Watlow PM6 LEGACY Quick Start Guide

Declaration of Conformity - Series EZ-ZONE

®

PM

) (Any

gory

g

(

g

A

t

g

g

A

g

y

be

g

(b)

(b)

A

g

A

QUICK START

Internal Circuit

Internal Circuit

Normally Open

–

–

+

+

2-wire

T1

S1

R1

T1

S1

S3

S1

S2

3-wire

R1

GUIDE

TM

PM6 LEGACY EXPRESS

PID CONTROLLER

for configurations:

PM6 C _ _ _ -_ AAAH_ _

NOTE: Express Only

For assistance contact Watlow: www.watlow.com

1-800-WATLOW2 (1-800-928-5692)

wintechsupport@watlow.com

Document No. 10-41691 - Part No. 2126-4397

June 30, 2020

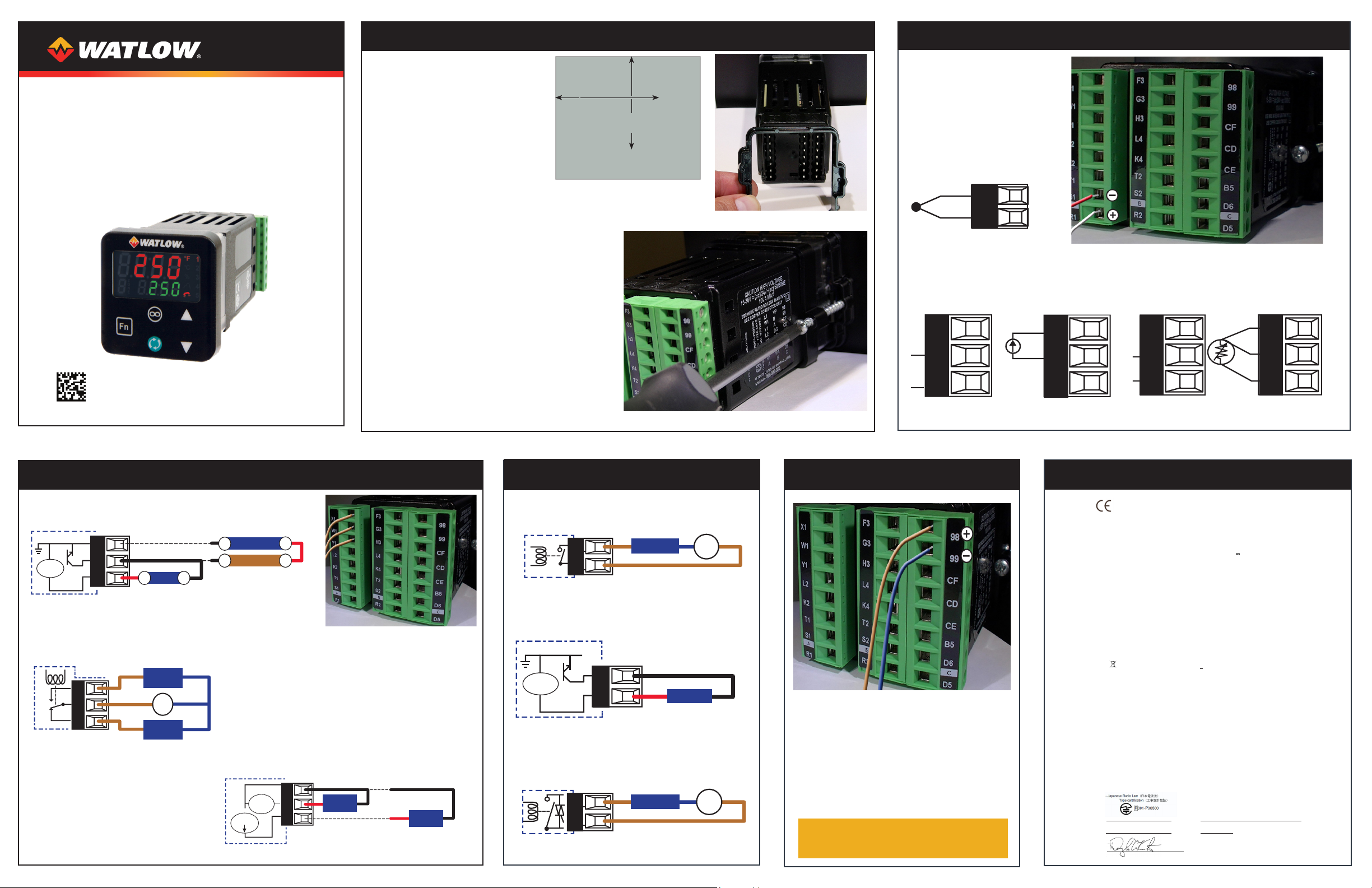

1 - MOUNT TO PANEL

1. Make the panel cutout using the

measurements in figure 1.

2. Remove the green terminal

connectors and the mounting collar

assembly.

3. Insert the controller into the panel

cutout from the front.

4. Orient the collar base so the flat side

faces front and the screw openings

are on the sides (see figure 2), then

slide the base over the back of the

controller.

5. Slide the mounting bracket over the

controller with the screws aligned to

the collar base. Push the bracket gently but

firmly until the hooks snap into the slots in the

case.

6. Tighten the two #6-19 x 1.5 in. screws with a

Phillips screwdriver until the device is flush to

the panel (3 to 4 in-lbs torque).

7. Reinstall the terminal connectors to their

original locations. (Or first connect field wiring

as indicated in this guide and then reinstall the

connectors).

44.96 to 45.47 mm

(1.77 to 1.79 in.)

44.96 to 45.47 mm

(1.77 to 1.79 in.)

Figure 1

NOTE: Mounting requires

access to the back of the panel.

