Page 1

SERIES PD SINGLE AND DUAL LOOP CONTROLLER

Precise

Temperature

Controller and

EtherNet/IP™

High Performance

Temperature and

Process Controller

with Web Server and

EtherNet/IP™

Watlow’s SERIES PD controllers utilize embedded Ethernet

technology to provide a convenient, economical means for

setting up and viewing key process variables such as temperature, pressure and humidity. The units also integrate control

of these variables with programmable logic controllers (PLC)

and other automation solutions. Available in single or dual

loop versions, the DIN-rail mounted SERIES PD controllers

offer up to four control/alarm outputs plus up to two

digital/current transformer inputs.

These controllers are ideally suited for a wide range of

temperature and process controller applications where the

operator interface is supported from a remote location or the

temperature and process control must be integrated with

other automation equipment including PLCs. For remote

operation, the SERIES PD serves web pages supporting

key functions including operation, alarm monitoring and

configuration directly to standard web browsers. The SERIES

PD can also generate e-mail messages for remote alarm

notification. Support for EtherNet/IP™, Modbus™ TCP and

PCCC protocols ensure robust and easy to implement

solutions for machine integration with a variety of automation

vendor’s products.

The SERIES PD controller is backed by a three-year

warranty and is UL

®

508, C-UL®, CSA and CE approved.

Features and Benefits

EtherNet/IP™ with explicit and implicit messages

• Reads or sets any control parameter from a PLC

• Moves data quickly and efficiently to ensure the best

process performance

• Easily obtains and sets the attributes critical to your

process with static and dynamic message assemblies

PCCC protocol messages

• Integrates with older Allen-Bradley PLCs that support

Ethernet but not EtherNet/IP™

Modbus™ TCP protocol for Ethernet communications

• Connects to Watlow’s WATVIEW software and other

HMI software

• Integrates with third-party solutions

Features and Benefits (con’t)

Embedded web pages for setup, monitoring and trending

• Provide a convenient, easy-to-use operator interface

• Simplify process monitoring

• Make troubleshooting processes quick and easy

On-board data logging option

• Ensures vital data is retained

E-mail notification of alarms and events

• Minimizes downtime

DIN-rail, sub panel mounting

• Reduces time and cost of installation

• Prevents unauthorized access

Watlow INFOSENSE™ sensor technology

• Improves sensor accuracy by a minimum of 50 percent

Heater burn out detection

• Improves process yield

WIN-PD-1005

1241 Bundy Boulevard

Winona, Minnesota 55987-5580 USA

Phone: +1 (507) 454-5300

Fax: +1 (507) 452-4507

Internet: www.watlow.com

e-mail: info@watlow.com

UL®and C-UL®are registered trademarks of Underwriter’s

Laboratories, Inc.

Windows®is a registered trademark of the Microsoft Corporation.

®

Modbus

EtherNet/IP™ is a trademark of ODVA.

is a registered trademark of AEG Schneider Automation.

To be automatically connected to the nearest North American Technical and Sales Office call:

1-800-WATLOW2

International Technical and Sales Offices: Asia, +65 6773-9488 • Europe—France, +33 (01) 3073-2425 • Germany, +49 (0) 7253-9400-0 •

Italy, +39 (02) 458-8841 • Spain, +34 916 751 292 • Sweden, +46 31 7014959 • United Kingdom, +44 (0) 115-964-0777 •

Latin America, +52 (442) 217-6235

© 2005 Watlow Electric Manufacturing Company Printed in the USA on Recycled Paper, 15 Percent Postconsumer Waste

Page 2

Specifications

Power

• 24Vı(ac/dc), +10/-15 percent, 50/60Hz, ±5 percent

• 12VA maximum power consumption

• Data retention upon power failure via nonvolatile memory

Environment

• 0 to 65°C (32 to 149°F) operating temperature

• -40 to 85°C (-40 to 185°F) storage temperature

• 0 to 90 percent RH, non-condensing

Accuracy

• Calibration accuracy and sensor conformity: ±0.1 percent of

span, ±1°C @ the calibrated ambient temperature and rated

line voltage

• Calibration ambient temperature = 25°C ±3°C (77°F ±5°F)

