Page 1

WATLOW

Optimizing Your Process System

with the Series 988 Controller

AN APPLICATION GUIDE

THE WATLOW

FOR

SERIES 988 FAMILY

Page 2

Watlow Mission Statement

To Become the Preferred Source of

Industrial Heaters, Sensors and

Controls by Totally Satisfying Our

Customers with Superior Products,

Quick Delivery on Specials, as well as

Standards, and Intelligent Sales

Support.

Copyright Watlow Winona, Inc., © 1994, with all rights reserved.

Page 3

Introduction

Welcome to the Watlow Series 988 application guide: Optimizing Your Process

System with the WATLOW Series 988. This application guide describes all the

features of the Series 988 and how they can be applied to your system. In

addition, this guide will walk you through the process of determining the optimal Series 988 for your application. Once you have purchased the controller, the Series 988 Users Manual will guide you through installation and setup

of the controller.

Start with Chapter One of this book, where “test drives” show the thought

process used for determining the correct Series 988 feature set for a specific

application. Chapter Two consists of a glossary and a question-and-answer

section that provides more details to help choose the right control. Chapters

Three through Five describe the features of the controller with a sample application for each feature. Chapter Six outlines the controllers’ specifications.

Use this chapter to ensure that the controller interfaces correctly with other

system components. Finally, Chapter Seven walks you through the feature

set selection for your specific application. Once you have used the guide a few

times, you will be able to skip to Chapter Seven and use the previous chapters

for reference.

The purpose of this technical guide is to assist you in the system design process. The final responsibility for the system design must remain with the system design engineer.

Watlow manufactures heaters, sensors and controls. We can provide a complete thermal system. For more information concerning the Series 988, contact your local sales representative listed on the back cover. Literature on the

Series 988 includes:

• Series 988/989 Users Manual

• Calibrating Watlow Process Controls

• How to Use Data Communications with the Watlow Series 988/989

or How to Use Data Communications with the Watlow Process Controls

Disclaimer of Warranty

The information presented here is of a general nature. Because of the diversity of conditions and hazards under which control products may be applied

and because of the differences in components and methods of installation,

representation or warranty of any kind, express or implied, is hereby made,

that the applications discussed herein will be effective in any particular application or set of circumstances, or that additional or different precautions will

not be reasonably necessary for a particular application.

no

We will be pleased to consult with you regarding a specific application, upon

request.

