Page 1

SERIES SD

Controllers Provide

Value and Accurate,

Cost-Effective

Temperature Control

The SERIES SD family of PID temperature controllers utilizes

today’s advanced technology to provide the value, benefits

and accuracy you’ve come to expect from Watlow. The

features and performance offered by SERIES SD controllers

make them ideally suited for a broad range of applications in

temperature and process control.

The SERIES SD single channel controllers include a

universal sensor input with up to three outputs that can be

programmed for heat or cool temperature control, or to

operate as process or deviation alarms. Programming Inverse

Scaling is also simplified with the user-friendly set-up menu,

providing additional value without additional cost.

Advanced features of SERIES SD controllers include EIA-485

Modbus™ Serial Communications, Watlow’s INFOSENSE™

sensor technology, Infrared Remote Communications

operation, Watlow’s patented User Definable Menu System

and a "Save and Restore" feature that allows the restoration

of either factory or user-defined settings.

The SERIES SD is available in FM Limit version and a fourprofile, 10-step Ramping version that includes Ramp, Soak,

Jump Loop, Link and End steps. The updated SERIES SD

family includes a new Variable Burst Fire feature that saves

wear and tear on heaters, thus prolonging heater life,

reducing downtime and saving money. Two non-linear PID

curves have also been added to improve performance in

plastics extruder applications.

Available in

1

⁄32, 1⁄16, 1⁄8 and 1⁄4 DIN panel mount sizes,

Watlow’s SERIES SD family is backed by an industry leading

three-year warranty from Watlow Winona. The SERIES SD

controllers are UL

®

and C-UL®listed, CSA, CE and NSF-2

certified and include the IP65/NEMA 4X seal.

SERIES SD

1241 Bundy Boulevard

Winona, Minnesota 55987-5580 USA

Phone: 507-454-5300

Fax: 507-452-4507

Internet: www.watlow.com

e-mail: info@watlow.com

WIN-SD-0506

Features and Benefits

TRU-TUNE+™ Adaptive Control Algorithm

• Tighter control for demanding temperature/process

applications

Watlow’s INFOSENSE™ sensor technology

• Thermal sensing technology improves sensor accuracy

by a minimum of 50 percent

Watlow’s patented User Defined Menu System

• Allows the user to assign up to 20 parameters in the

operations menu

• Improves operational efficiency

“Save and Restore” feature for user settings

• Allows the user to save individual or factory settings

• Eliminates the need to contact the OEM or factory to

restore settings

WATVIEW HMI (Human Machine Interface)

• Permits operation, configuration and data logging via a

standard Windows

®

PC

Infrared Communications

• Allows easier controller setup, operation and monitoring

Up to three outputs (two for

1

⁄32 DIN)

• Results in application versatility

Dual Displays for all models

• Provides better recognition of process changes

Ramp to set point

• Controls temperature rise

Variable Burst Fire

• Prolongs heater life

© 2006 Watlow Electric Manufacturing Company Printed in the USA on Recycled Paper, 15% Postconsumer Waste

UL®and C-UL®are registered trademarks of Underwriter’s

Laboratories, Inc.

Windows

®

is a registered trademark of the Microsoft Corporation.

Modbus™ is a trademark of Schneider Automation, Inc.

