Page 1

W A T L O W

Tubular and

Process Assemblies

Screw Plug

Immersion Heaters

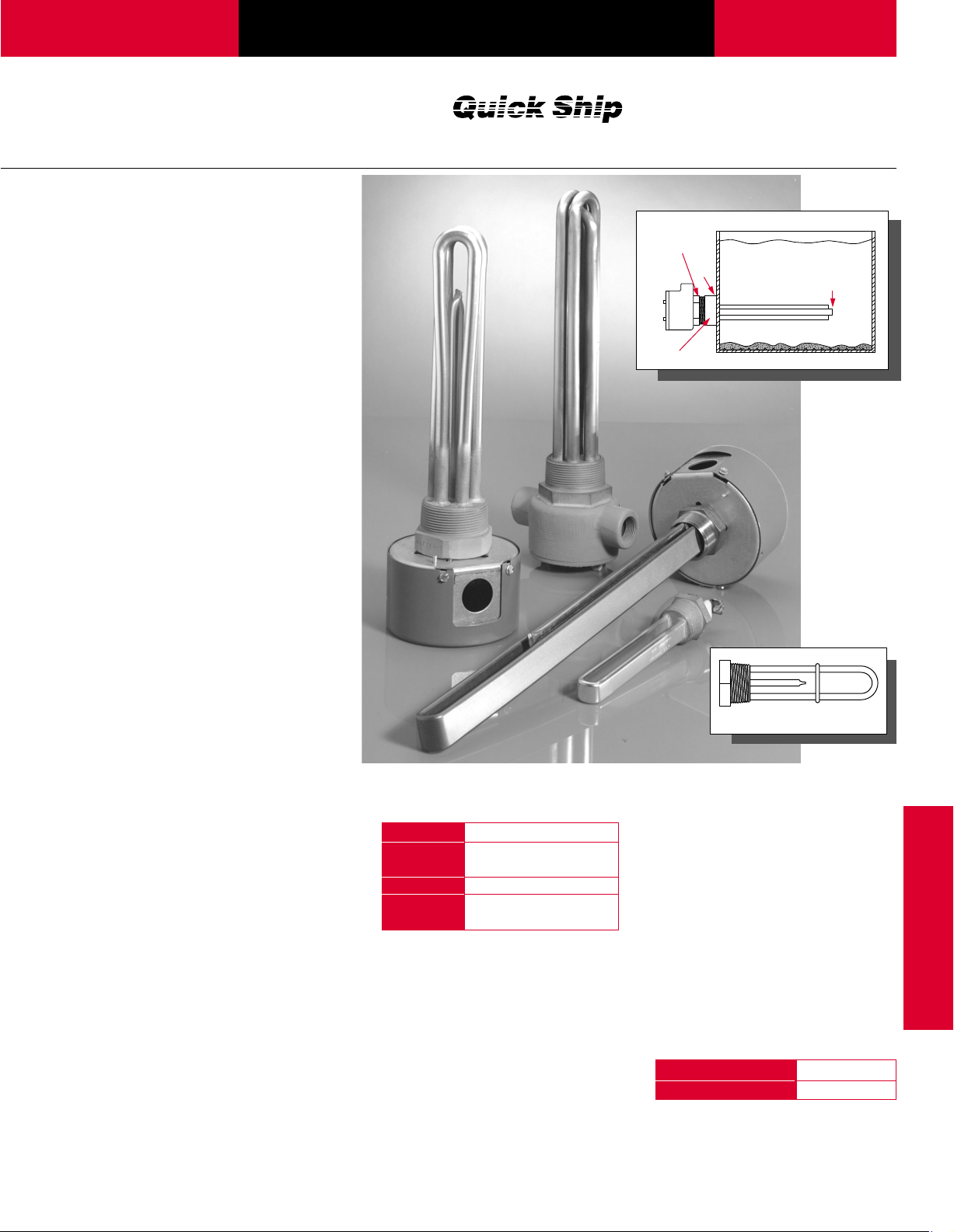

Screw plug immersion heaters are

ideal for direct immersion heating of

liquids, including all types of oils and

heat transfer solutions.

Available in a variety of stock and

made-to-order sizes, Watlow screw

plug immersion heaters feature both

WATROD round and FIREBAR®flat

tubular elements.

Heating elements are hairpin bent

and either welded or brazed into the

screw plug—depending on element

sheath and plug material

compatibility.

General purpose (NEMA 1) terminal

enclosures are standard; with

optional moisture resistant

(NEMA 4), explosion resistant

(NEMA 7) and explosion/moisture

resistant (NEMA 7/4) enclosures

available to meet specific

application needs.

Optional thermostats provide

convenient process temperature

regulation.

Performance Capabilities

• Watt densities to 120 W/in

(18.6 W/cm2)

• Wattages to 38kW

• UL®and CSA component

recognition to 480VÅ(ac) and

600VÅ(ac) respectively

• Incoloy®sheath temperatures to

1600°F (870°C)

• Passivated 316 stainless steel

sheath temperatures to 1200°F

(650°C)

• 304 stainless steel sheath

temperatures to 1200°F (650°C)

• Steel sheath temperatures to

750°F (400°C)

• Copper sheath temperatures to

350°F (175°C)

Incoloy®is a registered trademark of

Special Metals Corporation.

®

is a registered trademark of

UL

Underwriter's Laboratories, Inc.

2

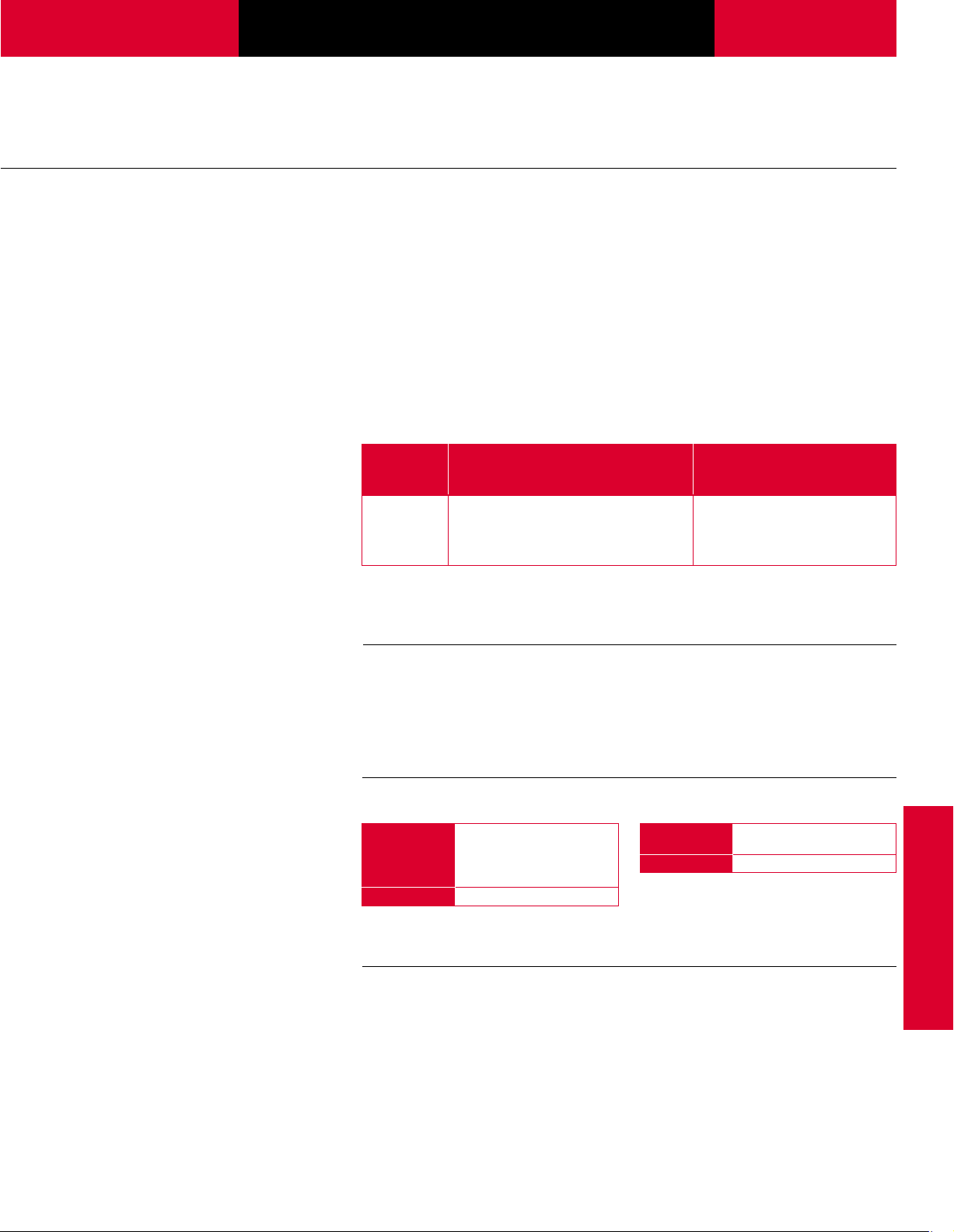

Features and Benefits

• Screw plug and element sizes:

1" NPT 0.315" WATROD

1

1

⁄4" NPT 0.315" WATROD

1" FIREBAR

2" NPT 0.475" WATROD

21⁄2" NPT 0.475" WATROD

1" FIREBAR

• A variety of element sheath and

screw plug materials to meet

application needs.

• Integral thermowells provide

convenient temperature sensor

insertion and replacement without

draining the fluid being heated.

• Terminal enclosures can be

rotated to simplify connection with

existing conduits.

On stock chart units:

• Same day on most heaters

• 10 working days on special voltages

and/or wattages

• 15 working days on special element lengths

NPT

Pipe

Thread

Half

Coupling

Weld

WATROD Heating Element

FIREBAR

Heating

Element

• Welding or brazing WATROD

and FIREBAR elements to the

screw plug provides a pressure

tight seal.

• WATROD hairpins are

repressed (recompacted) to

maintain MgO density, dielectric

strength, heat transfer and life.

• 21⁄2" NPT screw plug assemblies

feature element support(s) to

help ensure proper spacing for

maximizing heater performance

and life.

