Page 1

PPC-2000

User’s Guide

WATLOW

1241 Bundy Boulevard

Winona, Minnesota USA 55987

Phone: +1 (507) 454-5300,

Fax: +1 (507) 452-4507

Part No. 0600-3000-2000 Rev 2.3d

http://www.watlow.com

Page 2

Page 3

PPC-2000 Adaptive Control

Addendum

Scope

This document describes the additional features and functionality found

in the PPC-2010-xxB with adaptive control. Refer to the PPC-2000

User’s Guide regarding all other functionality which is the same as the

standard version.

Introduction

The Watlow Anafaze PPC-2000 controller offers these standard options:

• Forty-eight loops of conventional PID control with auto-tuning

capability

-or-

• Eight loops of adaptive control plus 24 loops of conventional PID

control with auto-tuning for a total of 32 loops (the option described

in this document)

ANAWIN3 HMI software is available to support either option. A mix of

these options is not supported by ANAWIN3.

ANAWIN3 Software Installation

Follow the standard instructions to install and setup ANAWIN3. In the

setup program select the Adaptive Control option.

Spreadsheet Overview Screen

Several new parameters and options appear on the Spreadsheet Overview

screen in support of the adaptive control option. These parameters and

options are applicable only for the first eight channels and are omitted or

ignored for channels 9 to 32.

Control Type

An additional option appears for Control Type. Select Adaptive to enable

adaptive control and tuning on a channel. This option is only valid for

channels 1 to 8.

Values: PID1 (0), PID2 (1), Adaptive (2) and Retransmit (3)

Default: PID1 (0)

Modbus Address (Channels 1 to 32): 46401 to 46432

Parameter Number: 19

LogicPro Driver: Database

LogicPro Address (Channels 1 to 32): 19.1 to 19.32

Adaptive Addendum PPC-2000 User's Guide

0600-0049-0001 rev C Watlow Anafaze 1

Page 4

Adaptive Mode

When Control Type is set to Adaptive, this parameter can be used to

pause tuning or to reset the adaptive algorithm and have it relearn the

system. This parameter has no effect on control if the Control Type for

the loop is set to an option other than Adaptive.

Values: Adapt (0), Reset (1) and Hold (2)

Default: Reset (1)

Modbus Address (Channels 1 to 32): 49001 to 49032

Parameter Number: 21

LogicPro Driver: Database

LogicPro Address (Channels 1 to 32): 21.1 to 21.32

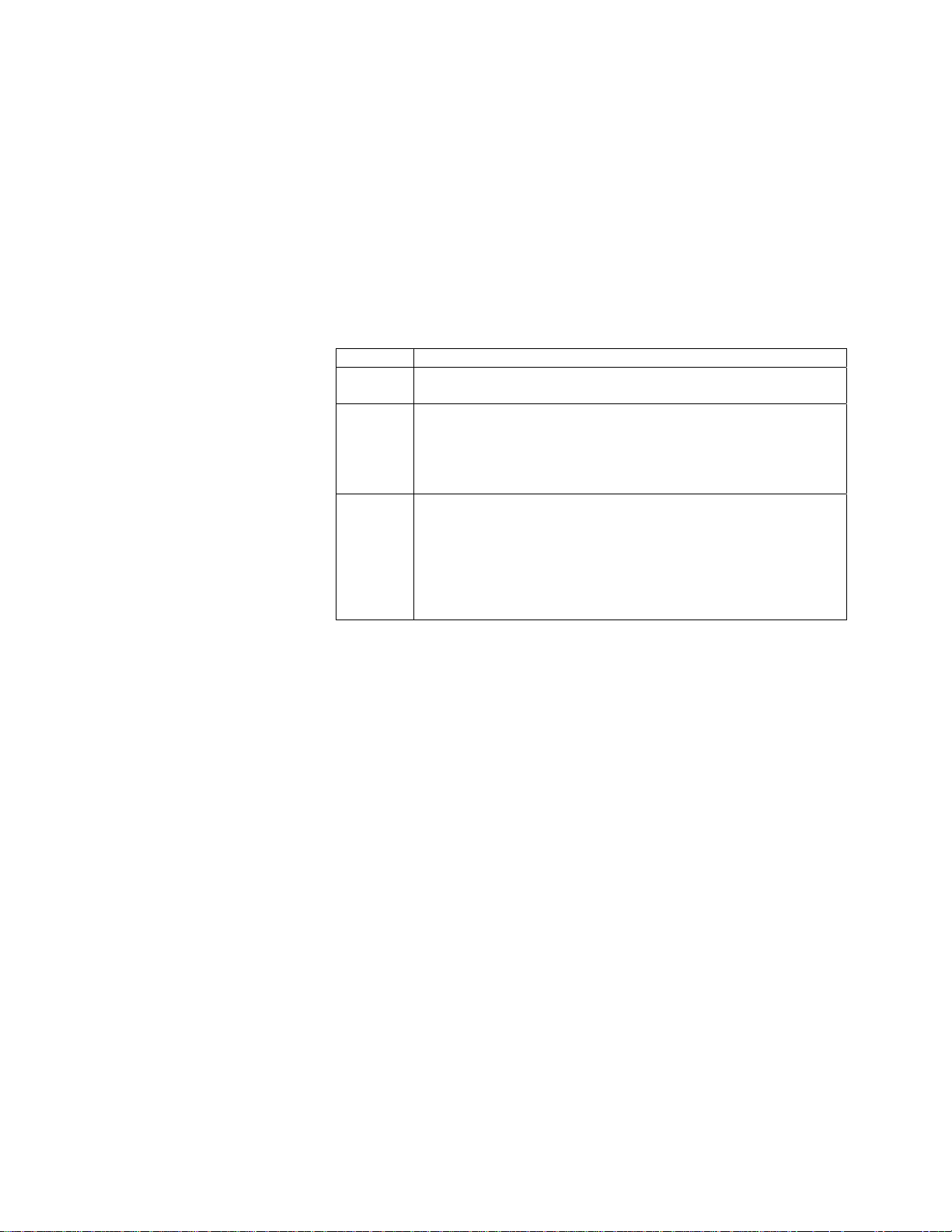

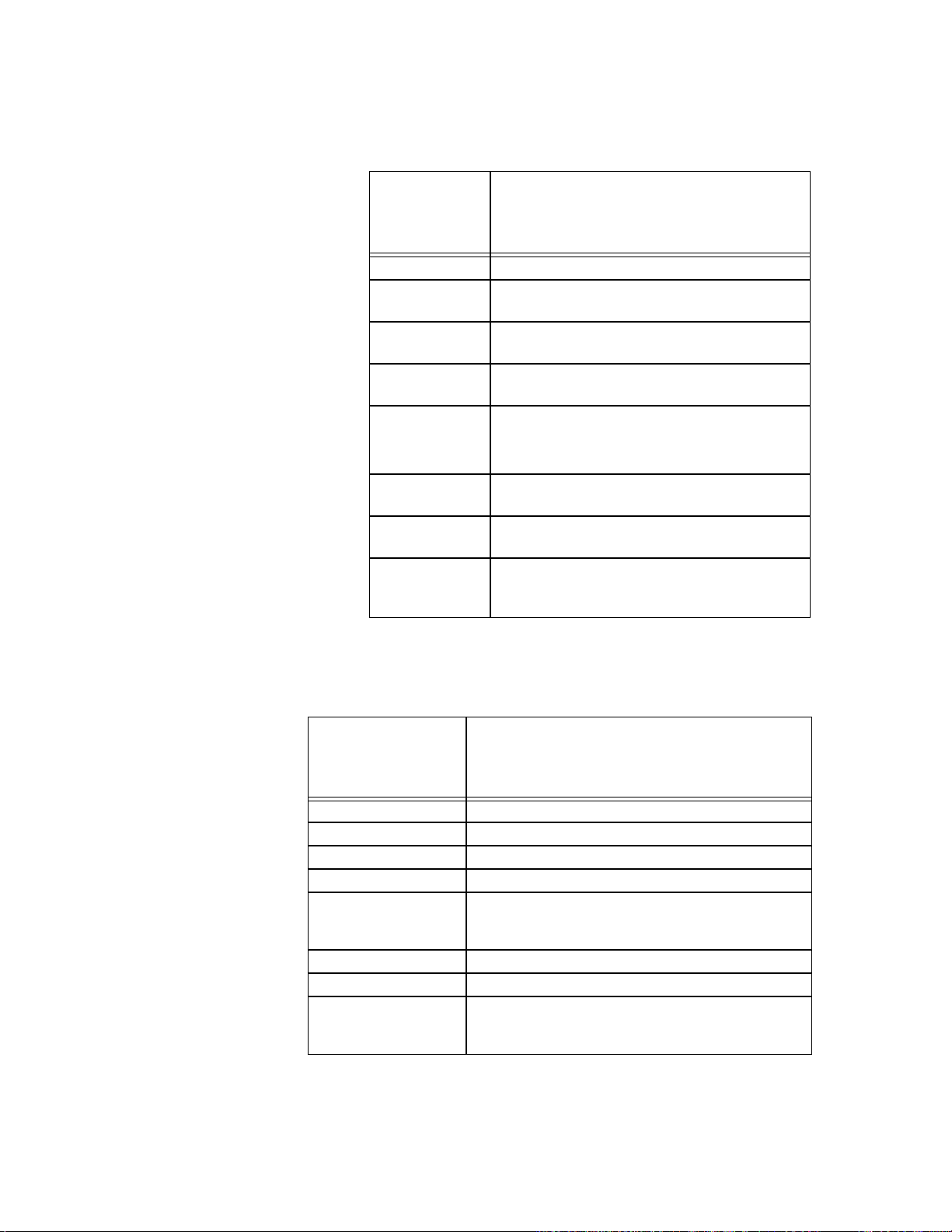

Table 1. Adaptive Mode Settings

Setting Description

Adapt The normal setting for a loop with Control Type set to

Adaptive. The loop is adapting and tuning while controlling.

Reset Select this option to have the control loop start from scratch

and relearn the load characteristics. The Control Mode must

be set to Off or Manual to select this option for an adaptive

loop. This is the normal setting for a loop with Control Type

set to a value other than Adaptive.

Hold Select this option to have the control loop stop learning

temporarily but retain the learned load characteristics. For

example in the event that maintenance will be performed, it

may be advantageous to pause adapting to avoid false data

being introduced. Select this option anytime you want the

controller to stop adapting and continue to control with the

parameters learned up to that point.

Plant Delay

This parameter indicates the amount of delay in seconds in the load. This

characteristic of the load or plant has a significant impact on adaptive

control. A larger number indicates a longer delay between, for example

an increase in heater power and an increase in the temperature.

Choose Automatic and then set the Control Mode to Auto to have the

adaptive algorithm determine the plant delay for the loop. The loop must

be at least 40 degrees below set point and the controller must observe a

temperature change of at least 20 degrees to determine the Plant Delay.

If you have determined the Plant Delay with the PPC-2000's adaptive

control previously and found the performance acceptable, you may

choose the delay directly and the loop will use the value you choose

rather than measure it.

This setting is not reset by the Adaptive Mode parameter's Reset option.

To have the controller relearn the Plant Delay, set the loop's Control

Mode to Manual or Off, set the Plant Delay to Automatic, and then set

the Control Mode to Auto again.

Adaptive Addendum PPC-2000 User's Guide

0600-0049-0001 rev C Watlow Anafaze 2

Page 5

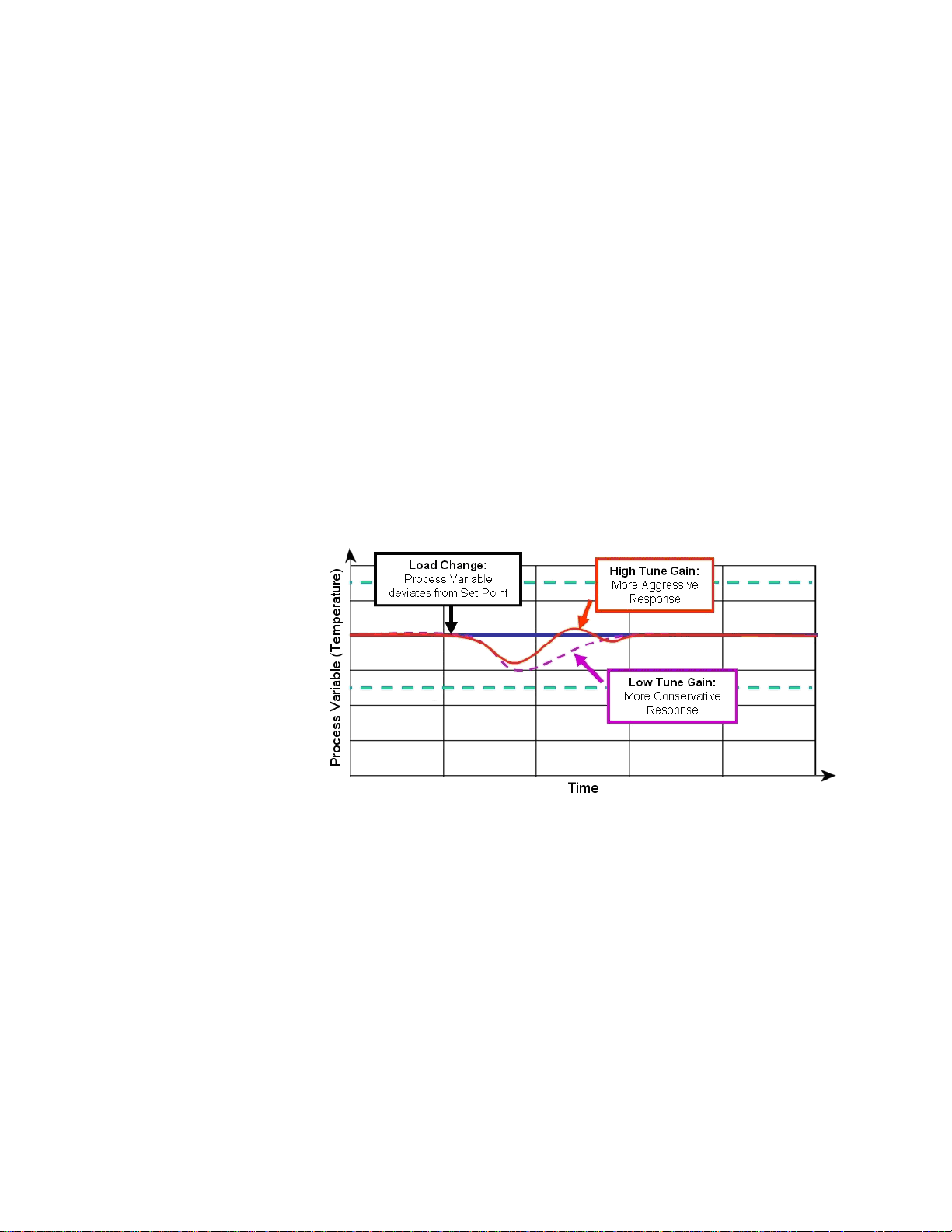

Tuning Gain

This parameter has no effect on control if the Control Type for the loop is

set to an option other than Adaptive.

Values: Automatic (0) and 1 (1) to 600 seconds (600)

Default: Automatic (0)

Modbus Address (Channels 1 to 32): 49051 to 49082

Parameter Number: 28

LogicPro Driver: Database

LogicPro Address (Channels 1 to 32): 28.1 to 28.32

This parameter indicates the amount of delay in seconds in the load. This

characteristic of the load or plant has a significant impact on adaptive

control. A larger number indicates a longer delay between, for example

an increase in heater power and an increase in the temperature.

Values: Aggressive (0), Nominal (1), Damped 1 (2), Damped 2 (3),

Damped 3 (4) and Damped 4 (5)

Default: Nominal (1)

Modbus Address (Channels 1 to 32): 46551 to 46682

Parameter Number: 29

LogicPro Driver: Database

LogicPro Address (Channels 1 to 32): 29.1 to 29.32

Figure 1. The Effect of Tuning Gain on Recovery from a

Load Change

Using Adaptive Control

To set up adaptive control on one or more channels:

1. Open the

2. On the

a. Choose the appropriate

b. Choose

c. For any linear voltage, current, or pulse sensors, set the linear

3. On the

Adaptive Addendum PPC-2000 User's Guide

0600-0049-0001 rev C Watlow Anafaze 3

Spreadsheet Overview screen in ANAWIN3.

Inputs spreadsheet for each analog input you have wired:

Input Type for the sensor.

Units.

scaling parameters (

and

PV Hi). See Setting up User Selectable Linear Inputs on

page 98 of the PPC-2000 User's Guide.

Channels spreadsheet for each channel:

Input Signal Lo, Input Signal Hi, PV Lo,

Page 6

a. In the PV Source field, choose the input that you want to

monitor or use as feedback for closed-loop control.

b. In the

Heat Output Dest and/or Cool Output Dest fields,

choose the outputs that you want to use for closed-loop control.

c. Choose a

d. Set the

Output Type

4. On the

a. Set the

Output.

5. On the

Heat/Cool Output Type for each output.

Heat/Cool Cycle Time for any outputs with Heat/ Cool

set to Time Prop.

Digital I/O spreadsheet:

Direction for each I/O point to be used for control to

Channels spreadsheet:

a. For channels other than the adaptive ones, if both heat and cool

outputs are used, set the

Spread.

b. For each channel that will perform adaptive control, for the

Control Type, choose Adaptive.

c. Set the

Set Point to the desired value at least 40 engineering

units (typically degrees) above the process variable.

d. Set the

Control Mode to Auto to begin adaptive closed-loop

control.

NOTE: Only channels 1 to 8 can be selected for adaptive control.

Adaptive Addendum PPC-2000 User's Guide

0600-0049-0001 rev C Watlow Anafaze 4

Page 7

PPC-2000 User's Guide

Addendum

Overview

This document contains additional specifications for the PPC-2000 system.

