Page 1

User’s Manual

Series PD

Ethernet-Enabled

Temperature/Process Controller

1241 Bundy Boulevard., Winona, Minnesota USA 55987

Phone: +1 (507) 454-5300, Fax: +1 (507) 452-4507 http://www.watlow.com

Registered Company

Winona, Minnesota USA

0600-0043-0010 Rev. B Made in the U.S.A.

November 2006 $15.00

Page 2

Safety Information

We use note, caution and warning symbols throughout this book to draw your attention to

important operational and safety information.

A “NOTE” marks a short message to alert you to an important detail.

A “CAUTION” safety alert appears with information that is important for protecting your

equipment and performance. Be especially careful to read and follow all cautions that apply

to your application.

A “WARNING” safety alert appears with information that is important for protecting you,

others and equipment from damage. Pay very close attention to all warnings that apply to

your application.

The safety alert symbol, ç (an exclamation point in a triangle) precedes a general CAUTION

or WARNING statement.

The electrical hazard symbol, Ó (a lightning bolt in a triangle) precedes an electric shock

hazard CAUTION or WARNING safety statement.

Technical Assistance

If you encounter a problem with your Watlow controller, review your configuration information to verify that your selections are consistent with your application: inputs, outputs,

alarms, limits, etc. If the problem persists, you can get technical assistance from your local

Watlow representative (see back cover), by e-mailing your questions to wintechsupport@wat

low.com or by dialing +1 (507) 494-5656 between 7 a.m. and 5 p.m., Central Standard Time

(CST). Ask for for an Applications Engineer. Please have the following information available

when calling:

• Complete model number • All Series PD configuration information

• Quick Start Guide or User’s Manual • Computer Hardware / Software Configuration

Warranty

The Series PD is manufactured by ISO 9001-registered processes and is backed by a threeyear warranty.

Return Material Authorization (RMA)

1. Call Watlow Customer Service, (507) 454-5300, for a Return Material Authorization

(RMA) number before returning any item for repair. We need this information:

• Ship to address • Bill to address

• Contact name • Phone number

• Method of return shipment • Your P.O. number

• Detailed description of the problem • Any special instructions

• Name and phone number of person returning the product.

2. Prior approval and an RMA number, from the Customer Service Department, is needed

when returning any unused product for credit. Make sure the RMA number is on the outside

of the carton, and on all paperwork returned. Ship on a Freight Prepaid basis.

3. After we receive your return, we will examine the unit and try to verify the reason for

the return.

4. In cases of manufacturing defect, we will enter a repair order, replacement order or issue

credit for material returned.

5. To return products that are not defective, goods must be be in new condition, in the original boxes and they must be returned within 120 days of receipt. A 20 percent restocking

charge is applied for all returned stock controls and accessories.

6. If the unit is unrepairable, it will be returned to you with a letter of explanation.

7. Watlow reserves the right to charge for no trouble found (NTF) returns.

The Series PD User’s Manual is copyrighted by Watlow Winona, Inc., © November 2003 with all

rights reserved. (2413)

ç

CAUTION or

WARNING

Ó

Electrical

Shock Hazard

CAUTION or WARNING

Page 3

Watlow Series PD ■ 1 ■ Table of Contents

Chapter 1 - Overview . . . . . . . . . . . . . . . . . . . . . . . . . .2

Chapter 2 - Install and Wire . . . . . . . . . . . . . . . . . . . .3

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Mounting/Removal . . . . . . . . . . . . . . . . . . . . . . . . . .4

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Chapter 3 - Indicator Lights . . . . . . . . . . . . . . . . . . .19

Chapter 4 - Ethernet Communications . . . . . . . . . .20

Chapter 5 - Monitor Device Page . . . . . . . . . . . . . . .22

Navigation Frame . . . . . . . . . . . . . . . . . . . . . . . . .23

Chapter 6 - Device Information Page . . . . . . . . . . . .25

Chapter 7 - Device Configuration Page . . . . . . . . . .28

Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Control Loops . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Datalogging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

File System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Chapter 8 - Calibration Page . . . . . . . . . . . . . . . . . . .59

Chapter 9 - Parameter Table . . . . . . . . . . . . . . . . . . .62

Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Control Loops . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

Datalogging . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

Chapter 10 - Features . . . . . . . . . . . . . . . . . . . . . . .129

Chapter 11 - Troubleshooting . . . . . . . . . . . . . . . . .144

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .146

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . .146

Ordering Information . . . . . . . . . . . . . . . . . . . . . .148

Declaration of Conformity . . . . . . .inside back cover

TC

Table of Contents

Page 4

Watlow Series PD ■ 2 ■ Chapter 1 Overview

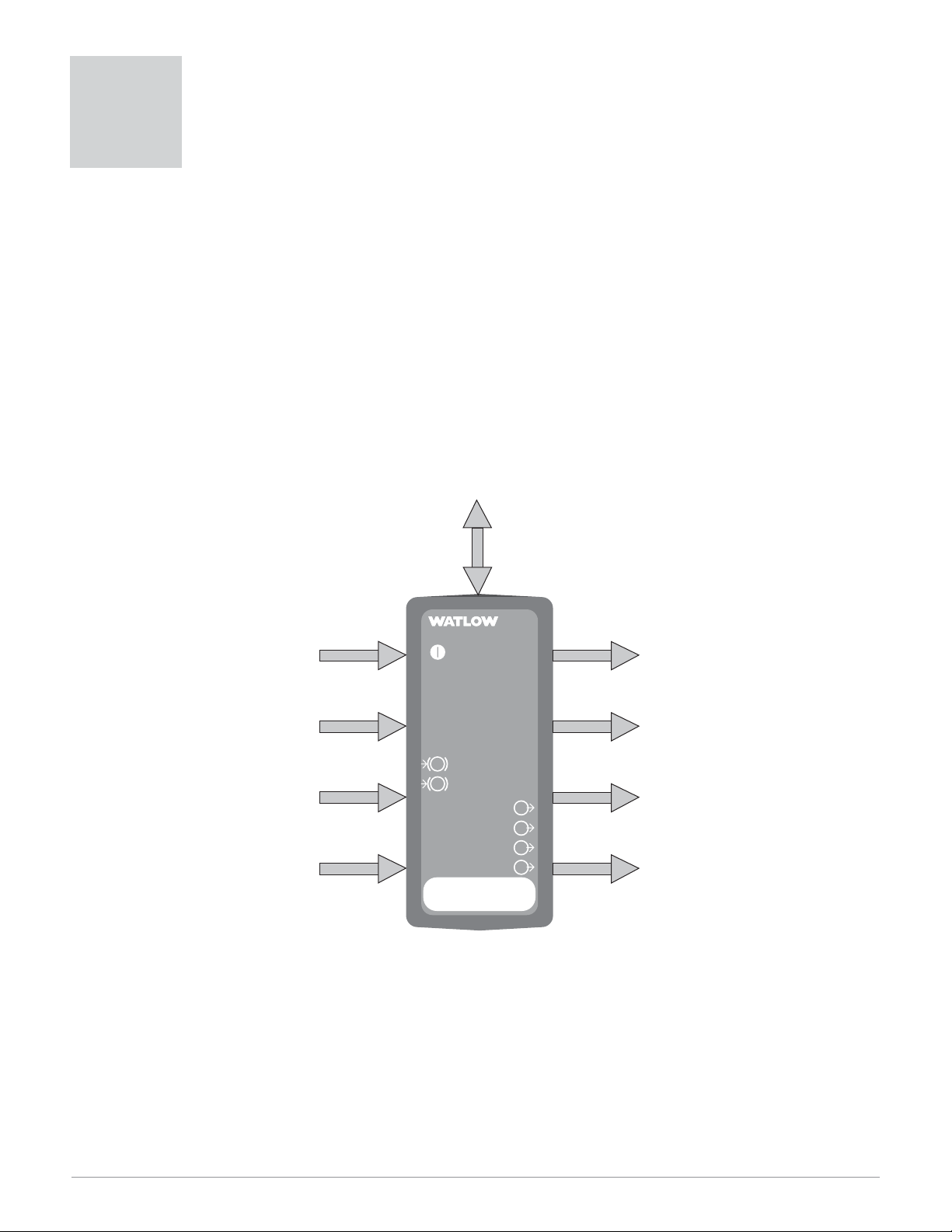

The Series PD controller is a DIN rail mounted, general purpose industrial PID temperature/

process controller. The Series PD is available in single and dual channel versions and features an

embedded web server to provide an easy to use interface for configuration and monitoring of

processes. The controller also features several popular communications protocols to facilitate easy

integration into most existing process management systems.

The Series PD accepts thermocouple, RTD and process signal control inputs and also features

auxiliary digital inputs or optional current transformer (CT) inputs. Up to four control or event

(alarm) outputs can be selected on either the single or dual channel versions.

Advanced features of the Series PD controllers include internal datalogging of key control parameters, INFOSENSE-P™ sensor technology, heater burn out detection and an enhanced control

algorithm.

The SERIES PD controller is backed by a three-year warranty from Watlow Winona and is

UL®508, C-UL®, CSA and CE approved.

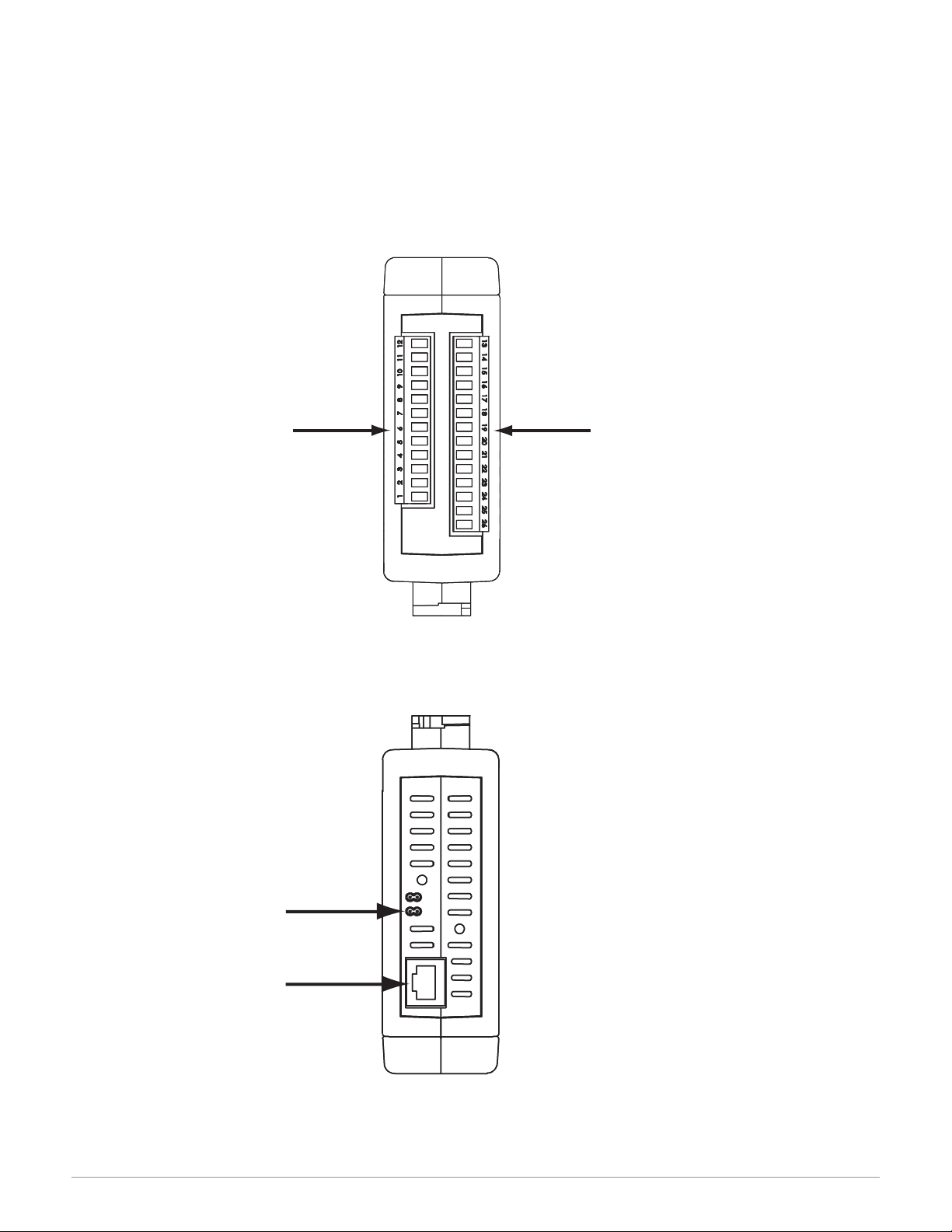

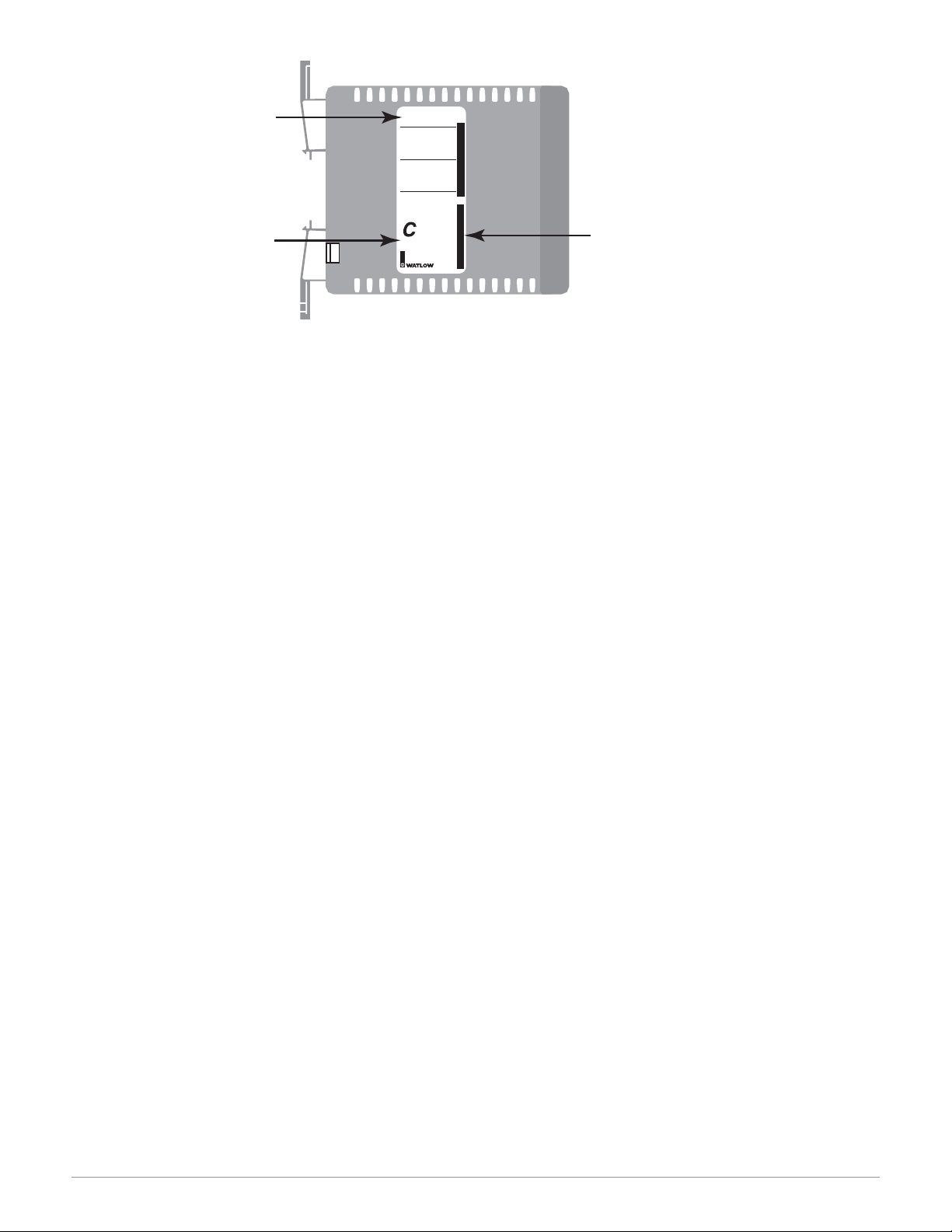

Figure 2 — Series PD inputs and outputs.

1

Overview

Ethernet Communications

1 or 2 Universal

Analog Inputs

(Single or dual channel)

1

2

Event or Current

Tr ansformer (CT) Inputs

Address

PID Controller

Power

Ethernet Link

Ethernet Activity

Input Error

Input Error

Output

Output

Output

Output

PD

4 outputs can be configured

as control or event (alarm)

outputs. Any output can be

assigned to either channel 1 or 2.

1

2

3

4

Page 5

Watlow Series PD ■ 3 ■ Chapter 2 Install and Wire

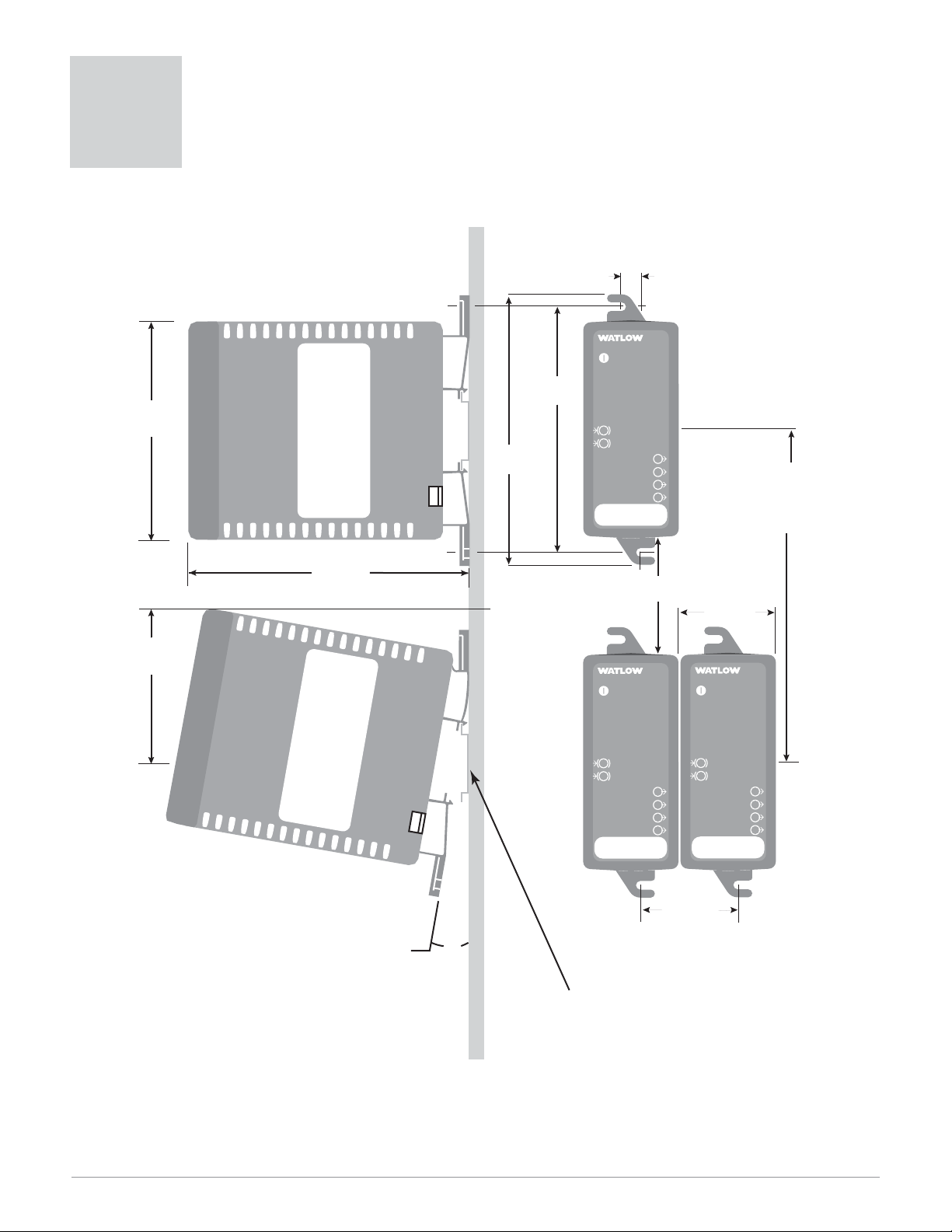

ç

Caution: Maintain the correct spacing between rows of controllers to allow sufficient air circulation and installation clearance. Failure to do so could result in

damage to equipment.

