Page 1

ISO 9001

6

PID/Integrated Controller

User's Guide

10-40670

December, 2019

1241 Bundy Boulevard., Winona, Minnesota USA 55987

Phone: +1 (507) 454-5300, Fax: +1 (507) 452-4507

http://www.watlow.com

TOTAL

CUSTOMER

SATISFACTION

3 Year Warranty

Registered Company

Winona, Minnesota USA

Made in the U.S.A.

Page 2

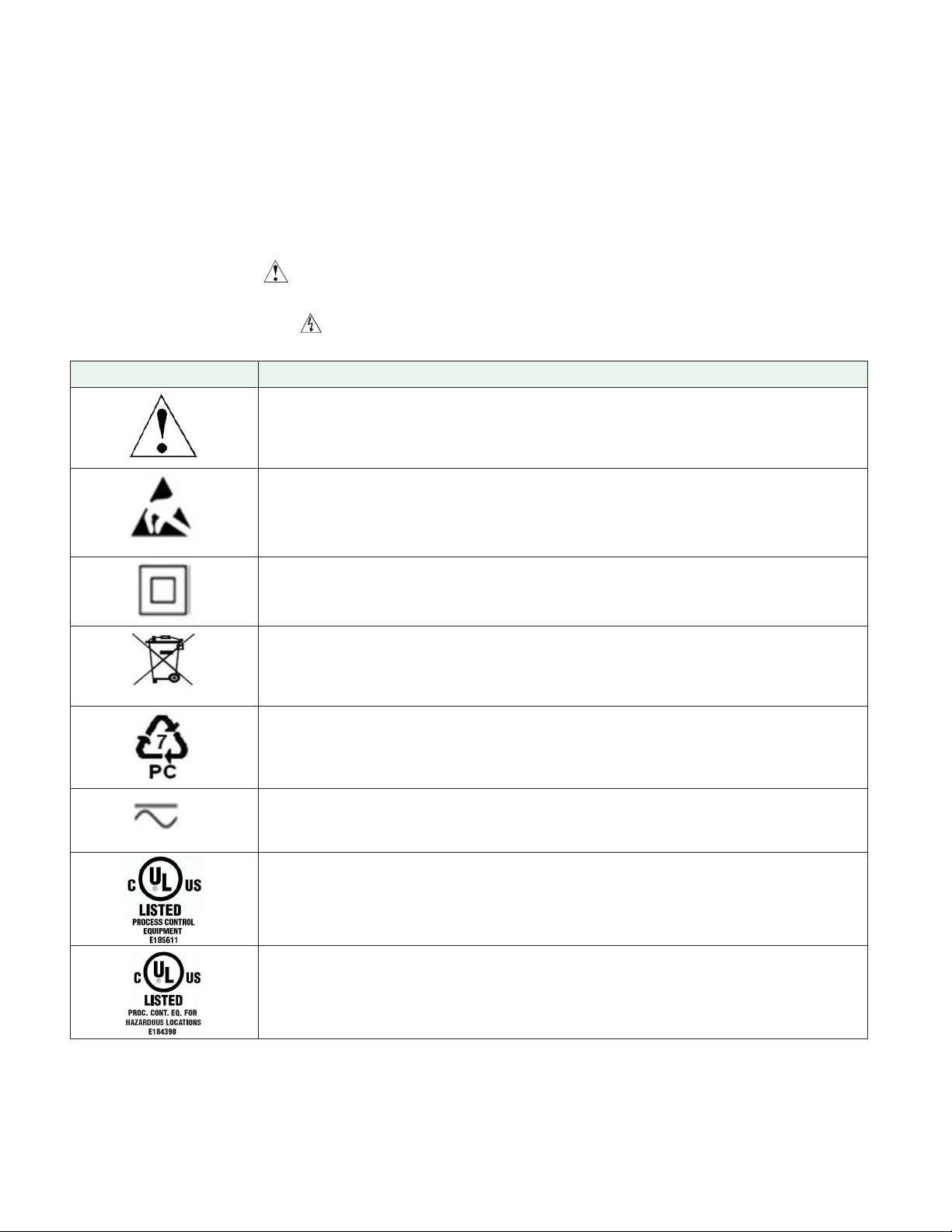

Safety Information

We use note, caution and warning symbols throughout this book to draw your attention to

important operational and safety information.

• A “NOTE” marks a short message to alert you to an important detail.

• A “CAUTION” safety alert appears with information that is important for protecting your

equipment and performance. Be especially careful to read and follow all cautions that apply to your application.

• A “WARNING” safety alert appears with information that is important for protecting you,

others and equipment from damage. Pay very close attention to all warnings that apply to your application.

• The safety alert symbol, (an exclamation point in a triangle) precedes a general

CAUTION or WARNING statement.

• The electrical hazard symbol, (a lightning bolt in a triangle) precedes an electric shock hazard CAUTION or

WARNING safety statement. Further explanations follow:

Symbol Explanation

CAUTION – Warning or Hazard that needs further explanation than label on unit

can provide. Consult User's Guide for further information.

ESD Sensitive product, use proper grounding and handling techniques when

installing or servicing product.

Unit protected by double/reinforced insulation for shock hazard prevention.

Do not throw in trash, use proper recycling techniques or consult manufacturer

for proper disposal.

Enclosure made of Polycarbonate material. Use proper recycling techniques or

consult manufacturer for proper disposal.

Unit can be powered with either alternating current (ac) voltage or direct current

(dc) voltage.

®

Unit is a Listed device per Underwriters Laboratories

. It has been evaluated to

United States and Canadian requirements for Process Control Equipment.

®

61010 and CSA C22.2 No. 61010. File E185611 QUYX, QUYX7.

UL

See: www.ul.com

®

Unit is a Listed device per Underwriters Laboratories

. It has been evaluated

to United States and Canadian requirements for Hazardous Locations Class

1 Division II Groups A, B, C and D. ANSI/ISA 12.12.01-2007. File E184390

QUZW, QUZW7. See: www.ul.com

Watlow PM PLUS™ 6 • 2 •

Page 3

Unit is compliant with European Union directives. See Declaration of Conformity for

further details on Directives and Standards used for Compliance.

Unit has been reviewed and approved by Factory Mutual as a Temperature Limit

Device per FM Class 3545 standard. See: www.fmglobal.com

Unit has been reviewed and approved by CSA International for use as Temperature

Indicating-Regulating Equipment per CSA C22.2 No. 24. See: www.csa-international.

org

Unit has been reviewed and approved by ODVA for compliance with DeviceNet

communications protocol. See: www.odva.org

Unit has been reviewed and approved by ODVA for compliance with Ethernet/IP

communications protocol. See: www.odva.org

Warranty

The PM PLUS is manufactured by ISO 9001-registered processes and is backed by a three-year warranty to

the first purchaser for use, providing that the units have not been misapplied. Since Watlow has no control

over their use, and sometimes misuse, we cannot guarantee against failure. Watlow's obligations hereunder,

at Watlow's option, are limited to replacement, repair or refund of purchase price, and parts which upon

examination prove to be defective within the warranty period specified. This warranty does not apply to

damage resulting from transportation, alteration, misuse or abuse. The purchaser must use Watlow parts to

maintain all listed ratings.

Technical Assistance

If you encounter a problem with your Watlow controller, review your configuration information to verify that your

selections are consistent with your application: inputs, outputs, alarms, limits, etc. If the problem persists, you can

get technical assistance from your local Watlow representative (see back cover), by e-mailing your questions to

wintechsupport@watlow.com or by dialing +1 (507) 494-5656 between 7 a.m. and 5 p.m., Central Standard Time

(CST). Ask for an Applications Engineer. Please have the following information available when calling:

• Complete model number

• All configuration information

• User’s Guide

• Factory Page

Return Material Authorization (RMA)

1. Using the form found on watlow.com/rma, submit a request for a Return Material Authorization (RMA)

number before returning any item for repair. If you do not know why the product failed, contact an

Application Engineer. All RMA’s require:

• Ship-to address

• Bill-to address

• Contact name

Watlow PM PLUS™ 6 • 3 •

Page 4

• Phone number

• Method of return shipment

• Your P.O. number

• Detailed description of the problem

• Any special instructions

• Name and phone number of person returning the product.

2. Prior approval and an RMA number from the Customer Service Department is required when returning any

product. Make sure the RMA number is on the outside of the carton and on all paperwork returned. Ship on a

Freight Prepaid basis.

3. After we receive your return, we will examine it to verify the reason for the product failure. Unless otherwise

agreed to in writing, Watlow's standard warranty provisions, which can be located at www.watlow.com/terms,

will apply to any failed product.

4. In the event that the product is not subject to an applicable warranty, we will quote repair costs to you and

request a purchase order from you prior to proceeding with the repair work.

5. Watlow reserves the right to charge for no trouble found (NTF) returns.

Third Party License Guide

Introduction

PM PLUS incorporates certain third party software within the product. The license terms associated with

this software require we give copyright and license information and this Third Party License Terms List

("TPLTL") provides those details.

Fonts

Roboto

Copyright (C) 2008 The Android Open Source Project

Licensed under the Apache License, Version 2.0 (the "License"); you may not use this file except in compliance

with the License. You may obtain a copy of the License at

http://www.apache.org/licenses/LICENSE-2.0

Unless required by applicable law or agreed to in writing, software distributed under the License is distributed on

an "AS IS" BASIS, WITHOUT WARRANTIES or CONDITIONS OF ANY KIND, either express or implied. See the License

for the specific language governing permissions and limitations under the License.

The PM Plus product firmware contains the Roboto Font. PM Plus product firmware is Copyright (C) 2019 Watlow

Electric Controls, Inc.

This PM PLUS User’s Guide is copyrighted by Watlow Electric, Inc., © December 2019 with all rights reserved.

Watlow PM PLUS™ 6 • 4 •

Page 5

Table of Contents

Chapter 1: Overview .......................................9

Introduction ......................................................9

Standard Features and Benefits .......................................9

PM PLUS™ Operational Overview ....................................11

Inputs ......................................................11

Internal Functions .............................................11

Outputs .....................................................11

Configuration and Monitoring of Features Through Lists ...............12

Profiles .....................................................12

System Diagrams .................................................13

Chapter 2: Installation .....................................17

Installing the Device ...............................................17

Wiring Your New PM PLUS™ .......................................18

Isolation Block Diagram ............................................20

Chapter 3: User Interface ...................................38

Touch Keys ......................................................38

Home Screen ....................................................38

Default Home Screen Parameters .................................38

Active Messages on the Home Screen .................................39

Chapter 4: Operations .....................................40

Operations List ...................................................40

Default Operations Parameters/Sublists ............................40

Adding Custom Parameters to the Operations List ...................42

Chapter 5: Setup .........................................44

Default Configurations for Quick Start .................................44

Configuring Parameters .........................................44

Using Watlow Software to Configure Parameters .....................44

Setup List .......................................................45

Analog Input List ..............................................45

Digital Bus List ...............................................47

Linearization List ..............................................49

Process Value List .............................................50

Digital Input/Output List ........................................51

Limit List ....................................................52

Control Loop List ..............................................53

Watlow PM PLUS™ 6 • 5 • Table of Contents

Page 6

Output List ...................................................56

Alarm List ...................................................57

Current List ..................................................59

Timer List ...................................................59

Math List ....................................................60

Special Output Function ........................................61

Function Key .................................................62

Global List ...................................................62

Communications List ...........................................64

Changing PM PLUS™ to PM PLUS™ Express ...........................67

How to Enact PM PLUS™ Express .............................67

Revert from PM Express to Original Configuration ................68

Saving and Restoring Settings

Reset Original Factory Settings ...................................68

.......................................68

Chapter 6: Profiles .......................................69

Setting Up Global Features ..........................................69

Setting Up Profiles ...............................................69

Starting a Profile ..................................................70

Configuring the Function Key to Start and Stop a Profile ...............70

Configuring a Digital Input to Start and Stop a Profile .................70

Profile List ......................................................71

Chapter 7: Factory List .....................................74

Chapter 8: Features

Autotune ........................................................77

TRU-TUNE+

Input Features ....................................................79

Calibration Offset ..............................................79

Calibration of Analog Inputs .....................................81

Filter Time Constant ...........................................82

Sensor Backup ...............................................83

Set Minimum Set Point and Maximum Set Point .....................83

Scale High and Scale Low ......................................83

Range High and Range Low .....................................84

Remote Set Point

Ten Point Linearization .........................................85

Output Features ..................................................85

.......................................77

® .................................................78

.............................................84

Duplex

NO-ARC Relay ................................................85

Retransmitting a Process Value or Set Point. . . . . . . . . . . . . . . . . . . . . . . . . 86

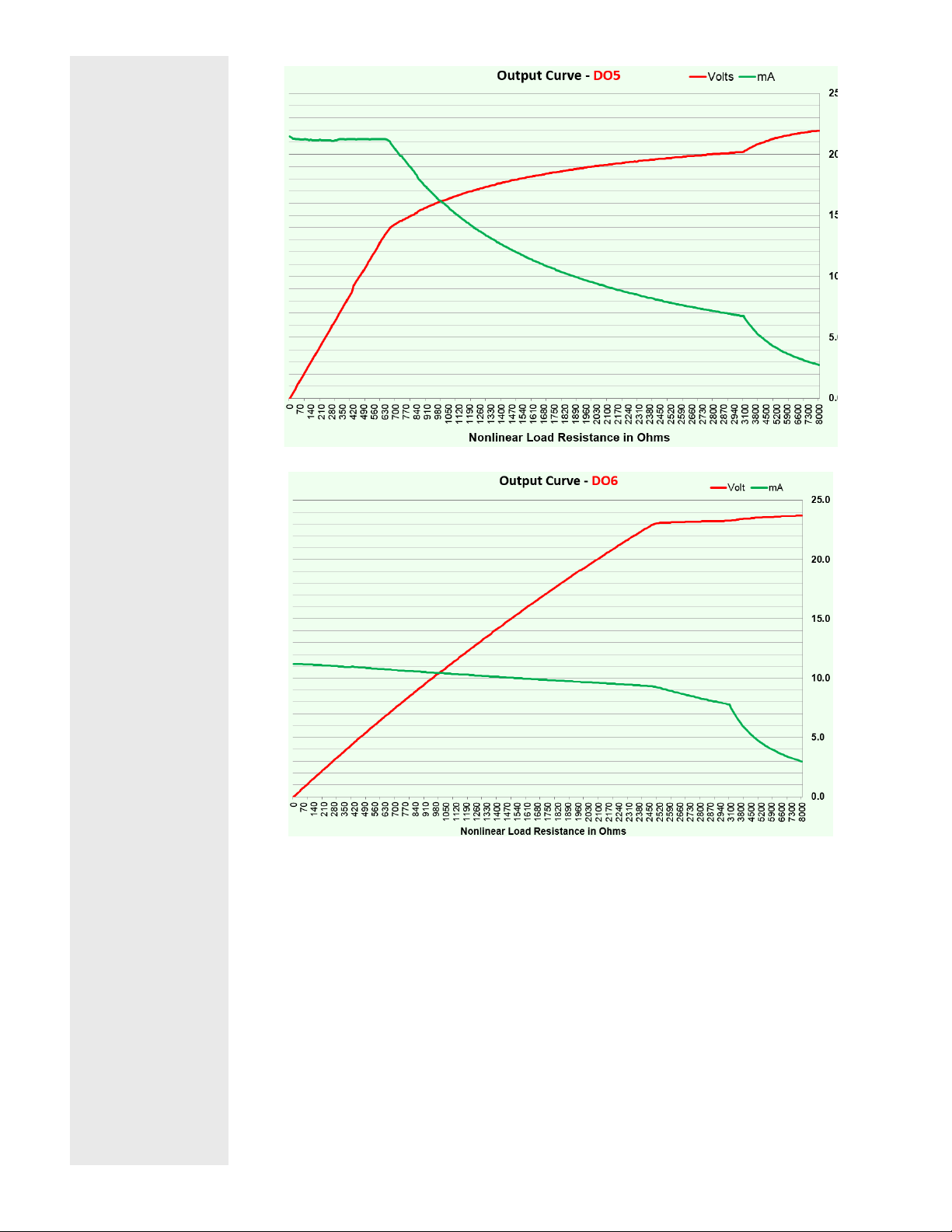

Cool Output Curve .............................................87

Resetting a Tripped Limit .......................................87

Watlow PM PLUS™ 6 • 6 • Table of Contents

......................................................85

Page 7

Control Methods ..................................................88

Output Configuration ...........................................88

Auto (closed loop) and Manual (open loop) Control ...................88

On-Off Control ................................................89

Proportional and (P) Control .....................................90

Proportional and Integral (PI) Control ..............................90

Proportional, Integral and Derivative (PID) Control ....................91

Dead Band ...................................................91

Variable Time Base ............................................92

Single Set Point Ramping .......................................92

Compressor Control ...........................................93

Differential Control ............................................94

Ratio Control .................................................94

Duplex Control ................................................94

Motorized Valve Control ........................................94

Timer Function ...................................................94

Alarms .........................................................96

Process and Deviation Alarms ....................................96

Set Points ...................................................96

Hysteresis ...................................................97

Latching .....................................................97

Silencing Alarms ..............................................98

Blocking Alarms ..............................................98

Current Sensing ..................................................98

Open and Shorted Load Circuit Detection ...........................98

Open Loop Detection ...........................................99

Programming the Function Key ......................................99

Security Features .................................................99

Read Lock and Set Lock Levels ...................................99

Passwords ..................................................101

Modbus® - Using Programmable Memory Blocks .......................102

CIP Communications: DeviceNet or EtherNet/IP .........................103

CIP Implicit Assemblies ........................................103

Compact Assembly Class ...................................104

Modifying Implicit Assembly Members ........................104

PCCC - (Programmable Controller Communications Commands) ..........104

Profibus DP (Decentralized Peripherals) ..............................105

Chapter 9: Applications ...................................106

Example 1: Single Loop Control .....................................106

Example 2: Sensor Backup .........................................106

Example 3: Square Root ...........................................107

Example 4: Ratio .................................................107

Example 5: Differential ............................................108

Example 6: Wet Bulb / Dry Bulb .....................................109

Watlow PM PLUS™ 6 • 7 • Table of Contents

Page 8

Example 7: Vaisala ...............................................109

Example 8: Motorized Valve Control ..................................110

Chapter 10: Appendix ....................................112

Troubleshooting Alarms, Errors and Control Issues ......................112

Modbus® Programmable Memory Blocks .............................117

CIP Implicit Assemblies ...........................................120

Compact Class Assembly Structure ..................................122

PM PLUS™ Integrated PID Configuration Options .......................129

PM PLUS™ PID Configuration Options ...............................130

Specifications ...................................................131

Watlow PM PLUS™ 6 • 8 • Table of Contents

Page 9

Chapter 1: Overview

Introduction

Watlow’s PM PLUS™ has an intuitive interface with a smooth touch keypad for easy programming and readability. This reduces complexity at the front of the control. Using Composer or Configurator is highly desirable to program the PM. The PM PLUS™ is compatible with legacy EZ-ZONE PM controllers and connects via

