Page 1

Relay Interface Board

User’s Guide

Watlow Controls

1241 Bundy Blvd.

Winona, MN 55987

Customer Service

Phone: (800) 414-4299

Fax: (800) 445-8992

Technical Support

Phone: (507) 494-5656

Fax: (507) 452-4507

Email: wintechsupport@watlow.com

Doc. No. 22822-00. Revision 2.1

June 1998

Page 2

Warranty

Watlow Anafaze, Incorporated warrants that the products furnished under this

Agreement will be free from defects in material and workmanship for a period of

three years from the date of shipment. The customer shall provide notice of any

defect to Watlow Anafaze, Incorporated within one week after the Customer's

discovery of such defect. The sole obligation and liability of Watlow Anafaze,

Incorporated under this warranty shall be to repair or replace, at its option and

without cost to the Customer, the defective product or part.

Upon request by Watlow Anafaze, Incorporated, the product or part claimed to be

defective shall immediately be returned at the Customer's expense to Watlow

Anafaze, Incorporated. Replaced or repaired products or parts will be shipped to the

Customer at the expense of Watlow Anafaze, Incorporated.

There shall be no warranty or liability for any products or parts that have been

subject to misuse, accident, negligence, failure of electric power or modification by

the Customer without the written approval of Watlow Anafaze, Incorporated. Final

determination of warranty eligibility shall be made by Watlow Anafaze,

Incorporated. If a warranty claim is considered invalid for any reason, the Customer

will be charged for services performed and expenses incurred by Watlow Anafaze,

Incorporated in handling and shipping the returned unit.

Page 3

If replacement parts are supplied or repairs made during the original warranty period,

the warranty period for the replacement or repaired part shall terminate with the

termination of the warranty period of the original product or part.

The foregoing warranty constitutes the sole liability of Watlow Anafaze,

Incorporated and the customer's sole remedy with respect to the products. It is in lieu

of all other warranties, liabilities, and remedies. Except as thus provided, Watlow

Anafaze, Inc. disclaims all warranties, express or implied, including any warranty of

merchantability or fitness for a particular purpose.

Page 4

Page 5

Relay Interface Board Installation Guide

Relay Interface Board Installation Guide

Introduction

The Relay Interface Board (RIB) replaces the standard I/O terminal board. It connects a Watlow Anafaze controller to a third-party I/O board with 8, 16, 24, or 32

relays.

This document lists system requirements, specifications and explains how to install

and wire the RIB.

1

Page 6

Relay Interface Board Installation Guide

System Requirements

Choose which of the controller’s digital inputs and outputs are needed. Refer to

Table 3 and 4

for a 32-module I/O board. An 8-module I/O board contains the first eight modules

of the 24-module board, a 16-module board contains the first 16 modules of the 24module board, etc.

8, 16 and 24-module I/O boards are connected to J2 and J3 on the RIB.

•

32-module boards connect to J4 only.

•

The system safe and global alarm outputs are available via J2 and TB1 only. To connect to all of the digital inputs and outputs, use two 24-module boards.

A 32-module board connected to J4 provides outputs for 32 heat-only loops or for 16

heat/cool loops.

MLS300 and CLS200 controllers have a 50-pin, SCSI-II, female connector for digital I/O. You will have to make or obtain from Watlow Anafaze a cable that connects

from SCSI to ribbon cable in order to use the RIB with these controllers.

for connections for 24-module I/O boards or

Tabl e 5

for connections

2

Page 7

Hardware Requirements

Relay Interface Board Installation Guide

Choose I/O modules designed to operate with +5 Vdc power. Watlow Anafaze

systems are designed to operate at this voltage.

Choose I/O boards which have 50-pin headers with long latch levers. Short latch

levers will not Watlow Anafaze cables.

Calculate the maximum current requirement of the desired I/O boards. If they require

more current than the controller can supply, use an external power supply.

3

Page 8

Relay Interface Board Installation Guide

Installation

These instructions assume the controller has previously been installed.

Tools Needed

Mounting

4

Four, #6 screws

Screwdriver

1. Choose a mounting location large enough to accommodate the RIB, the I/O

board or boards, the ribbon cable or cables and wires that connect them.

