Page 1

W A T L O W

99

RTDs and Thermistors

RTDs and

Thermistors

Resistance

Temperature Sensing

RTDs

Watlow’s platinum resistance

elements are specially designed to

ensure precise and repeatable

temperature versus resistance

characteristics. The sensors are

made with controlled purity platinum,

have high purity ceramic components

and constructed in a unique strainfree manner.

Performance Capabilities

• Ceramic elements are extremely

precise and stable within the wide

temperature range of -200 to 650°C

(-328 to1200°F).

Features and Benefits

Patented, strain-free construction

• Provides dependable, accurate

readings

• Allows elements from different lots

to be substituted without

recalibration

High signal-to-noise output

• Increases accuracy of data

transmission

• Permits greater distances between

sensor and measuring equipment

Temperature coefficient (alpha)

carefully controlled while

insulation resistance values

exceed DIN-IEC-751 standards

• Ensures sensor sensitivity

• Minimizes self heating

• Allows precise measurement

• Repeatable

Highly controlled manufacturing

process

• Ensures wide temperature range

• Stabilizes physical and chemical

attributes

Metric diameters and fittings are

available, please consult factory

Applications

• Air conditioning and refrigeration

servicing

• Furnace servicing

• Stoves and grills

• Textile production

• Plastics processing

• Petrochemical processing

• Micro electronics

• Air, gas and liquid temperature

measurement

• Exhaust gas temperature

measurement

Page 2

W A T L O W

105

RTDs and

Thermistors

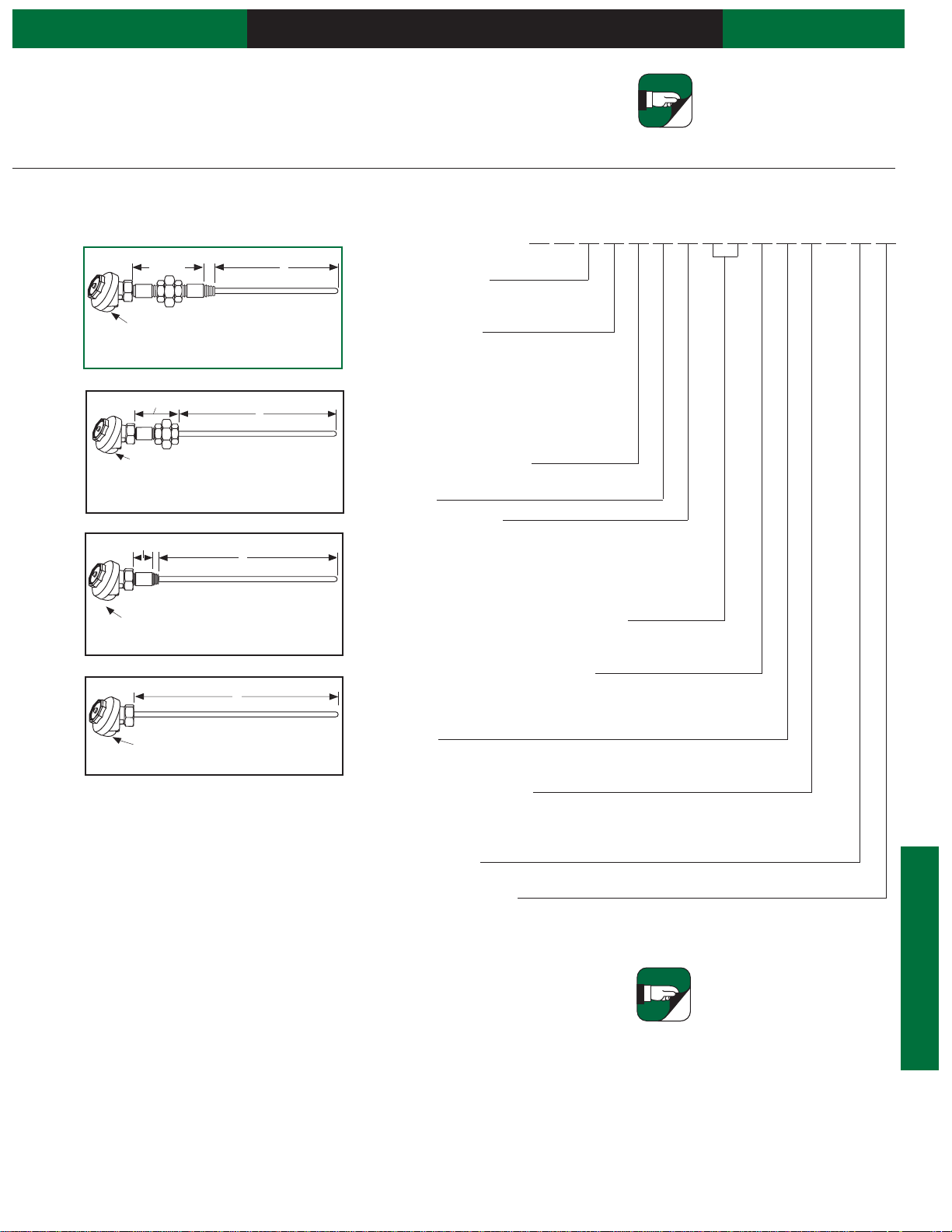

RTD Style RT

For Use with Thermowells

a

Units with transmitter, buyer to specify

range and degree C or F, as well as

temperature span.

b

Other sizes, lengths and materials available.

Consult factory.

Features and Benefits

High quality thermowells and pipe

wells

• Protect sensor

Mineral insulated construction

• Available in 0.125 to 0.250 inch

O.D.

Available with spring-loading

