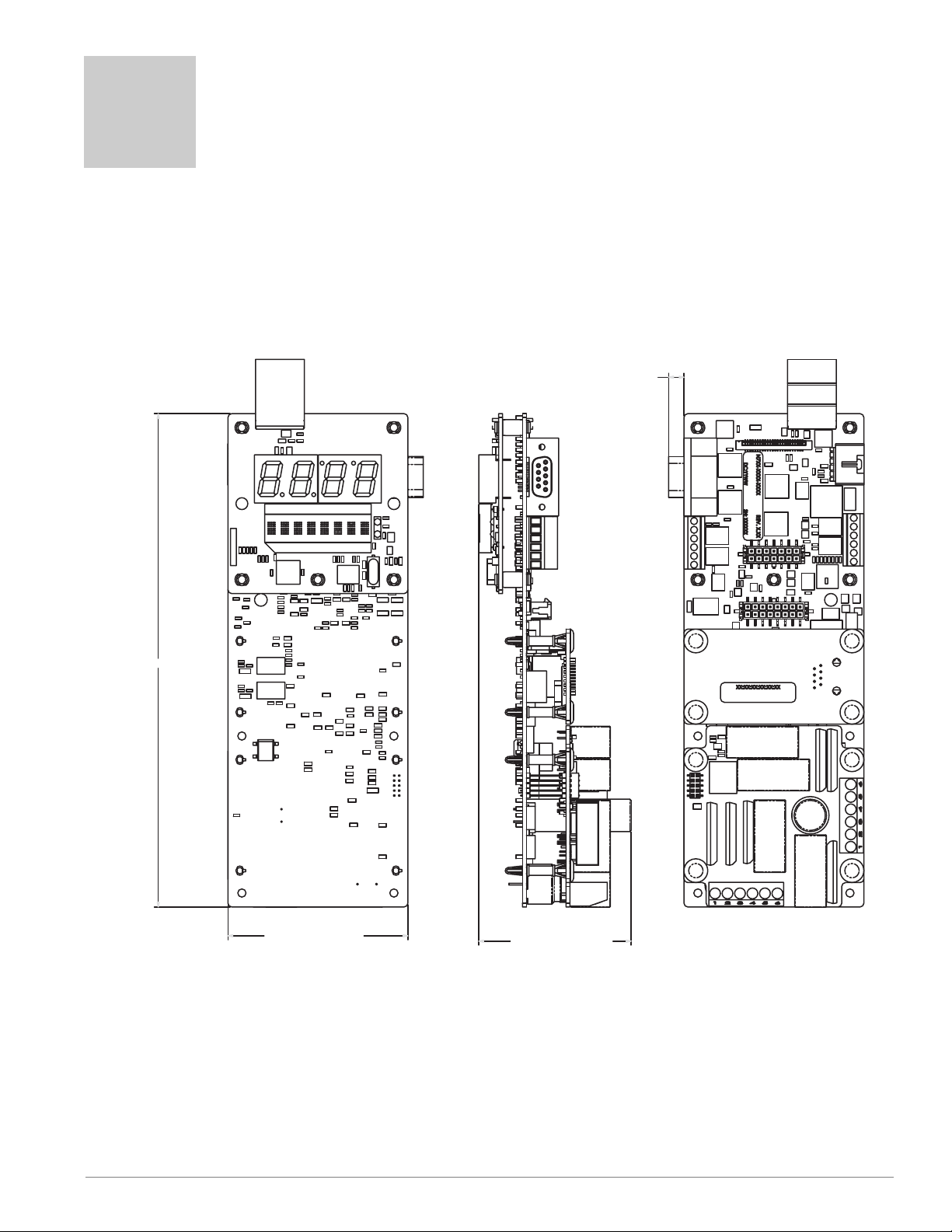

Series N7 Controller Dimensions

Vertical

Dimensions

with Add-on

Modules

6.15 mm

(0.24 in)

197.74 mm (7.79 in)

72.14 mm (2.84 in)

61.10 mm (2.41 in)