Bluetooth

ordered in the Part number.

The PM PLUS™ can be ordered as a PID controller or an integrated controller with multiple functions

combined. Look for the device configuration code on the product label to confirm which functional options are

included on your device. Upon power up, you can see the firmware revision and Bluetooth

the device display and if Bluetooth

Standard Features and Benefits

Intuitive list flow

• Reduces menu structure to a list of lists for easy configuration

• Offers easy to read characters and color coding for a display visible from many angles

• Reduces setup time and increases operator efficiency

®

to our EZ-LINK™ mobile app for remote access configuration and monitoring, if Bluetooth® was

®

®

is part of the Part number.

logo, if enabled, on

Smooth touch keypad

• Eliminates contamination points on the front of the controller and creates better seal

• No mechanical components to wear out, easy to clean

Bluetooth® compatible with EZ-LINK™ mobile app

• Provides full descriptions of parameters and error codes

• Allows remote access capabilities without the use of cables or converters

• Provides the ability to configure the product and save parameter sets, except for Factory parameters and Profile

parameters.

High amperage integrated PID and limit controller

• Reduces wiring time and termination complexity compared with connecting other products

• Decreases component count and required panel space

• Increases user and equipment safety for over/under temperature conditions

• Drives 15 ampere resistive loads directly

Standard Bus Communications with Configuration Software

• Includes Watlow standard bus communications used by COMPOSER® or CONFIGURATOR® software

Serial communication capabilities

• Provides a wide range of protocol choices including Modbus® RTU, EtherNet/IP™, Modbus® TCP, PROFIBUS DP,

DeviceNet™ and J1939 CAN bus

• Supports network connectivity to a PC or PLC for remote set point adjustment

Watlow PM PLUS™ 6 • 9 • Chapter 1 Overview

Page 10

Enhanced control options

• Handles complex process problems such as ratio, differential, square-root, motorized valve control without

slidewire feedback, wet-bulb/dry-bulb, compressor control and peltier loads

• Provides batch process control

• Supports set point change during countdown 10-point linearization curve

• Improves sensor accuracy

Current monitoring

• Detects heater current flow and provides alarm upon a failed output device or heater load

• Drives output on open or shorted heater

Advanced PID control algorithm

• Offers TRU-TUNE®+ adaptive control for demanding applications

• Provides auto-tune for fast, efficient start-up

Built-in sensor compensation curves

• Includes Vaisala RH and altitude (pressure) curves

Profile capability

• Offers pre-programmed process control with ramp/soak programming with 40 total steps

Retransmit output

• Supports industry needs for recording

Factory Mutual (FM) approved over/under limit with auxiliary outputs

• Increases user and equipment safety for over/under temperature conditions

Memory for saving and restoring parameter settings

• Decreases service calls and time down

Agency approvals

• UL® listed, CSA, CE, RoHS, W.E.E.E., FM, SEMI F47-0200, Class 1, Div. 2 rating on some models

Touch-safe package

• Increases safety for installer/operator

• Complies with IP2X requirements

Programmable function key

• Enables simple, one-touch operation of user-defined, repetitive activities

Watlow PM PLUS™ 6 • 10 • Chapter 1 Overview

Page 11

PM PLUS™ Operational Overview

The PMPLUS receives Information from an input, performs an internal function as a response to that input,

then causes a resulting output. All of these - the inputs, the internal functions, and the outputs - are

configurable. A single PM PLUS™ can carry out several functions at the same time, such as PID control, checking for a limit condition, monitoring for several alarm situations, etc.

You may configure up to four profiles to automate a sequence of up to ten steps per profile, to further

customize and extend the application of the device.

Inputs

Inputs provide the information a programmed procedure can act upon. A basic example is a sensor monitoring

the temperature of a part being heated or cooled. Each analog input typically uses a thermocouple or RTD to

read the process temperature or the volts, current or resistance from various devices.

Optional digital input/output (DIO) hardware can be used as either an input or an output. Each DIO must be

configured as either an input or output. A digital input allows for a specific function to occur. The Function Key

can also be programmed to allow for a specific function to occur.

Internal Functions

A function is a user-programmed internal process that uses input signals to calculate a value and then perform

an action, i.e.:

• Compare an input value to the set point and calculate the optimal power for a heater

• Detect a failure of the primary sensing device and trip a contactor to remove power from the heating

element

• When a digital input signal changes, allows for a specific function to occur.

• Evaluate an incoming temperature to determine an alarm state (on or off)

Each internal function is associated with one source, or instance. For example, a control equipped with DIO,

can be configured to respond to one of the four alarms.

Outputs

Outputs are functions or actions configured to respond to information provided by an internal function. Some

output examples are: removal of the control voltage to a contactor; operating a heater, turning a light on or off,

unlocking a door, etc.

You can assign outputs to any input, and may assign more than one output to respond to a single instance of a

function. For example, alarm 2 could be used to trigger a light connected to output 1 and a siren connected to

DIO 5.

Watlow PM PLUS™ 6 • 11 • Chapter 1 Overview

Page 12

Configuration and Monitoring of Features Through Lists

PM PLUS™ features and parameters are structured in lists that you can access via the smooth-touch key

interface on the front panel for easy configuration and monitoring. You can also access lists remotely if you

prefer, using our EZ-LINK app or our CONFIGURATOR software.

List Description

Operations List This list is used to monitor or change runtime settings such as the high set point of the

limit, or monitor things like the time remaining in a profile step. It is also used to access

the main configuration lists referenced here.

Setup List This is used prior to operation to set up equipment related settings such as input type

and output cycle time.

Profile List If equipped with this feature you will use this list to configure up to 4 profiles with up to

ten steps each.

Factory List This list doesn't affect runtime operations. It is used to adjust hardware settings like

passwords or the appearance of the Home Screen, or to view the control part number.

Profiles

A profile is a sequence of steps. When a profile runs, the controller automatically executes its steps in sequence. The step type determines what action the controller performs. Steps can change temperatures and

other process values gradually over time, maintain temperatures and process values for specific periods, or

repeat a sequence of steps numerous times. At each step the profile can activate or deactivate outputs that

control other equipment. Also a step can have the controller wait for specific conditions before proceeding such

as, waiting for a switch closure and/or a specific process value to be detected by a sensor.

Input Events and Output Events

When a Profile step is programmed as a "Wait For Event Input" will wait for the "Input Event" to be in the proper

state before it will proceeds to the next step of a Profile. Event Outputs will allow you to turn "On" or "Off", or

"leave as is"; in each step of a Profile.