Figure 2

Figure 3

?? ??

2 - CONNECT THE SENSOR INPUT

Connect your sensor as

indicated in the diagram for

your sensor input. Figure

4 is an example illustrating

the connection shown for a

Thermocouple.

Thermocouple

S1

+

R1

Process Voltage: 0 to 10V@ 20kΩ

Process Current: 0 to 20 mA @ 100Ω

T1

S1

R1

volts

–

Figure 4: Thermocouple Wiring Example

Platinum 100Ω

20Ω max. loop lead resistance

T1

S1

R1

amperes

3 - WIRE OUTPUT 1

Refer to the wiring diagram for your conguration code

and connect to the slots indicated.

PM6_ _ C _ - _ _ _ _ H _ _: Switched DC or Open Collector

X1

W

Y1

1

+

Load

–

Open Collector

–

Power Supply

–

Load

Switched DC

Internal Circuit

Common

–

24V(dc)

+

PM6_ _ E _ - _ _ _ _ H _ _: 5A Form C Relay

5A @240 V(ac) or 30 V (dc)

Normally

L1

K1

J1

Normally

Closed

Open

Common

Load

AC

Load

PM6_ _ F _ - _ _ _ _ H_ _: Universal Process

–

0 to 10 V

4 to 20mA

+

+

Figure 5: Switched DC Output Wiring

0 to 20 mA: 800 Ω max. load

0 to 10V: 1kΩ min. load

Voltage Load Current Loador

Load

+

+

F1

G1

H1

Load

4 - WIRE OUTPUT 2

PM6_ _ _ J - _ _ _ _ H _ _: 5A Form A Relay

L2

Load

AC

K2

Internal Circuit

PM6_ _ _ C - _ _ _ _H_ _: Switched DC

Common

–

24V(dc)

+

Internal Circuit

PM6_ _ _ H - _ _ _ _H_ _: No-Arc Relay

Common

W

2

Y2

Normally Open

L2

Load

Load

AC

K2

Internal Circuit

Common

5 - CONNECT POWER

Connect the power source for your

conguration code:

PM6 _ [1,2,3,4] _ _ - _ _ _ _ _ _ _

1 or 2:120-240 V (ac)

3 or 4: 24 V (ac or dc)

CAUTION

Do not connect high voltage to a controller that

requires low voltage.