Page 6

Chapter 2: Install and Wire ■ 6 ■ Watlow Series N7

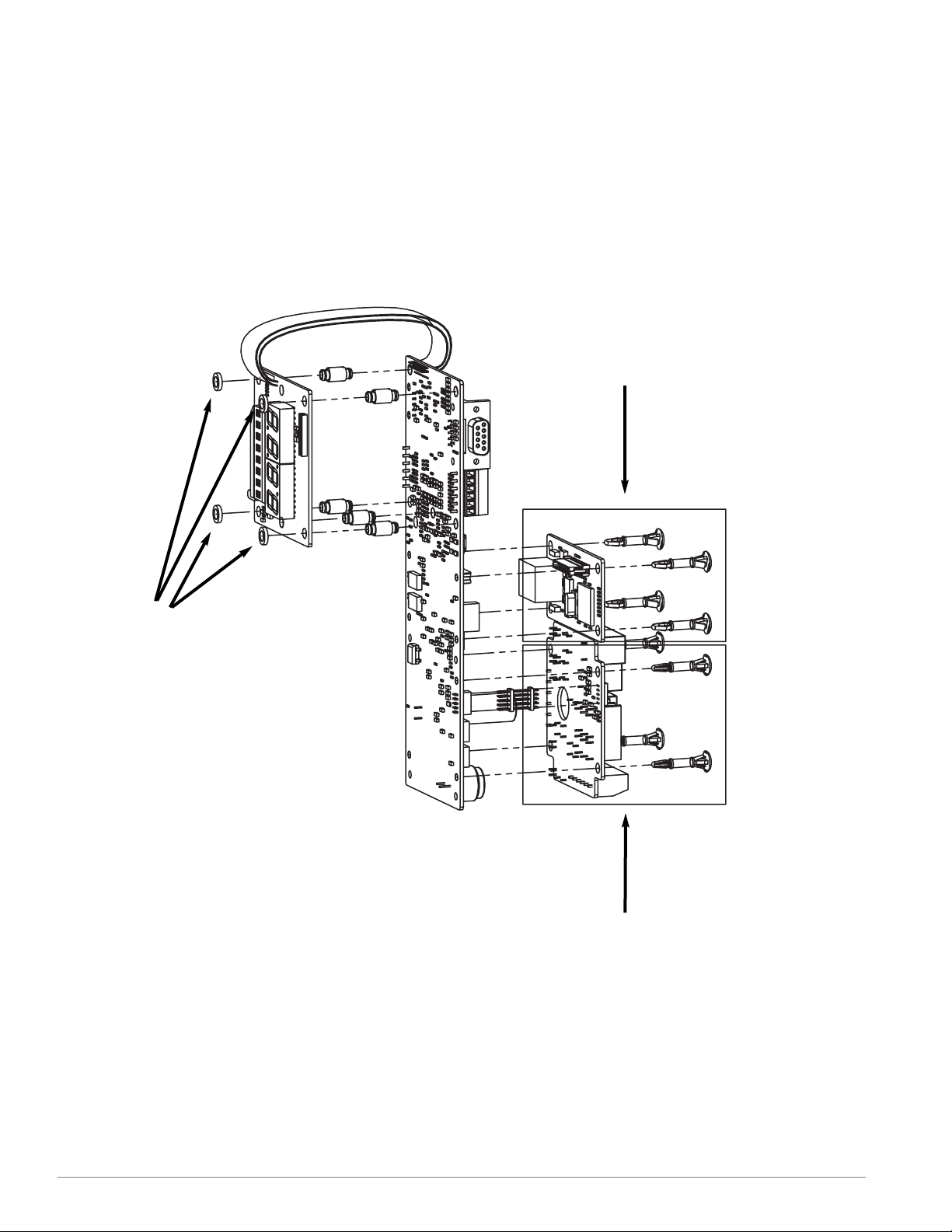

Vertical View with Add-on Modules

(exploded view)

(4) Nylon Spacers

(3/16 X 5/16 X 1/16)

Press spacer onto standoff

clips prior to mounting

Ethernet Add-on Module

(see Appendix for details)

Relay/High-Voltage Output Add-on

Module (see Appendix for details)

Page 7

Watlow Series N7 ■ 7 ■ Chapter 2: Install and Wire

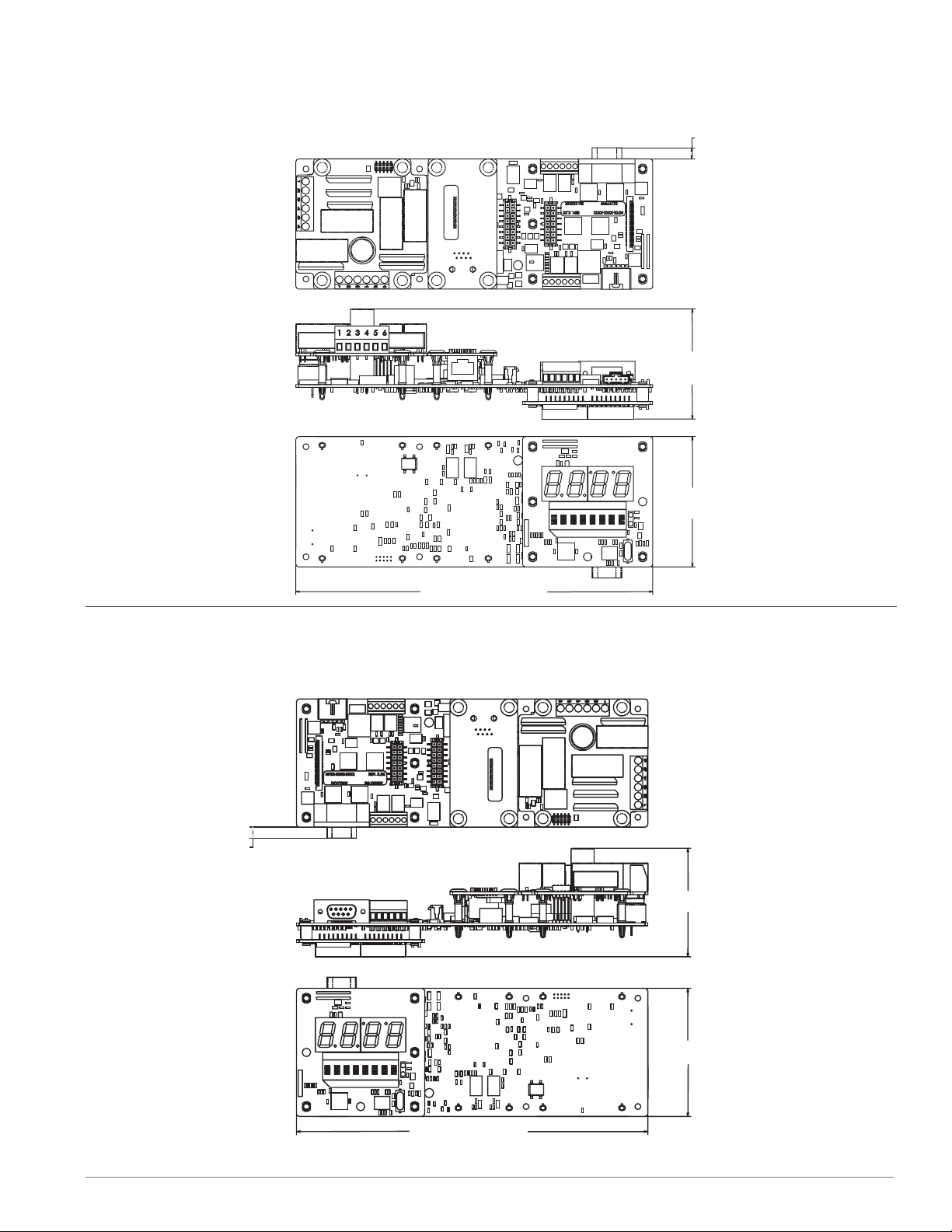

Horizontal Right

Horizontal Left

6.15 mm

(0.24 in)

61.10 mm (2.41 in)

72.14 mm (2.84 in)

6.15 mm

(0.24 in)

197.74 mm (7.79 in)

61.10 mm (2.41 in)

72.14 mm (2.84 in)

197.74 mm (7.79 in)