Watlow PM PLUS™ 6 • 12 • Chapter 1 Overview

Page 13

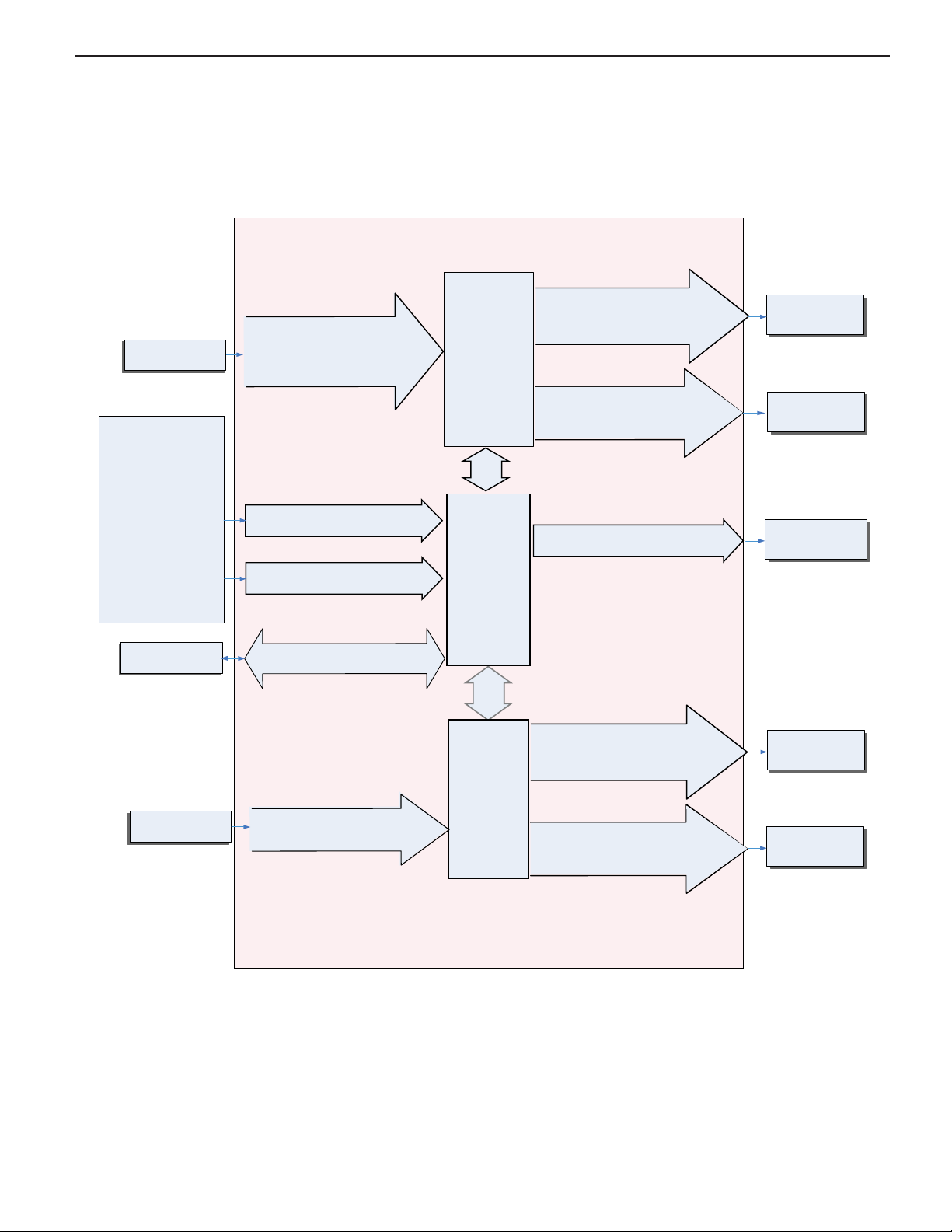

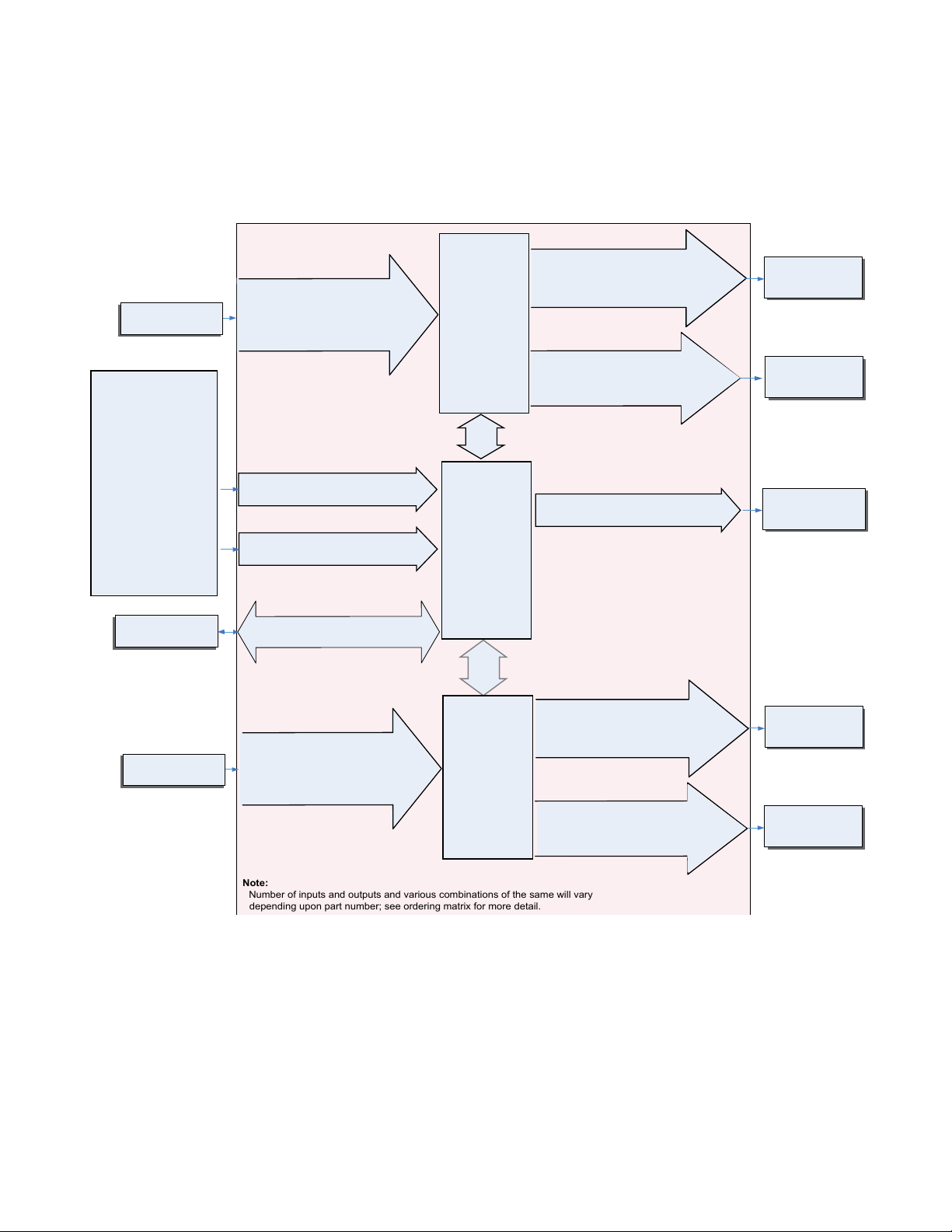

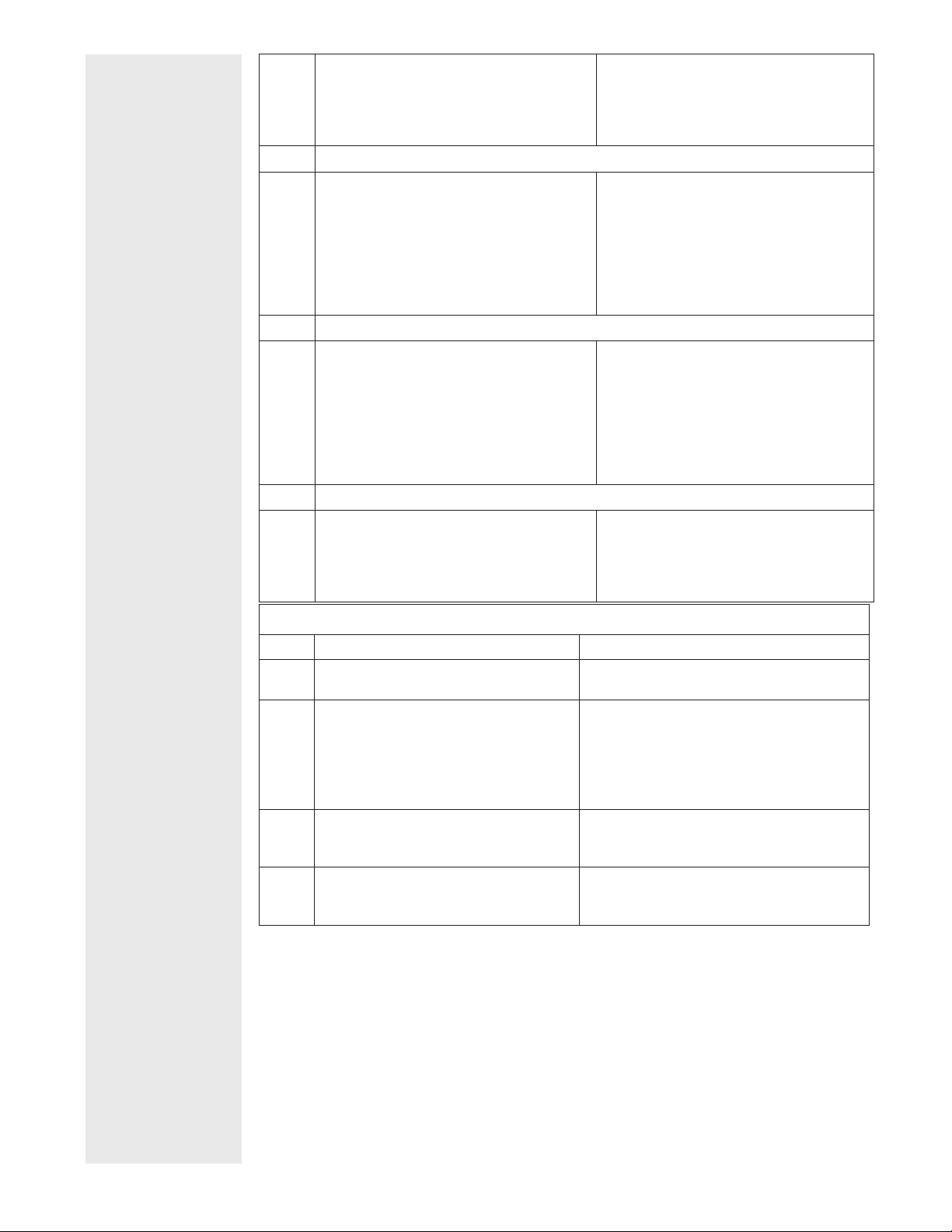

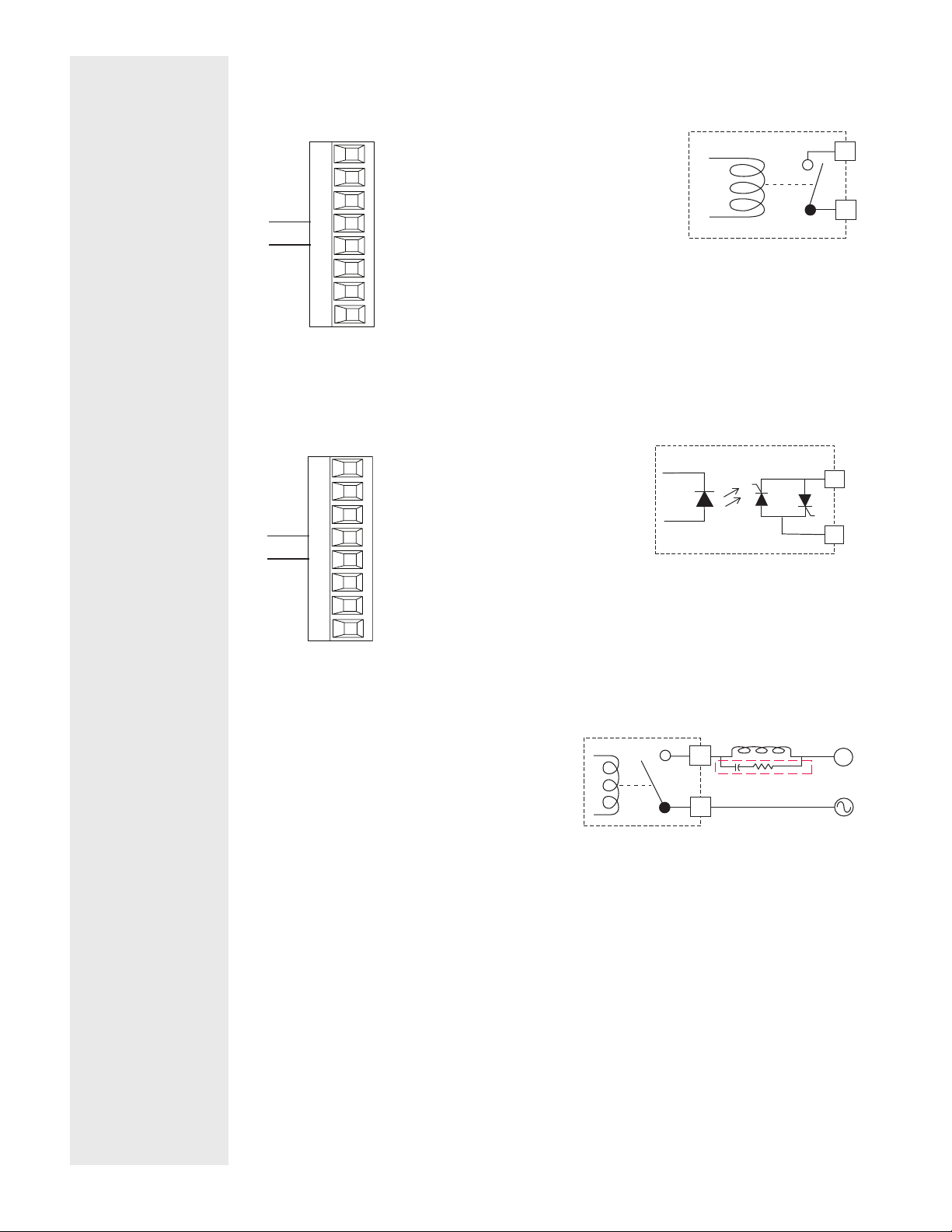

System Diagrams

Note:

Number of inputs and outputs and various combinations of the same will vary

depending upon part number; see ordering matrix for more detail.

Function Key

Programmable Event

Digital Output (or Input) 5 & 6

(optional) none, switched dc

Digital Input (or Output) 5 & 6

(optional) none, switch, volts dc

Current

Transformer

Board

(optional)

Slot B

Inputs

Outputs

- None

- Idle set point

- Tune

- Alarm clear, request

- Force alarm

- Silence alarm

- Manual/auto mode

- Control outputs off

- Remote set point

enable

- Lock keypad

- TRU-TUNE+® disable

- Loop & alarms off

- Profile disable

- Profile hold/resume

- Profile start

- Profile start/stop

- Restore user settings

- Event inputs

Analog Input 1

none, Thermocouple, RTD (100Ω,

1kΩ), Thermistor 5kΩ, 10kΩ, 20kΩ,

40kΩ) Process (V, mV, mA) or 1k

Potentiometer

Output 1

none, switched dc/open collector, 5A

mechanical relay (form C), process

(V, mA), or 0.5A SSR (form A)

Output 2

none, 15A NO-ARC, switched dc,

5A mechanical relay (form A), or

0.5A SSR (form A)

Analog Input 2

Current Transformer

PID

Controller

(Optional -

Ramp/Soak max 4

files, 40 steps)

Slot A

(Optional)

Input Sensor

off, heat, cool

alarm, retransmit,

duplex, event

off, heat, cool

alarm, event

off, heat, cool

alarm, retransmit,

duplex, event

off, heat, cool

alarm, event

off, heat, cool

alarm, event

Modbus

Address

1 - 247

Standard Bus

Zone Address

1 - 16

Supervisory &

Power Board

Slot C

Current

Transformer

EIA-485 Communication

Standard Bus

(optional Modbus RTU)

RUI, Controllers,

PLC, PC or HMI

Output 3

none, switched dc/open collector, 5A

mechanical relay (form C), process

(V, mA), or 0.5A SSR (form A)

Output 4

none, 15A NO-ARC, switched dc,

5A mechanical relay (form A), or

0.5A SSR (form A)

Current Monitoring - with Current Transformer, without Communications Card

• Detects heater current flow

• Provides an alarm indication of a failed-load issue.