Figure 3 — Series PD dimensions

2

Install and Wire

Series PD Dimensions

95.3 mm

(3.75 in)

72.9 mm

(2.87 in)

Side View

128.5 mm

(5.06 in)

DIN

rail

panel mounting

(M3.5 or #6

screw required)

118.4 mm

(4.66 in)

bracket for

107.7 mm

(4.24 in)

8.1 mm

(0.32 in)

PD

PID Controller

Power

Ethernet Link

Ethernet Activity

Input Error

1

2

Input Error

1

Output

2

Output

3

Address

Output

Output

4

Front View

Min. Clearance 51 mm

(2 in)

PD

PID Controller

Power

Ethernet Link

Ethernet Activity

Top/bottom

mount

hole offset

41.7 mm

(1.64 in)

PID Controller

Power

Ethernet Link

Ethernet Activity

Min. Clearance

between rail

centerlines

146.1 mm

(5.75 in)

PD

DIN

rail

1

2

Address

Input Error

Input Error

Output

Output

Output

Output

1

2

3

4

1

2

Address

Input Error

Input Error

Output

Output

Output

Output

1

2

3

4

41.9 mm

(1.65 in)

Attachment Angle

10˚

Use DIN EN 50022 35 X 7.5 mm rail

Page 6

Watlow Series PD ■ 4 ■ Chapter 2 Install and Wire

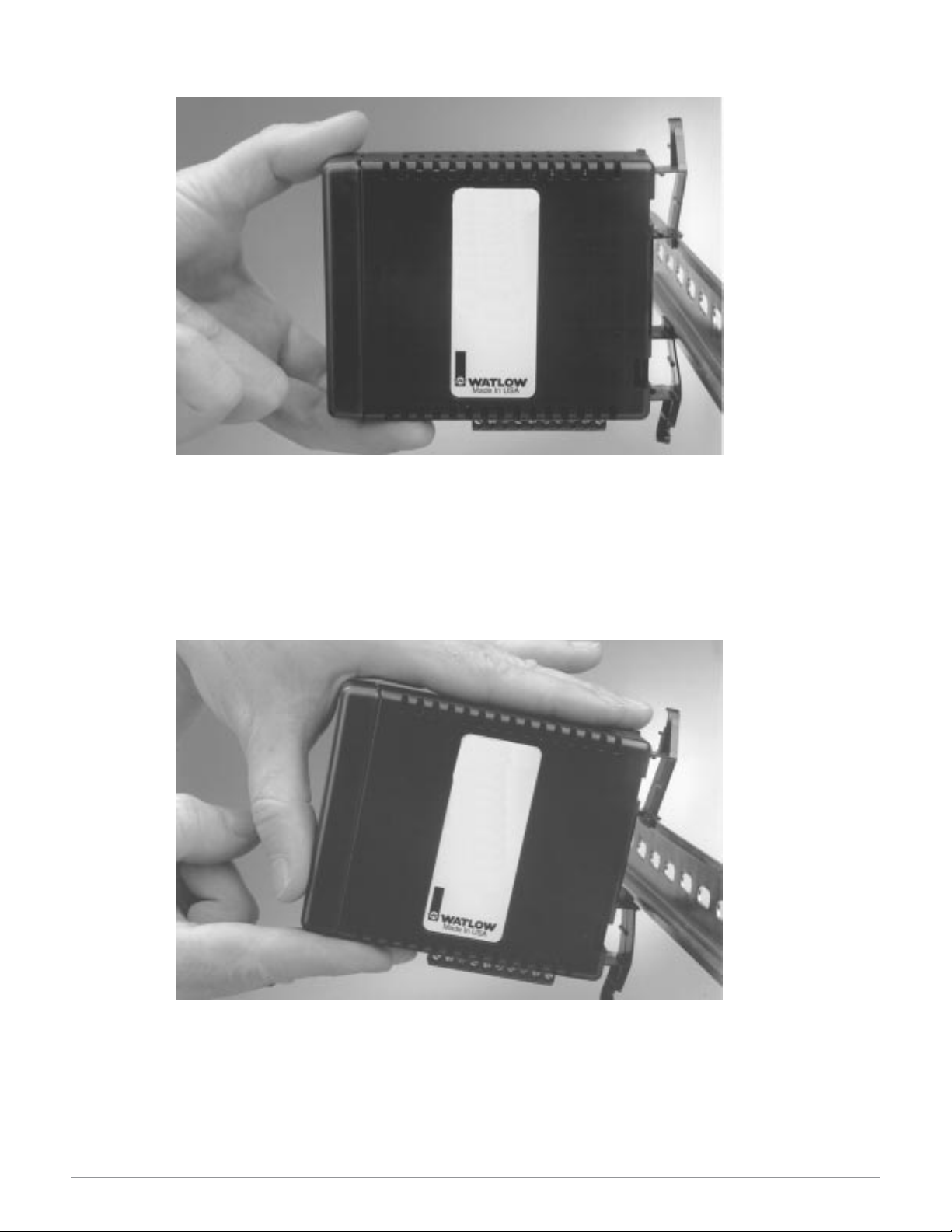

Mounting the Series PD

Figure 4a — Mounting

1. Push unit in and down to catch rail hook on top of rail.

2. Rotate bottom of unit toward rail.

3. Rail clasp will audibly “snap” into place. If the Series PD does not snap into place, check to

see if the rail is bent.

Removing the Series PD

Figure 4b — Removal

1. Press down on back of the Series PD until the bottom hook clears the rail.

2. Rotate bottom up and away from rail.

Page 7

Watlow Series PD ■ 5 ■ Chapter 2 Install and Wire

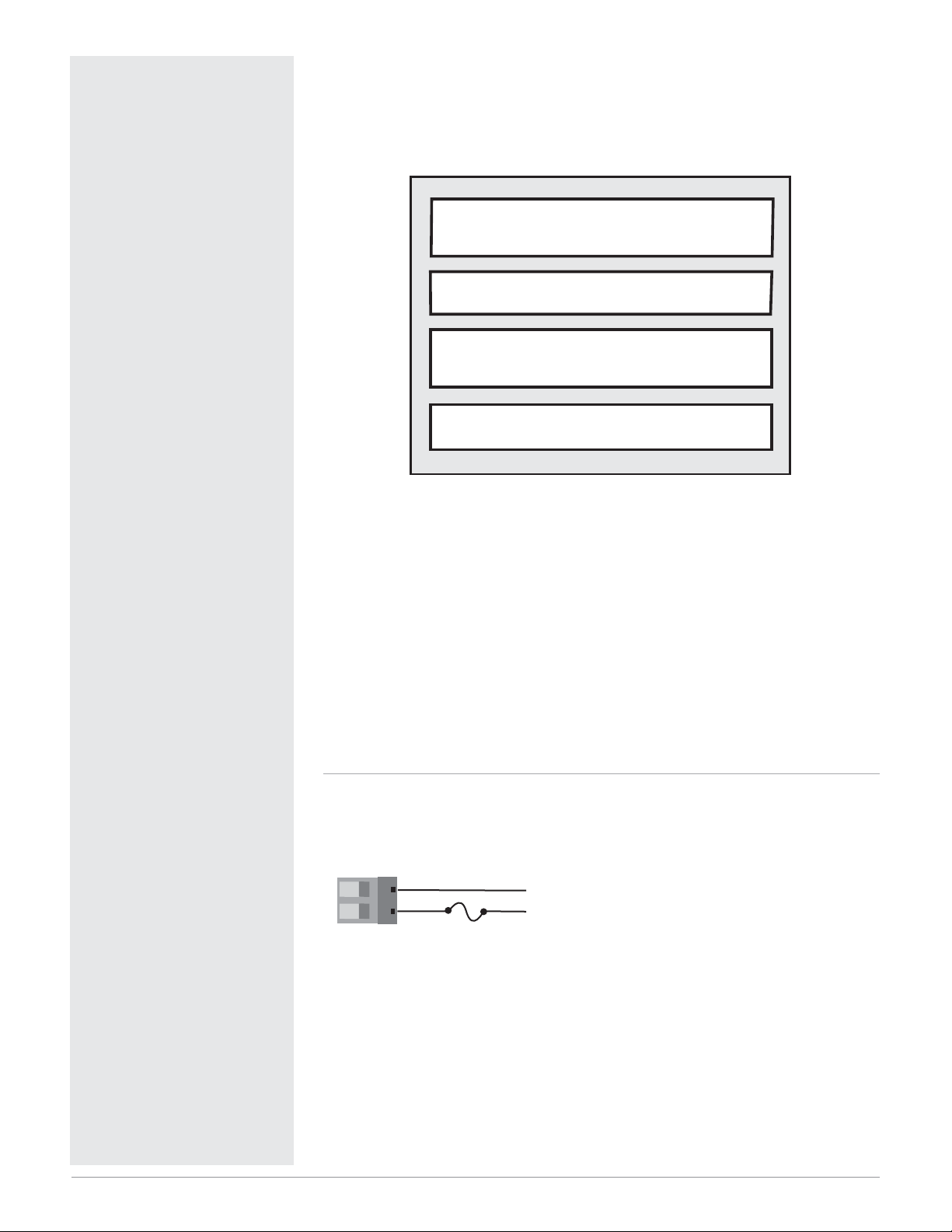

Series PD Connector Locations

Two connectors on the bottom of the unit provide connection points for the input power, inputs

and outputs. These connectors are removable and each terminal position is numbered.

The RJ-45 connector is located on the top of the Series PD to allow connection to an Ethernet

network.

Input and Output Connectors

Figure 5a — Input and Output Connectors

Ethernet RJ-45 Connector

Figure 5b — RJ-45 Connector

Bottom View

Input Connector

Controller Power and

Output Connector

Jumper to default

IP address on

power up

Ethernet RJ-45

Connector

Page 8

Watlow Series PD ■ 6 ■ Chapter 2 Install and Wire

Ó

Warning:

Use National Electric (NEC) or

other country-specific standard

wiring and safety practices when

wiring and connecting this controller to a power source and to

electrical sensors or peripheral

devices. Failure to do so may result in damage to equipment and

property, and/or injury or loss of

life.

Ó

WARNING: If high voltage is applied to the controller, irreversible damage will occur.

Note: 24 VÅÅinput power required to use single cycle,variable time base output function.

Wiring the Series PD

The model number for each output option appears with its wiring diagram.

Check the label on the controller and compare your model number to those

shown here and to the model number breakdown in the Appendix of this

manual.

All outputs are referenced to a de-energized state.

All wiring and fusing must conform to the National Electric Code and to

any locally applicable codes as well.

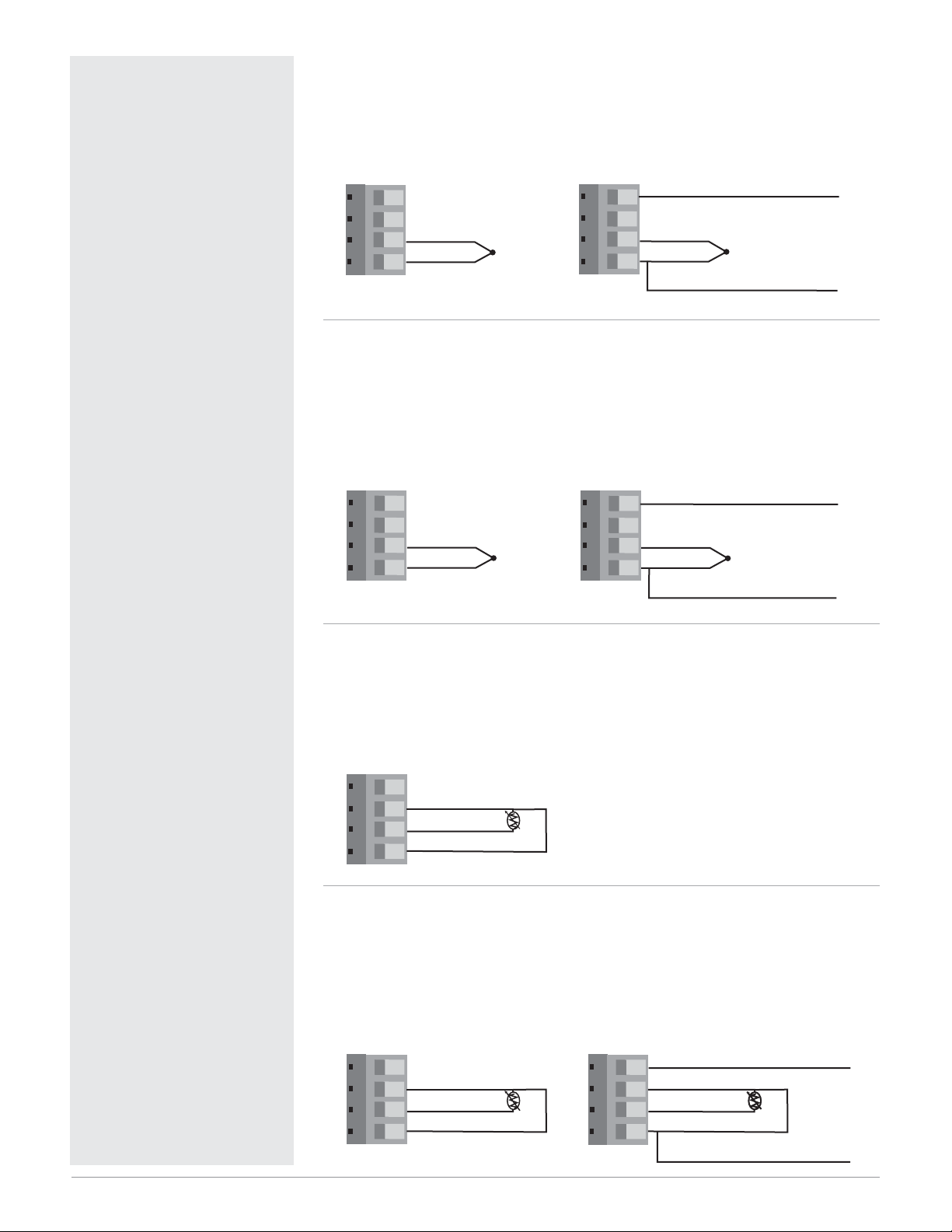

Figure 6a — Power Wiring

(all model numbers)

• Nominal voltage: 24V‡ (ac/dc)

Isolation Blocks

There are no electrical connections between these blocks

Relay outputs (mechanical and solid-state) provide isolation through their

relay contacts. Each relay output is isolated from the blocks above and is

isolated from other relay outputs.

Analog Input 1

Digital Inputs

Current Transformer Inputs

Analog Input 2

Control Outputs

Alarm Outputs

Retransmit Outputs

Communications

25 26

25

26

L2

L1

-

+

24V‡ (ac/dc)

Page 9

Watlow Series PD ■ 7 ■ Chapter 2 Install and Wire

Ó

Warning:

Use National Electric (NEC) or

other country-specific standard

wiring and safety practices when

wiring and connecting this controller to a power source and to

electrical sensors or peripheral

devices. Failure to do so may result in damage to equipment and

property, and/or injury or loss of

life.

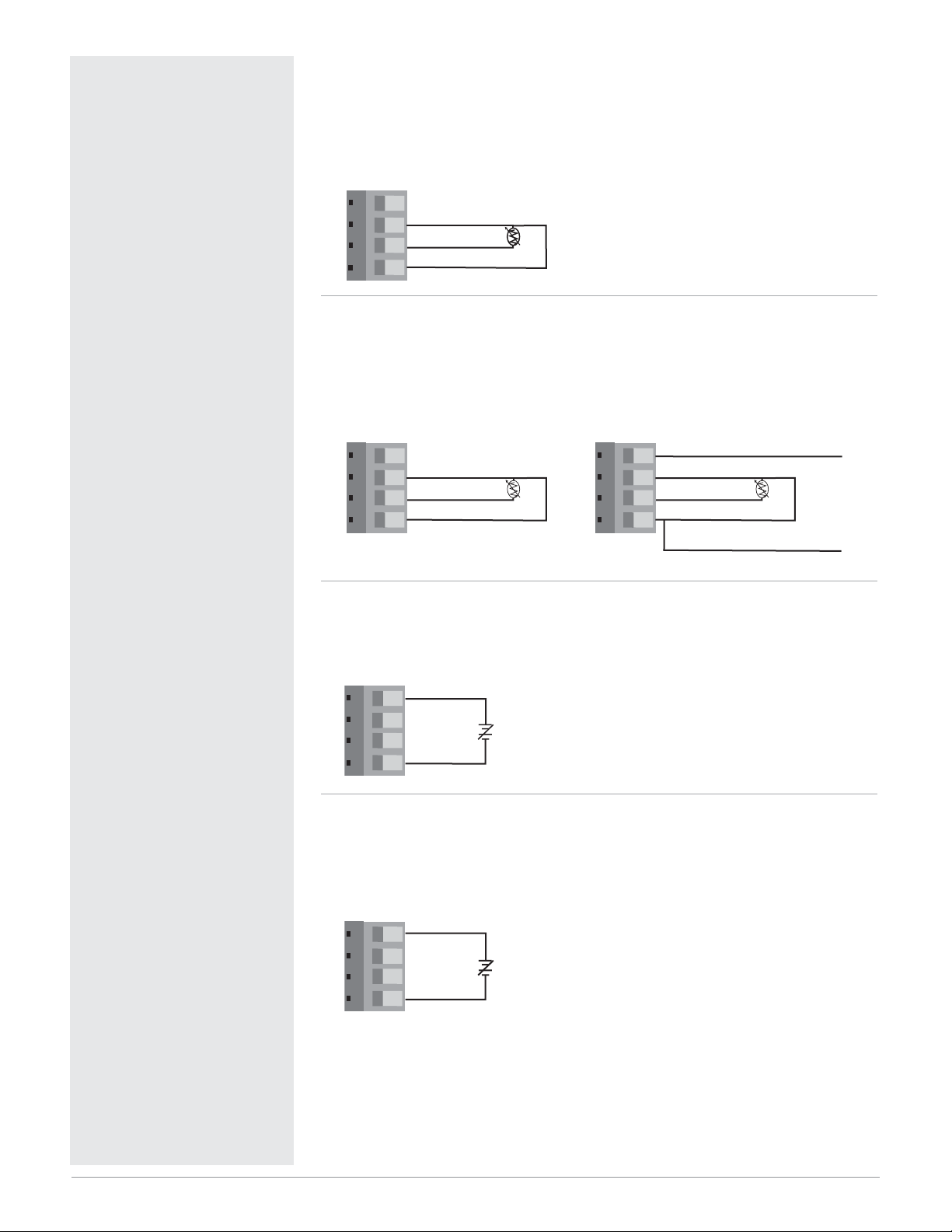

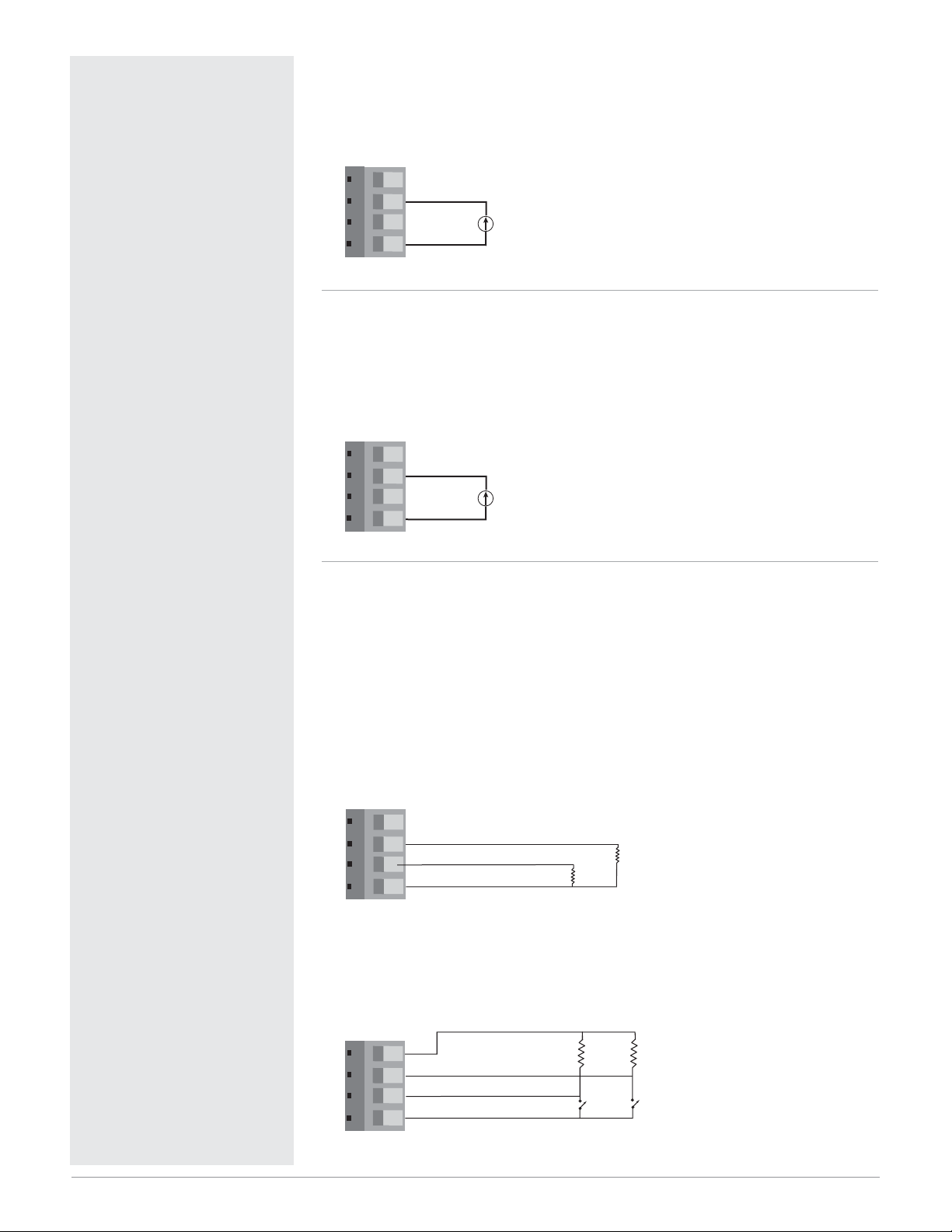

Figure 7a — Thermocouple Input 1

(all model numbers)

Thermocouples are polarity sensitive. The negative lead (usually red) must be

connected to terminal 9.