Page 4

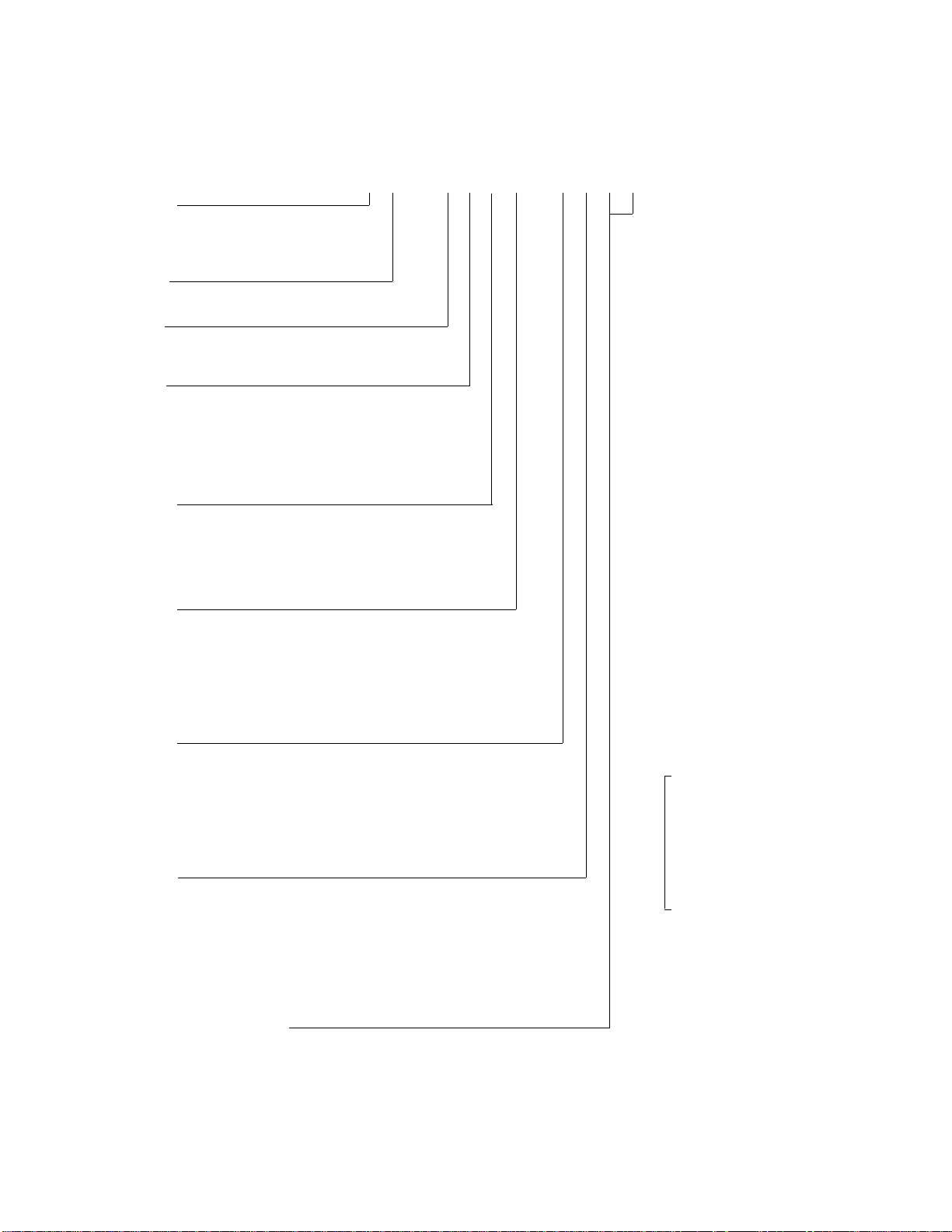

Table of Contents

Table of Contents

Watlow Mission

Introduction

Chapter 1 Test Drives 1.1

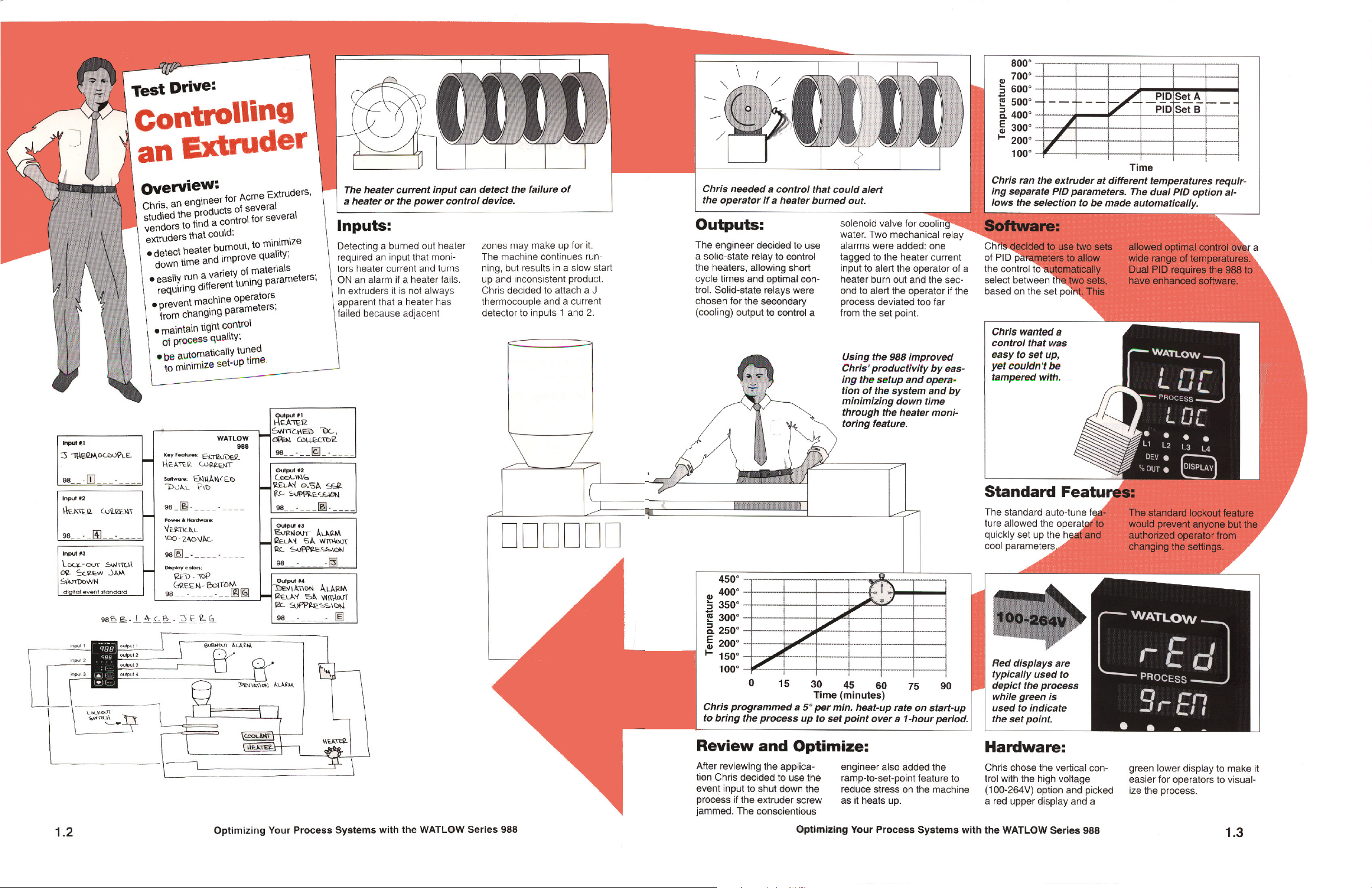

Controlling an Extruder 1.2

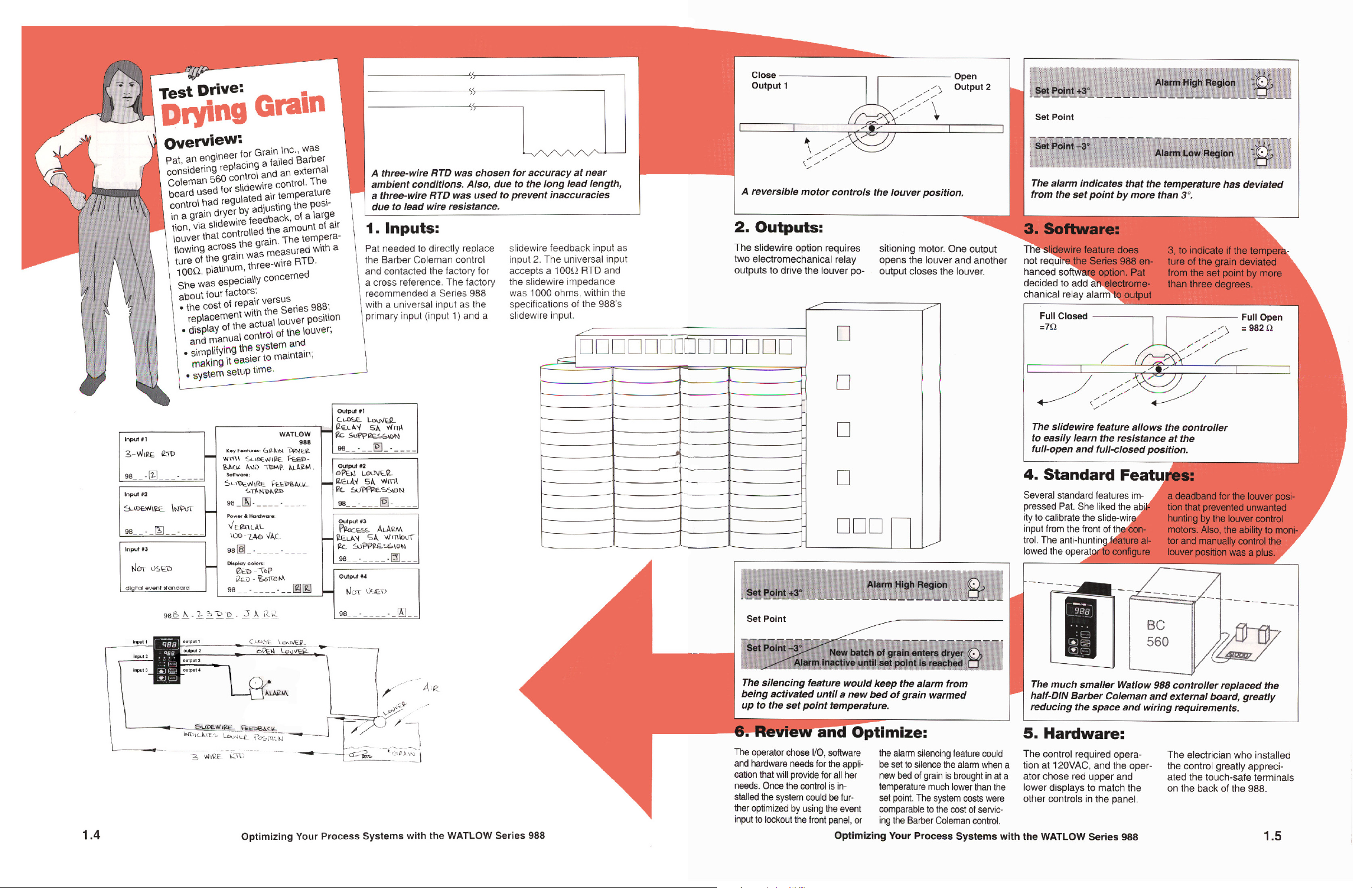

Drying Grain 1.4

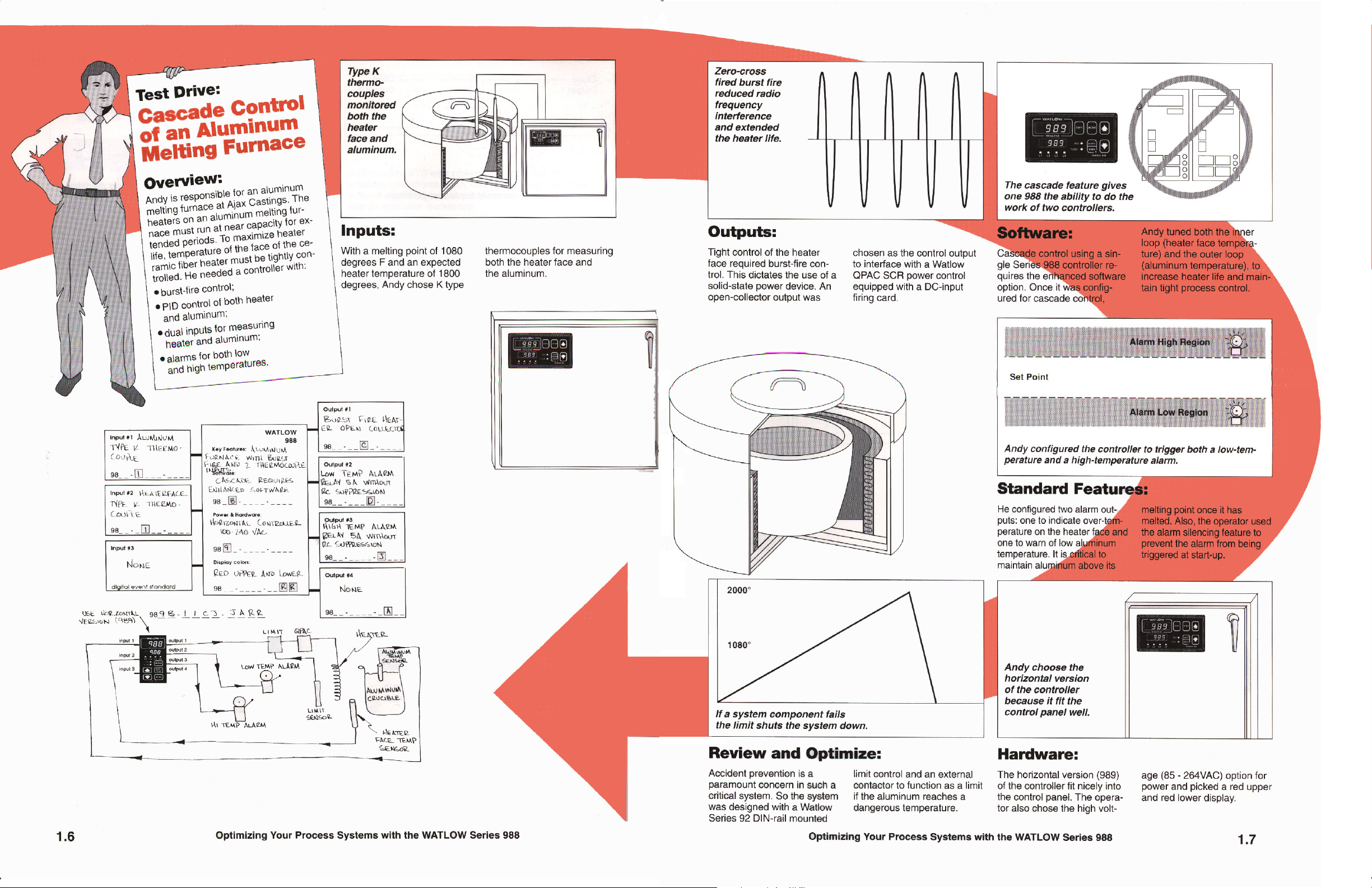

Melting Aluminum 1.6

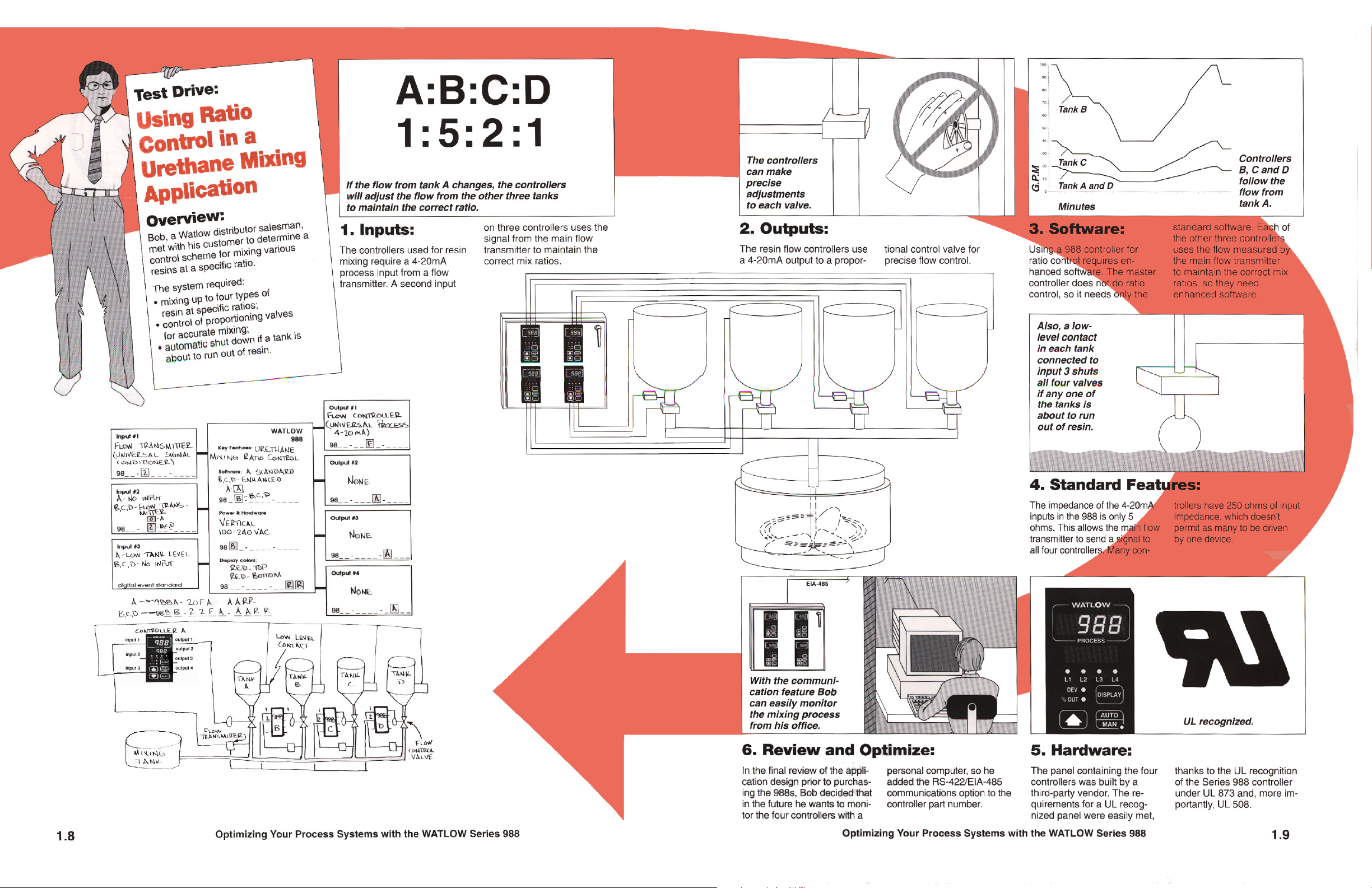

Mixing Urethane 1.8

Chapter 2 Basic Control Strategies and Terms 2.1

Glossary 2.2

Questions and Answers 2.5

Control Strategies 2.8

Chapter 3 General Software Features 3.1

Auto-tune 3.2

Burst fire 3.3

Communications 3.4

Dead band 3.5

Digital event 3.6

Heater current 3.7

Input filter 3.8

Input linearization 3.9

Ramp to set point 3.10

Remote set point 3.11

Retransmit (master/remote) 3.12

Slidewire feedback 3.13

Chapter 4 Enhanced Software Features 4.1

Cascade 4.2

Differential 4.4

Dual PID sets 4.5

Duplex 4.6

Ratio 4.7

Optimizing Your Process System with the WATLOW Series 988

Page 5

Table of Contents

Chapter 5 Standard Features 5.1

Alarms 5.2

Auto/Manual 5.4

Diagnostics 5.5

Input errors 5.6

Lockout 5.7

Transmitter power supply 5.8

Chapter 6 Specifications 6.1

Input Table 6.2

Output Table 6.3

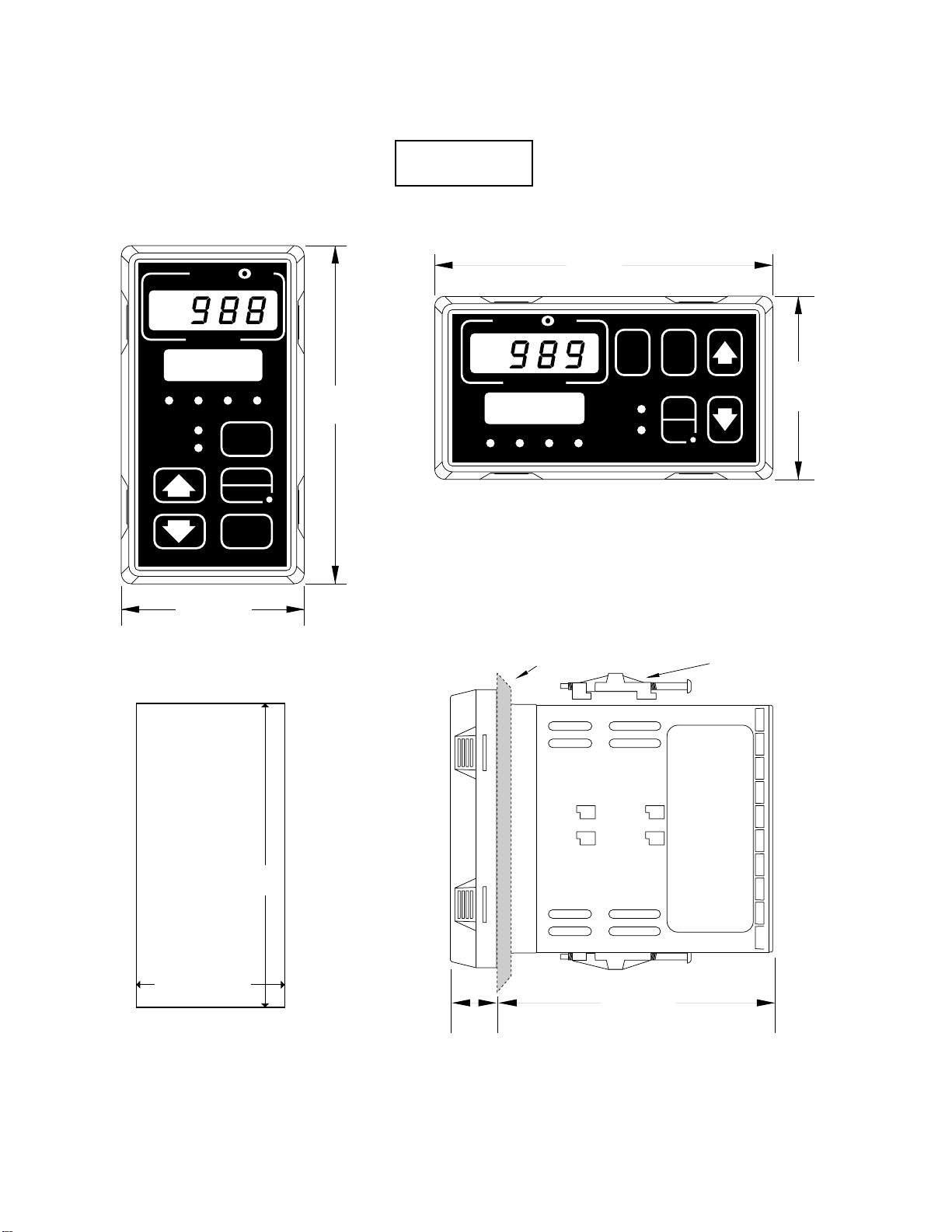

Dimensions 6.4

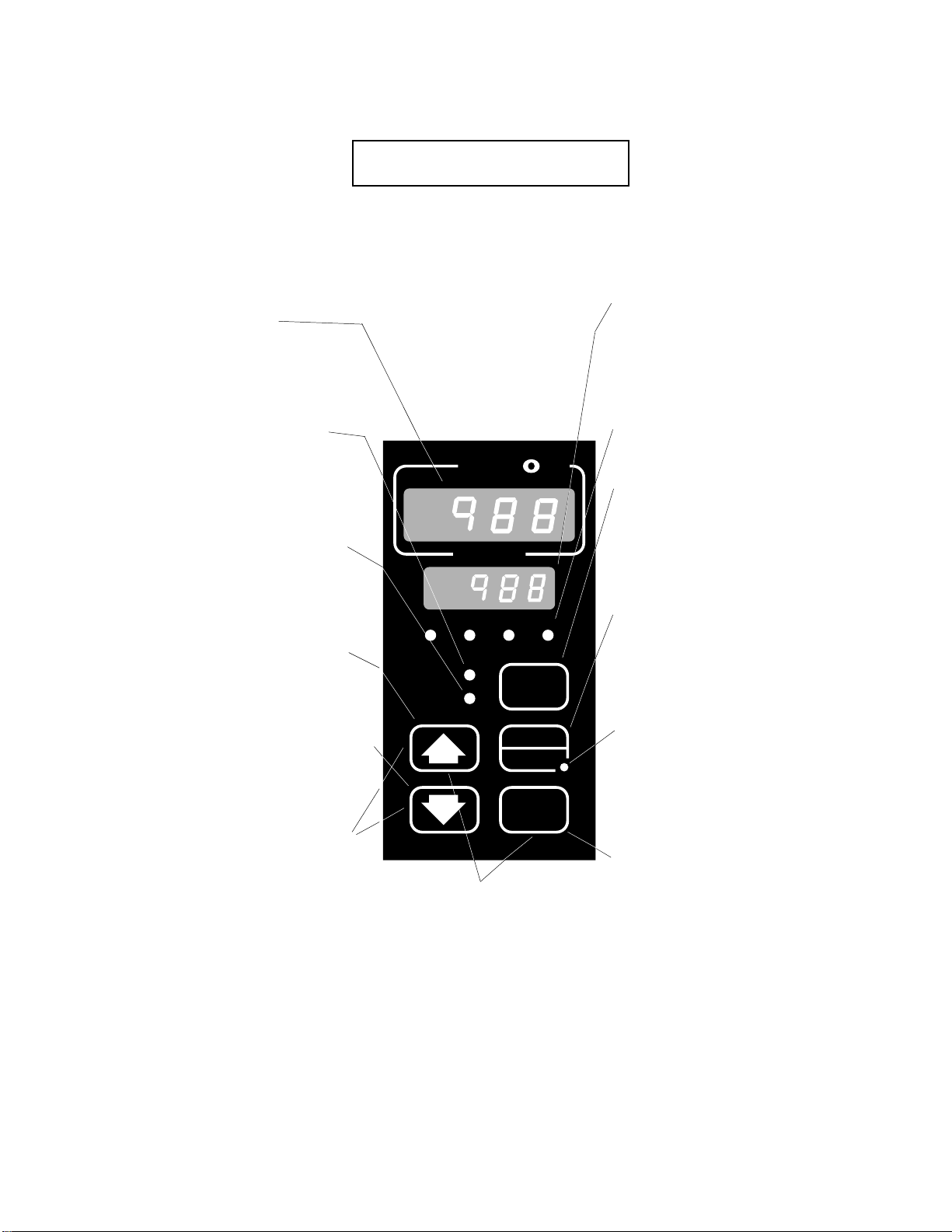

Displays and Keys Chart 6.5

Setup Requirements 6.6

User's Manual 6.7

Product Specifications 6.8

Warranty 6.9

Chapter 7 Select the 988 That Fits Your Application 7.1

Overview 7.2

Input 7.3

Output 7.4

Software 7.5

Standard Features 7.6

Hardware 7.7

Review and Optimize 7.8

Application Worksheet 7.10

Series 988 Model Number Worksheet 7.11

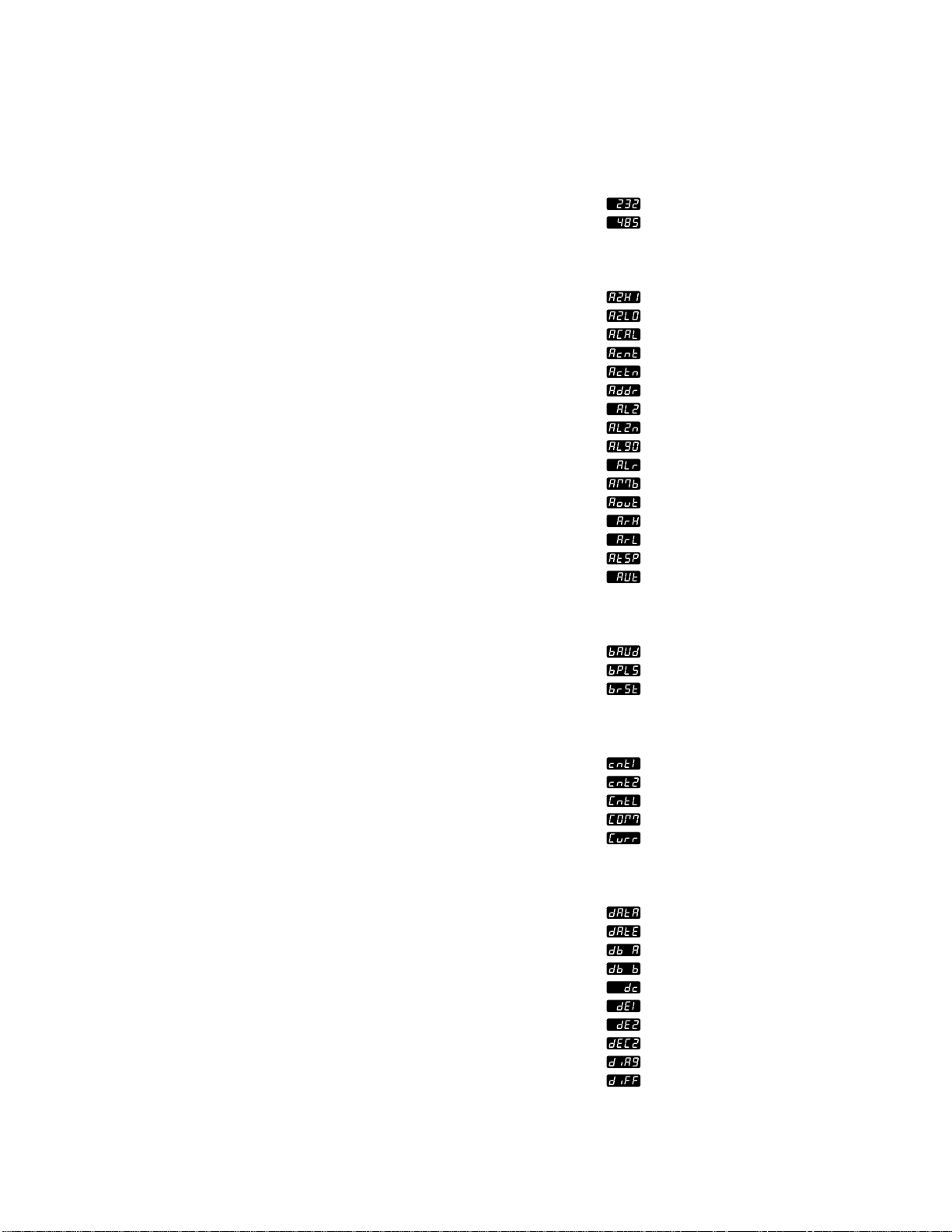

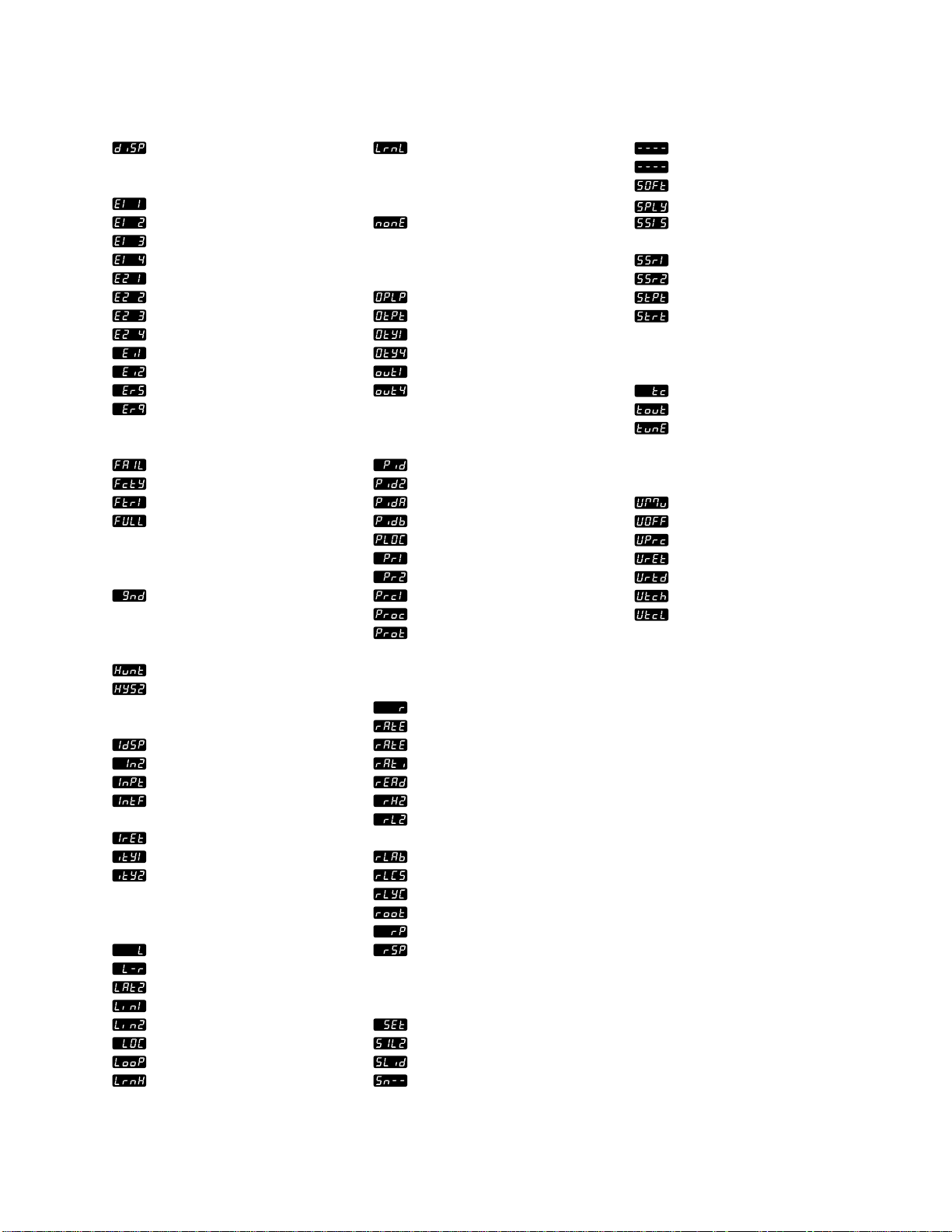

Index 8.1

Prompts, parameters and menus 8.4

Watlow Sales Offices back cover

Optimizing Your Process System with the WATLOW Series 988

Page 6

Test Drives

Chapter One

Test Drives

Controlling an Extruder 1.2

Drying Grain 1.4

Melting Aluminum 1.6

Mixing Urethane 1.8

How to use this chapter:

This chapter describes four actual applications in which processes are optimized

by using Watlow Series 988 controllers.

Optimizing Your Process System with the WATLOW Series 988

1.1

Page 7

Page 8

Page 9

Page 10

Page 11

Basic Control Strategies and Terms

Chapter Two

Basic Control Strategies and Terms

Control Strategies 2.2

Questions and Answers 2.5

Glossary 2.8

How to use this chapter:

This chapter explains control terms and

strategies, especially as they apply to the

Watlow Series 988 family of controllers.

It will help you identify issues specific to

your application, and allow you to implement the Series 988 controller in the

most cost effective manner, giving you

optimal control of your specific system.

Many of the decisions for system components are limited by factors not associated with the Series 988. The strategy

presented here is designed to get you

thinking of all the different parameters