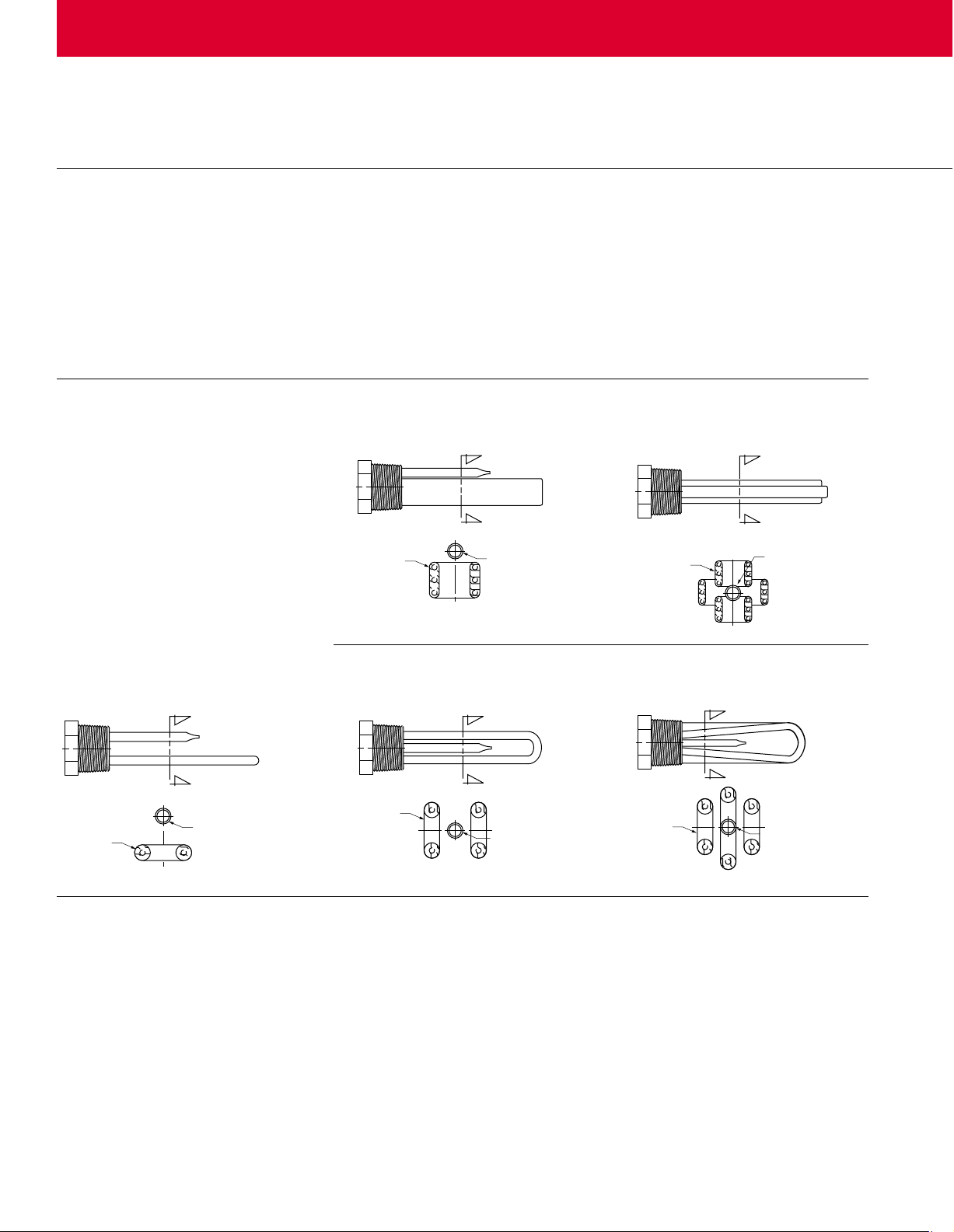

• Phase capability:

1" NPT 1-Phase

11⁄4", 2", 21⁄2" NPT 1- or 3-Phase

• UL®and CSA component

recognition under file numbers

E52951 and 31388 respectively.

See pages 268-271 for details.

321

Screw Plug

Page 2

Tubular and

View A-A

Thermowell

Element

Bundle

A

A

View A-A

Thermowell

Element

Bundle

A

A

View A-A

Thermowell

Element

Bundle

A

A

View A-A

Thermowell

Element

Bundle

A

A

View A-A

Thermowell

Element

Bundle

A

A

Process Assemblies

Screw Plug

Immersion Heaters

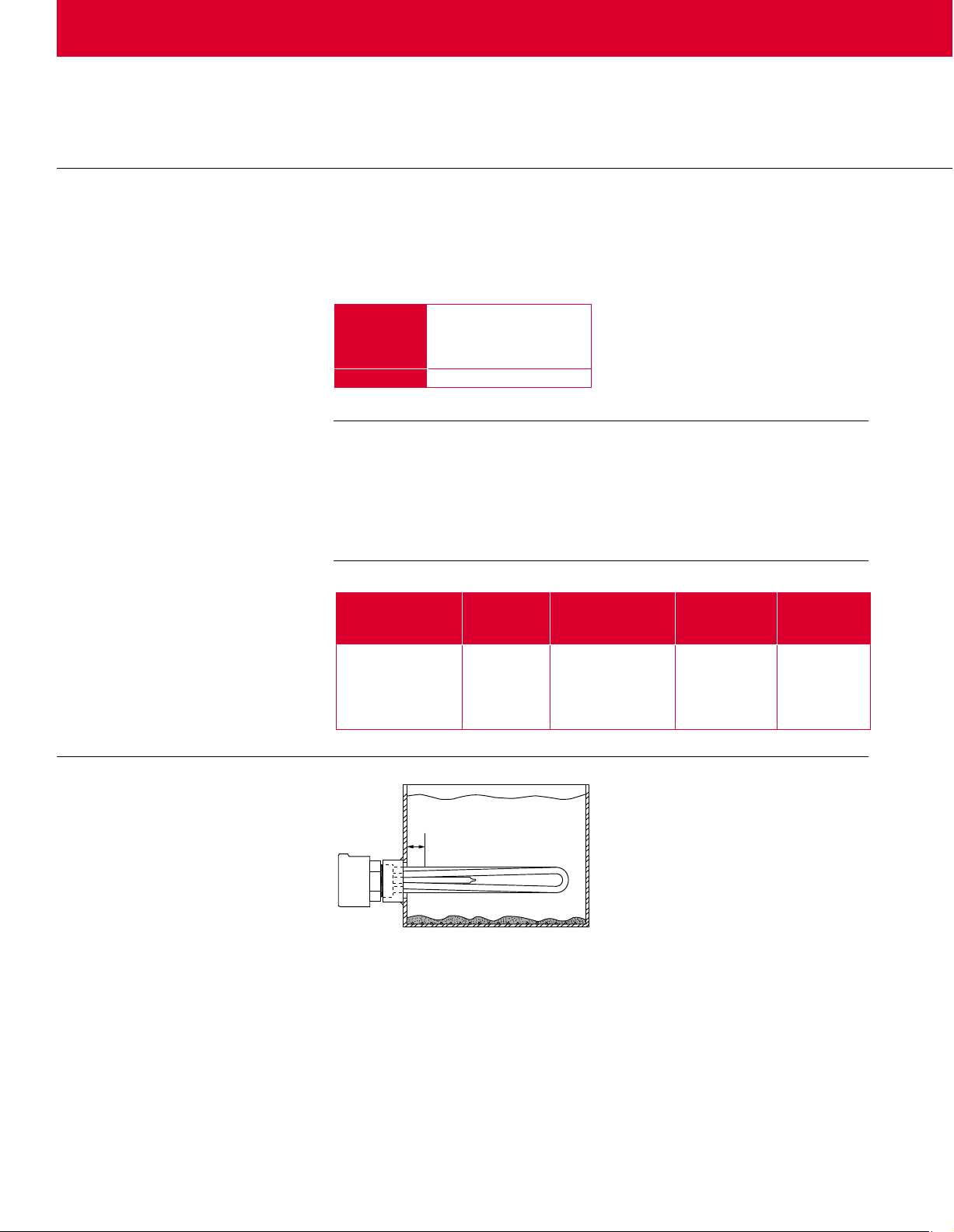

Screw Plug Orientation

Correct element/thermowell

orientation assures proper process

temperature sensing.

Correct horizontal mounting of

WATROD and FIREBAR screw plugs

is shown to the right. Correct

orientation assures optimum

performance and maximum heater

life. Additional mounting information

is provided in the Installation and

Maintenance Instructions.

Applications

• Water:

Deionized

Demineralized

Clean

Potable

Process

• Industrial water rinse tanks

• Vapor degreasers

• Hydraulic oil, crude, asphalt

• Lubricating oils at API specified

watt densities

• Air and gas flow

• Caustic solutions

• Chemical baths

• Anti-freeze (glycol) solutions

• Paraffin

FIREBAR Heating Element

11⁄4" NPT–One Element 21⁄2" NPT–Three Elements

WATROD Heating Element

1" NPT–One Element

Options

Terminal Enclosures

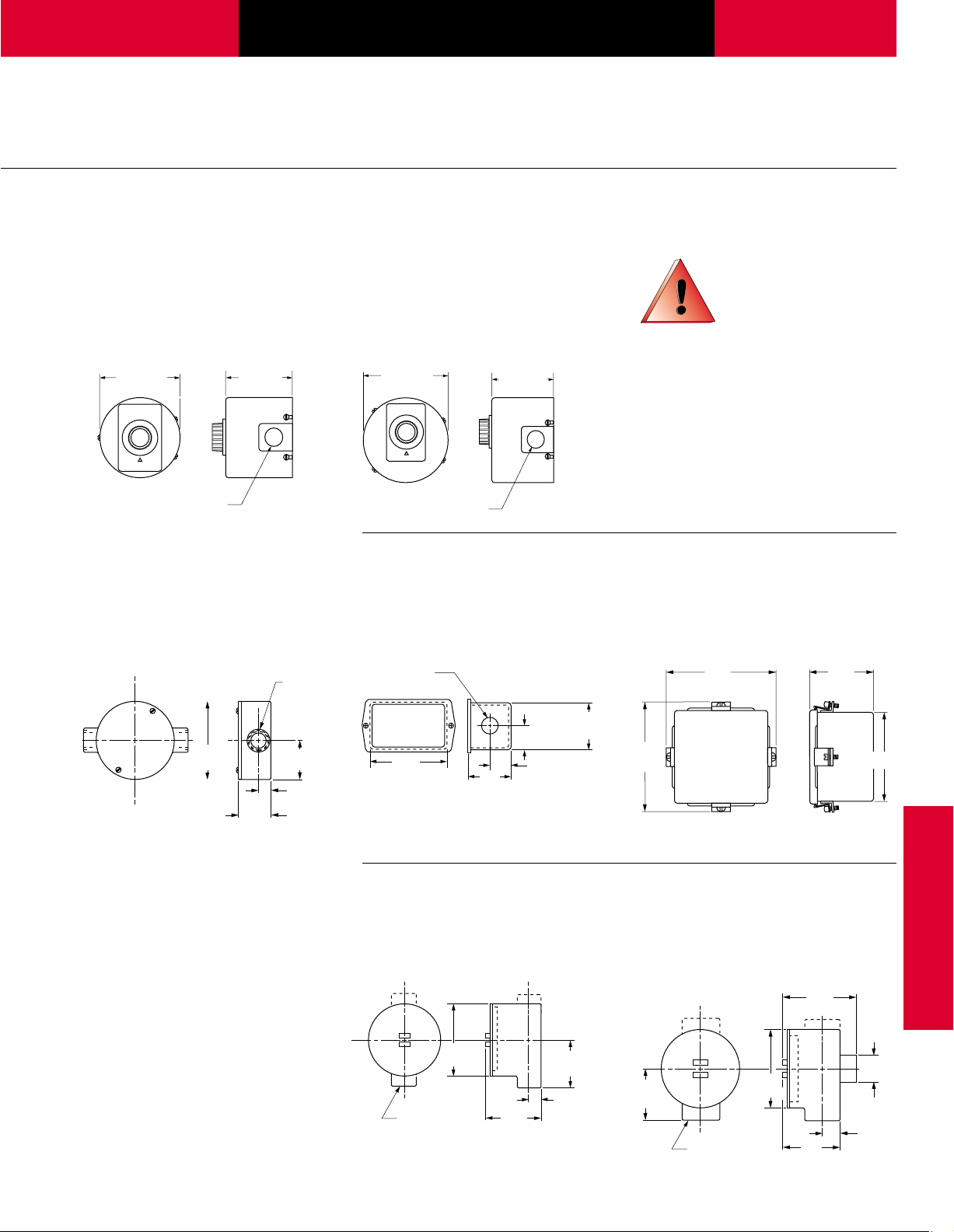

General purpose (NEMA 1) terminal

enclosures, without thermostats, are

standard on all screw plug

immersion heaters. To meet specific

application requirements, Watlow

offers the following optional terminal

enclosures:

• General purpose (NEMA 1) with

single or double pole thermostat

11⁄4" & 2" NPT–Two Elements 2" & 21⁄2" NPT–Three Elements

• Moisture resistant (NEMA 4) or

corrosion resistant (NEMA 4X) —

available with optional single or

double pole thermostat

• Explosion resistant (NEMA 7)

class 1, groups C and D

explosion resistant—available

with optional single or double pole

thermostat. For class 1, group B

enclosures, consult your Watlow

representative or refer to CSA

specifications on page 271.

• Explosion/moisture resistant

available with optional single or

double pole thermostat

Note: Unless otherwise stated on

the accompanying illustrations,

both WATROD and FIREBAR

screw plugs are centered on the

terminal enclosure. To order, add

the suffix letter(s) to the screw

plug heater’s base code number.

This is depicted on the Stock and

Options ordering example on

page 336. Also, specify class and

group, if applicable.

(NEMA 7/4) combination—

322

Page 3

W A T L O W

3

13

/

16

"

(97 mm)

3

/

4

"

Conduit Opening

4

5

/

8

"

(117 mm

)

4

"

(100 mm)

3

/

4

"

Conduit Opening

5

1

/

2

"

(140 mm)

4

1

/2

"

(114 mm)

2

5

/8

"

(67 mm)

1

5

/16

"

(33 mm)

1

7

/16

"

(37 mm)

2

7

/8

"

(73 mm) Ref.

(1) 1.093

"

(28 mm)

Dia. Hole

2

"

(51 mm)

2

"

(50 mm)

3

/4

"

Conduit

Opening

4

"

(100 mm)

13

/16

"

(21 mm)

6

9

/

16

"

6

9

/

16

"

(167 mm)

4

1

/

4

"

(108 mm)

6

"

(152 mm)

3

13

/16

"

(97 mm)

4

3

/8

"

(111 mm)

1

3

/8

"

(35 mm)

2

1

/2

"

(64 mm)

Dia.

6

1

/4

"

(159 mm)

5

3

/4

"

(146 mm)

1

1

/2

"

Conduit Opening

2

9

/16

"

(65 mm)

21

/32

"

(17 mm)

3

1

/16

"

(78 mm)

3

3

/4

"

(95 mm)

3

/4

"

Conduit Opening

Tubular and

Process Assemblies

Screw Plug

Immersion Heaters

Options

Continued

General Pupose (NEMA 1)

Single Pole Thermostat

All screw plug sizes

Double Pole Thermostat

All screw plug sizes

Caution:

Explosion-resistant terminal

enclosures are intended to provide

explosion containment in

the electrical termination/wiring

enclosure only. No portion of the

assembly outside of this enclosure

is covered under this NEMA rating.

NEMA rating effectiveness may

be compromised by abuse or

misapplication.

Moisture Resistant NEMA 4

Without Thermostat

All screw plug sizes

Single Pole Thermostat

1" & 11⁄4 " NPT–1 WATROD Element

Single or Double Pole Thermostat

11⁄4 " NPT–2 WATROD Elements

11⁄4 " NPT–1 FIREBAR Element

All 2" & 2 1⁄2 " NPT screw plugs

Note: The thermostat is not centered on the

WATROD screw plug immersion heater.

Note: The thermostat is not centered on the

screw plug immersion heater.

Explosion/Moisture Resistant (NEMA 7 or 7/4)

Without Thermostat

All WATROD screw plugs

Single or Double Pole Thermostat

11⁄4 " NPT–1 FIREBAR Element

All WATROD screw plugs

Screw Plug

➀

➀ All NEMA 7/4 rated terminal enclosures supplied with a gasket for the cover.

323

Page 4

Tubular and

3

1

/8

"

(79 mm)

3

5

/16

"

(84 mm)

3

1

/2

"

(89 mm)

O.D.

5

"

(127 mm)

4

1

/2

"

(114 mm)

1

5

/32

"

(29 mm)

1

1

/4

"

Conduit Opening

2

9

/16

"

(65 mm)

3

1

/16

"

(77 mm)

21

/32

"

(17 mm)

2

1

/2

"

(64 mm)

O.D.

4

3

/4

"

(121 mm)

3

3

/4

"

(95 mm)

3

/4

" Conduit

Opening

3

13

/16

"

(97 mm)

4

3

/8

"

(111 mm)

3

1

/2

"

(89 mm)

O.D.

6

3

/8

"

(162 mm)

5

3

/4

"

(146 mm)

1

3

/8

"

(35 mm)

1

1

/2

"

Conduit Opening

Process Assemblies

Screw Plug

Immersion Heaters

Options

Continued

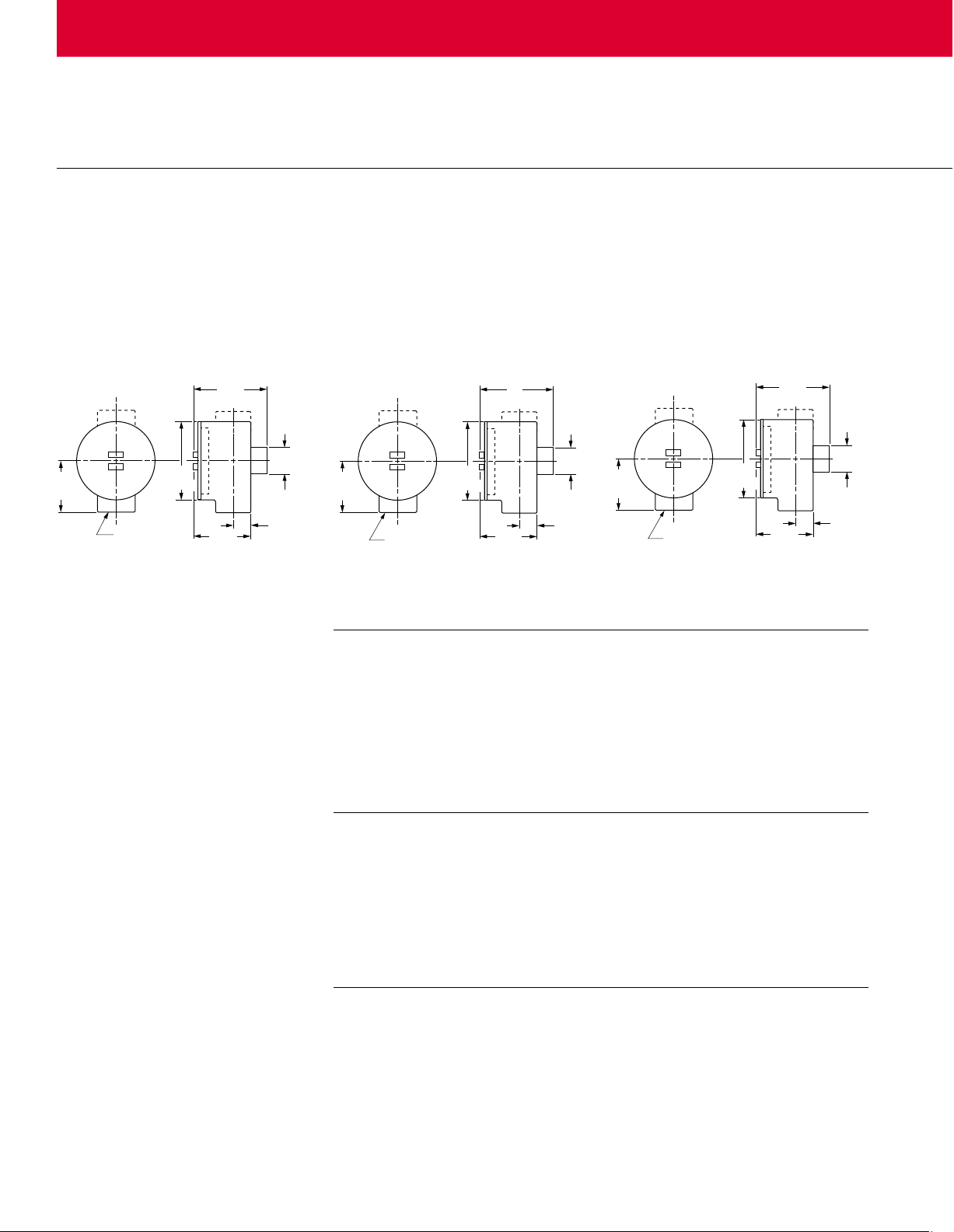

Explosion/Moisture Resistant (NEMA 7 or 7/4)

Without Thermostat

11⁄4 " NPT––1 FIREBAR element

➀

All NEMA 7/4 rated terminal enclosures supplied with a gasket for the cover.