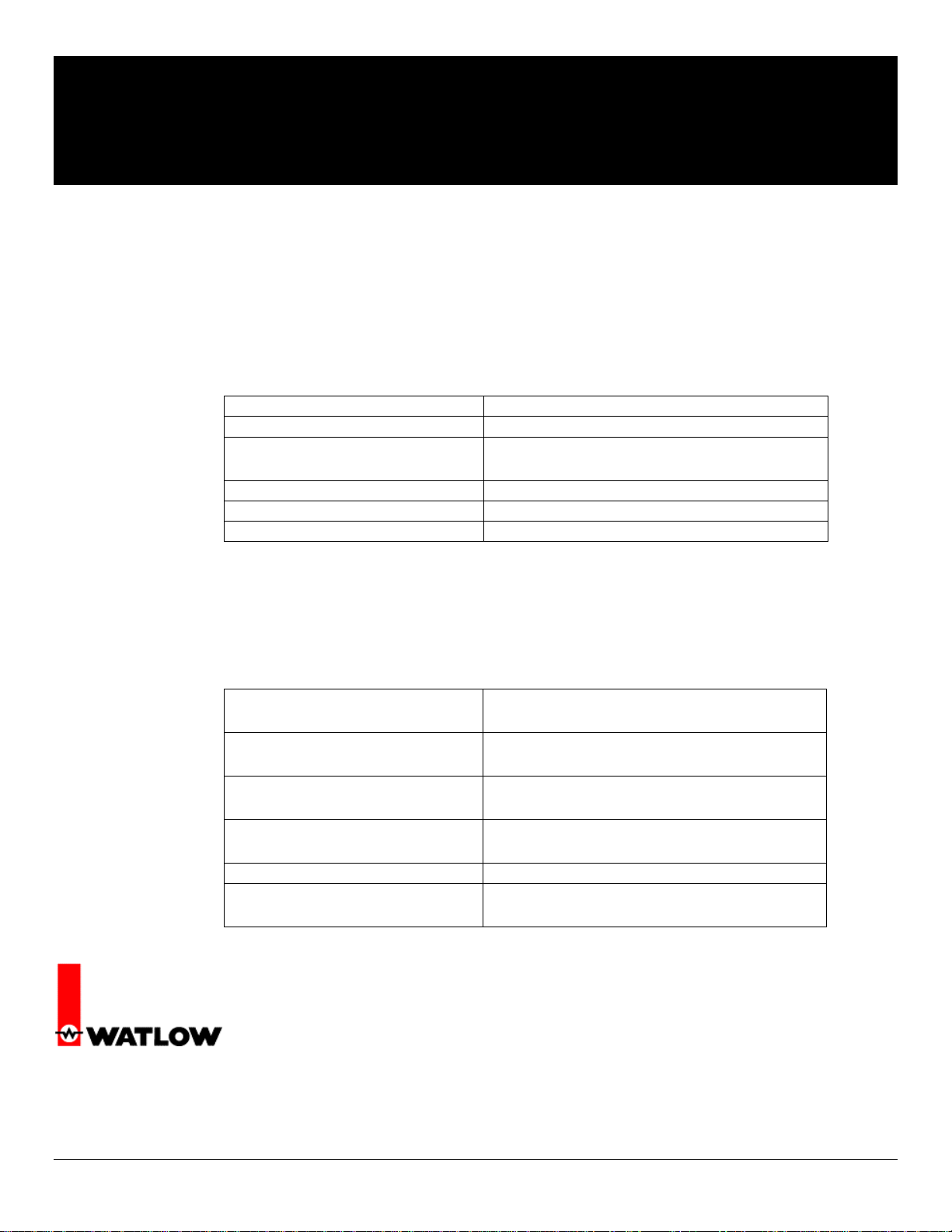

Environmental Specifications

Table 1 here contains specifications in addition to those found in tables 7.4, 7.15, 7.23,

7.31, 7.39, 7.46, 7.52, 7.57, 7.62, 7.67 in the PPC-2000 User's Guide.

TABLE 1. Environmental Specifications

Altitude 2000 meters max

Non-Condensing Humidity 10 to 95%

Relative Humidity 80% max (ambient temperature <= 31° C)

50% max (ambient temperature = 40° C)

Pollution Category Degree 2 (per IEC 664)

Operating Temperature Range 0 to 60° C (32 to140° F)

Storage Temperature Range -20 to 70° C (-4 to 158° F)

PPC IPS International Power Supply Specifications

Table 2 here contains specifications in addition to those found in table 7.75 in the PPC2000 User's Guide.

TABLE 2. Power Specifications

Input (Mains Supply) 88 to 132 Vac (120 Vac nominal)

176 to 264 Vac (240 Vac nominal)

Voltage Fluctuation < +10% of nominal voltage

Transient Over-Voltage Category II per IEC 664

Output V1: +5 Vdc @ 6 A

V2: +24 Vdc @ 4 A

Input Frequency 47 to 440 Hz

Peak Current Output 9A @ 5Vdc

6A @ 24 Vdc

1241 Bundy Blvd.

Winona, MN 55987

Phone: (507) 494-5656

Fax: (507) 452-4507

©2004 Watlow Page 1 of 1

Page 8

Copyright © 1998-2002

Watlow Anafaze

Information in this manual is subject to change without notice. No part of this publication may be

reproduced, stored in a retrieval system, or transmitted in any form without written permission

from Watlow Anafaze.

Warranty

Watlow Anafaze, Incorporated warrants that the products furnished under this Agreement will be

free from defects in material and workmanship for a period of three years from the date of shipment. The Customer shall provide notice of any defect to Watlow Anafaze, Incorporated within one

week after the Customer's discovery of such defect. The sole obligation and liability of Watlow

Anafaze, Incorporated under this warranty shall be to repair or replace, at its option and without

cost to the Customer, the defective product or part.

Upon request by Watlow Anafaze, Incorporated, the product or part claimed to be defective shall

immediately be returned at the Customer's expense to Watlow Anafaze, Incorporated. Replaced or

repaired products or parts will be shipped to the Customer at the expense of Watlow Anafaze,

Incorporated.

There shall be no warranty or liability for any products or parts that have been subject to misuse,

accident, negligence, failure of electric power or modification by the Customer without the written

approval of Watlow Anafaze, Incorporated. Final determination of warranty eligibility shall be

made by Watlow Anafaze, Incorporated. If a warranty claim is considered invalid for any reason,

the Customer will be charged for services performed and expenses incurred by Watlow Anafaze,

Incorporated in handling and shipping the returned unit.

If replacement parts are supplied or repairs made during the original warranty period, the warranty

period for the replacement or repaired part shall terminate with the termination of the warranty

period of the original product or part.

The foregoing warranty constitutes the sole liability of Watlow Anafaze, Incorporated and the Customer's sole remedy with respect to the products. It is in lieu of all other warranties, liabilities, and

remedies. Except as thus provided, Watlow Anafaze, Inc. disclaims all warranties, express or

implied, including any warranty of merchantability or fitness for a particular purpose.

Please Note

: External safety devices must be used with this equipment.

