Page 1

Registered Company

Winona, Minnesota USA

ISO 9001ISO 9001

TOTAL

3Year Warranty

CUSCUSTTOOMMERER

SSAATISFTISFAACTICTIOONN

Series SD

User’s Manual

0600-0041-0005 Rev. B Made in the U.S.A.

November 2004 $15.00

Limit Controller

1241 Bundy Boulevard., Winona, Minnesota USA 55987

Phone: +1 (507) 454-5300, Fax: +1 (507) 452-4507 http://www.watlow.com

Page 2

ç

CCAAUUTTIIOONN oorr

WWAARRNNIINNGG

Ó

EElleeccttrriiccaall

SShhoocckk HHaazzaarrdd

CCAAUUTTIIOONN oorr WWAARRNNIINNGG

Safety Information

We use note, caution and warning symbols throughout this book to draw your attention to important operational and safety information.

“NOTE” marks a short message to alert you to an important detail.

A

A “CAUTION” safety alert appears with information that is important for protecting your equip-

ment and performance. Be especially careful to read and follow all cautions that apply to your application.

A “WARNING” safety alert appears with information that is important for protecting you, others

nd equipment from damage. Pay very close attention to all warnings that apply to your application.

a

The safety alert symbol,

ARNING statement.

W

The electrical hazard symbol,

CAUTION or WARNING safety statement.

ç (an exclamation point in a triangle) precedes a general CAUTION or

Ó (a lightning bolt in a triangle) precedes an electric shock hazard

Technical Assistance

If you encounter a problem with your Watlow controller, review your configuration information to

verify that your selections are consistent with your application: inputs, outputs, alarms, limits, etc.

If the problem persists after checking the configuration of the controller, you can get technical assistance from your local Watlow representative (see back cover), or by dialing +1 (507) 494-5656

between 7 a.m. and 5 p.m., Central Standard Time (CST). Ask for for an Applications Engineer.

Please have the following information available when calling:

• Complete model number • All configuration information

• User’s Manual • Factory Page

Warranty

The series SD is manufactured by ISO 9001-registered processes and is backed by a three-year warranty.

Return Material Authorization (RMA)

1. Call Watlow Customer Service, (507) 454-5300, for a Return Material Authorization (RMA)

number before returning any item for repair. If you do not know why the product failed, contact an

Application Engineer or Product Manager. All RMA’s require:

• Ship to address • Bill to address

• Contact name • Phone number

Method of return shipment

•

• Detailed description of the problem • Any special instructions

• Name and phone number of person returning the product.

2. Prior approval and an RMA number from the Customer Service Department is required when

returning any product for credit, repair or evaluation. Make sure the RMA number is on the outside

of the carton and on all paperwork returned. Ship on a Freight Prepaid basis.

After we receive your return, we will examine it and try to verify the reason for returning it.

3.

4. In cases of manufacturing defect, we will enter a repair order, replacement order or issue credit

for material returned. In cases of customer mis-use, we will provide repair costs and request a purchase order to proceed with the repair work.

5. To return products that are not defective, goods must be be in new condition, in the original

boxes and they must be returned within 120 days of receipt. A 20 percent restocking charge is

applied for all returned stock controls and accessories.

6. If the unit is unrepairable, you will receive a letter of explanation. and be given the option to

have the unit returned to you at your expense or to have us scrap the unit.

Watlow reserves the right to charge for no trouble found (NTF) returns.

7.

•

Your P.O. number

The Series SD User’s Manual is copyrighted by Watlow Winona, Inc., © November 2004 with all

rights reserved.

Page 3

Watlow Series SD Limit ■ 1 ■ Table of Contents

Chapter 1: Overview . . . . . . . . . . . . . . . . . . . . . . . . . .2

Chapter 2: Install and Wire . . . . . . . . . . . . . . . . . . . . .4

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Chapter 3: Keys and Displays . . . . . . . . . . . . . . . . .19

Home Page Overview . . . . . . . . . . . . . . . . . . . . . .20

Operations Page Overview . . . . . . . . . . . . . . . . . .20

Setup Page Overview . . . . . . . . . . . . . . . . . . . . . .21

Programming Page Overview . . . . . . . . . . . . . . . .22

Factory Page Overview . . . . . . . . . . . . . . . . . . . . .22

Chapter 4: Home Page . . . . . . . . . . . . . . . . . . . . . . . .23

Chapter 5: Setup Page . . . . . . . . . . . . . . . . . . . . . . . .24

Chapter 6: Operations Parameters Table . . . . . . . .30

Chapter 7: Programming Page . . . . . . . . . . . . . . . .32

Chapter 8: Factory Page and Calibration . . . . . . . .34

Chapter 9: Features . . . . . . . . . . . . . . . . . . . . . . . . . .39

Saving and Restoring User Setings . . . . . . . . . . .40

Operations Page . . . . . . . . . . . . . . . . . . . . . . . . . .40

Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Retransmit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Communications . . . . . . . . . . . . . . . . . . . . . . . . . .43

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Ordering Information . . . . . . . . . . . . . . . . . . . . . . .51

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Declaration of Conformity . . . . . . .Inside back cover

TC

Table of Contents

Page 4

Watlow Series SD Limit ■ 2 ■ Chapter 1 Overview

The Watlow Series SD family of microprocessorbased limit controllers is available in 1/32, 1/16, 1/8

and 1/4 DIN panel mount sizes*. The Series SD limit is

added to applications to prevent over or under process

conditions. The Series SD limit provides safety assurances against instances where a process runaway condition occurs as a result of a failed sensor or output device.

The Series SD limit is recommended for any application where system runaway could result in large

product scrap costs, damage to system equipment,

potenial fire hazard or risk to personnel. All Series SD

limits are Factory Mutual approved.

The Series SD limit has a single, universal input

that accepts various thermocouples, RTDs (resistive

temperature devices) or process inputs. (See the Specifications in the Appendix for further details).

The Series SD limit offers up to two outputs on the

1/32 DIN, and up to three outputs on all others. Output 1 is always a mechanical relay operating as a

latching limit output. Any mechanical relay output can

be configured as a latching limit output. These can be

configured as a low limit, high limit or low/high limit.

Outputs 2 and 3 can be also configured as latching or

non-latching alarms. Standard Series SD limit features

include an IP65/NEMA 4X front panel rating; CE compliance; dual, four-digit displays. A low-voltage model is also

available.

Advanced features include Modbus, EIA-485 serial

communications to interface with PC software applications; INFOSENSE™ technology that provides lowcost, high-accuracy thermal sensing; and infrared remote communication for easy-to-use setup and monitoring.***

Other operator-friendly features include LED indicators to aid in monitoring and setting up the controller. The Watlow Series SD limit automatically

stores all information in non-volatile memory and provides an additional back-up for user-selected settings.

For more information on these and all other product features, refer to the Features Chapter and the Appendix.

* Also available in a temperature controller version.

** The 1/32 DIN limit comes only with a red

left and green right display.

*** Not available in the 1/32 DIN size.

Overview

1

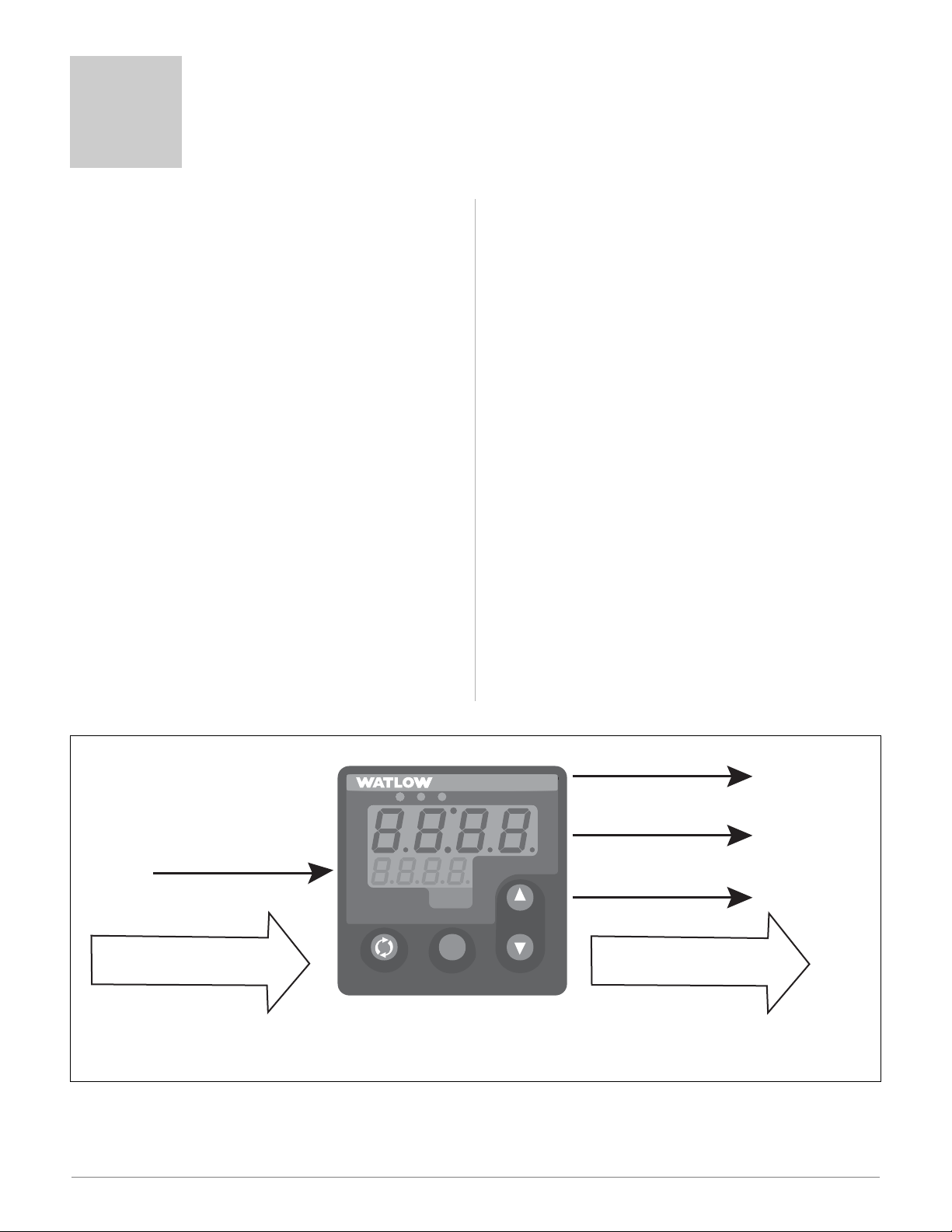

Figure 2 — Series SD limit inputs and outputs.

23231

231

LIMIT SD

Limit

Output 2

Output 1

Control Input

Limit, Alarm or Communications

Output 3

*

Limit or Alarm

Infrared

Configure**

RESET

Infrared

Monitor**

*1/32 DIN cannot have an Output 3.

**Infrared option is not available on 1/32 DIN.

Page 5

Watlow Series SD Limit ■ 3 ■ Chapter 1 Overview

Features and Benefits

Patented User Definable Menu System

• Simplifies operator interface.

User Defined Default Settings

• Restores user defined controller settings.

INFOSENSE™ Technology

• Improves sensor accuracy by a minimum of 50%.

INFOSENSE™ Technology

• Improves sensor accuracy by a minimum of 50%.

Infrared Communications

• Facilitates controller setup, operation and monitoring.

Up to three outputs (1/32 DIN two outputs only)

• Application versatility.

• Configuration flexibility

Dual Displays on all models

• Better monitoring of process changes.

Also available in an PID temperature controller

version.

How to use the Series SD limit

Before you use your Series SD limit, it must be installed and configured correctly. Which setup steps

you need to perform will depend on how you will

use it.

If you purchased the limit to design into your

products:

You will need to do the first three steps and maybe

some of the fourth step. Some wiring, such as the final

wiring of a communications connection or an alarm

output for signaling an external device, might be left to

the end user. In highly specialized applications with little variation in operation and heat load, the OEM

might configure almost all the parameters.

If you purchased the limit to design and install

into new equipment for your own use or to retrofit into existing equipment:

You will need to complete all four steps.

If you purchased the limit installed in equipment

designed around it:

You will probably only need to do the fourth step. In

some instances, you may need to wire it for serial communications and/or an alarm output. Some serial communications parameters in the Setup Page may need to

be changed.

Step 1: Mount and install the limit.

The Series SD limit is designed to be panel mounted

in a standard DIN opening. The Series SD is available

in 1/32 DIN, 1/16 DIN, 1/8 DIN-horizontal, 1/8 DINvertical and 1/4 DIN sizes. Cut the correct size hole into the panel and mount the limit, using its mounting

brackets. See Chapter Two for details on installation

and mounting.

If you retrofit the Series SD limit into an existing

application, you may need to modify an existing opening, either by cutting it larger for a larger limit or using

a Watlow adapter plate to adapt it to a smaller limit.

Step 2: Wire the limit.

The limit will need to have its power, input and output wiring installed. The wiring depends on the specific

model number of the Series SD limit. The dimension illustrations in Chapter Two show the location of the

model number on each DIN size. Use the model number to determine which wiring diagrams to follow for

your limit. See Chapter Two for wiring details.

Step 3: Configure the Setup Page.

Setup Page parameters tell the limit what input

and output devices are wired to the limit and how it

should function. Without the proper Setup Page settings, the limit will not operate or could operate erratically. Since these settings require detailed knowledge

on the wiring and operation of the equipment, the

OEM or the designer normally programs these parameters. Some settings, such as the baud rate or device address, are Setup Page parameters, but would probably

be set by the end user.

These settings should be recorded for future reference. The settings can also be stored using the [Us;rS]

parameter, in the Factory Page. For saving and restoring parameters, see Chapter Eight, Features. For details on configuring the Setup Page, see Chapter Five,

Setup Page.

Step 4: Configure the Operations Page.

The Operations Page contains the parameters that

the equipment operator may need to set or change from

time to time. This includes limit and alarm set points.

In some cases the OEM manufacturer may set most of

these parameters because the equipment operates with

little variation (i.e., always the same limit and alarm

set points, always the same heat load). In equipment

where demands could vary significantly, the OEM may

leave parameter adjustments to the end user (i.e.,

many different temperature settings, different heat

loads).

The Operations Page on the Series SD limit is customizable so that only the parameters that the operator

may need to use will appear in the display. Settings

that won’t need to be adjusted can be hidden from the

operator, using the Programing Page. For more details

on the Programing Page, see Chapter Eight, Features.