• Ensures positive contact

Complete assembly available

• Head mounted 4-20mA

transmitter, two- or three-wire

input and non-isolated

Variety of connection head options

• Meet your application

requirements

6 inch N-U-N Typical (2 each 1⁄2 X 3 inch steel

pipe nipples and 1 each malleable union)

4 inch N-U typical (1 each

1

⁄2 X 3 inch steel pipe

nipple and 1 each malleable union)

3

/4

in. (19 mm) NPT

Nom. 4 in. (152.4 mm)

L

1

⁄2 X 3 inch long steel pipe nipple typical

3

/4

in. (19 mm)

NPT

Nom. 2 in. (50.8 mm)

L

3

/4

in. (19 mm)

NPT

L

3. Sheath O.D. (inch)

G = 0.125 J = 0.250

H = 0.188

4. Connection Head

C = Polypropylene

D = Cast iron

E = Cast aluminum

H = Explosion proof

Ua= E head with 5750 transmitter

Va= C head with 5750 transmitter

Wa= H head with 5750 transmitter

5. Cold End Configuration

b

Type 1 Type 2 Type 3 Type 4

6. Enter “0”

7. Sheath Construction

-50 to 260°C -200 to 650°C

(-58 to 500°F) (-328 to 1200°F)

316 SS 316 SS

Standard Industrial A —

Mineral Insulated — K

8-9. Sheath Length “L” (see drawings at left)

When ordering a complete assembly with thermowell, specify “AR”

as required. Otherwise, specify the “L” dimension in whole inches.

10. Sheath Length “L” (fractional inch)

0 = No fraction, whole inches

1=

1

⁄8 3=3⁄8 5=5⁄8 7=7⁄8

2=1⁄4 4=1⁄2 6=3⁄4

11. Element

2-wire 3-wire 4-wire

100Ω Single A B C

12. Temperature Coefficient

DIN 0.00385

A = Class A

B = Class B

14. Spring-Loading

Y = Yes N= No

15. Special Requirements

0 = None

X = Special requirements, consult factory

RT 0 0

123456789101112131415

For further details on

Watlow connection heads

see the hardware section

of this catalog, pages

156 to 157.

For a complete RTD assembly, add thermowell part

number. See thermowell

section, pages 144 to 146.

3

/4

in. (19 mm) NPT

Nom. 6 in.

(152.4 mm)

L

Custom Ordering Information—Items in Bolded Green Type are preferred

with shorter lead times.

Type 1

Type 2

Type 3

Type 4

RTDs and Thermistors

Loading...

Loading...