• Input impedance: >20 MΩ

Figure 7b — Thermocouple Input 2

PDD _-_ _ _ _-_ _ _ _

Thermocouples are polarity sensitive. The negative lead (usually red) must be

connected to terminal 5.

• Input impedance: >20 MΩ

• Input 2 isolated from Input 1

Figure 7c — 2-Wire RTD Input 1 (100 Ω DIN curve 0.00385

Ω/Ω/°C)

(all model numbers)

Terminals 9 and 11 must be shorted for a two-wire RTD.

• Nominal excitation current: 250 µA

Figure 7d — 3-Wire RTD Input 1 (100 Ω DIN curve 0.00385

Ω/Ω/°C)

(all model numbers)

The S1 lead (usually white) must be connected to terminal 10.

• Nominal excitation current: 250 µA

12 INFOSENSE-P™ DATA

10 +

9 -

INFOSENSE-P™ GND

9 10 11 12

10 +

9 -

9 10 11 12

8 INFOSENSE-P™ DATA

5 6 7 8

6 +

5 -

5 6 7 8

6 +

5 -

INFOSENSE-P™ GND

11 S2

10 S1

9 10 11 12

9

12 INFOSENSE-P™ DATA

11 S2

10 S1

9 10 11 12

9 S3

9 10 11 12

11 S2

10 S1

9 S3

INFOSENSE-P™ GND

Page 10

Watlow Series PD ■ 8 ■ Chapter 2 Install and Wire

ç

Warning:

Use National Electric (NEC) or

other country-specific standard

wiring and safety practices when

wiring and connecting this controller to a power source and to

electrical sensors or peripheral

devices. Failure to do so may result in damage to equipment and

property, and/or injury or loss of

life.

ç

WARNING: Process input may

not have sensor break protection. Outputs can remain full on.

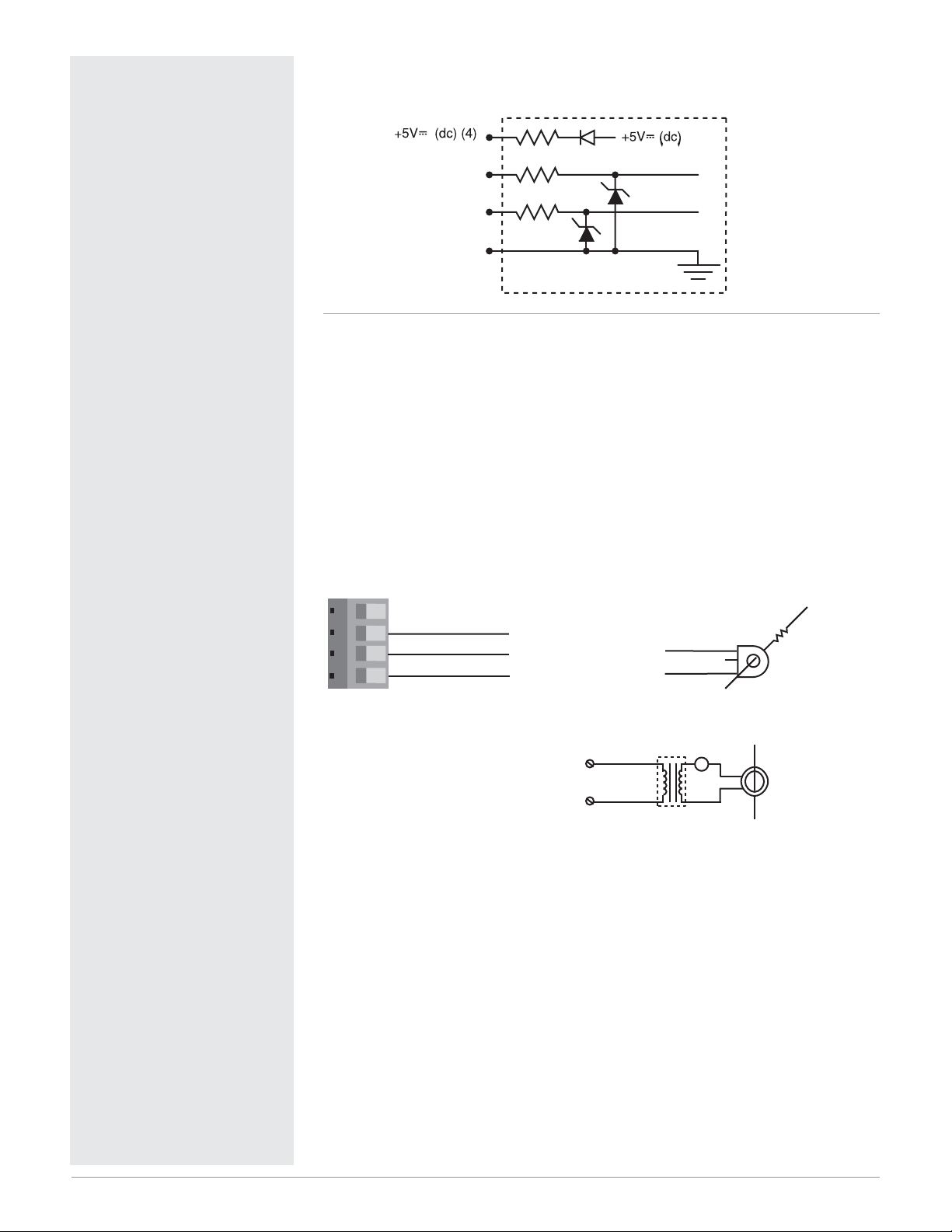

Figure 8a — 2-Wire RTD Input 2 (100 Ω DIN curve 0.00385

Ω/Ω/°C)

PDD _-_ _ _ _-_ _ _ _

Terminals 5 and 7 must be shorted for a two-wire RTD.

• Nominal excitation current: 250 µA

Figure 8b — 3-Wire RTD Input 2 (100 Ω DIN curve 0.00385

Ω/Ω/°C)

PDD _-_ _ _ _-_ _ _ _

The S1 lead (usually white) must be connected to terminal 6.

• Nominal excitation current: 250 µA

Figure 8c — Input 1, 0 to 10V

ÎÎ

(dc) Process Input

(all model numbers)

• Input impedance 20 kΩ, dc only

Figure 8d — Input 2, 0 to 10V

ÎÎ

(dc) Process Input

PDD _-_ _ _ _-_ _ _

• Input impedance 20 kΩ, dc only

• Input 2 isolated from Input 1

7 S2

6 S1

5 6 7 8

5

8 INFOSENSE™ DATA

5 6 7 8

7 S2

6 S1

5 S3

5 6 7 8

7 S2

6 S1

5 S3

INFOSENSE™ GND

12

9 10 11 12

+

-

9

+

8

-

5 6 7 8

5

Page 11

Watlow Series PD ■ 9 ■ Chapter 2 Install and Wire

Ó

Warning:

Use National Electric (NEC) or

other country-specific standard

wiring and safety practices when

wiring and connecting this controller to a power source and to

electrical sensors or peripheral

devices. Failure to do so may result in damage to equipment and

property, and/or injury or loss of

life.

ç

WARNING: Process input may

not have sensor break protection. Outputs can remain full on.

Note: Install a 1kΩ pull-down

resistor for each digital input using voltage inputs.

Note: Install a 10kΩ pull-up re-

sistor for each digital input

using contact closure inputs.

Figure 9a — Input 1, 0 to 20 mA Process Input

(all model numbers)

• Input impedance 100 Ω, dc only

• Controller does not supply power for the current loop

Figure 9b — Input 2, 0 to 20 mA Process Input

PDD _-_ _ _ _-_ _ _

• Input impedance 100 Ω, dc only

• Controller does not supply power for the current loop

• Input 2 isolated from Input 1

Dual Digital Inputs

PD_ 1-_ _ _ _-_ _ _

• Input impedance 10kΩ, dc only

• Input 2 isolated from Input 1

Figure 9c — Voltage input

0-1VÎ (dc) Event Input Low State

2-36VÎ (dc) Event Input High State

Figure 9d — Contact closure

0-2kΩ Event Input Low State

> 7kΩ Event Input High State

11

9 10 11 12

+

-

9

+

7

-

5 6 7 8

5

3

Digital Input 2 +

Digital Input 1 +

2

Digital Common

1 2 3 4

1 2 3 4

1

+5V‡ (dc)

4

3

Digital Input 2

Digital Input 1

2

1

Digital Common

1kΩ

-

10kΩ 10kΩ

1kΩ

Add a 1kΩ pull

down resistor for

each active input

Add a 10kΩ pull

up resistor for each

active input

Page 12

Watlow Series PD ■ 10 ■ Chapter 2 Install and Wire

ç

Warning:

Use National Electric (NEC) or

other country-specific standard

wiring and safety practices when

wiring and connecting this controller to a power source and to

electrical sensors or peripheral

devices. Failure to do so may result in damage to equipment and

property, and/or injury or loss of

life.

Note: Current transformer (CT)

must be purchased separately.

Note: A current transformer input

cannot be associated with a

process output on Output 1 or 3.

Figure 10a — Digital input internal circuit

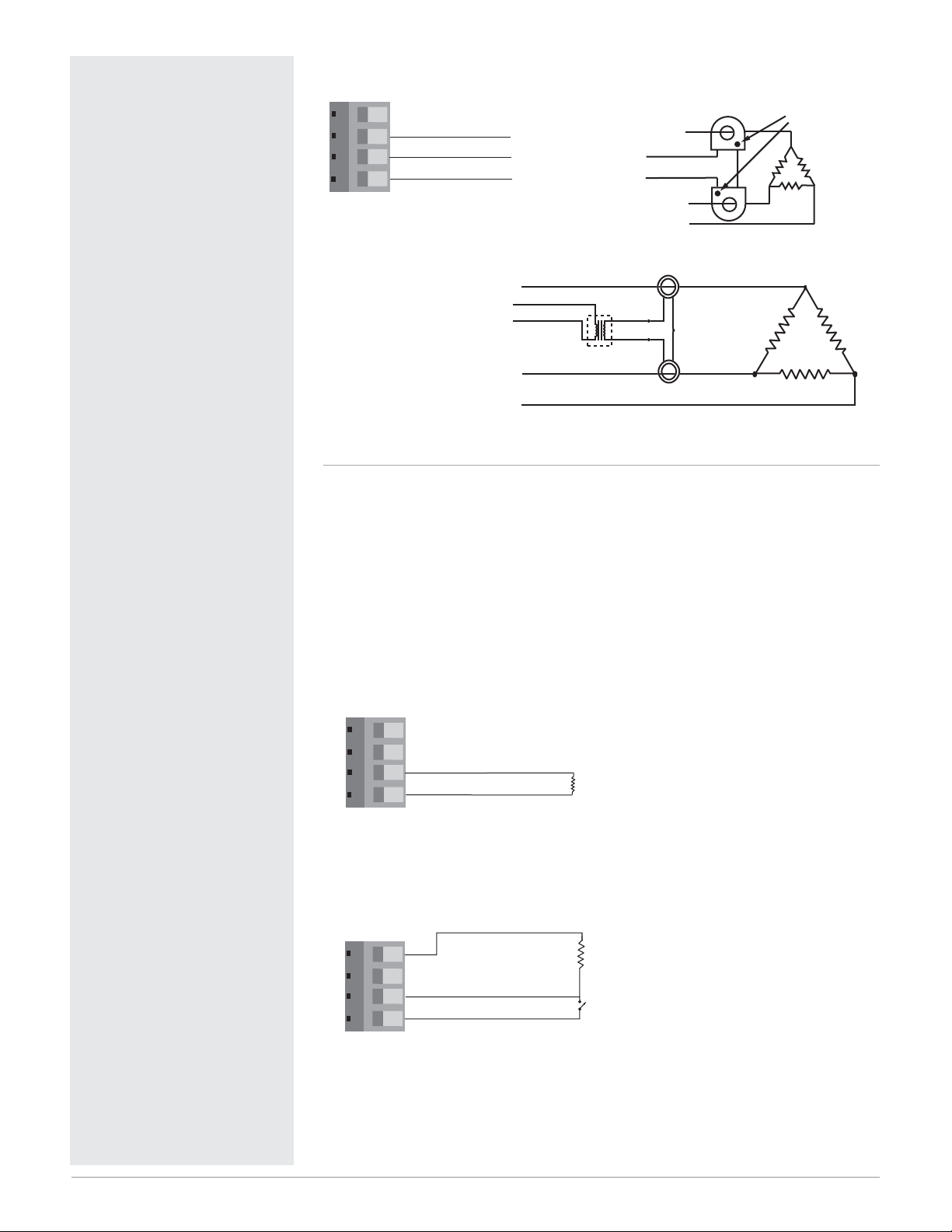

Dual Current Transformer (CT) Inputs

PD_ 3-_ _ _ _-_ _ _

• Input impedance 100Ω, Vac only.

The current transformer (CT) must be purchased separately. Watlow CT

part number is 16-0246 (up to 50 amps).

Systems that are more than 50 amps need an interstage transformer. For

example, if you use a 300 amp CT, part number 16-0073, and an interstage

transformer, part number 16-0176, the 300 amp CT provides a 5 amp signal

to the interstage transformer. In turn, the interstage transformer provides a

20 mA maximum signal to the controller.

Figure 10b — Single Phase

Digital Input 2 (3)

Digital Input 1 (2)

Digital Input Common (1)

Internal Circuitry

3

CT Input 2

CT Input 1

1 2 3 4

2

1

CT Common

To CT Input 1 or 2

CT Input 1 or 2

CT Common

Single phase current sensing up to 300 amp

To CT Common

0 to

20mA

Transformer

16-0176

Load wire

CT

Center leg not used

L1

AC Load

A

0 to 5A

AC

L2

Page 13

Watlow Series PD ■ 11 ■ Chapter 2 Install and Wire

ç

Warning:

Use National Electric (NEC) or

other country-specific standard

wiring and safety practices when

wiring and connecting this controller to a power source and to

electrical sensors or peripheral

devices. Failure to do so may result in damage to equipment and

property, and/or injury or loss of

life.

Note: Current transformer (CT)

must be purchased separately.

Note: A current transformer input

cannot be associated with a

process output on Output 1 or 3.

Note: Install a 1kΩ pull-down

resistor for each digital input using voltage inputs.

Note: Install a 10kΩ pull-up re-

sistor for each digital input

using contact closure inputs.

Figure 11a — Three Phase using Two Current Transformers

One Digital Input and One Current Transformer Input

PD_ 2-_ _ _ _-_ _ _

Digital Input 1

• Input impedance 10kΩ, dc only

Figure 11b — Voltage input

0-1VÎ (dc) Event Input Low State

2-36VÎ (dc) Event Input High State

Figure 11c — Contact closure

0-2kΩ Event Input Low State

> 7kΩ Event Input High State

Phase

dot

1 2 3 4

3

CT Input 2

CT Input 1

2

1

CT Common

L1

To CT Input 1 or 2

To CT Common

L3

L2

CT

L1

To CT Input 1 or 2

To CT Common

L3

L2

Red

Red

20mA

16-0176

Transformer

Bk

Bk

WhBk

5A

BkWh

CT

3-phase current sensing up to 300 amp

Digital Input 1 +

2

Digital Common

1 2 3 4

1 2 3 4

1

+5V‡ (dc)

4

3

Digital Input 1

2

1

Digital Common

Add a 1kΩ pull

down resistor for

1kΩ

-

10kΩ

each active input

Contact Closure

(add a 10kΩ pull

up resistor for each

active input)

Page 14

Watlow Series PD ■ 12 ■ Chapter 2 Install and Wire

ç

Warning:

Use National Electric (NEC) or

other country-specific standard

wiring and safety practices when

wiring and connecting this controller to a power source and to

electrical sensors or peripheral

devices. Failure to do so may result in damage to equipment and

property, and/or injury or loss of

life.

Note: Current transformer (CT)

must be purchased separately.

Note: A process output cannot be

installed on Output 1 or 3 when

using current transformer input.

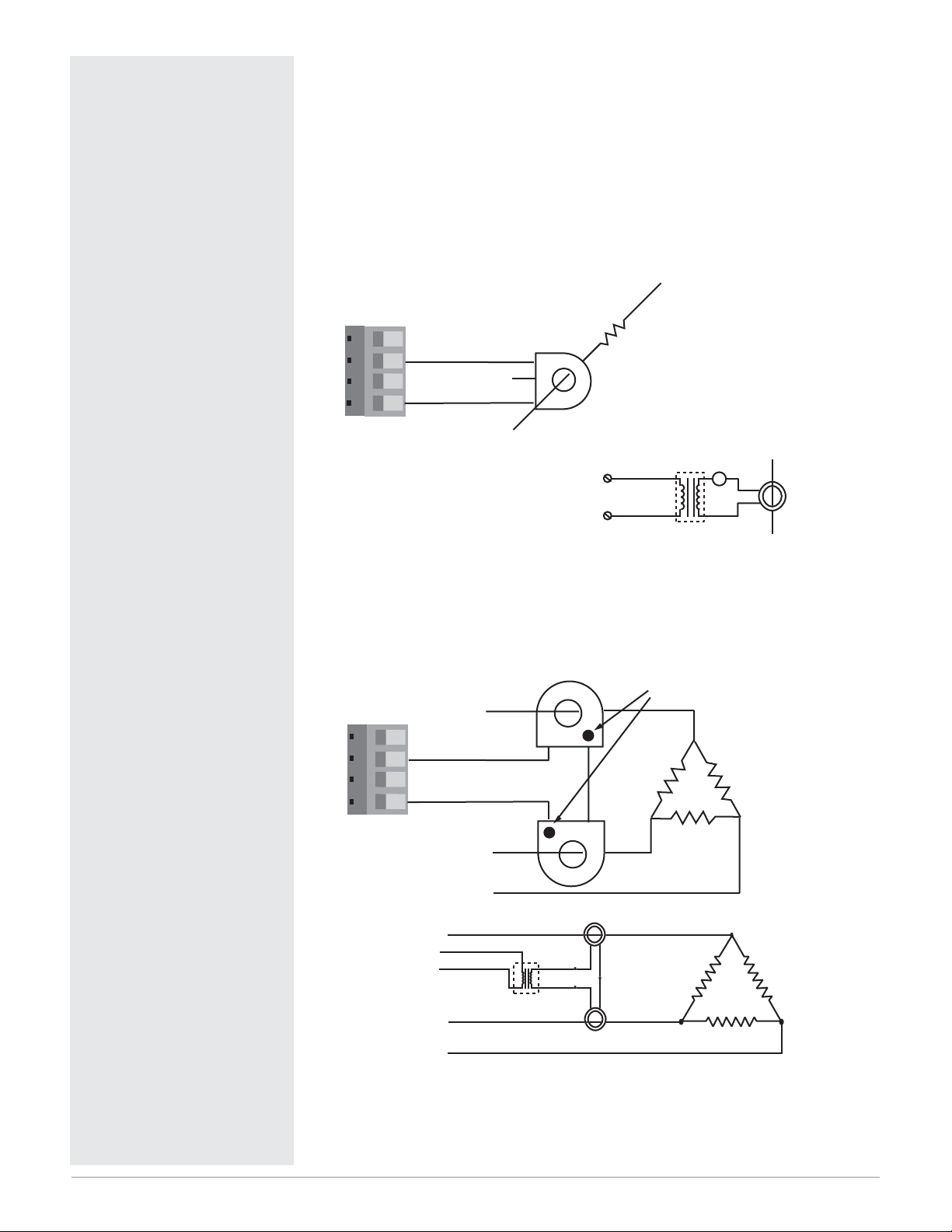

Figure 12a — Current Transformer Input 2, Single Phase

• Input impedance 100Ω, Vac only

The current transformer must be purchased separately. Watlow current

transformer part number is 16-0246 (up to 50 amps).