For details on configuring parameters in the Operations Page, see Chapter Six, Operations Parameters

Tables.

Once you have verified the limit is operating properly, be sure to document all of your parameter settings.

Each parameter table has a settings column for you to

write in your values.

Page 6

Watlow Series SD Limit ■ 4 ■ Chapter 2 Install and Wire

Install and Wire

2

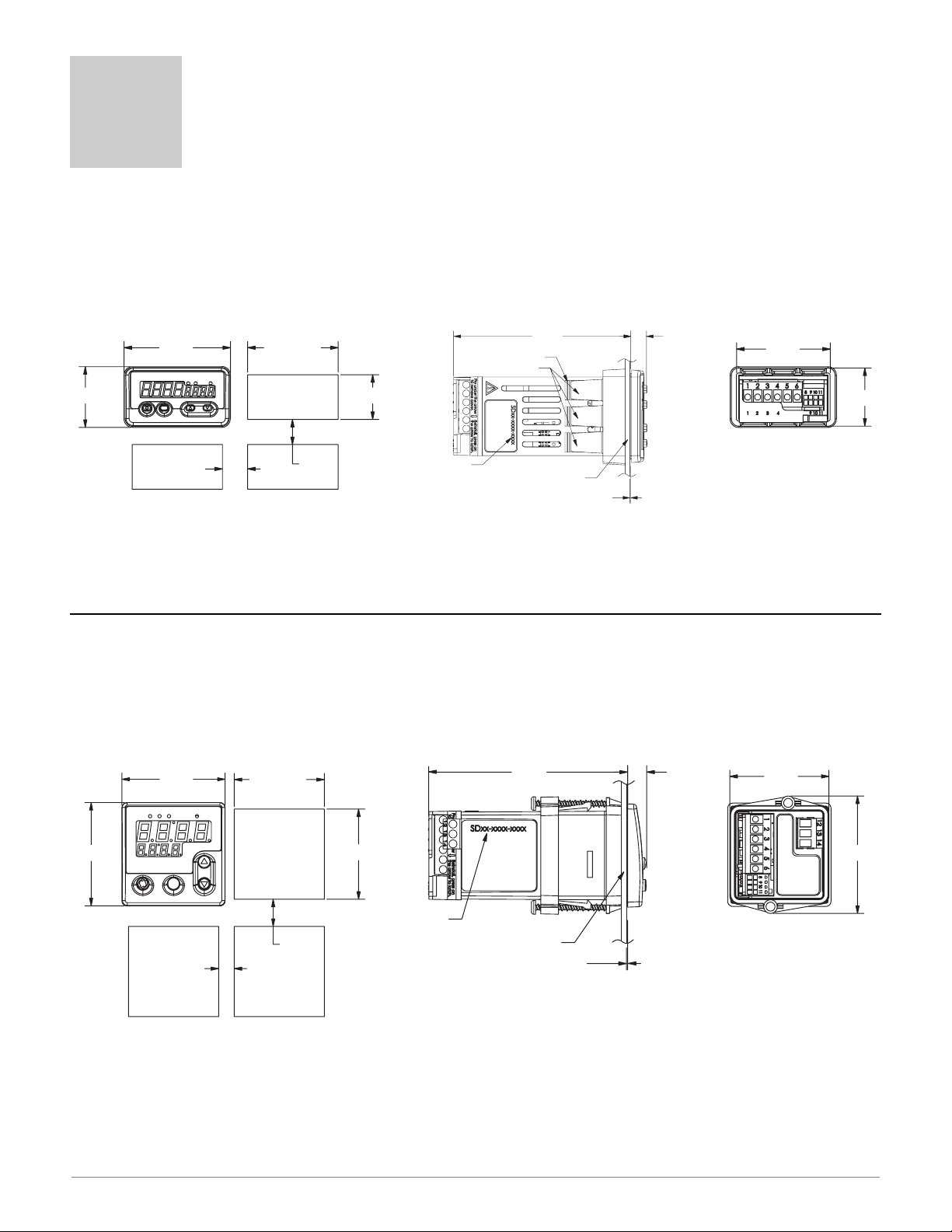

1/16 DIN Series SD Limit Dimensions

RESET

Front

Side Back

RESET

1/32 DIN Series SD Limit Dimensions

Front Top

Back

Contact your local Greenlee supplier for the appropriate punch kit and

cutout tools required for rapid mounting.

Contact your local Greenlee supplier for the appropriate punch kit and

cutout tools required for rapid mounting.

30.7 mm

(1.21 in)

53.6 mm

(2.11 in)

RESET

12.7 mm

minimum

(0.50 in)

45.0 to 45.6 mm

(1.77 to 1.79 in)

Panel Cutout

Panel Thickness

1.5 to 9.5 mm

(0.060 to 0.375 in)

12.7 mm

(0.50 in)

minimum

22.2 to 22.5 mm

(0.87 to 0.89 in)

Model Number

Tabs with Teeth

0.48 mm (0.019 in) maximum gap between

controller front and customer front panel

100.9 mm

(3.98 in)

Ridges

Customer Front Panel

8.6 mm

(0.34 in)

47.2 mm

(1.86 in)

29.3 mm

(1.15 in)

52.1 mm

(2.05 in)

45.0 to 45.5 mm

(1.77 to 1.79 in)

100.2 mm

(3.95 in)

9.3 mm

(0.37 in)

50.1 mm

(1.97 in)

Panel Cutout

52.1 mm

(2.05 in)

RESET

7.9 mm

(0.31 in)

minimum

Panel Thickness

1.5 to 9.5 mm

(0.060 to 0.375 in)

13.7 mm

(0.54 in)

minimum

45.0 to 45.5 mm

(1.77 to 1.79 in)

Model Number

0.6 mm (0.025 in) maximum gap between

controller front and customer front panel

Customer Front Panel

59.2 mm

(2.33 in)

Page 7

Watlow Series SD Limit ■ 5 ■ Chapter 2 Install and Wire

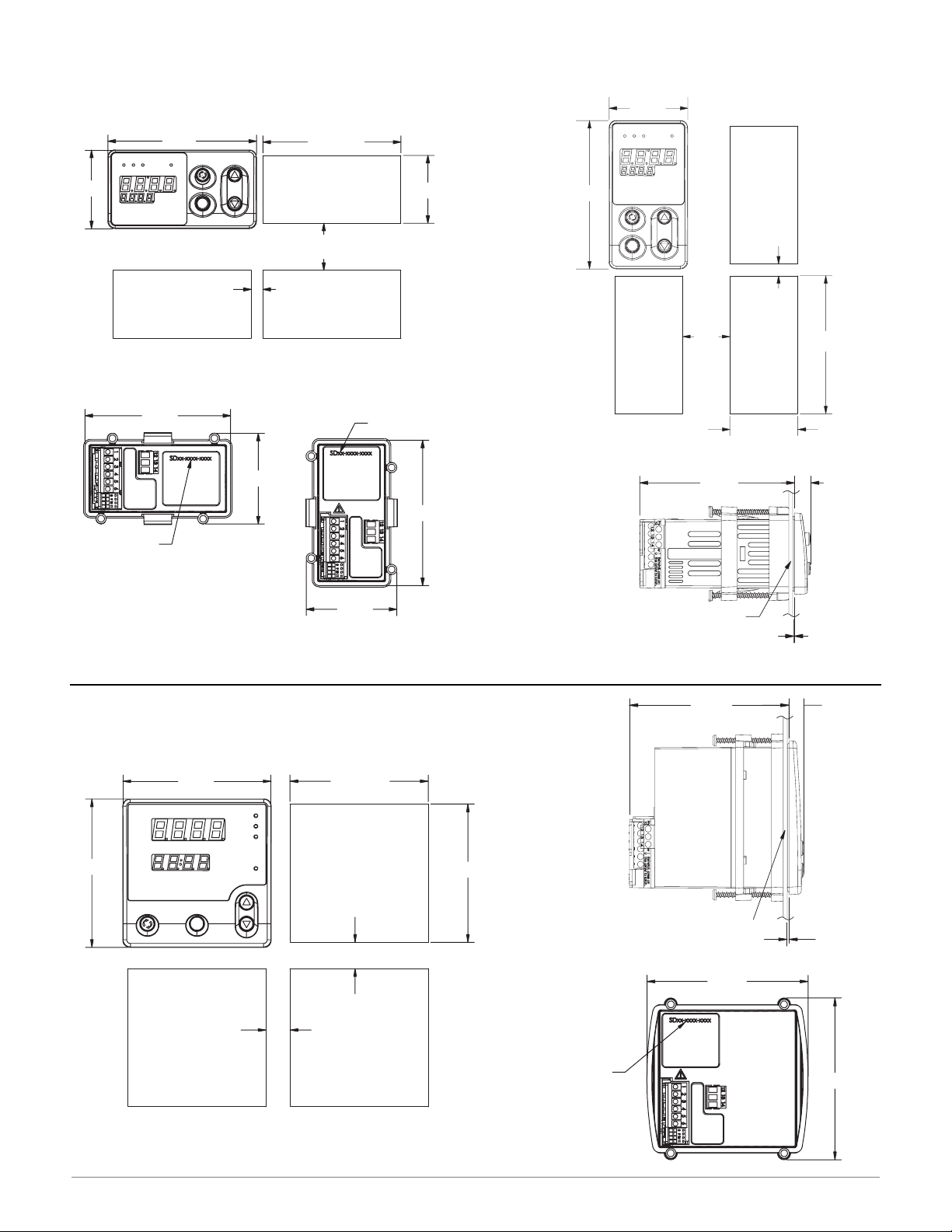

1/4 DIN Series SD Limit Dimensions

Model

Number

108.3 mm

(4.26 in)

108.8 mm

(4.28 in)

103.5 mm

(4.08 in)

9.6 mm

(0.38 in)

Customer Front Panel

0.5 mm (0.020 in) maximum gap between

controller front and customer front panel

RESET

Side

Back

Front

RESET

RESET

1/8 DIN Series SD Limit Dimensions

Back (horizontal)

Side (horizontal)

Front (vertical)

Back (vertical)

Front (horizontal)

Contact your local Greenlee supplier for the appropriate punch kit and

cutout tools required for rapid mounting.

Contact your local Greenlee supplier for the appropriate punch kit and

cutout tools required for rapid mounting.

99.8 mm

(3.93 in)

52.8 mm

(2.08 in)

97.8 mm

(3.85 in)

Model Number

RESET

minimum

7.9 mm

(0.31 in)

60.9 mm

(2.40 in)

92.0 to 93.0 mm

(3.62 to 3.65 in)

Panel Cutout

Panel Thickness

1.52 to 9.53 mm

(0.060 to 0.375 in)

31.8 mm

(1.25 in)

minimum

Model Number

45.0 to 45.6 mm

(1.77 to 1.79 in)

97.8 mm

(3.85 in)

99.8 mm

(3.93 in)

52.8 mm

(2.08 in)

RESET

Panel Cutout

31.8 mm

(1.25 in)

minimum

Panel Thickness

1.52 to 9.53 mm

(0.060 to 0.375 in)

45.0 to 45.6 mm

(1.77 to 1.79 in)

Dimensions for Horizontal or Vertical versions

100.2 mm

(3.95 in)

7.9 mm

(0.31 in)

minimum

92.0 to 93.0 mm

(3.62 to 3.65 in)

10.3 mm

(0.40 in)

60.9 mm

(2.40 in)

92.0 to 93.0 mm

(3.62 to 3.65 in)

Panel Cutout

Panel Thickness

1.52 to 9.53 mm

(0.060 to 0.375 in)

17.6 mm

(0.68 in)

minimum

16.0 mm

(0.63 in)

minimum

92.0 to 93.0 mm

(3.62 to 3.65 in)

99.8 mm

(3.93 in)

99.8 mm

(3.93 in)

RESET

Customer Front Panel

0.64 mm (0.025 in) maximum gap between

controller front and customer front panel

Page 8

ç

Caution: Follow the installation procedure exactly to

guarantee a proper IP65/NEMA 4X seal. Make sure the

gasket between the panel

and the rim of the case is

not twisted and is seated

properly. Failure to do so

could result in damage to

equipment.

Watlow Series SD Limit ■ 6 ■ Chapter 2 Install and Wire

Installing and mounting

requires access to the

back of the panel.