associated with your system and how the

Series 988 fits in.

Optimizing Your Process System with the WATLOW Series 988

2.1

Page 12

Basic Control Strategies and Terms

Control Strategies

Process Control

Process controls are of two basic types: open

loop and closed-loop. An open-loop control

device has no self-correcting feedback information. The closed loop system uses feedback

information from a sensor to adjust the system.

As the process changes, the feedback loop

provides up-to-date status information that the

controlling device uses to make self-correcting

adjustments. The closed-loop control device

provides much better process control.

Control Modes

A variety of control modes offer various degrees

of controllability. The most common modes are

on-off and PID control. The PID control category includes varying degrees of complexity

that provide accurate, stable control under a

variety of conditions.

ON/OFF Control

The operation of the ON/OFF control, as the

name implies, turns the output device full ON

or full OFF. Temperature or process sensitivity

(hysterisis) is designed into the control action

between the ON and OFF switching points to

prevent switching the output device ON and

OFF within a span that is too narrow. Switching repeatedly within such a narrow span will

create a condition of intermittent, rapid switching, known as output “chattering.” The process

is always controlled “about set point,” dictated

by the switching hysterisis of the ON/OFF

control. This form of control action further

dictates that there will always be a certain

amount of overshoot and undershoot. The

degree of overshoot and undershoot will be

dependent on the characteristics of the entire

system.

Time Proportioning

Time-proportioning control provides more

precise control of a process. A time-proportioning control operates in the same way as an ON/

OFF control, when the process is far enough

away from set point to be outside the proportional band. When the process approaches set

point and enters the proportional band, the

output device is switched ON and OFF at the

established cycle time. At the lower limit of the

band, the ON time is considerably greater than

the off time. As the process more closely

approaches set point, the ratio of ON to OFF

time changes: the amount of ON time decreases

as the OFF time increases. This change in

effective power to the load provides a throttlingback effect, resulting in less overshoot.

The ON and OFF cyclic action continues until a

stable relationship is achieved. At that time,

the system will be stabilized such that the

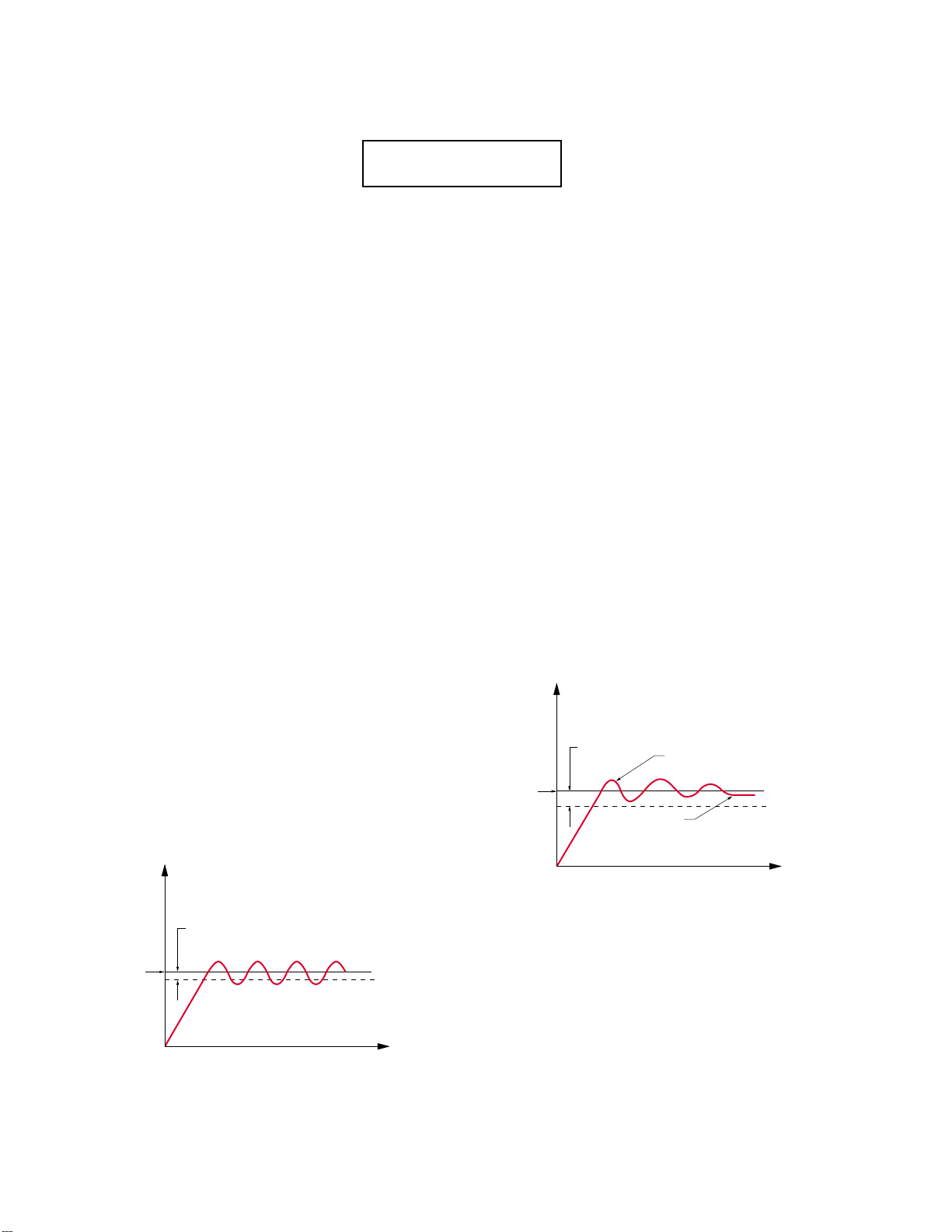

Time Proportioning

Temperature

Set

Point

Proportional

Band

Overshoot

Droop

On - Off

Switching

Sensitivity

Temperature

Set

Point

Time

Profile produced by ON-OFF control

Optimizing Your Process System with the WATLOW Series 9882.2

Time

Profile developed by proportioning control

process is controlled at a point below set point.