6- CE DECLARATION OF CONFORMITY

WATLOW Electric Manufacturing Company

1241 Bundy Blvd. Winona, MN 55987 USA

Declares that the following product meets the essential requirements of the following European Union Directives by using

the relevant standards show below to indicate compliance.

Designation: Series EZ-ZONE

e and Frequency: 100 to 240 V~(ac 50/60 Hz)or 15 to 36 V dc/ 24 V~ac 50/60 Hz

Rated Volta

Rated Power Consumption: 10 VA maximum PM3, PM6 Models.

EN 61326-1:2013 Electrical equipment for measurement, control and laboratory use – EMC

IEC 61000-4-2:2008 Electrostatic dischar

IEC 61000-4-3:2007 +A1/2008,

2/2010

IEC 61000-4-4:2012 Electrical fas

IEC 61000-4-5:2014 +A1/2017 Sur

IEC 61000-4-6:2013 +

endum 2015

Corri

IEC 61000-4-11:2004 +

EN 61000-3-2:2014 Limits for harmonic current emissions for equipment ≤ 16 Amps per phase

1

:2013 + A1/2017 Voltage fluctuations and flicker ≤ 16 Amps per phase

EN 61000-3-3

SEMI F47-0812 Specification for semiconductor sa

1

For mechanical relay loads, cycle time may need to be extended up to 160 seconds to meet flicker requirements

depending on load switched and source impedance.

2

EN 61010-1:2010

2

Compliance with 3rd Edition requirements with use of external surge suppressor installed on 230 Vac~ power line units.

Recommend minimum 1000 V peak to maximum 2000 V peak, 70 joules or better part be used.

Compliant with 2011/65/EU RoHS2 Directive Per 2012/19/EU W.E.E.E Directive

Please Recycle Properly. Models PM(4, 8 or 9)E contain a type BR1225 coin cell battery which shall

recycled at end of life per 2006/66/EC Battery Directive as amended by 2013/56/EU Directive.

Models PM6XXXX – (B, E, F, G, H, J, K)XXXXXX where (X = any letter or number allowed above)

Include Bluetooth

EN 61010-1:2010 Safety Requirements of electrical equipment for measurement, control and laboratory use.

EN 61326-1:2013 Electrical equipment for measurement, control and laboratory use – EMC requirements

EN 301 489-1 V2.1.1 ElectroMagnetic Compatibility (EMC) standard for radio equipment and services; Part 1: Common

EN 301 489-17 V3.1.1 ElectroMagnetic Compatibility (EMC)

EN 300 328 V1.9.1 Electromagnetic compatibility and Radio spectrum Matters (ERM); Wideband transmission

EN 300 328 V2.1.1 Additional Receiver blocking test for to cover requirements for 2014/53/EU.

Contains Module FCC ID: VPYLBZY Part 15C 2.

Contains Module IC: 772C-LBZY RSS 210

Dou

Name of Authorized Representative Place of Issue

Director of Operations May 2018

of Authorized Representative

Signature

H, J or K) – (Any letter or number)(Any letter or number)(A, C, E, F or K)(A, C,

H, J or K

14 VA maximum PM8, PM9, PM4 Models

2014/30/EU Electromagnetic Compatibility Directive

Industrial Immunity, Class B Emissions).

requirements

Radiated, radio-frequency electromagnetic field immunity 10V/M 80–1000 MHz, 3 V/M

1.4–2.7 GHz

-transient / burst immunity

e immunity

Immunity to conducted disturbances induced by radio-frequency fields

1/2017 Voltage dips, short interruptions and voltage variations immunity

2014/35/EU Low-Voltage Directive

Safety Requirements of electrical equipment for measurement, control and

use. Part 1: General requirements

laborator

®

wireless technology and have been reviewed to the following additional requirements.

2014/53/EU Radio Equipment Direcve (RED)

Part 1: General requirements

the essential requirements of article 3.1(a)or Directive 2014/53/EU

Coverin

(Industrial Immunity, Class A Emissions).