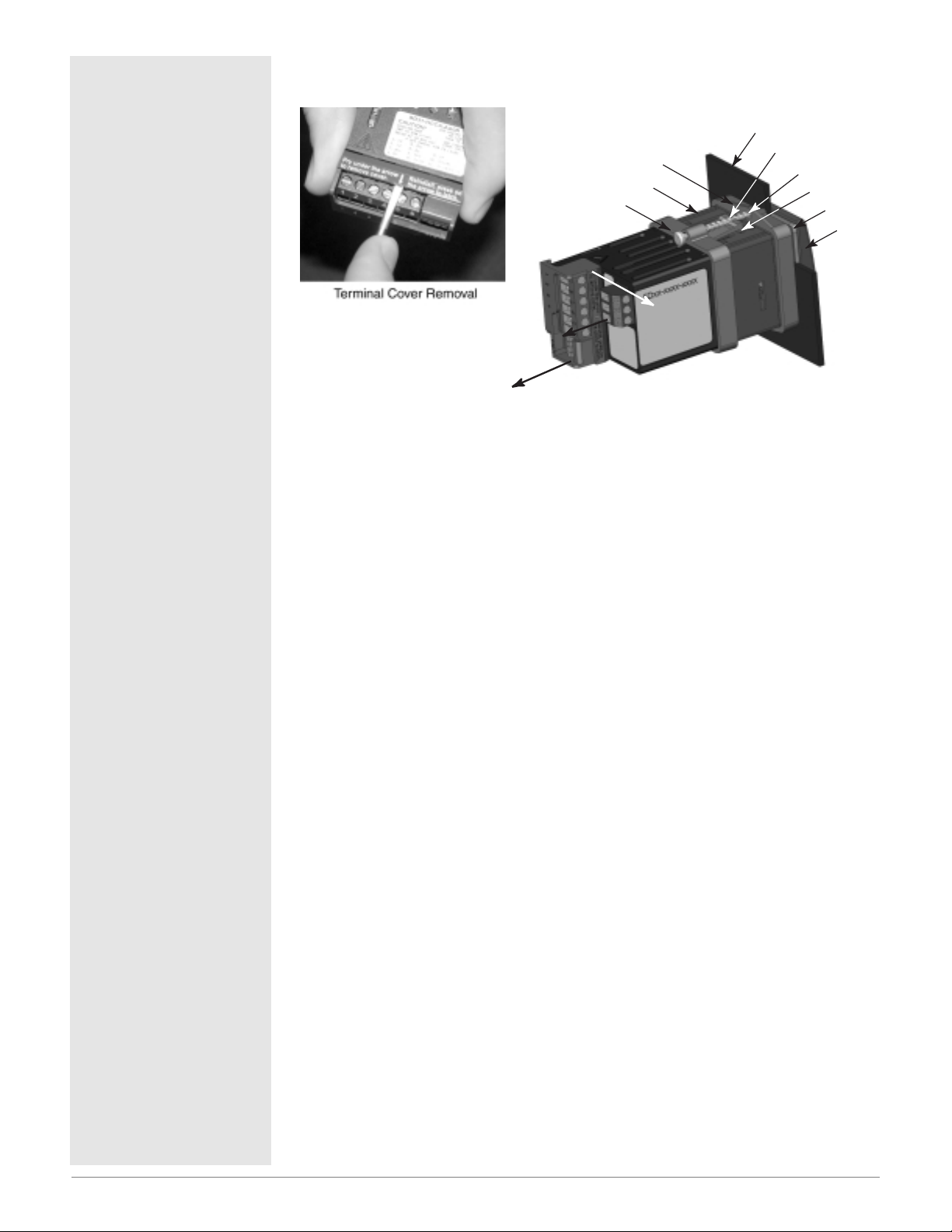

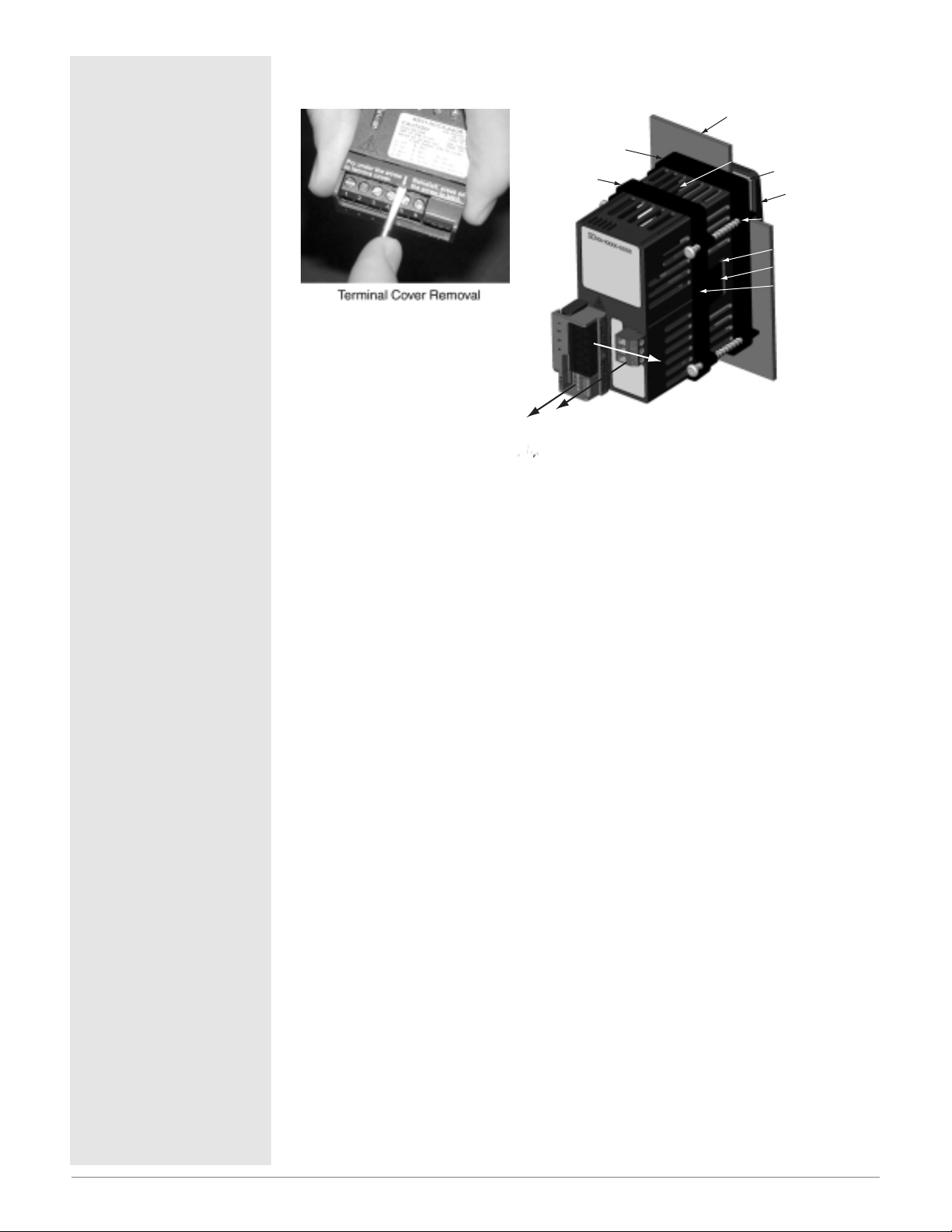

Installing the 1/32 DIN Series SD Limit

1. Make the panel cutout using the mounting template dimensions in this chapter.

2. Check that the rubber gasket lies in its slot at the back of the bezel. Insert the

limit into the panel cutout.

3. While pressing the bezel firmly against the panel, slide the mounting bracket

over the back of the limit.

4. If the installation does not require an IP65/NEMA 4X seal, slide the bracket

up to the back of the panel enough to eliminate the spacing between the gasket and the panel.

For an IP65/NEMA 4X seal, use your thumb to lock the tabs into place while

pressing the limit from side to side. Don’t be afraid to apply enough pressure

to properly install the limit. If you can move it back and forth in the cutout,

you do not have a proper seal. The tabs on each side of the bracket have teeth

that latch into the ridges.

Each tooth is staggered at a different depth (from the front) so only one of the

tabs on each side is ever locked into the ridges at any time. Either the two

middle tabs or the two tabs diagonal from each other will be engaged.

5. If the matching tabs are not engaged, you do not have an IP65/NEMA 4X seal.

The space between the bezel and panel must be 0 to 0.48 mm (0 to 0.019 in)

maximum.

Removing the 1/32 DIN Series SD Limit

1. Remove the terminal cover and all of the wiring connectors from the back of

the limit.

2. Slide a thin, wide tool (putty knife) under all three mounting tabs, top then

bottom, while pushing forward on the back of the case. Be ready to support

the limit as it slides out of the panel cutout.

Tools required:

Putty knife or equivalent

Arrows indicate the

direction of pull to

remove the

connectors.

Mounting

Bracket

Panel

Mounting Tab

Mounting Ridge

Gasket

Bezel

Case

IP65/NEMA 4X

Seal Example

Page 9

Watlow Series SD Limit ■ 7 ■ Chapter 2 Install and Wire

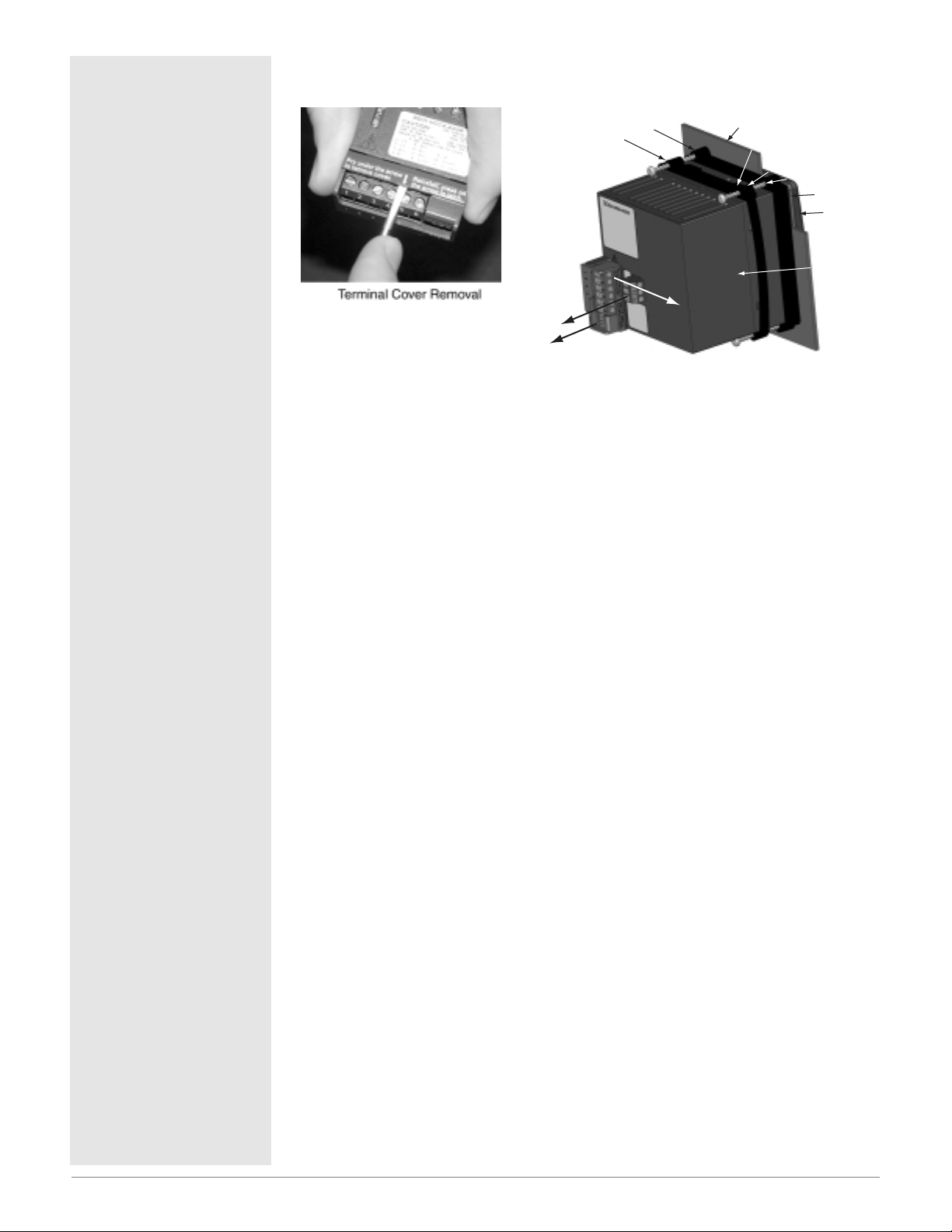

Installing the 1/16 DIN Series SD Limit

1. Make the panel cutout using the mounting template dimensions in this chapter.

2. Check that the rubber gasket lies in its slot at the back of the bezel. Insert the

limit into the panel cutout. Slide the retention collar over the limit, with the

locating holes on the top and bottom, facing the back of the limit.

3. Slide the mounting bracket over the back of the limit with the screw tips

pointed toward the panel, aligning with the locating holes in the retention collar. Push it gently but firmly over the limit until the hooks snap into the slots

at the front.

4. If the installation does not require an IP65/NEMA 4X seal, tighten the two

screws with the Phillips screwdriver just enough to eliminate the spacing between the rubber gasket and the panel.

For an IP65/NEMA 4X seal, tighten the two screws until the gap between the

bezel and panel surface is 0.6 mm (0.024 in) maximum. Make sure that you

cannot move it back and forth in the cutout. If you can, you do not have a

proper seal. Do not over-tighten. Over-tightening could damage the mounting

bracket.

Removing the 1/16 DIN Series SD Limit

1. Remove the terminal cover and all of the wiring connectors from the back of

the limit. While supporting the limit with one hand, use the Phillips screwdriver to unscrew the two screws on the mounting bracket until the tips are

flush or past the end of the hooks.

2. Squeeze the two screws together on the mounting bracket to release the hooks

from the slots and slide it off. Remove the retention collar and push the limit

out of the panel cutout. Be ready to support the limit as it comes through the

front panel.

Gasket

Bezel

Panel

Retention

Collar

Mounting

Bracket

Slot

Case

Locating Hole

Arrows indicate the

direction of pull to

remove the

connectors.

Hook

ç

Caution: Follow the installation procedure exactly to

guarantee a proper IP65/NEMA 4X seal. Make sure the

gasket between the panel

and the rim of the case is

not twisted and is seated

properly. Failure to do so

could result in damage to

equipment.

Note: Be careful not to overtighten the screws. This may

cause the mounting bracket

to fail. If the front bezel is

touching the front panel, the

mounting bracket is too

tight.

Installing and mounting

requires access to the

back of the panel.

Tools required:

one #2 Phillips screwdriver

Tools required:

one #2 Phillips screwdriver.

Page 10

ç

Caution: Follow the installation procedure exactly to

guarantee a proper IP65/NEMA 4X seal. Make sure the

gasket between the panel

and the rim of the case is

not twisted and is seated

properly. Failure to do so

could result in damage to

equipment.

Note: Be careful not to overtighten the screws. This may

cause the mounting bracket

to fail. If the front bezel is

touching the front panel, the

mounting bracket is too

tight.

Installing the 1/8 DIN Series SD Limit

1. Make the panel cutout using the mounting template dimensions in this chapter.

2. Check that the rubber gasket lies in its slot at the back of the bezel. Insert the

limit into the panel cutout. Slide the retention collar over the limit, with the

locating holes facing the back of the limit.

3. Slide the mounting bracket over the back of the limit with the screw tips

pointed toward the panel, aligning with the locating holes in the retention collar. Push it gently but firmly over the limit until the hooks snap into the slots

at the front.

4. If the installation does not require an IP65/NEMA 4X seal, tighten the four

screws with the Phillips screwdriver just enough to eliminate the spacing between the rubber gasket and the panel.

For an IP65/NEMA 4X seal, tighten the four screws until the gap between the

bezel and panel surface is 0.5 mm (0.020 in) maximum. Make sure that you

cannot move it back and forth in the cutout. If you can, you do not have a

proper seal. Do not over-tighten. Over-tightening could damage the the mounting bracket.

Removing the 1/8 DIN Series SD Limit

1. Remove the terminal cover and all of the wiring connectors from the back of

the limit. Using the Phillips screwdriver, unscrew the four screws on the

mounting bracket until they disengage from the retention collar.

2. Squeeze the release tabs on the long sides of the mounting bracket and slide

the mounting bracket off the back of theLimit. Remove the retention collar

and push the limit out of the panel cutout. Be ready to support the limit as it

comes through the front panel.