The process stabilizes with a resultant droop.

This condition will remain providing there are

no work-load changes in the system.

Integral

If the droop cannot be tolerated, there are ways

to compensate for it. Integral (automatic reset)

is an automatic adjustment to compensate for

Page 13

Basic Control Strategies and Terms

a droop condition before it exists. An integration function takes place that automatically

compensates for the difference between set

point and the actual process. This integration

automatically drives the process toward set

point. Integration action is prevented until the

process enters the proportional band. If it was

Time Proportioning

With Automatic Reset

Proportional

Temperature

Set

Point

Profile developed by a proportional plus

integral control

Band

Overshoot

Droop

Time

allowed to take place at any point, it would

cause a condition of extreme overshoot. This

function of eliminating the integration outside

of the proportional band is referred to as “antireset windup.”

Derivative

As all of the graphs have illustrated, overshoot

occurs with any of the previous control methods. Overshoot may be hazardous to certain

processes. It is preventable with a control

function known as “derivative” (rate).

Derivative is an anticipatory function in a

process control that measures the rate of

change of the process and forces the control

into a proportioning action on an accelerated

basis to slow that change. This action prevents

a large degree of overshoot on start-up and also

functions to prevent overshoot when system

disturbances would tend to drive the process

up or down. A proportioning control with

integral and derivative (PID) control provides

the type of control required for difficult processes with frequent system disturbances or

applications that need precision control.

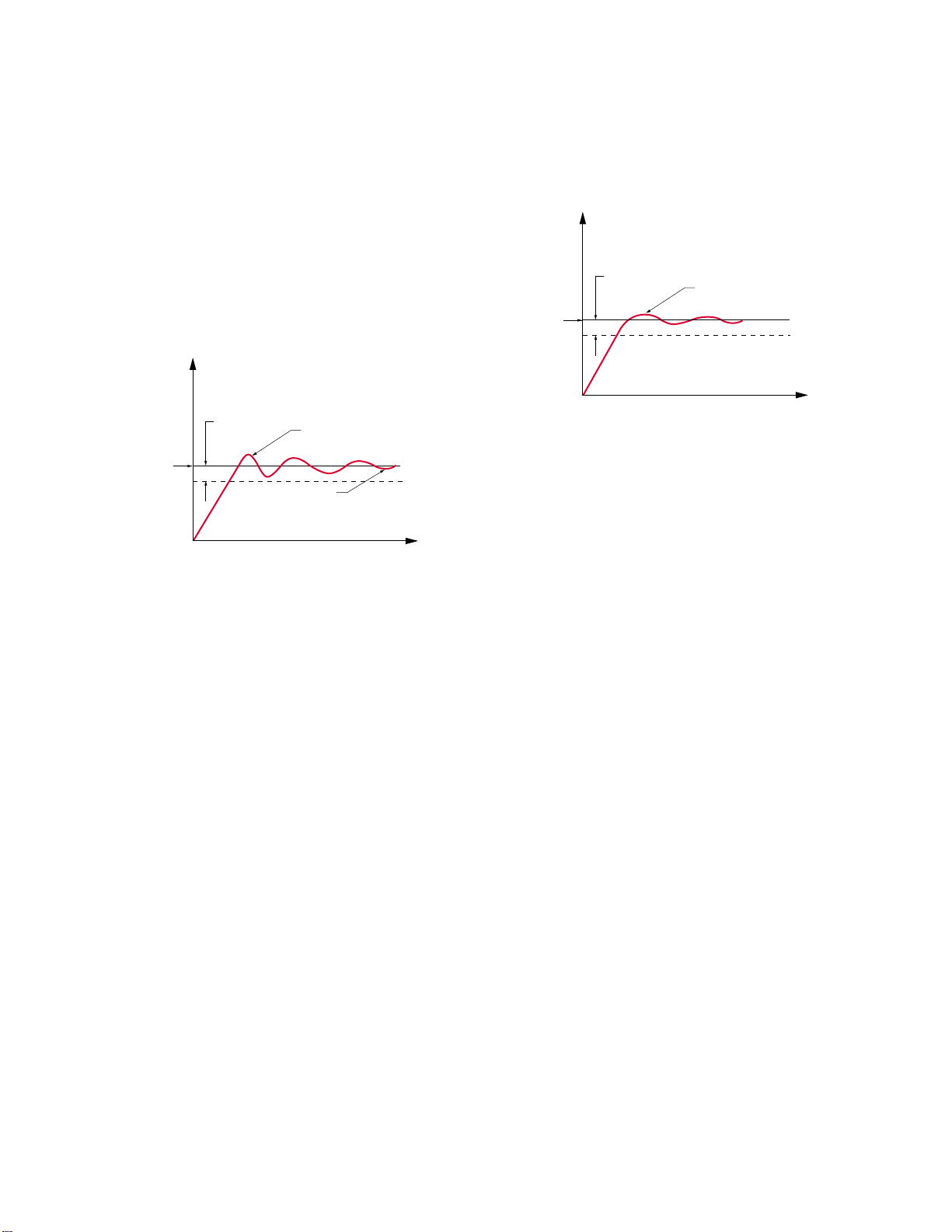

PID -Time Proportioning

With Auto Reset & Rate

Proportional

Temperature

Set

Point

Profile developed by a proportional plus

integral plus derivative (PID) control

Band

Reduced Overshoot

Time

Control System Tuning

In this phase of making the system work, we

will focus on the process controller as the

primary component of a closed-loop system

that must be adjusted for optimum performance. These adjustments provide a means to

compensate for system problems. For instance,

when the sensor cannot be placed in the most

desirable location because of physical limitations, a PID controller can compensate for the

sensor’s resulting thermal lag problem.

Tuning Methods

Process controls are tuned manually or automatically. Manual tuning requires manually

setting each of the controller’s operating parameters. Automatic tuning, or auto-tuning, is

accomplished by the 988’s digital, microprocessor-based, electronic circuitry. The controller

uses a program inside its memory that will

calculate the correct setting for each of the

controller parameters. For more information on

auto-tuning with the Series 988 refer to page

3.2.

Manual Tuning

The following steps are generally applicable to

most manually set process controllers. Please

take note of a few precautions:

• Take your time in tuning the control system.

If you do it right, it will work a long time

without further attention.

• Do not change more than one control adjustment at a time, allowing the system to settle

Optimizing Your Process System with the WATLOW Series 988

2.3

Page 14

Basic Control Strategies and Terms

down to a state of equilibrium before making

another change.

• Remember that the time you need to spend

tuning the electronic controller system is

relative to the precision of control you need.

Proportional Band

The proportional band adjustment is the means

of selecting the response speed (gain) or sensitivity of a proportioned controller to achieve

stability in the system. The proportional band

— whether measured in degrees, percent of

range or other units — must be wider than the

natural oscillations of the system and yet not

wide enough to dampen the system response.

The time proportioning output must be set to

switch faster than the natural oscillation of the

system, sometimes called, “system cycle time.”

The tuning procedure is very simple, if you can

use a recorder to monitor the actual process

variable. If a recorder is not available, observe

the process response and record readings over

a defined time period.

If the system oscillates when the proportional

band is at its narrowest setting (not zero), the

adjustment of the proportional band should be

increased in small increments until the oscillation stops. Because the proportional band has

been tuned (adjusted) to have the controller

seek stability of the system, very often an offset

(droop) from the set point occurs. At this point

in tuning the system, the process variable

should be in a state of equilibrium, but not

right on the desired set point.

Integral (Reset)

The reset adjustment is tuned at this point to

correct for the droop caused by the proportional output. While it does automatically

correct for offset errors, automatic reset has to

be tuned to each system. Each system has its

own characteristic response time (system cycle

time), thus, the auto reset time constant

(repeats per minute) must be tuned to match

the overall system response time.

small increments, allowing the system to settle

down (stabilize) before making additional

changes, until the system just starts to oscillate. Then back the setting off enough to reestablish system equilibrium.

Derivative (Rate)

Rate is the last control parameter adjustment

to be made. Rate’s function is to reduce or

eliminate overshoot (excursions above or below

set point). It has a time base (measured in

minutes) that must be tuned to work with the

overall system response time (system cycle

time). The initial setting for rate should be at

the smallest integer of minutes possible (least

corrective action). Increase the integer in small

increment, then after each adjustment increase

the set point moderately. Observe the approach

of the actual process to set point. If it overshoots, continue to increase the rate integer in

small increments. Then increase the set point

moderately until optimum approach to set

point is achieved. If at some point the system

becomes very sluggish or cannot reach the new

set point at all, too much rate (corrective

action) has been adjusted into the control

system. To reduce this “damping” effect,

decrease the number of minutes of rate.

Recommended Tuning Reference

There are many reference books on the art of

tuning electronic controllers to the systems

they control. If you are not an instrument

technician qualified to tune thermal systems,

we suggest that you become familiar with the

following reference before attempting to tune

your system:

Tuning of Industrial Control Systems

by Armando B. Corripio

Published by the Instrument Society of America

(ISA)

Member $48.00, list $60.00 (approx.).

Phone: (919) 549-8411

Initially auto reset should be set at the lowest

number of repeats per minute (least corrective

action). Increase the repeats per minute in

Optimizing Your Process System with the WATLOW Series 9882.4

Page 15

Basic Control Strategies and Terms

Questions and Answers

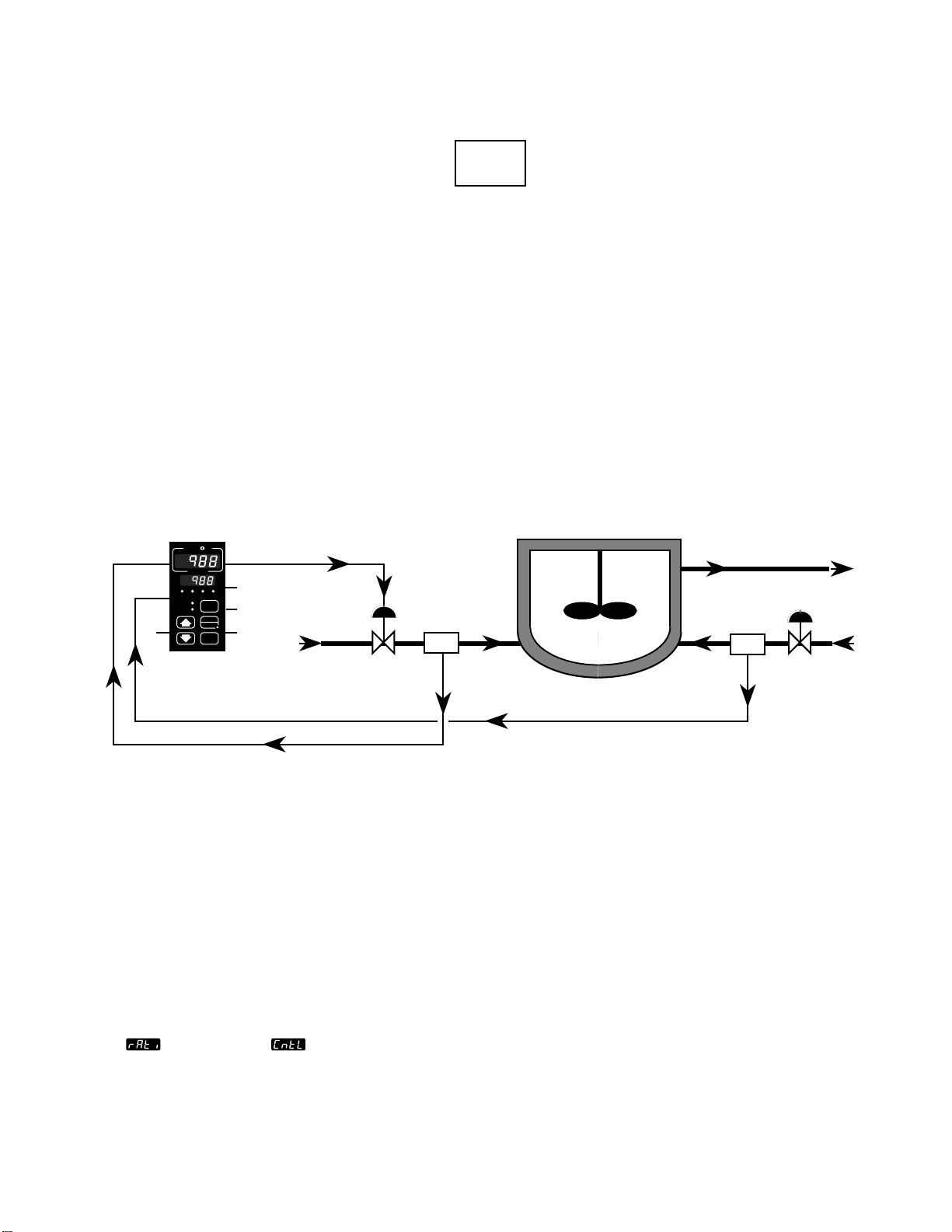

System Diagram

No matter what your application, you must

start with an accurate system diagram. A

blueprint of the system wiring is typically not a

faxable document. When consulting the factory,

it’s helpful to be able to fax a system diagram

similar to the hand drawings shown in the Test

Drives in Chapter One. This diagram should

include all inputs, outputs, the controller, the

load, any alarms and any connections to other

systems or equipment. This diagram should

show the expected signal types and ranges at

each interface point to allow you to properly

order and set up your 988 controller. For the

advanced user of the Series 988 this will be

second nature. For the less experienced operator, putting together a diagram including all

system components will allow a Watlow sales

rep or factory applications engineer to review

the system for correctness.