CAUTION: This equipment not intended for use in residential environments and may not provide

adequate protection to radio reception in such environments.

technical requirements; Harmonized Standard covering the essential requirementsof article

of Directive 2014/53/EU and the essential requirements of article 6 of Directive 2014/30/EU

3.1

Specific conditions for Broadband Data Transmission Systems; Harmonized Standardcovering

the essential requirements of article 3.1

systems; Data transmission equipment operating in the 2,4 GHz ISM band and using wide band

modulation techniques; Harmonized EN covering the essential requirements of article3.2 of the

R&TTE Directive

NVLAP Test Report 10928545H-

NVLAP Test Report 11649468H-E

Output Power: Frequency Range 2402.0 - 2480.0

Output Power 0.001 Watts Antenna gain: -0.6 dBi PCB antenna

®

PM (Panel Mount)

ro retteL ynA()4 ro 9 ,8 ,6 ,3( MP :srebmuN ledoM number)(1, 2, 3 or 4)(A, C, E, F or K) (A, C,

three letters or numbers)

e immunity

standard for radio equipment and services; Part 17:

II, Pollution degree 2, IP65

etaC noitallatsnI ,lortnoc erutarepmeT :noitacifissalC

immunityFigure R1-1

of Directive 2014/53/EU

SU ,atosenniM ,anoniW athcuK

FN

°

°

%

O

Z

N

E

‰

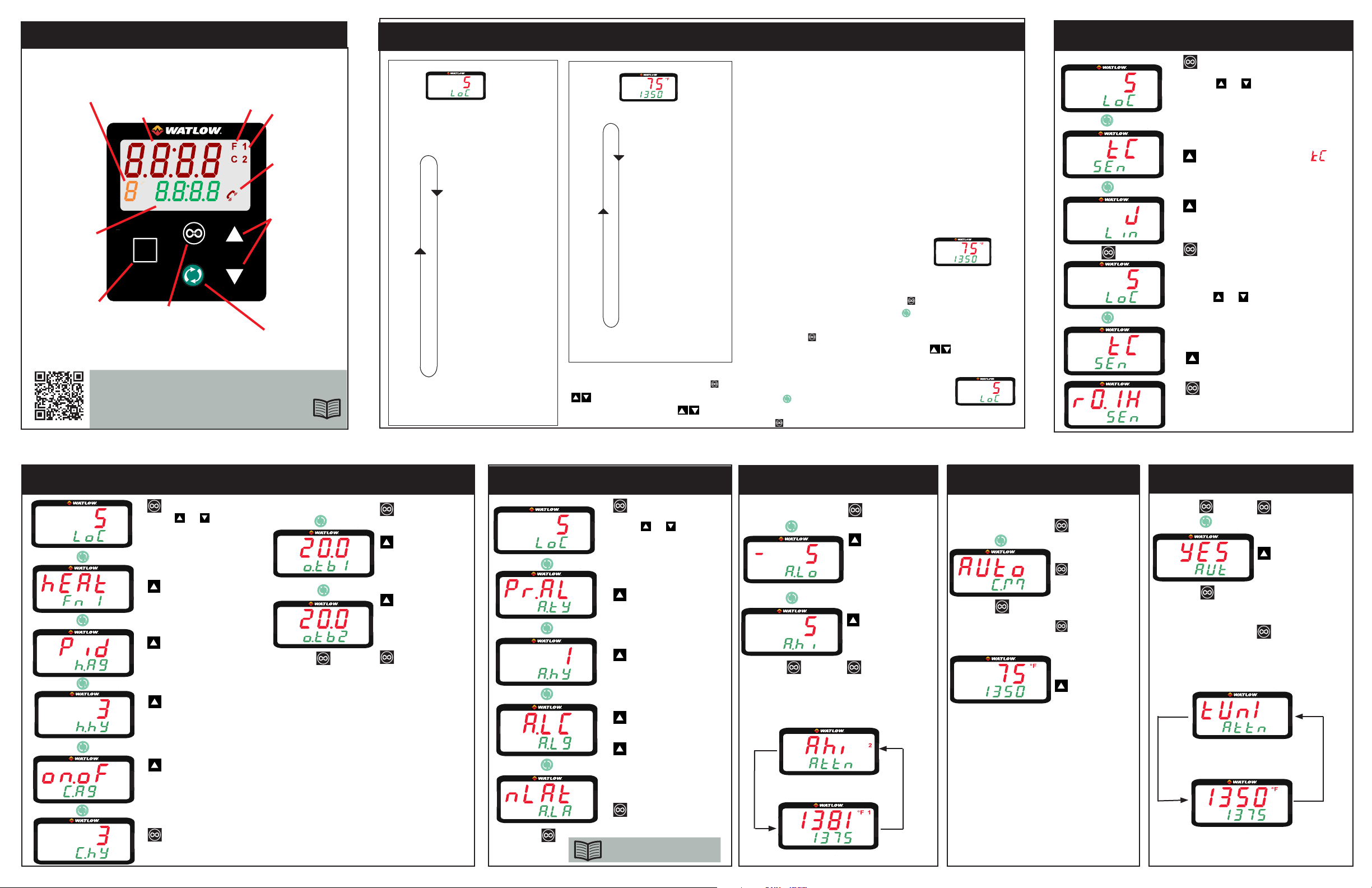

7 - KEYPAD OVERVIEW

Zone Display:

Indictes the controller

addess when using

communications.

[1] to [9] = zones 1

to 9

[A] = zone 10

[b] = zone 11

[C] = zone 12

[d] = zone 13

[E] = zone 14

[F] = zone 15

[h] = zone 16

Lower Display:

Indicates the set

point or output

power value during

operation or the

parameter whose