Watlow PM PLUS™ 6 • 13 • Chapter 1 Overview

Page 14

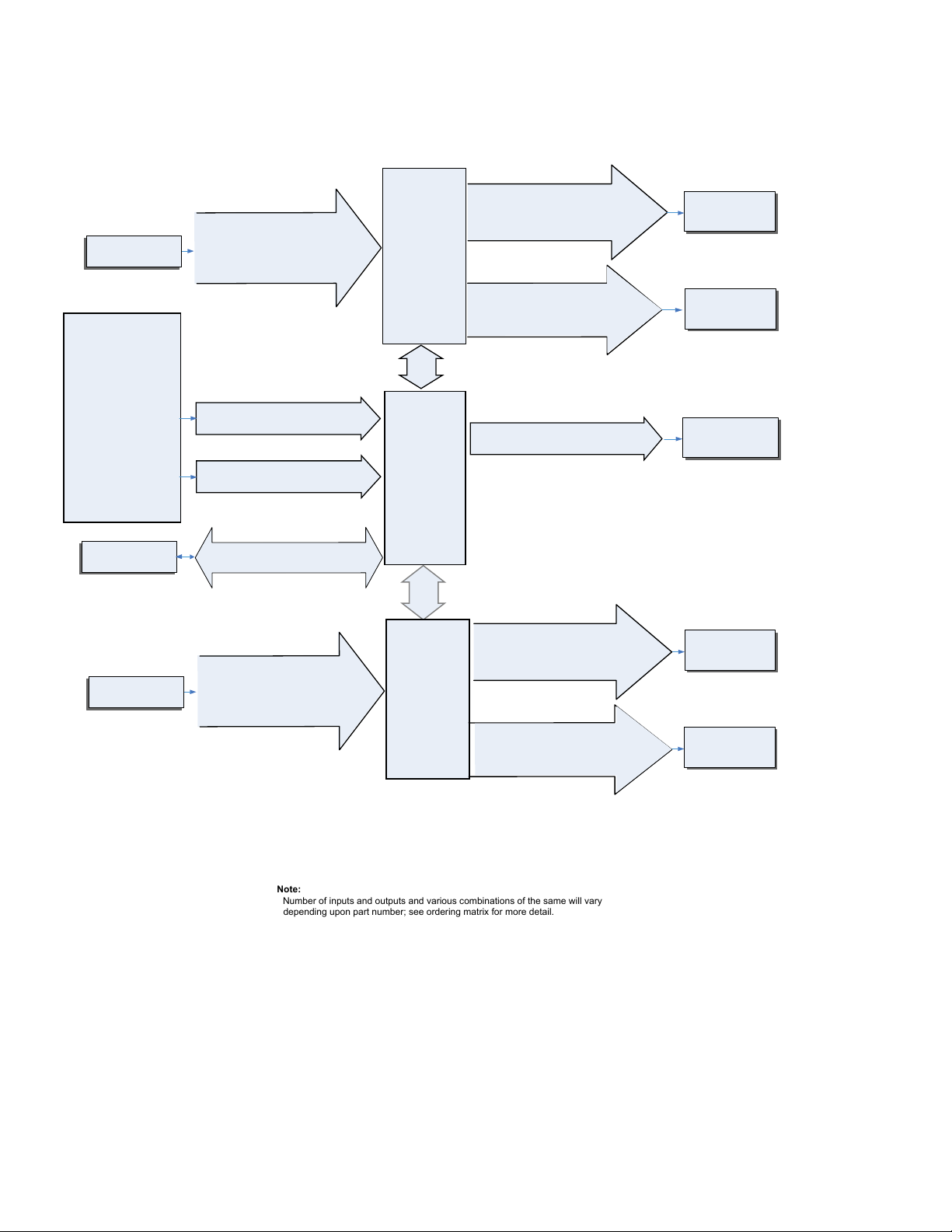

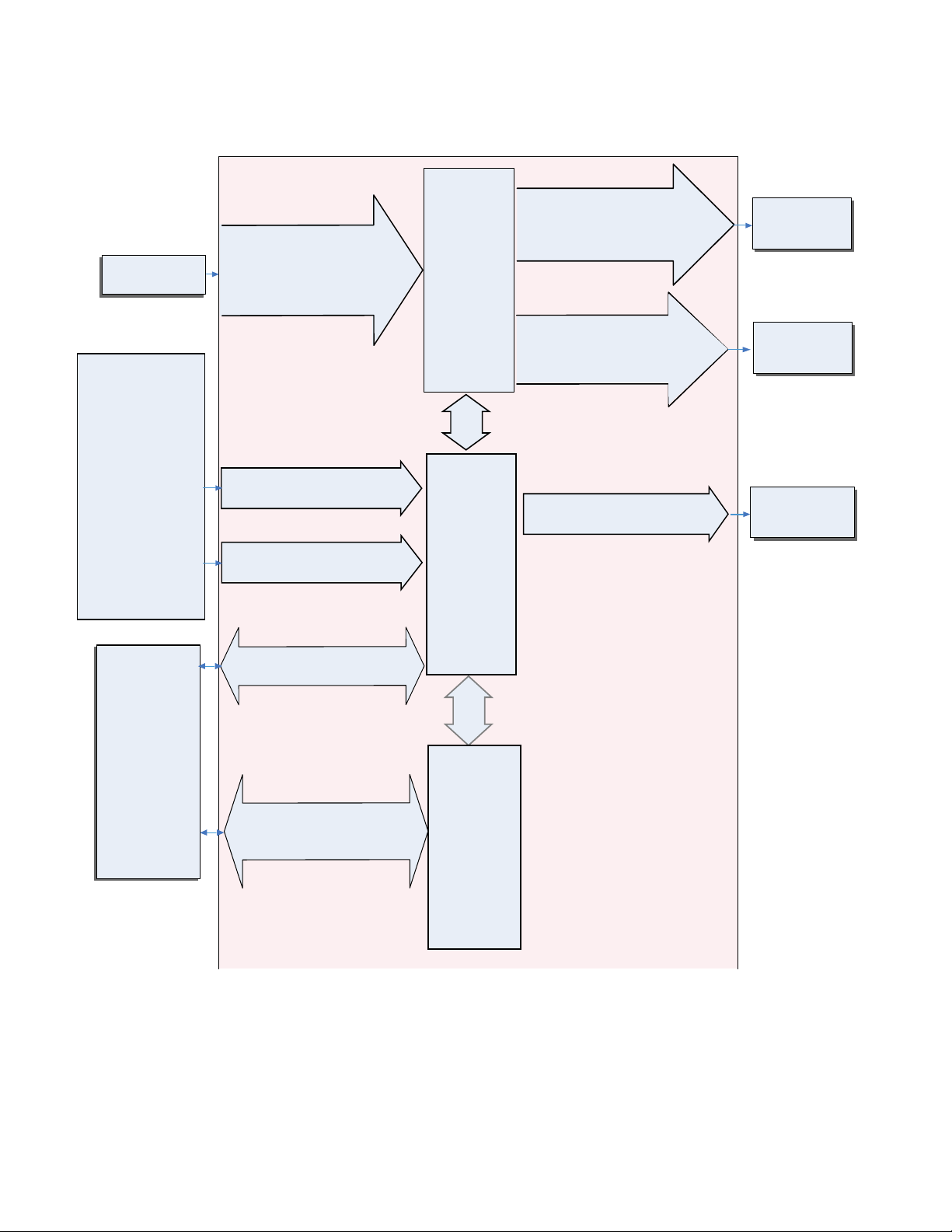

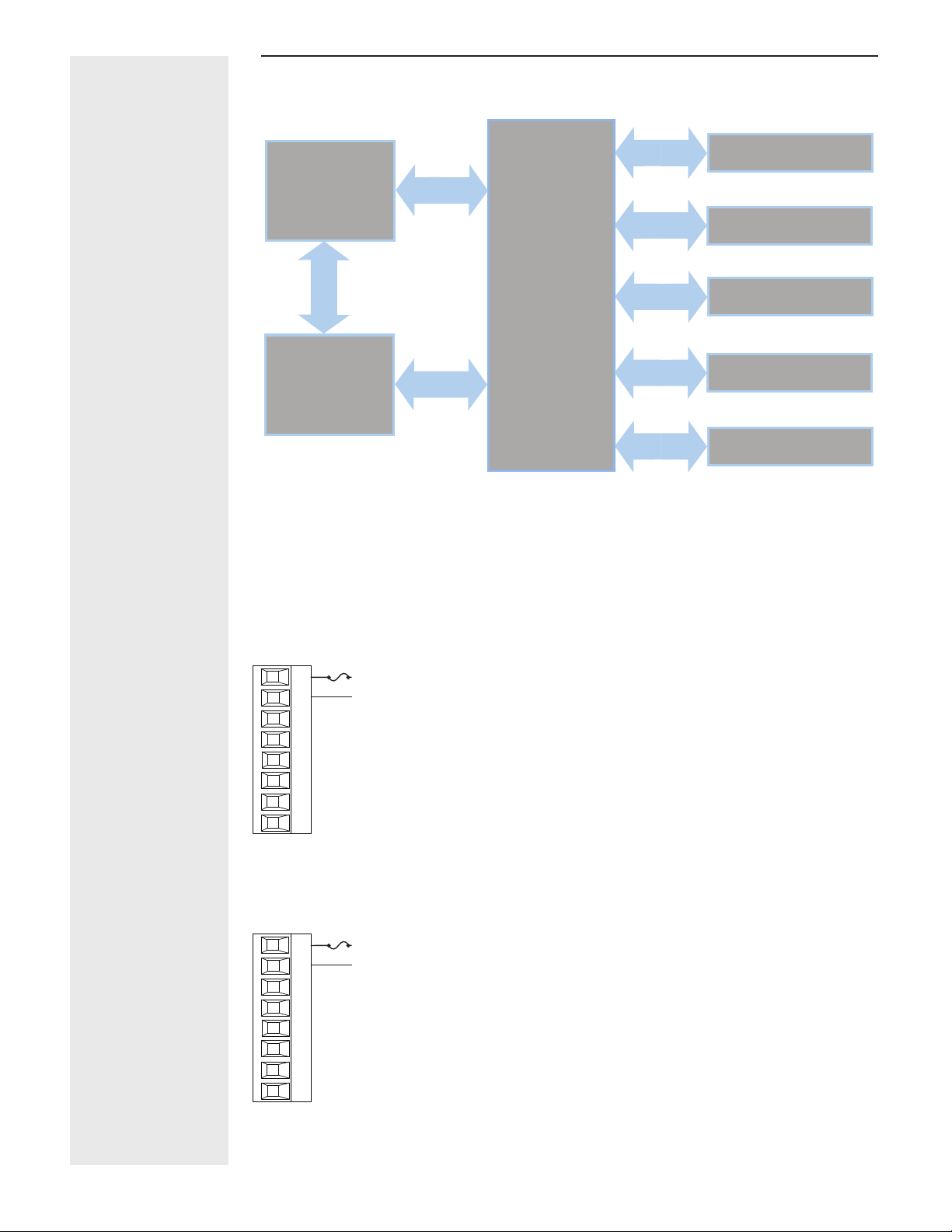

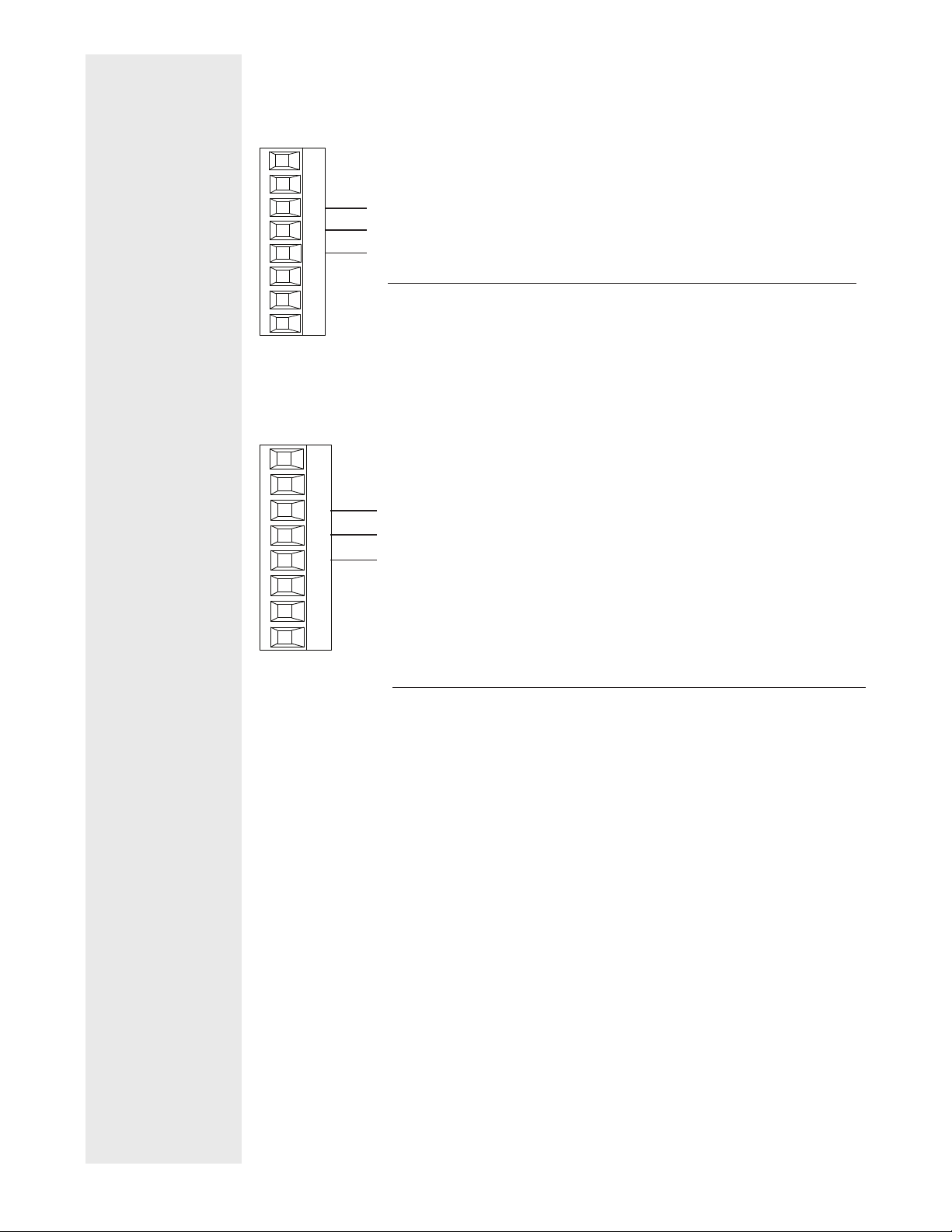

Remote Set Point Operation With Auxillary Input, Without Communications Card

Note:

Number of inputs and outputs and various combinations of the same will vary

depending upon part number; see ordering matrix for more detail.

• Remote Set Point Operation supports efficient set point manipulation from a remote device, such as a

master control or PLC.

Input

Functions

Input Sensor

- None

- Idle set point

- Tune

- Alarm clear, request

- Force alarm

- Silence alarm

- Manual/auto mode

- Control outputs off

- Remote set point

enable

- Lock keypad

- TRU-TUNE+

- Loop & alarms off

- Profile disable

- Profile hold/resume

- Profile start

- Profile start/stop

- Restore user settings

- Event inputs

®

disable

RUI, Controllers,

PLC, PC or HMI

Analog Input 1

none, Thermocouple, RTD (100Ω,

1kΩ), Thermistor 5kΩ, 10kΩ, 20kΩ,

40kΩ) Process (V, mV, mA) or 1k

Potentiometer

Digital Input (or Output) 5 & 6

(optional) none, switch, volts dc

Function Key

Programmable Event

EIA-485 Communication

Standard Bus

(optional Modbus RTU)

PID

Controller

(Optional -

Ramp/Soak max 4

files, 40 steps)

Slots A

(Optional)

Modbus

Address 1 - 247

Standard Bus

Zone Address

1 - 16

Supervisory &

Power Board

Slot C

Output 1

none, switched dc/open collector, 5A

mechanical relay (form C), process

(V, mA), or 0.5A SSR (form A)

Output 2

none, 15A NO-ARC, switched dc,

5A mechanical relay (form A), or

0.5A SSR (form A)

Digital Output (or Input) 5 & 6

(optional) none, switched dc

Output

Functions

off, heat, cool

alarm, retransmit,

duplex, event

off, heat, cool

alarm, event

off, heat, cool

alarm, event

Input Sensor

Analog Input 2

none, CT, Thermocouple, RTD (100

Ω, 1kΩ), Thermistor 5kΩ, 10kΩ,

20kΩ, 40kΩ) Process (V, mV, mA)

or 1k Potentiometer

Auxillary

Input

(optional)

Slot B

Output 3

none, switched dc/open collector, 5A

mechanical relay (form C), process

(V, mA), or 0.5A SSR (form A)

Output 4

none, 15A NO-ARC, switched dc,

5A mechanical relay (form A), or

0.5A SSR (form A)