Inputs

The 988 controller accepts a wide variety of

input signals and ranges, covering most temperature and process applications. Ask yourself

the following questions about your inputs:

What accuracy is required for each input?

(page 6.8)

• RTD’s will provide the most accurate measurement in a temperature-related system.

• The accuracy of a process sensor for flow, level,

pressure, etc. will depend strictly on the sensor

manufacturers specifications.

• The Series 988 measures the input and updates

the output 10 times per second with one input.

With 2 inputs, each input is measured five

times per second.

What is the wire length required to reach

controller? (page 6.8)

• When designing a system using thermocouple

or RTD sensors, if the lead length is excessive,

errors may be introduced into the system. By

using a signal transmitter to convert the

thermocouple or RTD signal to a process signal

the errors can be avoided.

RTD sensor. However, it almost never pays to

spend less on a sensor, which is arguably the

most important part of the thermal system.

• Process sensors can vary widely in cost. Other

factors, such as accuracy, response time and

durability, must be weighed.

Will this be a grounded or ungrounded application? (page 5.8)

• Although inputs are electrically isolated from

outputs in the 988, you must determine if

other sources of ground loops in the system

may affect the sensor. This can occur, in the

Series 988, if there are two grounded inputs or

if an output is tied to an input, such as using a

transmitter power supply output to power a

thermocouple transmitter.

Is the process relatively fixed or widely varying — what is the range? (page 6.8)

• Make sure you check (and re-check) the ranges

of the input options available in the 988.

Although the 988 can operate outside the ANSI

ranges for specific thermocouples and RTD’s, it

is not recommended and will shorten the life of

the sensor.

Are there concerns over electrical noise

immunity?

• Although the Series 988 is thoroughly tested for

electrical noise immunity, it is paramount that

you follow good engineering practices when

designing the placement of the sensor and

power wires. Refer to the Series 988 Users

Manual and the Watlow Catalog.

Outputs

The outputs command the system to heat, cool,

turn ON and OFF, and also trigger other

actions in this system or related systems.

It is very important that you maintain total

control over the process. External limits or

other devices to disable the outputs can protect

system components and provide an added layer

of safety. Consider the following:

Is cost a factor in the sensor selection?

• Typically, a thermocouple costs less than an

Optimizing Your Process System with the WATLOW Series 988

How frequently will the output need to cycle

to control the process? (page 6.8)

2.5

Page 16

Basic Control Strategies and Terms

• What is frequent? In order to tightly control a

process, the more frequent the better. Unless

absolutely necessary, mechanical relays should

not be used as the control output. A typical

mechanical relay application cycles ON and

OFF 86,400 times over a period of one month

(30 second cycle time, 24 hours per day). The

mechanical relay option is only warranted for

100,000 cycles.

• With a solid-state output a variable-time-base

burst fire option can provide the tightest load

control. Make sure the power control is compatible with the burst-fire output. (page 3.3)

What actuator interfaces are required? (page

6.8)

• Typically the output of the Series 988 does not

directly control the load. Instead it acts as a

pilot-duty output interfacing with another

device that actually controls the load. If this is

the case in your application, make sure that

the output of the Series 988 is compatible with

the input of the external device.

What alarm or annunciation outputs are

required? (page 5.1)

• The alarm options in the Series 988 can be

used to alert an operator to a system malfunction. These outputs should not be used as

safety limits to protect system components or

personnel. A separate safety limit device should

be used in any system where damage or injury

could occur due to a system component failure.

How should the alarms operate? (page 5.1)

• The alarm options can be field-configured to

function in any fashion. A process alarm can

be used to warn the operator of impending

equipment damage. A deviation alarm can be

used to warn that the system is operating

outside of the desired specifications. Each

alarm can be set for latching or non-latching,

silencing and reverse or normal logic.

process output (4-20mA, 0-5VDC, etc.). Also, it

limits the minimum on-time of the output.

Does the process require a retransmit output?

(page 3.12)

• Output 3 can be used as either a 4-20 or 020mA output or as a 0-5, 1-5 or 0-10VDC

output to retransmit the process value of either

of the inputs or the set point value. It allows

the controller to function as a master controller

in a master-remote application or to retransmit

a process value to a chart recorder.

What types of monitoring of the outputs is

required? (page 3.4)

• The retransmit option is one way to monitor the

system status.

• A serial communications option can be used to

monitor and/or change all the parameters in

the controller. With the EIA-485 option up to

32 controllers can be monitored from a single

communications port on a personal computer,

over distances of 4000 feet. The RS-422 option

can address up to 10 controllers over 4000

feet, and the RS-232 option can address a

single control over a distance of 50 feet. Make

sure the computer or other monitoring device is

equipped with the correct serial communications card and that the baud rate and other

capabilities are compatable.

Controller Environment

There are several factors to consider concerning the environment that the Series 988 controller operates in:

What are the physical dimensions of the

enclosure? (page 6.4)

• The Series 988 family of controls has a behindpanel depth of 4.06 inches, allowing the control

to fit an enclosure with a depth of 6.0 inches.

When mounting more than one controller in a

panel we recommend a minimum spacing of

1.66 inches between controllers.

Should you monitor the load current? (page

3.7)

• While this option is available as an input, it is

important to note that this feature in the Series

988 is not currently available when using a

Optimizing Your Process System with the WATLOW Series 9882.6

What is the ambient temperature inside the

enclosure? (page 6.8)

• The Series 988 can operate in ambient temperatures as low as 32°F (0°C) and as high as

150°F (65°C). The enclosure requires a non-

Page 17

Basic Control Strategies and Terms

condensing atmosphere, because the vented

case is susceptible to dripping water. If necessary, include an enclosure heater in your

system to maintain the proper environment.

Is the front panel subject to spray or hosedown conditions? (page 6.8)

• The Series 988 has a NEMA 4X-rated front

panel. This rating allows the controller to be

hosed down directly without damaging the

controller. Two gaskets protect the controller:

one seals the bezel of the control while the

other seals the controller face plate and the

panel cutout. When installing the controller be

sure that these gaskets are not twisted.

What are the agency requirements for the

controller and the system? (page 6.8)

• The Series 988 has a UL 873 and UL 508

recognition. CSA recognition is pending. Also,

the NEMA 4X rating was certified independently by UL under UL 50X.

Controller Operation

Operation of the Series 988 can be broken

down into three concerns: setup; operation;

and maintenance. The questions you ask

yourself should examine each of these areas.

Does the system have any interactive process

variables? (Chapter 4)

• Interactive process variables include ratio,

differential or cascade control or slidewire

feedback of valve position. Also, heater current

measurements can be used to detect system

faults.

Is an event input useful in this application?

(page 3.6)

• Before finalizing the design check out this basic

option. The event input can expand the userfriendliness and/or security of your system.

Is ramp to set point required? On start up?

On set point change? (page 3.10)

• Many systems are susceptible to damage if the

process changes too rapidly. The ramp to set

point feature can minimize system stress.

How should the controller respond to an

error? (page 5.6)

• In the event of an error, system response is

critical. Some systems might require that the

control output turn full ON to provide cooling.

Other systems would require that the control

outputs be turned OFF. The design of some

systems might allow the control to continue

operating in the manual mode without operator

action. All of these options are available with

the Series 988.

Are you shipping products overseas? (page 2.3)

• In some countries and in certain markets in the

U.S. the default units may be either degrees C

or degrees F and the PID parameters might use

proportional (in percent of span), integral and

derivative or proportional (in degrees), reset

and rate. The 988 can switch between these

default sets to suit the user's preference.

What level of operator security do you need?

(page 5.7)

• The Series 988 provides numerous levels of

both software and hardware lockout. Refer to

page 4.5 for more information on lockout.

What do you do if a system component fails?

(page 5.5)

• When investigating a system failure, the Series

988’s Diagnostics menu can be used to monitor

inputs and selectively activate outputs. The

menu also shows the software revision and the

I/O types.

What about field calibration?

• All Watlow microprocessor-based controls can

be field calibrated with the right equipment.

The calibration manual for the Series 988

family of controllers is available upon request.

Putting It All Together

You should now have a good idea of what types

of questions to ask when designing your system

with the Series 988. We suggest that you read

through the rest of this chapter and Chapters

Three through Seven for more detailed information on the features available in the Series 988.

If you are already familiar with the 988, skip to

Chapter Seven to select the 988 that fits your

application.

Optimizing Your Process System with the WATLOW Series 988

2.7

Page 18

Basic Control Strategies and Terms

Glossary

annunciator — a device that uses pilot lamps to

indicate the former or existing condition of a

system being monitored.

ANSI — American National Standards Institute.

burst fire — output that switches full AC cycles

ON and OFF repeatedly. Zero-cross burst fire

switches only at the zero-voltage point of the

AC sine wave. Variable-time-base burst fire

would switch ON and OFF 30 times a second to

achieve a 50-percent power level with a 60cycle AC power supply. Also see “zero switching.”

calibration offset — adjustment to the actual

process input and to the process values the

Series 988 uses for display and control.

cascade — control algorithm in which the output

of an outer control loop is the set point for an

inner loop. The inner loop, in turn, determines

the control action.

closed loop — control system that uses a sens-

ing device for process variable feedback.

derivative — anticipatory action that senses the

rate of change of the process, and compensates

to minimize overshoot and undershoot. Also

see “rate.”

differential control — With enhanced software,

the Series 988 controller can control one

process in relation to the difference of a second

process. A set point is added to the measured

value of the second process. This sum is used

as the set point for the input 1 process value.

DIN — Deutsche Industrial Norms, a widely

recognized German standard for engineering

units.

droop — difference between the set point and

stabilized process value.

duplex control — With enhanced software,

duplex control splits a single process output

into two individual outputs. For example, a 420mA output is split into a 4-12mA direct

acting (cooling) output and a 12-20mA reverse

acting (heating) output, thus allowing one

control output to function as two.

cold junction — point of connection between

thermocouple metals and the electronic instrument.

cold junction compensation — electronic

means to compensate for the effective temperature at the cold junction.

current transformer — a transformer, designed

for measuring electrical current, with its

primary winding connected in series with a

circuit carrying the current to be measured.

dead band — The dead band setting determines

the amount of interaction between heat (reverse

acting) and cool (direct acting) control outputs.

default parameters — the parameters, or pro-

grammed instructions, permanently stored in

the microprocessor software.

Optimizing Your Process System with the WATLOW Series 9882.8

duty cycle — percentage of load-ON time relative

to total-cycle time.

external transmitter power supply — a DC

voltage source of power for external devices.

filter — as applied to the Series 988, a low-pass

filter designed to minimize display or process

input fluctuations.

form A — single-pole, single-throw relay that

only utilizes the normally open (N.O.) and

common contacts. These contacts close when

the relay coil is energized. The contacts open

when power is removed from the coil.

form B — single-pole, single-throw relay that

only utilizes the normally closed (N.C.) and

common contacts. These contacts will open

when the relay coil is energized. The contacts

will close when power is removed from the coil.

Page 19

Basic Control Strategies and Terms

form C — single-pole, double-throw relay that

utilizes the normally open (N.O.), normally

closed (N.C.) and common contacts. The user

has the option of wiring for a form A or form B

contact. Refer to the form A and form B above

for more information.

hunting — oscillation or fluctuation of the

process between the set point and process

variable.

hysteresis — in ON/OFF control, the process

change necessary to change the output from

full on to full off.

input linearization — For thermocouple and

RTD inputs, the process variable is automatically linearized. Certain flow transmitters

generate a non-linear signal corresponding to

the flow being measured. The square root of the

signal is calculated to generate a linear signal.

integral — control action that automatically

eliminates the offset, or “droop,” between the

set point and actual process value. Also see

“reset.”

isolation — Electrical separation of sensor from

high voltage circuitry. Allows use of grounded

or ungrounded sensing element.

JIS — Joint Industrial Standards. Also Japanese

Industrial Standards Committee (JISC). Establishes standards for equipment and components.

open loop — control system without sensory

feedback.

output — action in response to difference be-

tween the set point and process variable.

overshoot — condition in which the process

exceeds set point due to initial power up or

process changes.

P control — proportioning control.

PD control — proportioning control with deriva-

tive (rate) action.

PDR control — proportional derivative control

with manual reset is used in fast responding

systems where the reset causes instabilities.

With PDR control, an operator can enter a

manual reset value that will eliminate any

droop in the system. The option requires

enhanced software.

PI control — proportioning control with integral

(auto-reset) action.

PID control — proportioning control with inte-

gral (auto-reset) and derivative (rate) action.

process variable — regulated system parameter,

such as time, temperature, flow, humidity, etc.

proportional band — span of the process from

the set point within which time proportional

control action takes place.

linearization — the extraction of a linear signal

from the non-linear signal of a flow transmitter.

Also see “input linearization.”

NEMA 4X — a front-panel rating that certifies

the control as washdown capable and corrosion

resistant.

ON/OFF control — control of a process by

turning the output full ON below set point and

full off above set point.

Optimizing Your Process System with the WATLOW Series 988

proportioning control — See "time proportion-

ing control."

rate band —

where the rate (derivative) function begins. The

Series 988 rate band centers on the set point

and is twice the width of the proportional band.

ratio — application in which the flow of an

uncontrolled stream is measured and used to

maintain the flow of a controlled stream at a

ratio to the uncontrolled stream.

a thermal control band that defines

2.9

Page 20

Basic Control Strategies and Terms

reference junction — synonymous with cold

junction. Also see “cold junction.”

retransmit — an analog signal representing a

control variable, either the process values or

the set point values.

RTD — resistance temperature detector. Resistive

temperature-sensing device that displays a

positive temperature coefficient.

slidewire feedback — closed-loop, valve-actuator

control using a potentiometer to indicate valve

position.

switching sensitivity — in ON/OFF control, the

process value change necessary to change the

output from full on to full off.

thermal system — a regulated environment

consisting of a heat source, heat transfer

medium, sensing device and a process variable

control instrument.

thermocouple — temperature-sensing device

constructed of two dissimilar metals that

generates a measurable, predictable voltage

that corresponds to its temperature.

supply power to external signal conditioners,

transducers or transmitters. With internal DIP

switches, the user selects between 5, 12 or

20VDC at 30mA ratings.

zero-cross — Action that provides output switch-

ing only at the zero-voltage crossing points of

the AC sine wave. Also see “burst fire.”

thermocouple break protection — fail-safe

operation that assures output shutdown upon

an open thermocouple condition.

three-mode control — proportioning control

with integral (reset) and derivative (rate). Also

see “PID.”

time proportioning control — action that varies

the amount of on and off time when “close” to

the set point, i.e., in the proportional band.