Watlow Series SD Limit ■ 8 ■ Chapter 2 Install and Wire

Installing and mounting

requires access to the

back of the panel.

Tools required:

one #2 Phillips screwdriver.

Tools required:

one #2 Phillips screwdriver.

Panel

Retention

Collar

Mounting

Bracket

Arrows indicate the

direction of pull to

remove the

connectors.

Case

Gasket

Bezel

Locating Hole

Slot

Hook

Release

Ta b

Page 11

ç

Caution: Follow the installation procedure exactly to

guarantee a proper IP65/NEMA 4X seal. Make sure the

gasket between the panel

and the rim of the case is

not twisted and is seated

properly. Failure to do so

could result in damage to

equipment.

Note: Be careful not to overtighten the screws. This may

cause the mounting bracket

to fail. If the front bezel is

touching the front panel, the

mounting bracket is too

tight.

Installing the 1/4 DIN Series SD Limit

1. Make the panel cutout using the mounting template dimensions in this

chapter.

2. Check that the rubber gasket lies in its slot at the back of the bezel. Insert the

limit into the panel cutout. Slide the retention collar over the limit, with the

locating holes facing the back of the limit.

3. Slide the mounting bracket over the back of the limit with the screw tips

pointed toward the panel, aligning with the locating holes in the retention collar. Push it gently but firmly over the limit until the hooks snap into the slots

at the front.

4. If the installation does not require an IP65/NEMA 4X seal, tighten the four

screws with the Phillips screwdriver just enough to eliminate the spacing between the rubber gasket and the panel.

For an IP65/NEMA 4X seal, tighten the four screws until the gap between the

bezel and panel surface is 0.5 mm (0.020 in) maximum. Make sure that you

cannot move it back and forth in the cutout. If you can, you do not have a

proper seal. Do not over-tighten. Over-tightening could damage the mounting

bracket.

Removing the 1/4 DIN Series SD Limit

1. Remove the terminal cover and all of the wiring connectors from the back of

the limit. Using the Phillips screwdriver, unscrew the four screws on the

mounting bracket (two on top, two on bottom) until they disengage from the

retention collar.

2. Slide the tip of a flat screwdriver between the limit and the center top side of

the mounting bracket. Rotate the screwdriver 90 degrees, stretching the

bracket away from the limit so the hooks on the bracket disengage from the

slots. Hold the bracket and press the limit forward slightly to prevent the disengaged hooks from snapping back into the slots.

3. Repeat this operation to disengage the hooks on the bottom side of the mounting bracket.

4. Press with one or two fingers on the lower half of the back of the unit so that

the limit slides forward toward the panel. Hold the bracket steady; do not pull

back. Be ready to support it as it comes through the front panel.

Watlow Series SD Limit ■ 9 ■ Chapter 2 Install and Wire

Installing and mounting

requires access to the

back of the panel.

Tools required:

one #2 Phillips screwdriver

Tools required:

• one #2 Phillips screwdriver

• one flat-head screwdriver

Retention

Collar

Mounting

Bracket

Arrows indicate the

direction of pull to

remove the

connectors.

Panel

Hook

Slot

Locating Hole

Gasket

Bezel

Case

Page 12

Watlow Series SD Limit ■ 10 ■ Chapter 2 Install and Wire

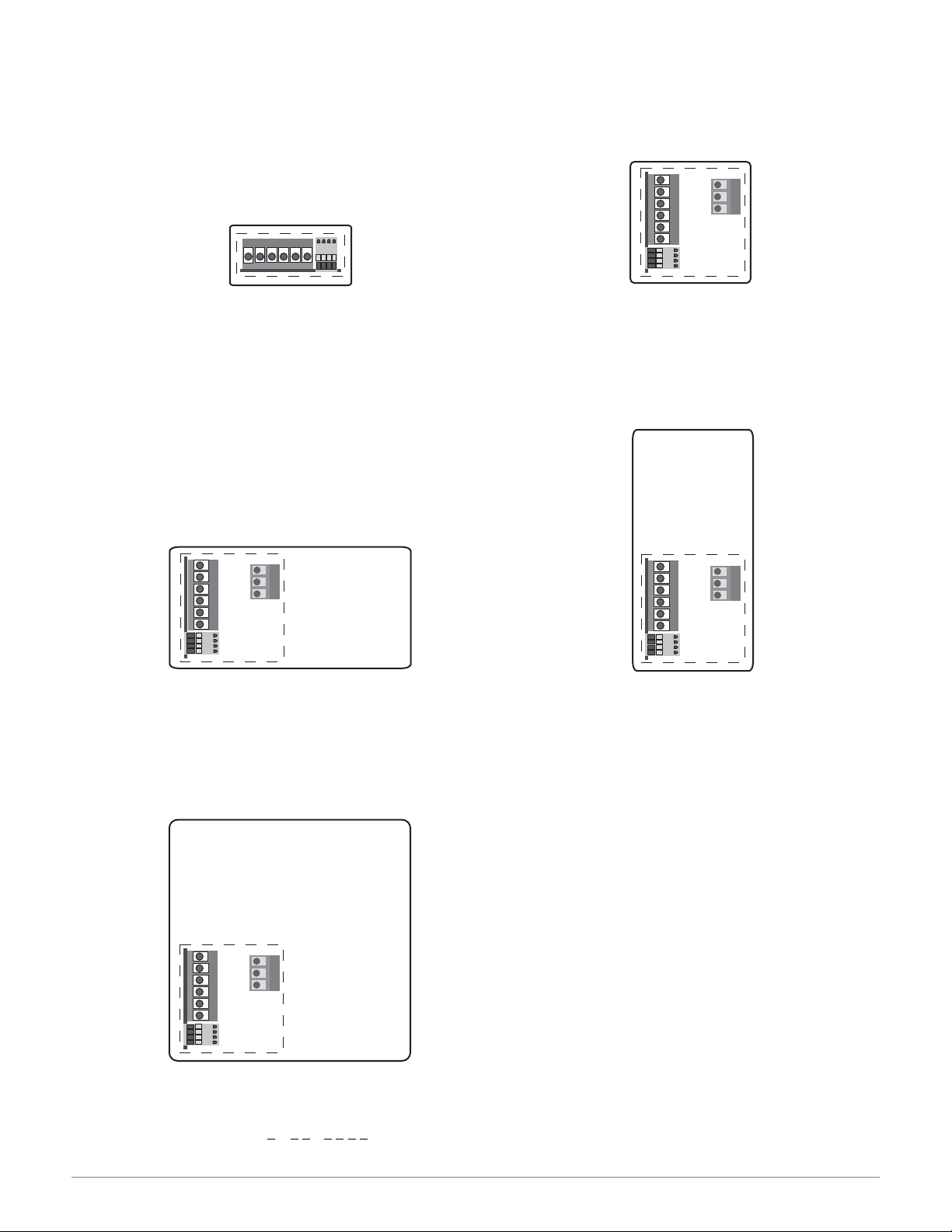

Figure 10e — 1/4 DIN

(S D 4 L - _ J__ -__ _ _).

Figure 10b — 1/16 DIN

(S D 6 L - _ J _ _ - _ _ _ _).

Figure 10d — 1/8 DIN Vertical

(S D 8 L - _ J _ _ - _ _ _).

Figure 10c — 1/8 DIN Horizontal

(S D 9 L - _ J _ _ - _ _ _ _).

Series SD Family — Back Views in Scale

NOTE:

Terminals 12, 13 and 14

are not installed on controllers without an output 3

(SD _ L-_ J _ A-_ _ _ _).

Figure 10a — 1/32 DIN

(S D 3 L - _ J _ _ - _ _ _ _).

NOTE: The SD model number determines which diagram applies to your unit.

234

1

56

89

10 11

8

9

10 11

1

2

3

4

56

12

13

14

8

9

10 11

1

2

3

4

56

12

13

14

8

9

10 11

1

2

3

4

56

12

13

14

8

9

10 11

1

2

3

4

56

12

13

14

Page 13

Watlow Series SD Limit ■ 11 ■ Chapter 2 Install and Wire

Ó

Warning:

Use National Electric (NEC) or

other country-specific standard

wiring and safety practices when

wiring and connecting this limit

to a power source and to electrical sensors or peripheral devices. Failure to do so may result in damage to equipment and

property, and/or injury or loss of

life.

Note: To prevent ground loops,

isolation needs to be maintained

from input to output when using

switched DC or analog process

outputs.

Ó

WARNING: If high voltage is applied to a low-voltage limit, irreversible damage will occur.

Wiring the Series SD

The model number for each output option appears with its wiring diagram. Check the label on the limit and compare your model number to those

shown here and to the model number breakdown in the Appendix of this

manual.

The connectors on the back of the Series SD are different for different

model numbers.

All outputs are referenced to a de-energized state.

All wiring and fusing must conform to the National Electric Code and to

any locally applicable codes as well.

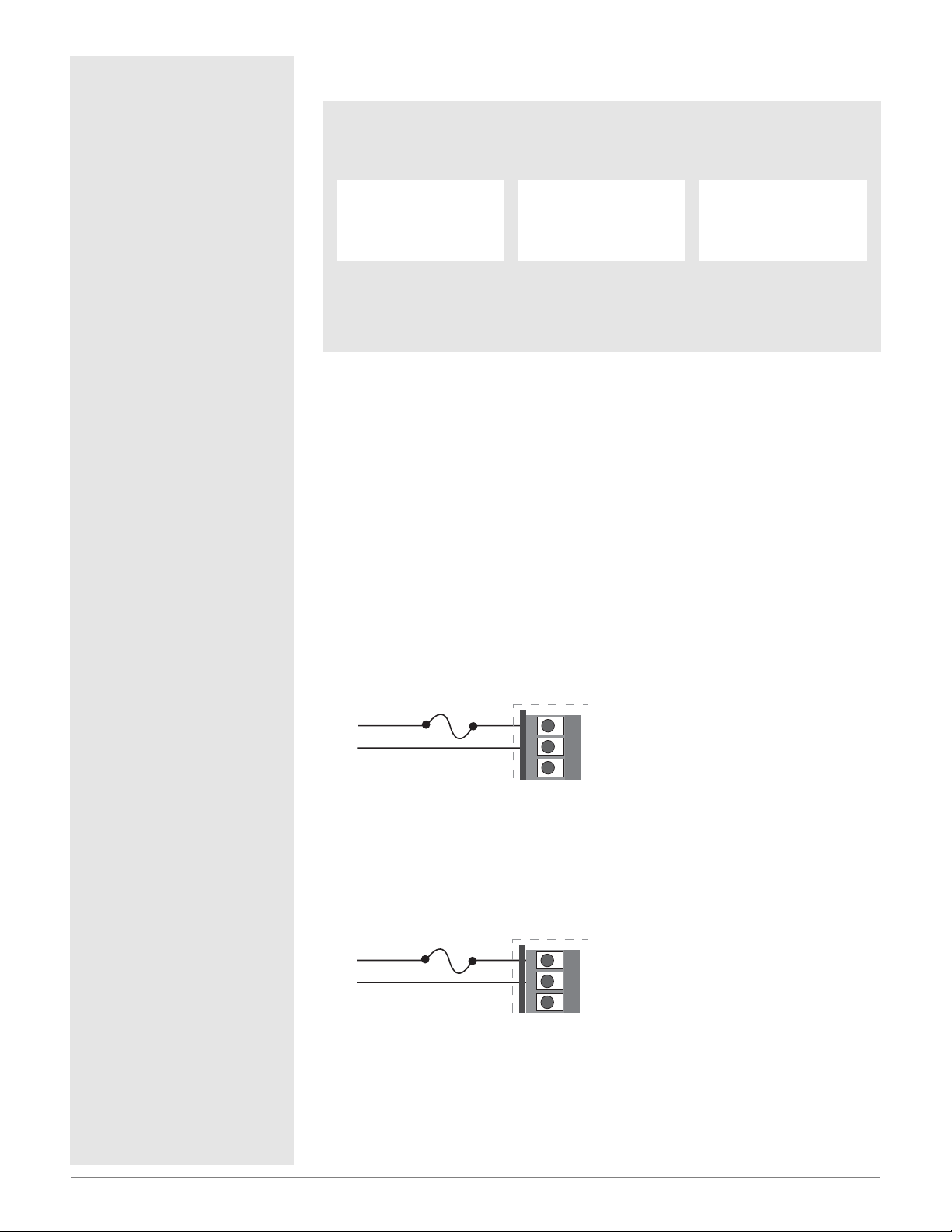

Figure 11a — High Voltage AC Power Wiring

SD_ L - H J _ _ - _ _ _ _ High

• Nominal voltage: 100 to 240VÅ (ac)

Figure 11b — Low Voltage AC Power Wiring

SD_ L - L J _ _ - _ _ _ _ Low

• Nominal voltage: 24‡ (ac/dc)

• Class 2 power source required for agency compliance

Isolation Blocks

There are no electrical connections between these blocks.

Relay outputs (mechanical and solid-state) provide isolation through their

relay contacts. Each relay output is isolated from the blocks above and is

isolated from other relay outputs.

Sensor Input

Switched DC Outputs

Analog Process Outputs

Power Supply Input EIA/TIA-485 Communi-

cations Input

L1

L2

1

2

1

2

3

+

1

2

-

1

2

3

Page 14

Ó

Warning:

Use National Electric (NEC) or

other country-specific standard

wiring and safety practices when

wiring and connecting this limit

to a power source and to electrical sensors or peripheral devices. Failure to do so may result in damage to equipment and

property, and/or injury or loss of

life.

Spring clamp wiring connector

note:

To insert the wire, push the wire

into the desired connection number, and it should automatically

lock into place. To remove the

wire, press and hold the orange

release tab with a small screwdriver. Pull the wire out of the

connection. Solid or tinned wire

recommended.

Note: To prevent ground loops,

isolation needs to be maintained

from input to output when using

switched DC or analog process

outputs.

ç

WARNING: Process input may

not have sensor break protection. Outputs can remain full on.

Check your input settings.