off, heat, cool

alarm, retransmit,

duplex, event

off, heat, cool

alarm, event

Watlow PM PLUS™ 6 • 14 • Chapter 1 Overview

Page 15

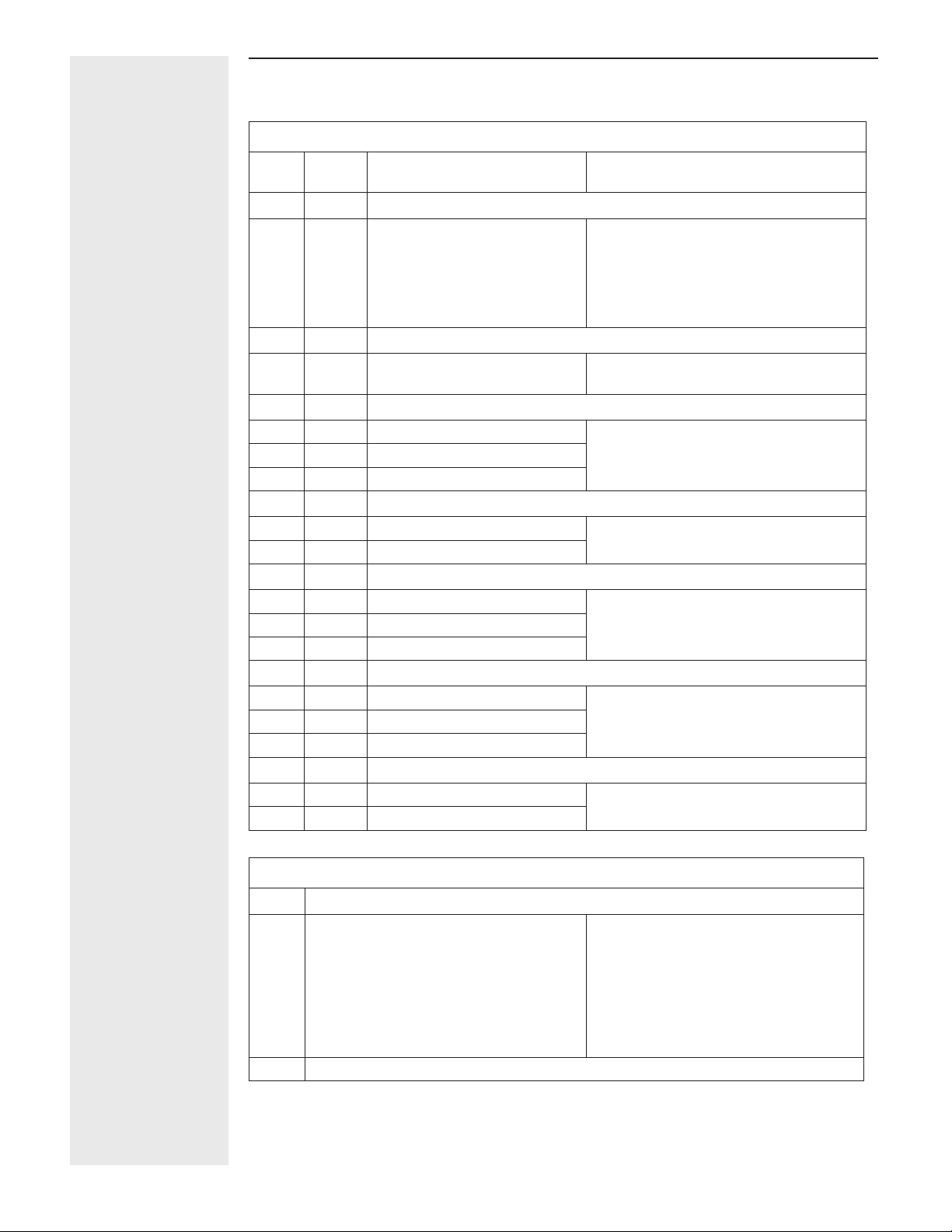

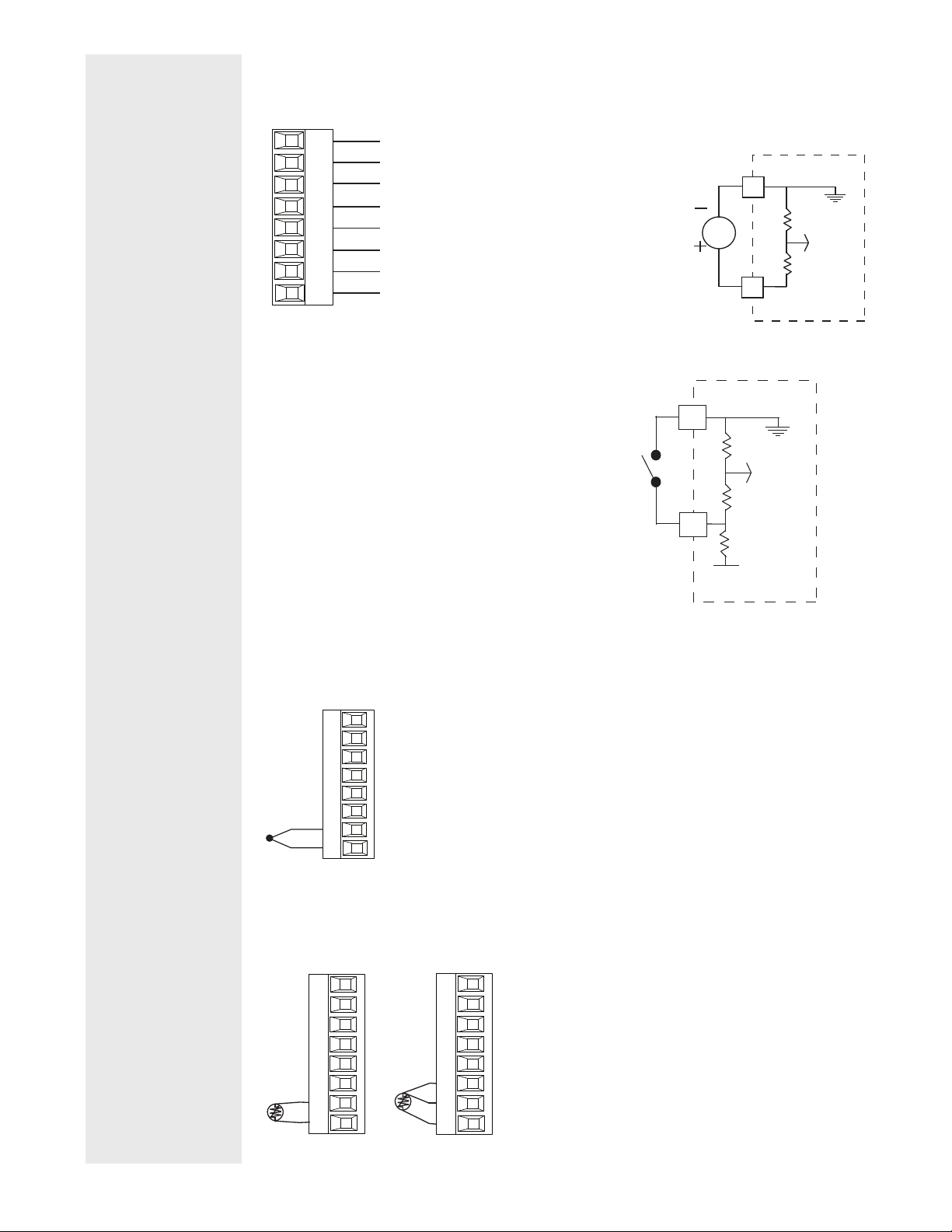

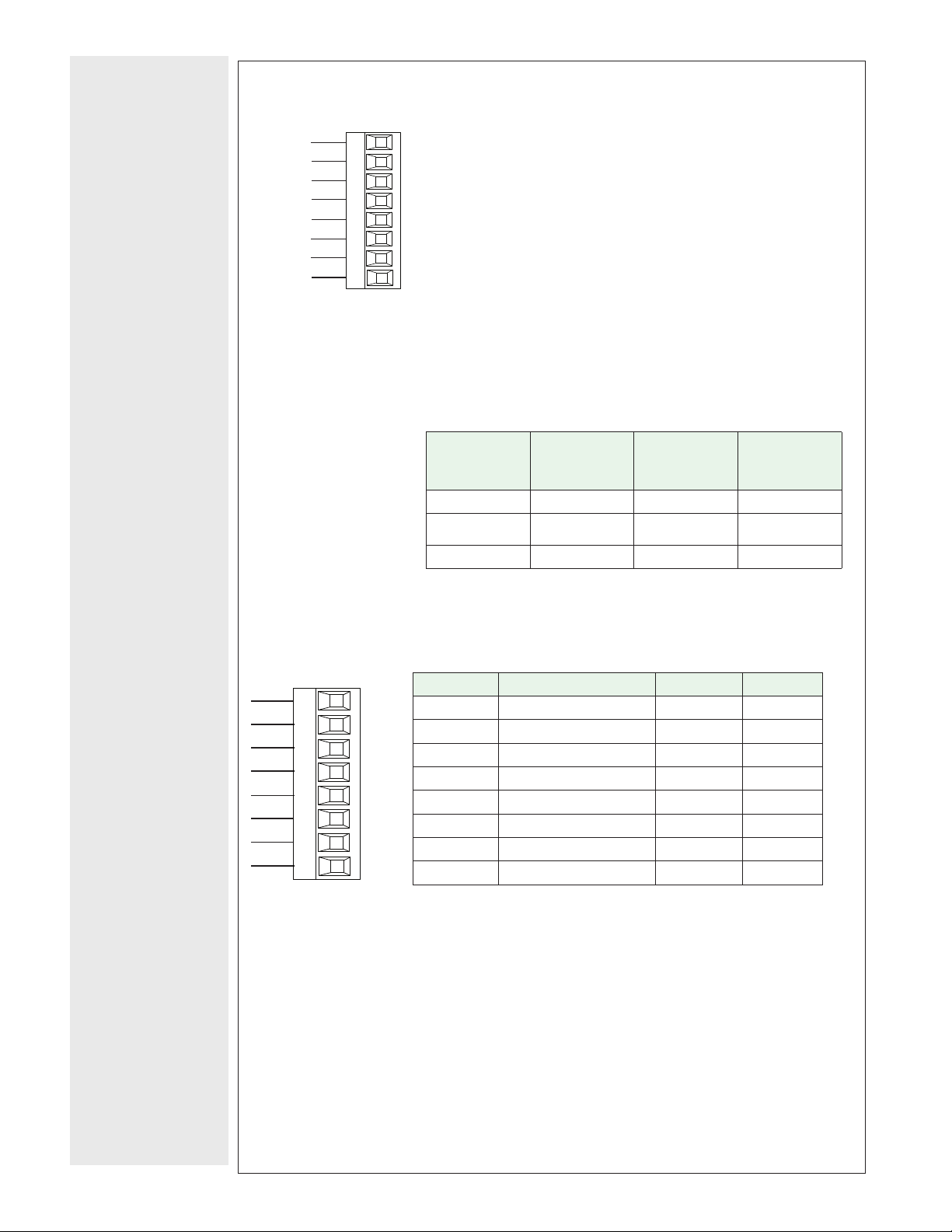

Integrated PID and Limit Controller with Limit, Without Communications Card

Note:

Number of inputs and outputs and various combinations of the same will vary

depending upon part number; see ordering matrix for more detail.

• Reduces wiring time and termination complexity compared to connecting separate products

• Reduces panel space

• Reduces installation costs

• Increases dependability with backup control sensor operation

• Increases user and equipment safety for over-under temperature conditions

Input

Functions

Input Sensor

- None

- Limit reset

- Idle set point

- Tune

- Alarm clear, request

- Force alarm

- Silence alarm

- Manual/auto mode

- Control outputs off

- Remote set point

enable

- Lock keypad

- TRU-TUNE+

- Loop & alarms off

- Profile disable

- Profile hold/resume

- Profile start

- Profile start/stop

- Restore user settings

- Event inputs

®

disable

RUI, Controllers,

PLC, PC or HMI

Analog Input 1

none, Thermocouple, RTD (100Ω,

1kΩ), Thermistor 5kΩ, 10kΩ, 20kΩ,

40kΩ) Process (V, mV, mA) or 1k

Potentiometer

Digital Input (or Output) 5 & 6

(optional) none, switch, volts dc

Function Key

Programmable Event

EIA-485 Communication

Standard Bus

(optional Modbus RTU)

PID

Controller

(Optional -

Ramp/Soak max 4

files, 40 steps)

Slots A

(Optional)

Modbus

Address 1 - 247

Standard Bus

Zone Address

1 - 16

Supervisory &

Power Board

Slot C

Output 1

none, switched dc/open collector, 5A

mechanical relay (form C), process

(V, mA), or 0.5A SSR (form A)

Output 2

none, 15A NO-ARC, switched dc,

5A mechanical relay (form A), or

0.5A SSR (form A)

Digital Output (or Input) 5 & 6

(optional) none, switched dc

Output

Functions

off, heat, cool

alarm, retransmit,

duplex, event

off, heat, cool

alarm, event

off, heat, cool

alarm, event

Input Sensor

Analog Input 2

none, CT, Thermocouple, RTD (100

Ω, 1kΩ), Thermistor 5kΩ, 10kΩ,

20kΩ, 40kΩ) Process (V, mV, mA)

or 1k Potentiometer

Limit Controller

Board

(optional)

Slot B

Output 3

none, switched dc/open collector, 5A

mechanical relay (form C), process

(V, mA), or 0.5A SSR (form A)

Output 4

5A mechanical relay (form A)

If Limit, this output must

be Limit

off, heat, cool

alarm, retransmit,

duplex or event

Limit

Watlow PM PLUS™ 6 • 15 • Chapter 1 Overview

Page 16

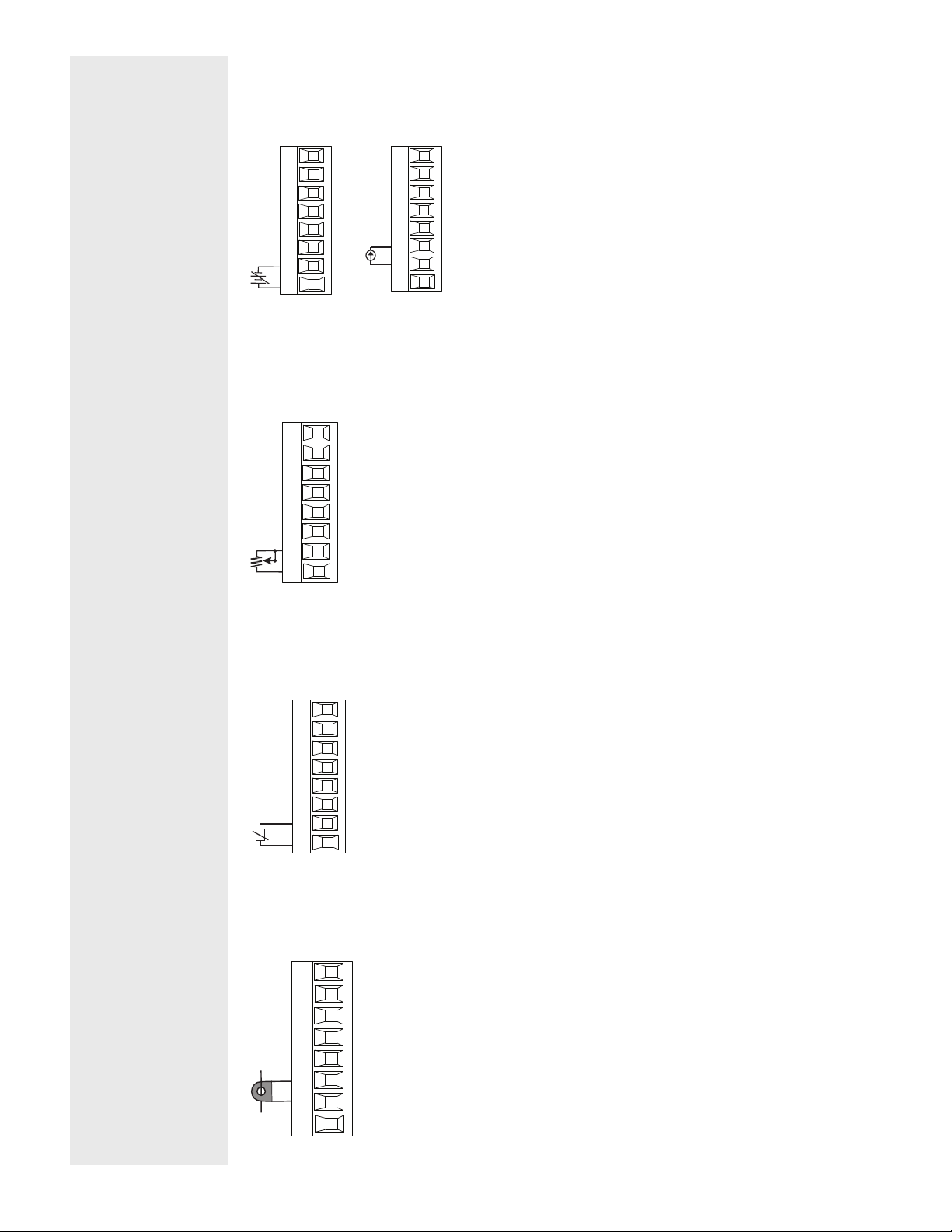

Expanded Serial Communications

Function Key

Programmable Event

Digital Output (or Input) 5 & 6

(optional) none, switched dc

Digital Input (or Output) 5 & 6

(optional) none, switch, volts dc

Input

Functions

Output

Functions

- None

- Idle set point

- Tune

- Alarm clear, request

- Force alarm

- Silence alarm

- Manual/auto mode

- Control outputs off

- Remote set point

enable

- Lock keypad

- TRU-TUNE+

®

disable

- Loop & alarms off

- Profile disable

- Profile hold/resume

- Profile start

- Profile start/stop

- Restore user settings

- Event inputs

Analog Input 1

none, CT, Thermocouple, RTD (100

Ω, 1kΩ), Thermistor 5kΩ, 10kΩ,

20kΩ, 40kΩ) Process (V, mV, mA)

or 1k Potentiometer

Output 1

none, switched dc/open collector, 5A

mechanical relay (form C), process

(V, mA), or 0.5A SSR (form A)

Output 2

none, 15A NO-ARC, switched dc,

5A mechanical relay (form A), or

0.5A SSR (form A)

PID

Controller

(Optional -

Ramp/Soak max 4

files, 40 steps)

Slot A

(Optional)

Input Sensor

off, heat, cool

alarm, retransmit,

duplex, event

off, heat, cool

alarm, event

off, heat, cool

alarm, event

EIA-485 Communication

Standard Bus

(optional Modbus RTU)

RUI, Controllers,

PLC, PC or HMI

Communications

EIA 232/485 Modbus RTU/TCP,

EtherNet/IP, DeviceNet, Profibus

Modbus Address

1 - 247

Standard Bus

Zone Address

1 - 16

Supervisory &

Power Board

Slot C

Communications

Board

Slot B

• Supports network connectivity to a PC or PLC

• Available in a wide range of protocol choices, including Modbus® RTU, EtherNet/IP™, Modbus® TCP

Watlow PM PLUS™ 6 • 16 • Chapter 1 Overview

Page 17

Chapter 2: Installation

D

C

7

6

5

4

3

2

1

REVISION

REV. DESCRIPTION DAT E ECO

1 PROTO

XX/XX/20XX

-

2 Updated

5/31/2019

--

4.164 in.

(105.8 mm)

0.4 in.

(10.2 mm)

D

C

4

3

2

1

REVISION

REV. DESCRIPTION DAT E ECO

1 PROTO

XX/XX/20XX

-

2 Updated

5/31/2019

--

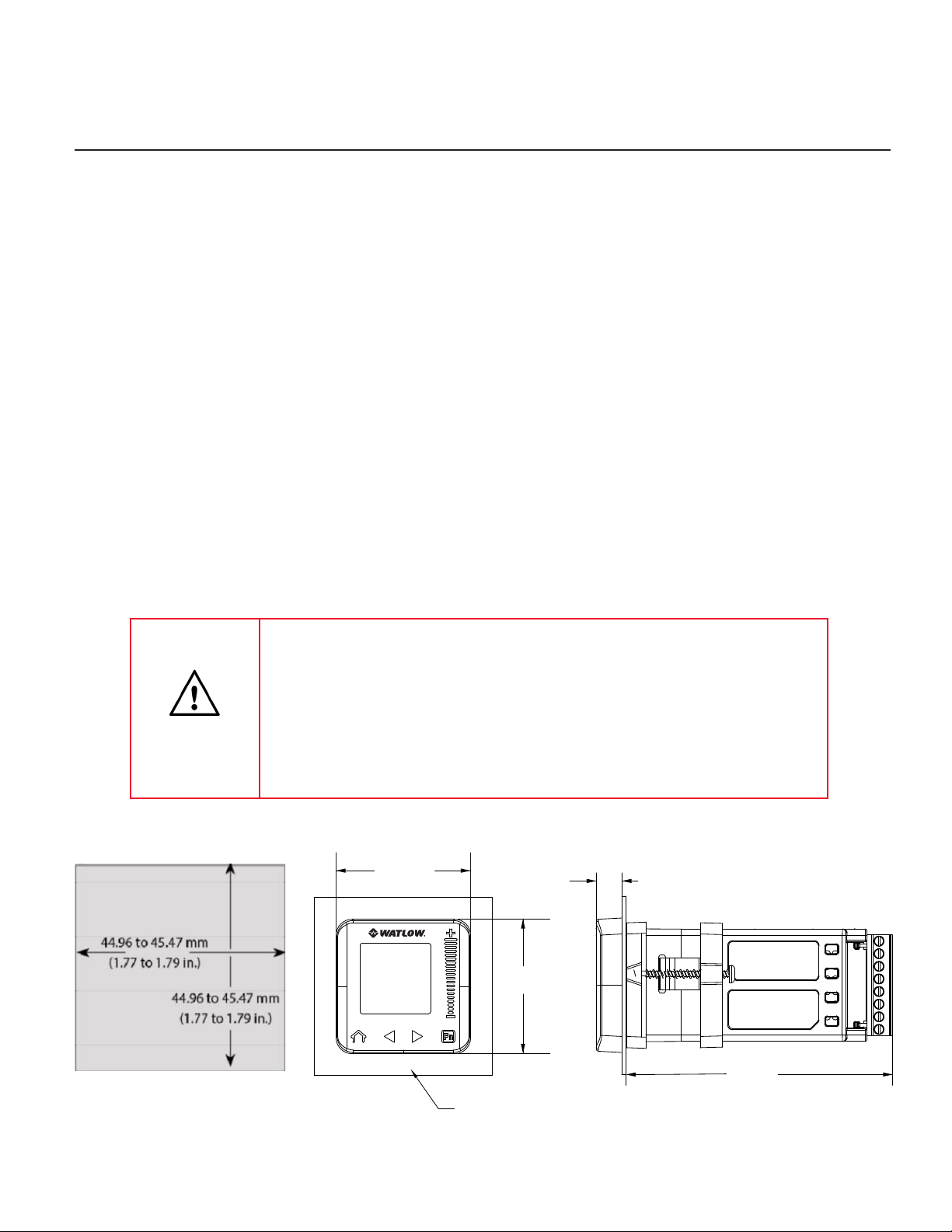

Installing the Device

1. Make the panel cutout using the measurements shown here. We recommend a minimum of 21.6 mm

between panel cutouts.