Page 2

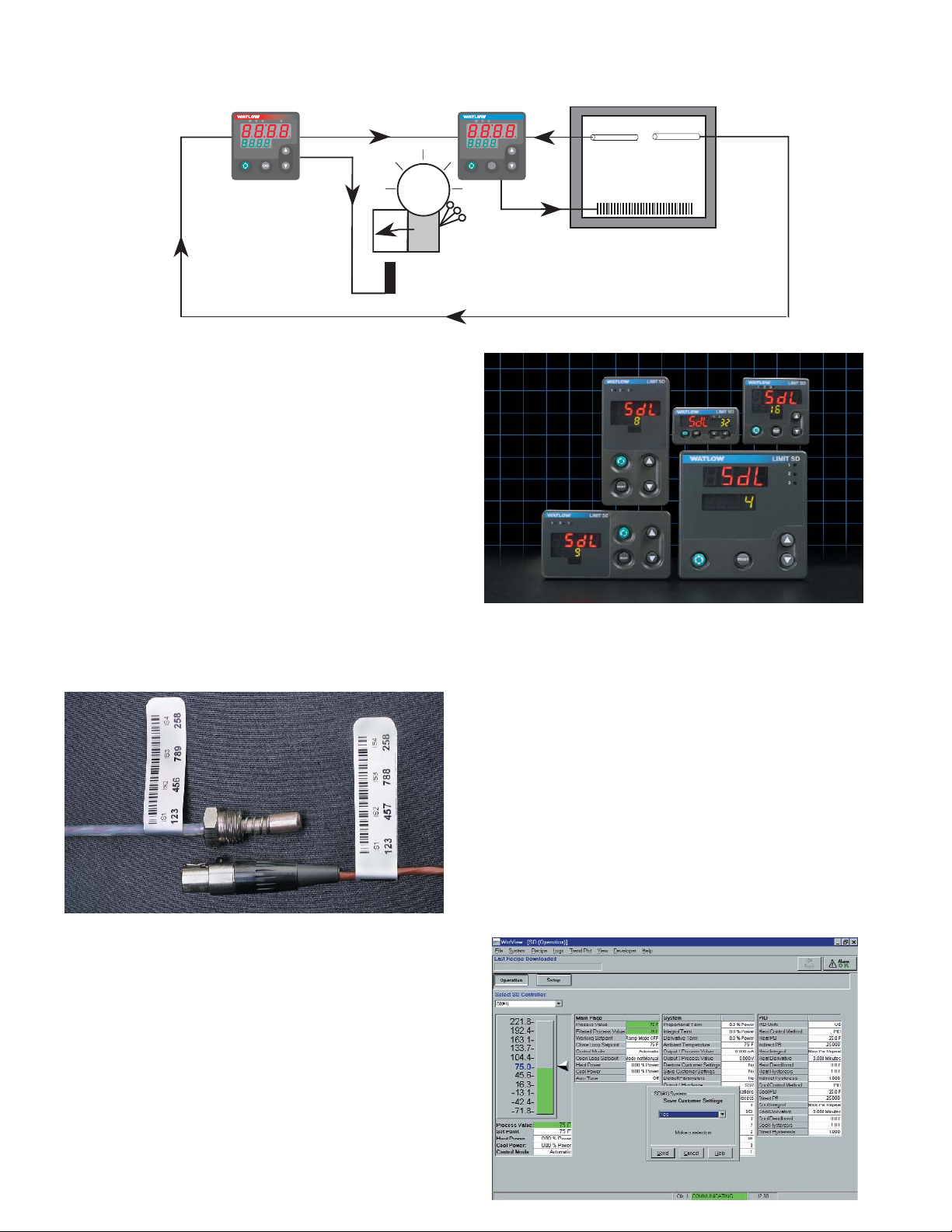

INFOSENSE™ Sensor Technology

Watlow’s INFOSENSE™ sensor technology improves

temperature sensing accuracy by 50 percent.

Each INFOSENSE "smart" sensor contains four numeric

values located on tags attached to each sensor that are

programmed into the SD controller memory. These values

characterize Watlow sensors and allow the controller to

provide enhanced accuracy.

Oven

Limit

Sensor

Temperature

Sensor

Output 1Input 1

Output 2

Heaters

Alarm

Form C Relay

SDSDSDSD

23 %SD231%1 23 %

SD

RESET

231

LIMIT SD

SERIES SD PID SERIES SD Limit

Typical Block Diagram

SERIES SD Limit Controllers

The SERIES SD family of limit controllers has been designed

with the same microprocessor-based technology as the

SERIES SD PID family of temperature controllers. The limits

come with the FM (Factory Mutual) agency approval — the

industry’s most recognized designation for insurance

concerns.

Limit controllers are typically added to thermal applications to

monitor an over-temperature condition as a safety precaution.

Limit controllers provide a redundant safety assurance to

guard against instances where a high temperature runaway

condition could result from a shorted input sensor, or from an

output device that fails in a closed position.

Limits are recommended and are often required in

applications where thermal runaway could result in costly

operator safety concerns, product scrap, damage to capital

equipment or a fire hazard.

WATVIEW HMI

WATVIEW, Watlow’s Windows®based HMI (Human Machine

Interface) software, supports the SERIES SD controllers. The

software can be used to setup, monitor and edit the values of

controller parameters, to monitor and manage alarms and to

log and graph process data.