Watlow Series SD Limit ■ 12 ■ Chapter 2 Install and Wire

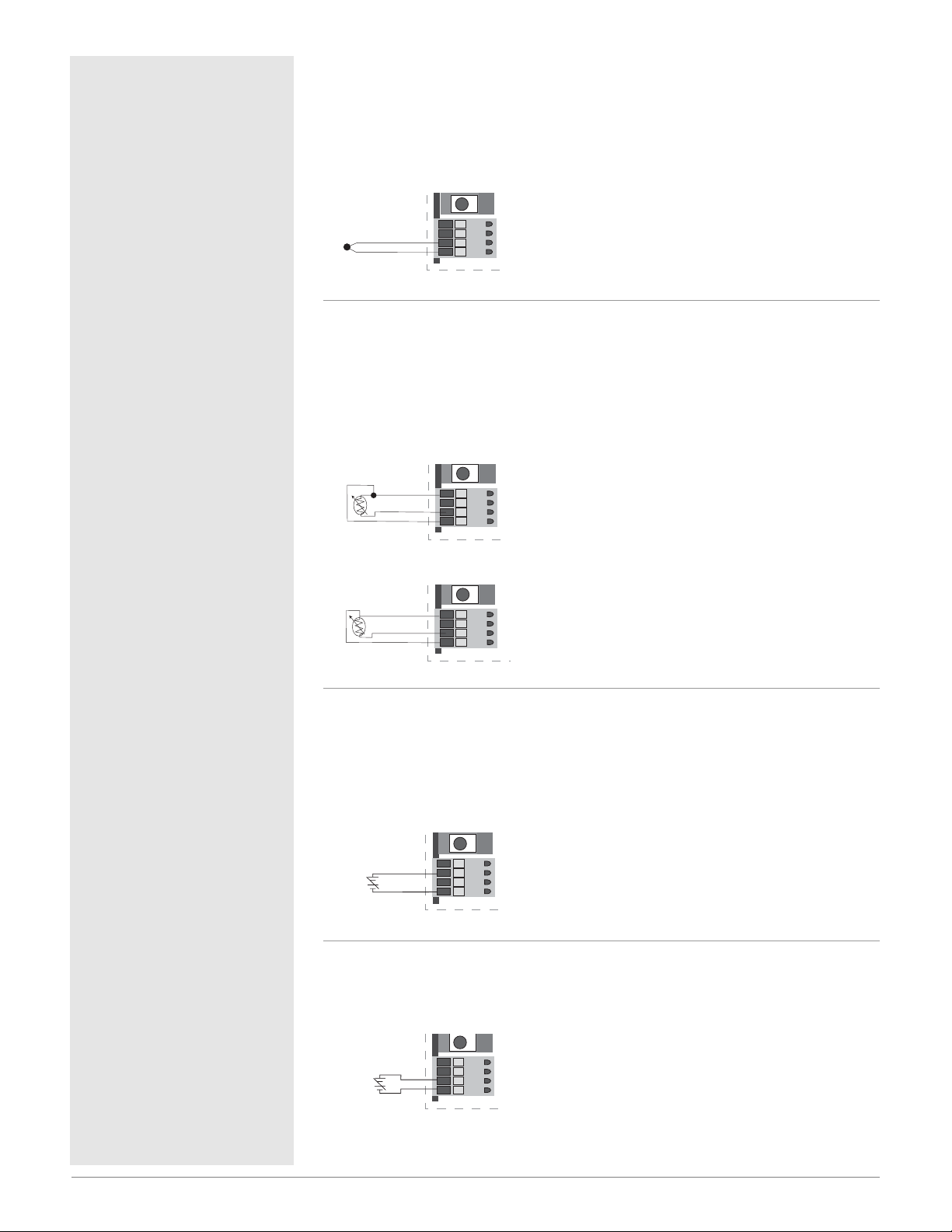

Figure 12a — Thermocouple Input

(all model numbers)

Thermocouples are polarity sensitive. The negative lead (usually red) must be

connected to terminal 11.

• Input impedance: >20 MΩ

Figure 12b — RTD Input (100 Ω DIN curve 0.00385 Ω/Ω/°C)

(all model numbers)

Terminals 8 and 11 must be shorted for a two-wire RTD. For three-wire RTDs,

the S1 lead (usually white) must be connected to terminal 10.

• Nominal excitation current: 390 µA

Figure 12c — 0 to 10V

ÎÎ

(dc) Process Input

(all model numbers)

• Input impedance 20 kΩ, dc only.

Figure 12d — 0 to 50mV

ÎÎ

(dc) Process Input

(all model numbers)

• Input impedance >20 MΩ, dc only.

3-wire RTD

2-wire RTD

6

8

9

+10

-11

10 11

6

S2 8

S1 10

11

S2 8

S1 10

S3 11

8

9

10 11

6

8

9

10 11

+

-

9

11

+

10

-

11

6

8

9

10 11

6

8

9

10 11

Page 15

Watlow Series SD Limit ■ 13 ■ Chapter 2 Install and Wire

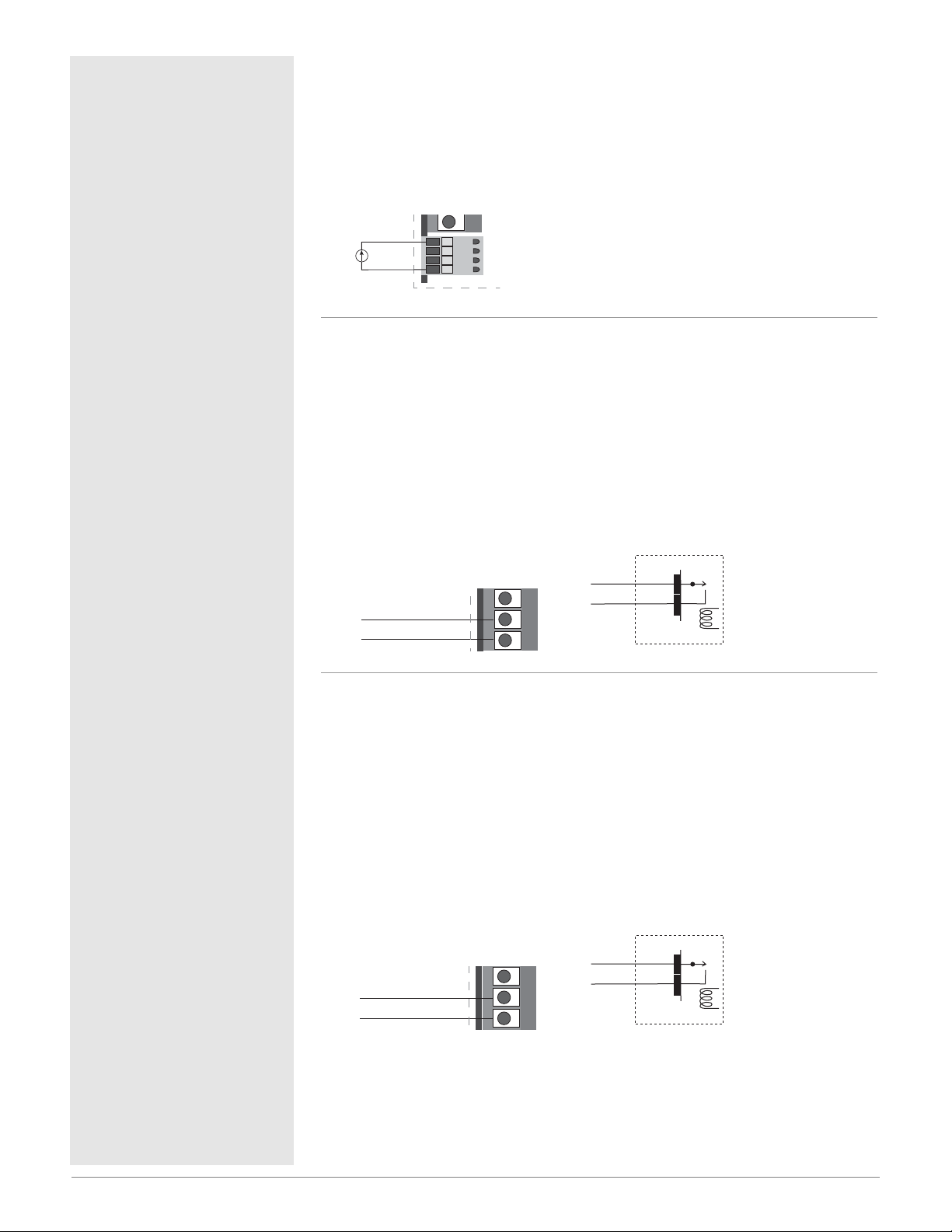

Figure 13a — 4 to 20 mA Process Input

(all model numbers)

• Input impedance 100 Ω, dc only.

• Limit does not supply power for the current loop.

Figure 13b — Output 1 Mechanical Relay

SD_ L - _ J _ _ - _ _ _ _

• 2 A, Form A.

• 240VÅ (ac) maximum.

• 30VÎ (dc) maximum.

• See Quencharc note.

• For use with ac or dc.

• Minimum load current 10 mA

• Output does not supply power.

Figure 13c — Output 2 Mechanical Relay

SD_ L - _ _ J _ - _ _ _ _

• 2 A; Form A.

• 240VÅ (ac) maximum.

• 30VÎ (dc) maximum.

• See Quencharc note.

• For use with ac or dc.

• Minimum load current: 10 mA

• Output does not supply power.

ç

WARNING: Process input may

not have sensor break protection. Outputs can remain full on.

Check your input settings.

Ó

Warning:

Use National Electric (NEC) or

other country-specific standard

wiring and safety practices when

wiring and connecting this limit

to a power source and to electrical sensors or peripheral devices. Failure to do so may result in damage to equipment and

property, and/or injury or loss of

life.

Quencharc Note:

Switching inductive loads (relay

coils, solenoids, etc.) with the

mechanical relay, switched dc or

solid-state relay output options

requires use of an R.C. suppressor.

Watlow carries the R.C. suppressor Quencharc brand name,

which is a trademark of ITW

Paktron. Watlow Part No. 08040147-0000.

Spring clamp wiring connector

note:

To insert the wire, push the wire

into the desired connection number, and it should automatically

lock into place. To remove the

wire, press and hold the orange

release tab with a small screwdriver. Pull the wire out of the

connection. Solid or tinned wire

recommended

Note: To prevent ground loops,

isolation needs to be maintained

from input to output when using

switched DC or analog process

outputs.

6

+

8

11

-

8

9

10 11

4

common 5

normally open 6

56

COM.

N.O.

Mechanical Relay

5

6

Internal Circuitry

Mechanical Relay

3

COM.

N.O.