2. Remove the green terminal connectors and the mounting collar assembly.

3. Insert the controller into the panel cutout from the front.

4. Orient the collar base so the flat side faces front and the screw openings are on the sides, then slide the base

over the back of the controller.

5. Slide the mounting bracket over the controller with the screws aligned to the collar base.

6. Push the bracket gently but firmly until the hooks snap into the slots in the case.

7. Tighten the two #6-19 x 1.5" screws with a Phillips screwdriver until the device is flush to the panel

(3 to 4 in-lbs torque).

8. Secure screws from the back with Philips screwdriver.

Reinstall the terminal connectors to their original locations. (Or first connect field wiring as indicated in this

guide and then reinstall the connectors).

• This equipment is suitable for use in Class 1, Div. 2, Groups A, B, C

and D or Non-Hazardous locations only. Temperature Code T4A. Note:

Class 1, Div 2 is only valid if the last 2 characters in the part # are "12".

• EXPLOSION HAZARD. Substitution of component may impair

suitability for Class 1, Div. 2.

• EXPLOSION HAZARD. Do not disconnect equipment unless power has

been switched off or the area is known to be nonhazardous.

2.10 in.

(53.3 mm)

2.10 in.

(53.3 mm)

(10.2 mm)

0.4 in.

4.164 in.

(105.8 mm)

Mounting Panel

Watlow PM PLUS™ 6 • 17 • Chapter 2: Installation

Page 18

Wiring Notes

Maximum wire size termination and torque rating:

0.0507 to 3.30 mm2 (30

to 12 AWG) single-wire

termination or two 1.31

mm2 (16 AWG)

0.56 Nm (5.0 in-lb.)

torque

Adjacent terminals may

be labeled differently

depending on the model

number.

Do not connect wires to

unused terminals.

Maintain electrical isolation between analog

input 1, digital inputoutputs, switched dc/

open collector outputs

and process outputs to

prevent ground loops.

This equipment is suitable for use in CLASS

I, DIVISION 2, Groups

A, B, C and D or NonHazardous locations only.

Temperature Code T4A

Wiring Warnings

Use National Electric

(NEC) or other countryspecic standard wiring

and safety practices

when wiring this controller to a power source,

electrical sensors or peripheral devices. Failure

to do so may result in

damage to equipment

and property, and/or injury or loss of life.

Explosion Hazard - Dry

contact closure Digital

Inputs shall not be used

in Class I Division 2 Hazardous Locations unless

switch used is approved

for this application.

Explosion Hazard – Substitution of component

may impair suitability for

CLASS I, DIVISION 2.

Explosion Hazard - Do

not disconnect while the

circuit is live or unless

the area is known to be

free of ignitable concentrations of ammable

substances.

ç

Wiring Your New PM PLUS™

Inputs and Outputs

Input 1Input

2

Slot A Slot B

T1

S1

R1

Slot A Slot B

Slot A Slot B

X1 X3 common Output 1: PM _ _ _[C] _ - _ _ _ _ _ _ _

W1 W3

Y1 Y3

Slot A Slot B

W2 W4 mA ac Output 2: PM _ _ _ _ [C] - _ _ _ _ _ _ _

Y2 Y4 mA ac

Slot A Slot B

F1 F3 voltage or current - Output 1: PM _ _ _ [F] _ - _ _ _ _ _ _ _

G1 G3 voltage +

H1 H3 current +

Slot A Slot B

L1 L3 normally open Output 1: PM _ _ _ [E] _ - _ _ _ _ _ _ _

K1 K3 common

K1 J3 normally closed

Slot A Slot B

L2 L4 normally open Output 2: PM _ _ _ _ [H] - _ _ _ [H*] _ _

K2 K4 common

Slot B

CB

CA

CC

CB

CA

C5

C3

C2

T2

S2

R2

T2

S2

Modbus® RTU 232/485 Communications

Modbus® RTU EIA-485 T+/R+

Modbus® RTU EIA-485 T-/RModbus® RTU EIA-485 common

Modbus® RTU EIA-485 T+/R+

Modbus® RTU EIA-485 T-/RModbus® RTU EIA-232 common

Modbus® RTU EIA-232 to DB9 pin 2

Modbus® RTU EIA-232 to DB9 pin 3

DeviceNet™ Communications

UNIVERSAL, RTD, THERMISTOR INPUTS

S2 (RTD) or current +

S3 (RTD), thermocouple -, current -, potentiometer wiper,

thermistor or volts S1 (RTD), thermocouple +, volts

+, potentiometer or thermistor

CURRENT TRANSFORMER INPUT 2

mA ac

mA ac

SWITCHED DC / OPEN COLLECTOR OUTPUTS

DC-

DC+

SWITCHED DC OUTPUTS

UNIVERSAL PROCESS OUTPUTS

MECHANICAL RELAY 5A, FORM C OUTPUTS

NO-ARC 15A FORM A

Input Function Configuration Code

Input 1: all configurations

Input 2: PM _ _ _ _ _ - _ [R,L] _ _ _ _ _

Input 2: PM _ _ _ _ _ - _ [T] _ _ _ _ _

Output 3: PM _ _ _ _ _ - _ _ [C] _ _ _ _

Output 4: PM _ _ _ _ _ - _ _ _ [C] _ _ _

Output 3: PM _ _ _ _ _ - _ _ [F] _ _ _ _

Output 3: PM _ _ _ _ _ - _ _ [E] _ _ _ _

_

Communications

Slot B: PM6 _ _ _ _ - [2] A A A _ _ _

Watlow PM PLUS™ 6 • 18 • Chapter 2: Installation

Page 19

Wiring Notes

Maximum wire size

termination and torque

rating:

0.0507 to 3.30 mm2 (30

to 12 AWG) single-wire

termination or two 1.31

mm2 (16 AWG)

0.56 Nm (5.0 in-lb.)

torque

Adjacent terminals may

be labeled differently

depending on the model

number.

Do not connect wires to

unused terminals.

Maintain electrical isolation between analog

input 1, digital inputoutputs, switched dc/

open collector outputs

and process outputs to

prevent ground loops.

This equipment is suitable for use in CLASS I,

DIVISION 2, Groups A,

B, C and D or Non-Hazardous locations only.

Temperature Code T4A

Wiring Warnings

Use National Electric

(NEC) or other countryspecic standard wiring

and safety practices

when wiring this controller to a power source,

electrical sensors or peripheral devices. Failure

to do so may result in

damage to equipment

and property, and/or injury or loss of life.

Explosion Hazard - Dry

contact closure Digital

Inputs shall not be used

in Class I Division 2 Hazardous Locations unless

switch used is approved

for this application.

Explosion Hazard – Substitution of component

may impair suitability for

CLASS I, DIVISION 2.

Explosion Hazard - Do

not disconnect while the

circuit is live or unless

the area is known to be

free of ignitable concentrations of ammable

substances.

ç

V+

CH

SH

CL

V-

DeviceNet power

Positive side of DeviceNet bus

Shield interconnect

Negative side of DeviceNet bus

DeviceNet power return

Slot B: PM6 _ _ _ _ - [5] A A A _ _ _

EtherNet/IP™ and Modbus® TCP

E8

E7

E6

E5

E4

E3

E2

E1

unused

unused

EtherNet/IP and Modbus® TCP receive unused

unused

EtherNet/IP and Modbus® TCP receive +

EtherNet/IP and Modbus® TCP transmit EtherNet/IP and Modbus® TCP transmit +

Slot B: PM6 _ _ _ _ - [3] A A A _ _ _

Profibus DP Communications

VP

B

A

DG

trB

B

A

trA

Voltage Potential

EIA-485 T+/R+

EIA-485 T-/RDigital ground (common)

Termination resistor B

EIA-485 T+/R+

EIA-485 T-/RTermination resistor A

Slot B: PM6 _ _ _ _ - [6] AAA _ _ _

J1939 CAN bus Communications

CL

CH

SH

V+

V-

Negative side of CAN bus

Positive side of CAN bus

Shield interconnect

CAN bus power

CAN bus power return

Slot B: PM6 _ _ _ _ - [7] A A A _ _ _

Slot C Power or Communications Wiring

Slot C Terminal Function Configuration

98

99

CC

CA

CB

CF

CD

CE

B5

D6

D5

Power input: ac or dc+

Power input: ac or dc-

®

Standard Bus or Modbus

common

Standard Bus or Modbus® RTU EIA-485

T-/RStandard Bus or Modbus® RTU EIA-485

T+/R+

Standard Bus EIA-485 common

Standard Bus EIA-485 T-/RStandard Bus EIA-485 T+/R+

Digital input-output common

Digital input or output 6

Digital input or output 5

RTU EIA-485

all

PM _ _ _ _ _ - [1] _ _ _ _ _ _

PM _ _ _ _ _ - [A,D,2,3,5] _ _ _ _ _ _

PM _ _ [2] _ _ - _ _ _ _ _ _ _

PM _ _ [4] _ _ - _ _ _ _ _ _ _

Watlow PM PLUS™ 6 • 19 • Chapter 2: Installation

Page 20

Wiring Notes

Maximum wire size termination and torque rating:

0.0507 to 3.30 mm2 (30

to 12 AWG) single-wire

termination or two 1.31

mm2 (16 AWG)

0.56 Nm (5.0 in-lb.)

torque

Adjacent terminals may

be labeled differently

depending on the model

number.

Do not connect wires to

unused terminals.

Maintain electrical isolation between analog

input 1, digital inputoutputs, switched dc/

open collector outputs

and process outputs to

prevent ground loops.

This equipment is suitable for use in CLASS

I, DIVISION 2, Groups

A, B, C and D or NonHazardous locations only.

Temperature Code T4A

Isolation Block Diagram

Controller Power Supply

12 to 40VDC

20 to 28VAC

100 to 240VAC

Safety Isolation

Mechanical Relay,

Solid-State Relay,

NO-ARC Relay

Outputs

Safety Isolation

Controller

Low Voltage Power Bus

Safety Isolation

Low-voltage Isolation: 42V peak

Safety Isolation: 2300VAC

No Isolation

No Isolation

Low Voltage

Isolation

Low-voltage

Isolation

Low-voltage

Isolation

Digital Inputs & Outputs

5-12

Switched DC, Open Collector,

Process outputs

Analog Input 1

Analog Input 2

Communications Ports

Wiring Warnings

ç

Use National Electric

(NEC) or other countryspecic standard wiring

and safety practices

when wiring this controller to a power source,

electrical sensors or peripheral devices. Failure

to do so may result in

damage to equipment

and property, and/or injury or loss of life.

Explosion Hazard - Dry

contact closure Digital

Inputs shall not be used

in Class I Division 2 Hazardous Locations unless

switch used is approved

for this application.

Explosion Hazard – Substitution of component

may impair suitability for

CLASS I, DIVISION 2.

Explosion Hazard - Do

not disconnect while the

circuit is live or unless

the area is known to be

free of ignitable concentrations of ammable

substances.

Low Power

PM_ _ [3,4] _ _ - _ _ _ _ _ _ _

Slot C

98

99

CF

CD

CE

B5

D6

D5

power

power

fuse

• Minimum/Maximum Ratings

• 12 to 40VDC

• 20 to 28VAC) Semi Sig F47

• 47 to 63 Hz

• 10VA maximum power consumption

High Power

PM_ _ [1,2] _ _ - _ _ _ _ _ _ _

Slot C

98

99

CF

CD

CE

B5

D6

D5

power

power

fuse

• Minimum/Maximum Ratings

• 85 to 264VAC

• 100 to 240VAC Semi Sig F47

• 47 to 63 Hz

• 10VA maximum power consumption

Watlow PM PLUS™ 6 • 20 • Chapter 2: Installation

Page 21

Wiring Notes

Maximum wire size

termination and torque

rating:

0.0507 to 3.30 mm2 (30

to 12 AWG) single-wire

termination or two 1.31

mm2 (16 AWG)

0.56 Nm (5.0 in-lb.)

torque

Adjacent terminals may

be labeled differently

depending on the model

number.

Do not connect wires to

unused terminals.

Maintain electrical isolation between analog

input 1, digital inputoutputs, switched dc/

open collector outputs

and process outputs to

prevent ground loops.

This equipment is suitable for use in CLASS I,

DIVISION 2, Groups A,

B, C and D or Non-Hazardous locations only.

Temperature Code T4A

Wiring Warnings

ç

Use National Electric

(NEC) or other countryspecic standard wiring

and safety practices

when wiring this controller to a power source,

electrical sensors or peripheral devices. Failure

to do so may result in

damage to equipment

and property, and/or injury or loss of life.

Explosion Hazard - Dry

contact closure Digital

Inputs shall not be used

in Class I Division 2 Hazardous Locations unless

switch used is approved

for this application.

Explosion Hazard – Substitution of component

may impair suitability for

CLASS I, DIVISION 2.

Explosion Hazard - Do

not disconnect while the

circuit is live or unless

the area is known to be

free of ignitable concentrations of ammable

substances.

Digital Input 5 - 6

PM _ _ [2,4] _ _ - _ _ _ _ _ _ _

Slot C

98

99

CF

CD

CE

B5

D6

D5

common

DC Input

DC Input

Digital Input

• Update rate 10 Hz

• Dry contact or dc voltage

DC Voltage

• Input not to exceed 36V (dc) at

3mA

• Input active when > 3V (dc) @

0.25mA

• Input inactive when < 2V

Dry Contact

Voltage Input

• Input inactive when > 500Ω

• Input active when < 100Ω

• Maximum short circuit 13mA

Dry Contact

Input 1, 2 Thermocouple

Input 1: PM _ [C,R] _ _ _ - _ _ _ _ _ _ _ (S1/R1)

Input 2: PM _ _ _ _ _ - _ [C,R,L] _ _ _ _ _ (S2/R2)

Slot A,B

• 2kΩ maximum source resistance

• >20MΩ input impedance

• 3µA open-sensor detection

• Thermocouples are polarity sensitive. The negative lead (usually red)

must be connected to S1 and/or S2.

• To reduce errors, the extension wire for thermocouples must be of the

-

S_

+

R_

same alloy as the thermocouple.

Input 1, 2 RTD

Input 1: PM _ [C,R,] _ _ _ - _ _ _ _ _ _ _ (S1/R1),(T1/S1/R1)

Input 2: PM _ _ _ _ _ - _ [C,R,L] _ _ _ _ _ (S2/R2), (T2/S2/R2)

Slot A,B

S3

S_

S1

R_

Slot A, B

S2

T_

S_

S3

R_

S1

• Platinum, 100 and 1kΩ @ 0°C

• Calibration to DIN curve (0.00385 Ω/Ω/°C)

• 20Ω total lead resistance

• RTD excitation current of 0.09mA typical. Each ohm of

lead resistance may affect the reading by 0.03°C.

• For 3-wire RTDs, the S1 lead (usually white) must be

connected to R1 and/or R2

• For accuracy use a 3-wire RTD to compensate for

lead-length resistance. All three lead wires must have

the same resistance

_

B

_

D

Vdc

common

24 Vdc

_

B

_

D

common

Watlow PM PLUS™ 6 • 21 • Chapter 2: Installation

Page 22

Wiring Notes

amperes

Maximum wire size termination and torque rating:

0.0507 to 3.30 mm2 (30

to 12 AWG) single-wire

termination or two 1.31

mm2 (16 AWG)

0.56 Nm (5.0 in-lb.)

torque

Adjacent terminals may

be labeled differently

depending on the model

number.

Do not connect wires to

unused terminals.

Maintain electrical isolation between analog

input 1, digital inputoutputs, switched dc/

open collector outputs

and process outputs to

prevent ground loops.

This equipment is suitable for use in CLASS

I, DIVISION 2, Groups

A, B, C and D or NonHazardous locations only.

Temperature Code T4A

Wiring Warnings

ç

Use National Electric

(NEC) or other countryspecic standard wiring

and safety practices

when wiring this controller to a power source,

electrical sensors or peripheral devices. Failure

to do so may result in

damage to equipment

and property, and/or injury or loss of life.

Explosion Hazard - Dry

contact closure Digital

Inputs shall not be used

in Class I Division 2 Hazardous Locations unless

switch used is approved

for this application.

Explosion Hazard – Substitution of component

may impair suitability for

CLASS I, DIVISION 2.

Explosion Hazard - Do

not disconnect while the

circuit is live or unless

the area is known to be

free of ignitable concentrations of ammable

substances.