Refer to the user manual for proper wiring instructions

Page 3

Infrared Communications

The Infrared Data Communications (IDC) option is available

on all SERIES SD controller models except the

1

⁄32 DIN and

can support complete SERIES SD parameter configuration

and operation. The IDC option supports wireless

communications with PDAs (personal digital assistants) or

other devices equipped with infrared communications that

support the Infrared Data Association (IrDA) 1.0 Standard.

The actual user interface or configuration is dependent on the

master device application software. A source for this software

is Instant HMI from Software Horizons. For more information,

visit www.instanthmi.com/watlow.

Advantages of IDC include automated logging of key process

variables, increased accuracy and ease of use for recipe or

configuration setups. Infrared data communications enhances

controller data exchange in physically restricting

environments (such as semiconductor clean rooms,

governmental radio-active test labs or those hard to reach

areas) and reduces the use of paper to record instrument

information as well as human transposition errors.

Specifications

Line Voltage/Power

• 100 to 240VÅ(ac), +10/-15 percent; (85-264V~[ac])

50/60Hz, ±5 percent

• 24Vı(ac/dc), +10/-15 percent; 50/60Hz, ±5 percent

• 10VA maximum power consumption

• Data retention upon power failure via nonvolatile memory

Environment

• -18 to 65°C (0 to 149°F) operating temperature

• -40 to 85°C (-40 to 185°F) storage temperature

• 0 to 90 percent RH, non-condensing

Accuracy

• Calibration accuracy and sensor conformity: ±0.1 percent

of span, ±1°C @ the calibrated ambient temperature and

rated line voltage

• Calibration ambient temperature = 25°C ±3°C (77°F ±5°F)

• Accuracy span: 540°C (1000°F) minimum

• Temperature stability: ±0.1°C/°C (±0.2°F/°F) rise in

ambient maximum

Agency Approvals

•UL

®

3121, C-UL®‚ CSA, CE, IP65/NEMA 4X and NSF-2

• Limit version features FM approval

Controller

• Microprocessor based user-selectable control modes

• Single universal input, up to three outputs

• Control sampling rates: input = 6.5Hz, display = 10Hz,

outputs = 6.5Hz

Operator Interface

• Dual 4 digit, 7 segment LED displays

• Advance, infinity and up down keys

• IrDA infrared port (not available on

1

⁄32 DIN)

• Isolated EIA 485 Modbus™ serial communications

Wiring Termination -Touch Safe Terminals

• Input power and control outputs 12 to 22 AWG

• Sensor inputs and process outputs 20 to 28 AWG

Universal Input

• Thermocouple, grounded or ungrounded sensors

• RTD 2- or 3-wire, platinum, 100Ω @ 0°C calibration to

DIN curve (0.00385 Ω/Ω/°C)

• Process, 0-20mA @ 100Ω, or 0-10VÎ(dc) @ 20kΩ input

impedance; Scalable

• 0-50mV

• Inverse scaling

• >20MΩ input impedance

• Maximum of 20Ω source resistance

Dimensions

DIN Size Behind Panel Width Height

(max.)

1

⁄32DIN 97.8 mm 52.6 mm 29.7 mm

(3.85 in.) (2.07 in.) (1.17 in.)

1

⁄16DIN 97.8 mm 52.1 mm 52.1 mm

(3.85 in.) (2.05 in.) (2.05 in.)

1

⁄8DIN 97.8 mm 52.8 mm 99.8 mm

Vertical (3.85 in.) (2.08 in.) (3.93 in.)

1

⁄8DIN 97.8 mm 99.8 mm 52.8 mm

Horizontal (3.85 in.) (3.93 in.) (2.08 in.)

1

⁄4DIN 101.1 mm 99.8 mm 99.8 mm

(3.98 in.) (3.93 in.) (3.93 in.)

Page 4

Ordering Information

To order, complete the model number on the right with the

information below.