value appears in

the upper display.

Function Key:

This key will toggle the control mode between the current value of the C.M prompt

(Off, MAn, AUto) and Manual

when the Function Key is

pushed and held for

3 seconds.

For assistance contact Watlow: www.watlow.com

Scan for full manual.

http://www.watlow.com/downloads/en/manuals/pmpmi.pdf

Upper Display:

In the Operations Menu,

displays the process

value, otherwise displays the value of the

parameter in the lower

display.

Infinity Key:

Clears and silences

alarms, press to back up

one level, or press and

hold for two seconds to

return to the Operations

Menu.

+1-(507)-494-5656

wintechsupport@watlow.com

Temperature Units

Indicator Lights:

Indicates whether the

temperature is displayed in Fahrenheit

or Celsius.

Output Activity:

Number lights

indicate activity

of outputs 1

and 2.

Communications

Activity:

Flashes when

another device is

communicating

with this controller.

Up and Down

Arrow Keys:

In the Operations

Menu, adjusts

the set point in

the lower display. In the other

pages, changes

the upper display to a higher

or lower value,

or changes a

parameter selection.

Advance Key:

Advances through

parameter

prompts.

8 - INTRODUCTION TO KEYPAD & MENU BASICS

Setting

Parameter

Set Up Menu

[`loC] Lockout Menu

[`SEn] Sensor Type

[`Lin] Linearization

[``t;C] Thermistor Curve

[``r;r] Resistance Range

[`deC] Decimal

[`C_F] Display Units

[`r;lo] Range Low

[`r;hi] Range High

[`fn1] Function Output 1

[`o;ty] Output Type

[`fn2] Function Output 2

[`h;ag] Heat Algorithm

[`h;sC] Hysteresis (Heat & Cool)