2. Place the RIB in a suitable location to be mounted and use a pencil to trace

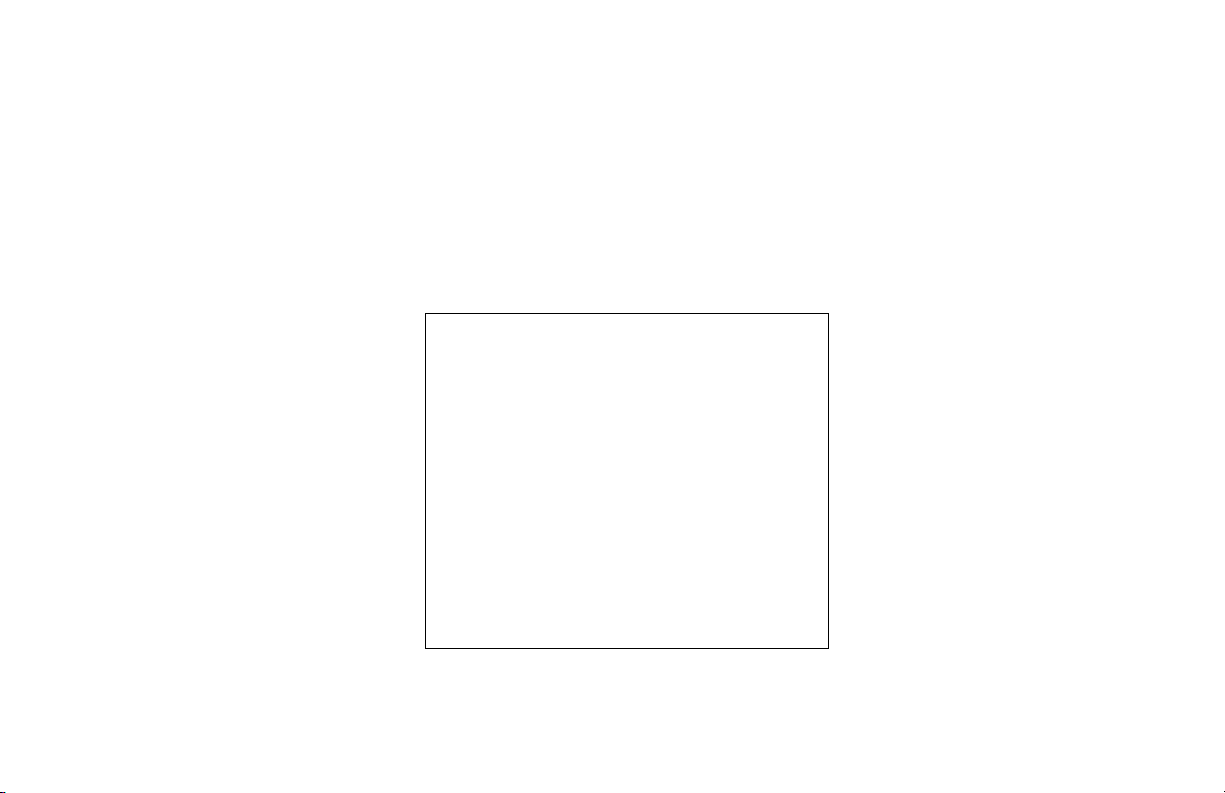

around the plastic standoffs or use the dimension diagram in Figure 1 to position the mounting holes.

3. Drill and tap #6-32 holes in the marked locations.

4. Place the Relay Interface Board in the mounting location and insert the #6

screws in the plastic standoffs.

5. Tighten the screws.

Page 9

Relay Interface Board Installation Guide

Figure 1 Relay Interface

Board

6.25"

(159 mm)

5.75"

(145 mm)

3.0"

(76 mm)

3.5"

(89 mm)

5

Page 10

Relay Interface Board Installation Guide

Wiring

These instructions explain how to connect the RIB to the Watlow Anafaze Controller

and to the I/O board.

Ribbon Cable

I/O Board Terminals

6

Connect the ribbon cable to the controller. Plug the other end of the ribbon cable into

the header labeled J1 on the Relay Interface Board. The red stripe on the ribbon cable

should line up with Pin 1 on the board.

Plug one end of the I/O board ribbon cable into the I/O board and the other end into

the RIB. See Tables 3, 4 and 5 for connection information. Repeat for each I/O board

installation.

Use a felt-tip pen to write the cable’s name and number in the white box next to the

header.

Refer to Tables 3, 4 and 5 for the controller signals that correspond to each I/O

module.