Systems that are more than 50 amps need an interstage transformer. For

example, if you use a 300 amp current transformer, part number 16-0073,

and an interstage transformer, part number 16-0176, the 300 amp current

transformer provides a 5 amp signal to the interstage transformer. In turn,

the interstage transformer provides a 20 mA maximum signal to the controller.

Figure 12b — Current Transformer Input 2, Three Phase

L2

Load wire

CT Input 2

CT

1 2 3 4

13CT Common

Center leg not used

L1

CT Input 2

CT Common

Single phase current sensing up to 300 amp

0 to

20mA

16-0176

Transformer

0 to 5A

AC Load

A

AC

Phase

dot

L1

CT Input 2

1 2 3 4

13CT Common

L3

L2

CT

L1

To CT Input 2

To CT Common

L3

L2

Red

Red

20mA

16-0176

Transformer

Bk

Bk

WhBk

5A

BkWh

CT

3-phase current sensing up to 300 amp

Page 15

Watlow Series PD ■ 13 ■ Chapter 2 Install and Wire

ç

Warning:

Use National Electric (NEC) or

other country-specific standard

wiring and safety practices when

wiring and connecting this controller to a power source and to

electrical sensors or peripheral

devices. Failure to do so may result in damage to equipment and

property, and/or injury or loss of

life.

Quencharc Note:

Switching pilot duty loads (relay

coils, solenoids, etc.) with the

mechanical relay or solid-state

relay output options requires use

of an R.C. suppressor.

Watlow carries the R.C. suppressor Quencharc brand name,

which is a trademark of ITW

Paktron. Watlow Part No. 08040147-0000.

Note: 24 VÅÅinput power required to use single cycle,variable time base output function.

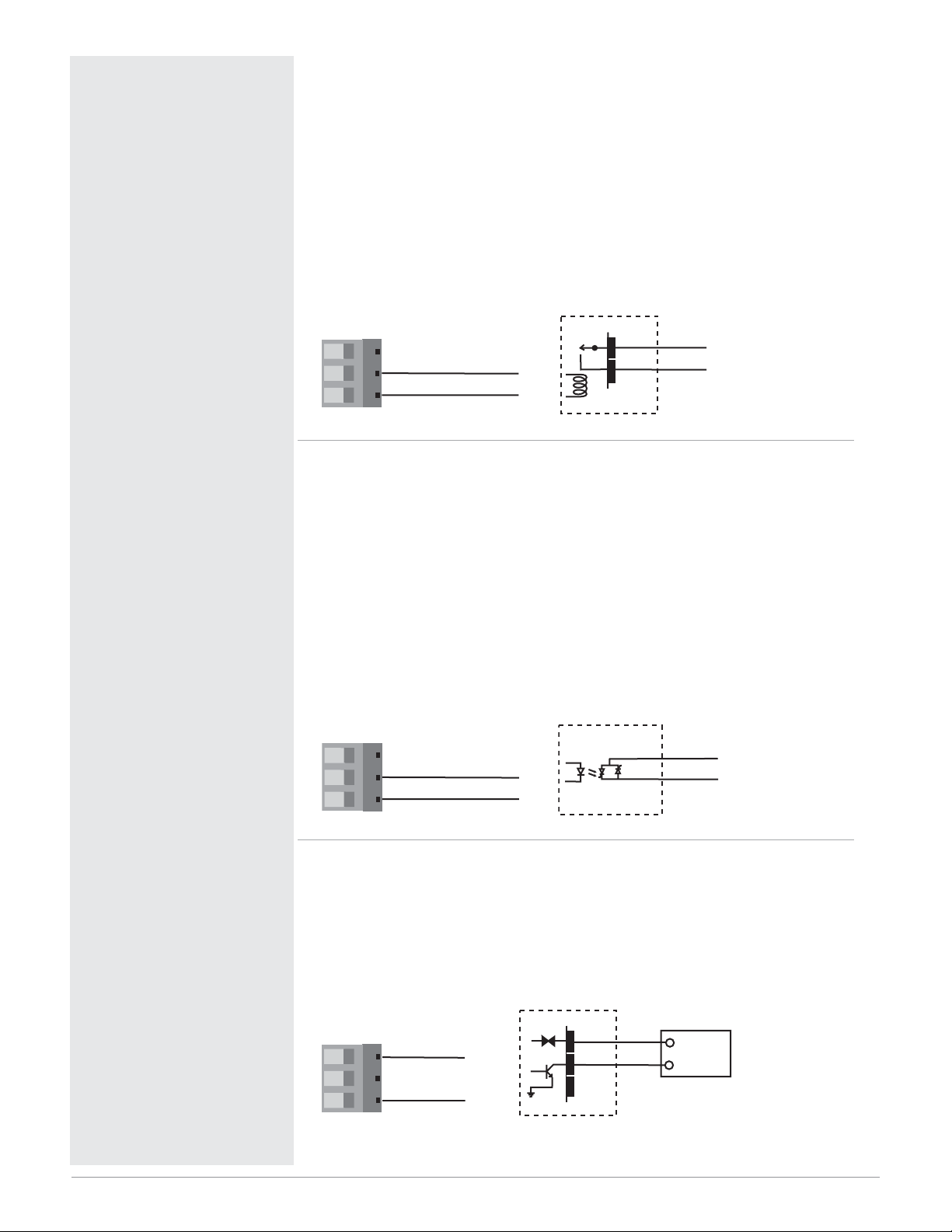

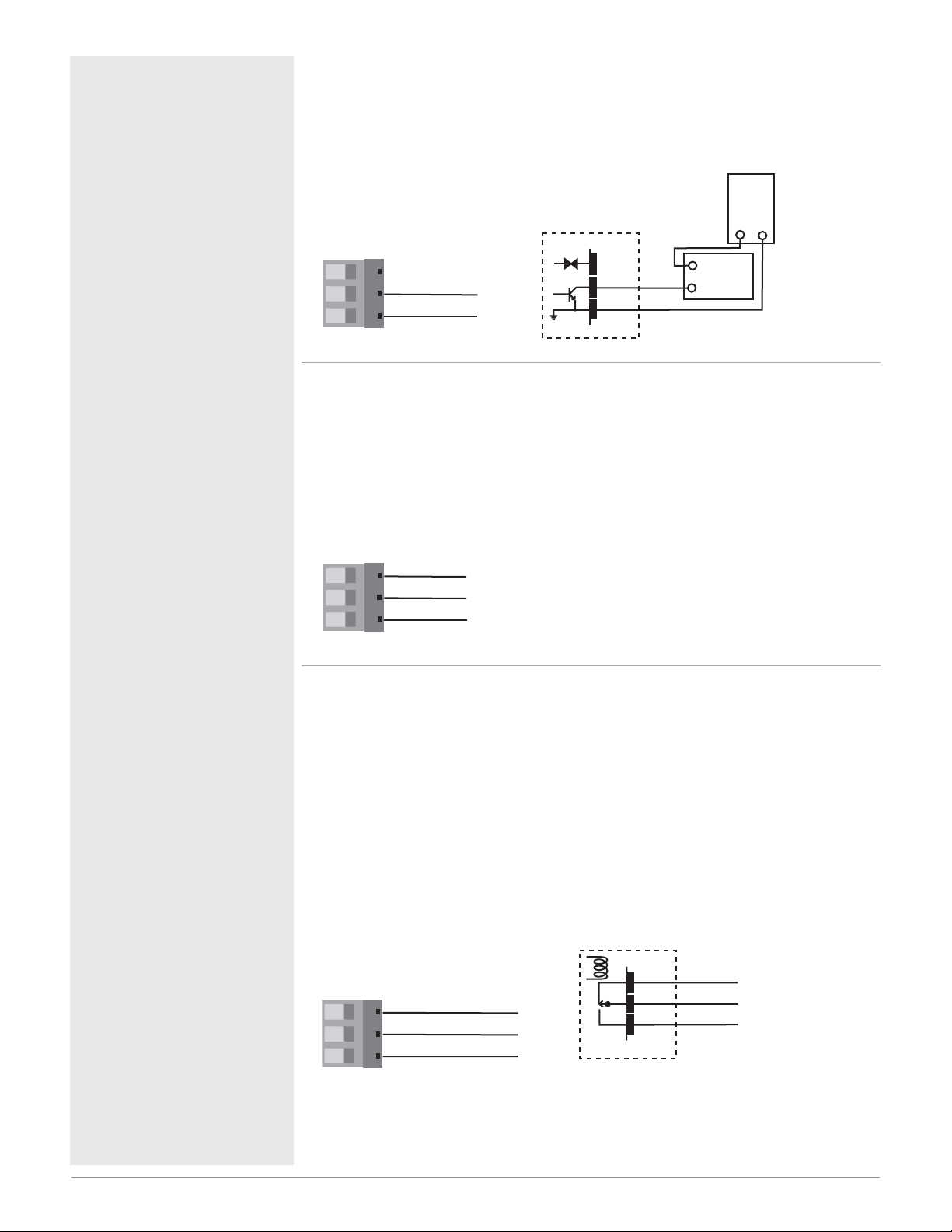

Figure 13a — Output 1 Mechanical Relay

PD_ _ - J _ _ _ - _ _ _ _

• Form A contact

• 2 A, resistive

• 125 VA pilot duty, 120/240VÅ (ac), inductive

• 240VÅ (ac) maximum

• 30VÎ (dc) maximum

• See Quencharc note

• For use with ac or dc

• Minimum load current 10 mA

• Output does not supply power

Figure 13b — Output 1 Solid-state Relay

PD_ _ - K _ _ _ - _ _ _ _

• Form A contact

• 0.5 A, resistive

• 20 VA pilot duty, 120/240VÅ (ac), inductive

• 24 to 240VÅ (ac)

• See Quencharc note

• Minimum load current 10 mA

• Maximum leakage current 100 µA

• Not for use with direct current (dc)

• Output does not supply power

Figure 13c — Output 1 Switched DC

PD_ _ - C_ _ _ - _ _ _ _

• Supply current 30 mAÎ (dc) maximum

• Supply voltage 24VÎ (dc)

• Not recommended for switching mechanical relays

• Output supplies power

Mechanical Relay

13 14 15

14 com

15 normally open

Internal Circuitry

13 14 15

14 com

15 normally open

Solid-state Relay

Solid-state Switch

Internal Circuitry

14

15

14

15

COM.

N.O.

COM.

N.O.

Switched DC

24VÎ (dc)

dc+

13 14 15

13 dc +

dc-

13

15

14 com

15 dc -

Internal Circuitry

+

Load

-

Page 16

Watlow Series PD ■ 14 ■ Chapter 2 Install and Wire

ç

Warning:

Use National Electric (NEC) or

other country-specific standard

wiring and safety practices when

wiring and connecting this controller to a power source and to

electrical sensors or peripheral

devices. Failure to do so may result in damage to equipment and

property, and/or injury or loss of

life.

Quencharc Note:

Switching pilot duty loads (relay

coils, solenoids, etc.) with the

mechanical relay or solid-state

relay output options requires use

of an R.C. suppressor.

Watlow carries the R.C. suppressor Quencharc brand name,

which is a trademark of ITW

Paktron. Watlow Part No. 08040147-0000.

Note: A current transformer input

is not available for Output 1 or 3

if a process output.

Note: 24 VÅÅinput power required to use single cycle,variable time base output function.

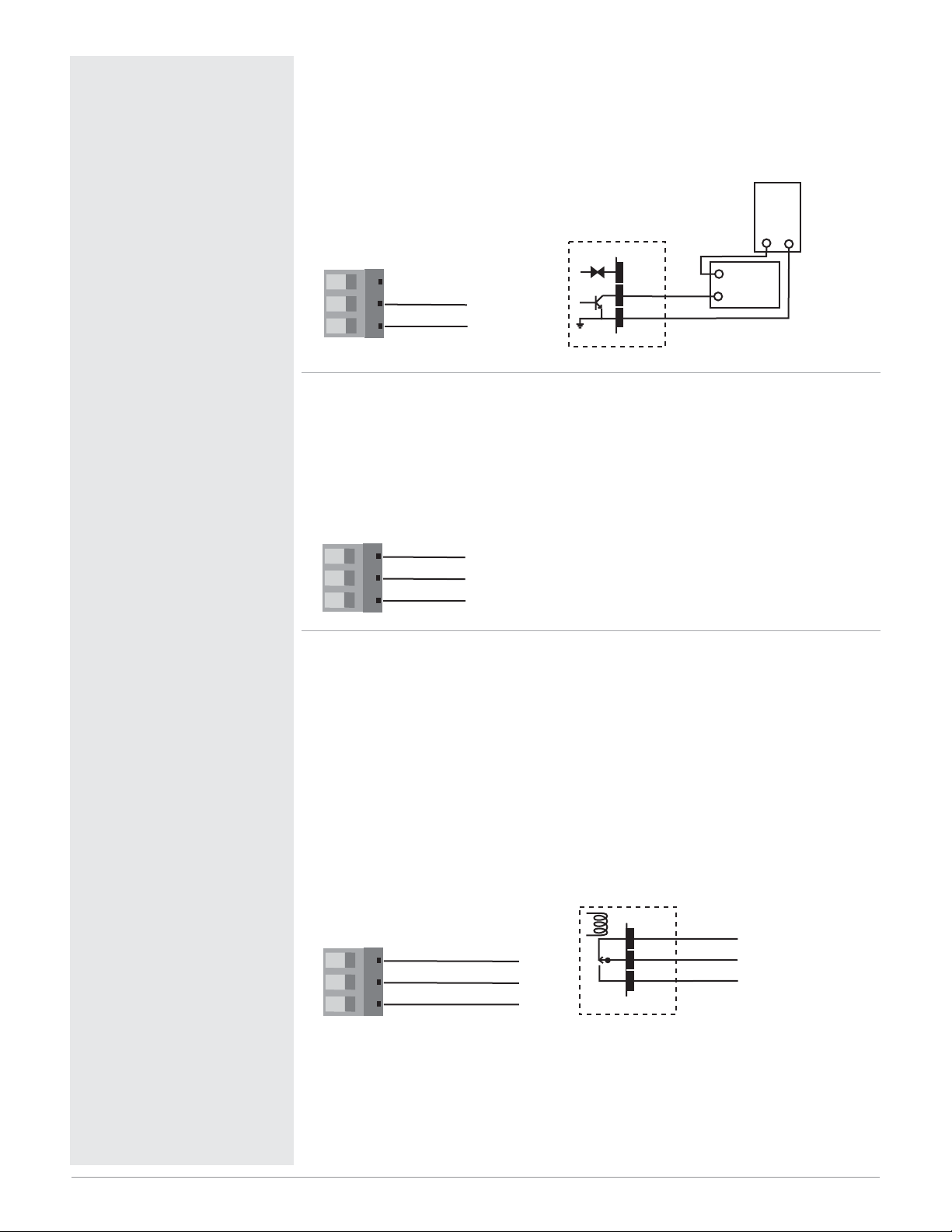

Figure 14a — Output 1 Open Collector

PD_ _ - C_ _ _ - _ _ _ _

• Maximum current sink 200 mAÎ (dc)

• Maximum supply voltage 42VÎ (dc)

• Output does not supply power

Figure 14b — Output 1 Process

PD_ _ - F_ _ _ - _ _ _ _

• Analog output is scalable between 0 to 10VÎ (dc) or 0 to 20 mAÎ (dc)

• Load capability: voltage 1 kΩ minimum; current 800 Ω maximum

• Output supplies power

• Cannot use voltage and current output at the same time

Figure 14c — Output 2 Mechanical Relay

PD_ _ - _ E _ _ - _ _ _ _

• Form C contacts

• 2 A, resistive

• 125 VA pilot duty, 120/240VÅ (ac), inductive

• 240VÅ (ac) maximum

• 30VÎ (dc) maximum

• See Quencharc note

• For use with ac or dc

• Minimum load current: 10 mA

• Output does not supply power

Class 2 power source

13 14 15

13 dc +

14 com

15 dc -

Open Collector

42VÎ (dc) maximum

dc+

dc-

COM.

Internal Circuitry

required for agency

compliance.

13

15

14

-

+

Load

Power

Supply

+

-

13 14 15

13 volts +

14 com 15 amps +

Mechanical Relay

16

16 17 18

16 normally closed

17 com

18 normally open

Internal Circuitry

N.C.

COM.

N.O.

17

18

Page 17

Watlow Series PD ■ 15 ■ Chapter 2 Install and Wire

ç

Warning:

Use National Electric (NEC) or

other country-specific standard

wiring and safety practices when

wiring and connecting this controller to a power source and to

electrical sensors or peripheral

devices. Failure to do so may result in damage to equipment and

property, and/or injury or loss of

life.

Quencharc Note:

Switching pilot duty loads (relay

coils, solenoids, etc.) with the

mechanical relay or solid-state

relay output options requires use

of an R.C. suppressor.

Watlow carries the R.C. suppressor Quencharc brand name,

which is a trademark of ITW

Paktron. Watlow Part No. 08040147-0000.

Note: 24 VÅÅinput power required to use single cycle,variable time base output function.