S D - _ _ _ _ - _ A _ _

DIN Sizes

3=

1

⁄32 DIN

①

6=1⁄16 DIN

8=

1

⁄8 DIN Vertical

9=

1

⁄8 DIN Horizontal

4=

1

⁄4 DIN

Control Type

C = PID Control Dual Display

L = Limit Control Dual Display

②

R = Ramping Dual Display

E = PID Control with TRU-TUNE+™

Power Supply

H = 100 to 240Vı(ac/dc)

L = 24 to 28Vı(ac/dc)

Output 1

C = Switched dc

K = SSR, Form A, 0.5A

F = Universal process

J = Mechanical relay, Form A, 2A

Output 2

A = None

C = Switched dc

K = SSR, Form A, 0.5A

J = Mechanical relay, Form A, 2A

U = EIA 485 Modbus™ communications

Output 3 (Not available on

1

⁄32 DIN)

A = None

C = Switched dc/open collector

K = SSR, Form A, 0.5A

F = Universal process

E = Mechanical relay, Form C, 5A

Infrared Comms Options (IrDA)

A = None (Default selection on

1

⁄32 DIN)

R = IrDA ready (Not available on

1

⁄32 DIN)

③

Display Colors and Custom Options

RG = Red Green (Dual display units)

RR = Red Red (Not available on

1

⁄32 DIN Dual Display)

XX = Custom options, special overlays, etc.

Your Authorized Watlow Distributor Is:

①

An SD Single Display 1⁄32 DIN and a separate spec sheet

are available.

②

Not all options above are available on the SD limit controllers.

Consult factory for proper configurations.

③

IrDA communication not available if product is specified with

TRU-TUNE+™ option.

Specifications (con’t)

Allowable Operating Range

Type J: 0 to 815°C or 32 to 1500°F

Type K: -200 to 1370°C or -328 to 2500°F

Type T: -200 to 400°C or -328 to 750°F

Type N: 0 to 1300°C or 32 to 2372°F

Type E: -200 to 800°C or -328 to 1470°F

Type C: 0 to 2315°C or 32 to 4200°F

Type D: 0 to 2315°C or 32 to 4200°F

Type PTII: 0 to 1395°C or 32 to 2543°F

Type R: 0 to 1760°C or 32 to 3200°F

Type S: 0 to 1760°C or 32 to 3200°F

Type B: 0 to 1816°C or 32 to 3300°F

RTD (DIN): -200 to 800°C or -328 to 1472°F

Process: -1999 to 9999 units

Control Outputs

Outputs 1, 2 , 3 (Output 3 not available on

1

⁄32 DIN)

• User selectable for heat/cool as on-off, P, PI, PD, PID, or

Alarm action. Not valid for limit controls

• Electromechanical relay. Form A, rated 2A @ 120VÅ(ac),

2A @ 240VÅ(ac) or 2A @ 30VÎ(dc)

• Switched dc non-isolated minimum turn on voltage of

6VÎ(dc) into a minimum 500Ω load with a maximum on

voltage of not greater than 12VÎ(dc) into an infinite load.

Maximum switched dc power supply current available for

up to two outputs is 60mA

• Solid-state relay, Form A, 0.5A @ 24VÅ(ac) minimum,

264VÅ(ac) maximum, opto-isolated, without contact

suppression

• Process output (Non Isolated)

User-selectable 0-10VÎ(dc), 0-5VÎ(dc), 1-5VÎ(dc) @

1KΩ minimum, 0-20mA, 4-20mA @ 800Ω maximum

• Electromechanical relay. Form C, rated 5A @ 120V~(ac),

5A @ 240V~(ac) or 5A @ 30VÎ(dc)

• Open collector 42VÎ(dc) @ 250mA maximum

• EIA 485 serial communications with Modbus™ protocol

To be automatically connected to the nearest North American Technical and Sales Office call:

1-800-WATLOW2

International Technical and Sales Offices: Australia, +61-3-9335-6449 • China, +86-21-3950-9510 • France, +33 (01) 3073-2425 •

Germany, +49 (0) 7253-9400-0 • Italy, +39 (02) 458-8841 • Japan, +81-3-3518-6630 • Korea, +82-2-575-9804 • Malaysia, +60-3-7980-7741 •

Mexico +52 (442) 217-6235 • Singapore, +65-6777-1266 • Spain, +34 916 751 292 • Sweden, +46 35-27-11-66 • Taiwan, +886-7-288-5168 •

United Kingdom, +44 (0) 115-964-0777

Loading...

Loading...