Page 11

Relay Interface Board Installation Guide

Power Connections

Choose one of the following options for installing and configuring the jumper on

JU1 appropriately for your I/O board.

•

Option 1: 8, 16, and 24-module I/O boards only:

get power from the controller to the I/O boards via the ribbon cable.

•

Option 2: 8, 16 and 24-module I/O boards only:

disconnect the controller power supply. Jumper the I/O boards to get power from

the ribbon cable. Use an external power supply to provide power to TB1. This

arrangement powers the I/O boards through their ribbon cables.

•

Option 3: For any I/O board:

an external power supply. Then connect power from TB1 to the terminals on the

I/O board.

•

Option 4: For any I/O board:

ply. Wire an external power supply directly to the terminals on the I/O board.

Jumper JU1 in position A. Set the I/O board for

Jumper the I/O board for an external power sup-

Jumper JU1 in position A to

Jumper JU1 in position B to

7

Page 12

Relay Interface Board Installation Guide

Additional Terminals

Jumpers

The Relay Interface Board contains a 5-pin terminal block (TB1) with these

functions:

TABLE 1. TB1 Functions

TB1 Function

1 +5 Vdc power

2 Power common

3 Global alarm output

4 CPU Watchdog output

5 Pulse input

These terminals are directly connected to the controller. They allow connection to

separate sensors, SSRs, PLCs and safety controls.

The RIB has three sets of jumpers: JU1, JU2 and JU3. JU2 and JU3 only affect the

I/O board connect to J2.

The jumpers let you choose between options listed in Table 2 .

8

Page 13

Relay Interface Board Installation Guide

TABLE 2. Jumper Positions

Jumper Jumper Position A Jumper Position B

JU1 Controller supplies

+5 Vdc to power both

24-module I/O boards.

TB1 terminal 1 can

supply power to a

32-module I/O board.

JU2 Module 3 (on the I/O

board connected to

connector J2) is connected to the controller’s digital input 1. The

module should be an

input module.

JU3 Module 2 (on the I/O

board connected to connector J2) is connected

to the controller’s pulse

input. The module

should be an input

module.

Controller power supply

is disconnected. TB1

terminal 1 can connect

+5 Vdc power from an

external supply to both

24-module I/O boards.

Module 3 (on the I/O

board connected to connector J2 is connected

to controller digital output 34. The module

should be an output

module.

Module 2 (on the I/O

board connected to connector J2) is connected

to the controller’s digital

input 2. The module

should be an input

module.

Jumper Position C

(JU3 only)

Module 2 (on the I/O

board connected to

connector J2) is connected to the controller’s digital output 33.

The module should be

an output module.

9

Page 14

Relay Interface Board Installation Guide

Applying Power

After wiring the I/O board modules and selecting the appropriate jumper positions,

power may be connected to the system.

If power is present at the RIB, the green LED labeled RLY PWR will light.

Testing Your System

Test the system after connecting power. For specific information on testing

controllers, refer to your controller manual.

To test a PID control output, set the appropriate loop to Manual mode and set the

•

output to 100%. The LED located on or next to the output module will light.

To test digital alarms, outputs and inputs, use the controller’s Manual I/O Test

•

menus.

10

Page 15

Relay Interface Board Installation Guide

Controller Connections

Tables 3, 4 and 5 describe connections for Watlow Anafaze controllers with the RIB.

TABLE 3. 24 I/O Rack #1 (J2)

Module # Controller Function CLS204-4CLS CLS208-8CLS CLS216-16CLS MLS316-16MLS MLS332-32MLS

0 CPU Watchdog CPU Watchdog CPU Watchdog CPU Watchdog CPU Watchdog CPU Watchdog

1 Global Out Global Out Global Out Global Out Global Out Global Out

2 (JU3-C)

2 (JU3-B)

2 (JU3-A)

3 (JU2-B)

3 (JU2-A)

1

1

1

2

2

4 Dig Out 1 Loop 1 Heat Loop 1 Heat Loop 1 Heat Loop 1 Heat Loop 1 Heat

Dig Out 33 Dig Out 33 Dig Out 33 Loop 16 Cool Dig Out 33 Pulse Loop Heat

Dig Input 2 Dig Input 2 Dig Input 2 Dig Input 2 Dig Input 2 Dig Input 2

Pulse Input Pulse Input Pulse Input Pulse Input Pulse Input Pulse Input

Dig Out 34 Dig Out 34 Dig Out 34 Pulse Loop Cool Dig Out 34 Dig Out 34

Dig Input 1 Dig Input 1 Dig Input 1 Dig Input 1 Dig Input 1 Dig Input 1

1

The function of module 2 depends on the setting of jumper JU3.