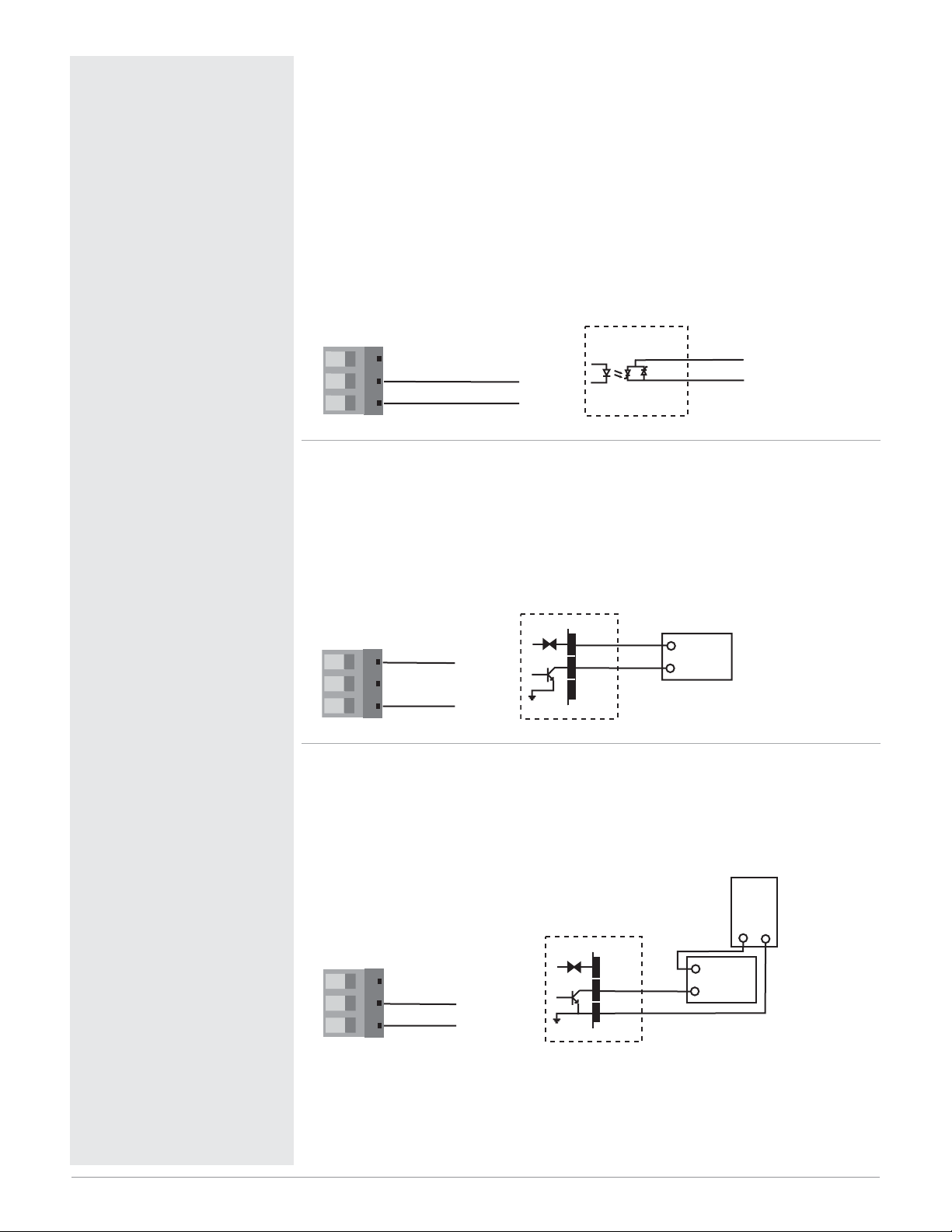

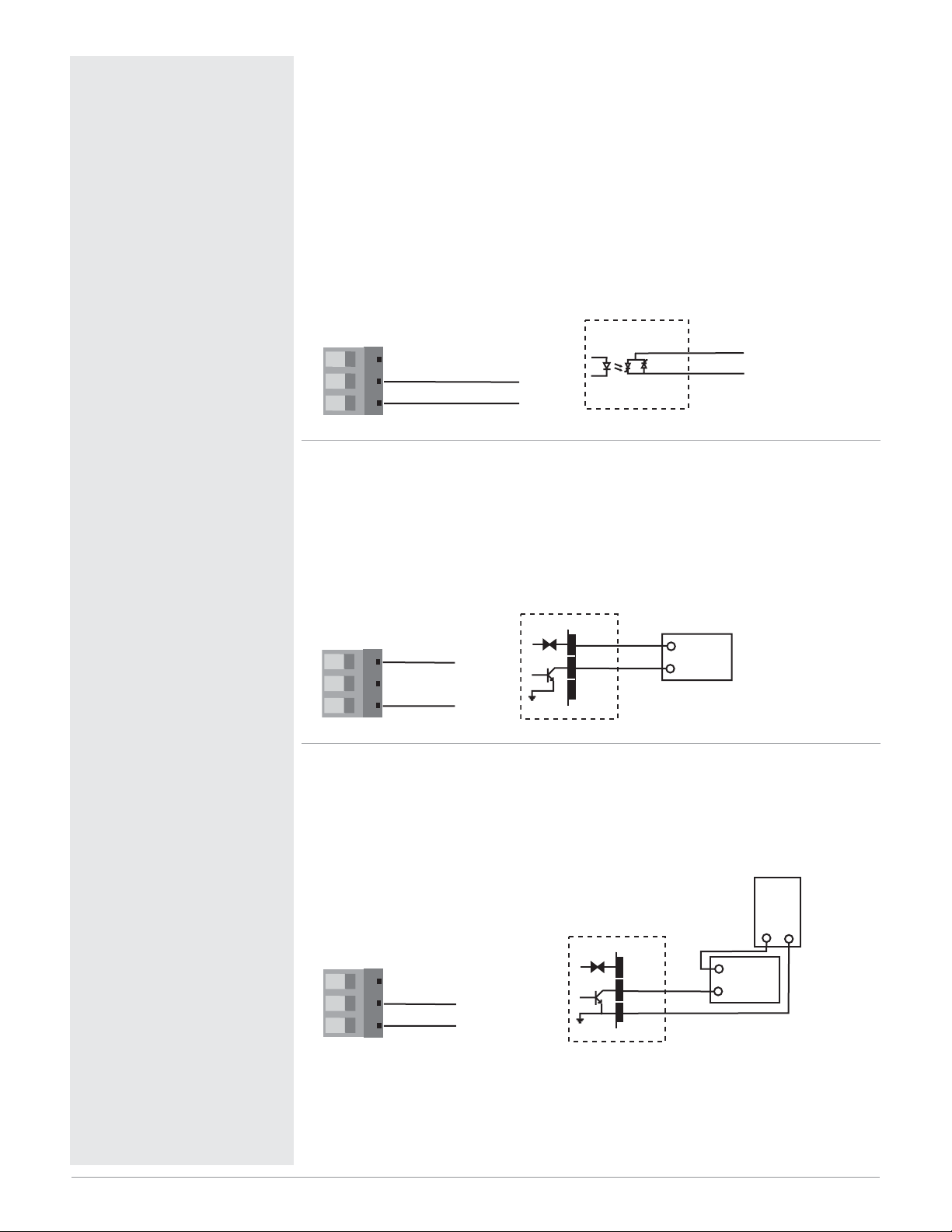

Figure 15a — Output 2 Solid-state Relay

PD_ _ - _ K _ _ - _ _ _ _

• Form A contact

• 0.5 A, resistive

• 20 VA pilot duty, 120/240VÅ (ac), inductive

• 24 to 240VÅ (ac)

• See Quencharc note

• Minimum load current 10mA

• Maximum leakage current 100µA

• Not for use with direct current (dc)

• Output does not supply power

Figure 15b — Output 2 Switched DC

PD_ _ - _ C _ _ - _ _ _ _

• Maximum supply current 30 mAÎ (dc)

• Supply voltage 24VÎ (dc)

• Not recommended for switching mechanical relays

• Output supplies power

Figure 15c — Output 2 Open Collector

PD_ _ - _ C _ _ - _ _ _ _

• Maximum current sink 200 mAÎ (dc)

• Maximum supply voltage 42VÎ (dc)

• Output does not supply power

16 17 18

Solid-state Relay

Solid-state Switch

17 com

18 normally open

Internal Circuitry

Switched DC

24VÎ (dc)

dc+

16 17 18

16 dc +

17 com

18 dc -

Internal Circuitry

dc-

16

18

+

-

17

18

Load

COM.

N.O.

Open Collector

42VÎ (dc) maximum

16 17 18

16 dc +

17 com

18 dc -

Internal Circuitry

Class 2 power source

required for agency

compliance.

dc+

16

dc-

18

COM.

17

+

-

Load

Power

Supply

+

-

Page 18

Watlow Series PD ■ 16 ■ Chapter 2 Install and Wire

ç

Warning:

Use National Electric (NEC) or

other country-specific standard

wiring and safety practices when

wiring and connecting this controller to a power source and to

electrical sensors or peripheral

devices. Failure to do so may result in damage to equipment and

property, and/or injury or loss of

life.

Quencharc Note:

Switching pilot duty loads (relay

coils, solenoids, etc.) with the

mechanical relay or solid-state

relay output options requires use

of an R.C. suppressor.

Watlow carries the R.C. suppressor Quencharc brand name,

which is a trademark of ITW

Paktron. Watlow Part No. 08040147-0000.

Note: 24 VÅÅinput power required to use single cycle,variable time base output function.

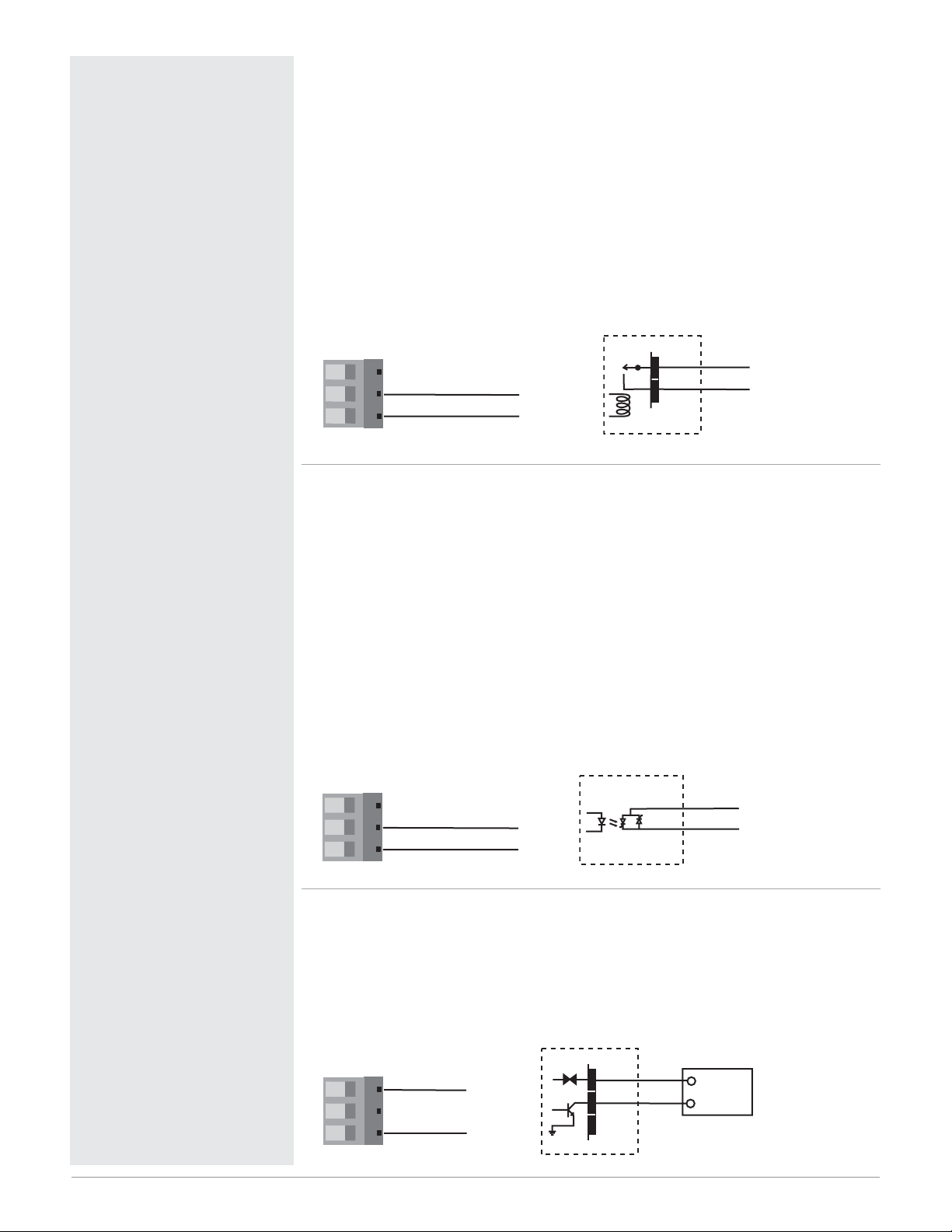

Figure 16a — Output 3 Mechanical Relay

PD_ _ - _ _ J _ - _ _ _ _

• Form A contact

• 2 A, resistive

• 125 VA pilot duty, 120/240VÅ (ac), inductive

• 240VÅ (ac) maximum

• 30VÎ (dc) maximum

• See Quencharc note

• For use with ac or dc

• Minimum load current: 10 mA

• Output does not supply power

Figure 16b — Output 3 Solid-state Relay

PD_ _ - _ _ K _ - _ _ _ _

• Form A.contact

• 0.5 A, resistive

• 20 VA pilot duty, 120/240VÅ (ac), inductive

• 24 to 240VÅ (ac)

• See Quencharc note

• Minimum load current 10 mA

• Maximum leakage current 100 µA

• Not for use with direct current (dc)

• Output does not supply power

Figure 16c — Output 3 Switched DC

PD_ _ - _ _ C _ - _ _ _ _

• Maximum supply current 30 mAÎ (dc)

• Supply voltage 24VÎ (dc)

• Not for switching mechanical relays

• Output supplies power

Mechanical Relay

19 20 21

20 com

21 normally open

Internal Circuitry

Solid-state Relay

19 20 21

20 com

21 normally open

Solid-state Switch

Internal Circuitry

20

21

20

21

COM.

N.O.

COM.

N.O.

19 20 21

19 DC +

20 com

Switched DC

24VÎ (dc)

dc+

dc-

19

21

+

-

Load

21 DC -

Internal Circuitry

Page 19

Watlow Series PD ■ 17 ■ Chapter 2 Install and Wire

ç

Warning:

Use National Electric (NEC) or

other country-specific standard

wiring and safety practices when

wiring and connecting this controller to a power source and to

electrical sensors or peripheral

devices. Failure to do so may result in damage to equipment and

property, and/or injury or loss of

life.

Quencharc Note:

Switching pilot duty loads (relay

coils, solenoids, etc.) with the

mechanical relay or solid-state

relay output options requires use

of an R.C. suppressor.

Watlow carries the R.C. suppressor Quencharc brand name,

which is a trademark of ITW

Paktron. Watlow Part No. 08040147-0000.

Note: A current transformer input

is not available for Output 1 or 3

if a process output.

Note: 24 VÅÅinput power required to use single cycle,variable time base output function.

Figure 17a — Output 3 Open Collector

PD_ _ - _ _ C _ - _ _ _ _

• Maximum current sink 200 mAÎ (dc)

• Maximum supply voltage 42VÎ (dc)

• Output does not supply power

Figure 17b — Output 3 Process

PD_ _ - _ _ F _ - _ _ _ _

• Analog output scalable from 0 to 10VÎ (dc) or 0 to 20 mAÎ (dc)

• Load capability: voltage, 1 kΩ minimum; current, 800 Ω maximum

• Output supplies power

• Cannot use voltage and current output at the same time

Figure 17c — Output 4 Mechanical Relay

PD_ _ - _ _ _ E - _ _ _ _

• Form C.contacts

• 2 A, resistive

• 125 VA pilot duty, 120/240VÅ (ac), inductive

• 240VÅ (ac) maximum

• 30VÎ (dc) maximum.

• See Quencharc note

• For use with ac or dc

• Minimum load current: 10 mA

• Output does not supply power

Class 2 power source

19 20 21

19 DC +

20 com

21 DC -

Open Collector

42VÎ (dc) maximum

dc+

dc-

COM.

Internal Circuitry

required for agency

compliance.

19

21

20

-

+

Load

Power

Supply

+

-

19 20 21

19 volts +

20 com 21 amps +

22 23 24

22 normally closed

23 com

24 normally open

Mechanical Relay

Internal Circuitry

N.C.

COM.

N.O.

22

23

24

Page 20

Watlow Series PD ■ 18 ■ Chapter 2 Install and Wire

ç

Warning:

Use National Electric (NEC) or

other country-specific standard

wiring and safety practices when

wiring and connecting this controller to a power source and to

electrical sensors or peripheral

devices. Failure to do so may result in damage to equipment and

property, and/or injury or loss of

life.

Quencharc Note:

Switching pilot duty loads (relay

coils, solenoids, etc.) with the

mechanical relay or solid-state

relay output options requires use

of an R.C. suppressor.

Watlow carries the R.C. suppressor Quencharc brand name,

which is a trademark of ITW

Paktron. Watlow Part No. 08040147-0000.

Note: 24 VÅÅinput power required to use single cycle,variable time base output function.

Figure 18a — Output 4 Solid-state Relay

PD_ _ - _ _ _ K - _ _ _ _

• Form A.contact

• 0.5 A, resistive

• 20 VA pilot duty, 120/240VÅ (ac), inductive

• 24 to 240VÅ (ac)

• See Quencharc note

• Minimum load current 10mA

• Maximum leakage current 100µA

• Not for use with direct current (dc)

• Output does not supply power

Figure 18b — Output 4 Switched DC

PD_ _ - _ _ _ C - _ _ _ _

• Maximum supply current 30 mAÎ (dc)

• Supply voltage 24VÎ (dc)

• Not recommended for switching mechanical relays

• Output supplies power

Figure 18c — Output 4 Open Collector

PD_ _ - _ _ _ C - _ _ _ _

• Maximum current sink 200 mAÎ (dc)

• Maximum supply voltage 42VÎ (dc)

• Output does not supply power

Solid-state Relay

Solid-state Switch

22 23 24

23 com

24 normally open

Internal Circuitry

Switched DC

24VÎ (dc)

dc+

22 23 24

22 dc +

23 com

24 dc -

Internal Circuitry

dc-

22

24

+

-

Load

23

24

COM.

N.O.

Open Collector

42VÎ (dc) maximum

22 23 24

22 dc +

23 com

24 dc -

Internal Circuitry

Class 2 power source

required for agency

compliance.

dc+

22

24

dc-

23

COM.

-

+

Load

Power

Supply

+

-

Page 21

Watlow Series PD ■ 19 ■ Chapter 3 Indicator Lights

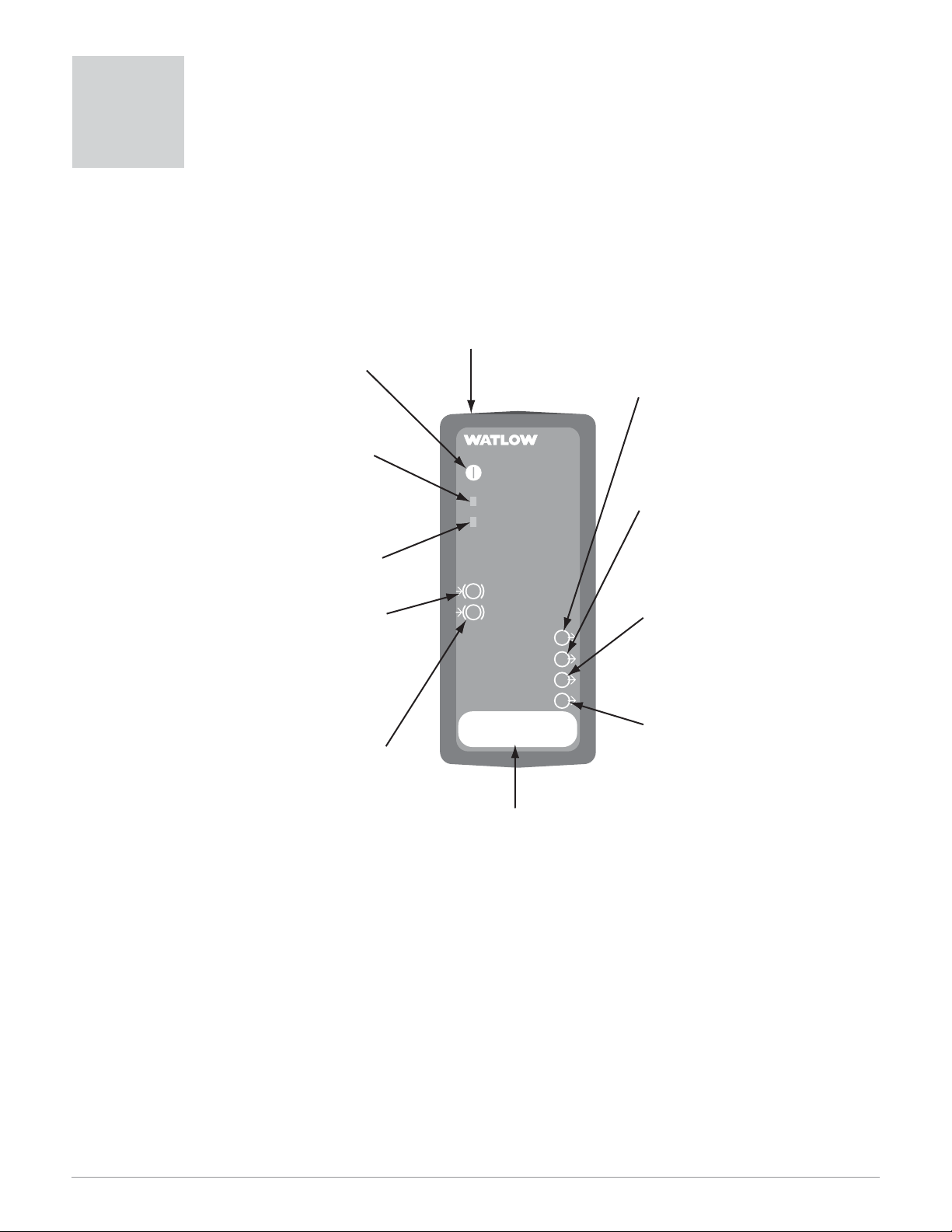

The Series PD controller may have up to nine LED indicator lights to help you monitor the

status of input power, Ethernet functions, input errors and outputs status. These LEDs can

provide a quick visual indication of basic controller functions. An additional heartbeat LED,

used for diagnostics, can be seen through the top vent at the back left side of the controller.