Page 8

Chapter 2: Install and Wire ■ 8 ■ Watlow Series N7

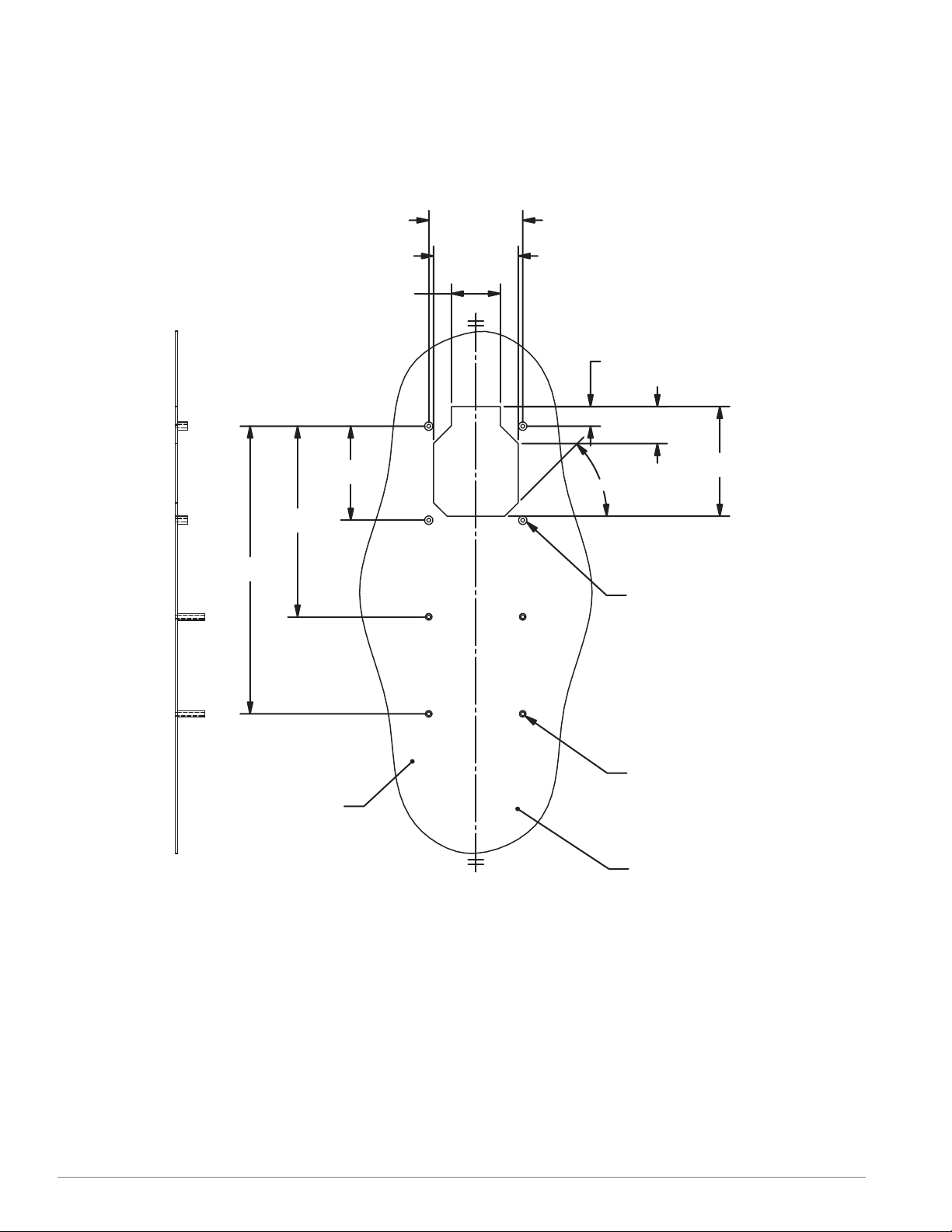

Cutout Standoff -Vertical

For Horizontal Left, rotate 90° counter-clockwise.

For Horizontal Right, rotate 90° clockwise.

4X 60.96 mm

(2.400 in

)

54.91 mm

(2.162 in

)

31.75 mm

(1.25 in

)

2X 60.96 mm

(2.400 in

)

2X 123.63 mm

(4.867 in

)

2X 186.57 mm

(7.345 in

)

2X 12.71 mm

(.500 in

)

2X 24.03 mm

(.946 in

)

71.12 mm

(2.800 in

)

4X 45

˚

Back side of pane

l

4X Blind #4-40 X .75 in

threaded standoff,

Pem BSOS-440-24

or equivalent.

(4X #4-40 X .25 in long

machine screw required

)

4X Blind #4-40 X .31 in

threaded standoff,

Pem BSOS-6440-10

or equivalent.

(4X #4-40 X .75 in long

machined screw required

)

C

L

C

L

Minimum panel thickness:

1.02 mm (0.040 in

)

Page 9

Watlow Series N7 ■ 9 ■ Chapter 2: Install and Wire

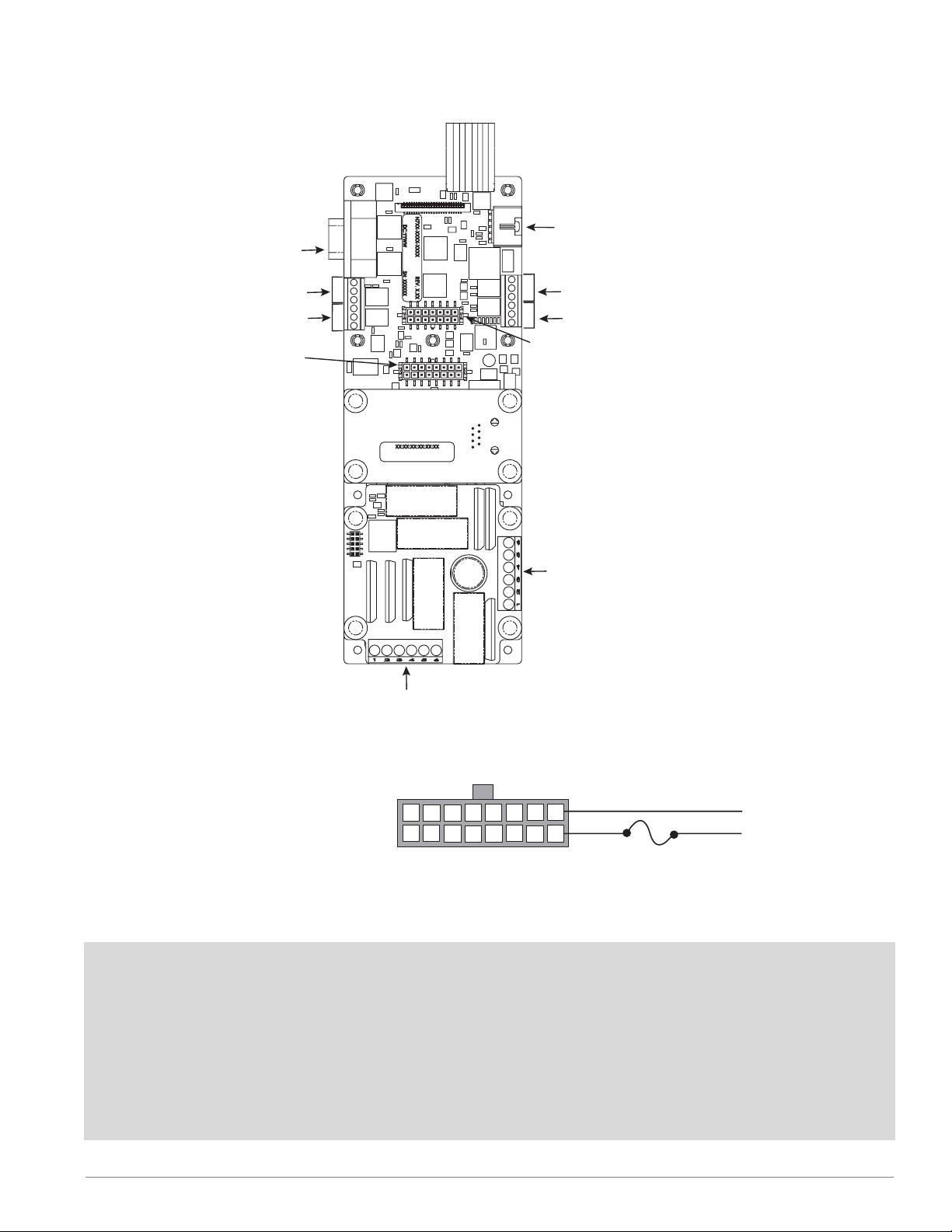

Location of Pins and Ports for Inputs and Outputs

Figure 9a — Power Wiring

• Nominal voltage: 24VÅ (ac)

• Class 2 power source required.