4

Internal Circuitry

3

common

normally open

4

2

3

4

Page 16

Watlow Series SD Limit ■ 14 ■ Chapter 2 Install and Wire

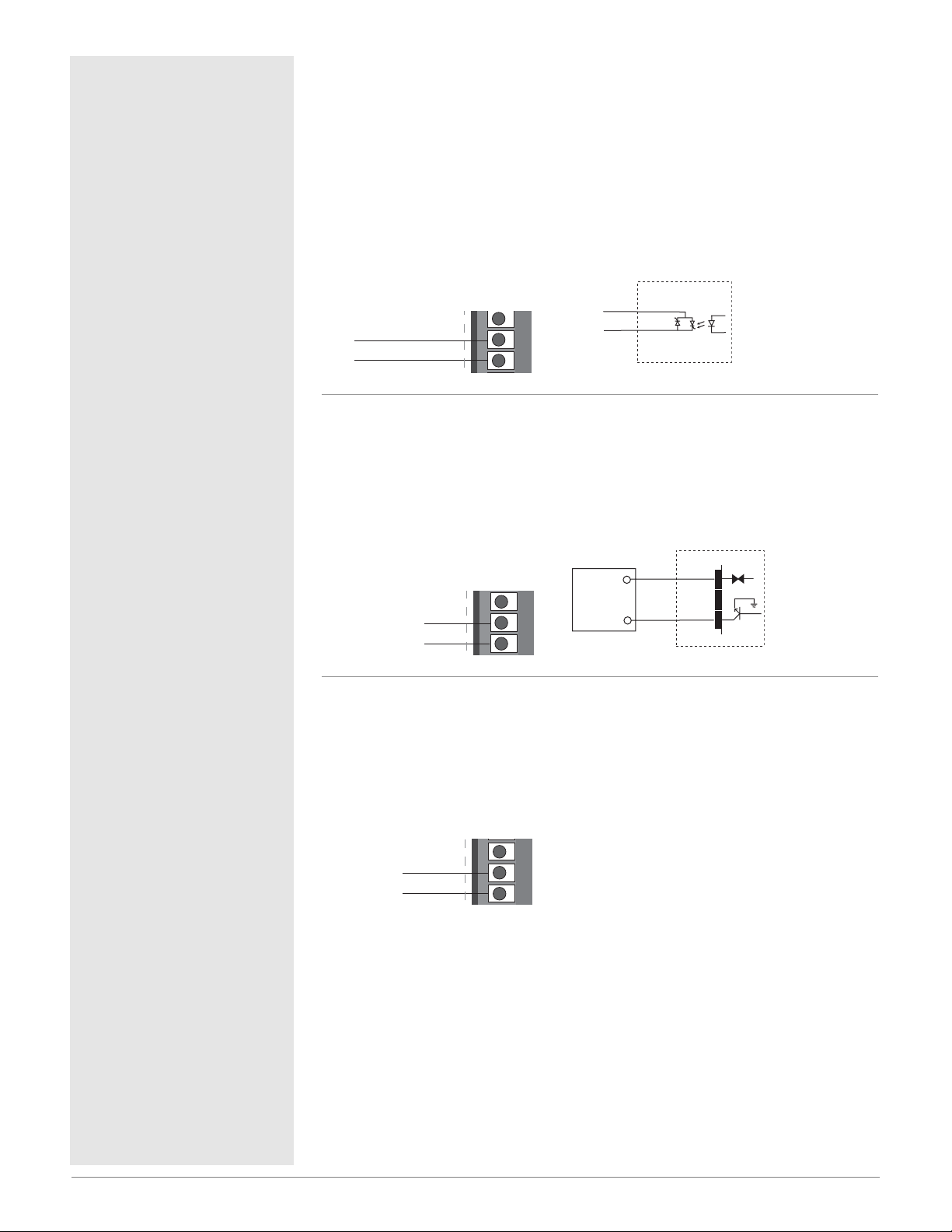

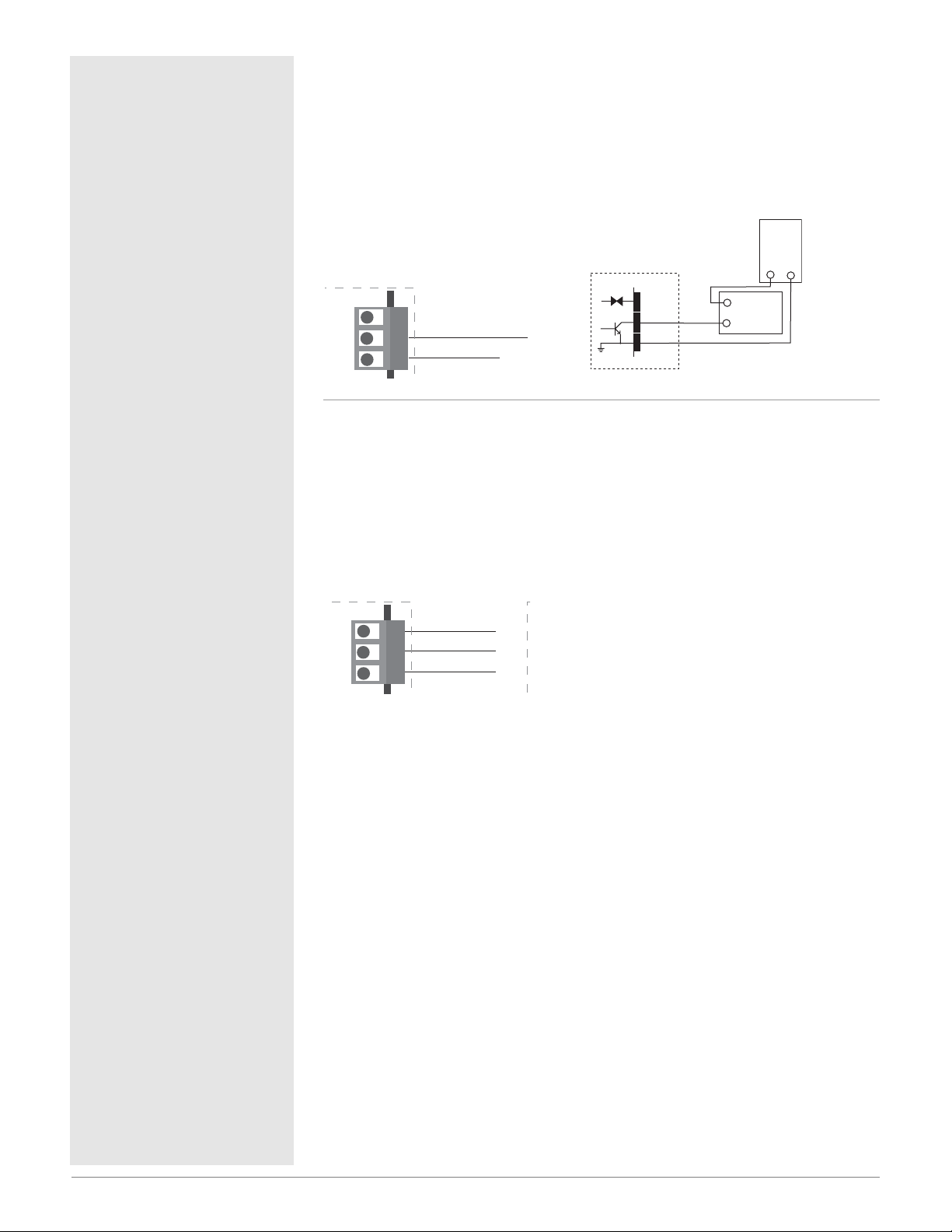

Figure 14a — Output 2 Solid-state Relay

SD_ L - _ _ K _ - _ _ _ _

• 0.5 A maximum, Form A.

• 24 to 240VÅ (ac).

• See Quencharc note.

• Minimum load current 10mA

• Maximum leakage current 100µA

• Not for use with direct current (dc).

• Output does not supply power...

Figure 14b — Output 2 Switched DC

SD_ L - _ _ C _ - _ _ _ _

• Maximum supply current 30 mAÎ (dc).

• Supply voltage 6 to 12VÎ (dc).

• Not recommended for switching mechanical relays.

• Output supplies power.

Figure 14c — Output 2 EIA/TIA-485

SD_ L - _ _ U _ - _ _ _ _

• Isolated [50VÎ (dc)]

• Half duplex

• For more communications information, see the Features chapter.

Ó

Warning:

Use National Electric (NEC) or

other country-specific standard

wiring and safety practices when

wiring and connecting this limit

to a power source and to electrical sensors or peripheral devices. Failure to do so may result in damage to equipment and

property, and/or injury or loss of

life.

Quencharc Note:

Switching inductive loads (relay

coils, solenoids, etc.) with the

mechanical relay, switched dc or

solid-state relay output options

requires use of an R.C. suppressor.

Watlow carries the R.C. suppressor Quencharc brand name,

which is a trademark of ITW

Paktron. Watlow Part No. 08040147-0000.

Note: To prevent ground loops,

isolation needs to be maintained

from input to output when using

switched DC or analog process

outputs.

2

3

common

normally open

4

3

4

Solid-state Relay

Solid-state Switch

3

COM.

4

N.O.

Internal Circuitry

3

4

-

dc+ 3

dc- 4

+

2

Load

3

4

Switched DC

6 to 12V (dc)

dc+

dc-

Internal Circuitry

2

T+/R+ 3

T-/R- 4

3

4

Page 17

Ó

Warning:

Use National Electric (NEC) or

other country-specific standard

wiring and safety practices when

wiring and connecting this limit

to a power source and to electrical sensors or peripheral devices. Failure to do so may result in damage to equipment and

property, and/or injury or loss of

life.

Quencharc Note:

Switching inductive loads (relay

coils, solenoids, etc.) with the

mechanical relay, switched dc or

solid-state relay output options

requires use of an R.C. suppressor.

Watlow carries the R.C. suppressor Quencharc brand name,

which is a trademark of ITW

Paktron. Watlow Part No. 08040147-0000.

Note: To prevent ground loops,

isolation needs to be maintained

from input to output when using

switched DC or analog process

outputs.

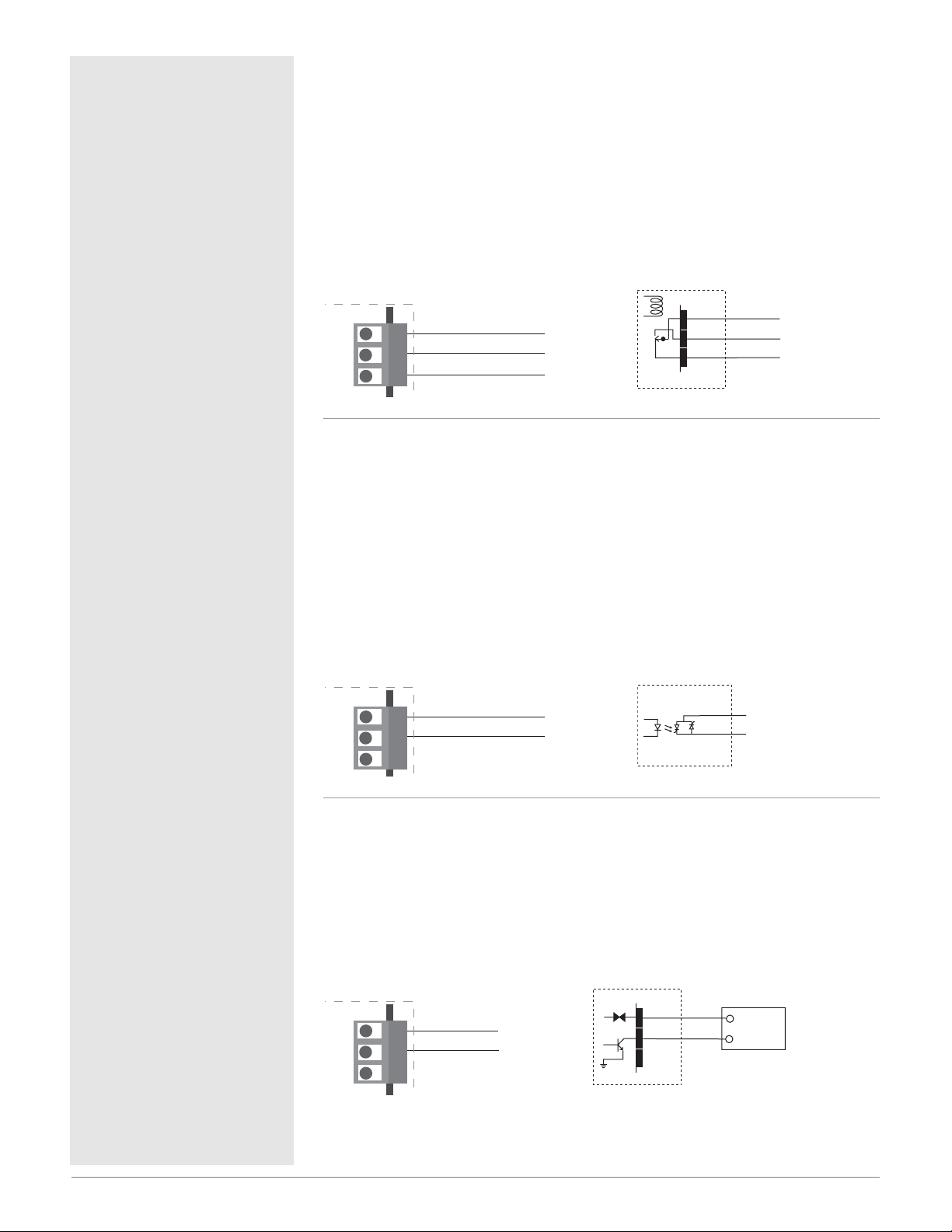

Figure 15a — Output 3 Mechanical Relay

SD_ L - _ _ _ E - _ _ _ _

• 5 A; Form C.

• 240VÅ (ac) maximum.

• 30VÎ (dc) maximum.

• See Quencharc note.

• For use with ac or dc.

• Minimum load current: 10 mA

• Output does not supply power.

Figure 15b — Output 3 Solid-state Relay

SD_ L - _ _ _ K - _ _ _ _

• 0.5 A maximum, Form A.

• 24 to 240VÅ (ac).

• See Quencharc note.

• Minimum load current 10 mA

• Maximum leakage current 100 µA

• Not for use with direct current (dc).

• Output does not supply power.

Figure 15c — Output 3 Switched DC

SD_ L - _ _ _ C - _ _ _ _

• Maximum supply current 30 mAÎ (dc).

• Supply voltage 6 to 12VÎ (dc).

• Not for switching mechanical relays.

• Output supplies power.

Watlow Series SD Limit ■ 15 ■ Chapter 2 Install and Wire

Mechanical Relay

12

12 common

13

13 normally open

14

14 normally closed

Internal Circuitry

COM.

N.O.

N.C.

12

13

14

12

12 common

13

13 normally open

14

Switched DC

6 to 12V (dc)

12

12 dc +

13

13 dc -

14

14 common

Internal Circuitry

Solid-state Relay

Solid-state Switch

COM.

N.O.

Internal Circuitry

dc+

12

dc-

13

12

13

+

-

Load

Page 18

Ó

Warning:

Use National Electric (NEC) or

other country-specific standard

wiring and safety practices when

wiring and connecting this limit

to a power source and to electrical sensors or peripheral devices. Failure to do so may result in damage to equipment and

property, and/or injury or loss of

life.

Quencharc Note:

Switching inductive loads (relay

coils, solenoids, etc.) with the

mechanical relay, switched dc or

solid-state relay output options

requires use of an R.C. suppressor.

Watlow carries the R.C. suppressor Quencharc brand name,

which is a trademark of ITW

Paktron. Watlow Part No. 08040147-0000.

Note: To prevent ground loops,

isolation needs to be maintained

from input to output when using

switched DC or analog process

outputs.

Figure 16a — Output 3 Open Collector

SD_ L - _ _ _ C - _ _ _ _

• Maximum current sink 250 mAÎ (dc).

• Maximum supply voltage 42VÎ (dc).

• For inductive loads, see Quencharc note.

• Output does not supply power.

Figure 16b — Output 3 Process

SD_ L - _ _ _ F - _ _ _ _

• Analog output scalable from 0 to 10VÎ (dc) or 0 to 20 mAÎ (dc).

• Load capability: voltage, 1 kΩ minimum; current, 800 Ω maximum.

• Output supplies power.

• Cannot use voltage and current output at the same time.

Watlow Series SD Limit ■ 16 ■ Chapter 2 Install and Wire

Class 2 power source

12

12 dc+

13

13 open collector

14

14 common

Open Collector

42V (dc) maximum

dc+

dc-

COM.

Internal Circuitry

required for agency

compliance.

12

13

14

Power

Supply

+

-

+

Load

-

12

12 amps +

13

13 volts +

14

14 com -

Page 19

Watlow Series SD Limit ■ 17 ■ Chapter 2 Install and Wire

When choosing an EIA/TIA 232 to 485 converter, look for

one with the following features:

Two-wire capability

EIA/TIA-485 can be implemented as a two-wire system or a four-wire system. Most Watlow controllers,

including the Series SD limit, use two-wire communications when working with EIA/TIA-485. The converter selected must have a two-wire mode. Some

converters can only be used in a four-wire mode.

Automatic Send Data control

In a two-wire system, both the transmitted signals

and the received signals travel over the same pair of

wires, so the converter must have a method of

changing from the transmit mode to the receive

mode. Some converters require the toggling of a control line (usually the RTS line) to perform this transition, while others use an automatic timing circuit.

The toggling method is dependent on the PC software to toggle the control line and the PC’s operating

system to make that transition happen in a timely

manner. Because of these dependencies, the best

choice for a converter is one with automatic control.

Isolation

Converters are available with or without input-tooutput isolation. An isolated converter is not a requirement when used with the Series SD, but it is

recommended to avoid ground loops. Also, isolation

could be a consideration when the Series SD will be

used on a network with other devices that may require isolation.

Power Supply

Many converters can be powered up either through

the signals of a serial port or through an external

power supply. Because some computers, such as laptops, do not always provide enough power to supply

the converter, we recommend using an external power supply with specifications as recommended by the

converter manufacturer. Isolated converters may require two supplies.

Biasing and termination

If the system does not work properly, it may need

termination resistors at each end of the network. A

typical installation would require a 120-ohm resistor

across the transmit/receive terminals (3 and 4) of the

last controller in the network and the converter box.

Pull-up and pull-down resistors may be needed at

the converter to maintain the correct voltage during

the idle state. The pull-up resistor is connected between the positive of the DC supply and the T+/R+

terminal. The pull-down resistor is connected between the negative of the DC supply and the T-/Rterminal.

Selecting an EIA/TIA-232 to EIA/TIA-485 Converter

Figure 17a — B&B Converter.

Isolated converter - 485OI9TB

Non-isolated converter - 485SD9TB

B&B Electronics Manufacturing Company,

(815) 433-5100, http://www.bb-elec.com/

Figure 17b — CMC Converter.