Without Thermostat

21⁄2 " NPT–3 FIREBAR elements

➀

CSA Certified Enclosures

CSA certified moisture and/or

explosion resistant terminal

enclosures protect wiring in

hazardous gas environments. These

terminal enclosures, covered under

CSA file number 61707, are

available on all WATROD and

FIREBAR screw plug immersion

heaters. For additional information,

consult your Watlow representative.

Single or Double Pole Thermostat

21⁄2 " NPT–3 FIREBAR elements

To order, specify CSA certified

enclosure, process temperature

(°F), maximum working pressure of

application (psig), media being

heated and heater mounting

orientation (horizontal or vertical)

and screw plug size.

Pilot Light

The optional pilot light gives the

operator visual indication of heater

on or off power status.

The PL10 pilot light is configured to a

maximum 250VÅ(ac), and supplied

with six inch (150 mm) leads.

Thermostats

To provide process temperature

control, Watlow offers optional single

pole, single throw (SPST) and double

pole, single throw (DPST)

thermostats.

324

The PL11 pilot light is rated for

480VÅ(ac), and supplied with four

inch (100 mm) leads.

Pilot lights may be attached to either

single or double pole thermostats

with general purpose (NEMA 1)

enclosure only. For moisture or

Unless otherwise specified,

thermostats are mounted inside the

terminal enclosure. For details and

ordering information, refer to

Thermostats on pages 423 to 425.

explosion resistant terminal

enclosures (NEMA 4 or NEMA 7),

consult factory.

To order, refer to the Build-a-Code

chart on page 336.

Please verify that the thermostat’s

sensing bulb O.D. is compatible with

the screw plug’s thermowell I.D.

Page 5

W A T L O W

Tubular and

Process Assemblies

Screw Plug

Immersion Heaters

Options

Continued

Thermocouples

Type J or K thermocouples offer

extremely accurate sensing of

process and/or sheath temperatures.

A thermocouple may be inserted into

the thermowell or attached to the

heater’s sheath.

Thermocouples are supplied with

120 inch (305 mm) leads (longer

lead lengths available). Unless

otherwise specified, thermocouples

are supplied with temperature

ranges detailed on the

Thermocouple Types chart.

Using a thermocouple requires an

appropriate temperature and power

control. These must be purchased

separately. Watlow offers a wide

variety of temperature and power

controls to meet virtually all

applications. Temperature controls

can be configured to accept

process variable inputs, too. Consult

your Watlow representative for

details.

To order, specify Type J or K

thermocouple and lead length.

Indicate if the thermocouple is for

process temperature sensing or

heater sheath high-limit protection.

Please specify if the screw plug will

be mounted vertical or horizontal in

the tank. If vertical, indicate if the

housing is on top or bottom.

If the screw plug heater is mounted

in an in-line circulation heating

application, indicate flow direction

relative to the heater’s enclosure.

Thermocouple Types

Recommended

ASTM Conductor Characteristics Temperature Range

Type Positive Negative °F (°C)

J Iron Constantan 0 to 1000 (-20 to 540)

(Magnetic) (Non-Magnetic)

K Chromel

(non-magnetic) (Magnetic)

➀

Type J and Type K thermocouples are rated 32 to 1382°F and 32 to 2282°F (0-750°C and

0-1250°C), respectively. Watlow does not recommend exceeding temperature ranges shown

on this chart for the tubular product line.

®

Alumel

®

0 to 2000 (-20 to 1100)

➀

Wattages and Voltages

Watlow routinely supplies screw plug

immersion heaters with 120 to

480VÅ(ac) as well as wattages from

Sheath Materials

The following sheath materials are

available on WATROD and FIREBAR

heating elements:

External Finishing

Passivation

During the manufacturing process,

particles of iron or tool steel may

become embedded in the stainless

steel or alloy sheath. If not removed,

these particles may corrode,

250 watts to 38kW. If required,

Watlow will configure heaters with

voltages and wattages outside these

special voltage and wattage

configurations, consult your Watlow

representative.

parameters. For more information on

Standard Sheath Materials Made-to-Order Sheath Materials

WATROD

FIREBAR

Incoloy

316 stainless steel

Steel

Copper

®

Incoloy

WATROD

FIREBAR

Exotic Sheath Materials

304 stainless steel

®

Monel

304 stainless steel

®

Consult your Watlow representative

for details and availability.

Other Finishes

produce rust spots and/or

contaminate the process. For critical

applications, passivation will remove

free iron from the sheath. To order,

Simple belt polishing and glass

beading are available to meet

cosmetic demands. Consult factory

for details.

specify passivation.

Screw Plug

Alumel®and Chromel®are registered trademarks of the Hoskins Manufacturing Company.

Monel®is a registered trademark of

Special Metals Corporation.

325

Page 6

Tubular and

1" (25 mm)

Minimum No-Heat Section

Process Assemblies

Screw Plug

Immersion Heaters

Options

Continued

Screw Plug Materials

The following screw plug materials

are available:

To order, specify screw plug size

and material.

Screw Plug Sizes

Including European

1

• NPT–1, 1

• Gas–G11⁄4, G11⁄2, G 2 inch

(brass only)

⁄4, 2, 21⁄2 inch

Standard Screw Plug Materials Made-to-Order Plug Materials

WATROD

FIREBAR

• BSP–1

1

⁄2

inch

304 stainless steel

316 stainless steel

Steel

Brass

304 stainless steel

(stainless steel only)

Consult factory for sizes and

materials not listed.

For both WATROD and FIREBAR,

consult factory about details and

availability.

To order, specify size, style (NPT,

Gas or BSP) and material.

BSP = British Standard Pipe

Gas = Gas pipe standard

Screw Plug to Flange Adaptors

Screw plug to flange adaptors permit

replacing flange heaters with screw

plug heaters. To order, specify the

appropriate code number.

Application Hints

• Select the recommended sheath

material and watt density for the

substance being heated. Use the

Supplemental Applications

Chart on pages 263 to 266. If

unable to determine the correct

heater material and type, consult

your Watlow representative.

• Extend the element’s no-heat

section completely into the fluid

being heated to help prevent

premature heater failure. See

accompanying illustration for

proper no-heat section placement.

• Locate screw plug heater low in

the tank, but above the sludge

level.

Screw Plug to Flange Adaptors

Screw Plug Estimated

to Flange Shipping Wt. Code

Adaptor Sizes Material lbs (kg) Availability Number

1

⁄4 to 3”-150# Steel 13 (5.9) Stock 125X3SA

1

1

2

⁄2 to 3”-150# Steel 11 (5.0) Stock 250X3SA

1

⁄2 to 4”-150# Steel 16 (7.3) Stock 250X4SA

2

2 1⁄2 to 5”-150# Steel 25 (11.3) Stock 250X5SA

2 1⁄2 to 6”-150# Steel 33 (15.0) Stock 250X6SA

• Minimize problems associated

with low liquid level conditions by

using a low liquid level sensor or

sheath temperature high-limit

control.

• Periodically remove the screw

plug assembly for inspection and

clean the heating element(s). This

preventive maintenance will

• Choose a FIREBAR element when

your application requires a

smaller system package or lower

watt density.

• Ensure wiring integrity by making

sure terminal enclosure

temperature does not exceed

400°F (205°C).

• Keep electrical connections

clean, dry and tight.

reduce premature failure and

optimize heater performance.

• Refer to the Installation and

Maintenance Instructions for

correct orientation of FIREBAR

elements. Correct element

orientation to flow minimizes

pressure drop, increases

buoyancy force and heater

performance.