Ó

Warning: Use National Electric (NEC) or other country-specific standard wiring and safety practices when wiring and

connecting this controller to a power source and to electrical sensors or peripheral devices. Failure to do so may

result in damage to equipment and property, and/or injury

or loss of life.

Ó

Warning: If high voltage is applied to the 24VÅ (ac) input,

irreversible damage will occur.

Note:

To prevent ground loops, maintain isolation from input to

output when using switched dc or analog process outputs.

Use ungrounded thermocouples.

5-pin Master

9-pin Slave

Communications Port

Communications Port

Input 3

Input 4

16 pins

Power

Control Outputs 1 & 2

Event Inputs 1 to 4

Event Outputs 1 to 4

1

2

3

4

5

6

High Voltage Module

High-voltage Control Outputs 4

High-voltage Event Outputs 5 & 6

6

5

Input 2

4

3

2

Input 1

1

14 pins

Control Outputs 3 & 4

Process Outputs 1 & 2

Event Inputs 5 to 8

High Voltage Module

High-voltage

Control Outputs 1 to 3

16

14

15

13

12

345678

2

9

91011

1

1

L2

L1

Page 10

Ó

Warning: Use National Electric (NEC) or other country-specific standard wiring and safety practices when wiring and

connecting this controller to a power source and to electrical sensors or peripheral devices. Failure to do so may

result in damage to equipment and property, and/or injury

or loss of life.

Note:

To prevent ground loops, maintain isolation from input to

output when using switched dc or analog process outputs.

Use ungrounded thermocouples.

Chapter 2: Install and Wire ■ 10 ■ Watlow Series N7

Thermocouple

• J and K: –46 to 316°C (–50 to 600°F)

• Input impedance: >100 kΩ

Figure 10d — Input 4

Figure 10c — Input 3

Figure 10b — Input 2

Figure 10a — Input 1

3 456

2

1

3456

2

1

+

–

+

–

2

1

5

4

–

1

2

3

+

4

5

6

6

5

4

3

2

1

Input 2

Input 1

–

+

1

2

1

2

3456

1

Input 3

Input 4

1

2

3456

2

3

4

5

6

4

5

Page 11

Watlow Series N7 ■ 11 ■ Chapter 2: Install and Wire

Ó

Warning: Use National Electric (NEC) or other country-specific standard wiring and safety practices when wiring and

connecting this controller to a power source and to electrical sensors or peripheral devices. Failure to do so may

result in damage to equipment and property, and/or injury

or loss of life.

Note:

To prevent ground loops, maintain isolation from input to

output when using switched dc or analog process outputs.

Use ungrounded thermocouples.

2-wire or 3-wire RTD

• 100 Ω : –46 to 316°C (–50 to 600°F)

• DIN curve: 0.00385 ohms/ohms/°C

• <700 µA excitation

3-wire 2-wire

3-wire 2-wire

3-wire 2-wire

3-wire 2-wire

Figure 11d — Input 4

Figure 11c — Input 3

Figure 11b — Input 2

Figure 11a — Input 1

3 456

2

1

3 456

2

1

3

S1

S2

2

1

S3

6

S1

S2

5

S3

4

3 456

2

1

3 456

2

1

3

1

S2

2

1

6

S1

5

S2

2

3

4

5

6

6

5

4

3

2

1

Input 2

Input 1

4

S1

S3

S2

S1

1

2

3

1

2

3 456

S2

S1

1

2

3 456

4

S3

S2

S1

5

6

S2

S1

1

2

3

1

2

3 456

1

2

3 456

Input 3

Input 4

1

2

3

4

5

6

4

5

6

Page 12

Chapter 2: Install and Wire ■ 12 ■ Watlow Series N7

Ó

Warning: Use National Electric (NEC) or other country-specific standard wiring and safety practices when wiring and

connecting this controller to a power source and to electrical sensors or peripheral devices. Failure to do so may

result in damage to equipment and property, and/or injury

or loss of life.

Note:

To prevent ground loops, maintain isolation from input to

output when using switched dc or analog process outputs.

Use ungrounded thermocouples.

Process Inputs

• Voltage: 0 to 10VÎ (dc)

• Current: 0 to 20 mA

• Voltage input impedance: 50 kΩ

• Current input impedance: 100 Ω

–

Figure 12d — Input 4

–

Figure 12c — Input 3

Figure 12b — Input 2

–

Figure 12a — Input 1

3 456

2

1

3 456

2

1

3

Common

Current

2

1

Voltage

Common

6

Current

5

Voltage

4

1

2

+

+

3

4

5

6

6

5

4

3

2

1

Input 2

Input 1

–

+

+

Voltage

+

Current

+

Common

Voltage

+

Current

+

Common

1

2

3

4

5

6

1

2

3 456

1

2

3456

Input 3

Input 4

1

2

3

4

5

6

Page 13

Watlow Series N7 ■ 13 ■ Chapter 2: Install and Wire

Ó

Warning: Use National Electric (NEC) or other country-specific standard wiring and safety practices when wiring and

connecting this controller to a power source and to electrical sensors or peripheral devices. Failure to do so may

result in damage to equipment and property, and/or injury

or loss of life.

Note:

To prevent ground loops, maintain isolation from input to

output when using switched dc or analog process outputs.

Use ungrounded thermocouples.

–

Figure 13b — Process Output 2

–

Figure 13a — Process Output 1

Process Outputs

Current

• 0 to 20 mA at 20V maximum

• Load: 1 kΩ maximum

Volts

• 0 to 10VÎ (dc) at 20 mA maximum

• Load: 500Ω minimum

4

+

3

1

89101112

10

+

3 4567

2

1

3 4567

2

89101112

13

13

14

14

14 pins

Control Outputs 3 & 4

Process Outputs 1 & 2

Event Inputs 5 to 8

11

Page 14

Chapter 2: Install and Wire ■ 14 ■ Watlow Series N7

Ó

Warning: Use National Electric (NEC) or other country-specific standard wiring and safety practices when wiring and

connecting this controller to a power source and to electrical sensors or peripheral devices. Failure to do so may

result in damage to equipment and property, and/or injury

or loss of life.