Non-isolated converter - ADA485L

CMC Connecticut Micro-Computer, Inc.,

1-800-426-2872, http://www.2cmc.com/

NOTE:

The CMC converter requires an external power supply when

used with a laptop computer.

Figure 17c — Wiring bias and termination resistors.

Controllers must be wired in a daisy chain configuration.

Add a 120Ω termination resistor on the last controller.

485SD9TB

Watlow p/n 0830-0473-0001

6 ft. comms cable Watlow p/n 0830-0473-0003

EIA-232

ADA485L

EIA-485

G

9VÎ

G

B

A

B

A

TD (A)

GND

TD (B)

GND

12VÎ (dc)

Power

–

Supply

+

Watlow p/n 0830-0473-0002

120VÅ (ac)

9VÎ (dc) (see note)

COM.

T+/R+

DI/ODI/O

T-/R-

7-ft. comms cable Watlow p/n 0219-0217-0000

T-/RT+/R+

120VÅ (ac)

3

4

4

3

Page 20

Watlow Series SD Limit ■ 18 ■ Chapter 2 Install and Wire

Notes

Page 21

Watlow Series SD Limit ■ 19 ■ Chapter 3 Keys and Displays

Keys and Displays

3

1/4 DIN

1/8 DIN Horizontal1/16 DIN1/32 DIN

1/8 DIN Vertical

Advance Key

Advances the lower display through parameter

prompts.

RESET Key

• Returns to the Home

Page.

• Resets a latching

alarm

• Resets a latching input sensor error.

• Resets the limit.

• Silence an alarm

Up and Down

Keys

In the Home Page, adjusts the limit set point.

In other pages, changes

the upper display to a

higher or lower value.

Active Output

Indicator Lights

Lit when the corresponding limit or alarm output is tripped.

Upper Display (Left Display on 1/32 DIN): Indicates the

process in the Home Page, or the value of the parameter in

the lower display in other pages.

Lower Display (Right Display on 1/32 DIN): Indicates the

set point or output power value during operation, or the parameter whose value appears in the upper display.

1/32 DIN

Note: After 60 seconds with no key presses, the controller reverts to the Home Page.

RESET

LIMIT SD

23231

LIMIT SD

LIMIT SD

LIMIT SD

1 2

SD

SD

231

123

1

LIMIT SD

LIMIT SD

SDSDSD

LIMIT SD

1

1

2

3

RESET

RESET

123

123 %

23

1

RESET

LIMIT SD

23231

231

LIMIT SD

RESET

LIMIT SD

LIMIT SD

LIMIT SD

1 2

SD

SD

RESET

RESET

RESET

123

Page 22

Watlow Series SD Limit ■ 20 ■ Chapter 3 Keys and Displays

Operations Page Overview

The Operations Page contains parameters accessed

during normal day-to-day operation. The Series SD

provides a patented user-definable menu system, allowing the user to customize the Operations Page contents. To go to the Operations Page, press the Advance

Key ‰ once from the Home Page.

• Press the Advance Key ‰ to move through the parameter prompts. At the end of the operations parameters, press the Advance Key ‰ to return to

the Home Page.

• Press the Up > or Down < keys to change the parameter value.

• Press the RESET Key at any time to return to the

Home Page.

Operations Page (defaults)

Note: Hardware configuration and programming selections determine what parameters appear on the Operations Page.

[L1;Lo] Limit 1 Low Set Point

[L1;HI] Limit 1 High Set Point

[L2;Lo] Limit 2 Low Set Point

[L2;Hi] Limit 2 High Set Point

[A2;Lo] Alarm 2 Low Set Point

[A2;Hi] Alarm 2 High Set Point

[L3;Lo] Limit 3 Low Set Point

[L3;Hi] Limit 3 High Set Point

[A3;Lo] Alarm 3 Low Set Point

[A3;Hi] Alarm 3 High Set Point

‰

Home Page Overview

The Home Page is the default display of the Series SD

limit controller. When the limit is powered up or you

exit any other page, the Home Page appears. The parameters that appear in the Home Page are determined by the Display Look settings in the Setup Page

(see Chapter 5). The process value is the default for the

upper display and the High Limit Set Point is the default for the lower display. Press the RESET key to exit

any other page and return to the Home Page display.

The Home Page also displays operational status information such as error messages, limit status and alarm

status.

Normal Operation (Default Displays)

Operating in Safe Condition.

Limit Tripped Operation

Operating in Limit Condition

Error condition

Alarm Message

Adjusting the limit set point value

Adjust the limit set point in the Operations Page. Limit

set points only appear if they are active and they have

been selected to appear due to settings in the Programmable Page.

To adjust the limit set point:

1. Be sure the display is at the Home Page. If you are

in any other page, press the RESET Key.

2. Press the Advance Key ‰ to step into the Operations Page.

3. Continue pressing the Advance Key ‰ until the desired limit set point parameter appears in the lower

display. The limit value appears in the upper display.

4. Press the UP Key ¿ to increase the value or the

DOWN Key ¯ to decrease the value.

5. Press the Advance Key ‰ to step to other limit set

point parameters and repeat steps 3 and 4. Press

the RESET Key to return to the Home Page

Note: The [`lOC] parameter can lock the ability to adjust/view the

settings in the Operation Page. If you are have trouble adjusting

the limit set points, check the [`lOC] setting in the Setup Page.

[``75] [``75] Process value

[``75] [A1;Lo} Alarm message alternates in lower display.

The corresponding output indicator light is on.

[----] [----] [----] Dashed lines

[Er;In] [L!hi] [A2;hi] Error message Error message

alternates with limit and/or alarm messages in lower display

[``75] [``75] Process Value

[``75] [L!hi]

Limit message alternates with high limit set point in lower display.

Output 1 indicator light is on.

[``75] Process Value

[``75] Limit high set point (Use Up > or Down < keys to

raise or lower the high limit set point.)

Page 23

Watlow Series SD Limit ■ 21 ■ Chapter 3 Keys and Displays

Setup Page

[`Sen] Sensor Type

[`Lin] Linearization

[`C-F] Temperature Units

[S;deC] Temperature Decimal Places

[P;dEC] Process Decimal Places

[IS;En] InfoSense Enable

[IS;P1] InfoSense Point 1

[IS;P2] InfoSense Point 2

[IS;P3] InfoSense Point 3

[IS;P4] InfoSense Point 4

[Sc;Lo] Process Scale Low

[Sc;hi] Process Scale High

[P1;LE] Process Input Low Error

[P1;HE] Process Input High Error

[rg;Lo] Units Scale Low

[rg;hi] Units Scale High

[SP;Lo] Set Point Low Limit

[SP;hi] Set Point High Limit

[`CAL] Calibration Offset

[Ftr;E] Enable Input Filter

[FLtr] Filter Value

[Ot~1] Output 1 Function

[LSd1] Limit 1 Sides

[hyS1] Limit 1 Hysteresis

[Ot`2] Output 2 Function

[LSd2] Limit 2 Sides

[hyS2] Alarm or Limit 2 Hysteresis

[Lgc2] Alarm 2 Logic

[LAt2] Alarm 2 Latching

[SiL2] Alarm 2 Silencing

[dSP2] Alarm 2 Message

[Ot`3] Output 3 Function

[LSd3] Limit 3 Sides

[hyS3] Alarm or Limit 3 Hysteresis

[Lgc3] Alarm 3 Logic

[LAt3] Alarm 3 Latching

[SiL3] Alarm 3 Silencing

[dSP3] Alarm 3 Message

[AO3;U] Analog Output 3 Units

[O3;Lo] Analog Output 3 Scale Low

[O3;hi] Analog Output 3 Scale High

[r3;So] Output 3 Retransmit Source

[r3;Lo] Output 3 Retransmit Low Scale

[r3;Hi] Output 3 Retransmit High Scale

[r3;CO] Output 3 Retransmit Offset

[I;Err] Input Error Latching

[UdSP] Upper Display Look

[LdSP] Lower Display Look

[Addr] Modbus Device Address

[bAud] Baud Rate

[`LOC] Lockout *

‰

Setup Page Overview

The Setup Page contains parameters that define

the basic limit functions. Go to the Setup Page for

initial configuration or if your application requirements change. Be sure to program the Setup

Page first!

To go to the Setup Page, press both the Up ¿ and

Down ¯ keys for three seconds from the Home

Page.

• Press the Advance Key ‰ to move through

the parameter prompts.

• Press the Up ¿ or Down ¯ keys to change

the parameter value.

• Press the RESET Key at any time to return

to the Home Page.

[`SEt]

[PAgE]

Note: Hardware configuration and programming selections determine what parameters appear in the Setup Page.

*Note: For FM Approval, the

[[``LLOOCC]]

parameter must be set to 3 or

the limit must be remotely mounted to restrict casual user adjustment.

Page 24

Watlow Series SD Limit ■ 22 ■ Chapter 3 Keys and Displays

Factory Page

[AMb] Ambient Temperature

[A;mn] Minimum Recorded Ambient Temperature

[A;ma] Maximum Recorded Ambient Temperature

[DSPL] Display Intensity

[rESt] Restore Factory Calibration

[Usr;r] Restore User Settings

[USr;S] Save User Settings

[dFLt] Default Parameters

[O;ty1] Output 1 Type

[O;ty2] Output 2 Type

[O;ty3] Output 3 Type

[`S;Id] Software ID

[S;UEr] Software Version

[S;bld] Software Build Number

[PWr] Power Type

[`Sn-] Serial Number 1

[`Sn_] Serial Number 2

[tc;50] Thermocouple, 50mV

[tc;00] Thermocouple, 0mV

[tc;32] Thermocouple, 32°F

[`r;15] RTD, 15 ohm

[r;380] RTD, 380 ohm

[``U;1] Input Calibrate, 1.0 Volt

[``U;9] Input Calibrate, 9.0 Volt

[``A;4] Input Calibrate, 4.0 mA

[`A;16] Input Calibrate, 16.0 mA

[03;1u] Output 3 Calibrate, 1.0 Volt

[03;9u] Output 3 Calibrate, 9.0 Volt

[03;4A] Output 3 Calibrate, 4.0 mA

[03;16] Output 3 Calibrate, 16.0 mA

‰

Factory Page Overview

The Factory Page contains information on diagnostics,

calibration and restore-parameter functions.

To go to the Factory Page, press both the Up ¿ and

Down ¯ keys for six seconds from the Home Page.

• Press the Advance Key ‰ to move through the pa-

rameter prompts.

• Press the Up ¿ or Down ¯ keys to change the pa-

rameter value of Read/Write (R/W) parameters.

• Press the RESET Key at any time to return to the

Home Page.

Note: Hardware configuration and programming selections determine what parameters appear in the Factory Page.

[FAct]

[page]

Programming Page Overview

The Programming Page determines what parameters

the user wants to appear in the Operations Page. Select a parameter for any of the 16 Programming Page

locations, P1 to P16. These now appear in the Operations Page. All 16 locations have parameters selected

as defaults.

To go to the Programming Page, hold down the RESET

key, then press the Advance Key ‰, and hold both

down for about six seconds.

• Press the Advance Key ‰ to move through the parameter prompts.

• Press the Up ¿ or Down ¯ keys to change the parameter value.

• Press the RESET Key at any time to return to the

Home Page.

Note: The hardware configuration and programming selections will

also determine what parameters appear in the Operations Page. A

Programming Page selection will not appear in the Operations

Page if the parameter is not active.

[Prog]

[PAgE]

Programming Page

[~~P1] Parameter Location 1 (48)

[~~P2] Parameter Location 2 (49)

[~~P3] Parameter Location 3 (50)

[~~P4] Parameter Location 4 (51)

[~~P5] Parameter Location 5 (52)

[~~P6] Parameter Location 6 (53)

[~~P7] Parameter Location 7 (54)

[~~P8] Parameter Location 8 (55)

[~~P9] Parameter Location 9 (56)

[~P10] Parameter Location 10 (57)

[~P11] Parameter Location 11 (58)

[~P12] Parameter Location 12 (59)

[~P13] Parameter Location 13 (60)

[~P14] Parameter Location 14 (61)

[~P15] Parameter Location 15 (62)

[~P16] Parameter Location 16 (63)

‰

[nonE]

[``P1]

.

. (48)*.

.

[`P16]

(63)*

*Programming Page parameters Modbus register numbers

P1 through P16 are 48 through 63

Calibration information for the Series SD controllers is available

in pdf format. Go to www.watlow.com > Literature > Product

User Manuals and search on Series SD Calibration Manual.

Page 25

Watlow Series SD Limit ■ 23 ■ Chapter 4 Home

Note: Some values will be rounded off to fit in the four-character display. Full values can be read with Modbus. All temperature parameters are in °F through Modbus.

* Low register numbers contain the two higher bytes; high register numbers contain the two lower bytes of the four-byte integer. Decimal

precision is implied at three decimal places unless otherwise noted.

Display Parameter Name

Description

Settings Range

(Integer values for Modbus

in parenthesis.)

Default Modbus*

(less 40,001

offset)

Read/Write

Appears if:

4

Home Page

Press the RESET Key at any time to go to the Home Page.

Depending upon the controller’s status, you will see some combination of the parameters listed below. Normally,

you will see the Process Value in the upper display and the Limit 1 High Set Point in the lower display. You cannot

adjust Home Page parameters from the front panel keys. See Home Page Overview in Chapter Three.

After 60 seconds with no key presses, the controller reverts to the Home Page.

Measured

Value

Process Value

Displays the current process value in the

upper (left in 1/32 DIN) display.

-1999 to 9999

degrees °F or units

(-1999000 to 9999000)

NA

*20, 21 R

There is no input error

and [Ftr;E] is set to

[`Off] or [Cont].

Measured

Value

Filtered Process Value

Displays the current filtered process value in the upper (left in 1/32 DIN) display.

-1999 to 9999

degrees °F or units

(-1999000 to 9999000)

NA

*22, 23 R

There is no input error

and [Ftr;E] is set to

[Disp] or [both].

Set Value Limit 1 High Set Point

Displays the high limit set point value

for Output 1 in the lower (right in the

1/32 DIN) display.

[SP;Lo] to [SP;hi]

75

*104, 105

R/W

[LSd1] is set to [both]

or [high].

[Er;In]

Input Error

Indicate an input error state.

None (0)

[----]

Error (1)

NA

24 R

There is an analog input error.

[L1;Lo]

Limit Low 1 Status

Indicate a low limit at output 1.

None (0)

Limit (1)

NA

29 R

Output 1 is in the low

limit condition.