Input 1, 2 Process

Input 1: PM _ [C,R,] _ _ _ - _ _ _ _ _ _ _ (-S1/+R1),(+T1/-S1)

Input 2: PM _ _ _ _ _ - _ [C,R,L] _ _ _ _ _ (-S2/+R2),(+T2/-S2)

Slot A, B

Slot A, B

• 0 to 20mA @ 100Ω input impedance

• 0 to 10VDC @ 20kΩ input impedance

• 0 to 50mVDC @ 20kΩ input impedance

• Scalable

+

T_

-

S_

+

R_

volts

-

S_

Input 1,2 Potentiometer

Input 1: PM _ [C,R] _ _ _ - _ _ _ _ _ _ _ (S1/R1)

Input 2: PM _ _ _ _ _ - _ [C,R,L] _ _ _ _ _ (S2/R2)

• Use a 1kΩ potentiometer.

CW

CCW

Slot A, B

S_

R_

Input 1, 2 Thermistor

Input 1: PM _ [J,N] _ _ _ _-_ _ _ _ _ _ _ (S1/R1)

Input 2: PM _ _ _ _ _ - _ [J,P,M] _ _ _ _ _ (S2/R2)

Slot A, B

• >20MΩ input impedance

• 3µA open-sensor detection

S_

R_

Input 2 Current Transformer

PM _ _ _ _ _ - _ [T] _ _ _ _ _

Slot B

T2

S2

• Input range is 0 to 50mA

• Current transformer part number: 16-0246

• 100Ω input impedance

• Response time: 1 second maximum

• Accuracy +/-1 mA typical

Watlow PM PLUS™ 6 • 22 • Chapter 2: Installation

Page 23

12A

Is = IpT/R = 50mA

ent

Wiring Notes

Maximum wire size

termination and torque

rating:

0.0507 to 3.30 mm2 (30

to 12 AWG) single-wire

termination or two 1.31

mm2 (16 AWG)

0.56 Nm (5.0 in-lb.)

torque

Adjacent terminals may

be labeled differently

depending on the model

number.

Do not connect wires to

unused terminals.

Maintain electrical isolation between analog

input 1, digital inputoutputs, switched dc/

open collector outputs

and process outputs to

prevent ground loops.

This equipment is suitable for use in CLASS I,

DIVISION 2, Groups A,

B, C and D or Non-Hazardous locations only.

Temperature Code T4A

Wiring Warnings

ç

Use National Electric

(NEC) or other countryspecic standard wiring

and safety practices

when wiring this controller to a power source,

electrical sensors or peripheral devices. Failure

to do so may result in

damage to equipment

and property, and/or injury or loss of life.

Explosion Hazard - Dry

contact closure Digital

Inputs shall not be used

in Class I Division 2 Hazardous Locations unless

switch used is approved

for this application.

Explosion Hazard – Substitution of component

may impair suitability for

CLASS I, DIVISION 2.

Explosion Hazard - Do

not disconnect while the

circuit is live or unless

the area is known to be

free of ignitable concentrations of ammable

substances.

Example Current Transformer:

L2 L1

3A x 4

Turns around CT

12A

:

x 4 = 48A

48mA

CT Secondary Current

CT Primary Current

Turns around CT

Total current

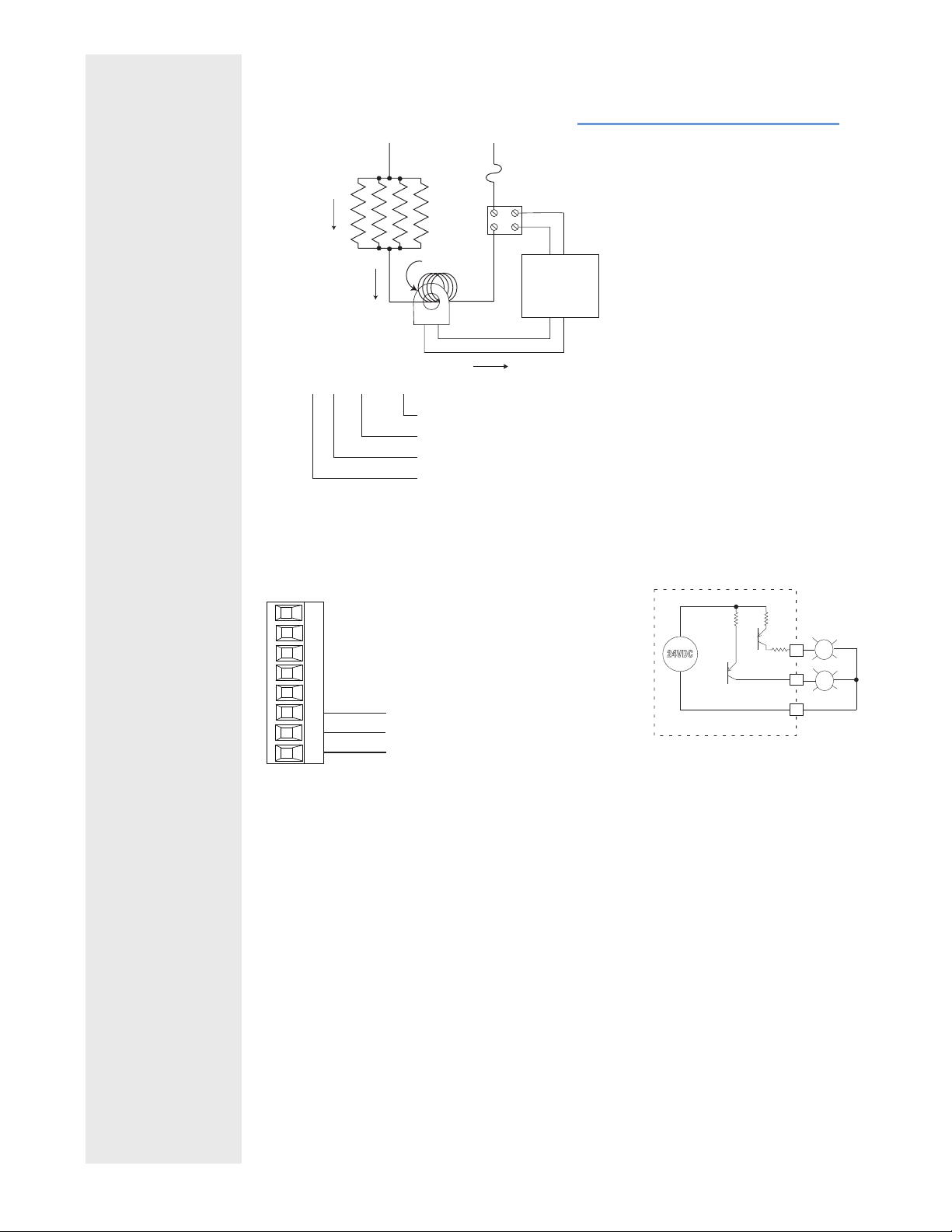

Digital Output 5 - 6

PM _ _ [2,4] _ _ - _ _ _ _ _ _ _

Slot C

98

99

CF

CD

CE

common

B5

switched dc

D6

switched dc

D5

Digital Output

• SSR drive signal

• Update rate 10 Hz

• Maximum open circuit voltage is

22 to 25V (dc)

• PNP transistor source

• Typical drive; 21mA @ 4.5V (dc)

for DO5, and 11mA @ 4.5V for

DO6

• Current limit 24mA for Output 5

and 12mA Output 6

• Output 5 capable of driving one

3-pole DIN-A-MITE

• Output 6 capable of driving one

1-pole DIN-A-MITE

Fuse

SSR

CT Ratio R = 1000:1

48mA

Output N

Controller

CT Input

p(full scale)

CSC = I

CSI = Output N

I

s = Current in secondary of current transformer

Ip = Current in primary of current transformer

T = Number of turns through the primary of the transformer

R = Number of turns in the secondary of the current

transformer (Turns ratio, assuming one primary turn)

CSC = Current Scaling (parameter found in Current Menu

of Setup Page)

CSI = Current Source Instance (parameter found in Curr

Menu of Setup Page)

= 50mA(R)/T

24VDC

switched dc outputs

D5

D6

B5

Internal Circuitry

Watlow PM PLUS™ 6 • 23 • Chapter 2: Installation

Page 24

Wiring Notes

Maximum wire size termination and torque rating:

0.0507 to 3.30 mm2 (30

to 12 AWG) single-wire

termination or two 1.31

mm2 (16 AWG)

0.56 Nm (5.0 in-lb.)

torque

Adjacent terminals may

be labeled differently

depending on the model

number.

Do not connect wires to

unused terminals.

Maintain electrical isolation between analog

input 1, digital inputoutputs, switched dc/

open collector outputs

and process outputs to

prevent ground loops.

This equipment is suitable for use in CLASS

I, DIVISION 2, Groups

A, B, C and D or NonHazardous locations only.

Temperature Code T4A

Wiring Warnings

Use National Electric

(NEC) or other countryspecic standard wiring

and safety practices

when wiring this controller to a power source,

electrical sensors or peripheral devices. Failure

to do so may result in

damage to equipment

and property, and/or injury or loss of life.

Explosion Hazard - Dry

contact closure Digital

Inputs shall not be used

in Class I Division 2 Hazardous Locations unless

switch used is approved

for this application.

Explosion Hazard – Substitution of component

may impair suitability for

CLASS I, DIVISION 2.

Explosion Hazard - Do

not disconnect while the

circuit is live or unless

the area is known to be

free of ignitable concentrations of ammable

substances.

ç

Watlow PM PLUS™ 6 • 24 • Chapter 2: Installation

Page 25

Wiring Notes

Limit Control

SSR-240-25A-DC1

Maximum wire size

termination and torque

rating:

0.0507 to 3.30 mm2 (30

to 12 AWG) single-wire

termination or two 1.31

mm2 (16 AWG)

0.56 Nm (5.0 in-lb.)

torque

Adjacent terminals may

be labeled differently

depending on the model

number.

Do not connect wires to

unused terminals.

Maintain electrical isolation between analog

input 1, digital inputoutputs, switched dc/

open collector outputs

and process outputs to

prevent ground loops.

This equipment is suitable for use in CLASS I,

DIVISION 2, Groups A,

B, C and D or Non-Hazardous locations only.

Temperature Code T4A

Wiring Warnings

ç

Use National Electric

(NEC) or other countryspecic standard wiring

and safety practices

when wiring this controller to a power source,

electrical sensors or peripheral devices. Failure

to do so may result in

damage to equipment

and property, and/or injury or loss of life.

Explosion Hazard - Dry

contact closure Digital

Inputs shall not be used

in Class I Division 2 Hazardous Locations unless

switch used is approved

for this application.

Explosion Hazard – Substitution of component

may impair suitability for

CLASS I, DIVISION 2.

Explosion Hazard - Do

not disconnect while the

circuit is live or unless

the area is known to be

free of ignitable concentrations of ammable

substances.

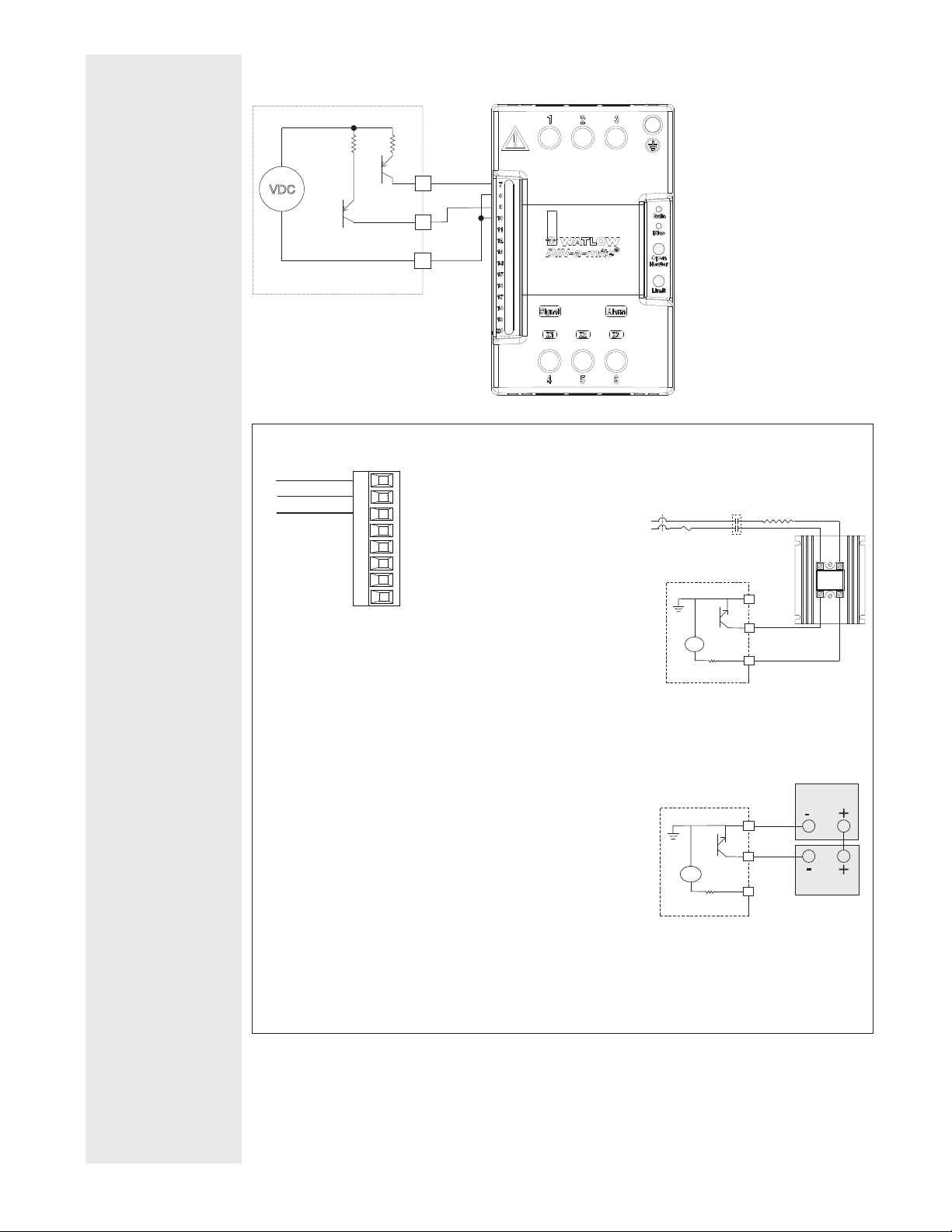

Switched DC Wiring Example Using DO 5-6

switched dc outputs

Htr 1

VDC

Internal Circuitry

Output 1, 3 Switched DC/Open Collector

common

dc - (open collector)

dc +

Slot A, B

X_

W_

Y_

D5

Htr 2

D6

B5

Switched DC

• Maximum open circuit voltage is

22 to 25VDC

• 30mA max. per single output /

40mA max. total per paired outputs

(1 & 2, 3 & 4)

• Typical drive; 4.5V (dc) @ 30mA

• Short circuit limited to <50mA

•

• NPN transistor sink

• Use dc- and dc+ to drive external

solid-state relay

• 1-pole DIN-A-MITE: up to 4 in

parallel or 4 in series

• 2-pole DIN-A-MITE: up to 2 in

parallel or 2 in series

• 3-pole DIN-A-MITE: up to 2 in

series

Open Collector

• 100mA maximum output current

sink

• 30V (dc) max. supply voltage

• Any switched dc output can use the

common terminal.

• Use an external power supply to

control a dc load, with the load

positive to the positive of the power

supply, the load negative to the

open collector and common to the

power supply negative.

+

-

+

-

DC80-60C0-0000

Switched DC

Contacts

(If Required)

X

W

Y

_

common

dc -

_

dc +

_

Heater

1(–) (+)2

4(–) (+)3

(-) (+)

L2

L1

Semiconductor

Fuse

Switched DC

24VDC

Open Collector

Power Supply

common

_

X

dc -

_

W

24VDC

_

Y

Output 1: (X1,-W1,+Y1)

PM _ _ _ [C] _ - _ _ _ _ _ _ _

Output 3: (X3,-W3,+Y3)

PM _ _ _ _ _ - _ _ [C] _ _ _ _

Load

Watlow PM PLUS™ 6 • 25 • Chapter 2: Installation

Page 26

Wiring Notes

Maximum wire size termination and torque rating:

0.0507 to 3.30 mm2 (30

to 12 AWG) single-wire

termination or two 1.31

mm2 (16 AWG)

0.56 Nm (5.0 in-lb.)

torque

Adjacent terminals may

be labeled differently

depending on the model

number.

Do not connect wires to

unused terminals.

Maintain electrical isolation between analog

input 1, digital inputoutputs, switched dc/

open collector outputs

and process outputs to

prevent ground loops.

This equipment is suitable for use in CLASS

I, DIVISION 2, Groups

A, B, C and D or NonHazardous locations only.