Page 9

Table of Contents iii

List of Figures ix

List of Tables xv

Overview 1

Manual Contents 1

Getting Started 2

Safety symbols 2

Contacting Watlow Anafaze 2

Initial Inspection 2

Product Features 3

System Components 3

PPC-2000 Modules 6

PPC-2000 Terminal Boards 8

Additional Components 9

Safety 9

External Safety Devices 10

External Switch Disconnect 11

Battery Safety 11

Product Markings and Symbols 11

Table of Contents

Hardware Installation 13

Power Supply Requirements 13

Mounting the Power Supply 15

Hardware Configuration 17

Module Addresses 17

PPC-2010 Jumper Settings 18

PPC-2030 Dip Switch Settings 19

PPC-2030 Jumper Settings 20

PPC-2040 Jumper Settings 21

PPC-205x Jumper Settings 22

Module Disassembly 26

Mounting Modules 26

DIN Rail Mounting 27

Doc.# 30002-00 Rev 2.3 Watlow Anafaze iii

Page 10

Table of Contents PPC-2000 User’s Guide

Mounting Terminal Boards 28

DIN Rail Mounting 31

DIN Rail Removal 32

Panel Mounting 33

System Wiring 34

Wiring Recommendations 35

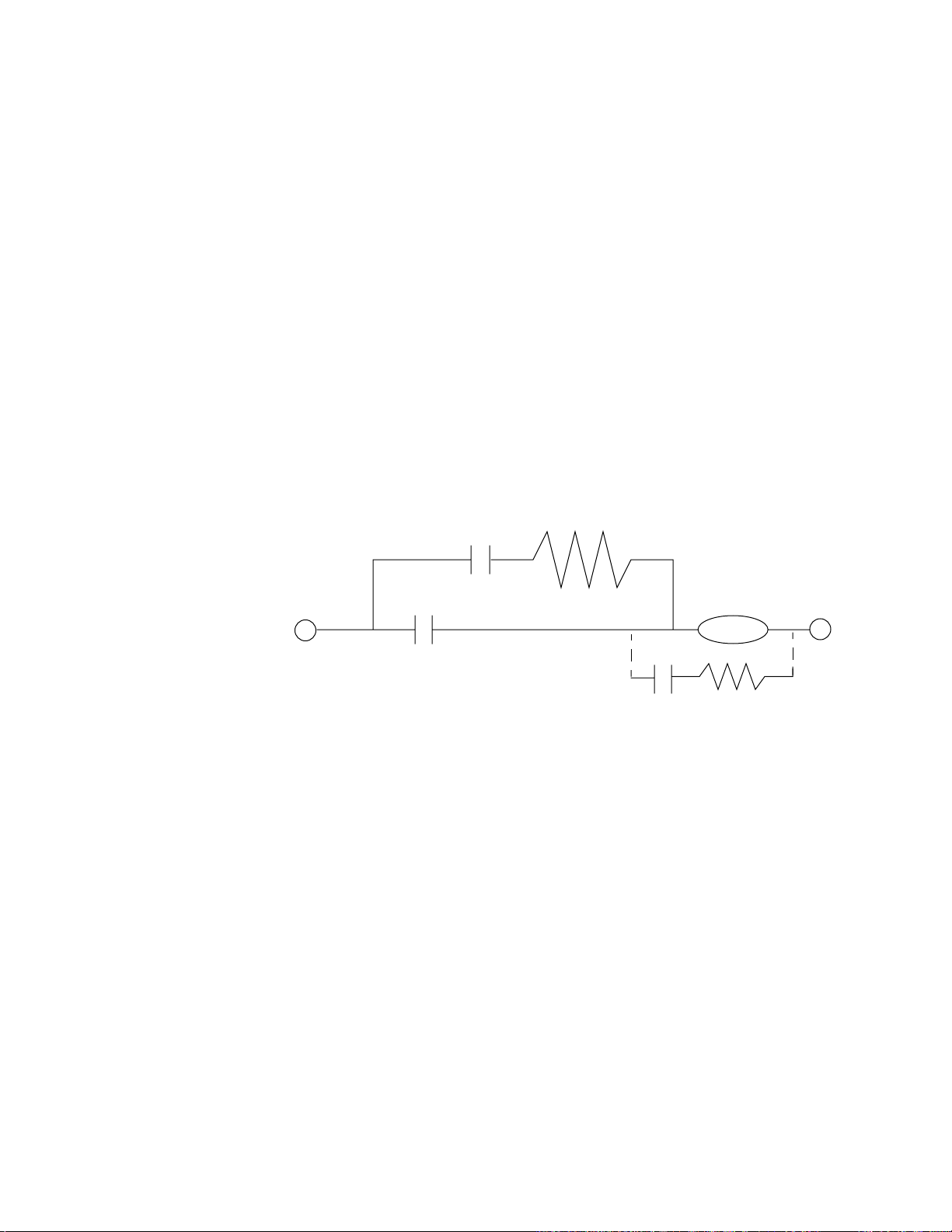

Noise Suppression 35

Avoiding Ground Loops 37

Connecting I/O to the PPC-2010 37

Connecting the TB50 to the PPC-2010 Module 37

TB50 Connections 38

Connecting Digital Inputs 40

Connecting Counter or Frequency Inputs 41

Connecting Digital Outputs 41

SDAC Connections 43

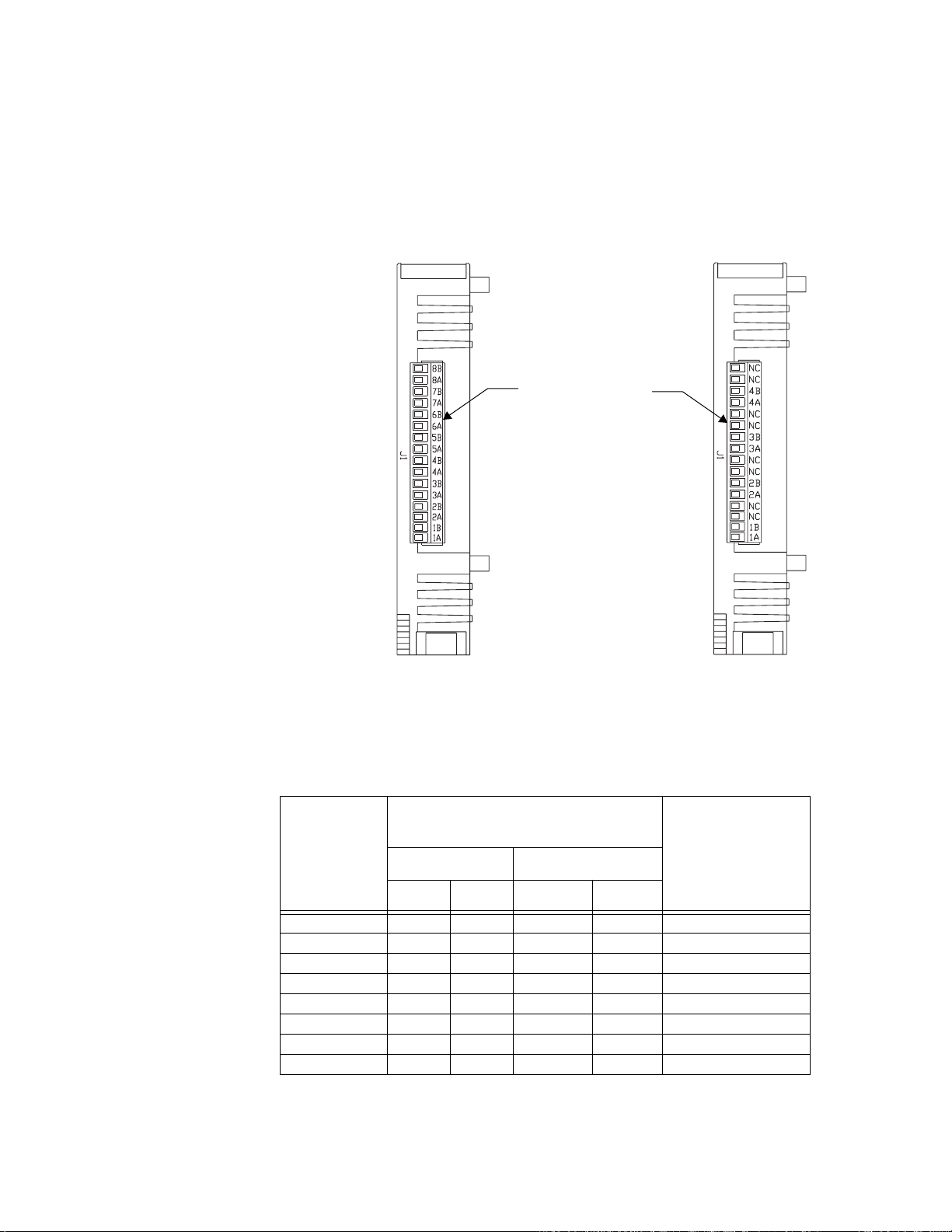

Connecting Analog Inputs to the PPC-2021 — 2025 45

Connecting the AITB to the PPC-202x 45

Sensor Keys 46

AITB Connections 47

Connecting Thermocouples 49

Connecting RTDs 50

Connecting Sensors with Linear Voltage Signals 52

Connecting Sensors with Linear Current Signals 53

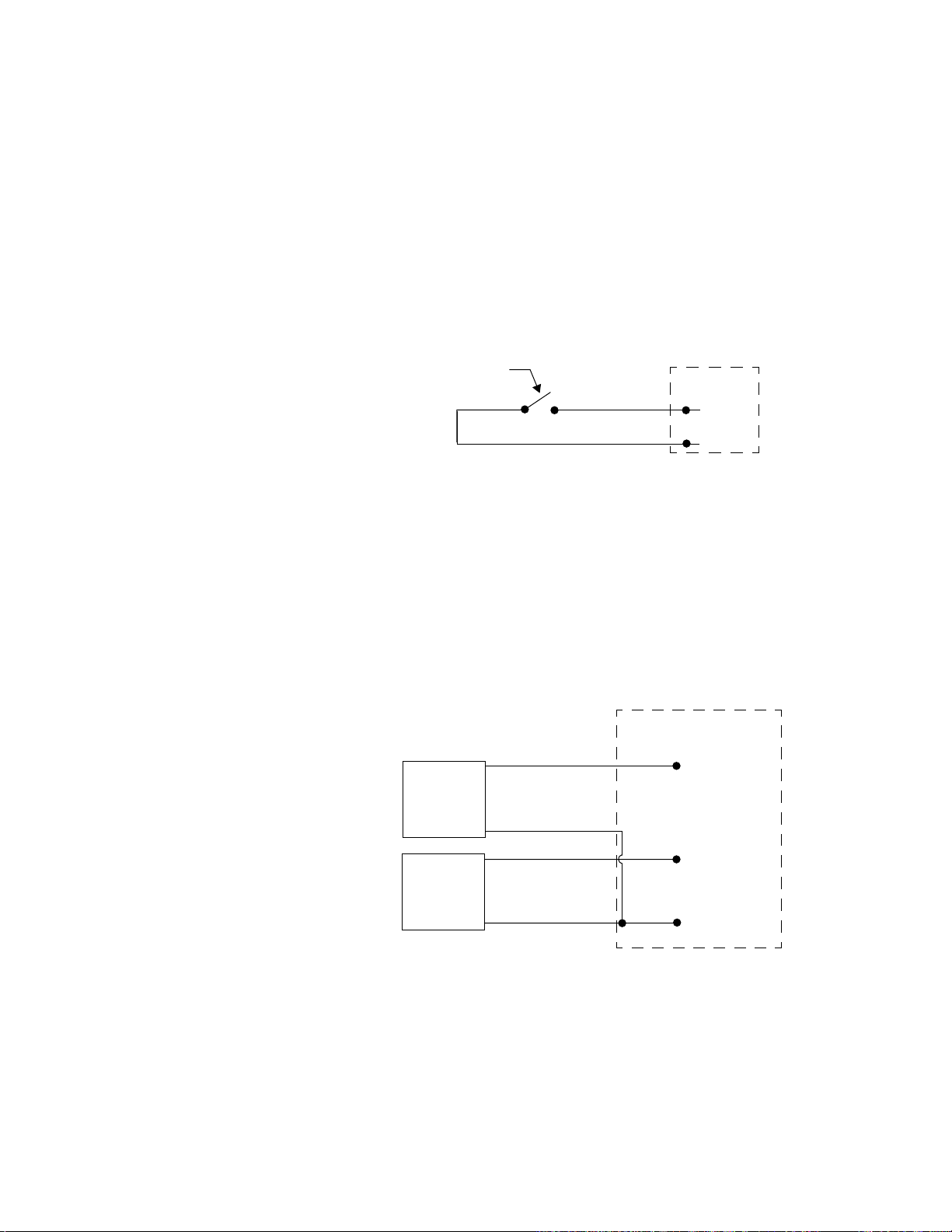

Connecting the Encoder Input Cable to the PPC-2030 55

Encoder Wiring 57

Encoder Connections without the EITB 59

Analog Output Connections 60

Connecting I/O to the PPC-2040 61

Connecting the TB50 to the PPC-2040 Module 61

TB50 Connections 62

Connecting Digital Inputs 64

Connecting Counter or Frequency Inputs 64

Connecting Digital Outputs 65

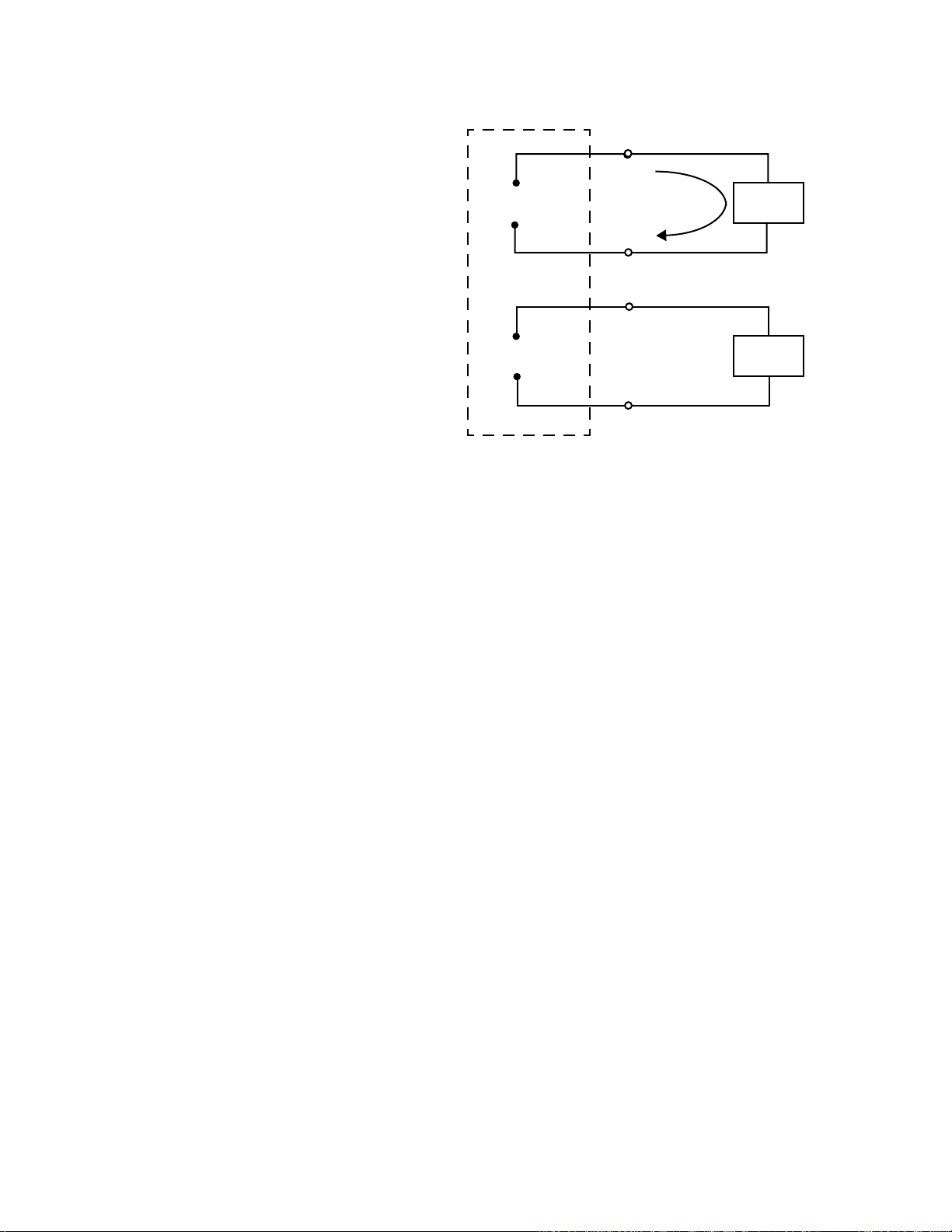

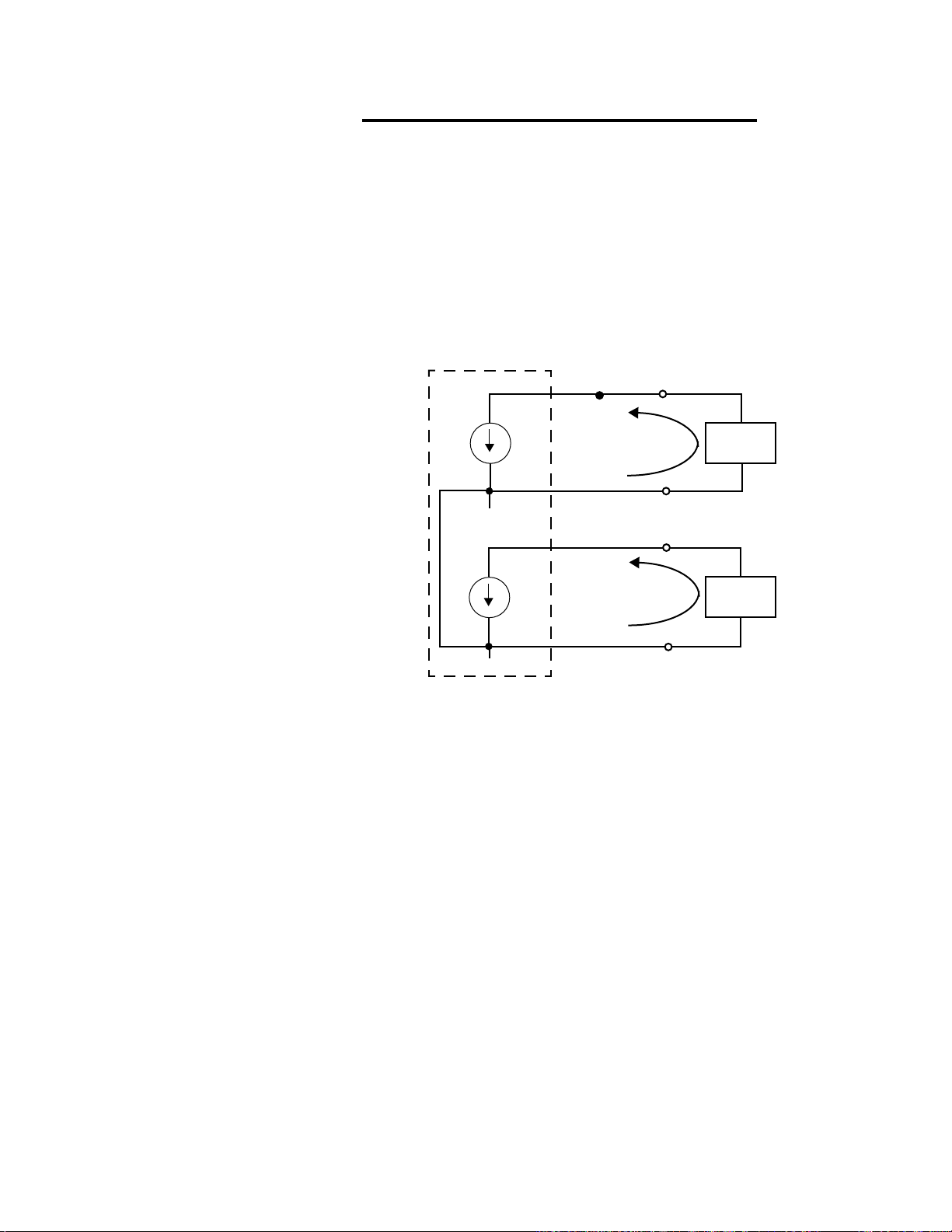

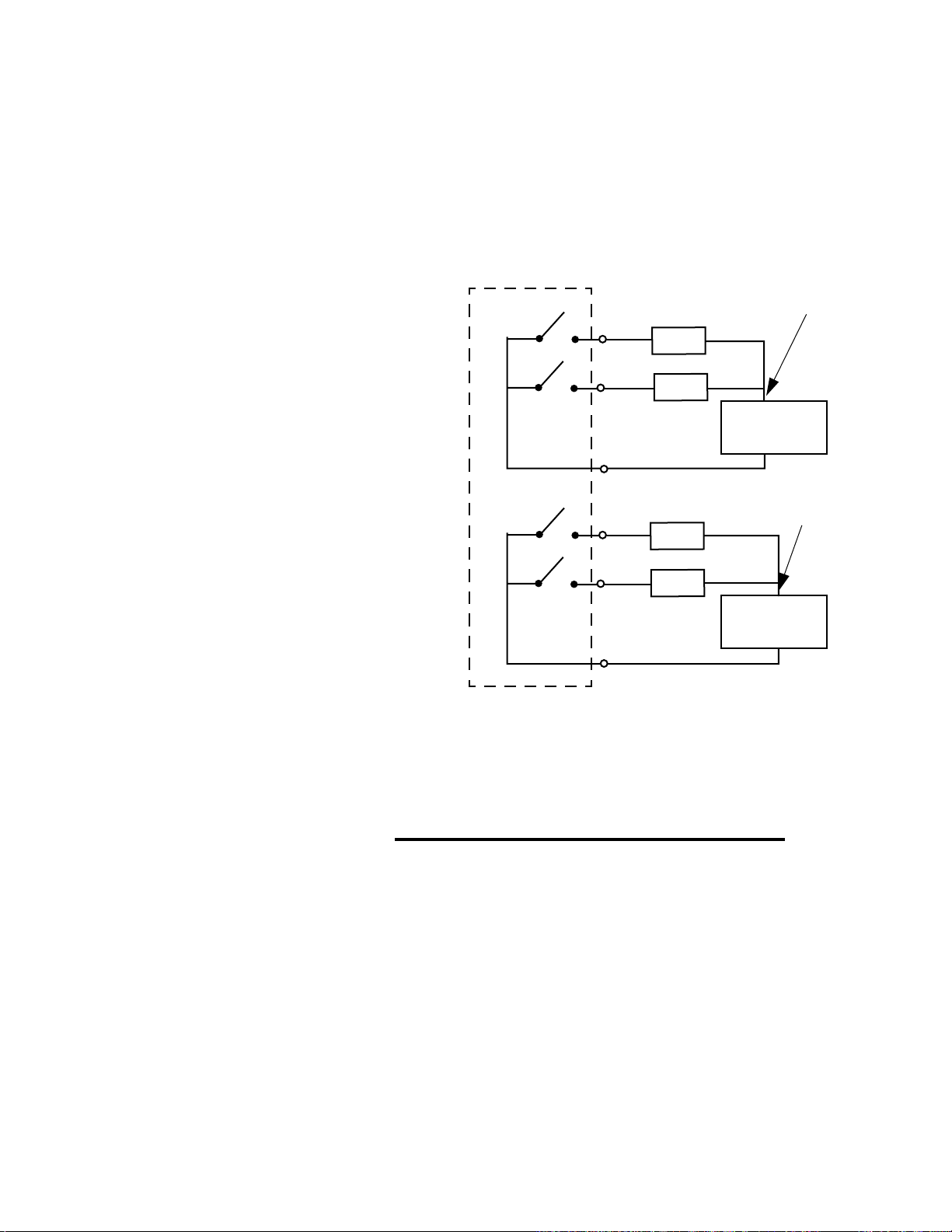

Connecting to the Relay Outputs on the PPC-206x 70

Wiring PPC-2062 Relay Outputs 71

Using Snubbers for Relay Outputs 73

Connecting Power 77

PPC-IPS-2 Power Supply 77

Processor Module 77

Connecting Communication Ports 78

Communication Ports 78

Connecting RS-485 Communications 81

iv Watlow Anafaze Doc.# 30002-00 Rev 2.3

Page 11

PPC-2000 User’s Guide Table of Contents

Operating with AnaWin3 89

Type Definitions 89

Closed-Loop Control 89

Feedback 90

Control Algorithm 90

Control Output Signal Forms 90

Heat and Cool Outputs 90

Prerequisites 93

Background 93

Using AnaWin3 to Tune 94

Alarms 95

Failed Sensor Alarms 95

Global Alarm 95

Process Alarms 95

Alarm Delay 96

Setting up Process and Deviation Alarms 97

Setting Input Signal Lo and Input Signal Hi 99

Setting Engineering Units 99

Setting PV Lo and PV Hi 99

Setting Decimal Places 100

Linear 4-20mA Input Example 101

Process Variable Retransmit 102

Setting up Process Variable Retransmit 103

Process Variable Retransmit Example 104

Cascade Control 105

Setting up Cascade Control 106

Cascade Control Example 106

Ratio Control 109

Setting up Ratio Control 110

Differential Control 112

Remote Set Point 112

Logic Programs 112

Setting up Outputs for Use with a Logic Program 113

Using Logic to Set an Analog Input 113

Starting and Stopping Logic Programs 113

Controller Parameters 115

Channels 115

Digital I/O 132

Soft Integer 136

Soft Boolean 137

Doc.# 30002-00 Rev 2.3 Watlow Anafaze v

Page 12

Table of Contents PPC-2000 User’s Guide

Troubleshooting 141

General Description 141

PPC-2010 Processor 141

Processor Module LEDs 147

PPC-2040 Digital I/O 151

PPC-207x Digital In 153

Troubleshooting and Corrective Actions 154

Digital Inputs and Outputs 154

Process Variable 154

Communications 155

Resetting Closed-Loop Control Parameters 156

Disabling Control 157

LogicPro and Modbus Reference 159

Overview 159

Text Conventions in the Database Sections 159

The PPC-2000 Database 160

Data Table Organization 161

How LogicPro Accesses the Database 162

Analog and Counter Input Parameters in the Database 163

Accessing Analog and Counter Input Parameters with Modbus 163

Accessing Analog and Counter Input Parameters with LogicPro 163

Analog Input Numbers and Address Offsets 164

Analog and Encoder Input Parameters 168

Channel Parameters in the Database 172

Accessing Channel Parameters with Modbus 172

Accessing Channel Parameters with LogicPro 173

Channel Parameters for Heat and Cool Outputs 173

Channel Parameters 173

State and Logic 195

Accessing Digital I/O Parameters with Modbus 195

Digital I/O Numbers and Address Offsets 196

Digital I/O Parameters 200

Accessing Analog Outputs with Modbus 202

Accessing Analog Outputs with LogicPro 202

Analog Outputs and Modbus Addresses 202

Analog Output Value 204

Soft Bool and Soft Int Registers in the Database 205

Accessing Soft Bool and Soft Int Registers with Modbus 205

Accessing Soft Bool and Soft Int Registers with LogicPro 205

Soft Bool and Soft Int Registers 205

Global Parameters in the Database 206

Accessing Global Parameters with Modbus 206

Communications Parameters 207

Global Database Parameters 209

vi Watlow Anafaze Doc.# 30002-00 Rev 2.3

Page 13

PPC-2000 User’s Guide Table of Contents

Tuning and Control 219

Introduction 219

Control Algorithms 220

On/Off Control 220

Output Control Forms 224

Output Filter 225

Proportional Band (PB) Settings 226

Integral Settings 226

Derivative Settings 227

General PID Constants by Application 228

Proportional Band Only (P) 228

Proportional with Integral (PI) 228

PI with Derivative (PID) 228

Specifications 229

System Specifications 229

Safety and Agency Approvals 229

Physical Specifications 230

Power Specifications 230

PPC-2010 Processor Specifications 231

PPC-205x Analog Out Specifications 247

PPC-206x Digital Output Specifications 250

PPC-207x Digital In Specifications 253

PPC-EITB-1 Encoder Input Terminal Block Specifications 258

PPC-TB50-SCSI, 50-Pin Specifications 261

SDAC Specifications 265

Inputs 266

Analog Outputs 267

Appendix A: Modbus Protocol 269

Query 270

Response 270

Message Framing 271

Address Field 272

Function Field 272

Data Field 273

Error Checking Field 273

Field Format 273

Parity Checking 274

CRC Checking 275

Read Examples 280

Appendix B: Declaration of Conformity 283

Glossary 285

Doc.# 30002-00 Rev 2.3 Watlow Anafaze vii

Page 14

Table of Contents PPC-2000 User’s Guide

viii Watlow Anafaze Doc.# 30002-00 Rev 2.3

Page 15

Overview 1

Figure 1.1—System Diagram 4

Figure 1.2—Sample PPC-2000 System 6

Hardware Installation 13

Figure 2.1—PPC-IPS-2 DIN Mounting Dimensions 15

Figure 2.2—PPC-IPS-2 Panel Mounting Dimensions 16

Figure 2.3—Sample Addresses 17

Figure 2.4—PPC-2010 Jumpers 19

Figure 2.5—PPC-2030 Jumpers and Switches 20

Figure 2.6—PPC-2040 Jumper Settings 21

Figure 2.7—PPC-205x Jumpers 23

Figure 2.8—Assembled Modules Top View 24

Figure 2.9—Assembled Modules Bottom View 25

Figure 2.10—Modules Bottom/Side View 25

Figure 2.11—DIN Rail Latches 27

Figure 2.12—Mounting Assembled PPC Modules on a DIN rail (side) 27

Figure 2.13—AITB Dimensions / Clearances 29

Figure 2.14—EITB Dimensions / Clearances 30

Figure 2.15—TB50 Dimensions / Clearances 31

Figure 2.16—TB50 Mounted on DIN Rail (Front) 32

Figure 2.17—TB50 Mounted on DIN Rail (Side) 32

Figure 2.18—TB50 Panel Mounted 33

Figure 2.19—SDAC Dimensions 34

Figure 2.20—PPC-2010 Connection to TB50 38

Figure 2.21—Wiring Digital Inputs 41

Figure 2.22—Encoder with 5Vdc TTL Signal 41

Figure 2.23—Powering Output with 5Vdc from PPC Supply 42

Figure 2.24—Powering Output with 12-24Vdc from PPC supply 42

Figure 2.25—Powering Output with Separate Power Supplies 42

Figure 2.26—Recommended circuitry for CPUWatchdog 43

Figure 2.27—Wiring Single/Multiple SDACs 44

Figure 2.28—PPC-2021 — 2025 Connection to AITB 45

Figure 2.29—Inserting Sensor Keys in AITB 46

Figure 2.30—An Input Key 47

Figure 2.31—Thermocouples Connected to Differential Inputs 1 and 2 49

Figure 2.32—Thermocouples Connected to Single-ended Inputs 1 and 2 50

Figure 2.33—Wiring 2-Wire RTDs: Input 1 and 2 Shown 51

Figure 2.34—Wiring 3-Wire RTDs: Input 1 and 2 Shown 51

List of Figures

Doc.# 30002-00 Rev 2.3 Watlow Anafaze ix

Page 16

List of Figures PPC User’s Guide

Figure 2.35—Connecting Linear Voltage Signals to Differential Inputs 1 and 2 52

Figure 2.36—Connecting Linear Voltage Signals to Single-ended Inputs 1 and 2 53

Figure 2.37—Connecting Current Inputs to a Differential Input Module:

Input 1, 2, and 3 Shown 53

Figure 2.38—Connecting Current Inputs to a Single-ended Analog Input

Module: Input 1 and 2 Shown 54

Figure 2.39—PPC-2030 Connections (Bottom View) 55

Figure 2.40—PPC-EITB-1 56

Figure 2.41—EITB Single-ended Single Phase Connections: Input 1 and 2 Shown 57

Figure 2.42—EITB Single-ended Quadrature Connections: Input 1 and 2 Shown 58

Figure 2.43—EITB Differential Single Phase Connections: Input 1 and 2 Shown 58

Figure 2.44—EITB Differential Quadrature Connections: Input 1 and 2 Shown 59

Figure 2.45—PPC-2030 Analog Out Terminal Block 60

Figure 2.46—Analog Output Connections on a PPC-2030: Outputs 1 and 2 Shown 61

Figure 2.47—PPC-2040 Connection to TB50 62

Figure 2.48—Wiring Digital Inputs 64

Figure 2.49—Single Phase Connections: Input 1 and 2 Shown 64

Figure 2.50—Quadrature Connections: Inputs 1 and 2 Shown. 65

Figure 2.51—Powering Output with 5Vdc from PPC Supply 65

Figure 2.52—Powering Output with 12-24Vdc from PPC supply 66

Figure 2.53—Powering Output with Separate Power Supplies 66

Figure 2.54—PPC-205x Connections (Bottom View) 67

Figure 2.55—Analog Output Connections on a PPC-2050 Configured for Current:

Outputs 1 and 2 Shown 68

Figure 2.56—Analog Output Connections on a PPC-2050 Configured for Voltage:

Outputs 1 and 2 shown 69

Figure 2.57—Analog Output Connections on a PPC-2051 Configured for Current and

Voltage: Outputs 1 and 2 shown 69

Figure 2.58—PPC-206x Connections (bottom view) 70

Figure 2.59—Relay Output Connections on a PPC-2061:

Outputs 1, 2, 9 and 10 shown 71

Figure 2.60—Relay Output Connections on a PPC-2062: Outputs 1 and 2 Shown 72

Figure 2.61—Snubber Connections 73

Figure 2.62—PPC-207x Connections (bottom view) 74

Figure 2.63—Input Connections to a PPC-2070 or PPC-2072:

Inputs 1 and 2 shown 74

Figure 2.64—Input Connections to a PPC-2071 or PPC-2073:

Inputs 1,2, 9 and 10 Shown 75

Figure 2.65—Connecting a Current Sinking Field Device to a PPC-2072 or PPC-2073:

Input 1 Shown 75

Figure 2.66—Connecting a Current Sourcing Field Device to a PPC-2072 or

PPC-2073: Input 1 Shown 76

Figure 2.67—PPC-IPS-2 Power Connections 78

Figure 2.68—RS-232 and RS-485 RJ-Type Connectors 79

Figure 2.69—Connecting One PPC to a Computer Using RS-232 81

Figure 2.70—Connecting Multiple PPCs to a Computer Using RS-485 81

Figure 2.71—RS-485 Wiring 82

Figure 2.72—Two Wire RS-485 Wiring 84

Figure 2.73—Connecting Several PPCs with Short Cable Runs 84

x Watlow Anafaze Doc.# 30002-00 Rev 2.3

Page 17

PPC User’s Guide List of Figures

Operating with AnaWin3 89

Figure 3.1—Sample Screen Text 89

Figure 3.2—Process Variable Alarms 96

Figure 3.3—Linear Input Example 98

Figure 3.4—Linear Scaling of the Analog Input for Retransmit on the Heat or Cool

Output 102

Figure 3.5—Sample Application Using Process Variable Retransmit 104

Figure 3.6—How the Secondary Channel’s Set Point is Determined When the

Primary Channel Has Heat and Cool Outputs 105

Figure 3.7—How the Secondary Channel’s Set Point is Determined When the Primary

Channel Has Only a Heat Output 106

Figure 3.8—Sample Application Using Cascade Control 107

Figure 3.9—The Secondary Channel’s Set Point is Determined by the Primary

Channel’s Process Variable 109

Figure 3.10—Relationship between the Master Channel’s Process Variable and the

Ratio Channel’s Set Point. 110

Figure 3.11—Sample Application Using Ratio Control 111

Figure 3.12—Channels Spreadsheet 115

Figure 3.13—Output Scaling (Heat/Cool) Curves 121

Figure 3.14—Alarms Spreadsheet 123

Figure 3.15—Inputs Spreadsheet 127

Figure 3.16—Analog Input Names 127

Figure 3.17—Pulse Input Names 128

Figure 3.18—Soft Input Names 128

Figure 3.19—Channel Output Names 129

Figure 3.20—Dig I/O Spreadsheet 132

Figure 3.21—PPC-2010 and PPC-204X Digital I/O Names 133

Figure 3.22—PPC-206X and PPC-207X Digital I/O Names 133

Figure 3.23—Outputs Spreadsheet 135

Figure 3.24—Analog Output Names 135

Figure 3.25—Soft Int Spreadsheet 136

Figure 3.26—Soft BOOL Spreadsheet 137

Figure 3.27—PPC Globals Screen 138

Troubleshooting 141

Figure 4.1—Assembled Modules Top View 143

Figure 4.2—Assembled Modules Bottom View 143

Figure 4.3—PPC-2010 Internal View 144

Figure 4.4—PPC Assembled Modules Top View 145

Figure 4.5—PPC Assembled Modules Bottom View 146

Doc.# 30002-00 Rev 2.3 Watlow Anafaze xi

Page 18

List of Figures PPC User’s Guide

LogicPro and Modbus Reference 159

Figure 5.1—Sample Text 160

Figure 5.2—Output Scaling Curves 185

Tuning and Control 219

Figure 6.1—On/Off Control 220

Figure 6.2—Proportional Control 221

Figure 6.3—Proportional and Integral Control 222

Figure 6.4—Proportional, Integral and Derivative Control 223

Figure 6.5—Example Time Proportioning and Distributed Zero Crossing

Waveforms 224

Specifications 229

Figure 7.1—System Footprint 230

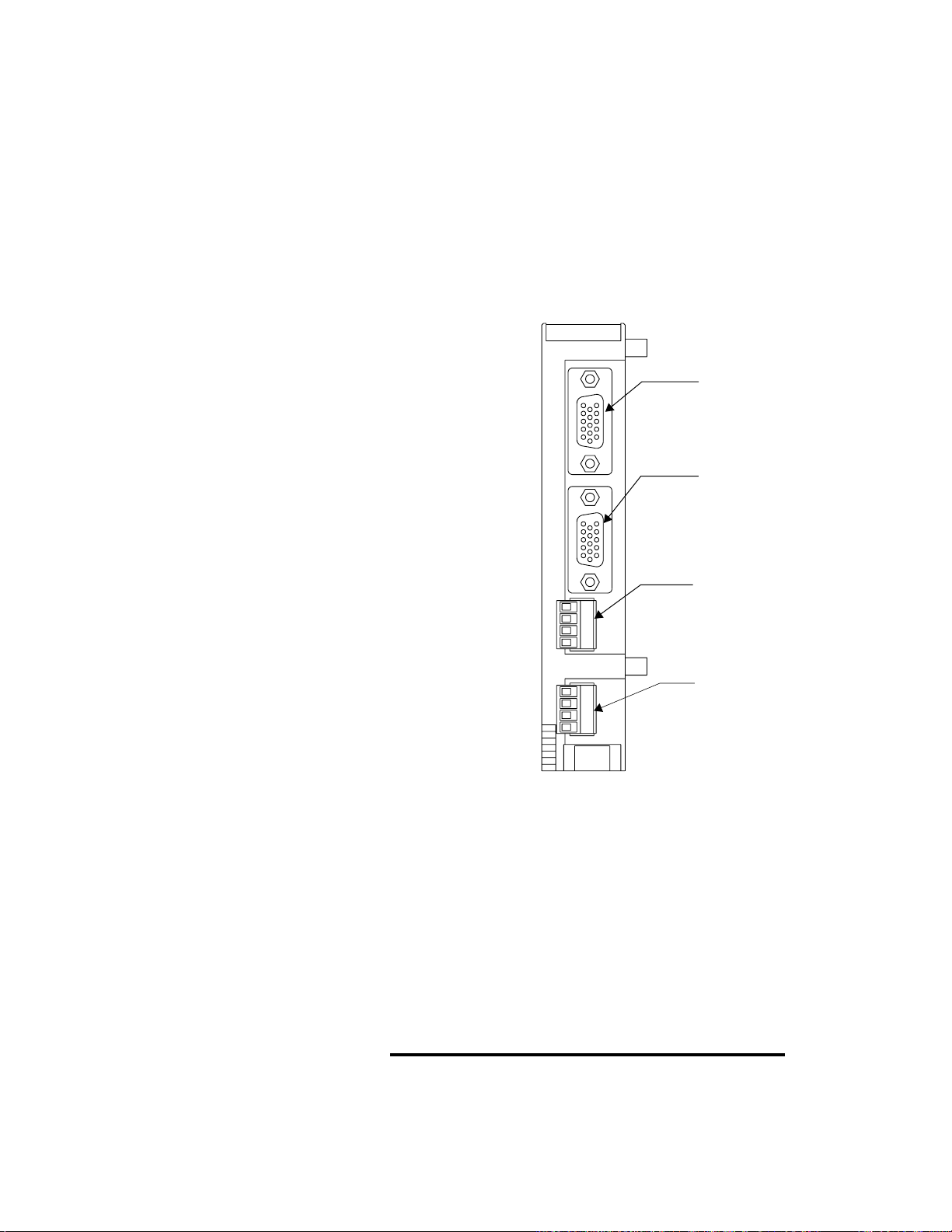

Figure 7.2—PPC-2010 Front View 231

Figure 7.3—PPC-2010 Bottom View 232

Figure 7.4—PPC-2021 Front View 236

Figure 7.5—PPC-2021 - 2025 Bottom View 236

Figure 7.6—PPC-2030 Front View 240

Figure 7.7—PPC-2030 Bottom View 241

Figure 7.8—PPC-2040 Front View 244

Figure 7.9—PPC-2050 Front View 247

Figure 7.10—PPC-2050 Bottom View 248

Figure 7.11—PPC-206x Front View 250

Figure 7.12—PPC-206x Bottom View 251

Figure 7.13—PPC-2070, PPC-2071 Front Views 253

Figure 7.14—PPC-207x Bottom Views 254

Figure 7.15—PPC-AITB-1 256

Figure 7.16—PPC-AITB Dimensions with Straight SCSI Cable 257

Figure 7.17—PPC-EITB-1 258

Figure 7.18—PPC-EITB Dimensions with HD-Type Cable 260

Figure 7.19—PPC-TB50-SCSI Dimensions 261

Figure 7.20—PPC-TB50-SCSI Dimensions with Straight SCSI Cable 262

Figure 7.21—PPC-TB50-SCSI Dimensions with Right-Angle SCSI Cable 263

Figure 7.22—PPC-IPS-2 264

Figure 7.23—SDAC Dimensions 266

Appendix A: Modbus Protocol 269

Figure A.1—Query—Response Cycle 270

xii Watlow Anafaze Doc.# 30002-00 Rev 2.3

Page 19

Overview 1

Table 1.1—PPC-2000 System Modules 5

Table 1.2—PPC-2000 Terminal Boards and Peripheral Modules 5

Table 1.3— Analog Terminal Board Keys 5

List of Tables

Hardware Installation 13

Table 2.2—Power Supply Current Requirements at 24Vdc 14

Table 2.3—Power Supply Screw Mounting 16

Table 2.4—System Modules and Addressing 18

Table 2.5—PPC-2010 Processor Module Jumpers 18

Table 2.6—PPC-2030 Analog Output Jumpers 21

Table 2.7—PPC-2040 Counter Input Jumpers 21

Table 2.8—PPC-205x Analog Out Jumpers 22

Table 2.9—Cable Recommendations 35

Table 2.10—Processor Module I/O Connections 39

Table 2.11—Sensor Keys 46

Table 2.12—Numbers and Types of Inputs by Module Type 47

Table 2.13—Sensor Connections to the AITB 48

Table 2.14—Power Connections on AITB 49

Table 2.15—Encoder Connections to the EITB Connected to J3 on the PPC-2030 56

Table 2.16—Encoder Connections to the EITB Connected to J4 on the PPC-2030 56

Table 2.17—Power Connections on EITB 57

Table 2.18—HD-15 Encoder Signal Connections 59

Table 2.19—HD-15 Power Connections 60

Table 2.20—Analog Output Connections on Encoder In Analog Out Module 60

Table 2.21—Digital I/O Module Connections 63

Table 2.22—Analog Output Connections on Analog Out Module 67

Table 2.23—Relay Output Connections on PPC-206x Digital Output Modules 72

Table 2.24—Digital Input Connections on PPC-207x Modules 76

Table 2.25—PPC-IPS-2 Voltage Input Switch Settings 77

Table 2.26—Power Supply Connections 77

Table 2.27—RS-232 Connector Pin Outs 79

Table 2.28—RS-485 Connector Pin Out and Connections 80

Table 2.29—RTS/CTS Pins in DB-9 and DB-25 Connectors 80

Table 2.30—485 Terminal Block Pin Assignment 83

Table 2.31—PPC-2010 Rotary Switch Configuration 86

Doc.# 30002-00 Rev 2.3 Watlow Anafaze xiii

Page 20

List of Tables PPC User’s Guide

Operating with AnaWin3 89

Table 3.1—Control Types PID1 and PID2 91

Table 3.2—Alarm Types 95

Table 3.3—Range and Sensitivity of theCustom Linear Input Types 99

Table 3.4—PV Range permitted for various Decimal Places Settings 100

Table 3.5—Scaling Parameters for 0-10Vdc Linear Input Example 101

Table 3.6—Scaling Parameters for 4-20mA Linear Input Example 101

Table 3.7—Scaling Parameters for 0-1Vdc Linear Input Example 102

Table 3.8—Retransmit Channel Parameter Settings 104

Table 3.9—Primary Channel Parameter Settings 107

Table 3.10—Secondary Channel Parameter Settings 108

Table 3.11—Ratio Channel Parameter Settings 111

Table 3.12—AnaWin3 Control Types 118

Table 3.14—Module Abbreviations Seen on the Inputs Spreadsheet 127

Table 3.16—Units 131

Table 3.18—Function Values 134

Table 3.19—Module Abbreviations Seen on the Outputs Spreadsheet 135

Table 3.20—System Status 139

Table 3.21—Global Settings 139

LogicPro and Modbus Reference 159

Table 5.1—Parameter Names & Abbreviations 159

Table 5.2—Example Database Table 160

Table 5.3—Addresses for Analog Inputs on the PPC-202x Modules 164

Table 5.4—Addresses for Encoder Inputs on the PPC-2030 Encoder In Analog Out

Module 165

Table 5.5—Addresses for Counter Inputs on the PPC-2010 Processor Module 166

Table 5.6—Addresses for Soft Inputs and Channel Outputs 166

Table 5.7—Addresses for Encoder Inputs on the PPC-2040 Digital I/O Modules 167

Table 5.8—Input Parameters 168

Table 5.9—Input Status 169

Table 5.11—Temperature Scale Conversion 171

Table 5.13—Process Variable and Setpoint Source Settings for Analog Inputs on the