Heartbeat LED Diagnostics:

• Application Mode (normal operation) - 1 flash per second

• Test Mode (internal factory calibration) - 10 flashes per second

• Boot Code (internal factory configuration) - 1 flash per 2 seconds

Both Input Error LEDs Lit

• TFTP Mode (flash download in progress)

Figure 18 — Series PD LED Indicator Lights

Indicator Lights

3

Heartbeat (diagnostics)

Green light can be seen on the left

side pc board, through the top vents

Power

Green light stays lit when the

power is on.

• If not lit or flashing, check

your power source.

Ethernet Link:

Green light is lit if the Ethernet

cable is correctly wired and

connected to a 10BaseT port.

• If not lit, check for the correct

RJ-45 cable and switch/hub speed.

Ethernet Activity

Green light is lit when communication activity occurs.

(1) Input Error

Red light is lit if there is a sensor

problem on Input 1. Lights momentarily after power up.

• If it stays lit:

- Verify the sensor wiring, polarity

and function.

- Rewire or replace as necessary.

(2) Input Error

Red light is lit if there is a sensor

problem on Input 2. Lights momentarily after power up.

• If it stays lit:

- Verify the sensor wiring, polarity

and function.

- Rewire or replace as necessary.

at the back of the unit.

(1) Output

Red light is lit or flashes when

control Output 1 is active. If it does

not light up, the output is not active.

The output may be configured as an

event (alarm) or control.

(2) Output

Red light is lit or flashes when

control Output 2 is active. If it does

not light up, the output is not active.

The output may be configured as an

event (alarm) or control.

(3) Output

Red light is lit or flashes when

control Output 3 is active. If it does

not light up, the output is not active.

The output may be configured as an

event (alarm) or control.

(4) Output

Red light is lit or flashes when

control Output 4 is active. If it does

not light up, the output is not active.

The output may be configured as an

event (alarm) or control.

Output

Output

Output

Output

PD

1

2

3

4

PID Controller

Power

Ethernet Link

Ethernet Activity

Input Error

1

2

Input Error

Address

Address Field

Record the unit's Device Name

in erasable marker here. For example,

PD012345.

Page 22

Watlow Series PD ■ 20 ■ Chapter 4 Ethernet Communications

Network security is a critical issue for any network. Be sure to work with your network administrator

to ensure that you follow best security practices to ensure a secure network environment. Here are some

items to consider when installing Ethernet based controls on any network.

• Use private IP addresses.

• Separate the process network(s) from business network(s).

• If external access is required, then have a single point of access to the process network.

• External access points should be protected by a firewall.

• External access points should be protected by a layer 3 switch or router.

• Access to the Internet should be indirect, going through an access point to the business

network on the way.

• Separate processes or cells using VLANs.

• Run virus protection software on all PC's on the process network.

Refer to the bottom of the web page navigation frame for the browser versions supported. You may access the Series PD and view controller parameters via an onboard Web (HTTP) server.

The Series PD supports full product configuration and monitoring of runtime parameters via MODBUS TCP over TCP/IP using a third party software package such as Lookout™, created and sold by National Instruments.

The 10BaseT Ethernet connection supports the TCP/IP stack. At the application layer it has an HTTP

(web) and Modbus server. The HTTP server provides a means of changing runtime parameters via

HTML. The TCP/IP stack supports DHCP client, Auto IP, Static IP, DNS client, and Netbios name

resolution.

Getting Started

1. Connect the Series PD to your computer's Ethernet port using a cross-wired RJ45 cable or connect the

Series PD to a switch/hub or network using a straight wired RJ45 Category 5 cable. The Series PD is

limited to a 10BaseT connection and will not work on an Ethernet port set for 100BaseT only. Use of a

10/100 switch/hub will overcome this issue if your PC has only a 100BaseT port.

2. Wire a 24V‡ (ac/dc) power supply to the Series PD power terminals. See wiring section.

3. Wire sensor inputs and controller outputs. See wiring section.

4. Power up the controller, switch/hub and PC.

5. Start your Internet browser. Enter the Browse at address of the Series PD into the browser’s address

field. See figure on next page for the Browse at address location on the left side label. Two different

Netbios names may be used to access the Series PD. Either PDxxxxxx, where xxxxxx is the first six

digits of the serial number, located on the left side label, or WATxxxxxx, where xxxxxx is the last six

digits of the Series PD MAC address. The MAC address is also printed on the left side label of the Series PD in the form xx:xx:xx:xx. See figure on next page.

Note: Browsing the Series PD using the Netbios name only works with Windows. The computer and Series PD must

be on the same logical network. Browsing using the IP address always works.

Note: If you are not using a DHCP server, it may take several minutes for both the Series PD and your computer to

get their IP addresses.

Ethernet Communications

4

Page 23

Figure 21 — Browse at address, MAC address, and Serial number locations

6. When you change data on the Monitor Device page or access other web pages, you are prompted to en-

ter a Network Security user name and password. The factory defaults are:

user name - new

password - user

7. Once you enter the user name and password you can access the other controller pages. If you browse

another address or close your browser, you will be required to enter this information again.

8. To change security level passwords, go to Device Configuration > Network > Security.

9. To configure the Series PD, go to Device Configuration and set up the unit.

Note: The controller leaves the factory with all inputs, outputs and control loops set to off.

Go through each Device Configuration page and make the appropriate selections for your application.

Click the Submit button at the bottom of each page.

Note: Be sure to click the Submit button at the bottom of any Device Configuration screen to send your changes to

the controller. Changes are not entered into the controller until you submit them.

9. Select the Monitor Device page. The process values and set points are displayed. You can change con-

troller set point and the mode of operation, auto or manual. Select the parameter value you want to

change by clicking on it, enter the new parameter value and click the Submit button. This sends the

Series PD the new value and refreshes the Monitor Device page.

Note: Information on the Monitor Device page, including alarms and errors, is automatically refreshed once per second, if your browser supports Java Virtual Machine and is enabled to allow Java applets to run.

Network Services

The Series PD supports DHCP client, Auto IP, and Static IP for address assignment. Normally you

will not need to make any changes. The user is able to configure preferences as to which services are used

if available. Intelligence is employed within the Series PD to revert to backup IP assignment methods if

the primary method is unavailable. It will try DHCP first, then Auto IP to assign an IP address. This is

the same method that a Windows based computer uses to get an IP address.

When using Auto IP, the Series PD starts with the IP address 169.254.10.10. If this address is already

in use, it will randomly attempt other addresses in the 169.254.XX.XX subnet. As with any IP networking

device, the IP address assigned to the Series PD must be compatible with the network it is physically connected to.

Note: If you are using Auto IP, it may take several minutes for both the Series PD and your computer to get their IP

addresses.

The Series PD does support DNS client and Netbios name resolution. Configuration information may

be entered at the Network Display Setup page.

Note: If you forget the fixed IP address of your Series PD, short the jumper connections on the top of the unit (see page 5), turn

the input power off and back on again. This causes the Series PD to use DHCP first, AutoIP and finally fixed IP addressing to try

assigning an IP address. This allows you to read the current fixed IP address. Once the unit is powered up without the jumper

connections shorted, the Series PD returns to using the previous IP addressing settings.

PDxx-xxxx-xxxx

Watlow Series PD ■ 21 ■ Chapter 4 Ethernet Communications

Serial number

Type PD012345

Browse at address

Type PD012345

Auxiliary Inputs

1.

2.

3.

4.

Input 2

5.

6.

7.

8.

Input 1

9. TC-/S3/V-/I-

10. TC+/S1

11. I+/S2

12. V+/Info.Data

W

O

L

T

A

onnectivity

W

-solutions

Browse at:

http://PD012345

Made In USA

DC: YYWWSN: 012345

00:01:23:45:67:89

MAC Address:

MAC Address

Type WAT456789

Page 24

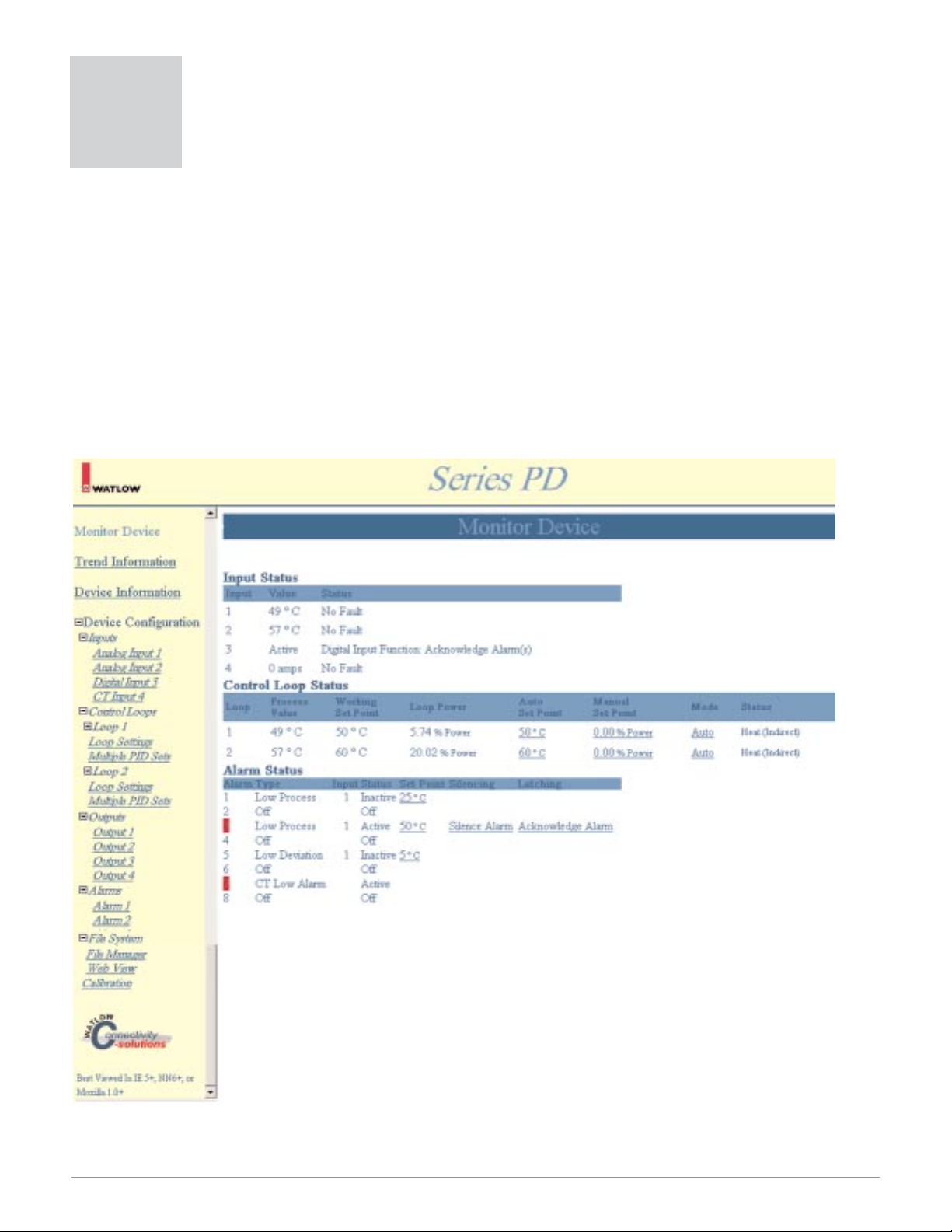

Watlow Series PD ■ 22 ■ Chapter 5 Monitor Device Page

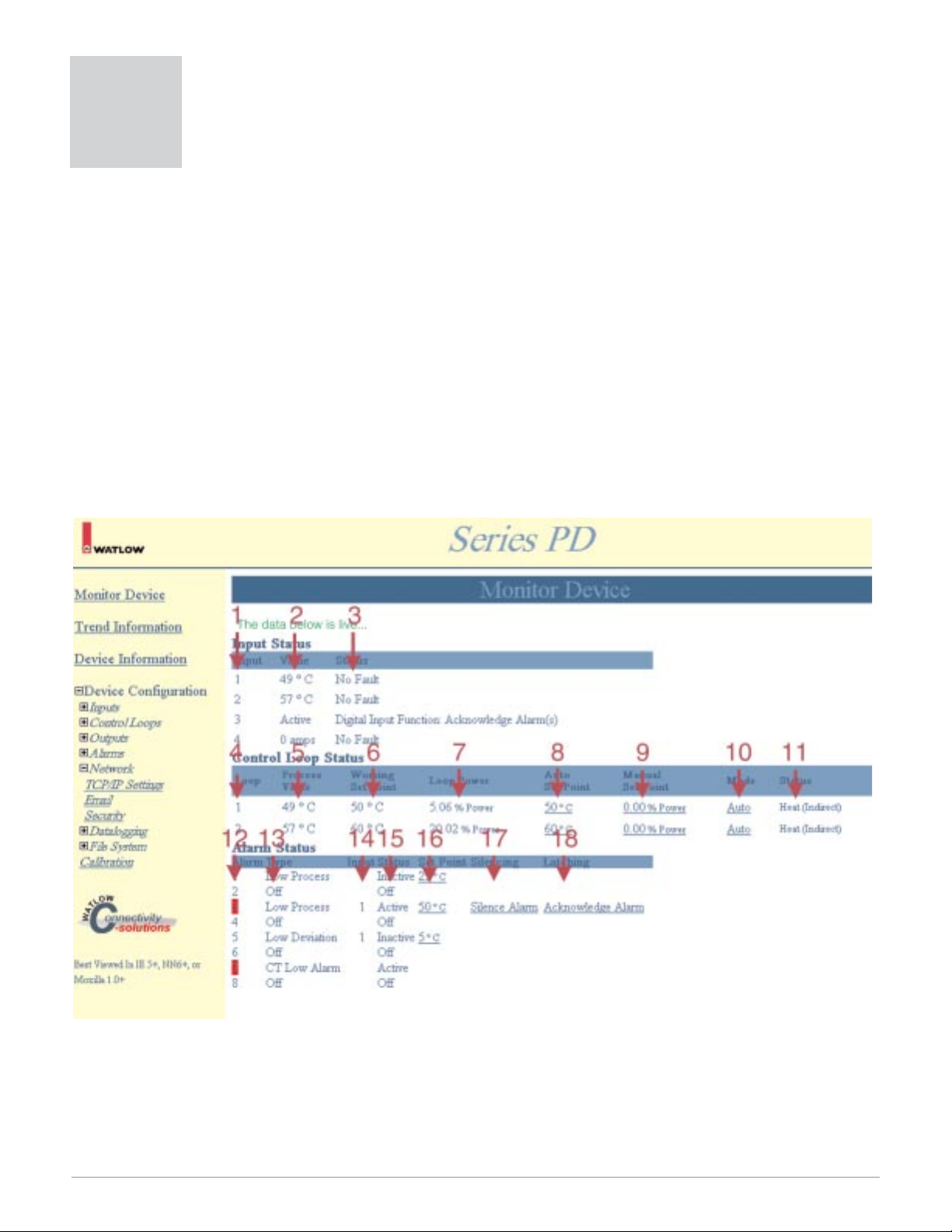

When accessing a Series PD controller through a browser, the Monitor Device page appears. The Monitor Device page contains real-time information representing the current process conditions. This information is loaded

when the Monitor Device page is browsed and is automatically refreshed once every second. The Monitor Device

page provides real-time information on:

• Input Status

• Control Loop Status

• Alarm Status.

Input errors and alarms appear on this page as a red box next to the related input or output. These are refreshed once a second.

If you try to change any values on the Monitor Device page, you are prompted to enter Network Password

information. The User Name is new and Password is user. Be sure to change your user name and password if

controller security is a concern. If you want your browser to remember the User Name and Password after you

enter it the first time, check the box, Save this password in your password list. If you close your browser, you

must re-enter your user name and password information.

Note: You must have Java Virtual Machine installed on your computer and Java must be enabled for the Monitor Device page to display

properly in your browser. Most browsers will already have this configured by default.

Figure 22 — Monitor Device Web Page Example

Note: Red tag arrows and tag numbers are links to item descriptions. Click on a red tag arrow or number to go to a description of the item.

Monitor Device Page

5

Page 25

Watlow Series PD ■ 23 ■ Chapter 5 Monitor Device Page

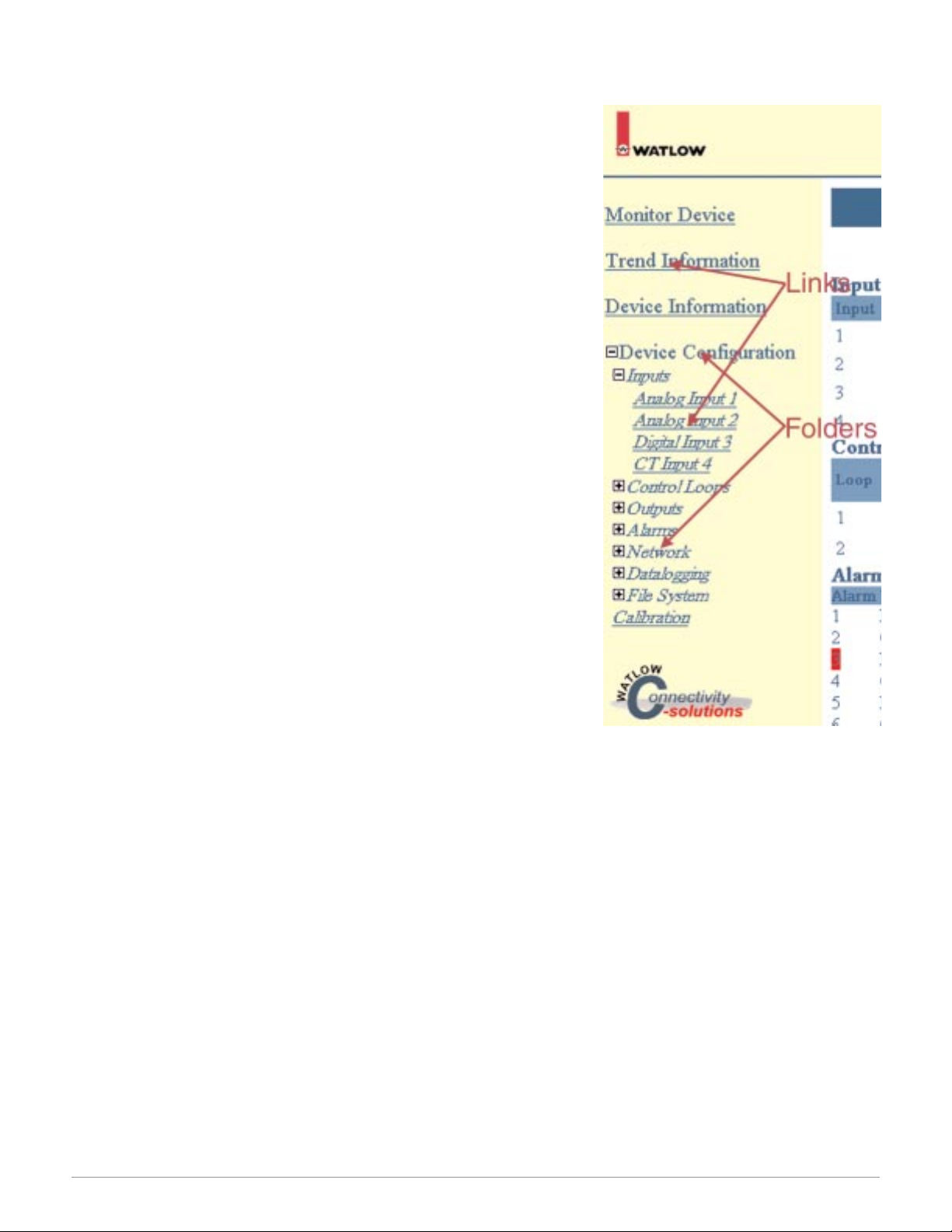

Navigation Frame

The left side of the Series PD web pages contain a navigation frame

that looks and operates much like Windows Explorer™. This frame does

not change as web pages are accessed and changed. The navigation area

contains folders and web page links. A plus (+) sign in front of a folder

indicates the folder can be expanded to show more information. A minus

(-) sign in front of a folder indicates the folder can be contracted to show

less information.