• Accuracy span: 540°C (1000°F) minimum

• Temperature stability: ± 0.1°C/°C (±0.2°F/°F) rise in ambient

maximum

Agency Approvals

•UL®508, C-UL®, CSA and CE

• ODVA: EtherNet/IP

Controller

• Microprocessor-based user-selectable control modes

• Single or dual channel universal inputs

• Current transformer inputs/digital inputs

• Up to four programmable outputs

• Update rates, inputs = 10Hz, outputs = 10Hz

Operator Interface

• Browser based HMI

Wiring Termination

• Touch safe removable terminals

• 14 to 22 AWG

Universal Inputs (Electrically Isolated)

• Thermocouple, grounded or ungrounded sensors

• RTD 2 or 3-wire, platinum, 100

DIN curve (0.00385

• Process 0-20mA @ <100

impedance (50,000 bits @ full scale)

Digital Inputs

• Contact or dc voltage

• 10K

Ω input impedance

Current Transformer Inputs

• 0 to 50mA CT input into 100Ω impedance

Allowable Input Operating Range

Type J: -200 to 1200°C or -340 to 2192°F

Type K: -270 to 1370°C or -454 to 2500°F

Type T: -270 to 400°C or -454 to 750°F

Type N: -270 to 1300°C or -454 to 2372°F

Type E: -270 to 975°C or -454 to 1790°F

Type C: 0 to 2315°C or 32 to 4200°F

Type D: 0 to 2315°C or 32 to 4200°F

Type PTII: 0 to 1395°C or 32 to 2543°F

Type R: 0 to 1760°C or 32 to 3200°F

Type S: 0 to 1760°C or 32 to 3200°F

Type B: 0 to 1815°C or 32 to 3300°F

RTD (DIN): -200 to 800°C or -328 to 1470°F

Process V: 0 to 10V

Control/Alarm Outputs (1 - 4)

• User selectable as: on-off, P, PI, PD, PID, heat, cool, alarm

action or retransmit with process output type hardware

• Open collector/switched dc

• Open collector 42V

• Switched dc 22 to 28V

• Solid-state relay, Form A, 0.5A @ 24V~(ac) minimum,

264V~(ac) maximum, opto-isolated, without contact

suppression

• User-selectable 0-10V

0-20mA @ 800

• Electromechanical relay. Form C, rated 5A @ 120V~(ac) or

5A @ 240V~(ac) or 5A @ 30V

™

Ω @ 0°C calibration to

Ω/Ω/°C)

Ω, or 0-10VÎ(dc) @ 10kΩ input

Î(dc) Process I: 0 to 20mA

Î(dc) maximum@ 0.5A

Î(dc) limited @30mA

Î(dc), 1KΩ minimum, scalable,

Ω maximum, scalable

Î(dc)

Communications

• EtherNet/IP™ with static and dynamic assemblies

• PCCC protocol messages

• TCP/IP/Ethernet

• Modbus™ TCP

• Ethernet RJ 45 connector, 10 base T

• HTTP interface

• DHCP, auto IP or fixed IP address

Dimensions

• Width x height x depth, 42 mm x 116 mm x 132 mm

(1.64 in. x 4.56 in. x 5.19 in.)

• DIN-rail or chassis mount, DIN-rail spec DIN 5022

35 mm x 7.5 mm (1.38 in. x 0.30 in.)