Note:

To prevent ground loops, maintain isolation from input to

output when using switched dc or analog process outputs.

Use ungrounded thermocouples.

Figure 14b — Control Output 1

Figure 14c — Control Output 2

NOTE: Terminals 5, 6, 13 or 14 can be used for the common connection.

Figure 14d — Control Output 3

Figure 14e — Control Output 4

NOTE: Terminals 2, 5, 9 or 12 can be used for the common connection.

1

2

3 4567

891011 1 2

13

14

(common) 9

8

+

(common) 5

2

+

1

2

345678

91011

12

13

14

15

16

Control Outputs

If the high voltage output module is installed, the

state of each high-voltage control output mirrors the

state of the corresponding control output.

• Switched dc

• Current: 30 mA at 5VÎ (dc) nominal

Figure 14a — Switched DC

+

Load

5VÎ (dc) @ 30 mA (dc)

(common)

Internal Circuitry

16 pins

Outputs 1 & 2

Event Inputs 1 to 4

Event Outputs 1 to 4

Switched DC

+5VÎ (dc)

dc+

dc-

1

2

3

4

5

6

(common) 13

10

16

14

15

13

12

91011

1

345678

2

+

(common) 2

+

1

1

2

891011 1 2

3 4567

13

14

14 pins

Control Outputs 3 & 4

Process Outputs 1 & 2

Event Inputs 5 to 8

Page 15

Watlow Series N7 ■ 15 ■ Chapter 2: Install and Wire

Ó

Warning: Use National Electric (NEC) or other country-specific standard wiring and safety practices when wiring and

connecting this controller to a power source and to electrical sensors or peripheral devices. Failure to do so may

result in damage to equipment and property, and/or injury

or loss of life.

Ó

Warning: All high-voltage outputs must be powered by the

same source (phase), as shown in the example above.

Figure 15d — High-voltage Control Output 4

Figure 15c — High-voltage Control Output 3

Figure 15b — High-voltage Control Output 2

Figure 15a — High-voltage Control Output 1

HV Control Out 1 HV Control Out 2 HV Control Out 3 HV Control Out 4

N7_ _ - _ _ _ _ - 2 _ _ _ mechanical relay mechanical relay mechanical relay mechanical relay

N7_ _ - _ _ _ _ - 3 _ _ _ solid-state relay solid-state relay solid-state relay solid-state relay

N7_ _ - _ _ _ _ - 4 _ _ _ mechanical relay solid-state relay mechanical relay solid-state relay

N7_ _ - _ _ _ _ - 5 _ _ _ no-arc relay no-arc relay no-arc relay no-arc relay

• Operating temperature: 0 to

80° C

• Contact type: normally open

• Maximum current: 8 amps

• Maximum voltage: 250VÅ

(ac)

High-voltage Control Outputs

The state of each high-voltage control output mirrors the state of the corresponding control output.

6

45

3

2

1

6

45

3

2

1

6

45

3

2

1

Load

Load

Load

L2

L1

L2

L1

L2

L1

1

2

3

4

5

6

High Voltage Module

High-voltage

Control Outputs 1 to 3

1

2

3

4

5

6

1

2

3

45

6

Load

L1

L2

High Voltage Module

High-voltage Control Output 4

High-voltage Event Outputs 5 & 6

Page 16

Chapter 2: Install and Wire ■ 16 ■ Watlow Series N7

Ó

Warning: Use National Electric (NEC) or other country-specific standard wiring and safety practices when wiring and

connecting this controller to a power source and to electrical sensors or peripheral devices. Failure to do so may

result in damage to equipment and property, and/or injury

or loss of life.

Note:

To prevent ground loops, maintain isolation from input to

output when using switched dc or analog process outputs.

Use ungrounded thermocouples.

Event Inputs

• Voltage input

–0.5 to +0.5VÎ (dc), event input low (closed)

3 to 30VÎ (dc), event input high (open)

• Contact closure

less than 250 Ω, event input low (closed)

more than 10 kΩ, event input high (open)

Note: Terminals 5, 6, 13 or 14 can be used for the common connection.

Figure 16d — Event Input 4

Figure 16c — Event Input 3

Figure 16b — Event Input 2

Figure 16a — Event Input 1

16

15

14

13

12

(common) 6

91011

1

345678

2

–

Outputs 1 & 2

7

+

Event Inputs 1 to 4

Event Outputs 1 to 4

16 pins

1

2

3

4

5

6

15

(common) 14

16

14

15

13

12

91011

1

345678

2

16

14

15

13

12

16

14

15

13

12

91011

1

345678

2

(common) 6

16

(common) 14

91011

1

345678

2

8

+

–

–

+

+

–

Page 17

Ó

Warning: Use National Electric (NEC) or other country-specific standard wiring and safety practices when wiring and

connecting this controller to a power source and to electrical sensors or peripheral devices. Failure to do so may

result in damage to equipment and property, and/or injury

or loss of life.

Note:

To prevent ground loops, maintain isolation from input to

output when using switched dc or analog process outputs.

Use ungrounded thermocouples.

Watlow Series N7 ■ 17 ■ Chapter 2: Install & Wire

Note: Terminals 2, 5, 9 or 12 can be

used for the common connection.

Figure 17d — Event Input 8

Figure 17c — Event Input 7

Figure 17b — Event Input 6

Figure 17a — Event Input 5

+

–

(common) 5

1

891011 1 2

(common) 12

–

+

+

–

(common) 5

6

3 4567

2

13

1

3 4567

2

89101112

13

7

1

3 4567

2

89101112

14

13

14

13

14

14 pins

Control Outputs 3 & 4

Process Outputs 1 & 2

Event Inputs 5 to 8

1

2

89101112

(common) 12

–

+

14

3 4567

13

14

Page 18

Chapter 2: Install and Wire ■ 18 ■ Watlow Series N7

Ó

Warning: Use National Electric (NEC) or other country-specific standard wiring and safety practices when wiring and

connecting this controller to a power source and to electrical sensors or peripheral devices. Failure to do so may

result in damage to equipment and property, and/or injury

or loss of life.

Note:

To prevent ground loops, maintain isolation from input to

output when using switched dc or analog process outputs.

Use ungrounded thermocouples.

Event Outputs

• Switched dc

• 30 mA at 5VÎ (dc) nominal

Figure 18a — Switched DC

NOTE: Terminals 5, 6, 13 or 14 can be used for the common connection.