[L1;hi]

Limit High 1 Status

Indicate a high limit at output 1.

None (0)

Limit (1)

NA

30 R

Output 1 is in the high

limit condition.

[L2;Lo]

Limit Low 2 Status

Indicate a low limit at output 2.

None (0)

Limit (1)

NA

31 R

Output 2 is in the low

limit condition.

[L2;hi]

Limit High 2 Status

Indicate a high limit at output 2.

None (0)

Limit (1)

NA

32 R

Output 2 is in the high

limit condition.

[A2;Lo]

Alarm Low 2 Status

Indicate a low alarm at output 2.

None (0)

Alarm (1)

NA

31 R

Output 2 is in the low

alarm condition.

[A2;hi]

Alarm High 2 Status

Indicate a high alarm at output 2.

None (0)

Alarm (1)

NA

32 R

Output 2 is in the high

alarm condition.

[L3;Lo]

Limit Low 3 Status

Indicate a low limit at output 3.

None (0)

Limit (1)

NA

33 R

Output 3 is in the low

limit condition.

[L3;hi]

Limit High 3 Status

Indicate a high limit at output 3.

None (0)

Limit (1)

NA

34 R

Output 3 is in the high

limit condition.

[A3;Lo]

Alarm Low 3 Status

Indicate a low alarm at output 3.

None (0)

Alarm (1)

NA

33 R

Output 3 is in the low

alarm condition.

[A3;hi]

Alarm High 3 Status

Indicate a high alarm at output 3.

None (0)

Alarm (1)

NA

34 R

Output 3 is in the high

alarm condition.

Page 26

Watlow Series SD Limit ■ 24 ■ Chapter 5 Setup

Note: Some values will be rounded off to fit in the four-character display. Full values can be read with Modbus. All temperature parameters are in °F through Modbus.

* Low register numbers contain the two higher bytes; high register numbers contain the two lower bytes of the four-byte integer. Decimal

precision is implied at three decimal places unless otherwise noted.

Display Parameter Name

Description

Settings Range

(Integer values for Modbus

in parentheses.)

Default Modbus*

(less 40,001

offset)

Read/Write

Appears if:

5

Setup Page

[`Sen]

[ SEn]

Sensor Type

Set the analog sensor type.

[``tc]

(0)

[`rtd]

(1)

[`MA]

(2)

[uolt]

(3)

[~mu]

(5)

[``tc]

(0)

70 R/W

Always active.

[`Lin]

[ Lin]

Thermocouple Linearization

Set the analog input thermocouple

linearization.

[```J]

J (0)

[```D]

D (6)

[```H]

K (1)

[Pt11]

PTII (7)

[```t]

T (2)

[```R]

R (8)

[```E]

E (3)

[```S]

S (9)

[```n]

N (4)

[```B]

B (10)

[```C]

C (5)

[```J]

(0)

71 R/W

[`Sen]

is set to [``tc].

[`C-F]

[ C-F]

Temperature Units

Set the temperature units for thermocouple and RTD inputs.

[```F]

Fahrenheit (0)

[```C]

Celsius (1)

[```F]

(0)

40 R/W

[`Sen]

is set to [``tc]

or [`rtd].

[S;deC]

[S.dEC]

Temperature Decimal Places

Set the decimal places for the displayed

input value for thermocouple and RTD

types.

[```0]

(0)

[``0;0]

(1)

[```0]

(0)

41 R/W

[`Sen]

is set to [``tc]

or [`rtd].

[P;dEC]

[P.dEC]

Process Decimal Places

Set the decimal places for the displayed

input value for process types.

[```0]

(0)

[``0;0]

(1)

[`0;00]

(2)

[0;000]

(3)

[```0]

(0)

42 R/W

[``Sen]

is set to

[`mA], [uoLt]

.or

[`mu].

[IS;En]

[IS.En]

INFOSENSE

TM

Enable the sensor feature, which synchronizes the controller with a Watlow sensor.

[``no]

(0)

[`Yes]

(1)

[``No]

(0)

91 R/W

Always active.

[IS;P1]

[IS.P1]

INFOSENSETM1

Set sensor point 1 code.

0 to 999 500

92 R/W

[IS;En]

is set to

[`yes]

.

[IS;P2]

[IS.P2]

INFOSENSETM2

Set sensor point 2 code.

0 to 999 500

93 R/W

[IS;En]

is set to

[`yes]

.

[IS;P3]

[IS.P3]

INFOSENSETM3

Set sensor point 3 code.

0 to 999 500

94 R/W

[IS;En]

is set to

[`yes]

.

[IS;P4]

[IS.P4]

INFOSENSETM4

Set sensor point 4 code.

0 to 999 500

95 R/W

[IS;En]

is set to

[`yes]

.

To go to the Setup Page, press both the Up ¿ and Down ¯ keys for three seconds from the Home Page.

[`SEt]

will appear in the upper display and

[PAgE]

will appear in the lower display.

• Press the Advance Key ‰ to move through the parameter prompts.

• Press the Up ¿ or Down ¯ keys to change the parameter value.

• Press the RESET Key at any time to return to the Home Page display.

Page 27

Watlow Series SD Limit ■ 25 ■ Chapter 5 Setup

Display Parameter Name

Description

Settings Range

(Integer values for Modbus

in parentheses.)

Default Modbus*

(less 40,001

offset)

Read/Write

Appears if:

Note: Some values will be rounded off to fit in the four-character display. Full values can be read with Modbus. All temperature parameters are in °F through Modbus.

* Low register numbers contain the two higher bytes; high register numbers contain the two lower bytes of the four-byte integer. Decimal

precision is implied at three decimal places unless otherwise noted.

[Sc;Lo]

[Sc.Lo]

Process Scale Low

Set the low scale for process inputs.

1.00 to 20.00 mA: if

[`Sen]

is set to

[`mA]

(1000 to 20000)

0.50 to 10.00V: if

[`Sen]

is

set to

[uoLt]

(500 to 10000)

10.00 to 50.00 mV: if

[`Sen]

is set to

[~mu]

(10000 to 50000)

4.00 mA

1.00V

10.00 mV

*73, 74

R/W (mA)

*77, 78

R/W (V)

*331, 332

R/W (mV)

[`Sen]

is set to

[`mA]

,

[`Sen]

is set to

[uolt].

[`Sen]

is set to

[`mu].

[Sc;hi]

[Sc.hi]

Process Scale High

Set the high scale for process inputs.

1.00 to 20.00 mA: if

[`Sen]

is set to

[`mA]

(1000 to 20000)

0.50 to 10.00V: if

[`Sen]

is

set to

[uoLt]

(500 to 10000)

10.00 to 50.00 mV: if

[`Sen]

is set to

[~mu]

(10000 to 50000)

10.00 to 20.00 mA

(1000 to 2000)

5.00 to 10.00 V

(500 to 1000)

25.00 to 50.00 mV

(2500 to 5000)

(two decimal places implied

for Modbus)

20.00 mA

5.00V

50.00 mV

*75, 76

R/W (mA)

*79, 80

R/W (V)

*333, 334

R/W (mV)

[`Sen]

is set to

[`mA]

,

[`Sen]

is set to

[uolt]

.

[`Sen]

is set to

[`mu]

[rg;Lo]

[rg.Lo]

Units Scale Low

Set the low range for process input units.

-1999 to 9999

(-1999000 to 9999000)

(Set precision with

[P;dEC]

,

Process Decimal Places.)

-1999

*81, 82

R/W

[`Sen]

is set to

[`mA]

or

[uolt]

.

[rg;hi]

[rg.hi]

Units Scale High

Set the high range for process input units.

1.00 to 10.00 mA

(100 to 1000)

0.50 to 5.00 V

(050 to 500)

5.00 to 25.00 mV

(500 to 2500)

(two decimal places implied

for Modbus)

-1999 to 9999

(-1999000 to 9999000)

(Set precision with

[P;dEC]

,

Process Decimal Places.)

9999

*83, 84

R/W

[`Sen]

is set to

[`mA]

or

[uolt]

.

[SP;Lo]

[SP.Lo]

Set Point Low Limit

Set the low range for the set point.

Min. operating range (of

sensor) to

[SP;Hi]

-0.100: if

{`sen}

is set to

{``tc}

-328 to

[SP;hi]

-0.100: if

{`sen] is set to {`rtd}

-1999 to

[SP;hi]

-0.001: if

{``sen}

is set to

[`MA]

,

[uolt], or[`Mu].

(Set precision with

[P;dEC]

,

Process Decimal Places.)

Min. operating range (J

type):

{``tc}

-328:

{`rtd}

-999:

[`MA]

,

[uolt],

and

[`Mu].

*231, 232

R/W (thermocouple)

*235, 236

R/W (RTD)

*239, 240

R/W (mA, V,

or mV)

Always active.

20.00 mA

10.00 V

50.00 mV

[P1;LE]

[P1.LE]

Process Input Low Error

Set the low process value that will cause

an error to occur for the process input.

1.00 mA

0.50 V

5.00 mV

325 R/W

(mA)

327 R/W

(V)

329 R/W

(mV)

[`Sen]

is set to

[`mA]

.

[`Sen]

is set to

[uolt]

.

[`Sen]

is set to

[`mu]

.

[P1HE]

[P1.HE]

Process Input High Error

Set the high process value that will cause

an error to occur for the process input.

326 R/W

(mA)

328 R/W

(V)

330 R/W

(mV)

[`Sen]

is set to

[`mA]

.

[`Sen]

is set to

[uolt]

.

[`Sen]

is set to

[`mu]

.

Page 28

Watlow Series SD Limit ■ 26 ■ Chapter 5 Setup

Display Parameter Name

Description

Settings Range

(Integer values for Modbus

in parentheses.)

Default Modbus*

(less 40,001

offset)

Read/Write

Appears if:

Note: Some values will be rounded off to fit in the four-character display. Full values can be read with Modbus. All temperature parameters are in °F through Modbus.

* Low register numbers contain the two higher bytes; high register numbers contain the two lower bytes of the four-byte integer. Decimal

precision is implied at three decimal places unless otherwise noted.

Output 1 Function

Set Output 1 function.

[LIM]

Limit (2)

[LIM]

(2)

143 R

Always active.

Output 1 Limit Sides

Selects Output 1 limit active sides.

[both]

(0) (both high and

low sides active)

[high] (1) (high side active)

[low] (2) (low side active)

[Ftr;E] is not set to

[`OFF]

.

[both]

(0)

111 R/W

Always active.

Limit 1 Hysteresis

Set the hysteresis for the limit. This determines how far into the safe region the input needs to move before the limit can be

cleared.

0.0 to 999.0

(0000 to 999000)

1.0

*106, 107

R/W

Always active.

Output 2 Function

Set Output 2 function.

[`OFF]

Off (0)

[Pr;;AL]

Process Alarm (1)

[LIM] Limit (2)

[`OFF]

(0)

164 R/W

Output 2 is installed

and is not a communications output.

0.0 to 60.0 seconds

(0000 to 60000)

Set Point High Limit

Set the high range for the set point.

[rg;Lo]

to max. operating

range (of sensor): if

{`sen}

is set to

{``tc}

[SP;Lo]

+0.100 to 1472: if

{`sen}

is set to

{`rtd}

[SP;Lo]

+0.001 to 9999: if

{`sen}

is set to

[`MA]

,

[uolt], or {`Mu].

(Set precision with

[P;dEC]

,

Process Decimal Places)

Max. operating range (J

type):

{``tc}

1472:

{`rtd]

999:

[`MA]

,

[uolt], and

[`Mu].

*233, 234

R/W (thermocouple)

*237, 238

R/W (RTD)

*241, 242

R/W (mA

or V)

Always active.

Calibration Offset

Offset the input reading.

-999 to 999

(-999000 to 999000)

0

[sP;hi]

[SP.hi]

Filter Value

Set the input filter value.

0.0

*87, 88

R/W

*85, 86

R/W

Always appears.

Input Filter

Select filtering action.

[`OFF]

(0) (no filtering)

[DiSP]

(1) (filter only the

display value)

[Cont]

(2) (filter the

control input values)

[both]

(3) (filter the

display and control input

values)

[`OFF] (0)

89 R/W

Always active.

[Ot`1]

[Ot 1]

[Lsd1]

[LSd1]

[hyS1]

[hyS1]

[Ot`2]

[ Ot2]

[`Cal]

[ CAL]

[FLtr]

[FLtr]

[Ftr;E]

[Ftr.E]

[Lsd2]

[LSd2]

Output 2 Limit Sides

Selects Output 2 limit

[both]

(0) (both high and

low sides active)

[high] (1) (high side active)

[low] (2) (low side active)

[both]

(0)

126 R/W

[Ot`2]

is set to

[LIM]

.

0.0 to 999.0

(0000 to 999000)

Output 2 Hysteresis

Set the hysteresis for the output. This determines how far into the safe region the

input needs to move before the output

can be cleared.

1.0

*121, 122

R/W

[Ot`2]

is set to

[Pr;;AL]

or [LIM]

.

[hyS2]

[hyS2]

Output 2 Logic

Select the output condition in the alarm

state.

[AL`C]

closed on alarm (0)

[AL`O]

open on alarm (1)

[AL`C]

(0)

169 R/W

[Ot`2]

is set to

[Pr;;AL]

.

[Lgc2]

[Lgc2]

Page 29

Watlow Series SD Limit ■ 27 ■ Chapter 5 Setup

Display Parameter Name

Description

Settings Range

(Integer values for Modbus

in parentheses.)

Default Modbus*

(less 40,001

offset)

Read/Write

Appears if:

Note: Some values will be rounded off to fit in the four-character display. Full values can be read with Modbus. All temperature parameters are in °F through Modbus.

* Low register numbers contain the two higher bytes; high register numbers contain the two lower bytes of the four-byte integer. Decimal

precision is implied at three decimal places unless otherwise noted.

[Lsd3]

[LSd3]

Output 3 Limit Sides

Selects Output 3 limit

[both]

(0) (both high and

low sides active)

[high] (1) (high side active)

[low] (2) (low side active)

[both]

(0)

141 R/W

[Ot`3]

is set to

[LIM]

.

[hyS3]

[hyS3]

Output 3 Hysteresis

Set the hysteresis for the output. This determines how far into the safe region the

input needs to move before the output can

be cleared.

0.0 to 999.0

(0000 to 999000)

1.0

*136, 137

R/W

[Ot`3]

is set to

[Pr;;;AL]

or [LIM]

.

[Lgc3]

[Lgc2]

Output 3 Logic

Select the output condition in the alarm

state.

[AL`C]

closed on alarm (0)