PPC-202x Modules 176

Table 5.16—Process Variable and Setpoint Source Settings for Soft Input and

Channel Out Registers 178

Table 5.18—Control Mode 180

Table 5.19—Control Types 181

Table 5.21—Heat/Cool Curve 184

Table 5.22—Output Destinations for Digital Outputs on the PPC-2010 Module 186

Table 5.26—Output Destinations for Analog Outputs on the PPC-205x Modules 189

Table 5.27—Output Destinations for Soft Boolean and Soft Integers 190

Table 5.28—Alarm Status 190

Table 5.30—Alarm and Control Functionality 192

Table 5.31—Alarm Acknowledge 192

Table 5.32—Alarm Enable/Disable 192

Table 5.33—Database Offsets and Sample Modbus Addresses for Digital I/O 196

Table 5.37—Digital I/O Uses 200

xiv Watlow Anafaze Doc.# 30002-00 Rev 2.3

Page 21

PPC User’s Guide List of Tables

Table 5.38—Digital I/O Parameters 200

Table 5.39—State and Logic 201

Table 5.40—Direction 201

Table 5.41—Logic 201

Table 5.44—Soft Bool and Soft Int Parameters 205

Table 5.45—Soft Bool Values 205

Table 5.46—Soft Bool and Soft Int Registers 206

Table 5.47—Rotary Switch Configuration 207

Table 5.48—Communications Parameters 208

Table 5.49—Database Offsets for Baud Rate 208

Table 5.50—Baud Rate 208

Table 5.51—System HW Parameters 209

Table 5.52—Miscellaneous System Parameters 209

Table 5.54—Zero Reference Readings 210

Table 5.55—Ambient Temperature Readings 211

Table 5.56—Modules Present 211

Table 5.57—Module Types 212

Table 5.59—System Status 214

Table 5.60—System Status Bits 214

Table 5.63—Real Time Clock Format 218

Tuning and Control 219

Table 6.1—Proportional Band Settings 226

Table 6.2—Integral Term and Reset Settings 227

Table 6.3—Derivative Term vs. Rate 227

Table 6.4—General PID Constants 228

Specifications 229

Table 7.1—Safety and Agency Approvals 229

Table 7.2—PPC System Dimensions 230

Table 7.3— Model Number 232

Table 7.4—Environmental Specifications 232

Table 7.5—Physical Specifications 232

Table 7.7—Power Specifications 233

Table 7.8—Capacity and Programming 233

Table 7.9—Control Specifications 234

Table 7.10—Counter/Frequency Input Specifications 234

Table 7.11—Digital Input Specifications 234

Table 7.12—Digital Output Specifications 235

Table 7.13—Serial Interface 235

Table 7.14—Model Numbers 237

Table 7.15—Environmental Specifications 237

Table 7.16—Physical Specifications 237

Table 7.17—Connections 237

Table 7.18—Power Specifications 237

Table 7.21—Sensor Reference Voltage Output 239

Table 7.22—Model Number 241

Table 7.23—Environmental Specifications 241

Doc.# 30002-00 Rev 2.3 Watlow Anafaze xv

Page 22

List of Tables PPC User’s Guide

Table 7.24—Physical Specifications 241

Table 7.25—Connections 242

Table 7.26—Power Specifications 242

Table 7.27—Input Specifications 242

Table 7.29—Safety and Agency Approvals 243

Table 7.30—Model Number 244

Table 7.31—Environmental Specifications 244

Table 7.32—Physical Specifications 245

Table 7.33—Connections 245

Table 7.34—Power Specifications 245

Table 7.35—Counter/Frequency Specifications 245

Table 7.37—Digital Output Specifications 246

Table 7.38—Model Number 248

Table 7.39—Environmental Specifications 248

Table 7.40—Physical Specifications 248

Table 7.41—Connections 249

Table 7.42—Power Specifications PPC-2050 249

Table 7.43—Power Specifications PPC-2051 249

Table 7.44—Output Specifications 249

Table 7.45—Model Number 251

Table 7.46—Environmental Specifications 251

Table 7.47—Connections 251

Table 7.48—Physical Specifications 252

Table 7.49—Power Specifications 252

Table 7.50—Output Specifications 252

Table 7.51—Model Number 254

Table 7.52—Environmental Specifications 254

Table 7.53—Physical Specifications 254

Table 7.54—Connections 255

Table 7.55—Power Specifications 255

Table 7.56—Digital Input Specifications 255

Table 7.57—Environmental Specifications 256

Table 7.58—Physical Specifications 256

Table 7.59—Connections 257

Table 7.60—PPC-AITB with Straight SCSI 257

Table 7.61—Sensor Key Cards 258

Table 7.62—Environmental Specifications 259

Table 7.63—Physical Specifications 259

Table 7.64—Connections 259

Table 7.65—PPC-EITB with HD-Type Cable 259

Table 7.66—Safety and Agency Approvals 259

Table 7.67—Environmental Specifications 261

Table 7.68—Physical Specifications 261

Table 7.70—PPC-TB50-SCSI with Straight SCSI 262

Table 7.72—Environmental Specifications 264

Table 7.73—Physical Specifications 264

Table 7.74—Dimensions with Din Rail Bracket 265

Table 7.75—Power Specifications 265

Table 7.76—Connections 265

Table 7.77—Safety and Agency Approvals 265

xvi Watlow Anafaze Doc.# 30002-00 Rev 2.3

Page 23

PPC User’s Guide List of Tables

Table 7.78—Environmental Specifications 265

Table 7.79—Physical Specifications 266

Table 7.80—Safety and Agency Approvals 266

Table 7.81—Inputs 267

Table 7.82—Power Requirements 267

Table 7.83—Analog Output Specifications 267

Appendix A: Modbus Protocol 269

Table A.1—Example Message Frame 271

Table A.2—Function Codes 276

Table A.3—Sample Packet for Host Query 280

Table A.4—Sample Packet for Slave Response 280

Table A.5—Sample Packet for Host Query 281

Table A.6—Sample Packet for Slave Response 281

Doc.# 30002-00 Rev 2.3 Watlow Anafaze xvii

Page 24

List of Tables PPC User’s Guide

xviii Watlow Anafaze Doc.# 30002-00 Rev 2.3

Page 25

1

Overview

Manual Contents

This manual describes how to install, set up, and operate a

PPC-2000 controller. Each chapter covers a different aspect of

your control system and may apply to different users. The

following describes each chapter’s purpose.

• Chapter 1: Overview. Provides component list and

• Chapter 2: Hardware Installation. Provides detailed

• Chapter 3: Software Setup. Describes how to use your

• Chapter 4: Troubleshooting. Includes troubleshooting,

• Chapter 5: Custom Interfacing. Provides information

• Chapter 6: Tuning and Control. Describes available

• Chapter 7: Specifications. Lists detailed specifications

summary of features for the PPC-2000.

instructions on installing the PPC-2000 system and its

peripherals.

PPC system with AnaWin3 , the Watlow Anafaze HumanMachine Interface (HMI) software.

upgrading and reconfiguring procedures for technical

personnel.

on setting up third-party software or an operator interface

terminal for operating and monitoring a PPC System. Also

provides information needed to address parameters when

writing programs using LogicPro .

control algorithms and provides suggestions for

applications.

of the controller and optional components.

Doc.# 30002-00 Rev 2.3 Watlow Anafaze 1

Page 26

Chapter 1: Overview PPC-2000 User’s Guide

Getting Started

The following sections provide information regarding product

features, system components, safety requirements, and

preparation for operation.

Safety symbols

These symbols are used throughout this manual:

∫

WARNING!

Indicates a potentially hazardous situation which, if

not avoided, could result in death or serious

injury.

ç

CAUTION!

NOTE!

Contacting Watlow Anafaze

Indicates a potentially hazardous situation which, if

not avoided, could result in minor or moderate injury

or property damage.

Indicates pertinent information or an item that may be

useful to document or label for later reference.

To contact Watlow Anafaze, send correspondence to:

Watlow Anafaze, Inc.

314 Westridge Drive

Watsonville, CA 95076

Our technical support and customer service departments may

be reached Monday-Friday, 8 a.m. to 5 p.m. Pacific time:

Telephone: +1 (831) 724-3800

Email: anafazetechsupport@watlow.com

Be sure to specify PPC2000 when asking for technical support.

Initial Inspection

Accessories may or may not be shipped in the same container

as the PPC-2010 controller, depending upon their size. Check

the shipping invoice carefully against the contents received in

all boxes.

2 Watlow Anafaze Doc.# 30002-00 Rev 2.3

Page 27

PPC-2000 User’s Guide Chapter 1: Overview

Product Features

The PPC-2000 (PPC) offers high performance closed-loop (PID)

control and the ability to manipulate process control

algorithms and sequential logic in a very user friendly way. It

is a modular programmable process control system that utilizes

plug-in modules to meet different system requirements. The

controller can be configured for as many as 48 channels of PID

control and supports up to 288 programmable digital I/O

points. A motor interface module allows for operating up to 16

motor speed control systems. Seven types of hardware modules

are supported by the PPC system. AnaWin3 HMI software is

used for configuration, operation and data acquisition.

LogicPro software is available as an option and can be used to

write logic programs for sequential and process control.

The PPC controller includes the following features:

• Multiple channels of closed-loop control and

programmable logic in an integrated package

• User-programmable, advanced control algorithms

• Modular hardware

• Bus expansion up to 9 additional modules

• Serial communication

• AnaWin3 operator interface compatible (single or multiple

PPC modbus network capability

• Analog inputs (as many as 128) per PPC system

• Multiple sensor inputs: multiple TC types, RTD, voltage,

current

• As many as 288 digital I/O points

• 48 closed-loop control channels with autotune

• Windows

• Third-party operator interface terminal (OIT) support

(option)

®

-based logic programming software (option)

System Components

Any system must include a power supply and a processor

module (PPC-2010) with built-in digital I/O. The appropriate

additional modules are added for analog inputs, analog

outputs, and expanding the digital I/O.

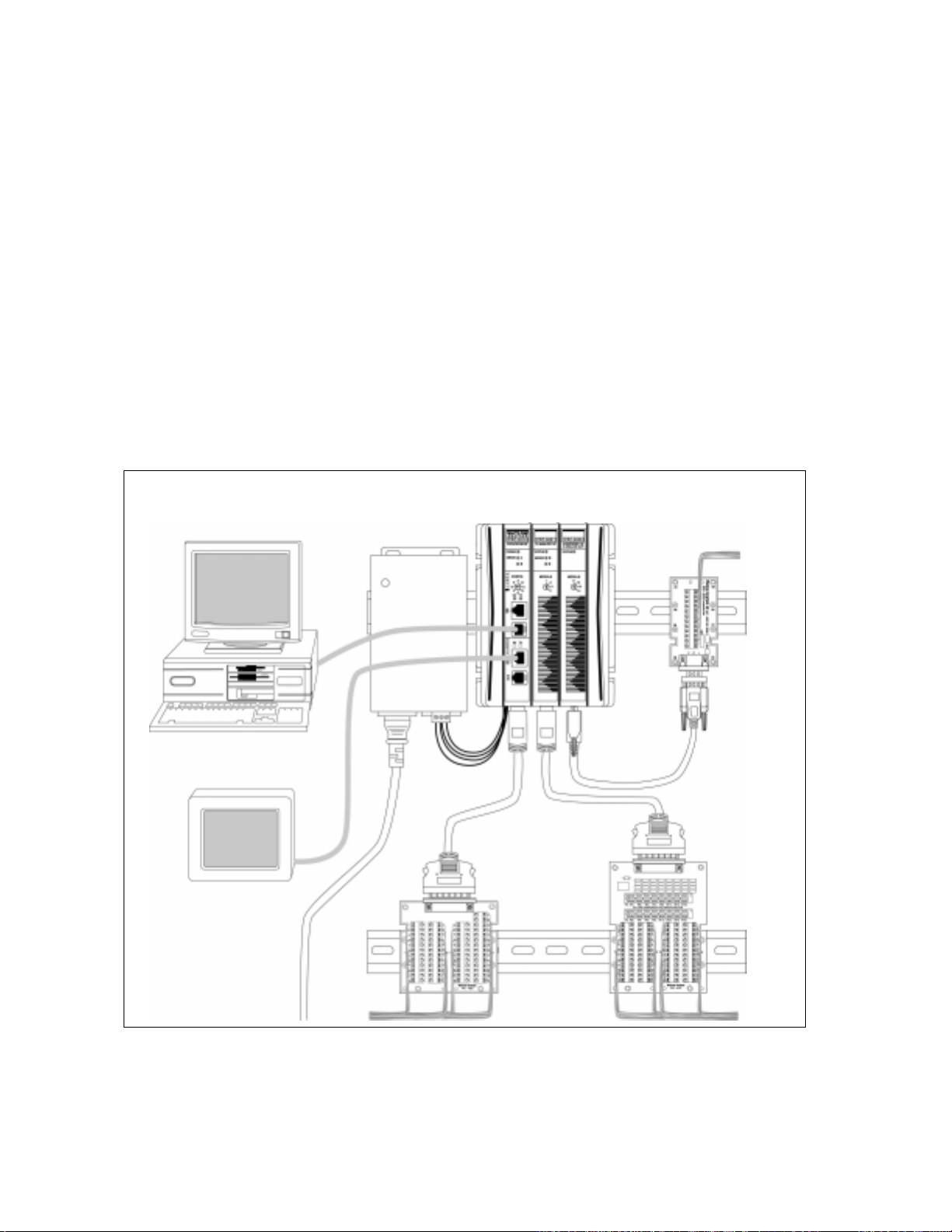

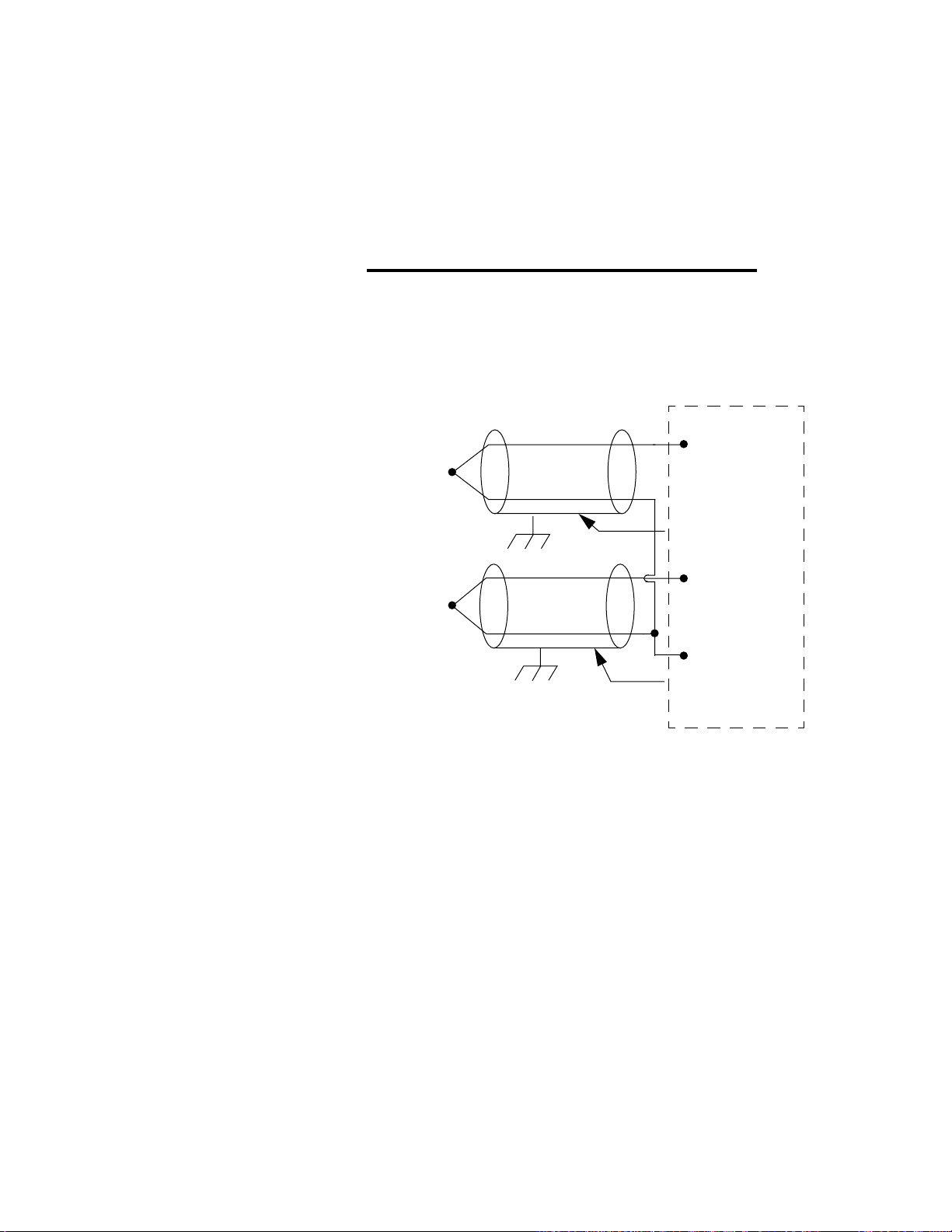

See Figure 1.1 on page 6-4 and Figure 1.2 on page 6-6 for

illustrations of the PPC’s system components and modules.

Refer to Table 1.1 on page 5 for a description of the modules and

their functions.

The number and types of I/O are determined by which modules

are selected for the application. Field wiring connects to DIN

rail or panel mounted terminal block boards. Terminal block

boards connect to I/O modules via 50-pin SCSI cables.