2

The function of module 3 depends on the setting of jumper JU2.

11

Page 16

Relay Interface Board Installation Guide

TABLE 3. 24 I/O Rack #1 (J2)

Module # Controller Function CLS204-4CLS CLS208-8CLS CLS216-16CLS MLS316-16MLS MLS332-32MLS

5 Dig Out 2 Loop 2 Heat Loop 2 Heat Loop 2 Heat Loop 2 Heat Loop 2 Heat

6 Dig Out 3 Loop 3 Heat Loop 3 Heat Loop 3 Heat Loop 3 Heat Loop 3 Heat

7 Dig Out 4 Loop 4 Heat Loop 4 Heat Loop 4 Heat Loop 4 Heat Loop 4 Heat

8 Dig Out 5 Pulse Loop Heat Loop 5 Heat Loop 5 Heat Loop 5 Heat Loop 5 Heat

9 Dig Out 6 Loop 1 Cool Loop 6 Heat Loop 6 Heat Loop 6 Heat Loop 6 Heat

10 Dig Out 7 Loop 2 Cool Loop 7 Heat Loop 7 Heat Loop 7 Heat Loop 7 Heat

11 Dig Out 8 Loop 3 Cool Loop 8 Heat Loop 8 Heat Loop 8 Heat Loop 8 Heat

12 Dig Out 9 Loop 4 Cool Pulse Loop Heat Loop 9 Heat Loop 9 Heat Loop 9 Heat

13 Dig Out 10 Pulse Loop Cool Loop 1 Cool Loop 10 Heat Loop 10 Heat Loop 10 Heat

14 Dig Out 11 Dig Out 11 Loop 2 Cool Loop 11 Heat Loop 11 Heat Loop 11 Heat

15 Dig Out 12 Dig Out 12 Loop 3 Cool Loop 12 Heat Loop 12 Heat Loop 12 Heat

16 Dig Out 13 Dig Out 13 Loop 4 Cool Loop 13 Heat Loop 13 Heat Loop 13 Heat

17 Dig Out 14 Dig Out 14 Loop 5 Cool Loop 14 Heat Loop 14 Heat Loop 14 Heat

18 Dig Out 15 Dig Out 15 Loop 6 Cool Loop 15 Heat Loop 15 Heat Loop 15 Heat

19 Dig Out 16 Dig Out 16 Loop 7 Cool Loop 16 Heat Loop 16 Heat Loop 16 Heat

20 Dig Out 17 Dig Out 17 Loop 8 Cool Pulse Loop Heat Loop 1 Cool Loop 17 Heat/

Loop 1 Cool

12

Page 17

Relay Interface Board Installation Guide

TABLE 3. 24 I/O Rack #1 (J2)

Module # Controller Function CLS204-4CLS CLS208-8CLS CLS216-16CLS MLS316-16MLS MLS332-32MLS

21 Dig Out 18 Dig Out 18 Pulse Loop Cool Loop 1 Cool Loop 2 Cool Loop 18 Heat/

Loop 2 Cool

22 Dig Out 19 Dig Out 19 Dig Out 19 Loop 2 Cool Loop 3 Cool Loop 19 Heat/

Loop 3 Cool

23 Dig Out 20 Dig Out 20 Dig Out 20 Loop 3 Cool Loop 4 Cool Loop 20 Heat/

Loop 4 Cool

13

Page 18

Relay Interface Board Installation Guide

TABLE 4. 24 I/O Rack #2 (J3)

Module # Controller Function CLS204-4CLS CLS208-8CLS CLS216-16CLS MLS316-16MLS MLS332-32MLS