For example, if you click on the + sign in front of the Device Configuration folder or click on the Device Configuration folder itself, you expand the Device Configuration folder. The folders that appear contain

additional folders as indicated by the + sign in front of each folder. Click

on the + or - sign in front of any folder or click on the folder itself to expand or contract that folder.

When you see page links (underlined text), you can click on a link to

take you to a specific Series PD web page. For example, with the Inputs

folder expanded, click on the Analog Input 1 link to go to the Analog Input 1 Configuration page.

Figure 23 — Navigation Frame Example

Page 26

Watlow Series PD ■ 24 ■ Chapter 5 Monitor Device Page

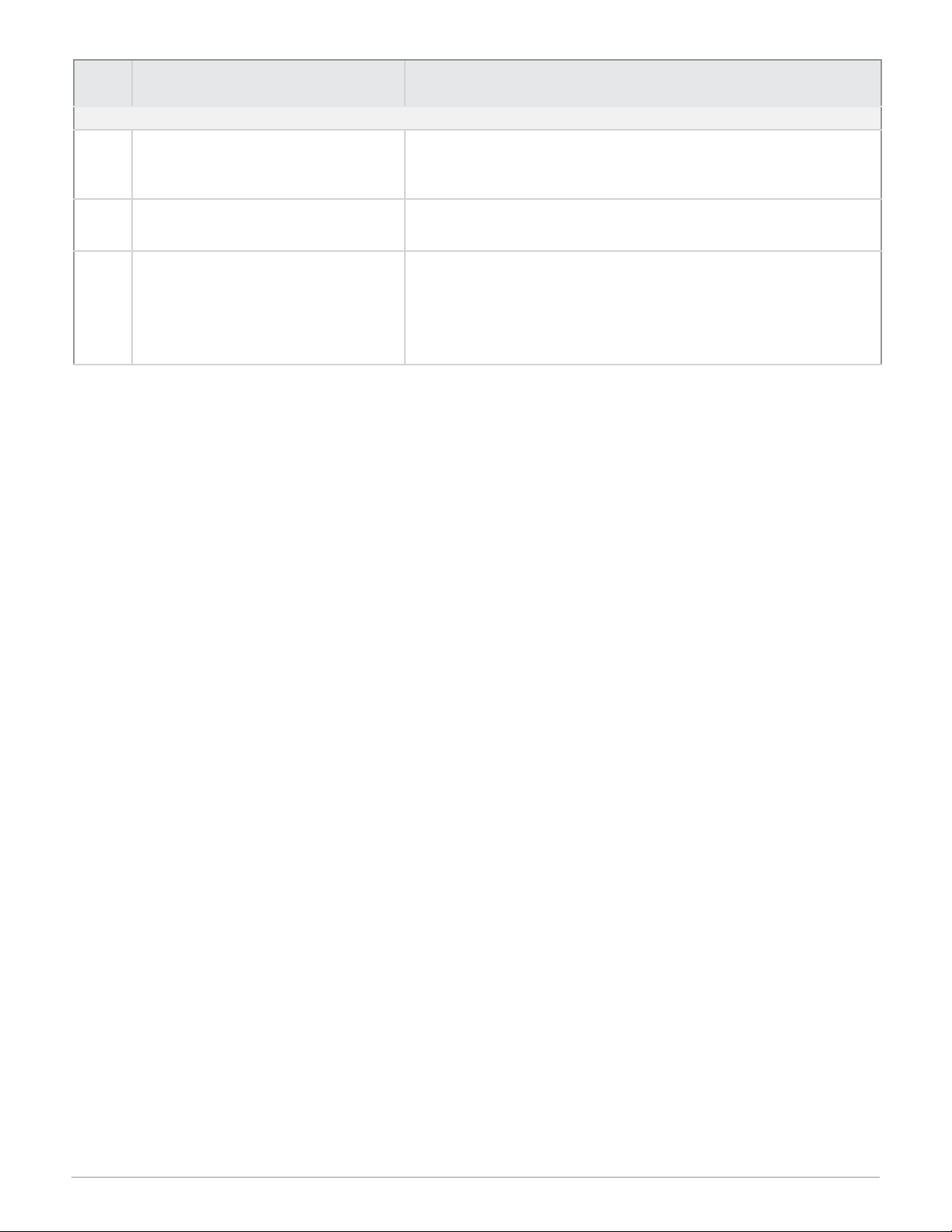

Figure 24 — Monitor Device Web Page Tag Descriptions

Tag # Monitor Device Page Parameters Parameter Description

Input Status

1. Input Number Identifies input hardware that is installed. Red box appears for

any input that is in a fault condition.

2. Input Value Actual analog input value for Inputs 1 and 2.

Digital Input condition or Current Transformer input value for

Inputs 3 and 4.

3. Input Status Input error status for analog, digital or current transformer inputs.

Control Loop Status

4. Control Loop Number Identifies control loop hardware that is installed. Loop 2 appears

only on dual loop models.

5. Control Loop Process Value Actual analog input value for the control loop(s). Active analog

inputs can be assigned to either control loop.

6. Control Loop Working Set Point Active set point. Could be one of several set point sources, Auto

Set Point, Digital Set Point, or Ramp to Set Point

7. Control Loop Power Actual ouput power level for each control loop.

8. Control Loop Auto Set Point Automatic mode (closed loop) set point. Click on the desired loop

set point, enter the new Auto Set Point value in the pop up window and click Submit. The page refreshes and displays the new

Monitor Device page data.

9. Control Loop Manual Set Point Manual mode (open loop, % power) set point. Click on the desired

loop manual set point, enter the new Manual Set Point value in

the pop up window and click Submit. The page refreshes and displays the new Monitor Device page data.

10. Control Loop Mode Loop control mode. Automatic mode (closed loop control), Manual

mode (open loop control) or Off (loop disabled).

11. Control Loop Status Control loop output function. Heat, Cool, Heat/Cool or Off (dis-

abled) output operation.

Alarm Status

12. Alarm Number Identifies alarms. Red box appears for any alarm that is active.

13. Alarm Type Deviation Alarm, Process Alarm or Off (disabled).

14. Alarm Input Analog input assigned to the alarm.

15. Alarm Status Indicates if an alarm is inactive, active or off (disabled). Red box

appears in Alarm Number column when alarm is active

16. Alarm Set Point Trip point for the alarm. Click on the desired alarm set point, en-

ter the new Alarm Set Point value in the pop up window and click

Submit. The page refreshes and displays the new Monitor Device

page data.

17. Alarm Silencing If enabled, the alarm output can be disabled. A Silence Alarm link

appears on the Monitor Device page when the alarm trips. Click

this link to disable the alarm output.

18. Alarm Latching If enabled, the alarm output latches when tripped. An Acknowl-

edge link appears on the Monitor Device page when the alarm

trips. Once the process returns to the safe region, click this button

to reset the latched alarm output.

Page 27

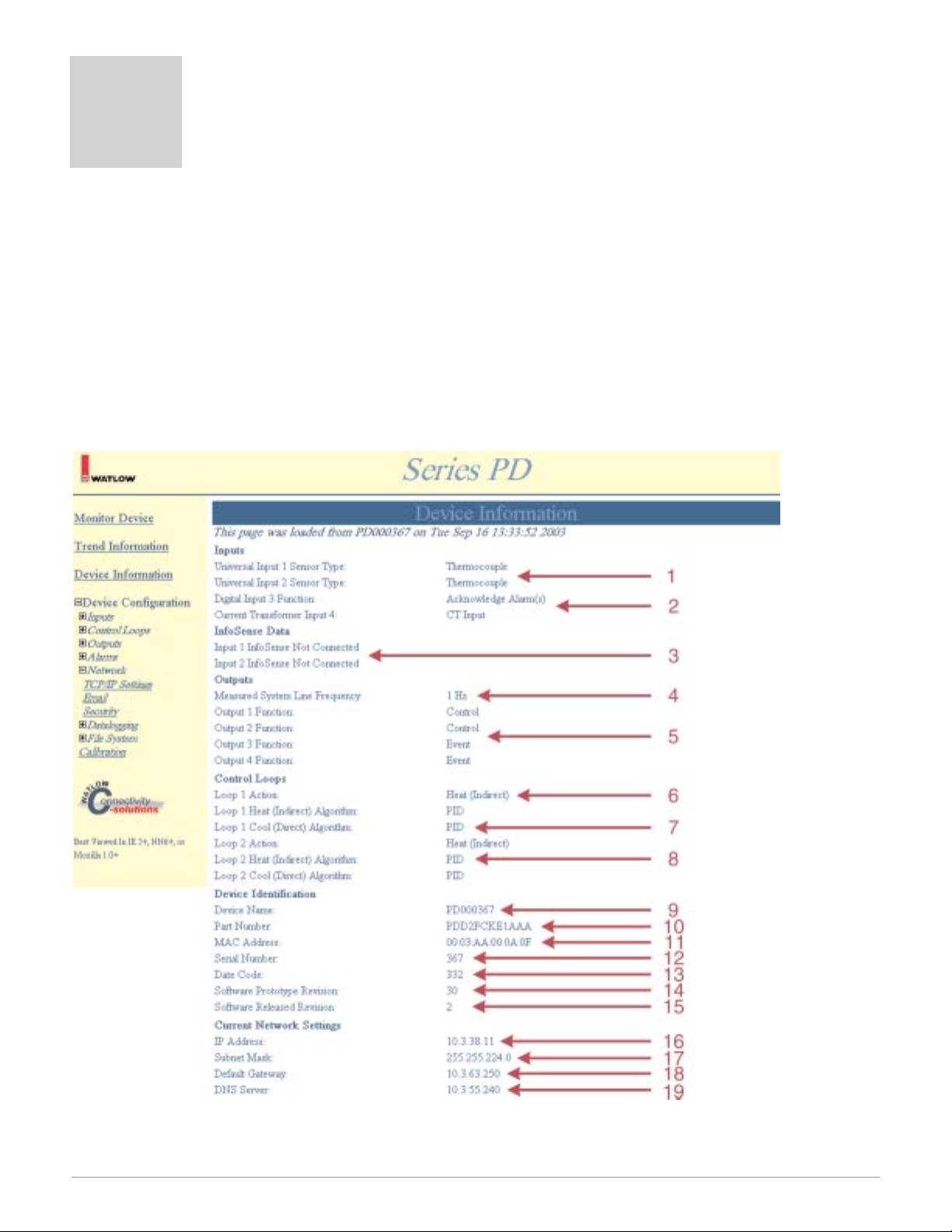

Watlow Series PD ■ 25 ■ Chapter 6 Device Information

The Device Information page provides important information about the Series PD controller. Information on the

controller hardware, its configuration and network settings can be easily accessed from this page. The time and

date the page was loaded appears at the top of the page. This page is not automatically refreshed. The Device Information page provides information on:

• Inputs

• INFOSENSE™ Data

• Outputs

•Control Loops

• Device Identification

• Current Network Settings

Note: If you are going to Restore Factory Defaults or Restore User Settings, we strongly recommend that you document all of your settings

first. Be sure to document your Current Network Setttings, found at the bottom of the Device Information page.

Figure 25 — Device Information Web Page Example

Note: Red tag arrows and tag numbers are links to item descriptions. Click on a red tag arrow or number to go to a description of the item.

Device Information Page

6

Page 28

Watlow Series PD ■ 26 ■ Chapter 6 Device Information

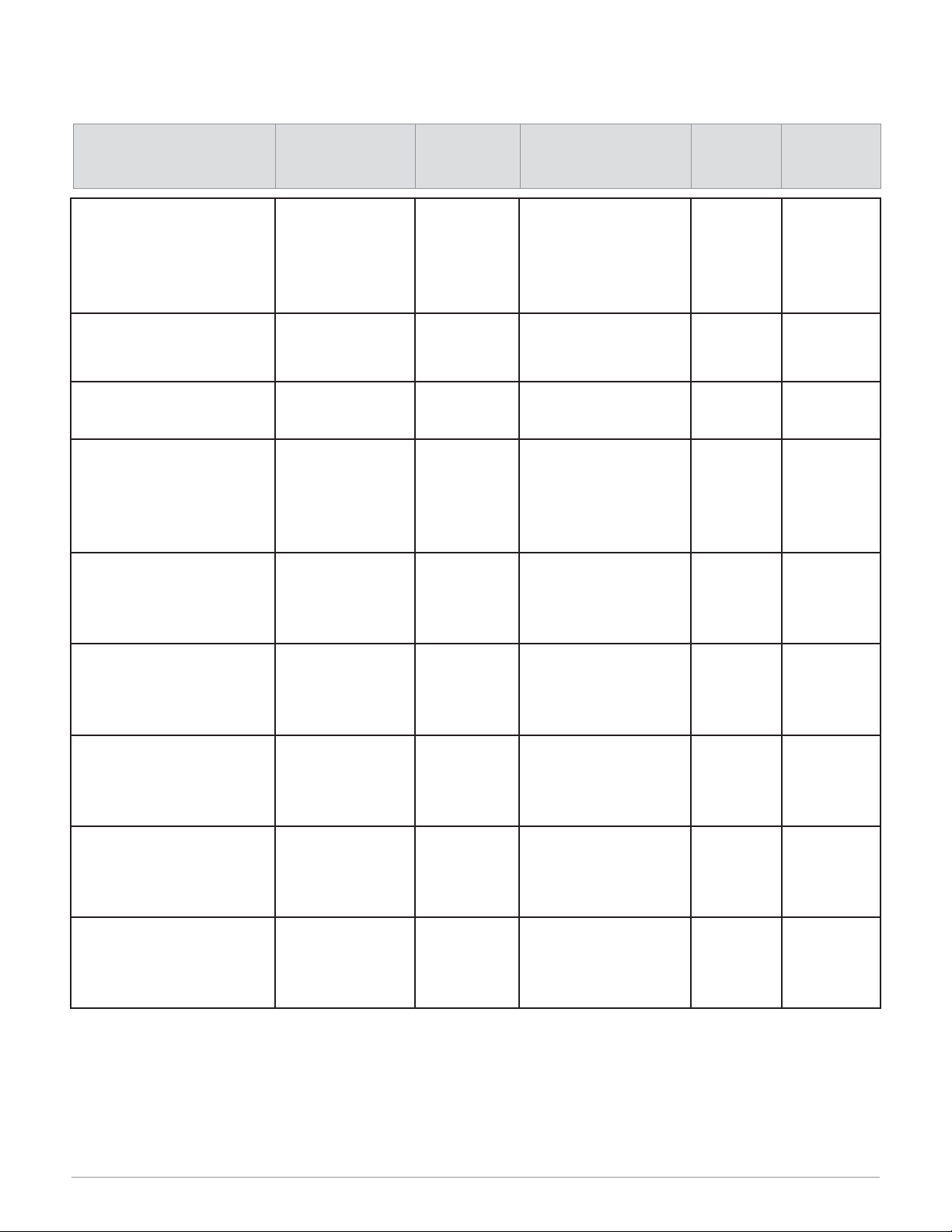

Figure 26 — Device Information Web Page Tag Descriptions

Tag # Device Information

Configuration Parameters

Section Description

Inputs

1. Universal Input Sensor Type Displays what input hardware is present and input configuration

information. Inputs 1 and 2 are universal analog inputs and will

accept a wide variety of input signals. Input 2 is an ordering option. See model number information

2. Digital Input Function

Current Transformer Input

Inputs 3 and 4 can be ordered as digital or current transformer inputs. See model number information.

Digital Input Function - displays what action is taken when the

digital input condition is satisfied.

Current Transformer Input - displays what CT hardware is present and enabled.

INFOSENSE

3. INFOSENSE Data Displays specific sensor data when connected to an INFOSENSE

sensor. The part number, serial number and calibration date information is retrieved from the INFOSENSE sensor.

4. Measured System

Line Frequency

Displays system power line frequency. If correct frequency is not

detected, single cycle burst firing mode not available. See Features

chapter.

Outputs

5. Output 1-4 Displays what output hardware is present and output configura-

tion information.

Control Loops

6. Loop Action Displays control loop action; heat, cool, heat/cool or off (disabled).

7. Loop Cool Algorithm Displays control loop cool algorithm selected, On/Off or PID.

8. Loop Heat Algorithm Displays control loop heat algorithm selected, On/Off or PID.

Device Identification

9. Device Name Displays the assigned Netbios name. The default device name is

PDXXXXXX, where XXXXXX is the serial number. This name can

be changed on the TCP/IP Settings page in the Network folder.

Not all computer networking configurations support Netbios

names.

10. Part Number Displays the Series PD model number.

11. MAC Address Displays the assigned MAC address. You can also use the MAC

address as another Netbios name to browse the Series PD by using WATXXXXXX, where XXXXXX are the last six digits of the

MAC address without colons. Not all computer networking configurations support Netbios names.

Page 29

Watlow Series PD ■ 27 ■ Chapter 6 Device Information

Figure 27 — Device Information Web Page Tag Descriptions (continued)

Tag # Device Information

Configuration Parameters

Section Description

12. Serial Number Displays the Series PD serial number.

13. Date Code Displays the date the unit was manufactured. The format is year

week. For example, 345 would be 2003, 45th week.

14. Software Prototype Revision Displays firmware prototype revision.

15. Software Released Revision Displays firmware release revision.

Current Network Settings

16. IP Address Displays IP address number. Series PD supports DHCP client,

autoIP and fixed IP address assignment.

17. Subnet Mask Displays current subnet mask.

18. Default Gateway Displays current default gateway.

19. DNS Server Displays current DNS server.

Page 30

Watlow Series PD ■ 28 ■ Chapter 7 Configuration Page

The Device Configuration page contains folders and links for configuring the Series PD. The controller leaves

the factory with default settings that disable most input and output functions. To get the Series PD operational,

you must go through the Device Configuration folders and set up the controller. The Device Configuration folders

are:

• Inputs

•Control Loops

• Outputs

• Alarms

• Network

• Datalogging

• File System

Note: You may not see all of the Device Configuration page folders listed above. Your model number determines what folders appear.

Figure 28 — Device Configuration Navigation Frame Expanded Example

Device Configuration Page

7

Page 31

Watlow Series PD ■ 29 ■ Chapter 7 Configuration Page

Inputs

The Inputs folder contains links for configuring the inputs installed in the Series PD. The controller leaves the

factory with default settings that disable all input functions. To get the Series PD operational, you must go through

the Inputs links and set up the controller inputs. The Inputs folder links are:

• Analog Input 1

• Analog Input 2 (dual channel model only)

• Digital Input 3 or 4

• Current Transformer Input 3 or 4

Note: You may not see all of the Inputs folder links listed above. Your model number determines what input parameters appear.

Analog Input Configuration Page

Inputs 1 and 2 are analog inputs. Analog inputs are used to measure process variables like temperature, humid-

ity, pressure, flow, level, etc. The universal analog inputs accept most common thermocouple types, 100Ω Platinum

RTD (DIN curve) and process input signals. Input 2 only appears on dual channel models.

You can see and change all of the parameters on the Analog Input Configuration page. Only those that apply to

the sensor type selected will be relevant. For example, you can set all of the process parameters even though you

have thermocouple enabled. Only parameters relating to thermocouples have any effect on the controller. If you

change the sensor type to process, those process parameter values previously entered are used.

Note: You must click Submit to send the new values to the Series PD.

Figure 29 — Analog Input Configuration Web Page Example

Note: Red tag arrows and tag numbers are links to item descriptions. Click on a red tag arrow or number to go to a description of the item.

Page 32

Watlow Series PD ■ 30 ■ Chapter 7 Configuration Page

Figure 30 — Analog Input Web Page Tag Descriptions

Tag # Analog Input

Configuration Parameters

Parameter Description

Analog Input

1. Sensor Type Selects the analog input sensor type. Off (disabled), thermocouple,

RTD, voltage process, current process or INFOSENSE PnP

Thermocouple Parameters

2. Thermocouple Type Selects the analog input thermocouple linearization. Type J, K, B,

T, E, N, C, D, PTII, R or S.

RTD Parameters

3. RTD Curve Sets the RTD calibration curve. DIN curve only.

Process Parameters

4. Process Precision Sets the decimal position for the process input. 0, 0.0, 0.00 or

0.000.

5. Process Units Selects the units label displayed on the web page. Up to four al-

pha- numeric characters.

6. Low Process Scale Sets the low scale value for the process input signal. For example,

if you want 4-20 mA to represent 0 to 100%RH, set low process

scale to 0.