Temperature Code T4A

Wiring Warnings

ç

Use National Electric

(NEC) or other countryspecic standard wiring

and safety practices

when wiring this controller to a power source,

electrical sensors or peripheral devices. Failure

to do so may result in

damage to equipment

and property, and/or injury or loss of life.

Explosion Hazard - Dry

contact closure Digital

Inputs shall not be used

in Class I Division 2 Hazardous Locations unless

switch used is approved

for this application.

Explosion Hazard – Substitution of component

may impair suitability for

CLASS I, DIVISION 2.

Explosion Hazard - Do

not disconnect while the

circuit is live or unless

the area is known to be

free of ignitable concentrations of ammable

substances.

Output 1, 3 Mechanical Relay, Form C

Output 1: (L1,K1,J1 PM _ _ _ [E] _ - _ _ _ _ _ _ _

Output 3: (L3,K3,J3) PM _ _ _ _ _ - _ _ [E] _ _ _ _

normally open

common

normally closed

Slot A, B

L_

K_

J_

• 5A at 240VÅ (ac) or 30VÎ (dc) maximum resistive load

• 20mA at 24V minimum load

• 125VA pilot duty at 120/240VÅ (ac),

25VA at 24VÅ (ac)

• 100,000 cycles at rated load

• Output does not supply power.

• For use with ac or dc

Output 1, 3 Universal Process

Output 1: (F1,G1,H1) PM _ _ _ [F] _ - _ _ _ _ _ _ _

Output 3: (F3,G3,H3) PM _ _ _ _ _ - _ _ [F] _ _ _ _

volts or current -

volts +

current +

Slot A, B

F_

G_

H_

• 0 to 20mA into 800 Ω maximum

load

• 0 to 10VÎ (dc) into 1 kΩ minimum

load

• Scalable

• Output supplies power

• Cannot use voltage and current

outputs at same time

• Output may be used as retransmit

or control.

Output 1, 3 Solid-State Relay, Form A

Output 1: (L1, K1) PM _ _ _ [K] _ - _ _ _ _ _ _ _

Output 3: (L3, K3) PM _ _ _ _ _ - _ _ [K] _ _ _ _

Slot A, B

normally open

L_

common

K_

• 0.5A at 20 to 264VÅ (ac) max resistive

load

• 20VA 120/240VÅ (ac) pilot duty

• Opto-isolated, without contact suppression

• Maximum off state leakage of 105µA

• Output does not supply power

• Minimum holding current of 10mA

• Do not use on dc loads.

• See Quencharc note

4 to 20 mA

0 to 10 V

_

L

normally open

_

K

common

_

J

normally closed

3

F

negative

3

G

volts +

H3

current +

_

L

_

K

Watlow PM PLUS™ 6 • 26 • Chapter 2: Installation

Page 27

Wiring Notes

Maximum wire size

termination and torque

rating:

0.0507 to 3.30 mm2 (30

to 12 AWG) single-wire

termination or two 1.31

mm2 (16 AWG)

0.56 Nm (5.0 in-lb.)

torque

Adjacent terminals may

be labeled differently

depending on the model

number.

Do not connect wires to

unused terminals.

Maintain electrical isolation between analog

input 1, digital inputoutputs, switched dc/

open collector outputs

and process outputs to

prevent ground loops.

This equipment is suitable for use in CLASS I,

DIVISION 2, Groups A,

B, C and D or Non-Hazardous locations only.

Temperature Code T4A

Output 2, 4 Switched DC

Output 2: (-W2, +Y2) PM _ _ _ _ [C] - _ _ _ _ _ _ _

Output 4: (-W4, +Y4) PM _ _ _ _ _ - _ _ _ [C] _ _ _

dc-

dc+

Slot A, B

W_

Y_

• Maximum open circuit voltage 22 to 25VÎ (dc)

• 30mA max. per single output / 40mA max. total per paired outputs (1 & 2,

3 & 4)

• Typical drive; 4.5VÎ (dc) @ 30mA

• Short circuit limited to <50mA

• NPN transistor sink

• Use dc- and dc+ to drive external solid-state relay

• 1-pole DIN-A-MITE: up to 4 in parallel or 4 in series

• 2-pole DIN-A-MITE: up to 2 in parallel or 2 in series

• 3-pole DIN-A-MITE: up to 2 in series

Wiring Warnings

ç

Use National Electric

(NEC) or other countryspecic standard wiring

and safety practices

when wiring this controller to a power source,

electrical sensors or peripheral devices. Failure

to do so may result in

damage to equipment

and property, and/or injury or loss of life.

Explosion Hazard - Dry

contact closure Digital

Inputs shall not be used

in Class I Division 2 Hazardous Locations unless

switch used is approved

for this application.

Explosion Hazard – Substitution of component

may impair suitability for

CLASS I, DIVISION 2.

Explosion Hazard - Do

not disconnect while the

circuit is live or unless

the area is known to be

free of ignitable concentrations of ammable

substances.

Output 2, 4 NO-ARC Relay, Form A

Output 2: (L2, K2) PM _ _ _ _ [H] - _ _ _ _ _ _ _

Output 4: (L4, K4) PM [4, 8, 9] _ _ _ _ - _ _ _ [H] _ _ _

• 12A at 85 to 264VÅ (ac) resistive load only

• 2,000,000 cycle rating for NOARC circuit

• 100mA minimum load

• 2mA maximum off state leakage

• Do not use on dc loads

• Output does not supply power

normally open

common

Slot A, B

L_

K_

_

L

_

K

Watlow PM PLUS™ 6 • 27 • Chapter 2: Installation

Page 28

Wiring Notes

nor

Slot A, B

nor

Slot A, B

Maximum wire size termination and torque rating:

0.0507 to 3.30 mm2 (30

to 12 AWG) single-wire

termination or two 1.31

mm2 (16 AWG)

0.56 Nm (5.0 in-lb.)

torque

Adjacent terminals may

be labeled differently

depending on the model

number.

Do not connect wires to

unused terminals.

Maintain electrical isolation between analog

input 1, digital inputoutputs, switched dc/

open collector outputs

and process outputs to

prevent ground loops.

This equipment is suitable for use in CLASS

I, DIVISION 2, Groups

A, B, C and D or NonHazardous locations only.

Temperature Code T4A

Wiring Warnings

ç

Use National Electric

(NEC) or other countryspecic standard wiring

and safety practices

when wiring this controller to a power source,

electrical sensors or peripheral devices. Failure

to do so may result in

damage to equipment

and property, and/or injury or loss of life.

Explosion Hazard - Dry

contact closure Digital

Inputs shall not be used

in Class I Division 2 Hazardous Locations unless

switch used is approved

for this application.

Explosion Hazard – Substitution of component

may impair suitability for

CLASS I, DIVISION 2.

Explosion Hazard - Do

not disconnect while the

circuit is live or unless

the area is known to be

free of ignitable concentrations of ammable

substances.

Output 2, 4 Mechanical Relay, Form A

Output 2: (L2, K2) PM _ _ _ _ [J] - _ _ _ _ _ _ _

Output 4: (L4, K4) PM _ _ _ _ _ - _ _ _ [J] _ _ _

• 5A at 240VÅ (ac) or 30VÎ (dc) maximum

resistive load

• 20mA at 24V minimum load

• 125VA pilot duty @ 120/240VÅ (ac), 25VA

mally open

common

L_

K_

at 24VÅ (ac)

• 100,000 cycles at rated load

• Output does not supply power

• For use with ac or dc

• See Quencharc Wiring Example

Output 2, 4 Solid-State Relay, Form A

Output 2: (L2, K2) PM _ _ _ _ [K] - _ _ _ _ _ _ _

Output 4: (L4, K4) PM _ _ _ _ _ - _ _ _ [K] _ _ _

• 0.5A at 20 to 264VÅ (ac) maximum

resistive load

• 20VA 120/240VÅ (ac) pilot duty

• Opto-isolated, without contact sup-

mally open

common

L_

K_

pression

• Maximum off state leakage of 105µA

• Minimum holding current of 10mA

• Output does not supply power

• Do not use on dc loads.

• See Quencharc Wiring Example

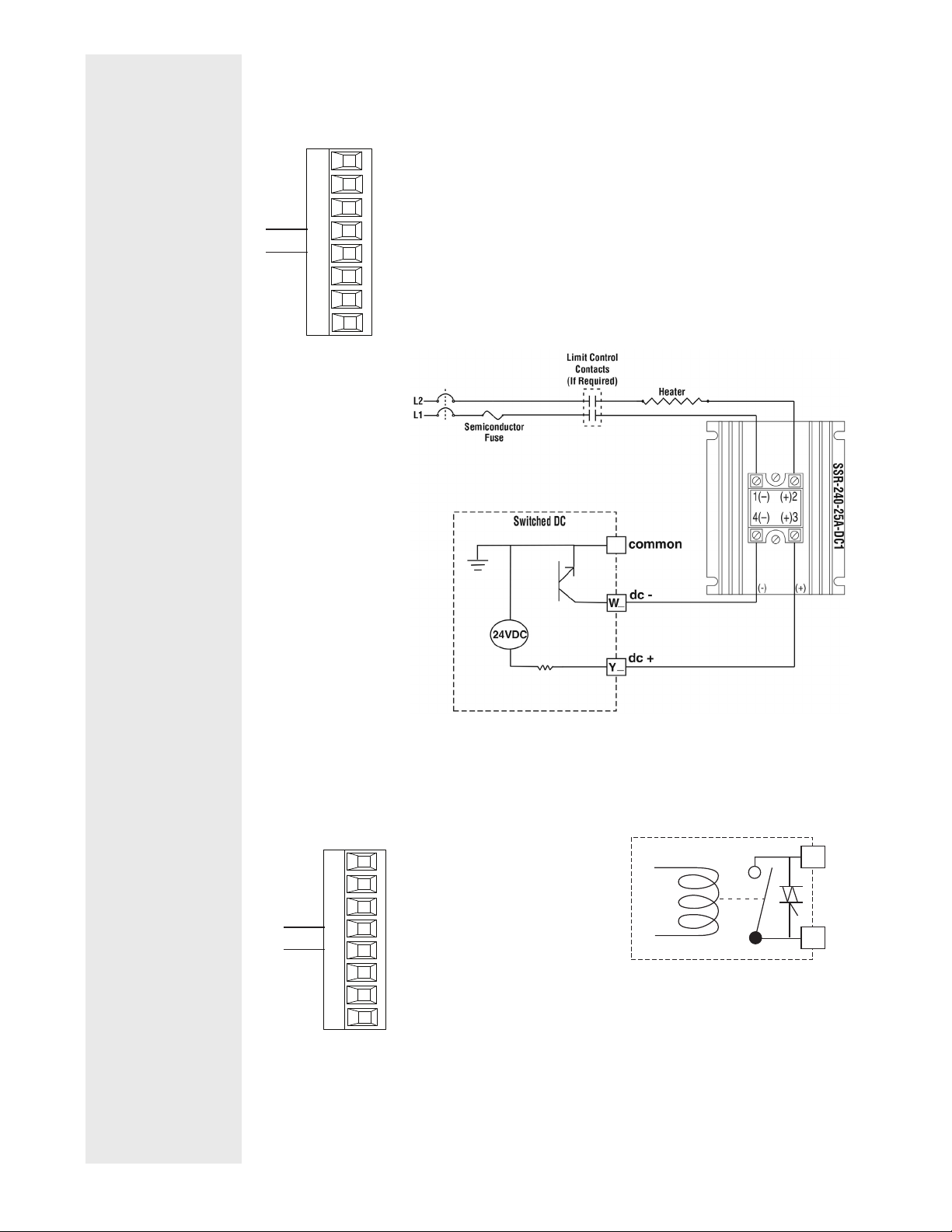

Quencharc Wiring Example

In this example the Quencharc circuit (Watlow part#

0804-0147-0000) is used to protect PM internal circuitry from the counter electromagnetic force from

the inductive user load when de-engergized. It is

recommended that this or an equivalent Quencharc

be used when connecting inductive loads to PM

outputs.

_

L

_

K

_

L

_

K

User Load

_

L

Quencharc

_

K

N

Watlow PM PLUS™ 6 • 28 • Chapter 2: Installation

Page 29

Wiring Notes

Maximum wire size

termination and torque

rating:

0.0507 to 3.30 mm2 (30

to 12 AWG) single-wire

termination or two 1.31

mm2 (16 AWG)

0.56 Nm (5.0 in-lb.)

torque

Adjacent terminals may

be labeled differently

depending on the model

number.

Do not connect wires to

unused terminals.

Maintain electrical isolation between analog

input 1, digital inputoutputs, switched dc/

open collector outputs

and process outputs to

prevent ground loops.

This equipment is suitable for use in CLASS I,

DIVISION 2, Groups A,

B, C and D or Non-Hazardous locations only.

Temperature Code T4A

Wiring Warnings

ç

Use National Electric

(NEC) or other countryspecic standard wiring

and safety practices

when wiring this controller to a power source,

electrical sensors or peripheral devices. Failure

to do so may result in

damage to equipment

and property, and/or injury or loss of life.

Explosion Hazard - Dry

contact closure Digital

Inputs shall not be used

in Class I Division 2 Hazardous Locations unless

switch used is approved

for this application.

Explosion Hazard – Substitution of component

may impair suitability for

CLASS I, DIVISION 2.

Explosion Hazard - Do

not disconnect while the

circuit is live or unless

the area is known to be

free of ignitable concentrations of ammable

substances.

Standard Bus EIA-485 Communications

PM _ _ _ _ _ - [*] _ _ _ _ _ _

*All models include Standard Bus communications (instance 1)

Slot C

98

99

CF

CD

CE

B5

D6

D5

common

T-/R-

T+/R+

• Wire T-/R- to the A terminal of the EIA-485 port.

• Wire T+/R+ to the B terminal of the EIA-485 port.

• Wire common to the common terminal of the EIA-485 port.

• Do not route network wires with power wires. Connect network wires in

daisy-chain fashion when connecting multiple devices in a network.

• Do not connect more than 16 controllers on a network.

• Maximum network length: 1,200 meters (4,000 feet)

• 1/8th unit load on EIA-485 bus

Note: Do not leave a USB to EIA-485 converter connected to Standard Bus without power (i.e., disconnecting the USB end from the PC and leave the converter

connected on Standard Bus). Disturbance on the Standard Bus may occur.

Modbus® RTU or Standard Bus EIA-485 Communications

PM _ _ _ _ - [1] _ _ _ _ _ _

Slot C

98

99

CC

CA

CB

B5

D6

D5

common

T-/R-

T+/R+

• Wire T-/R- to the A terminal of the EIA-485 port.

• Wire T+/R+ to the B terminal of the EIA-485 port.

• Wire common to the common terminal of the EIA-485 port.

• Do not route network wires with power wires. Connect network wires in

daisy-chain fashion when connecting multiple devices in a network.

• A termination resistor may be required. Place a 120 Ω resistor across T+/

R+ and T-/R- of last controller on network.

• Only one protocol per port is available at a time: either Modbus® RTU or

Standard Bus.

• Do not connect more than 16 controllers on a Standard Bus network.

• Maximum number of controllers on a Modbus® network is 247.

• Maximum network length: 1,200 meters (4,000 feet)

• 1/8th unit load on EIA-485 bus.

• Communications instance 1

Note: Do not leave a USB to EIA-485 converter connected to Standard Bus without power (i.e., disconnecting the USB end from the computer while leaving the

converter connected on Standard Bus). Disturbance on the Standard Bus may

occur.

Watlow PM PLUS™ 6 • 29 • Chapter 2: Installation

Page 30

Wiring Notes

Maximum wire size termination and torque rating:

0.0507 to 3.30 mm2 (30

to 12 AWG) single-wire

termination or two 1.31

mm2 (16 AWG)

0.56 Nm (5.0 in-lb.)

torque

Adjacent terminals may

be labeled differently

depending on the model

number.

Do not connect wires to

unused terminals.

Maintain electrical isolation between analog

input 1, digital inputoutputs, switched dc/

open collector outputs

and process outputs to

prevent ground loops.

This equipment is suitable for use in CLASS

I, DIVISION 2, Groups

A, B, C and D or NonHazardous locations only.

Temperature Code T4A

EIA-232/485 Modbus® RTU Communications

PM [6] _ _ _ _ - [2] _ _ _ _ _ _

485 T+/R+

485 T-/R-

485 common

485 T+/R+

485 T-/R-

232 common

232 (TX) to DB9 pin 2 (RD)

232 (RD) to DB9 pin 3 (TX)

Slot B, E

CB

CA

CC

CB

CA

C5

C3

C2