This variance is proportional to the difference

between the set point and the actual process.

In other words, the amount of time the output

relay is energized depends on the system

process value.

transmitter power supply — When Option “T” is

ordered for output 2, 3 or 4, the Series 988 can

Optimizing Your Process System with the WATLOW Series 9882.10

Page 21

General Software Features

Chapter Three

General Software Features

Auto-tune 3.2

Burst fire 3.3

Communications 3.4

Dead band 3.5

Digital event 3.6

Heater current 3.7

Input filter 3.8

Input linearization 3.9

Ramp to set point 3.10

Remote set point 3.11

Retransmit (master/remote) 3.12

Slidewire feedback 3.13

How to use this chapter:

This chapter describes the software

features that are available in Watlow

Series 988 controllers. Enhanced software options provide additional features

that are described in Chapter Four.

3.1Optimizing Your Process System with the WATLOW Series 988

Page 22

General Software Features

TL

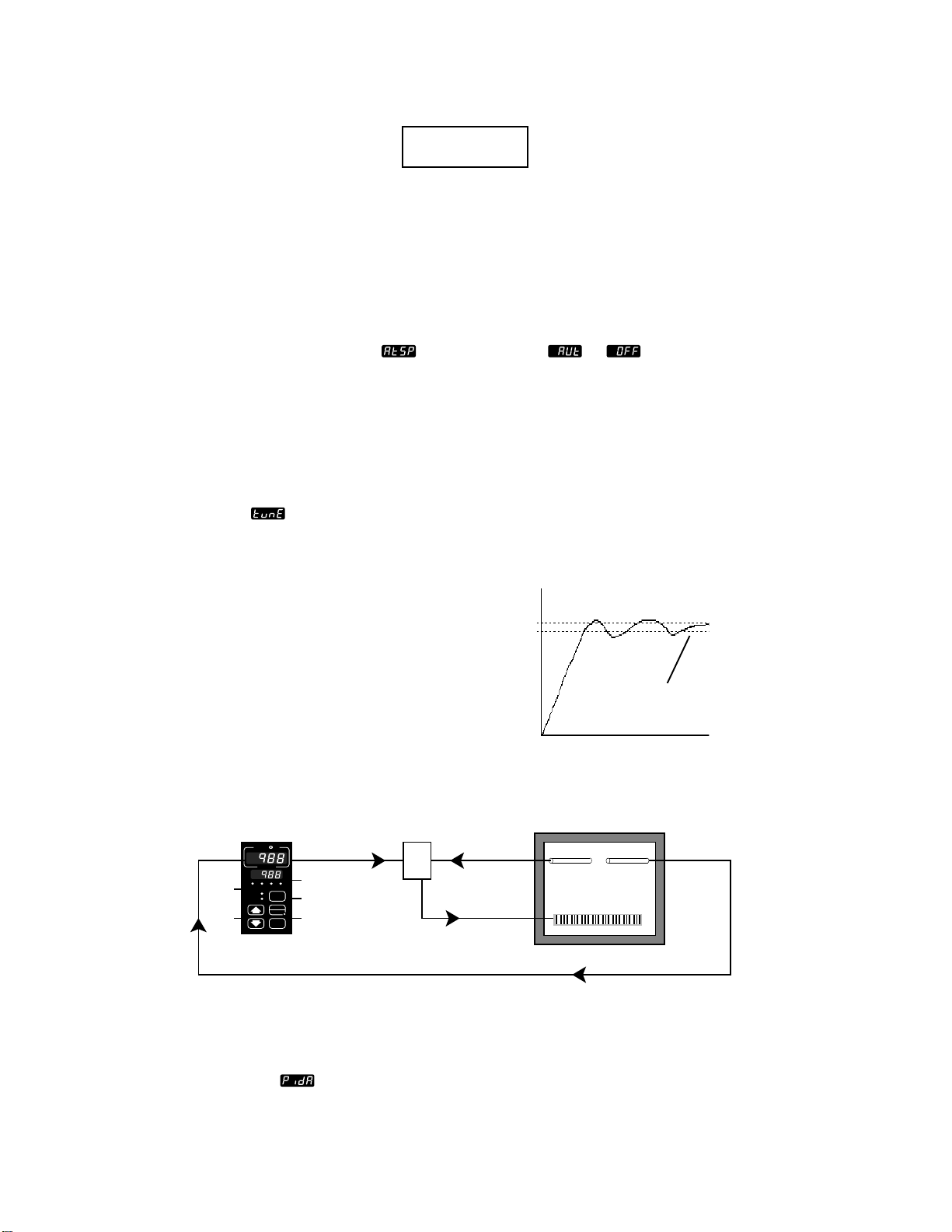

Overview:

The auto-tune feature allows the controller to

manipulate the process and calculate PID

values based on the process response. This

relieves the operator from the tedious task of

manually tuning the PID parameters to match

the characteristics of the thermal system.

Auto-tune

During an auto-tune the controller monitors

how fast the process increases and decreases,

and from this information calculates proportional band, reset and rate values and automatically enters them into non-volatile

memory.

The point at which the auto-tune takes place is

determined by the auto-tune set point

parameter. It is adjustable from 50 percent to

150 percent of the current set point, with 90

percent being the factory default setting. If the

auto-tune set point is 90 and the current

setpoint is 300 degrees, the control goes into

ON/OFF mode of control at 270 degrees (300

deg. x 0.9). The displayed setpoint is unchanged and the bottom display information

alternates with tune

at a one-second rate

until the auto-tune is completed. Any changes

to the set point during an auto-tune will cause

the auto-tune sequence to start over, based on

the new set point.

To abort an auto-tune, set the auto-tune

prompt

to or press the AUTO/MAN

key twice, or cycle the power OFF and ON. The

previous PID parameters will be restored.

Requirements

The Series 988 can be ordered with two complete sets of heat/cool PID sets. This requires

the enhanced software option. A single set of

PID parameters is available with the standard

software option.

350°

315°

auto-tune

complete

temperature →

time →

Oven

heater

input 1

A

TL

W

PROCESS

L1 L2 L3 L4

DEV

% OUT

SERIES 988

DISPLAY

AUTO

MODE

W

MAN

output 1

limit

limit

sensor

Sample Application:

In this example the oven needs to hold at 350 degrees F. To complete the

tuning sequence set the set point for 350 degrees and auto-tune by setting

the auto-tune prompt to

3.2

Optimizing Your Process System with the WATLOW Series 988

.

temperature

sensor

Page 23

General Software Features

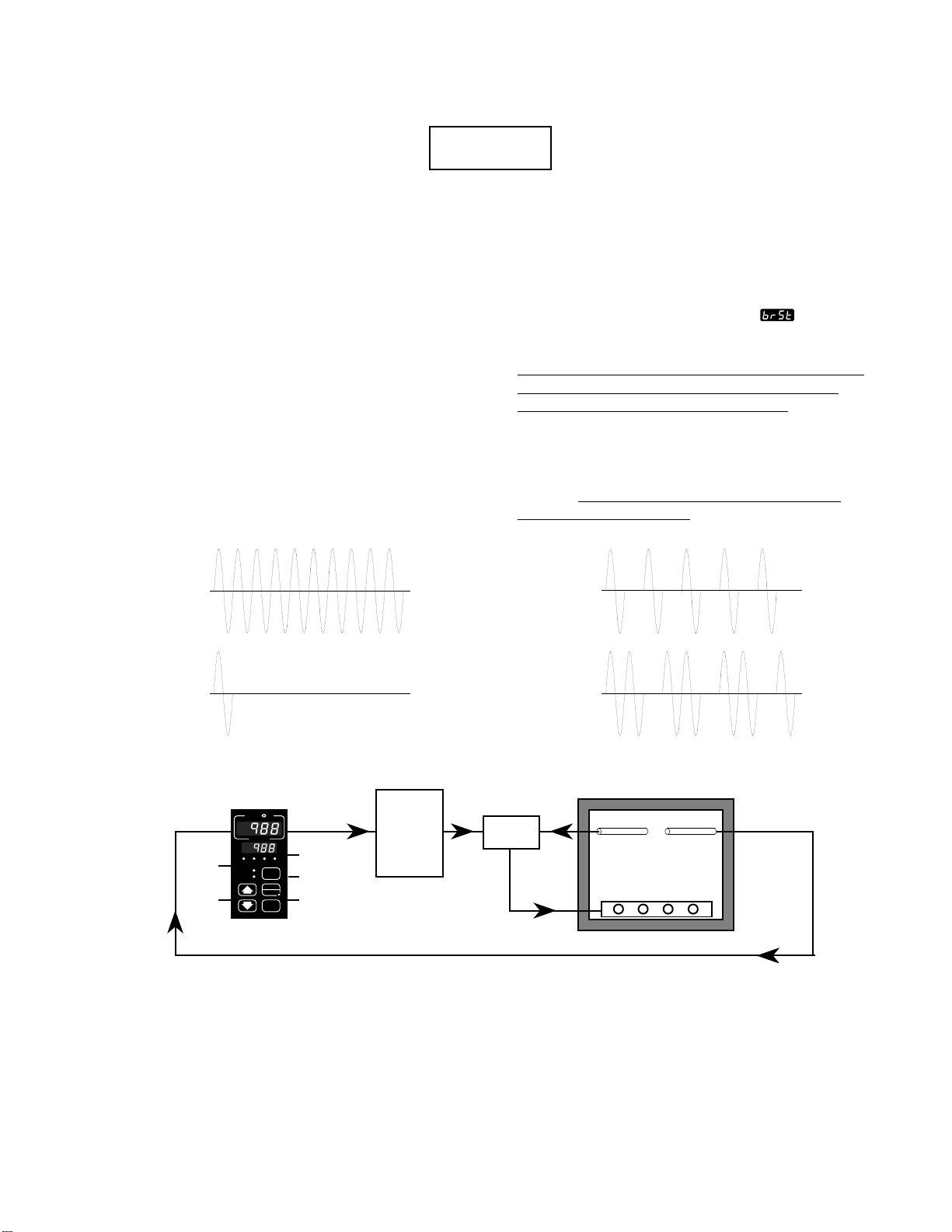

TL

Overview

Variable, time-base burst firing from the 988

provides a command signal to an SSR or SCR

firing card that translates into a burst of AC

cycles. The output is zero-cross fired and

always allows at least one AC cycle to pass

within the variable time base. The fact that we

are zero-cross switching the power device

means we enjoy the benefits of low radio

frequency (RFI) noise. Burst firing is the preferred mode to control resistive loads.

The burst fire time base in the 988 varies from

a maximum 1.66-second time base (1-percent

output) down to a 33.3-millisecond time base

(50-percent output). The examples below show

how the time base varies depending on the

percent output.

Burst Fire

Requirements

The 988 family has built in zero-cross detection

circuitry. Therefore special firing circuitry is

normally not required for triggering SCR’s. To

enable burst fire the 988 must have an open

collector or solid-state relay output. The feature

is enabled by selecting burst fire

cycle time prompt for the appropriate output.

You should note that the short time bases used

by burst fire makes it incompatible with the

heater current feature (see page 3.7). The

heater current option requires a minimum of

300 msec. ON-time to get a reading.

Only the 988 and 989 can use the burst fire

feature.

cannot use burst firing.

at the

The low-voltage units (986 and 987)

50% Output100% Output

10 ON, 0 OFF 1 ON, 1 0FF

10% Output

1 ON, 9 OFF 2 ON, 1 OFF

input 1

A

TL

W

PROCESS

L1 L2 L3 L4

DEV

% OUT

SERIES 988

W

DISPLAY

AUTO

MAN

MODE

output 1

QPAC

with

QCD

input

66% Output

Semiconductor Oven

limit

limit

sensor

Sample Application

The 988 is being used to control a heated platen in a semiconductor oven.

Previously it required a power control requiring a 4-20mA signal to implement

burst-fire control. We have replaced the power control with a Watlow Loyola

QPAC with a QCD card that accepts a signal directly from an open-collector

output of the 988. This gives smooth control at a lower overall system cost.

temperature

sensor

heated platen

3.3Optimizing Your Process System with the WATLOW Series 988

Page 24

General Software Features

TL

TL

TL

TL

TL

Communications

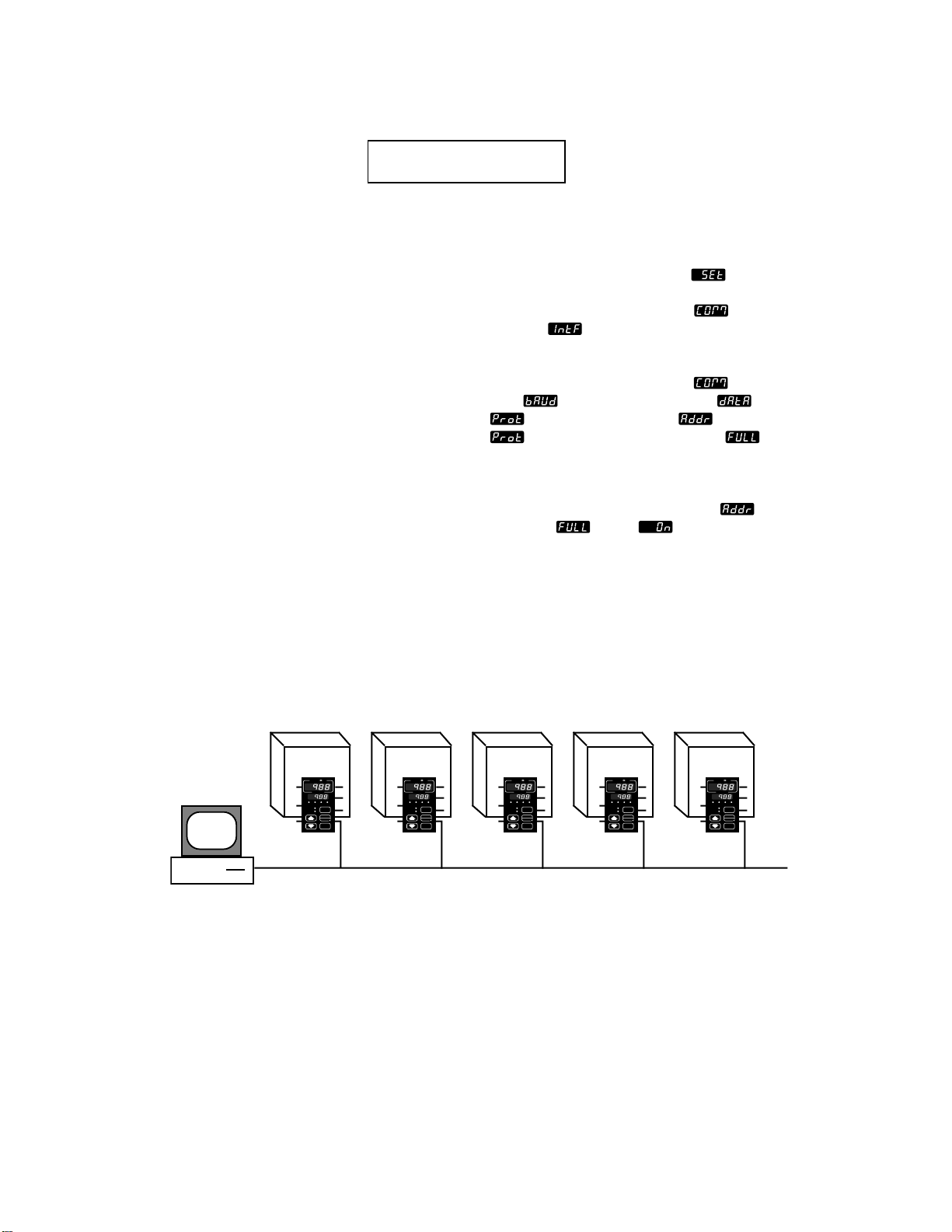

Overview

The serial communications feature allows the

Series 988 family to receive commands from

and transmit data to a master device, usually a

computer. Any function that can be performed

via the front panel, can also be accomplished

using the serial communications port, allowing

you to operate the controller from a computer

and to store process data on a computer.