[`C;Ag] Cool Algorithm

[`A;ty] Alarm Type

[`A;hy] Alarm Hysteresis

[`A;lg] Alarm Logic

[`A;lA] Alarm Latching

[`A;bl] Alarm Blocking

[`A;si] Alarm Silencing

[A;dsp] Alarm Display

[``rp] Ramp Action

[`r;rt] Ramp Rate

[`s;lo] Scale Low

[`s;hi] Scale High

[o;hi1] Power Scale High Output 1

[o;hi2] Power Scale High Output 2

[`Ad;s] Zone Address

[ ] Bluetooth

btth

Menu and Keypad Basics

PV

SP

Operations Menu

[`AUt] Autotune

[`C;M] Control Mode

‰

[`h;pb] Heat Proportional Band

[`C;pb] Cool Proportional Band

[``ti] Time Integral

[``td] Time Derivative

[o;tb1] Time Base

[o;tb2] Time Base

[`A;lo] Alarm Low Set Point

[`A;hi] Alarm High Set Point

[`i;Ca] Calibratin Offset

Set Up Menu

To enter the Setup Menu press to return to Home Page. Press both Arrow Keys

for 6 seconds. Press green Advance Key

choice. Use Arrow Keys to increment or decrement settings or change selection.

At any point within the Setup Menu, push the Infinity Key to return to the Home Page.

NOTE: You must read and understand the role of each key on

your controller keypad before proceeding.

See Panel 7 - Keyboard Overview.

These instructions are not inclusive. This Quick Start Guide

(QSG) is meant to be a quick reference guide. It will show you

how to navigate to frequently used areas of your controller. As

an example, settings process outputs are not documented in

this QSG. Refer to the User Manual for more detailed instructions. NOTE: These diagrams might vary depending on the

Controller programming.

Introduction to the Set Up & Operating Menus

Upon power up, the display will default

to the home page in the Operations

Menu. The upper red row displays the

process value (PV). The lower green

row displays the set point (SP).

Operations Menu

To enter the Operations Menu, press to return to Home

Page. Press the green advance key

the various prompts found in the Operations Menu. Press

the Infinity key at any point within the Operations Menu to

return to the Home Page. Use Arrow Keys to increment

or decrement settings or change selection.

to scroll through to the prompt of

to scroll through

PV

SP

9 - SET UP THE INPUT

Start from Home.

to

to

to

OR

Press

to enter Setup Menu.

Must be level 5 to make

changes.

If Thermocouple select

Select thermocouple type.

(J, K is letter H or T is letter t)

Return Home.

OR

Press

enter Setup Menu.

Must be level 5 to make changes.

If rtd 100 ohm select rtd.

Return Home

for 6 seconds

for 6 seconds to

( ).

10 - SET UP OUTPUTS FOR HEAT, COOL AND ALARM

Start From Home.

Press for 6

to

seconds to enter

Setup Menu. Must be

to

level 5 to make changes.

Heat, Cool, Alarm, or Off.

to

Select function output 1.

to

(See Fn 2 for output 2).

Advance to

PID, on/off, none.

Select heat control method.

to

If on/off enter degrees.

Select at switching

hysteresis.

to

to

Advance to PID, on/off, none.

Select cool control method.

If on/off, enter degrees. Select

cool switching hysteresis.

Start from

Home.

If heat or cool

>= 20 if mechanical

relay. Select time

base output 1.

If heat or cool

>= 20 if mechanical

relay. Select time

base output 2.

Return Home.

.

11 - SET UP AN ALARM

Start from Home.

Press

for

6 seconds to enter

Setup Menu.

to

Must be level 5 to make

changes.

12 - SET ALARM SET POINTS

Start from

to

Home.

Enter degrees.

Select low set

point. (- for dev

alarm type).

Advance to

to

Process, deviation.

Select type, enter.

to

Enter degrees.

Select high set

Enter degees.

Select Hysteresis.

to

Close, open.

Alarm active

point.

Return Home.

13 - LOOP CONTROL MODE/

LOOP SET POINT

Set Loop Control Mode

Start from

to

Home.

Enter degrees.

Ensure that

CM is set to

Auto

Return Home.

Adjust Loop Set Point

Enter degrees.

Select set point.

14- AUTOTUNE THE

CONTROL LOOP

to

Tuning in progress

Start from

Home.

No/yes.

Select Auto

Tune. (Returns

to no when

completed).

Return Home.

Select logic.

Non-latching,

to

latching.

Alternates

Select latching.

Alternates

Return Home

Return Home.

For other alarm settings see

the user manual.

Loading...

Loading...