326

Page 7

W A T L O W

E

C

B

± 1%

Immersed Length

(1)

3

/4

"

Knockouts

F

D

H Bundle

304 Stainless Steel NPT Fitting

0.276" I.D. Thermowell

FIREBAR Element

G

A

No-Heat

Section

F

G

E

C

B

± 1%

Immersed Length

D

H Bundle

(1)

3

/4

"

Knockouts

NPT Fitting

Thermowell

-0.250" I.D. on 1" and 1

1

/4" NPT Plug

-0.375" I.D. on 2" and 2

1

/2" NPT Plugs

WATROD Element

A

No-Heat

End

Tubular and

Process Assemblies

Screw Plug

Immersion Heaters

Screw Plug Heater Dimensions

WATROD and FIREBAR Screw Plug Immersion Heater Dimensions

Heater NPT Size A Dimension C Dimension D Dimension E Dimension F Dimension G Dimension H Dimension*

Type in in (mm) in (mm) in (mm) in (mm) in (mm) in (mm) in (mm)

7

WATROD 1 1 (25)

WATROD 1 1⁄

4 1

WATROD 2 Steel 2

15

16 (24)

⁄

9

⁄16 (65) 1 (25) 1 11⁄16 (43) 2 5⁄8 (67) 4 5⁄8 (117) 2 1⁄2 (64) 2 1⁄4 (57)

⁄8 (22) 1 1⁄4 (32) 2 5⁄8 (67) 4 5⁄8 (117) 1 3⁄8 (35) 1 1⁄8 (29)

15

16 (24) 1

⁄

5

16 (33) 2

⁄

WATROD 2 Brass 2 11⁄16 (68) 1 1⁄16 (27) 1 9⁄16 (40) 2 5⁄8 (67) 4 5⁄8 (117) 2 1⁄2 (64) 2 1⁄4 (57)

WATROD 2 S. Steel 2 13⁄

WATROD 2

FIREBAR 1 1⁄4

FIREBAR 2

1

⁄2 2 3⁄16 (56) 1 5⁄16 (33) 2 1⁄16 (52) 2 5⁄8 (67) 4 5⁄8 (117) 3 1⁄2 (76) 2 1⁄2 (64)

3

1

⁄2 3 3⁄8 (86) 1 1⁄4 (32) 1 1⁄2 (38) 2 5⁄8 (67) 4 5⁄8 (117) 3 1⁄2 (76) 2 1⁄2 (64)

16 (71) 1 (25) 1

7

(98)

⁄8

13

⁄16

(21) 1

5

8 (41) 2

⁄

1

(27) 2

⁄16

* Note: All plug bundles fit into equivalent NPT coupling. They do not fit in equivalent pipe sizes.

1" NPT Screw Plug – WATROD Element

WATROD Immersed Code No. Est. Ship.

Screw Plug

Description kW B Dimension

Immersion Heaters

inch (mm) 1-Phase 1-Phase lbs (kg)

120VÅ(ac) 240VÅ(ac)

Application: Clean Water

2

60 W/in

Brass Plug 0.75 61⁄2 (165) BCC6J1 BCC6J10 3 (2)

1-Copper 1.0 6

(9.3 W/cm

Applications: Lightweight Oils, Degreasing Solutions, Heat Transfer Oils

2

23 W/in

Steel Plug 0.35 91⁄4

1-Steel 0.5 9

(3.6 W/cm

0.5 41⁄2 (114) BCC4J1 BCC4J10 3 (2)

5

2

) 1.25 8 (203) BCC8A1 BCC8A10 4 (2)

⁄8 (168) BCC6L1 BCC6L10 3 (2)

1.5 105⁄8 (270) BCC10L1 BCC10L10 4 (2)

1

2.0 12

2.5 14

3.0 163⁄4 (426) BCC16N1 BCC16N10 6 (3)

4.0 21 (533) BCC21A10 6 (3)

0.25 61⁄2 (165) BCS6J1 BCS6J10 3 (2)

2

) 0.75 131⁄2 (343) BCS13J1 BCS13J10 5 (3)

1.0 163⁄4

1.5 23

⁄2 (318) BCC12J1 BCC12J10 5 (3)

3

⁄4 (375) BCC14N1 BCC14N10 5 (3)

(235) BCS9E1 BCS9E10 4 (2)

3

⁄8 (238) BCS9G1 BCS9G10 4 (2)

(425) BCS16N1 BCS16N10 6 (3)

3

⁄4 (603) BCS23N1 BCS23N10 7 (4)

5

8 (67) 4

⁄

5

8 (67) 4

⁄

5

(67) 4

⁄8

Weight

5

8 (117) 1

⁄

5

8 (117) 2

⁄

5

(117) 1

⁄8

3

4 (44) 1

⁄

1

2 (64) 2

⁄

3

(44) 1

⁄4

3

8 (35)

⁄

1

4 (49)

⁄

3

(35)

⁄8

All heating elements are Assembly Stock

unless otherwise noted.

Availability

Assembly Stock: Three to five working days

327

Screw Plug

Page 8

Tubular and

Process Assemblies

Screw Plug

Immersion Heaters

11⁄4" NPT Screw Plug – WATROD Element

WATROD Immersed Code No. Est. Ship.

Description kW B Dimension

120VÅ(ac) 120/240VÅ(ac) 240VÅ(ac)

inch (mm) 1-Phase 1-Phase 1-Phase lbs (kg)

Application: Clean Water

2

60 W/in

Brass Plug 0.75 6

0.5 43⁄8 (111) BDC4G1 BDC4G10 3 (2)

3

⁄8 (162) BDC6G1 BDC6G10 3 (2)

1-Copper

2

(9.3 W/cm

60 W/in

Brass Plug 1.5 6

)

➃

2

1.0 43⁄8 (111) BEC4G6 4 (2)

3

⁄8 (162) BEC6G6 4 (2)

2-Copper 2.0 81⁄2 (216) BEC8J6 5 (3)

(9.3 W/cm

2

) 2.5 103⁄4 (273) BEC10N6 5 (3)

3.0 15 (381) BEC15A6 6 (3)

4.0 19 (483) BEC19A10 7 (4)

5.0 231⁄2 (597) BEC23J10 8 (4)

1

6.0 27

⁄2 (699) BEC27J10 9 (4)

Applications: Lightweight Oils, Degreasing Solutions, Heat Transfer Oils

23 W/in

Steel Plug 0.5 7

0.5 63⁄8 (162) BES6G6 4 (2)

3

⁄8 (187) BES7G6 4 (2)

➃

2

2-Steel 0.7 87⁄8 (225) BES8R6 5 (3)

2

(3.6 W/cm

) 0.75 101⁄16 (256) BES10B6 5 (3)

1.0 12

1.5 19

3

⁄4 (324) BES12N6 6 (3)

3

⁄8 (492) BES19G6 7 (4)

2.0 253⁄8 (645) BES25G6 8 (4)

3.0 36

7

⁄8 (937) BES36R6 9 (4)

Applications: Forced Air and Gases, Caustic Solutions, Degreasing Solutions

➃

2

23 W/in

304 SS Plug 1.5 19 (483) BEN19A6 7 (4)

2-Incoloy

®

(3.6 W/cm2)

1.0 133⁄8 (340) BEN13G6 6 (3)

2.0 243⁄8 (619) BEN24G6 8 (4)

Weight

11⁄4" NPT Screw Plug– FIREBAR Element

FIREBAR Immersed Code No. Est. Ship.

Description kW B-Dimension

inch (mm)

240VÅ(ac) 240VÅ(ac) 480VÅ(ac)

1-Phase 3-Phase 3-Phase

Weight

lbs (kg)

Applications: Clean and Potable Water

2

90 W/in

304 SS Plug 3.0 11

1-Incoloy

(14 W/cm

⑧

®

2

1.5 75⁄8 (194) BDNF7R10

1

⁄8 (283) BDNF11G10

5.0 161⁄8 (410) BDNF16G3 BDNF16G5 7 (4)

) 6.5 191⁄8 (486) BDNF19G3 BDNF19G5 8 (4)

8.5 24

3

⁄8 (619) BDNF24L3 BDNF24L5 9 (4)

10.5 295⁄8 (753) BDNF29R3 BDNF29R5 10 (5)

5

12.7 34

17.0 451⁄8

21.5 55

⁄8 (879) BDNF34R3 BDNF34R5 11 (5)

(1146) BDNF45G3 BDNF45G5 13 (6)

5

⁄8 (1413) BDNF55R5 15 (7)

➁ Standard

➃ Wired for higher voltage.

➆ Not available as 3-phase – 1-phase only.

⑧ Can be wired 1-phase.

➁ ➆

➁ ➆

BDNF7R11

BDNF11G11

➁ ➆

➁ ➆

CONTINUED

328

5 (3)

6 (3)

All heating elements are

Assembly Stock unless

otherwise noted.

Availability

Assembly Stock: Three to five

working days

Standard: 10 working days

Page 9

W A T L O W

Tubular and

Process Assemblies

Screw Plug

Immersion Heaters

11⁄4" NPT Screw Plug – FIREBAR Element

FIREBAR Immersed Code No. Est. Ship.

Description kW B Dimension

inch (mm)

240VÅ(ac) 240VÅ(ac) 480VÅ(ac)

1-Phase 3-Phase 3-Phase

Applications: Process Water, Ethylene Glycol (50%)

2

45 W/in

⑧

2.0 13 (330) BDNF13A27 6 (3)

304 SS Plug 2.5 151⁄2 (394) BDNF15J27 7 (4)

1-Incoloy

(7 W/cm2) 4.0 221⁄

®

3.0 18 (457) BDNF18A27 8 (4)

2 (572) BDNF22J27 BDNF22J28 9 (4)

5.0 27

6.0 321⁄

1

⁄2 (699) BDNF27J27 BDNF27J28 10 (5)

2 (826) BDNF32J27 BDNF32J28 11 (5)

8.0 42 (1067) BDNF42A27 BDNF42A28 13 (6)

10.0 51

1

⁄2 (1308) BDNF51J27 BDNF51J28 15 (7)

Applications: Cooking Oils, Ethylene Glycol (100%)

2

30 W/in

304 SS Plug 2.2 191⁄

1-Incoloy

➂

®

1.7 161⁄8 (410) BDNF16G12 BDNF16G13 7 (4)

8 (486) BDNF19G12 BDNF19G13 8 (4)

2.8 243⁄8 (619) BDNF24L12 BDNF24L13 9 (4)

(4.7 W/cm2) 3.5 295⁄8 (752) BDNF29R12 BDNF29R13 10 (5)

5

4.25 34

5.7 45

7.2 55

⁄8 (880) BDNF34R12 BDNF34R13 11 (5)

1

⁄8 (1146) BDNF45G12 BDNF45G13 13 (6)

5

⁄8 (1413) BDNF55R12 BDNF55R13 15 (7)

Applications: Heat Transfer Oils, Mineral Oils, Degreasing Solutions

2

23 W/in

304 SS Plug 1.65 19

1-Incoloy

(3.6 W/cm

➇

®

1.25 161⁄8 (410) BDNF16G20 7 (4)

1

⁄8 (486) BDNF19G20 8 (4)

2.15 243⁄8 (619) BDNF24L20 BDNF24L19 9 (4)

2

) 2.65 295⁄8 (752) BDNF29R20 BDNF29R19 10 (5)

3.2 34

5

⁄8 (879) BDNF34R20 BDNF34R19 11 (5)

4.25 451⁄8 (1146) BDNF45G20 BDNF45G19 13 (6)

5

(1413) BDNF55R20 BDNF55R19 15 (6)

5.4 55

⁄8

Applications: Medium Weight Oils, Heat Transfer Oils, Lubrication Oils, Liquid Paraffin

2

15 W/in

304 SS Plug 0.83 15

1-Incoloy

(2.3 W/cm

➂

®

0.67 13 (330) BDNF13A29 6 (3)

1.0 18 (457) BDNF18A29 8 (4)

2

) 1.33 221⁄2

1.67 27

2.0 321⁄2 (826) BDNF32J29 BDNF32J30 11 (5)

2.67 42 (1067) BDNF42A29 BDNF42A30 13 (6)

3.33 511⁄2 (1308) BDNF51J29 BDNF51J30 15 (7)

1

⁄2 (394) BDNF15J29 7 (4)

(572) BDNF22J29 BDNF22J30 9 (4)

1

⁄2 (699) BDNF27J29 BDNF27J30 10 (5)

Weight

lbs (kg)

Screw Plug

Applications: Bunker C and #6 Fuel Oils, Asphalt

2

8 W/in

304 SS Plug 0.55 191⁄8 (486) BDNF19G22 8 (4)

1-Incoloy

(1.3 W/cm

➂ Must be operated 3-phase only.