The 988 is available with a choice of serial

hardware interfaces. An RS-232 interface

allows for one master (computer) and one

controller, with a maximum network length of

50 feet (15 meters).

The EIA-485/RS-422 option equips the controller for a multi-drop interface: up to 32 total

network devices with EIA-485 and up to 10

total network devices with RS-422. Each

controller will have its own unique address.

The total maximum network length is 4,000

feet (1,219 meters). These are isolated interfaces.

To select between EIA-485 or RS-422, enter the

setup prompts by holding the increment (uparrow) and decrement (down-arrow) keys

simultaneously until setup

appears in the

bottom display. Use the decrement key to select

the Communications menu

prompt

selects between 485 or 422.

. The interface

Other parameters that must be configured in

the Communications menu

rate

, data bits and parity , protocol

are the baud

, and device address . The protocol

prompt must be set to full (ANSI

X3.28 2.2-A3) if multiple devices are used with

the EIA-485 or RS-422 interface. If the full

protocol is selected, a device address must be

selected at the address prompt

232, full

or on (XON/XOFF) protocol

. For RS-

may be selected.

Requirements

Choose which interface your application will

use: RS-232 serial communications; EIA-485;

or RS-422 serial communications. The computer must have a compatible serial port.

Personal Computer

with RS-422 port

Test

Chamber 1

W

A

TL

W

PROCESS

L1 L2 L3 L4

DEV

DISPLAY

% OUT

AUTO

MAN

MODE

SERIES 988

Test

Chamber 2

W

A

TL

W

PROCESS

L1 L2 L3 L4

DEV

DISPLAY

% OUT

AUTO

MAN

MODE

SERIES 988

Test

Chamber 3

W

A

TL

W

PROCESS

L1 L2 L3 L4

DEV

DISPLAY

% OUT

AUTO

MAN

MODE

SERIES 988

Test

Chamber 4

W

A

TL

W

PROCESS

L1 L2 L3 L4

DEV

DISPLAY

% OUT

AUTO

MAN

MODE

SERIES 988

output 4 output 4 output 4 output 4 output 4

Sample Application

A test engineer uses 988’s to control the temperatures of several automated

test chambers. His computer is linked to the controllers through its RS-422

serial communications port. His computer program monitors the temperatures of the 988’s and initiates automatic test sequences when certain program parameters have been met. After completing a sequence, the computer

loads the next temperature to the controller. The computer periodically

interrogates each controller for its process temperature, set point and alarm

status. This information is stored on a disk to provide test verification data for

the completed products.

3.4

Optimizing Your Process System with the WATLOW Series 988

Test

Chamber 5

W

A

TL

W

PROCESS

L1 L2 L3 L4

DEV

DISPLAY

% OUT

AUTO

MAN

MODE

SERIES 988

Page 25

General Software Features

TL

Dead band

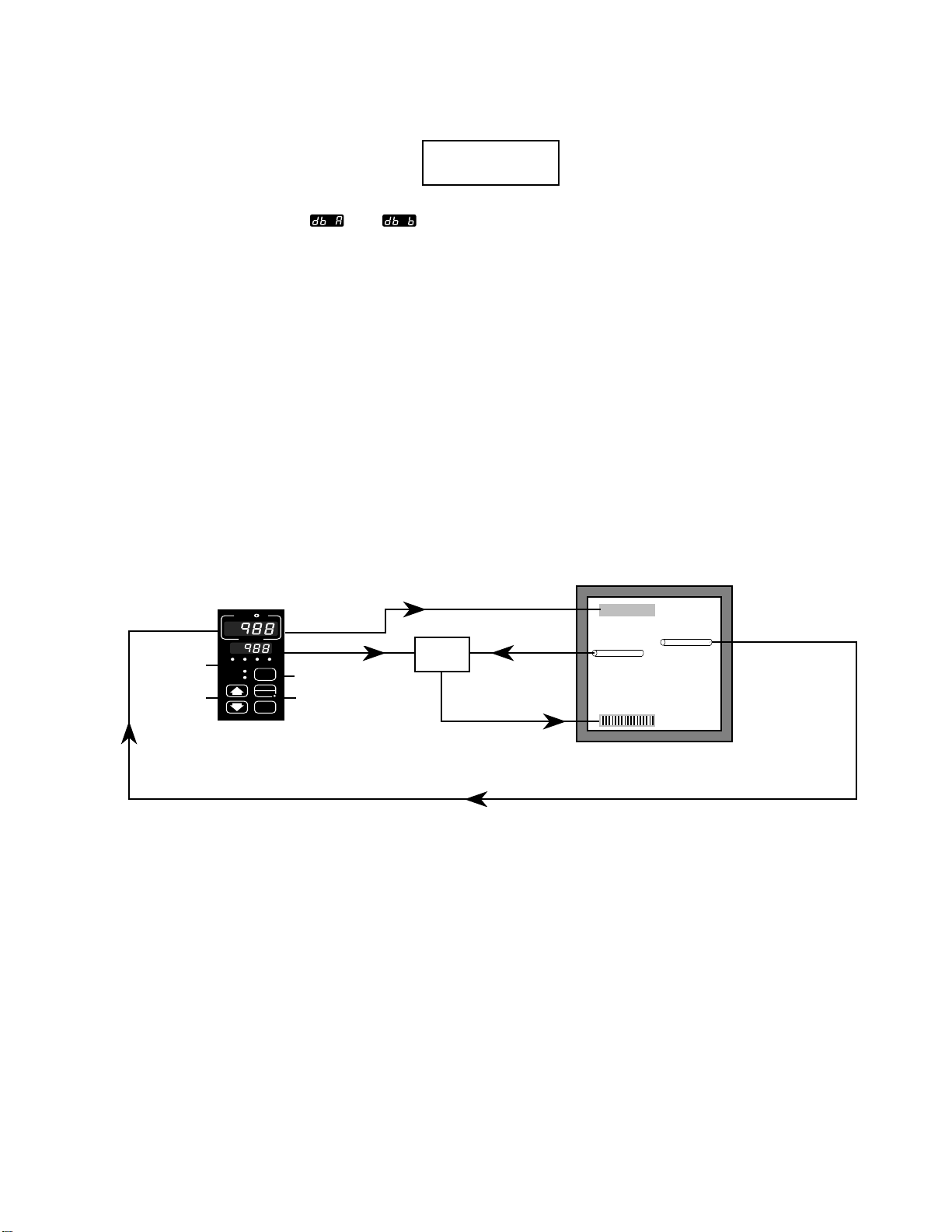

Overview

The dead band prompts,

located in the PID menus, determine the

amount of interaction between heat (reverse

acting) and cool (direct acting) control outputs.

The dead band directly offsets the target set

point of the cool control output.

With a positive dead band, both control outputs will never be on at the same time. With

the process in a positive dead band, the output

value is determined by adding the percent heat

output to the percent cool output and only

applying the result to the correct output —

cooling action if the sum is negative and

heating action if it is positive.

and ,

If the dead band is set to a negative value, the

heat and cool outputs can both be ON at the

same time.

Requirements

The dead band feature is standard on any

Series 988 controller with two control outputs.

The dead band prompts will appear if the

control outputs are configured for heat/cool or

cool/heat.

Environmental Chamber

W

A

TL

input 1

W

PROCESS

L1 L2 L3 L4

DEV

% OUT

SERIES 988

DISPLAY

AUTO

MAN

MODE

output 1

output 2

limit

chiller

limit

sensor

heater

Sample Application

An engineer for an environmental chamber manufacturer, who is designing the heating and cooling system for a new chamber, wants to minimize

the energy costs of operating the chamber. She has chosen the 988 and

will configure the heat and cool outputs with a positive dead band.

When the chamber temperature is near ambient the cooling and heating

systems had a tendency to buck one another, resulting in inefficient use

of energy. The engineer started with a dead band of five degrees, but in

the process of tuning the system for optimal control, the setting was

reduced to two degrees. This made the system more energy efficient and

reduced wear on the refrigeration system.

temperature sensor

3.5Optimizing Your Process System with the WATLOW Series 988

Page 26

General Software Features

TL

Digital Event

Overview

The digital event input options on the Series

988 controller allow the operator to select one

of several software functions with the close of a

customer-supplied switch or by a change in DC

voltage.

The list below outlines the functions that can

be controlled with the digital event input.

Idle set point

with the close of a switch, a second (idle) set

point.

Turn control outputs OFF

closed input to inhibit the control outputs.

Alarm reset

lets the operator select,

allows a

resets alarms from a remote

location with a momentary closed input.

Switch PID sets

selects between PID set

A or B (requires enhanced software).

Remote set point

switches between local

and remote set points.

Front panel lockout

locks out the front

panel keys to prevent tampering.

Control output action

switches the

control action of Output 1 from heating to

cooling, or vise versa.

Requirements

A single digital event input is standard on all

controls. A second digital input is available as

an option for Input 2.

Incubator

W

A

TL

input 1 output 1

W

PROCESS

L1 L2 L3 L4

DEV

DISPLAY

% OUT

AUTO

MAN

MODE

SERIES 988

input 3

(event input 1)

switch

limit

limit

sensor

heater

Sample Application

A manufacturing engineer is building an application that needs to switch to

an idle temperature at the end of a batch and maintain that temperature until

the next batch is loaded, with minimum operator interaction.

By connecting an external switch to the digital event input, he can select

either the operating temperature or the idle temperature with the flip of a

switch. The idle set point prompt is enabled by setting the event input 1

prompt

, in the Global menu, to the idle set point . The idle set point

value is accessed by pressing the MODE key from anywhere in the display

loop. When the switch closes, the lower display will indicate the idle set point,

and the controller will maintain this new set point.

temperature

sensor

3.6

Optimizing Your Process System with the WATLOW Series 988

Page 27

General Software Features

TL

Heater Current

Overview

The heater current feature measures and

responds to heater current in a system. This is

an ideal method for detecting heater loss in

multiple heater applications. The current is

measured when output 1 is ON. For instance, if

a system has five, 10-amp heaters, the heater

current input measures 50 amps regardless of

the percent output.

To view the heater current press the DISPLAY

key and advance to the process 2 prompt

The upper display indicates the last valid

current reading.

The input 2 prompt

menu

error detect

can be set to current or loop

. Current allows you to

monitor heater current and set alarm set

points based on high and low heater current

values. Alarms can only be configured as

process alarms (see Alarms, page 5.2). Setting

to loop error detect

and alarm functions, and also triggers an error

and shuts OFF all outputs if current is present

with output 1 OFF or when no current is

present and output 1 power is more than zero.

under the Input

enables monitoring

There are limits associated with this feature:

•

To obtain a reading, the output ON-time must

be a minimum of 0.3 seconds. To calculate

this, multiply the percent output by the cycle

time setting. Example: With 30-percent output

and a 2.0 second cycle time, the on-time would

be: 0.30 x 2.0 = 0.6 seconds. This would yield a

valid reading. If a valid reading is not possible,

the 988 will display the last valid reading.

•

It will not function with burst-fire outputs. This

.

does not necessarily apply to the loop error

detect feature. If enabled, any current detected

with no output triggers an error.

•

It will not function when the 988 has a process

output for output 1. A known cycle time is

required to detect the current. There is no cycle

time associated with process outputs.

The maximum signal the input can accept from

the current transformer secondary is 50mA.

So, you must calculate the output range of the

current transformer before wiring the system.

Requirements

Choose the heater current option for input 2.

Output 1 cannot be used as a process output.

Heater current monitors only output 1.

input 1

input 2

W

PROCESS

L1 L2 L3 L4

DEV

% OUT

SERIES 988

DISPLAY

AUTO

MAN

MODE

output 1

current

transformer

limit

Compression Molding Press

limit

sensor

10A heaters

temperature

sensor

W

A

TL

Sample Application

The Series 988 controls the lower platen of a compression molding press that contains five, 10ampere heaters. A 50A:50mA current transformer is used to monitor heater current.

Set the input 2 prompt

prompt

range high 2 =

The application uses a Watlow current transformer (CT) part# 16-0233, which has a maximum input of 50 amperes, which corresponds to a maximum output of 50mA.

range high 2 =

(maximum output from CT secondary (input))

50mA

to 50. Find the range high 2 value with the following equation:

(maximum CT primary current (load current))

(50Amps)

x 50mA

to current , the range low 2 prompt to 0 and the range high 2

x 50mA

Solving for rH2 gives you 50. This is the range high 2 setting.

3.7Optimizing Your Process System with the WATLOW Series 988

Page 28

General Software Features

Overview

In certain applications the process being

measured can be unstable, which makes it

difficult to control and also makes the constantly changing display difficult to read. The

Series 988 input filter can solve these problems

by smoothing out just the display or the display

and the input signal.

You can set a time constant, in seconds, for a

Input Filter

low-pass filter that will affect the display only,

or you can configure the option to filter the

input signal itself. Use this feature with caution, because a large time constant could hide

system upsets.