–

Figure 18e — Event Output 4

Figure 18d — Event Output 3

–

Figure 18c — Event Output 2

Figure 18b — Event Output 1

Load

Switched DC

5VÎ (dc) @ 30 mA (dc)

+5VÎ (dc)

(common)

dc+

dc-

Internal Circuitry

+

16

14

15

13

12

345678

13

12

13

12

(common) 13

16

14

15

16

14

15

16

14

15

13

12

91011

1

2

(common) 5

91011

1

345678

2

91011

1

345678

2

(common) 5

(common) 13

91011

1

345678

2

11

3

12

+

–

Outputs 1 & 2

Event Inputs 1 to 4

Event Outputs 1 to 4

16 pins

1

2

3

4

5

6

+

4

+

–

+

Page 19

Watlow Series N7 ■ 19 ■ Chapter 2: Install and Wire

Ó

Warning: Use National Electric (NEC) or other country-specific standard wiring and safety practices when wiring and

connecting this controller to a power source and to electrical sensors or peripheral devices. Failure to do so may

result in damage to equipment and property, and/or injury

or loss of life.

Ó

Warning: All high-voltage outputs must be powered by the

same source (phase), as shown in the example above.

Figure 19b — High-voltage Event Output 6

Figure 19a — High-voltage Event Output 5

High-voltage Event Outputs

• Solid-state relay

• Operating temperature: 0 to 80° C

• Contact type: normally open

• Maximum operating current: 0.4 amps

• Maximum operation voltage: 250VÅ (ac)

L1

1

L1

1

2

3

45

L2

2

3

45

Load

L2

Load

6

1

2

3

4

5

6

6

High Voltage Module

High-voltage Control Output 4

High-voltage Event Outputs 5 & 6

Page 20

Chapter 2: Install and Wire ■ 20 ■ Watlow Series N7

Ó

Warning: Use National Electric (NEC) or other country-specific standard wiring and safety practices when wiring and

connecting this controller to a power source and to electrical sensors or peripheral devices. Failure to do so may

result in damage to equipment and property, and/or injury

or loss of life.

Note:

To prevent ground loops, maintain isolation from input to

output when using switched dc or analog process outputs.

Use ungrounded thermocouples.

Communications using an EIA/TIA-232 to EIA/TIA-485 Converter

The circuit board illustration on page 9 shows the location of the master and slave ports.

Figure 20d — Slave, CMC Converter

• RS-232: 19,200 or 9,600 baud

• RS-485: 9,600 baud

• 0 to 16 nodes

Figure 20c — Master, CMC Converter

• 19,200 baud

• 0 to 16 nodes

• RS-485

Figure 20b — Slave, B&B Converter

• RS-232: 19,200 or 9,600 baud

• RS-485: 9,600 baud

• 0 to 16 nodes

Figure 20a — Master, B&B Converter

• 19,200 baud

• 0 to 16 nodes

• RS-485

Slave communications

The Series N7 can only respond to communications

on this port, as in the case of several N7s networked

to a Modbus master or a PC connected to this port to

monitor or adjust settings and process values. This is

how most Watlow controllers communicate.

Master communications

The Series N7 can initiate communications to controllers networked on this port. An implementation

might include a custom modbus I/O board and modbus motor control connected to the N7 master port

controlled by the N7's custom firmware.

120VÅ (ac)

120VÅ (ac)

TD (A)

GND

TD (B)

GND

485SD9TB

485SD9TB

Power

Supply

Power

Supply

12V Î (dc)

T+/R+

T–/R–

+

–

TD (A)

GND

TD (B)

GND

12V Î (dc)

+

–

T+/R+

T–/R–

5

1

6

6

4

2

345

789

2345

1

3

4

5

EIA-232

ADA485L

EIA-232

ADA485L

120VÅ (ac)

EIA-485

EIA-485

G

9VÎ

G

B

A

B

A

G

9VÎ

G

B

A

B

A

DI/ODI/O

DI/ODI/O

9VÎ (dc) (see note)

COM.

T–/R–

T+/R+

0219-0217-0000

7-ft. comms cable

120VÅ (ac)

9VÎ (dc) (see note)

COM.

T–/R–

T+/R+

0219-0217-0000

7-ft. comms cable

5

5

1

4

6

6

3

2

345

78

234

1

9

5

4

Page 21

Watlow Series N7 ■ 21 ■ Appendix

Appendix

A

Specifications

Controller

• Up to four sensor inputs, eight switched dc outputs, eight dc

inputs, two process outputs

• Battery backed, real-time clock

• One non-isolated slave communications channel

• One non-isolated master communications channel

• Optional ethernet communications module

• Optional high-voltage output module

Operator Interface

• Four-character, 0.56-inch, seven-segment display

• Eight-character, 0.2 inch, alphanumeric display

• Overlay interface supports up to 32 keys and LED indicator

lights

Overlay interface

• Switch closed input < 100 Ω

• Switch open input > 100 kΩ

• LED current limiting resistor: 200 Ω

• LED supply voltage: 5V

Operating Environment

•0 to 80°C (32 to 176°F) @ 0 to 90% RH, non-condensing

Standard Conditions For Specifications

• Ambient temperature 25°C (77°F) ±3°C, 24VÅ (ac), 50 to 60 Hz

Configured Sensor Inputs

• Update rate: 5Hz

Thermocouple

• Multiple channel applications require at least one ungrounded

thermocouple.

• Input current: 0.5 nA

• Maximum source resistance: 20 Ω

• Accuracy: ± 1.1°C (2°F)

• Drift: ± 0.10°C/°C (± 0.10°F/°F)

• Input ranges:

Type J: -46 to 316°C (-50 to 600°F)

Type K: -46 to 316°C (-50 to 600°F)

RTD

• 2- or 3-wire platinum

• DIN curve (.00385 curve)

• 700 µA maximum excitation current

• Accuracy: ± 1.1°C (2°F)

• Drift: ± 0.10°C/°C (± 0.10°F°/F)

• Range: -46 to 316°C (-50 to 600°F)

Voltage

• Input impedance 60 kΩ

• Input range: 0 to 12V

• Accuracy: ± 25 mV

• Drift: ± 5mV/F

Current

• Input impedance 100 Ω

• Input range: 0 to 22mA

• Accuracy: ± 40 µA

• Drift: ± 5 µA/F

Event Input

• Input high: 3 to 30V or >10 kΩ

• Input low: -0.5 to 0.5V or < 250 Ω

Outputs

Switched DC Outputs

• 5V at 30mA maximum

Voltage Output

• Range: 0 to 12V at 20 mA maximum

• Minimum: load impedance 500 Ω

• Accuracy: ± 100mV

• Drift: ± 2.1mV/F

Current Output

• Range 0 to 22mA at 20V maximum

• Maximum load impedance 1,000 Ω

• Accuracy: ± 100µA

• Drift: ± 4.3µA/F

Agency

•UL60730, c-UL File E43684

• EU LV Directive 72/23/EEC EN 60730

• EU EMC Directive 89/336/EEC

emissions

immunity

• NSF Option, File 49660-0003-000

• NAFEM Communications/Evaluate proper listing

• CSA standard E60730-2-9

Power/Line Voltage

• 24 VÅ (ac) power input (20.4 to 26.4Å (ac)), Class 2 power

source required

• 47 to 63 Hz

• 15VA maximum

• Program retention upon power failure via non-volatile memory

• Battery/real time clock option: six-year lithium battery, pro-

vides power upon backup power failure, operation resumption

after power recovery, ability to display time.