0 Dig Out 21 Dig Out 21 Dig Out 21 Loop 4 Cool Loop 5 Cool Loop 21 Heat/

Loop 5 Cool

1 Dig Out 22 Dig Out 22 Dig Out 22 Loop 5 Cool Loop 6 Cool Loop 22 Heat/

Loop 6 Cool

2 Dig Out 23 Dig Out 23 Dig Out 23 Loop 6 Cool Loop 7 Cool Loop 23 Heat/

Loop 7 Cool

3 Dig Out 24 Dig Out 24 Dig Out 24 Loop 7 Cool Loop 8 Cool Loop 24 Heat/

4 Dig Out 25 Dig Out 25 Dig Out 25 Loop 8 Cool Loop 9 Cool Loop 25 Heat/

5 Dig Out 26 Dig Out 26 Dig Out 26 Loop 9 Cool Loop 10 Cool Loop 26 Heat/

6 Dig Out 27 Dig Out 27 Dig Out 27 Loop 10 Cool Loop 11 Cool Loop 27 Heat/

7 Dig Out 28 Dig Out 28 Dig Out 28 Loop 11 Cool Loop 12 Cool Loop 28 Heat/

8 Dig Out 29 Dig Out 29 Dig Out 29 Loop 12 Cool Loop 13 Cool Loop 29 Heat/

9 Dig Out 30 Dig Out 30 Dig Out 30 Loop 13 Cool Loop 14 Cool Loop 30 Heat/

Loop 8 Cool

Loop 9 Cool

Loop 10 Cool

Loop 11 Cool

Loop 12 Cool

Loop 13 Cool

Loop 14 Cool

14

Page 19

Relay Interface Board Installation Guide

TABLE 4. 24 I/O Rack #2 (J3)

Module # Controller Function CLS204-4CLS CLS208-8CLS CLS216-16CLS MLS316-16MLS MLS332-32MLS

10 Dig Out 31 Dig Out 31 Dig Out 31 Loop 14 Cool Loop 15 Cool Loop 31 Heat/

Loop 15 Cool

11 Dig Out 32 Dig Out 32 Dig Out 32 Loop 15 Cool Loop 16 Cool Loop 32 Heat/

Loop 16 Cool

12 Dig Out 33 Dig Out 33 Dig Out 33 Loop 16 Cool Dig Out 33 Pulse Loop Heat

13 Dig Out 34/

SDAC Clock

14 Dig Input 2 Dig Input 2 Dig Input 2 Dig Input 2 Dig Input 2 Dig Input 2

15 Dig Input 3 Dig Input 3 Dig Input 3 Dig Input 3 Dig Input 3 Dig Input 3

16 Dig Input 4 Dig Input 4 Dig Input 4 Dig Input 4 Dig Input 4 Dig Input 4

17 Dig Input 5 Dig Input 5 Dig Input 5 Dig Input 5 Dig Input 5 Dig Input 5

18 Dig Input 6 Dig Input 6 Dig Input 6 Dig Input 6 Dig Input 6 Dig Input 6

19 Dig Input 7 Dig Input 7 Dig Input 7 Dig Input 7 Dig Input 7 Dig Input 7

20 Dig Input 8 Dig Input 8 Dig Input 8 Dig Input 8 Dig Input 8 Dig Input 8

Dig Out 34/

SDAC Clock

Dig Out 34/

SDAC Clock

Pulse Loop Cool/

SDAC Clock

Dig Out 34/

SDAC Clock

Dig Out 34/

SDAC Clock

15

Page 20

Relay Interface Board Installation Guide

TABLE 5.

32 I/O Rack (J4)

Module # Controller Function CLS204-4CLS CLS208-8CLS CLS216-16CLS MLS316-16MLS MLS332-32MLS