Doc.# 30002-00 Rev 2.3 Watlow Anafaze 3

Page 28

Chapter 1: Overview PPC-2000 User’s Guide

The following hardware and software interfaces are provided:

Hardware

• Serial ports for interfacing host computers and thirdparty operator displays

• Analog input and output terminal block connections

• Digital input and output terminal block connections

Software / Firmware

• Remote third-party operator interface panel software

using Modbus protocol (option)

• AnaWin3 Configurator edition: Windows configuration

utility

• LogicPro: Windows logic programming utility (option)

• AnaWin3 Developer edition: Windows user interface, data

monitoring and trend logging utility (option)

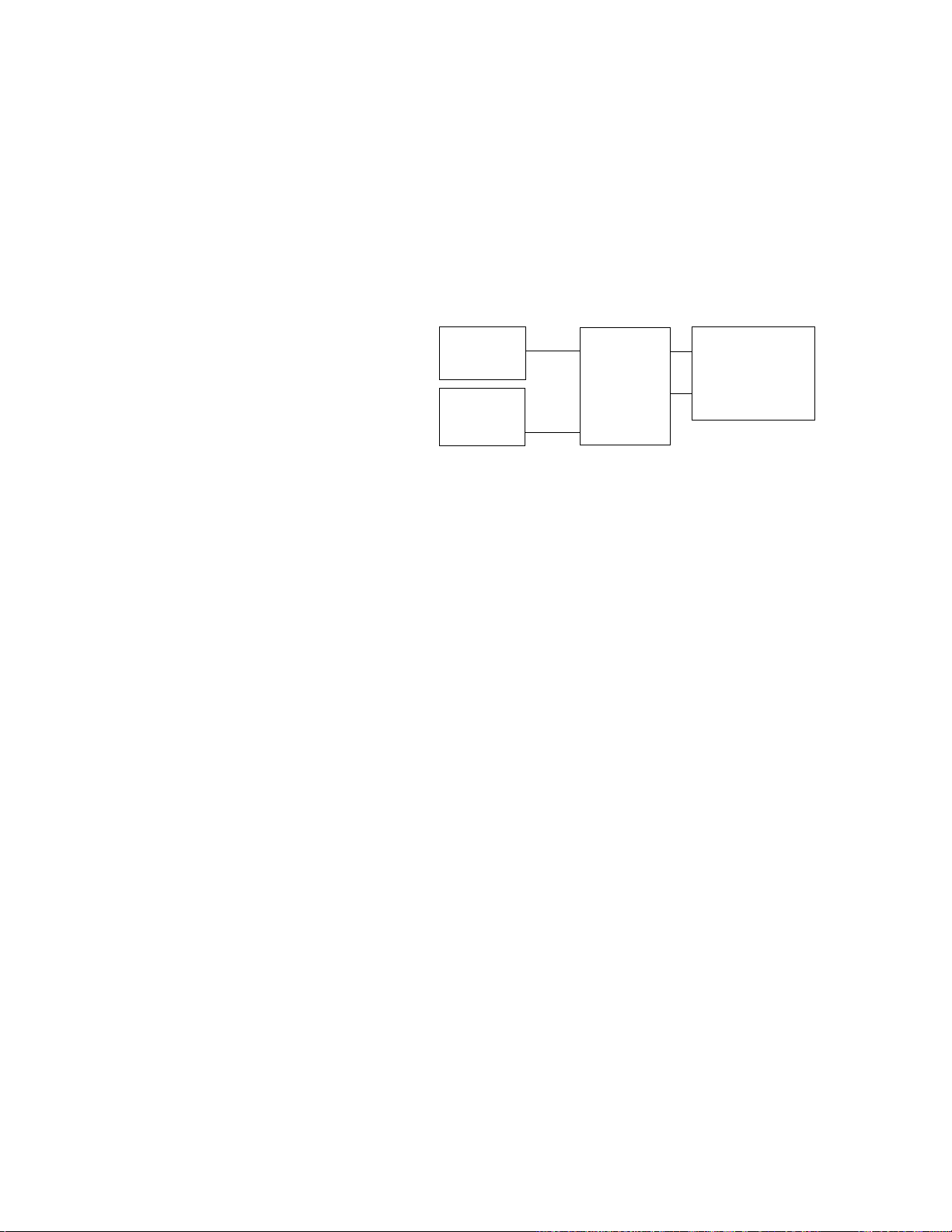

PC for AnaWin3 HMI

Software and/or LogicPro

Operator

Interface

Terminal

Power

Supply

PPC-2000

Assembly

TB50 for

Digital I/O

Encoder Input

Terminal Block

(EITB)

Analog Input

Terminal Board

(AITB)

Figure 1.1 System Diagram

4 Watlow Anafaze Doc.# 30002-00 Rev 2.3

Page 29

PPC-2000 User’s Guide Chapter 1: Overview

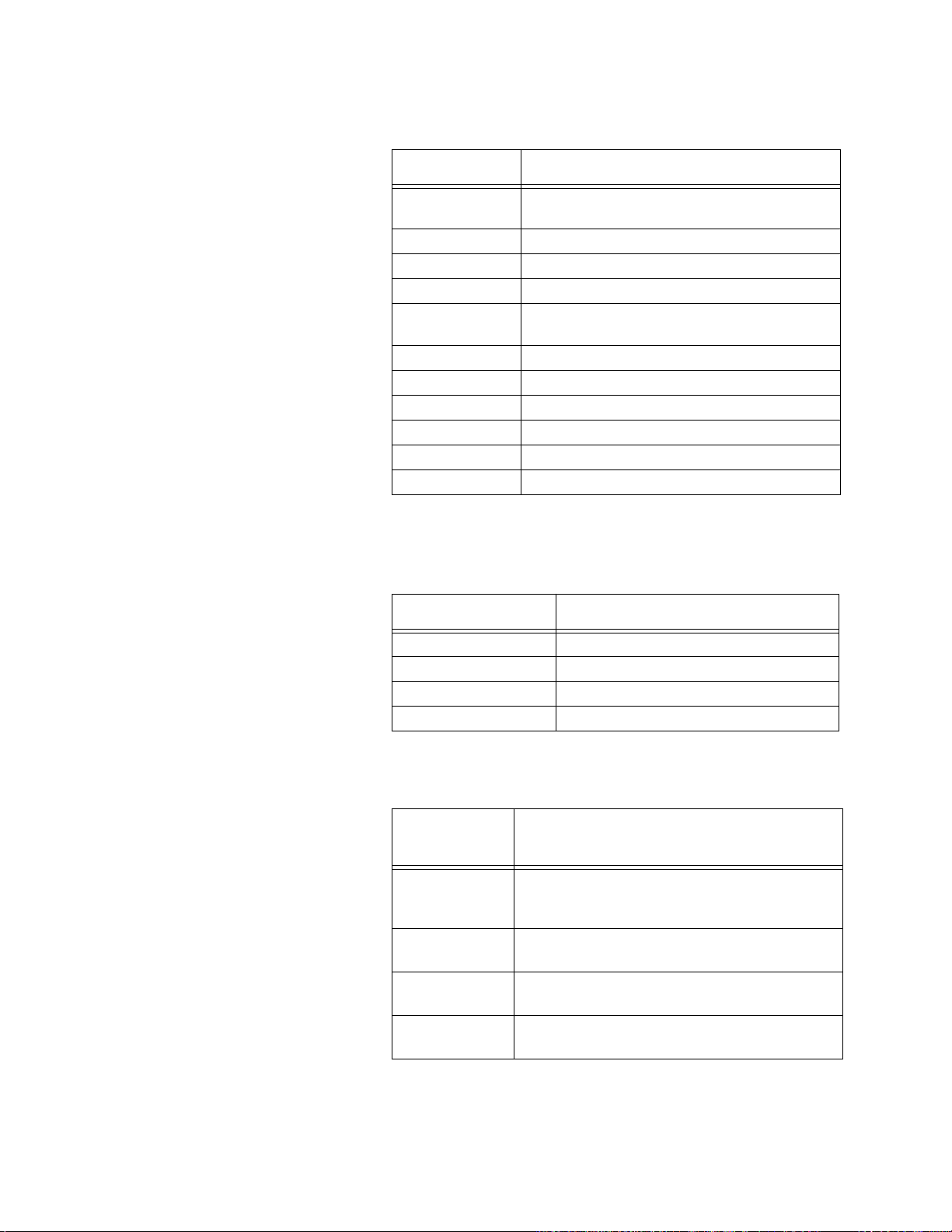

Table 1.1 PPC-2000 System Modules

Module Description

PPC-2010

PPC-2021, 2022 16 differential or 32 single-ended analog inputs

PPC-2024, 2025 8 or 16 highly isolated analog inputs

PPC-2030 4 encoder inputs and 4 analog outputs

PPC-2040

PPC-2050 8 analog outputs

PPC-2051 4 analog outputs

PPC-2061 16 relay outputs

PPC-2062 8 relay outputs

PPC-2070, 2071 8,16 120Vac inputs

PPC-2072, 2073 8,16 24V AC/DC inputs

Processor, 48 digital I/O, 2 serial ports,

1 counter/frequency input

32 configurable digital I/O, 2 counter/frequency

inputs

Table 1.2 PPC-2000 Terminal Boards and

Peripheral Modules

Terminal Board Description

PPC-IPS-2 International Power Supply, 120W

PPC-AITB-1 Analog Input Terminal Board

PPC-TB50-SCSI Terminal board for digital I/O

PPC-EITB-1 Encoder Input Terminal Board

Table 1.3 Analog Terminal Board Keys

Key

(Color Code)

PPC-KEY-20

(none)

PPC-KEY-30

(blue)

PPC-KEY-40

(black)

PPC-KEY-50

(red)

Doc.# 30002-00 Rev 2.3 Watlow Anafaze 5

Adapts AITB for:

Thermocouples (differential or single-ended)

Linear voltages (differential or single-ended)

Adapts AITB for 0-20mA linear current

(differential)

Adapts AITB for 0-20mA linear current

(single-ended)

Adapts AITB for 2-wire RTDs (differential) or

3-wire RTDs (differential)

Descriptions

Page 30

Chapter 1: Overview PPC-2000 User’s Guide

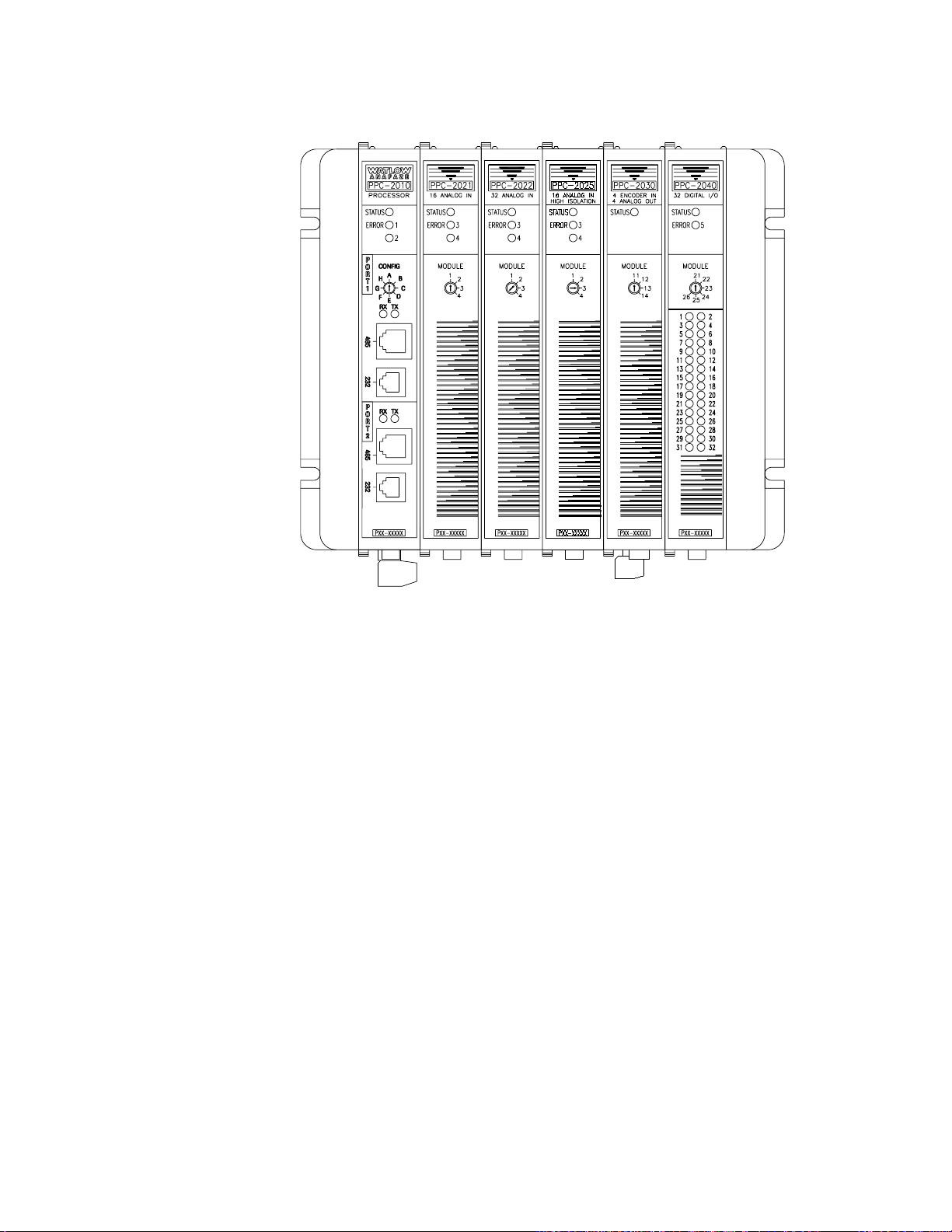

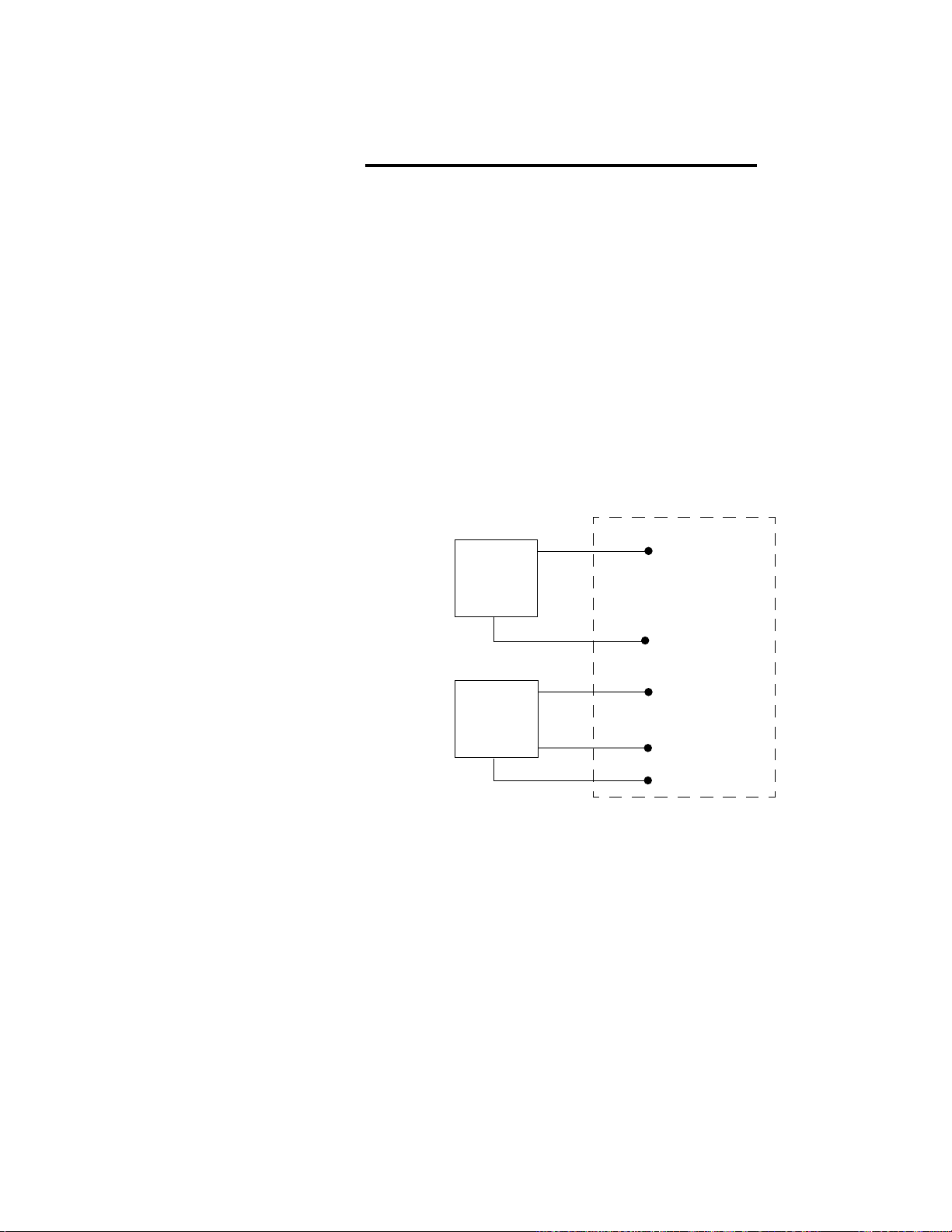

Figure 1.2 Sample PPC-2000 System

PPC-2000 Modules

The following sections describe the purpose and features of

each type of module available with the PPC-2000 system.

PPC-2010 Processor Module

The PPC-2010 processor module houses the system

microprocessor, memory and controller programs. Modular

communication ports support connections with a PC running

AnaWin3

connections with third-party operator interface panels or other

devices that communicate using Modbus protocol. Communications ports one and two may be used simultaneously.

Additional modules may be connected to the processor module’s

expansion bus to add capabilities to the PPC system.

Precision analog outputs can be provided using Serial Digital to

Analog Converters (SDAC). Each SDAC unit converts a control

output from the processor module to an analog voltage or

current signal. For more specific information, see

Analog-to-Digital Converter on page 9

and

LogicPro

or third-party interface software, and

SDAC Serial

.

6 Watlow Anafaze Doc.# 30002-00 Rev 2.3

Page 31

PPC-2000 User’s Guide Chapter 1: Overview

The PPC-2010 has 48 built-in digital I/O points. 24 points are

outputs only. 22 of these outputs are user configurable for PID

control, alarms or logic outputs. The other 2 outputs are

dedicated to system status and global alarm. The remaining 24

I/O points are individually configurable as either inputs or

outputs.

The following summarizes the processor’s features:

• 2 isolated communication ports

• Transmit/receive indicators

• Rotary switch for setting the Modbus network address

• 46 user configurable digital I/O

• System status and digital output overload indicators

• Real time clock

• Flash PROM and battery backed RAM

• Connects to terminal block board via 50-pin SCSI cable

PPC-2021 - 2022 Analog In Modules

The PPC-2021 and 2022 modules plug in to the module

expansion bus. The analog input modules support 16

differential inputs or 32 single-ended inputs, and accommodate

various sensors such as thermocouples (TCs), Resistive

Temperature Sensing Devices (RTDs) and linear transducers

using the terminal boards described later in this section.

• Supports TCs, RTDs and linear voltage and current

signals

• LED status indicator

• DIN rail/panel mount

• Connects to analog input terminal board via 50-pin SCSI

cable

PPC-2024 - 2025 Analog In High Isolation Modules

The PPC-2024 and 2025 modules plug in to the module

expansion bus. The high isolation analog input modules accept

8 or 16 differential analog inputs and accommodate various

sensors such as TCs, RTDs and linear transducers using the

terminal boards described later in this section.

• High voltage isolation capability

• Supports TCs, RTDs and linear voltage & current signals

• LED status indicator

• DIN rail/panel mount

• Connects to analog input terminal board via 50-pin SCSI

cable

Doc.# 30002-00 Rev 2.3 Watlow Anafaze 7

Page 32

Chapter 1: Overview PPC-2000 User’s Guide

PPC-2030 Encoder In Analog Out Module

The PPC-2030 is used in applications including monitoring and

controlling belt speeds, motor speeds, positioning, etc.

Four isolated analog outputs are jumper configurable for

current or voltage. These outputs may be used to provide

software selectable analog output signals to field devices.

Four counter inputs are used for interfacing to motor encoder

signals. The counters interface to both single-ended and

differential styles of encoder signals and count quadrature

signals for increased resolution, accuracy and direction.