➇ Can be wired 1-phase.

➂

®

0.43 161⁄8 (410) BDNF16G22 7 (4)

0.7 243⁄8

2

) 0.88 295⁄8 (753) BDNF29R22 BDNF29R21 10 (5)

1.08 34

1.4 45

(619) BDNF24L22 BDNF24L21 9 (4)

5

(880) BDNF34R22 BDNF34R21 11 (5)

⁄8

1

⁄8 (1146) BDNF45G22 BDNF45G21 13 (6)

1.8 555⁄8 (1413) BDNF55R22 BDNF55R21 15 (7)

All heating elements are

Assembly Stock unless

otherwise noted.

Availability

Assembly Stock: Three to five

working days

329

Page 10

Tubular and

Process Assemblies

Screw Plug

Immersion Heaters

2" NPT Screw Plug – WATROD Element (Note: Will not fit into a two inch pipe)

WATROD Immersed Code No. Est. Ship.

Description kW B Dimension

inch (mm)

120VÅ(ac) 120/240VÅ(ac) 240/480VÅ(ac) 240VÅ(ac) 480VÅ(ac)

1-Phase 1-Phase 1-Phase 3-Phase 3-Phase

Application: Clean Water

60 W/in

2.0 81⁄8 (206) BGC78C6 BGC78C7 4 (2)

d

2

Brass Plug 3.0 111⁄8 (283) BGC711C6 BGC711C7 5 (3)

2-Copper 4.0 151⁄8 (384) BGC715C6 BGC715C7 6 (3)

(9.3 W/cm2) 5.0 181⁄8 (460) BGC718C6 BGC718C7

b

6.0 211⁄8 (537) BGC721C7 7 (4)

8.0 265⁄8 (676) BGC726L7 7 (4)

10.0 321⁄8 (816) BGC732C7 8 (4)

60 W/in

2

3.0 81⁄8 (206) BHC78C1 BHC78C3 BHC78C13

bc

Brass Plug 4.5 111⁄8 (283) BHC711C1 BHC711C3 BHC711C5 6 (3)

3-Copper 6.0 151⁄8 (384) BHC715C3 BHC715C5 7 (4)

(9.3 W/cm2) 7.5 181⁄8 (460) BHC718C3 BHC718C5 7 (4)

9.0 21

12.0 26

15.0 32

1

8 (537) BHC721C3 BHC721C5 8 (4)

⁄

5

8 (676) BHC726L3 BHC726L5 8 (4)

⁄

1

8 (816) BHC732C3 BHC732C5 9 (4)

⁄

Application: Process Water

d

2

48 W/in

304 SS Plug 3.0 131⁄4 (337) BGN713E6 BGN713E7 5 (3)

2-Incoloy

®

(7.5 W/cm2) 5.0 201⁄4 (514) BGN720E6 BGN720E7 7 (4)

e

2

48 W/in

304 SS Plug 4.5 13

3-Incoloy

®

(7.5 W/cm2) 7.5 201⁄4 (514) BHN720E3

2.0 93⁄4 (248) BGN79N6 BGN79N7 4 (2)

4.0 173⁄4 (451) BGN717N6 BGN717N7 6 (3)

6.0 251⁄4 (641) BGN725E7 7 (4)

8.0 323⁄

10.0 40

3.0 93⁄4 (248) BHN79N1 BHN79N3

6.0 173⁄4 (451) BHN717N3

9.0 251⁄4 (641) BHN725E3

12.0 323⁄4 (832) BHN732N3

15.0 401⁄4 (1022) BHN740E3 BHN740E5

18.0 473⁄4 (1213) BHN747N3

4 (832) BGN732N7 8 (4)

1

4 (1022) BGN740E7 9 (4)

⁄

b

1

⁄4 (337) BHN713E1 BHN713E3

BHN79N5 5 (3)

b

b

b

b

b

b

BHN713E5

BHN717N5

BHN720E5

BHN725E5

BHN732N5

BHN747N5

b

b

b

b

b

b

b

Weight

lbs (kg)

6 (3)

5 (3)

6 (3)

7 (4)

8 (4)

9 (4)

9 (4)

10 (5)

11 (5)

CONTINUED

All heating elements are Assembly Stock

unless otherwise noted.

Availability

Assembly Stock: Three to five working days

330

b Stock

c Must be operated 3-phase only.

d Wired for higher voltage.

e 240VÅ(ac) can be wired wye and operated at 480VÅ(ac) 3-phase to produce

1

⁄3 more kW

Page 11

W A T L O W

Tubular and

Process Assemblies

Screw Plug

Immersion Heaters

2" NPT Screw Plug – WATROD Element (Note: Will not fit into a two inch pipe)

WATROD Immersed Code No. Est. Ship.

Description kW B Dimension 120VÅ(ac) 120/240VÅ(ac) 240/480VÅ(ac) 240VÅ(ac) 480VÅ(ac) Weight

Applications: Forced Air and Gases, Caustic Solutions, Degreasing Solutions

ef

2

23 W/in

304 SS Plug 4.5 251⁄

3-Incoloy

®

(3.6 W/cm2) 7.5 401⁄

Applications: Lightweight Oils, Degreasing Solutions, Heat Transfer Oils

d

2

23 W/in

Steel Plug 1.5 13

2-Steel 2.0 171⁄2 (445) BGS717J6

(3.6 W/cm2) 2.5 201⁄2 (521) BGS720J6 BGS720J7 7 (4)

2

23 W/in

Steel Plug 3.0 171⁄2 (445) BHS717J1 BHS717J3 BHS717J5

3-Steel 4.5 25 (635) BHS725A1 BHS725A3 BHS725A5 9 (4)

(3.6 W/cm2) 6.0 321⁄2 (826) BHS732J3 BHS732J5 12 (6)

Applications: Medium Weight Oils, Heat Transfer Oils, Liquid Paraffin

c

2

16 W/in

304 SS Plug 1.5 131⁄4 (337) BHN713E12 BHN713E13 6 (3)

3-Incoloy

(2.5 W/cm2) 2.5 201⁄4 (514) BHN720E12 BHN720E13 8 (4)

15 W/in

Steel Plug 2.0 171⁄

3-Steel 2.5 20

(2.3 W/cm

All heating elements are Assembly Stock

unless otherwise noted.

Availability

Assembly Stock: Three to five working days

Stock: Same day shipment

®

2

2

) 3.0 25 (635) BHSS25A3 BHSS25A5 9 (4)

inch (mm) 1-Phase 1-Phase 1-Phase 3-Phase 3-Phase lbs (kg)

3.0 173⁄4 (451) BHNA17N1 BHNA17N3

4 (641) BHNA25E1 BHNA25E3 BHNA25E5 9 (4)

6.0 323⁄

9.0 47

12.5 64

15.0 76

1.0 91⁄

4 (832) BHNA32N3 BHNA32N5

4 (1022) BHNA40E3 BHNA40E5 10 (5)

3

4 (1213) BHNA47N3 BHNA47N5 11 (5)

⁄

1

4 (1632) BHNA64E3 BHNA64E5 15 (7)

⁄

3

4 (1950) BHNA76E3 BHNA76E5 18 (9)

⁄

2 (241) BGS79J6 BGS79J7 4 (2)

1

⁄2 (343) BGS713J6

a

BGS713J7

a

BGS717J7 6 (3)

a

a

BHNA17N5

a

a

7 (4)

9 (4)

5 (3)

3.0 25 (635) BGS725A6 BGS725A7 7 (4)

4.0 321⁄2 (826) BGS732J6 BGS732J7 8 (4)

5.0 40 (1016) BGS740A6 BGS740A7 9 (4)

6.0 471⁄2 (1207) BGS747J7 10 (5)

1.5 91⁄2 (241) BHS79J1 BHS79J3 BHS79J13

c

a

5 (3)

7 (4)

7.5 40 (1016) BHS740A3 BHS740A5 13 (6)

9.0 471⁄2 (1207) BHS747J3 BHS747J5 13 (6)

12.5 64 (1626) BHS764A3 BHS764A5 17 (8)

1.0 93⁄4 (248) BHN79N12 BHN79N13 5 (3)

2.0 173⁄4 (451) BHN717N12 BHN717N13 7 (4)

(641) BHN725E12 BHN725E13 9 (4)

3.0 251⁄

4.0 32

5.0 40

6.0 47

1.5 131⁄

4.0 321⁄

5.0 40 (1016) BHSS40A3 BHSS40A5 13 (6)

6.0 47

7.5 58

9.0 69

4

3

(832) BHN732N12 BHN732N13 9 (4)

4

⁄

1

(1022) BHN740E12 BHN740E13 10 (5)

4

⁄

3

(1213) BHN747N12 BHN747N13 11 (5)

4

⁄

(337) BHSS13E3 BHSS13E13

4

(445) BHSS17J3 BHSS17J5 7 (4)

2

1

(521) BHSS20J3 BHSS20J5 8 (4)

2

⁄

(826) BHSS32J3 BHSS32J5 12 (6)

2

1

(1207) BHSS47J3 BHSS47J5 13 (6)

2

⁄

1

(1486) BHSS58J3 BHSS58J5 16 (8)

2

⁄

3

(1772) BHSS69N3 BHSS69N5 20 (9)

4

⁄

c

6 (4)

a Stock

c 3-phase wye only.

d Wired for higher voltage.

e 240VÅ(ac) can be wired wye and operated at 480VÅ(ac) 3-phase to produce 1⁄3

and watt density.

f Can be rewired wye to produce

1

of original kW and watt density (3-phase only).