7. High Process Scale Sets the high scale value for the process input signal. For exam-

ple, if you want 4-20 mA to represent 0 to 100%RH, set high

process scale to 100.

8. Low Voltage Scale Sets the low range value for the voltage input signal. For example,

if you need 1-5 Vdc, set low voltage scale to 1.

9. High Voltage Scale Sets the high range value for the voltage input signal. For exam-

ple, if you need 1-5 Vdc, set high voltage scale to 5.

10. Low Current Scale Sets the low range value for the current input signal. For exam-

ple, if you need 4-20 mA, set low current scale to 4.

11. High Current Scale Sets the high range value for the current input signal. For exam-

ple, if you need 4-20 mA, set high current scale to 20.

Temperature Process Value Configuration

12. Temperature Process

Value Units

Sets the temperature measurement units. Celcius or Fahrenheit.

13. Temperature Process

Value Precision

Selects the decimal location for temperature inputs. 0 or 0.0.

Input Filtering

14. Filter Method Selects the filtering action for the input signal. Off (disabled) or

First Order.

15. Filter Time Base Sets the time constant for the first order filter. 0.1 to 60.0 seconds.

Offsets

16. Single Offset Value Shifts the input signal up or down.

Page 33

Watlow Series PD ■ 31 ■ Chapter 7 Configuration Page

Digital Input Configuration Page

Inputs 3 and 4 can be ordered as digital inputs. The digital input accepts a contact closure or a dc voltage input,

and performs some function based upon the digital event input status. For example, when the digital event input is

low, switch to a different auto set point value. If the digital event input goes back high, switch back to the original

control auto set point value. See Features chapter.

You can see and change all of the parameters on the Digital Input Configuration page. Only those that apply to

the function selected will be relevant. For example, you can set all of the Acknowledge Alarm parameters even

though you have Switch to Digital Set Point enabled. Only parameters relating to Switch to Digital Set Point have

any effect on the controller. If you change the function to Acknowledge Alarms, those alarm related parameters

previously entered are used.

Note: You must click Submit to send the new values to the Series PD.

Figure 31 — Digital Input Configuration Web Page Example

Note: Red tag arrows and tag numbers are links to item descriptions. Click on a red tag arrow or number to go to a description of the item.

Page 34

Watlow Series PD ■ 32 ■ Chapter 7 Configuration Page

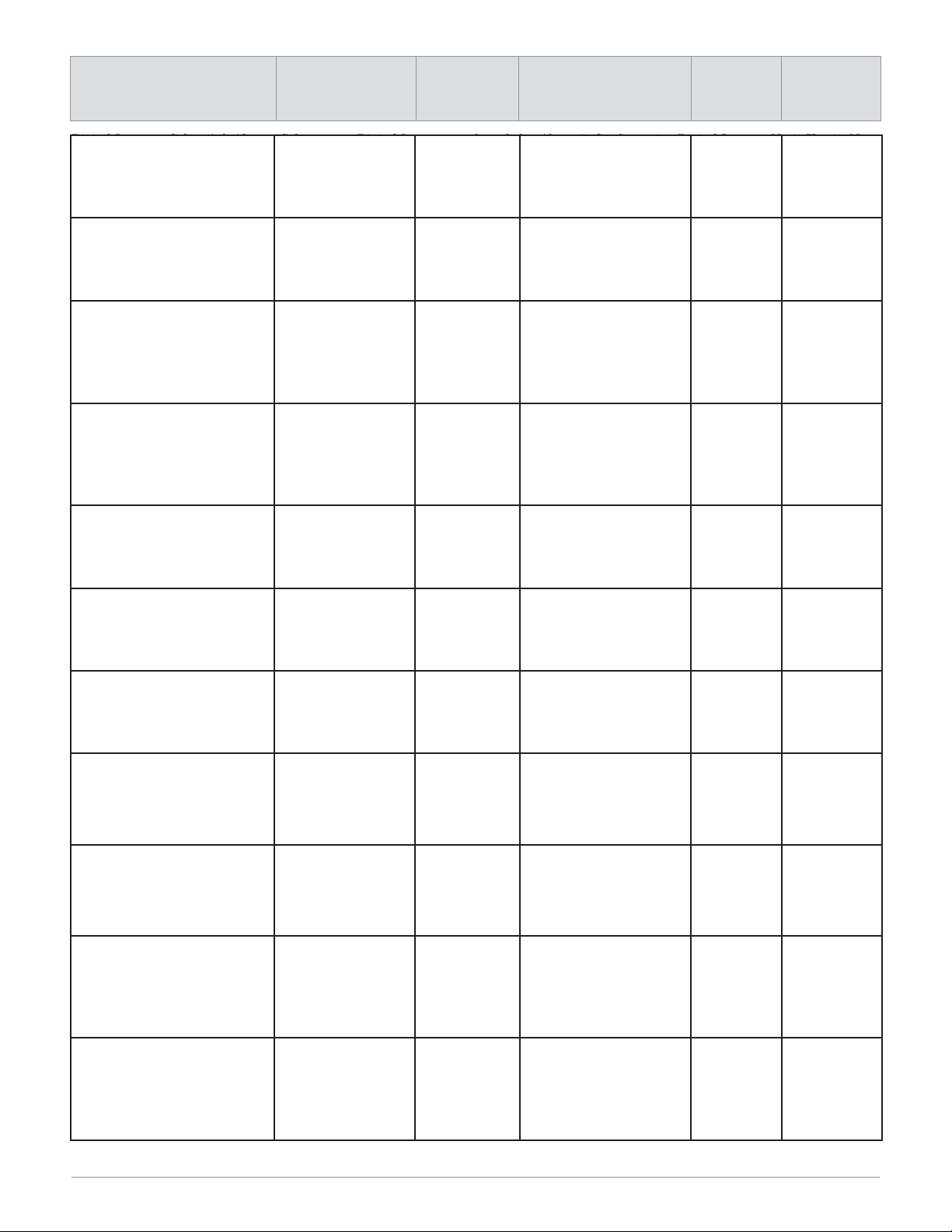

Figure 32 — Digital Input Web Page Tag Descriptions

Tag # Digital Input

Configuration Parameters

Parameter Description

1. Function Selects the digital input function when the digital input active

condition is satisfied. Off (disabled), Switch to Digital Set Point,

Acknowledge Alarm(s), Switch to Manual Control, Switch Control

Loop Off or Pause Data Logging.

2. Active State Selects the type of signal change required to trigger the digital in-

put. Low/Falling Edge or High/Rising Edge.

Acknowledge Alarm

3. Alarm Action Selects the alarm actions to be taken when the digital input active

state is satisfied. Silence, Acknowledge or Silence and Acknowledge.

4. Which Alarms Sets the alarms that are affected by the alarm action setting.

Alarm 1 through Alarm 8.

Switch to Manual Control

5. Which Loops Sets the Control Loop that switches to Manual Control when the

digital input active state is satisfied. Loop 1 or Loop 2.

Switch Control Loop Off

6. Which Loops Sets the Control Loop that switches to Off (disabled) when the

digital input active state is satisfied. Loop 1 or Loop 2.

Digital Set Point

7. Which Loop Sets the Control Loop that switches to the Digital Set Point when

the digital input active state is satisfied. Loop 1 or Loop 2.

8. Digital Set Point Sets the Digital Set Point used when the digital input active state

is satisfied. Value must be within the set point range limits.

Page 35

Watlow Series PD ■ 33 ■ Chapter 7 Configuration Page

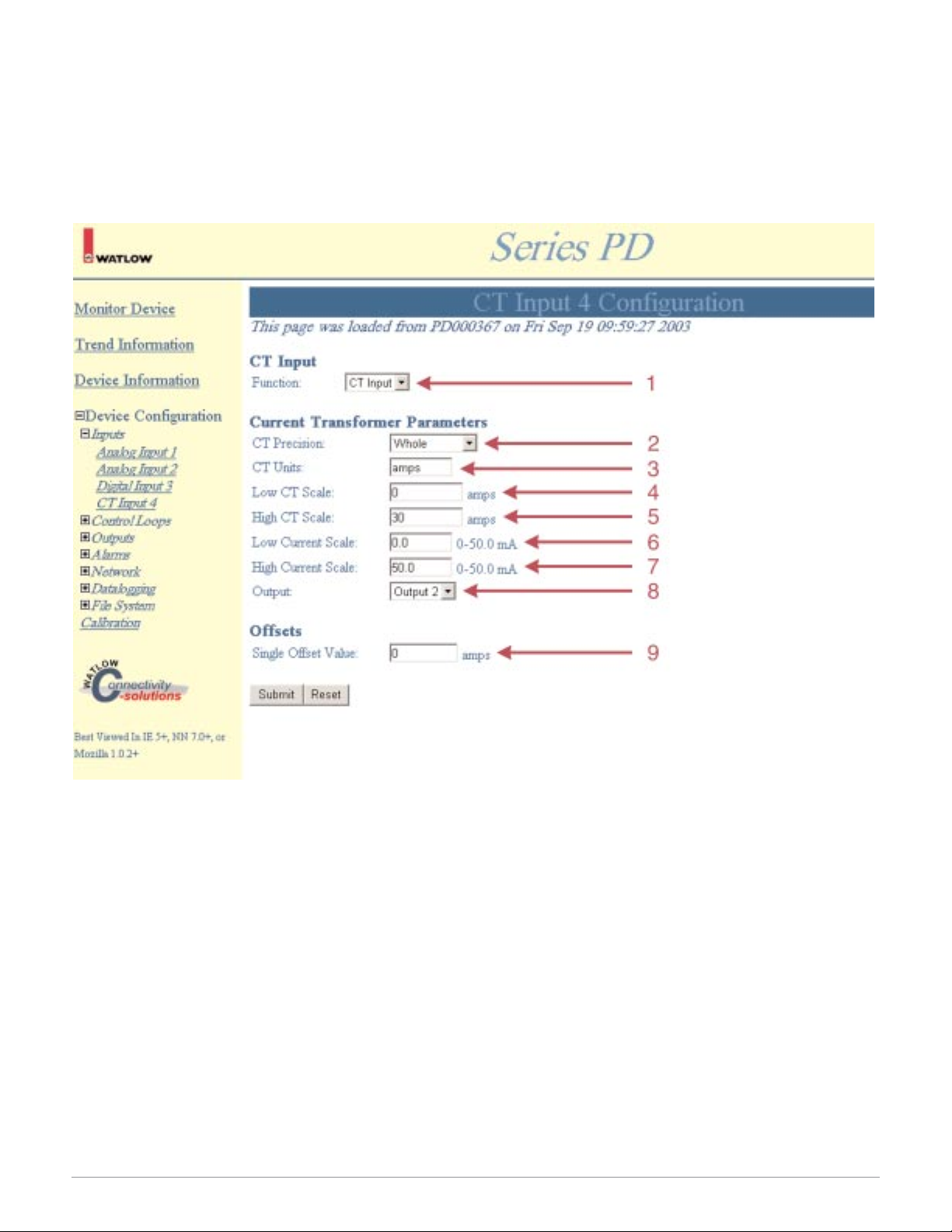

CT (current transformer) Input Configuration Page

The CT input accepts a signal from a CT monitoring heater current. The CT develops an output signal proportional to the current flowing through the wire passing through the center hole of the CT. You can assign one or

more alarm outputs to any CT input. The alarm can be configured to trip if the heater current gets too low or too

high. The CT input cannot be used with a process output. See Features chapter.

Note: You must click Submit to send the new values to the Series PD.

Figure 33 — CT(current transformer) Input Configuration Web Page Example

Note: Red tag arrows and tag numbers are links to item descriptions. Click on a red tag arrow or number to go to a description of the item.

Page 36

Watlow Series PD ■ 34 ■ Chapter 7 Configuration Page

Figure 34 — CT Input Web Page Tag Descriptions

Tag # CT Input

Configuration Parameters

Parameter Description

CT Input

1. Function Turn the CT input on or off.

Current Transformer Parameters

2. CT Precision Selects the decimal position for the CT input. 0, 0.0, 0.00 or 0.000.

3. CT Units Selects the CT units label displayed on the web page. Up to four

alphanumeric characters.

4. Low CT Scale Sets the low value displayed with the minimum input signal.

-30000 to 30000.

5. High CT Scale Sets the high value displayed with the maximum input signal.

-30000 to 30000.

6. Low Current Scale Sets the minimum input signal value from the CT. 0.0 to 50.0.

7. High Current Scale Sets the maximum input signal value from the CT. 0.0 to 50.0.

8. Output Selects the output being monitored by the CT. Any output type,

except a process output, can be assigned to a CT input. Mimimum

on time required for valid CT readings. See Features chapter.

Offsets

9. Single Offset Value Sets the offset value for the CT input signal. -9999 to 9999.

Page 37

Watlow Series PD ■ 35 ■ Chapter 7 Configuration Page

Control Loops

The Control Loops folder contains folders and links for configuring the control loops installed in the Series PD.

The controller leaves the factory with default settings on the Loop Setting page that disable all output functions. To

get the Series PD operational, you must go through the Loop Settings links and set up the control loops. The Loop

folder links are:

• Loop Settings

• Multiple PID Sets

Note: Loop 2 folder appears on dual channel models only.

Loop Settings

The Control Loop Configuration page sets the parameters for the control loops installed. The control loop functions, input failure parameters, set point limits, on/off parameters, autotune start/stop, PID parameters and ramp

to set point settings are configured on this page.

You can see and change all of the parameters on the Control Loop Configuration page. Only those that apply

will be relevant. For example, you can set the On/Off Hysteresis even though you have the Loop Algorithms set to

PID control. Only parameters relating to PID have any effect on the controller. If you change the Loop Algorithm to

On/Off, the hysteresis values previously entered are used.

Note: You must click Submit to send the new values to the Series PD.

Figure 35 — Control Loop Configuration Web Page Example

Note: Red tag arrows and tag numbers are links to item descriptions. Click on a red tag arrow or number to go to a description of the item.

Page 38

Watlow Series PD ■ 36 ■ Chapter 7 Configuration Page

Figure 36 — Control Loop Web Page Tag Descriptions

Tag # Control Loop

Configuration Parameters

Parameter Description

Control Loop

1. Loop Action Sets the Control Loop output action Off (disabled), heat, cool or

heat/cool.

2. Loop Heat (indirect) Algorithm Sets the Heat output method of control. PID or On/Off.

3. Loop Cool (direct) Algorithm Sets the Cool output method of control. PID or On/Off.

Input Failure Parameters

4. Failure Latching Sets the input sensor failure latching action. Latching or Non-

latching.

5. Output transition from

Auto Mode to:

Selects the controller’s output mode upon input failure. Off (disabled), Bumpless Power or Fixed Power.

6. Failure Fixed Power Sets the fixed output power level for fixed output power level upon

input failure. -100 to 100%.

Set Point Limits

7. Low Limit Sets the minimum value for auto set point adjustment. Range de-

pends upon sensor selected.

8. High Limit Sets the maximum value for auto set point adjustment. Range de-

pends upon sensor selected.

On/Off Parameters

9. Hysteresis Heat (indirect) Sets the switching differential when configured as On/Off method

of control.

10. Hysteresis Cool (direct) Sets the switching differential when configured as On/Off method

of control.

PID Parameters

11. Start Autotune Start an autotune.

12. Autotune Set Point Sets the autotune set point as a percentage of the auto set point.

50 to 150%.

13. PID Sets Sets the PID capability for single or multiple PID sets.

14. PID Set 1, Proportional Band Sets proportional band value for PID Set 1.

15. PID Set 1, Integral Sets integral value for PID Set 1.

16. PID Set 1, Derivative Sets derivative value for PID Set 1.

17. PID Set 1, Dead Band Sets dead band value for PID Set 1.

Ramp to Set Point Parameters

18. Ramp Action Selects the ramp to set point action for the single set point ramp

function. Off (disabled), Ramp on Power Up, Ramp on Set Point

Change, or Ramp on Power Up and Set Point Change.

19. Ramp Rate Sets the ramp rate for the ramp to set point function.

20. Ramp Rate Time Units Sets the ramp rate time units for the ramp to set point function.

Ramp time in degrees/units per hour or per minute.

Page 39

Watlow Series PD ■ 37 ■ Chapter 7 Configuration Page

Multiple PID Loop Configuration

The Multiple PID Loop Configuration page allows access to all of the PID sets for each loop available. You can

see and change all of the parameters on the Multiple PID Loop Configuration page, but only those that apply will

be relevant.

For example, you can set the Cool PID values even though the Series PD is set for heat PID control. Only parameters relating to heat PID values have any effect on the controller. If you change the Loop Action to Heat/Cool,

the cool PID values previously entered are used.

Note: Multiple PID Loop 2 Configuration appears on dual channel models only.

Note: You must click Submit to send the new values to the Series PD.

Figure 37 — Multiple PID Loop Configuration Web Page Example

Note: Red tag arrows and tag numbers are links to item descriptions. Click on a red tag arrow or number to go to a description of the item.

Page 40

Watlow Series PD ■ 38 ■ Chapter 7 Configuration Page

Figure 38 — Multiple PID Loop Web Page Tag Descriptions

Tag # Multiple PID Loop

Configuration Parameters

Parameter Description

1. Cross Over Source Sets the source that triggers switching PID sets. Process or Set

Point.

PID Set No. 1 - Prop Band

2. Heat (indirect) Sets the proportional band value for the heat outputs.

3. Cool (direct) Sets the proportional band value for the cool outputs.

PID Set No. 1 - Integral

4. Heat (indirect) Sets the integral value for the heat outputs.

5. Cool (direct) Sets the integral value for the cool outputs.

PID Set No. 1 - Derivative

6. Heat (indirect) Sets the derivative value for the heat outputs.

7. Cool (direct) Sets the derivative value for the cool outputs.

PID Set No. 1 - Dead Band

8. Heat (indirect) Sets the offset value of the heating proportional band from the set

point.

9. Cool (direct) Sets the offset value of the cooling proportional band from the set

point.

PID Set No. 1 - Cross Over Point

10. Cross Over Point Sets the process or set point value where the PID sets cross over.

Greater than or equal to this value activates this PID set. Must be

within set point range limits.

Page 41

Watlow Series PD ■ 39 ■ Chapter 7 Configuration Page

Outputs

The Outputs folder contains links for configuring the outputs installed in the Series PD. The controller leaves

the factory with default settings on the Output pages that disable all output functions. To get the Series PD operational, you must go through the Output links and set up the outputs. The Outputs folder links are:

• Outputs 1

• Outputs 2

• Outputs 3

• Outputs 4

Process Output Configuration Page

The Process Output Configuration pages set the parameters for the process outputs installed. Outputs can be

configured as control outputs, event (alarm) outputs or retransmit outputs. The Process Output Configuration page

is shown below.

You can see and change all of the parameters on the Output Configuration page. Only those that apply will be

relevant. For example, you can set the Retransmit Parameters even though you have the Control Function set to

Control. Only parameters relating to control outputs have any effect on the controller. If you change the Output

Function to Retransmit, the Retransmit Parameters previously entered are used.

Note: You must click Submit to send the new values to the Series PD.

Figure 39 — Process Output Configuration Web Page Example

Note: Red tag arrows and tag numbers are links to item descriptions. Click on a red tag arrow or number to go to a description of the item.

Page 42

Watlow Series PD ■ 40 ■ Chapter 7 Configuration Page

Figure 40 — Process Output Configuration Web Page Tag Descriptions

Tag # Process Output

Configuration Parameters

Parameter Description

Output

1. Function Selects the output function. Off (disabled), Control, Event or

Retransmit

Control Output Parameters

2. Output Direction Selects the output direction. Off (disabled), Heat or Cool

3. Loop Selects the control loop assigned to that output. Loop 1 or Loop 2.

Loop 2 available on dual channel model only.

4. Low Power Scale Sets the minimum output power level available for the output. 0 to

100%.

5. High Power Scale Sets the maximum output power level available for the output. 0 to

100%.

Process Parameters

6. Analog Signal Selects the type of analog signal for the output. Voltage or Current.

7. Low Voltage Scale Sets the minimum value for the voltage signal scaling. For exam-

ple, if you want a 1-5 Vdc signal, set Low Voltage Scale to 1.

8. High Voltage Scale Sets the maximum value for the voltage signal scaling. For exam-

ple, if you want a 1-5 Vdc signal, set Low Voltage Scale to 5.

9. Low Current Scale Sets the minimum value for the current signal scaling. For exam-

ple, if you want a 4-20 mA signal, set Low Current Scale to 4.