PPC-2040 Digital I/O Module

Up to four PPC-2040 modules may be added to a PPC system.

Each module includes 32 digital I/O points which are

individually configurable as inputs or outputs and two counter

and frequency inputs.

PPC-2050 - 2051 Analog Out Modules

Up to four PPC-2050 and PPC-2051 modules may be added to

a PPC system. Modules include four or eight analog outputs.

PPC-2061 - 2062 Digital Out Relays Module

Up to six PPC-2060, PPC-2061, and PPC-2062 modules may be

added to a PPC system. The PPC-2061 features 16

electromechanical relays. These relays can switch AC or DC

loads. Two sets of eight relays each have a common. The PPC2062 features eight electromechanical relays.

PPC-2070 - 2073 Digital In Modules

Up to four modules of this type may be added to a PPC system.

Each module includes either 8 or 16 discrete inputs. The PPC2070 and 2071 modules accept 120Vac signals. The PPC-2072

and 2073 modules accept either 24Vac or 24Vdc.

PPC-2000 Terminal Boards

The following sections describe the terminal boards that

support field I/O connections to some modules.

PPC-AITB-1 Analog Input Terminal Board

The AITB is a compact field wiring interface for all analog

input modules. The AITB includes terminal blocks and

removable keys used for different types of inputs such as TCs,

RTDs and linear signals. For more information on these

signals, refer to PPC-KEY-01 through 04 in Table 1.1 on page

5. The keys allow easy configuration of the terminal block for

different types of inputs on different channels. The AITB is

DIN rail or panel mount compatible.

8 Watlow Anafaze Doc.# 30002-00 Rev 2.3

Page 33

PPC-2000 User’s Guide Chapter 1: Overview

PPC-EITB-1 Encoder Input Terminal Board

The EITB is a DIN rail or panel mountable terminal block card

which provides means to interface with motor encoders. Two

pulse inputs (single ended or differential, single or quadrature

phased) may be connected to the screw terminals. A 5Vdc

power source interconnect is provided to supply encoders.

PPC-TB50-SCSI 50-Pin Terminal Board

The TB50 connects to the Processor or Digital I/O module

through the SCSI connector. The terminal blocks interface to

digital I/O field wiring (sensors, actuators, relays, SSRs, etc.).

The TB50 has 48 input/output points. This terminal board is

DIN rail or panel mount compatible.

Additional Components

The following sections describe the optional SDAC module and

the PPC-IPS-2 power supply.

SDAC Serial Analog-to-Digital Converter

The SDAC peripheral module can be connected to a digital

output on the PPC-2010 Processor module. The SDAC converts

a special serial signal to an analog output.

One digital output is required for each SDAC module. Up to 5

SDACS may be connected. When using one or more SDACs, the

SDAC clock output from the PPC-2010 is used as well. The

Processor/SDAC clocks are tied together (the same clock line is

used for each SDAC).

PPC-IPS-2

Safety

WARNING!

The PPC-IPS-2 accepts power in two switch-selectable ranges:

88 to 132Vac and 176 to 264Vac at 47 to 440Hz. It has overload

and overvolt protection. The PPC-IPS-2 powers the PPC

system with 24Vdc and has 5Vdc available for powering loads.

Watlow Anafaze has made every effort to ensure the reliability

and safety of this product. In addition, we have provided

recommendations that will allow you to safely install and

maintain this controller. This product should not be used in any

manner not specified by Watlow Anafaze.

∫

Ensure that power has been shut off to your entire

process before you begin installation or servicing of

the controller.

Doc.# 30002-00 Rev 2.3 Watlow Anafaze 9

Page 34

Chapter 1: Overview PPC-2000 User’s Guide

CAUTION: This product is intended for indoor use only.

∫

WARNING!

Power, input or output circuits with hazardous

voltage levels should not have any live accessible

parts.

∫

WARNING!

External Safety Devices

In any application, failures can occur. These failures

can result in full control output (100% power), or the

occurrence of other output failures which can cause

damage to the controller, or to the equipment or

process connected to the controller. Therefore,

always follow good engineering practices, electrical

codes, and insurance regulations when installing and

operating this equipment.

External safety devices should be used to prevent potentially

dangerous and unsafe conditions upon equipment failure.

Always assume that this device can fail with outputs full-on, or

full-off, by the occurrence of an unexpected external condition.

∫

WARNING!

Always install high or low temperature protection in

installations where an over-temperature or undertemperature fault will present a potential hazard.

Failure to install external protection devices where

hazards exist can result in damage to equipment and

property as well as loss of human life.

Contact Watlow Anafaze immediately if you have any

questions about system safety or system operation.

10 Watlow Anafaze Doc.# 30002-00 Rev 2.3

Page 35

PPC-2000 User’s Guide Chapter 1: Overview

External Switch Disconnect

∫

WARNING!

Provide a labeled switch or circuit breaker connected

to the PPC-2000 power wiring as the means of

disconnection for servicing. Failure to do so could

result in damage to equipment and/or property, and/

or injury or death to personnel. The disconnect

should be located so that operators and technicians

can access it quickly and easily.

Battery Safety

ç

CAUTION!

Product Markings and Symbols

The battery used in this device may result in a fire or

chemical burn hazard if mistreated. Do not

disassemble, heat above 100˚C (212˚F) or incinerate.

Dispose of used battery properly. Keep away from

children.

This symbol indicates that the products meets the essential

requirements of applicable European Union Directives.

CUS

LISTED

Î

Doc.# 30002-00 Rev 2.3 Watlow Anafaze 11

This symbol indicates that the product is listed by

Underwriters Laboratory and Canadian Underwriters

Laboratory.

The terminals adjacent to this symbol should be connected to

DC voltage only.

Page 36

Chapter 1: Overview PPC-2000 User’s Guide

12 Watlow Anafaze Doc.# 30002-00 Rev 2.3

Page 37

Hardware Installation

This section describes how to install your PPC system

hardware. It provides detailed instructions for each component

and peripheral item. Read this chapter before installing your

PPC-2000 system.

Power Supply Requirements

Watlow Anafaze provides the PPC-IPS2 power supply for the

PPC-2000 system. This unit supplies sufficient current for a

processor and various combinations of I/O modules. For

specification information on the power supply, refer to Chapter

7, Specifications.

Any power supply connected to the PPC-2000 should meet

these requirements:

2

• Transformer isolation

• Reliable operation without noise or feedback

• Provides specified voltage and current

• UL Listed

• Suitable for use in a 60°C ambient environment

Regardless of which power supply you use, you must provide

sufficient current in the specified voltage range, 10-28Vdc. The

current requirement depends on the type and number of

modules used. A separate power supply is required for each

controller. Use Table 2.1 on page 14 to calculate the current

requirements for your system.

Doc.# 30002-00 Rev 2.3 Watlow Anafaze 13

Page 38

Chapter 2: Hardware Installation PPC-2000 User’s Guide

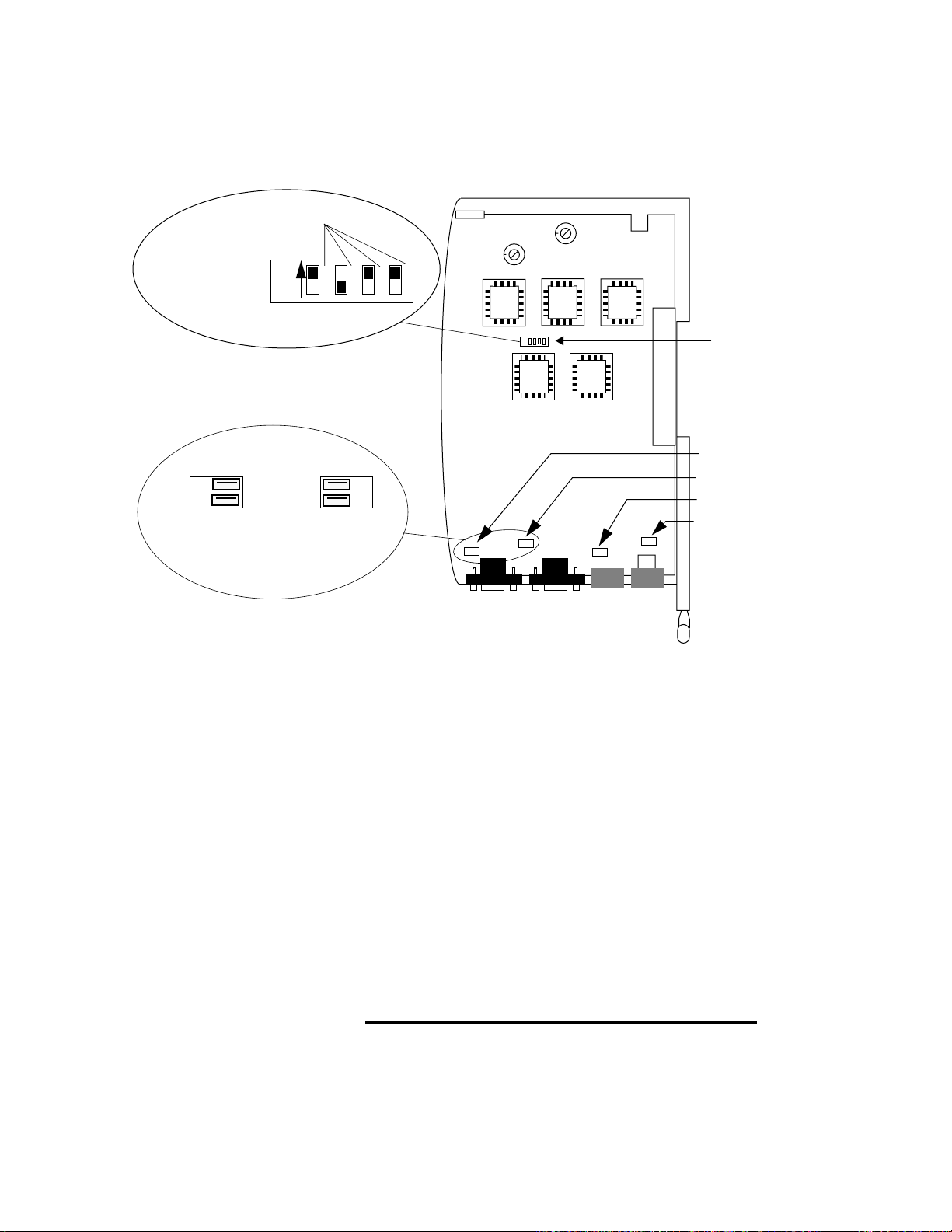

Table 2.1 Power Supply Current

Requirements at 12Vdc

Module Number

of

modules

Current

(startup)

per

Current

module

PPC-2010 1 x 250mA = 250mA

PPC-202x

(max. 4)

PPC-2030

(max. 4)

PPC-2040

(max. 6)

PPC-2050

PPC-2051

(max. 4)

PPC-206x

(max. 6)

PPC-207x

(max. 4)

Total Number of

Modules

(max. 10)

x 390mA =

x 900mA =

x 300mA =

xx800mA

500mA

x 250mA =

x 100mA =

total

current

required

=

=

=

Table 2.2 Power Supply Current Requirements

at 24Vdc

Module Number

of

modules

PPC-2010 1 x 125mA = 125mA

PPC-202x (max. 4) x 195mA =

PPC-2030 (max. 4) x 450mA =

PPC-2040 (max. 6) x 150mA =

PPC-2050

PPC-2051

(max. 4)

PPC-206x (max. 6) x 125mA =

PPC-207x (max. 4) x 50mA =

Total Number of

Modules (max. 10)

x

Current

(startup)

per

module

400mA

250mA =

total

current

required

Current

=

14 Watlow Anafaze Doc.# 30002-00 Rev 2.3

Page 39

PPC-2000 User’s Guide Chapter 2: Hardware Installation

∫

WARNING!

The PPC is designed to operate on 12-28Vdc.

Connection to a power source other than this will

cause damage to the PPC.

To avoid electrical shock, correctly connect the

power supply’s earth ground.

Mounting the Power Supply

Mount the hardware in an area free of moisture or corrosive

chemicals. Mount the power supply vertically with adequate

vent space. Locate the power supply for the PPC such that the

AC supply and DC connections to the PPC may be made. The

PPC-IPS-2 can be DIN rail or screw mounted. Refer to Figure

2.1 for power supply mounting clearances. All dimensions are

measured in inches.

2.5 in. min.

Air Flow Space

ADJ

1.2 in.

V2 COM COM V1 V1 V1

L N

1.97 in.

3.1 in.

Figure 2.1 PPC-IPS-2 DIN Mounting

Dimensions

Doc.# 30002-00 Rev 2.3 Watlow Anafaze 15

Page 40

Chapter 2: Hardware Installation PPC-2000 User’s Guide

All

Vented

1.97 in.

1.32 in.

115

0.93 in.

0.24 in.

7.5 in. 7.84 in.

0.10 in.

Figure 2.2 PPC-IPS-2 Panel Mounting

Dimensions

To DIN rail mount the PPC-IPS-2:

1. Locate a space with sufficient room for the power supply

and connecting wires. Refer to Figure 2.1 on page 15.

2. Install a section of DIN rail.

3. Hook the top of the DIN rail latch over the DIN rail such

that the spring is under the lip of the rail.

4. Push down on the power supply, compressing the spring

then rock the bottom of the latch onto the rail.

To panel mount the PPC-IPS-2:

1. Locate a space with sufficient room for the power supply

and connecting wires. Refer to Figure 2.2.

2. Mark the mounting holes. See Table 2.3 on page 16.

3. Drill and tap the mounting holes.

4. Place the power supply such that the holes are aligned,

insert the screws and tighten them

Table 2.3 Power Supply Screw Mounting

PPC-IPS-2

Number of Screws 3

Drill and tap size #6

16 Watlow Anafaze Doc.# 30002-00 Rev 2.3

Page 41

PPC-2000 User’s Guide Chapter 2: Hardware Installation

Hardware Configuration

In order for multiple PPC modules to function together, each

needs to be addressed correctly. Some of the PPC modules may

require jumper or switch settings to work with field input and

output devices. The following sections describe the

configuration options and procedures.

Module Addresses

Each module in a PPC assembly must have a unique address.

The PPC-2010 module is fixed as module address 0 in the

firmware. The other modules’ addresses are set with rotary

switches on the face of each module. Set a unique address on

each module by turning the arrow to an appropriate address

number. See Figure 2.3.

ç

CAUTION!

NOTE!

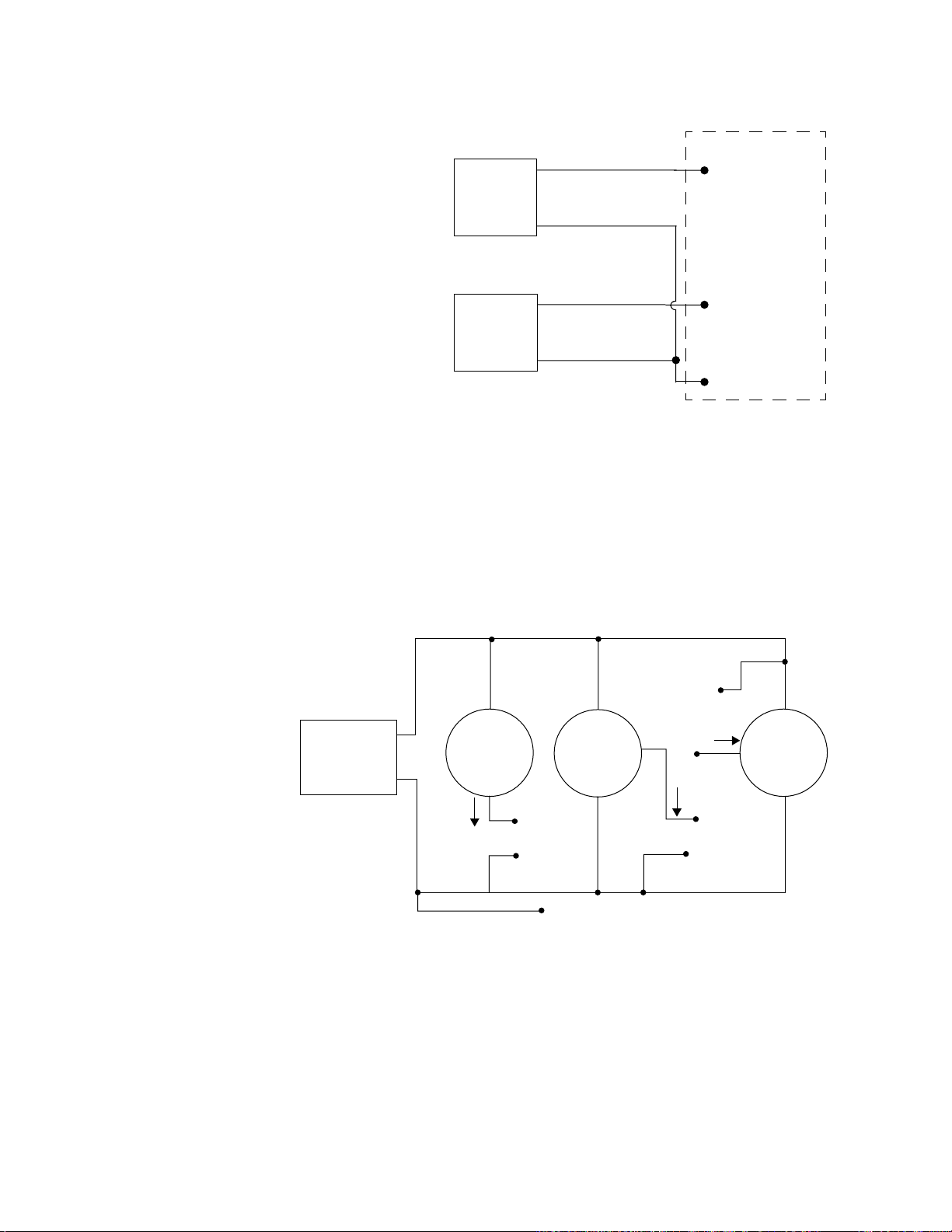

Figure 2.3 Sample Addresses

Table 2.4 on page 18 lists the maximum number allowable of

each type of module per system, as well as the available

address settings. Pay close attention when using more than one

module of a particular type in a system. For example, one PPC

system allows up to four analog input modules (PPC-2021 -

2025) and each must have a unique address setting, as shown

in Figure 2.3.