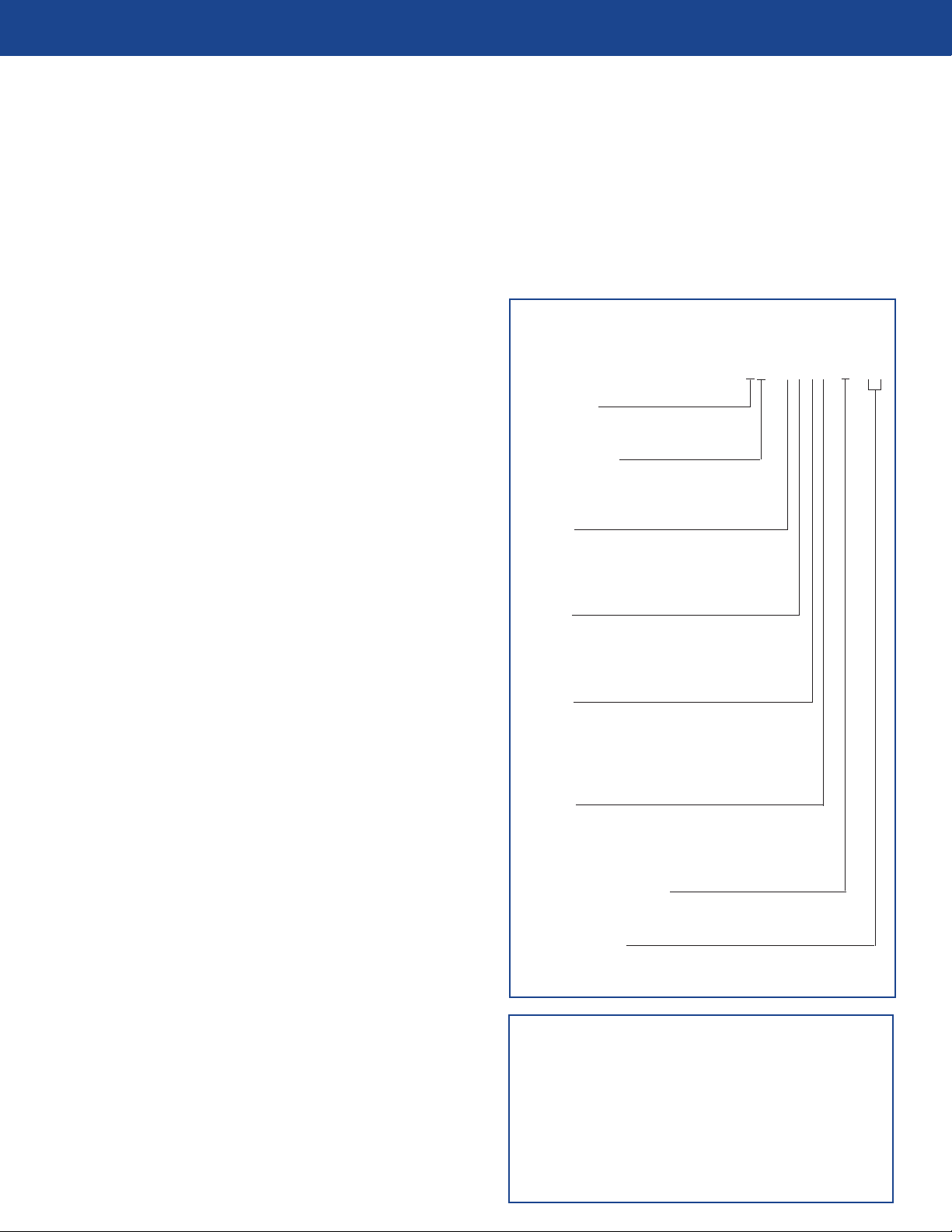

Ordering Information

To order, complete the model number on the right with the

information below.

P D - _ _ _ _ - _ _ _ _

Control Type

S = Single channel

D = Dual channel

Auxiliary Inputs

1 = Dual digital inputs

2 = One CT input and one digital input

3 = Dual CT inputs (dual channel only)

Output 1

C = Switched dc, open collector

K = SSR, Form A, 0.5A

F = Universal process

J = Mechanical relay, Form A, 2A

Output 2

A = None

C = Switched dc, open collector

K = SSR, Form A, 0.5A

E = Mechanical relay, Form C, 2A

Output 3

A = None

C = Switched dc, open collector

K = SSR, Form A, 0.5A

F = Universal process (If output 1 is F only)

J = Mechanical relay, Form A, 2A

Output 4

A = None

C = Switched dc, open collector

K = SSR, Form A, 0.5A

E = Mechanical relay, Form C, 2A

On Board Data Logging

0 = None

1 = On board data logging

Custom Options

AA = Watlow logo

BB = No logo

A

Your Authorized Watlow Distributor Is:

Loading...

Loading...