⁄3

more kW

Screw Plug

331

Page 12

Tubular and

Process Assemblies

Screw Plug

Immersion Heaters

21⁄2" NPT Screw Plug – WATROD Element

WATROD Immersed Code No. Est. Ship.

Description kW B Dimension

inch (mm)

120VÅ(ac) 240VÅ(ac) 480VÅ(ac)

1-Phase 3-Phase 3-Phase

Applications: Deionized Water, Demineralized Water

2

60 W/in

3.0 75⁄8

316 SS Plug 4.5 10

3-316 SS 6.0 14

Passivated 7.5 175⁄8

(9.3 W/cm

2

)

9.0 205⁄8

12.0 26

15.0 315⁄8

18.0 37

(194) BLR77L1 BLR77L3 BLR77L5 6 (3)

5

(270) BLR710L1 BLR710L3 BLR710L5 7 (4)

⁄8

5

⁄8 (372) BLR714L3 BLR714L5 9 (4)

(448) BLR717L3 BLR717L5 9 (4)

(524) BLR720L3 BLR720L5 11 (5)

1

⁄8 (664) BLR726C3 BLR726C5 12 (6)

(803) BLR731L3 BLR731L5 14 (7)

1

(943) BLR737C3 BLR737C5 15 (7)

⁄8

Application: Clean Water

2

60 W/in

3.0 75⁄8 (194) BLC77L1 BLC77L3 BLC77L13 6 (3)

Brass Plug 4.5 105⁄8 (270) BLC710L1 BLC710L3 BLC710L5 7 (4)

3-Copper 6.0 145⁄8

(9.3 W/cm

2

) 7.5 175⁄8 (448) BLC717L3 BLC717L5 9 (4)

9.0 205⁄8 (524) BLC720L3 BLC720L5

12.0 261⁄8

(371) BLC714L3 BLC714L5 9 (4)

a

(664) BLC726C3 BLC726C5

a

15.0 315⁄8 (803) BLC731L3 BLC731L5 14 (7)

18.0 371⁄8

(943) BLC737C3 BLC737C5 15 (7)

Application: Process Water

2

48 W/in

3.0 93⁄8

304 SS Plug 4.5 12

3-Incoloy

®

6.0 173⁄

(7.5 W/cm2) 7.5 197⁄8 (505) BLN719R3 BLN719R5 11 (5)

9.0 247⁄8 (632) BLN724R3 BLN724R5

12.0 32

15.0 39

18.0 473⁄8 (1203) BLN747G3 BLN747G5

(238) BLN79G1 BLN79G3 BLN79G5 6 (3)

7

⁄8 (327) BLN712R1 BLN712R3 BLN712R5 7 (4)

8 (441) BLN717G3 BLN717G5

3

8 (822) BLN732G3 BLN732G5

⁄

7

⁄8 (1013) BLN739R3 BLN739R5 15 (7)

a

a

a

a

Weight

lbs (kg)

11 (5)

12 (6)

9 (4)

12 (6)

14 (7)

17 (8)

CONTINUED

All heating elements are Assembly Stock

unless otherwise noted.

Availability

Assembly Stock: Three to five working days

Stock: Same day shipment

332

➀ Stock

Page 13

W A T L O W

Tubular and

Process Assemblies

Screw Plug

Immersion Heaters

21⁄2" NPT Screw Plug – WATROD Element

WATROD Immersed Code No. Est. Ship.

Description kW B Dimension 120VÅ(ac) 240VÅ(ac) 480VÅ(ac) Weight

Applications: Forced Air and Gases, Caustic Solutions, Degreasing Solutions

ef

2

23 W/in

304 SS Plug 4.5 24

3-Incoloy

®

(3.6 W/cm2) 7.5 397⁄

Applications: Lightweight Oils, Degreasing Solutions, Heat Transfer Oils

f

2

23 W/in

Steel Plug 4.5 243⁄

3-Steel 6.0 32

(3.6 W/cm2) 7.5 393⁄4 (1010) BLS739N3 BLS739N5 15 (7)

Applications: Medium Weight Oils, Heat Transfer Oils, Liquid Paraffin

c

2

16 W/in

304 SS Plug 1.5 12

3-Incoloy

®

(2.5 W/cm2) 2.5 197⁄8

Applications: Bunker C and #6 Fuel Oils

c

2

8 W/in

Steel Plug 1.5 24

3-Steel 2.0 321⁄4 (819) BLS732E12 BLS732E13 14 (7)

(1.3 W/cm2) 2.5 393⁄

inch (mm) 1-Phase 3-Phase 3-Phase lbs (kg)

3.0 173⁄

6.0 323⁄

9.0 47

12.5 63

15.0 76

3.0 171⁄4 (438) BLS717E1 BLS717E3 BLS717E5

8 (441) BLNA17G1 BLNA17G3 BLNA17G5 9 (4)

7

⁄8 (632) BLNA24R1 BLNA24R3 BLNA24R5 12 (5)

8 (822) BLNA32G3 BLNA32G5

8 (1013) BLNA39R3 BLNA39R5 15 (7)

3

8 (1203) BLNA47G3 BLNA47G5 17 (8)

⁄

7

8 (1622) BLNA63R3 BLNA63R5 20 (9)

⁄

3

⁄8 (1940) BLNA76G3 BLNA76G5 23 (11)

4 (629) BLS724N1 BLS724N3 BLS724N5 12 (6)

1

⁄4 (819) BLS732E3 BLS732E5

a

a

a

14 (7)

9 (4)

14 (7)

9.0 471⁄4 (1200) BLS747E3 BLS747E5 17 (8)

12.5 633⁄4 (1619) BLS763N3 BLS763N5 20 (9)

15.0 761⁄4

1.0 93⁄8

(1937) BLS776E3 BLS776E5 27 (13)

(238) BLN79G12 BLN79G13 6 (3)

7

⁄8 (327) BLN712R12 BLN712R13 7 (4)

2.0 173⁄8 (441) BLN717G12 BLN717G13 9 (4)

(505) BLN719R12 BLN719R13 11 (5)

7

3.0 24

4.0 32

(632) BLN724R12 BLN724R13 12 (6)

8

⁄

3

⁄8 (822) BLN732G12 BLN732G13 14 (7)

5.0 397⁄8 (1013) BLN739R12 BLN739R13 15 (7)

(1203) BLN747G12 BLN747G13 17 (8)

6.0 473⁄

1.0 171⁄

3.0 47

4.0 633⁄

5.0 76

8

(438) BLS717E12 BLS717E13 9 (4)

4

3

⁄4 (629) BLS724N12 BLS724N13 12 (6)

(1010) BLS739N12 BLS739N13 15 (7)

4

1

⁄4 (1200) BLS747E12 BLS747E13 17 (8)

(1619) BLS763N12 BLS763N13 20 (9)

4

1

⁄4 (1937) BLS776E12 BLS776E13 23 (11)

Screw Plug

All heating elements are Assembly Stock

unless otherwise noted.

Availability

Assembly Stock: Three to five working days

Stock: Same day shipment

a Stock

c Must be operated 3-phase only.

e 240VÅ(ac) can be wired wye and operated at 480VÅ(ac) 3-phase to

produce 1⁄3 more kW and watt density.

f Can be rewired wye to produce 1⁄3 of original kW and watt density

(3-phase only).

333

Page 14

Tubular and

Process Assemblies

Screw Plug

Immersion Heaters

21⁄2" NPT Screw Plug – FIREBAR Element

FIREBAR Immersed Code No. Est. Ship.

Screw Plug

Description kW B Dimension

Immersion Heaters

inch (mm)

240VÅ(ac) 480VÅ(ac)

3-Phase 3-Phase

Applications: Clean and Potable Water

h

2

90 W/in

15 151⁄8

304 SS Plug 20 18

3-Incoloy

®

25 231⁄8 (587) BLNF23C5 14 (7)

(14 W/cm2)32285⁄

38 33

(384) BLNF15C3 BLNF15C5 10 (5)

1

8 (460) BLNF18C3 BLNF18C5

⁄

8 (727) BLNF28L5 17 (8)

5

8 (854) BLNF33L5 18 (9)

⁄

Applications: Process Water, Ethylene Glycol (50%)

45 W/in

6 12 (305) BLNF12A27 10 (5)

h

2

304 SS Plug 7.5 141⁄2 (368) BLNF14J27 11 (5)

3-Incoloy

(7 W/cm2)1221

®

9 17 (432) BLNF17A27 12 (6)

1

⁄2 (546) BLNF21J27 BLNF21J28 14 (7)

15 261⁄2 (673) BLNF26J27 BLNF26J28 17 (8)

18 311⁄

2 (800) BLNF31J27 BLNF31J28 18 (9)

24 41 (1041) BLNF41A28 20 (9)

30 50

1

⁄2 (1283) BLNF50J28 22 (10)

Applications: Cooking Oils, Ethylene Glycol (100%)

30 W/in

304 SS Plug 6.5 181⁄

3-Incoloy

®

5151⁄8 (384) BLNF15C12 BLNF15C13 10 (5)

8 (460) BLNF18C12 BLNF18C13 12 (6)

8.5 231⁄8 (587) BLNF23C12 BLNF23C13 14 (7)

c

2

(4.7 W/cm2) 10.5 285⁄8 (727) BLNF28L12 BLNF28L13 17 (8)

12.8 335⁄8 (854) BLNF33L12 BLNF33L13 18 (9)

17 441⁄8 (1121) BLNF44C12 BLNF44C13 20 (9)

5

21.5 54

⁄8 (1388) BLNF54L13 22 (10)

Applications: Heat Transfer Oils, Mineral Oils, Degreasing Solutions

h

2

23 W/in

304 SS Plug 4.9 181⁄8

3-Incoloy

®

(3.6 W/cm2) 7.9 285⁄8 (727) BLNF28L20 BLNF28L19 17 (8)

3.8 151⁄8 (384) BLNF15C20 10 (5)

(460) BLNF18C20 12 (6)

6.4 231⁄8 (587) BLNF23C20 BLNF23C19 14 (7)

9.6 335⁄8 (854) BLNF33L20 BLNF33L19 18 (9)

12.8 441⁄8 (1121) BLNF44C20 BLNF44C19 20 (9)

5

(1387) BLNF54L20 BLNF54L19 22 (10)

16.1 54

⁄8

c

CONTINUED

Weight

lbs (kg)

12 (6)

All heating elements are Assembly Stock

unless otherwise noted.