If address settings are changes, modules added or

removed after the system has been initialized,

modules may not function correctly. To assure proper

operation, perform a RAM Clear after changing the

number of modules or address settings in a PPC

system. Refer to Chapter 4, Resetting Closed-Loop

Control Parameters on page 156.

It may be useful to label each module with the address

you select.

Doc.# 30002-00 Rev 2.3 Watlow Anafaze 17

Page 42

Chapter 2: Hardware Installation PPC-2000 User’s Guide

Table 2.4 System Modules and Addressing

Module Max.

#*

2010 (PROCESSOR) 1 0 (not switch selectable)

2021, 2022

(ANALOG IN)

2023, 2024, 2025

(ANALOG IN

HIGH ISOLATION)

2030

(ENCODER IN

ANALOG OUT)

2040

(DIGITAL I/O)

2050, 2051

(ANALOG OUT)

2061, 2062

(DIGITAL OUT)

2070, 2071

(DIGITAL IN, 120Vac)

2072, 2073

(DIGITAL IN, 24Vac/DC)

4 1-4

4 11-14

6 21-26,

4 31-34

6 41-46

4 51-54

Rotary Switch

Address Range

* Maximum number of this type of module in a system

PPC-2010 Jumper Settings

Jumper settings in the PPC-2010 select whether the

communication lines are terminated or not. Each

communication port is configured separately. For installation

information, refer to Connecting RS-485 Communications on

page 81.

Wear a grounding strap and place components on static-free

grounded surfaces only. Locate jumpers 1 and 2. Table 2.5

describes the PPC-2010 jumper configuration. Install the

jumper in the orientation shown in Figure 2.4 on page 19.

Table 2.5 PPC-2010 Processor Module Jumpers

Port Jumper #

1 JU1 A B

2 JU2 A B

Terminated

Position

Unterminated

Position

18 Watlow Anafaze Doc.# 30002-00 Rev 2.3

Page 43

PPC-2000 User’s Guide Chapter 2: Hardware Installation

Flash memory

Chip (firmware)

Notch

Termination

Jumper

Port 1

JU1

B A

Not T erminated

Position

JU1

B A

B A

JU2

Figure 2.4 PPC-2010 Jumpers

Battery

Notch

PPC-2030 Dip Switch Settings

Switch settings in the PPC-2030 determine whether encoder

inputs accept single phase or quadrature encoder signals. Each

of the four inputs is configured individually, therefore single

phase and quadrature inputs may be mixed in a module.

Wear a grounding strap and place components on static-free

grounded surfaces only. Locate switch bank 1 near the center

of the PPC-2030 module. Refer to Figure 2.5 on page 20. Set

each switch for the corresponding input to the single phase (on)

or quadrature (off) position. The switch is on when in the

direction indicated by the arrow.

ç

CAUTION!

Be sure to take antistatic precautions.

Doc.# 30002-00 Rev 2.3 Watlow Anafaze 19

Page 44

Chapter 2: Hardware Installation PPC-2000 User’s Guide

{Improve illustration. More like 2.6 and 2.7.}

Counter Input Number

Single Phase

Quadrature

51

SV4

Analog Output Jumpers

. . .

. . .

v

i

Voltage

Position

Current

Position

432

1

S1

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . .

. . .

v

i

...

...

...

JU1

...

...

JU2

...

Figure 2.5 PPC-2030 Jumpers and Switches

...

...

JU4

JU3

Dip Switch

JU1 (Output 4)

JU2 (Output 3)

JU3 (Output 2)

JU4 (Output 1)

PPC-2030 Jumper Settings

Each of the four analog outputs on the PPC-2030 may be

configured either as a voltage output or a current output. A

mixture of current and voltage outputs may be used on a

particular module. The jumpers only determine if the output

signal is current or voltage. The actual span of the signal is

software selectable. See Output Type in Channels on page 115

for the various analog output signal settings.

Locate Jumpers 1 through 4. Table 2.6 on page 21 describes the

analog output jumper configuration. Install the jumper in the

orientation shown in Figure 2.5.

ç

CAUTION!

20 Watlow Anafaze Doc.# 30002-00 Rev 2.3

Incorrectly installing the jumper may damage the

PPC-2030 module.

Page 45

PPC-2000 User’s Guide Chapter 2: Hardware Installation

Table 2.6 PPC-2030 Analog Output Jumpers

Analog

Output

1 JU4 0-20mA 0-10Vdc

2 JU3 0-20mA 0-10Vdc

3 JU2 0-20mA 0-10Vdc

4 JU1 0-20mA 0-10Vdc

* Listed values are maximum ranges. Other ranges within these

limits may be selected in software.

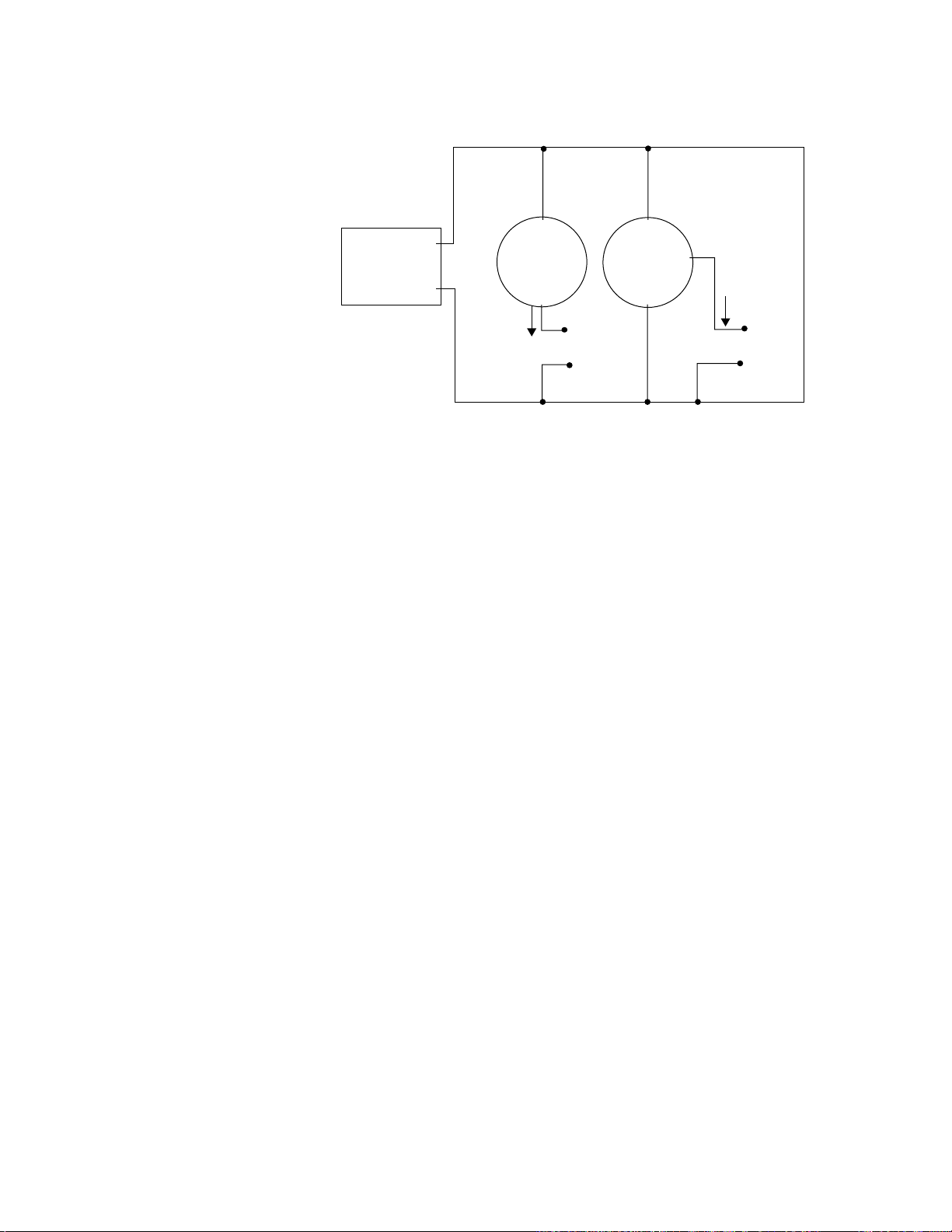

PPC-2040 Jumper Settings

Each of the counter inputs on the PPC-2040 can be configured

for single phase or quadrature input. Jumper positions

determine the counter input configuration. To select single

phase or quadrature, see Table 2.7 and Figure 2.6 to determine

which jumper to set and appropriate position.

Table 2.7 PPC-2040 Counter Input Jumpers

Counter

Input

Jumper #

Jumper

PPC-2040

i (current)

position*

Single Phase

Position

V (volt)

position*

Quadrature

Position

1 JU1 A B

2 JU2 A B

JU2

JU1

A B

A B

Figure 2.6 PPC-2040 Jumper Settings

Doc.# 30002-00 Rev 2.3 Watlow Anafaze 21

Page 46

Chapter 2: Hardware Installation PPC-2000 User’s Guide

PPC-205x Jumper Settings

Each of the analog outputs on the PPC-205x modules may be

configured either as a voltage output or a current output. A

mixture of current and voltage outputs may be used on a

particular module. The jumpers only determine if the output

signal is current or voltage. The actual span of the signal is

software selectable. See Heat/Cool Output Type in Channels

section on page 119 for the various analog output signal

settings.

To configure an output, see Table 2.8 on page 22 and Figure 2.7

on page 23 to determine which jumper to set. Set the jumper in

the indicated position and orientation.

Table 2.8 PPC-205x Analog Out Jumpers

Analog

Output

1 JU1 JU1 0-20mA 0-10Vdc

2 JU2 JU3 0-20mA 0-10Vdc

3 JU3 JU5 0-20mA 0-10Vdc

4 JU4 JU7 0-20mA 0-10Vdc

5 JU5 n/a 0-20mA 0-10Vdc

6 JU6 n/a 0-20mA 0-10Vdc

7 JU7 n/a 0-20mA 0-10Vdc

8 JU8 n/a 0-20mA 0-10Vdc

Jumper

PPC-2050

* Listed values are maximum ranges. Other ranges within these

limits may be selected in software.

Jumper

PPC-2051

i (current)

Position*

v (voltage)

Position*

22 Watlow Anafaze Doc.# 30002-00 Rev 2.3

Page 47

PPC-2000 User’s Guide Chapter 2: Hardware Installation

Analog Output Jumpers

. . .

. . .

I

Voltage

Position

V

. . .

. . .

I

Current

Position

V

JU7

JU6

JU5

JU8

I

V

I

I

V

V

JU4

JU3

JU2

JU1

I

I

I

V

I

I

V

V

V

V

JU8 (2050: Output 8)

JU7 (2050: Output 7, 2051: Output 4)

JU6 (2050: Output 6)

JU5 (2050: Output 5, 2051: Output 3)

JU4 (2050: Output 4)

JU3 (2050: Output 3, 2051: Output 2)

JU2 (2050 Output 2)

JU1 (Output 1)

Figure 2.7 PPC-205x Jumpers

Doc.# 30002-00 Rev 2.3 Watlow Anafaze 23

Page 48

Chapter 2: Hardware Installation PPC-2000 User’s Guide

Module Assembly

Modules should be assembled prior to mounting. The processor

module is always the first module (left side) on a PPC system.

To connect other modules, use the following procedure.

ç

CAUTION!

ç

CAUTION!

To avoid damaging your PPC system, never connect

or disconnect modules that are powered.

PPC modules contain sensitive electronic

components. Be sure to observe ESD safety

precautions such as wearing a ground strap.

1. Make sure the red top and bottom module latches on the

module to be added are in the unlocked position (pushed

toward the back of the module. Refer to Figure 2.8.

Back

Module

top

latch

(unlocked)

Module

top

latch

(locked)

Front

Figure 2.8 Assembled Modules Top View

24 Watlow Anafaze Doc.# 30002-00 Rev 2.3

Page 49

PPC-2000 User’s Guide Chapter 2: Hardware Installation

2. Align the 4 interconnect tabs and their related slots, as

well as the module expansion bus connector.

Front

Module

bottom

latch

(locked)

Module

bottom

latch

Back

(unlocked)

Figure 2.9 Assembled Modules Bottom View

Slot

Tab

Module

bottom

latch

(locked)

Module

bottom

latch

(unlocked)

Figure 2.10 Modules Bottom/Side View

3. Gently press the modules together while observing the

alignment of the tabs and slots, as well as the pins on the

expansion bus connector.

4. When the module is properly seated, close the module

latches on the processor by pushing the latch toward the

front of the module. The modules are properly locked when

there is a firm connection with no rocking or shifting.

5. Repeat these steps for any additional modules. When

there are no additional modules, install the right end cap

in a similar manner.

Doc.# 30002-00 Rev 2.3 Watlow Anafaze 25

Page 50

Chapter 2: Hardware Installation PPC-2000 User’s Guide

Module Disassembly

To separate modules, reverse the procedure in Module

Assembly on page 24. When separating modules, gently rock

and pull the modules apart.

ç

CAUTION!

To avoid damaging your PPC system, never connect

or disconnect modules that are powered.

Mounting Modules

Once the modules have been assembled, the PPC system may

be mounted on a DIN rail or fastened directly to a vertical

surface inside an electrical cabinet or other enclosure that

requires a key or tool to open, or that has a safety interlock

system. Consult Table 7.2 on page 230 and Figure 7.1 on page

230 to determine mounting hole spacing and installed

clearances. See Figure 1.1 on page 4 for a sample configuration

of PPC system hardware.

∫

WARNING!

Install the PPC-2000 in a controlled environment,

relatively free of contaminants, to

reduce the risk of fire or electric shock.

ç

CAUTION!

NOTE!

26 Watlow Anafaze Doc.# 30002-00 Rev 2.3

The controller may function incorrectly if the ambient

temperature exceeds the operating specification.

Make sure the air temperature surrounding the

controller does not exceed 140°F (60°C).

During wiring and cabinet assembly, prevent debris

from falling inside the PPC by removing the unit from

the area, or cover the ventilation holes on the PPC

system.

Page 51

PPC-2000 User’s Guide Chapter 2: Hardware Installation

DIN Rail Mounting

1. Each module in the assembly has a DIN rail latch. Pull all

the latches to the open position. See Figure 2.11.

DIN Rail Latch

(closed)

DIN Rail Latch

(open)

Figure 2.11 DIN Rail Latches

2. Place the module assembly on the upper lip of the DIN

rail; push the lower side of the assembly over the lower lip

of the DIN rail. See Figure 2.12.

Upper lip of

DIN Rail

DIN Rail Latch

(open)

Push to lock

Figure 2.12 Mounting Assembled PPC

Modules on a DIN rail (side)

3. Push the DIN rail latches up and under the lower lip of the

DIN rail.

Doc.# 30002-00 Rev 2.3 Watlow Anafaze 27

Page 52

Chapter 2: Hardware Installation PPC-2000 User’s Guide

Panel Mounting

The PPC modules may be panel mounted using the mounting

holes located on the end plates. The width of a system varies

depending on the number of modules. Consult Figure 7.1 on

page 230 to determine installed clearances.

To panel mount the modules:

1. Locate a space with sufficient room for the appropriate

number of modules and connecting wires. Refer to Figure

7.1 on page 230 for a system footprint and dimensions.

2. The mounting holes are located on the end caps of the

module assembly. Mark each mounting hole.

3. Drill and tap the four #10 mounting holes.

4. Place the modules such that the holes are aligned, insert

the screws and tighten them.

Mounting Terminal Boards

Terminal boards support interfacing field I/O devices with the

PPC modules. All terminal boards may be DIN rail or panel

mounted. The following sections provide procedures for

mounting the terminal boards.

There are smaller holes on each terminal board that may be

used to secure wiring with tie wraps.

Refer to Figure 2.13 on page 29 for AITB dimensions.

Refer to Figure 2.14 on page 30 for EITB dimensions.

Refer to Figure 2.15 on page 31 for TB50 dimensions.

28 Watlow Anafaze Doc.# 30002-00 Rev 2.3

Page 53

PPC-2000 User’s Guide Chapter 2: Hardware Installation

5.756"

(146 mm)

5.1"

(128 mm)

For more detailed specification information, refer to Chapter 7,

Specifications.

3.6"

(91 mm)

2.0"

(51 mm)

4.70" 5.10" L

(130 mm)(119 mm)

2.6"

(66 mm)

4.0" W

(102 mm)

Figure 2.13 AITB Dimensions / Clearances

Doc.# 30002-00 Rev 2.3 Watlow Anafaze 29

Page 54

Chapter 2: Hardware Installation PPC-2000 User’s Guide

2.2 in.

(56 mm)

3.4 in.

(86 mm)

1.6 in.

(41 mm)

2.0 in. W

(51 mm)

3.8 in. L

(97 mm)

Figure 2.14 EITB Dimensions / Clearances

30 Watlow Anafaze Doc.# 30002-00 Rev 2.3

Page 55

PPC-2000 User’s Guide Chapter 2: Hardware Installation

3.6 in.

(91 mm)

2.3 in.

(58 mm)

DIN Rail Mounting

3.4 in.

(86 mm)

2.6 in.

(66 mm)

4.2 in.W

(102 mm)

4.1in. L

(104 mm)

Figure 2.15 TB50 Dimensions / Clearances

All factory terminal boards snap onto a DIN rail. A TB50 is

shown in the following figures for illustration purposes only.

To install a terminal board on a DIN rail, place the hook side of

the mounting mechanism over one of the DIN rail lips and snap

the board over the other lip.

Doc.# 30002-00 Rev 2.3 Watlow Anafaze 31

Page 56

Chapter 2: Hardware Installation PPC-2000 User’s Guide

DIN Rail Removal

Hook side

Figure 2.16 TB50 Mounted on DIN Rail (Front)

Place a flat blade screw driver through the slot in the board and

hook the blade into the snap latch. Pry the snap latch away

from the DIN rail lip and repeat for the other side. See Figure

2.17.

Removal

catch for

screwdriver

DIN Rail

snap latch

Hook side

Figure 2.17 TB50 Mounted on DIN Rail (Side)

32 Watlow Anafaze Doc.# 30002-00 Rev 2.3

Page 57

PPC-2000 User’s Guide Chapter 2: Hardware Installation