0 Dig Out 1 Loop 1 Heat Loop 1 Heat Loop 1 Heat Loop 1 Heat Loop 1 Heat

1 Dig Out 2 Loop 2 Heat Loop 2 Heat Loop 2 Heat Loop 2 Heat Loop 2 Heat

2 Dig Out 3 Loop 3 Heat Loop 3 Heat Loop 3 Heat Loop 3 Heat Loop 3 Heat

3 Dig Out 4 Loop 4 Heat Loop 4 Heat Loop 4 Heat Loop 4 Heat Loop 4 Heat

4 Dig Out 5 Pulse Loop Heat Loop 5 Heat Loop 5 Heat Loop 5 Heat Loop 5 Heat

5 Dig Out 6 Loop 1 Cool Loop 6 Heat Loop 6 Heat Loop 6 Heat Loop 6 Heat

6 Dig Out 7 Loop 2 Cool Loop 7 Heat Loop 7 Heat Loop 7 Heat Loop 7 Heat

7 Dig Out 8 Loop 3 Cool Loop 8 Heat Loop 8 Heat Loop 8 Heat Loop 8 Heat

8 Dig Out 9 Loop 4 Cool Pulse Loop Heat Loop 9 Heat Loop 9 Heat Loop 9 Heat

9 Dig Out 10 Pulse Loop Cool Loop 1 Cool Loop 10 Heat Loop 10 Heat Loop 10 Heat

10 Dig Out 11 Dig Out 11 Loop 2 Cool Loop 11 Heat Loop 11 Heat Loop 11 Heat

11 Dig Out 12 Dig Out 12 Loop 3 Cool Loop 12 Heat Loop 12 Heat Loop 12 Heat

12 Dig Out 13 Dig Out 13 Loop 4 Cool Loop 13 Heat Loop 13 Heat Loop 13 Heat

13 Dig Out 14 Dig Out 14 Loop 5 Cool Loop 14 Heat Loop 14 Heat Loop 14 Heat

14 Dig Out 15 Dig Out 15 Loop 6 Cool Loop 15 Heat Loop 15 Heat Loop 15 Heat

15 Dig Out 16 Dig Out 16 Loop 7 Cool Loop 16 Heat Loop 16 Heat Loop 16 Heat

16 Dig Out 17 Dig Out 17 Loop 8 Cool Pulse Loop Heat Loop 1 Cool Loop 17 Heat/

Loop 1 Cool

16

Page 21

Relay Interface Board Installation Guide

Module # Controller Function CLS204-4CLS CLS208-8CLS CLS216-16CLS MLS316-16MLS MLS332-32MLS

17 Dig Out 18 Dig Out 18 Loop 2 Cool Pulse Loop Cool Loop 2 Cool Loop 18 Heat/

Loop 2 Cool

18 Dig Out 19 Dig Out 19 Dig Out 19 Loop 2 Cool Loop 3 Cool Loop 19 Heat/

Loop 3 Cool

19 Dig Out 20 Dig Out 20 Dig Out 20 Loop 3 Cool Loop 4 Cool Loop 20 Heat/

Loop 4 Cool

20 Dig Out 21 Dig Out 21 Dig Out 21 Loop 4 Cool Loop 5 Cool Loop 21 Heat/

Loop 5 Cool

21 Dig Out 22 Dig Out 22 Dig Out 22 Loop 5 Cool Loop 6 Cool Loop 22 Heat/

Loop 6 Cool

22 Dig Out 23 Dig Out 23 Dig Out 23 Loop 6 Cool Loop 7 Cool Loop 23 Heat/

Loop 7 Cool

23 Dig Out 24 Dig Out 24 Dig Out 24 Loop 7 Cool Loop 8 Cool Loop 24 Heat/

Loop 8 Cool

24 Dig Out 25 Dig Out 25 Dig Out 25 Loop 8 Cool Loop 9 Cool Loop 25 Heat/

Loop 9 Cool

25 Dig Out 26 Dig Out 26 Dig Out 26 Loop 9 Cool Loop 10 Cool Loop 26 Heat/

Loop 10 Cool

26 Dig Out 27 Dig Out 27 Dig Out 27 Loop 10 Cool Loop 11 Cool Loop 27 Heat/

Loop 11 Cool

27 Dig Out 28 Dig Out 28 Dig Out 28 Loop 11 Cool Loop 12 Cool Loop 28 Heat/

Loop 12 Cool

17

Page 22

Relay Interface Board Installation Guide

Module # Controller Function CLS204-4CLS CLS208-8CLS CLS216-16CLS MLS316-16MLS MLS332-32MLS

28 Dig Out 29 Dig Out 29 Dig Out 29 Loop 12 Cool Loop 13 Cool Loop 29 Heat/

Loop 13 Cool

29 Dig Out 30 Dig Out 30 Dig Out 30 Loop 13 Cool Loop 14 Cool Loop 30 Heat/

Loop 14 Cool

30 Dig Out 31 Dig Out 31 Dig Out 31 Loop 14 Cool Loop 15 Cool Loop 31 Heat/

Loop 15 Cool

31 Dig Out 32 Dig Out 32 Dig Out 32 Loop 15 Cool Loop 16 Cool Loop 32 Heat/

Loop 16 Cool

18

Loading...

Loading...