Audible Alarm

• Internal audible alarm, 85 dB @ 10cm @ 2 KHz. Output fre-

quencies supported: 250, 500, 1,000, 2,000, 4,000 Hz.

Storage Temperature

• -40 to 80°C (-40 to 176°F)

Optional High-Voltage Board

• Optional high-voltage board will have six outputs, either solid-

state relay, electromechanical relay or no-arc relay

Relay Specification:

Contact type: normally open

Maximum operating current: 8 A

Maximum operating voltage: 250VÅ (ac)

Pilot duty: 250 VA

Page 22

Appendix ■ 22 ■ Watlow Series N7

SSR Specification

Contact type: normally open

Maximum operating current: 0.4 A

Maximum operating voltage: 250VÅ (ac)

Pilot duty: 100 VA

No Arc Specification

Contact type: normally open

Maximum operating current: 8 A

Maximum operating voltage: 250VÅ (ac)

Note: These specifications are subject to change without

prior notice.

High-Voltage Modules Ordering Information

• A007-2660-0000 - 2 solid-state relays (0.4 A)

• A007-2660-0001 - 2 solid-state relays (0.4 A) and

4 mechanical relays (8 A)

• A007-2660-0002 - 6 solid-state relays (0.4 A)

• A007-2660-0003 - 4 solid-state relays (0.4 A) and

2 mechanical relays (8 A)

• A007-2660-0004 - 2 solid-state relays (0.4 A) and

4 no-arc relays*

Customer-Supplied Connectors

Standard I/O 16-pin connector housing - Molex part no.

43025-1600

Optional I/O 14-pin connector housing - Molex part no.

43025-1400

Pins - Molex part no. 43030-0007

*No-Arc Relay Definition:

A thyristor carries the load current for a brief period before the

relay contacts close. The voltage across the relay contacts prior

to closing is only a volt or two (the voltage drops across the

thyristor). When the relay contacts close, the load current flows

through the relay contacts, and the thyristor turns off. When

it’s time to turn the load off, the thyristor is gated ON just prior

to the relay contacts opening. As the relay contacts begin to

separate and the line voltage crosses zero, the thyristor again

goes into conduction and extinguishes the arcing between the

relay contacts. This great reduction in contact arcing (mainly

on relay opening) minimizes contact erosion and extends the

switch life of the relay.

Page 23

Watlow Series N7 ■ 23 ■ Appendix

Ordering Information and Model Numbers

Customer Name

Inputs 1 & 2

1 Input 1 & Input 2 thermocouple

2 Input 1 thermocouple, Input 2 process

3 Input 1 thermocouple, Input 2 RTD

4 Input 1 & Input 2 process

5 Input 1 RTD, Input 2 process

6 Input 1 & Input 2 RTD

Inputs 3 & 4

0 none

1 Input 3 & Input 4 thermocouple

2 Input 3 process, Input 4 thermocouple

3 Input 3 RTD, Input 4 thermocouple

4 Input 3 & Input 4 process

5 Input 3 RTD, Input 4 process

6 Input 3 & Input 4 RTD

Note: The thermocouple options for Inputs 3 and 4 need thermocouple population for Input 1.

Process Outputs 1 & 2, Event Inputs 5 to 8, Control Outputs 3 & 4

0 none

13 & 4 switched dc control outputs, event inputs

21 current output, 3 & 4 switched dc control outputs, event inputs

31 & 2 current outputs, 3 & 4 switched dc control outputs, event inputs

41 current output, 2 volts output, 3 & 4 switched dc control outputs, event inputs

51 volts output, 3 & 4 switched dc control outputs, event inputs

61 & 2 volts outputs, 3 & 4 switched dc control outputs, event inputs

71 volts output, 2 current output, event inputs

Ethernet Add-on Module

0 none

1 Ethernet

High-voltage Add-on Module

0 none

12 solid-state relays

24 mechanical relays and 2 solid-state relays

36 solid-state relays

42 mechanical relays; 4 solid-state relays

54 no-arc relays*; 2 solid-state relays

Horizontal or Vertical Display

1 vertical

2 horizontal left

3 horizontal right

Software and Customer Options

N 7

__ __ __ __ - __ __ __ __ - __ __ __ __

Page 24

Appendix ■ 24 ■ Watlow Series N7

Install or Replace the Relay/High Voltage Output Module (Z100-0817-000X)

1. Remove power from the controller.

2. Pre-assemble the circuit board spacers onto the

Relay/High Voltage Output circuit board.

• Insert the pointed end of a circuit board spacer

into one of the four mounting holes of the

Relay/High Voltage Output circuit board from

the side of the circuit board that has the output

terminal blocks.

• Using firm pressure, seat the circuit board spacer’s “head” onto the surface of the Relay/High

Voltage Output circuit board.

• Repeat with the remaining three circuit board

spacers.

3. Pre-assemble the board stacking header onto the

Relay/High Voltage Output circuit board.

• Align the pins of the board stacking header to

the socket on the Relay/High Voltage Output

circuit board. Make sure all pins are aligned

properly.

• Using firm pressure insert the board stacking

header into the socket.

• Make sure all pins of the board stacking header

are seated properly.

4. Install the Relay/High Voltage Output circuit board.

• Align the pins of the board stacking header to

the socket on the main circuit board. Make sure

all pins are aligned properly.

• Align the pointed end of the four circuit board

spacers with the four mounting holes on the

main circuit board.

• While maintaining alignment of the pins of the

board stacking header and the circuit board

spacers, firmly press the Relay/High Voltage

Output circuit board onto the main circuit

board.

•Verify that all pins of the board stacking header

and the circuit board spacers are seated properly.

5. Verify Output Wiring.

• Install wiring to the appropriate output terminals.

6. Test the Controller.

• Reapply power to the controller and test.

Figure 24 — Install the Relay/High Voltage Output Module.