Availability

Assembly Stock: Three to five working days

Stock: Same day shipment

334

c Must be operated 3-phase only.

h Can be wired 1-phase.

Page 15

W A T L O W

Tubular and

Process Assemblies

Screw Plug

Immersion Heaters

21⁄2" NPT Screw Plug – FIREBAR Element

FIREBAR Immersed Code No. Est. Ship.

Screw Plug

Description kW B Dimension

Immersion Heaters

inch (mm)

240VÅ(ac) 480VÅ(ac)

3-Phase 3-Phase

Applications: Medium Weight Oils, Heat Transfer Oils,

Lubrication Oils, Liquid Paraffin

15 W/in

304 SS Plug 2.5 141⁄2 (368) BLNF14J29 11 (5)

3-Incoloy

(2.3 W/cm2)4211⁄2

®

2 12 (305) BLNF12A29 10 (5)

3 17 (432) BLNF17A29 12 (6)

(546) BLNF21J29 BLNF21J30 14 (7)

526

6311⁄2

8 41 (1041) BLNF41A29 BLNF41A30 20 (9)

10 50

1

⁄2 (673) BLNF26J29 BLNF26J30 17 (8)

(800) BLNF31J29 BLNF31J30 18 (9)

1

⁄2 (1283) BLNF50J29 BLNF50J30 22 (10)

c

2

Applications: Bunker C and #6 Fuel Oils, Asphalt

c

2

8 W/in

304 SS Plug 1.63 181⁄8

3-Incoloy

(1.3 W/cm2) 2.63 285⁄8 (727) BLNF28L22 BLNF28L21 17 (8)

®

1.25 151⁄8 (384) BLNF15C22 10 (5)

(460) BLNF18C22 12 (6)

2.13 231⁄8 (587) BLNF23C22 BLNF23C21 14 (7)

3.19 335⁄8 (854) BLNF33L22 BLNF33L21 18 (9)

4.25 441⁄8 (1121) BLNF44C22 BLNF44C21 20 (9)

5.38 545⁄

8 (1388) BLNF54L22 BLNF54L21 22 (10)

Weight

lbs (kg)

All heating elements are Assembly Stock

unless otherwise noted.

Availability

Assembly Stock: Three to five working days

Stock: Same day shipment

➂ Must be operated 3-phase only.

Screw Plug

335

Page 16

Tubular and

Process Assemblies

Screw Plug

Immersion Heaters

Build-a-Code

F.O.B.: Hannibal, Missouri

Stock Screw Plug Code Number

a

(Includes general purpose terminal enclosure (NEMA 1)

Optional Terminal Enclosure

S = General purpose with thermostat (NEMA 1)

W = Moisture resistant (NEMA 4)

E = Explosion resistant (NEMA 7)

E/W = Explosion/moisture resistant (NEMA 7/4)

Optional Thermostat

Optional Pilot Light

b

or Thermocouple

c

d

PL10 = 250VÅ(ac) Max.

PL11 = 480VÅ(ac) Max.

a Screw plug immersion heaters are supplied with a general purpose terminal enclosure

(NEMA 1). A thermostat will not fit inside the standard 25/

terminal enclosure. If a thermostat is required, a taller terminal enclosure will be supplied.

b Thermostat code numbers are shown in the Thermostat Stock chart on page 425.

c Pilot lights are configured for general purpose enclosure (NEMA 1) applications.

For pilot light availability with other terminal enclosure ratings, consult factory.

d Specify Type J or K thermocouple. If overtemp thermocouple specify orientation horizontal,

vertical up or vertical down.

How to Order

To order a stock screw plug heater,

please specify:

• Watlow code number

• NPT screw plug size and material

If our stock units do not meet your

application needs, Watlow can

provide made-to-order heaters.

For a made-to-order unit, please

specify:

• Application, including heated

• Volts/watts

• Phase

• Options

• Quantity

• Volts/watts

• Watt density

8 inch (67 mm) tall general purpose

material, process temperature

and flow rate, etc.

• Phase

• Screw plug size, style and

material

• Element diameter

• Number of heating element(s)

• Sheath material

• Immersed (‘B’ dimension) length

• No-heat section below the plug

• Terminal enclosure type

• Options

• Quantity

Availability

Stock: Same day shipment

Assembly Stock: Three to five

working days

➃

Modified Stock

: Five to seven

working days

Standard: 10 working days

Made-to-Order: Four to six weeks

Options, complexity and quantity

may affect availability and lead

times. Consult factory.

d Stock and assembly stock units with

catalog options.

336

Page 17

W A T L O W

Tubular and

Process Assemblies

Screw Plug

Immersion Heaters

with Control Assembly

On stock chart units:

• Five working days on all heaters

• 10 working days on special voltages

and/or wattages

• 15 working days on special element lengths

Constructed from a WATROD screw

plug heater, a moisture resistant

(NEMA 4) terminal enclosure and

built-in temperature sensor and

power control, this assembly comes

pre-wired and ready for hook-up to

any 120VÅ(ac) control circuit.

Optional sheath materials, NPT

screw plug sizes and materials,

wattages, voltages and terminal

enclosures extend application

versatility.

Performance Capabilities

• Watt densities to 60 W/in

2

(9.3 W/cm2)

• Wattages to 20kW

• Voltages to 600VÅ(ac)

• Incoloy®sheath temperatures

to 1400°F (760°C)

Features and Benefits

• Three 0.475 inch (12 mm)

diameter WATROD elements are

brazed to a two inch NPT brass

screw plug to produce a

pressure-tight seal.

• WATROD hairpins are

repressed (recompacted) after

bending to maintain MgO density,

dielectric strength, heat transfer

and life.

• Two built-in thermostats, one

on-off with manual reset, help

ensure safe operation by

automatically cycling on and

off when process or sheath

temperatures reach a

predetermined set point

selectable from 30° to 250°F

(0° to 120°C).

• Internal mechanical contactor

works on a 120VÅ(ac) control

circuit to switch higher volts/amps

to the heating elements.

WATROD Heating Element

• Hinged, moisture resistant

(NEMA 4) terminal enclosure

has two conduit openings to

3

accommodate

⁄4 inch NPT conduit

fittings.

• Terminal enclosures can be

rotated to mate with existing

conduits.

• Thermowells allow replacing the

thermostat sensing element

without draining the fluid being

heated.

2" NPT Pipe Thread

Internal

Thermostat

On-off

Manual

Reset

Thermostat

Mechanical Contactor

Applications

• Water heating

• Commercial dishwashers and

glass washers

• Sterilizing equipment

Construction Features

Same as Screw Plug Immersion

Heaters. See pages 321 to 322 for

details.

Application Hints

Same as Screw Plug Immersion

Heaters. See page 326 for details.

Accessories

Clamping Nut, Gasket and Washers–

for mounting to thin-wall tanks, use

optional clamping nut, gasket and

washers. To order, specify NGW.

337

Screw Plug

Page 18

Tubular and

Process Assemblies

Screw Plug

Immersion Heaters

with Control Assembly

Incoloy® Sheath

Conduit Openings

3

for

/4" NPT

2" NPT Brass Plug

B

Immersed Length

1

"

2

/4

(57 mm)

1

"

4

/4

(108 mm)

"

10

(250 mm)

2" NPT Brass Screw Plug With Control Box (Assembly Stock)

WATROD Immersed Code Number Est.Net

Descript. kW Length

Inch (mm)

2

50 W/in

Brass Plug 12 30 (762) BHNB30A2W2C11BHNB30A3W2C11 BHNB30A8W2C11 BHNB30A5W2C11 BHNB30A16W2C11 24 (11)

3-Incoloy®16 355⁄

(7.8 W/cm

9243⁄4 (629) BHNB24N3W2C11 BHNB24N5W2C11 BHNB24N16W2C11 23 (10)

2

)20 455⁄8 (1159) BHNB45L3W2C11 BHNB45L8W2C11 BHNB45L5W2C11 BHNB45L16W2C11 27 (12)

8 (905) BHNB35L2W2C11 BHNB35L3W2C11 BHNB35L8W2C11 BHNB35L5W2C11 BHNB35L16W2C11 25 (11)

How to Order

To order an Assembly Stock unit,

please specify:

• Watlow code number

• Volts/watts

• Options, if applicable

• Quantity

208VÅ(ac) 240VÅ(ac) 380VÅ(ac) 480VÅ(ac) 575VÅ(ac)

3-Phase 3-Phase 3-Phase 3-Phase 3-Phase

If our assembly stock units do not

meet your application needs,

Watlow can provide made-to-order

assemblies. For made-to order units,

please specify:

• Volts/watts

• Phase

• Screw plug size and materials

• Number of elements

• Sheath material

• Immersed (‘B’ dimension) length

• No-heat section below the plug

• Options

Availability

Assembly Stock: Five working days

Modified Stocka: Five to seven

working days

Made-to-Order: Four to six weeks

Options, complexity and quantity

may affect availability and lead

times. Consult factory.

Replacement Heater Only

To order a replacement screw plug

heater, simply delete the last five

characters from the original Screw

Plug Immersion with Control

Assembly base code number.

Weight

lbs (kg)

• Quantity

a Assembly Stock units with catalog options.

338

Loading...

Loading...