Main Circuit Board

Relay/High Voltage

Output Circuit Board

Relay/High Voltage

Output Socket

Relay/High Voltage

Output Board

Sticking Header

Circuit Board Spacer

Relay/High Voltage

Output Socket

Pointed End

Head

Page 25

Watlow Series N7 ■ 25 ■ Appendix

Install or Replace the Ethernet Module (Z100-0816-0000)

1. Remove power from the controller.

2. Pre-assemble the circuit board spacers onto the

Ethernet circuit board.

• Insert the pointed end of a circuit board spacer

into one of the four mounting holes of the

Ethernet circuit board from the side of the circuit board that has the label on it.

• Using firm pressure seat the circuit board spacer until the head of the spacer is flush with the

surface of the Ethernet circuit board.

• Repeat with the remaining three circuit board

spacers.

3. Install the Ethernet circuit board.

• Align the Ethernet connector with the Ethernet

module connector.

• Align the pointed ends of the four circuit board

spacers with the four mounting holes on the

main circuit board.

• While maintaining alignment of the Ethernet

connectors and the circuit board spacers, firmly

press the Ethernet circuit board onto the main

circuit board.

•Verify that the Ethernet connector and the circuit board spacers are seated properly.

4. Verify Output Wiring.

• Install RJ-485 Ethernet connector.

5. Test the Controller.

• Reapply power to the controller and test.

Figure 25 — Install the Ethernet Module.

N7 Main Circuit Board

Ethernet Module Connector

Ethernet Module Circuit Board

RJ-485 Ethernet

Connector

Circuit Board Spacer

Page 26

Appendix ■ 26 ■ Watlow Series N7

Notes:

Page 27

Watlow Series N7 ■ 27 ■ Appendix

Declaration of Conformity

Series N7

Watlow Winona, Inc.

1241 Bundy Blvd.

Winona, MN 55987 USA

Declares that the following product:

Designation: Series N7

Model Numbers: N7 (any two letters or numbers) - (1 to 6) (0 to 6) (0 to 7) (0 or 1) - (0 to 5)

(1, 2 or 3) (any two letters or numbers)

Classification: Temperature control, Installation Category II, Pollution degree 2

Rated Voltage: 24 VÅ ac

Rated Frequency: 50 or 60 Hz

Rated Power Consumption: 15VA maximum

Meets the essential requirements of the following European Union Directives by using the relevant

standards shown below to indicate compliance.

89/336/EEC Electromagnetic Compatibility Directive

EN 60730-1:1995 with A1, 2, 3, Automatic electrical controls for household and similar

use - Part 1 General requirements. Clause H.26 EMC

requirements Immunity, Clause H.23 Class B* Emissions

EN 61000-4-2: 1996 With A1, 1998: Electrostatic Discharge Immunity

EN 61000-4-3: 1997: Radiated Field Immunity

EN 61000-4-4: 1995: Electrical Fast-Transient / Burst Immunity

EN 61000-4-5: 1995 With A1, 1996: Surge Immunity

EN 61000-4-6: 1996: Conducted Immunity

EN 61000-4-11: 1994: Voltage Dips, Short Interruptions and Voltage Variations

Immunity

EN 61000-3-2: ED.2. 2000: Harmonic Current Emissions

EN 61000-3-3: 1995 With A1:1998: Voltage Fluctuations and Flicker

*Class B emissions contingent upon use of a Steward Ferrite (28A2029-0A0) to Ethernet cable on main board.

73/23/EEC Low-Voltage Directive

EN 60730-1:1995 with A1, 2, 3, Automatic electrical controls for household and similar

use - Part 1 General requirements and Part 2-9:1995 -

Temperature sensing controls.

Raymond D. Feller, III Winona, Minnesota, USA

Name of Authorized Representative Place of Issue

General Manager February 2004

Title of Authorized Representative Date of Issue

Signature of Authorized Representative

4 and 5

4 and 5

Page 28

How to Reach Us

CUS

ER

TISF

CTI

Your Authorized Watlow Distributor:

Corporate Headquarters in the

U.S.:

Watlow Electric Manufacturing Co.

12001 Lackland Road

St. Louis, Missouri, USA 63146

Telephone: +1 (314) 878-4600

Fax: +1 (314) 878-6814

Europe:

Watlow GmbH

Industriegebiet Heidig

Lauchwasenstr. 1, Postfach 1165

Kronau 76709 Germany

Telephone: +49 (0) 7253-9400 0

Fax: +49 (0) 7253-9400-44

Watlow France S.A.R.L.

Immeuble Somag,16 Rue Ampère

Cergy Pontoise CEDEX 95307 France

Telephone: +33 (1) 3073-2425

Fax: +33 (1) 3073-2875

Watlow Italy S.R.L.

Via Meucci 14

20094 Corsico MI

Italy

Telephone: +39 (02) 4588841

Fax: +39 (02) 458-69954

Watlow Limited

Robey Close, Linby Industrial Estate

Linby Nottingham England, NG15 8AA

Telephone: +44 (0) 115 9640777

Fax: +44 (0) 115 9640071

Latin America:

Watlow de México

Av. Fundición #5

Col. Parques Industriales

Querétaro, Qro. México CP-76130

Telephone: +52 (442) 217-6235

Fax: +52 (442) 217-6403

Asia/Pacific:

Watlow Australia Pty., Ltd.

23 Gladstone Park Drive

Tullamarine, Victoria 3043 Australia

Telephone: +61 (39) 335-6449

Fax: +61 (39) 330-3566

Watlow China, Inc.

179 Zhong Shan Xi Road

Hong Qiao Cointek Bldg, Fl. 4, Unit P

Shanghai 200051 China

Telephone: +86 (21) 6229-8917

Fax: +86 (21) 6228-4654

Watlow Japan Ltd. K.K.

Azabu Embassy Heights 106

1-11-12 Akasaka

Minato-ku, Tokyo 107-0052 Japan

Telephone: +81 (03) 5403-4688

Fax: +81 (03) 5403-4646

Watlow Korea Co., Ltd.

3rd F. Taehong Bldg.

20-6, Seocho-gu, Yangjae-dong

Seoul, 137-130 Korea

Telephone: +82 (2) 575-9804

Fax: +82 (2) 575-9831

Watlow Malaysia Sdn Bhd

38B Jalan Tun Dr Awang

11900 Bayan Lepas

Penang Malaysia

Telephone: +60 (4) 641-5977

Fax: +60 (4) 641-5979

Watlow Singapore Pte. Ltd.

Ayer Rajah Crescent

#03-23, Ayer Rajah Industrial Estate

Singapore 139949

Telephone: +65 773 9488

Fax: +65 778 0323

Watlow Electric Taiwan

10F-1 No. 189

Chi-Shen 2nd Road

Kaohsiung, Taiwan

Telephone: +886 (7) 288-5168

Fax: +886 (7) 288-5568

TOTAL

CUS

TOMER

SATISF

ACTI

3 Year Warranty

ON

Loading...

Loading...