Requirements

This feature is standard on all Series 988

controllers.

input 1

input 2

A

TL

W

PROCESS

L1 L2 L3 L4

DEV

% OUT

SERIES 988

W

DISPLAY

AUTO

MAN

MODE

Display readings with input

filter off

%RH →

output 1

limit

Display readings with input

filter on

%RH →

time →time →

Humidity Chamber

limit

sensor

heater

temperature

sensor

humidity

transmitter

Sample Application

A Series 988 controls the humidity in an environmental chamber. The

relative humidity (RH) sensor provides a 4-20mA signal over a 0-100% RH

range. The sensor is very sensitive to changes caused by air flow in the

chamber. The turbulence in the chamber has the 988 display jumping two

to three percent. To remove this display dithering the filter time constant

for input 1 is set to 2 seconds. This will smooth the display and

provide a more realistic reading.

3.8

Optimizing Your Process System with the WATLOW Series 988

Page 29

General Software Features

TL

Input Linearization

Overview:

In many flow applications the output signal

from a flow transmitter represents a squared

value of the actual flow. The square root must

be extracted from the signal to make it useful

to the operator. Many flow transmitters offer

this feature in the transmitter itself, but this

can add significantly to the cost. Using the

square root extraction option in the Series 988

controller can save the operator money. The

feature is enabled simply by setting input 1

linearization

to square root extraction .

input 1

or input 2 linearization

W

A

TL

W

PROCESS

L1 L2 L3 L4

DEV

% OUT

SERIES 988

DISPLAY

AUTO

MAN

MODE

output 1

Flow in gallons

transmitter

per minute

flow

Requirements:

The square root extraction feature is standard

on any Series 988 controller with universal

signal conditioner inputs. The linearization

prompt will appear if a process input is selected via the universal signal conditioner DIP

switches.

16

14

12

10

8

6

4

2

0

J

4 6 8 101214161820

J

J

linearized signal

J

J

J

J

J

J

J

non-linearized signal

J

J

J

4-20mA input signal

Water Treatment Pond

J

J

J

J

Sample Application:

A waste water process engineer needs to control the flow of a solution to be

mixed with waste water for treatment of the water. The transmitter provides a

4-20mA output without square root extraction. The engineer used the Series

988 with a universal signal conditioner input and a 4-20mA process output to

control the flow. The input signal was linearized using the square root extraction feature of the 988.

The above system has a flow range of 0 to 16 gallons per minute. The range

low and range high parameters for input 1 would be set to 0 and 16 respectively. The input 1 linearization prompt

extraction

extraction to linearize the signal it would not be useful for controlling the

. You can see from the above graph that without square root

would then be set to square root

process.

3.9Optimizing Your Process System with the WATLOW Series 988

Page 30

General Software Features

Ramp To Set Point

Overview

Ramp to set point enables the 988 to ramp the

set point at a user defined rate. This allows the

988 to start up a system or change between set

points at a rate that will not stress the product

or system components. The ramp rate is

defined in degrees per minute. Ramp to set

point can be initiated at start up only, or at

start up and also on any set point changes.

When a ramp is initiated, the starting point for

the ramp is the current process value. If the

ramp is initiated on start up, the 988 looks at

the process value upon power up, and uses

that value as the starting point for the ramp. If

a set point change initiates the ramp to set

point function, the 988 looks at the process

value when the change is made and uses that

value as the starting point for the ramp. If the

set point is changed during a ramp, the process

value at the time of the change becomes the

starting point for the new ramp.

Requirements

This feature is standard on all units.

From start up to set point without ramping

1200

1000

800

600

°C

400

200

0

0246810121416

hours after startup

W

A

TL

input 1

W

PROCESS

L1 L2 L3 L4

DEV

% OUT

SERIES 988

DISPLAY

AUTO

MAN

MODE

output 1

limit

From start up to set point with 1°/min. ramping

1200

1000

800

600

°C

400

200

0

0246810121416

hours after startup

limit

sensor

Sample Application

An engineer needs to control the temperature of a muffle furnace. The furnace set

point must be ramped up at a defined rate to prevent stressing the muffle and

other system components. By enabling the ramp to set point function in the 988,

the engineer can control the rate at which the set point will rise. Ramp to set point

is enabled in the Global menu using the ramping function prompt

on start up only, select start

changes, select set point

. To ramp on start up and on any set point

. The ramp rate is in degrees per minute.

. To ramp

heaters

temperature

sensor

heaters

For further protection of the system, output 2, 3 or 4 can be configured as a rate

alarm, monitoring the rate of increase or decrease in the process variable on input

1. The alarm low

and alarm high prompts (The "2" in these examples

refer to output 2.) establish the ramp-down and ramp-up rate set points, respectively, in degrees per minute.

3.10

Optimizing Your Process System with the WATLOW Series 988

Page 31

General Software Features

TL

TL

TL

TL

TL

TL

TL

TL

Remote Set Point

Overview

The remote set point feature allows the 988 to

use a thermocouple, RTD or process signal at

input 2, to establish the set point. This feature

gives the 988 the ability to have its set point

value manipulated by an external source. A

common application would use one ramping

controller with a set-point retransmit output to

ramp multiple 988’s using the remote set point.

Or you could use an analog output from a PLC

to send set point values to a 988.

Requirements

Input 2 must be either a thermocouple or

universal signal conditioner, options 1 or 2.

If the application uses a master controller,

choose one of the retransmit options — M (020, 4-20mA) or N (0-5, 1-5 or 0-10VDC) — for

output 3 of the master.

Match input and output impedances.

zone 1

Master

W

A

TL

W

PROCESS

L1 L2 L3 L4

DEV

DISPLAY

% OUT

AUTO

MAN

MODE

SERIES 988

output 3

zone 2 zone 3 zone 4 zone 5 zone 6 zone 7 zone 8

Remote

W

A

TL

W

PROCESS

L1 L2 L3 L4

DEV

DISPLAY

% OUT

AUTO

MAN

MODE

SERIES 988

Remote

W

A

TL

W

PROCESS

L1 L2 L3 L4

DEV

DISPLAY

% OUT

AUTO

MAN

MODE

SERIES 988

Remote

W

A

TL

W

PROCESS

L1 L2 L3 L4

DEV

DISPLAY

% OUT

AUTO

MAN

MODE

SERIES 988

Remote

W

A

TL

W

PROCESS

L1 L2 L3 L4

DEV

DISPLAY

% OUT

AUTO

MAN

MODE

SERIES 988

Remote

W

A

TL

W

PROCESS

L1 L2 L3 L4

DEV

DISPLAY

% OUT

AUTO

MAN

MODE

SERIES 988

input 2 input 2 input 2 input 2 input 2 input 2

Sample Application

An engineer has a machine with eight independent zones of heat. He wants to

to change set points on all zones without having to adjust each control individually. This can be achieved using a 988 with a 0-5VDC retransmit output

as the master controller. The seven remote 988’s will use the 0-5VDC signal

on input 2 as a remote set point. When the set point is changed on the master

controller, the retransmit output changes the set points of the seven remote

controllers. By enabling the ramp to set point feature in the master 988, all

eight zones are ramped up to set point at a user-defined rate on power up.

The retransmit output from the master 988 is set so that 0VDC represents

0°F and 5VDC represents 800°F. On the remote controllers, set the input 2

DIP switch to the position for the 0-5, 1-5, 0-10VDC process input. In the

Input menu, under the input 2 prompt

prompt

low 2

should be set to ON and decimal 2 set to 0. The range

and the range high 2 parameters will establish the scaling for

, select 0-5. The remote set point

the remote set point input. Range low 2 should be set to 0 and range high 2

should be set to 800. To operate a specific zone ten degrees hotter than the

others, increase the range low 2

to 10 and the range high 2 to 810.

Remote

W

A

TL

W

PROCESS

L1 L2 L3 L4

DEV

DISPLAY

% OUT

AUTO

MAN

MODE

SERIES 988

Remote

A

TL

W

PROCESS

L1 L2 L3 L4

DEV

% OUT

SERIES 988

input 2

W

DISPLAY

AUTO

MAN

MODE

With remote set point

remote prompt

in the System menu, the set point is adjusted using the

enabled and local selected under the local-

increment (up-arrow) and decrement (down-arrow) keys. Selecting remote

under the local-remote prompt , disables the increment and decrement

keys, allowing the set point value to be manipulated via the input 2 signal.

3.11Optimizing Your Process System with the WATLOW Series 988

Page 32

General Software Features

Overview:

The retransmit output can be used to transmit

an analog signal representing the value of

either input process variable or the target set

point variable. The retransmit signal is factory

configured as either a milliamp or a voltage

signal. In choosing the type of retransmit signal

the operator must take into account the input

impedance of the device to be retransmitted to

and the required signal type, either voltage or

milliamps.

Retransmit

chart recorder or to generate a set point for

other controls in a multi-zone application (see

page 3.11).

Requirements:

Output 3 is used for the retransmit option.

Choose output type M (0-20, 4-20mA) or N (05, 1-5 or 0-10VDC), depending on the signal

type. Select the output range in the Output

menu.

Typically applications might use the retransmit

option to record one of the variables with a

W

A

TL

input 1

W

PROCESS

L1 L2 L3 L4

DEV

% OUT

SERIES 988

DISPLAY

AUTO

MAN

MODE

output 1

output 3

limit

Chart

Recorder

Enhanced software is not required for this

feature.

Heat-treat Oven

limit

sensor

heaters

Sample Applications:

The 988 is being used to control the temperature of a heat-treat oven. The

temperature of the process must be recorded on a chart recorder. The

oven temperature range stays between 600 to 900 degrees F. The chart

recorder requires a 4-20mA signal.

temperature

sensor

In the Output menu

set analog output to to tag the input

1 process value as the parameter to be retransmitted. Set retransmit low

limit

retransmit high limit

signal to 900. Set retransmit calibrate offset

to 600 to set the low range for the retransmit signal to 600. Set

to 900 to set the high range for the retransmit

to 0, assuming there is

no calibration offset required.

The retransmit output will be 4mA until the oven temperature is greater

than 600 degrees F, at which point the signal will increase with temperature to 20mA at 900 degrees F and will not exceed 20mA.

3.12

Optimizing Your Process System with the WATLOW Series 988

Page 33

General Software Features

TL

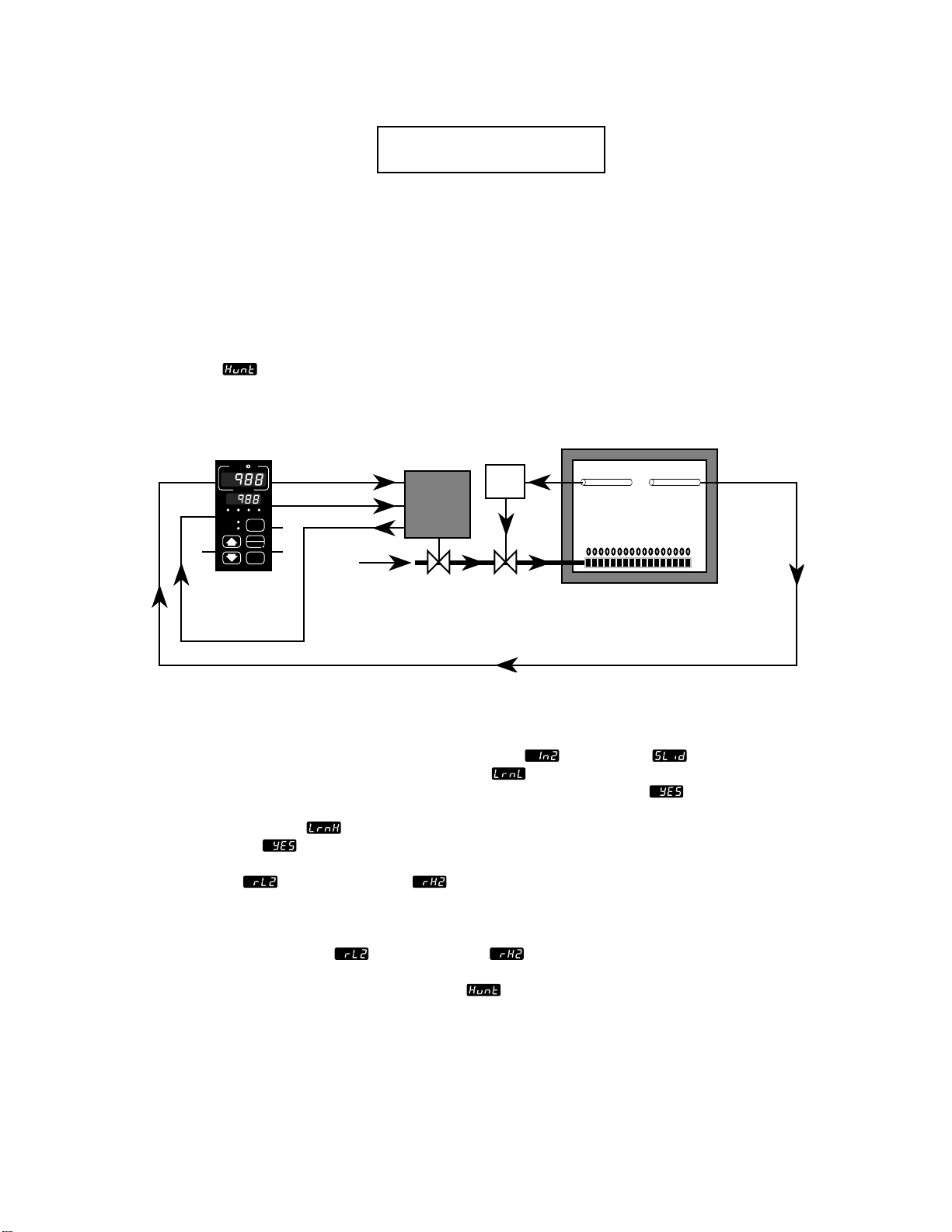

Slidewire Feedback

Overview

The 988 can control the position of a valve with

a slidewire feedback position indicator. The 988

senses the resistance of the slidewire and

compares it to the range low and range high

settings to determine the valve position. The

controller compares this to the percent output

and takes action to match the two by opening

or closing the valve.

Set the hunt

hunting. The value is set for the percent of

output (0.0 to 100.0). When the valve is within

input 1 output 1 (close)

input 2

parameter to limit valve

W

A

TL

W

PROCESS

output 2 (open)

L1 L2 L3 L4

DEV

DISPLAY

% OUT

AUTO

SERIES 988

MAN

MODE

gas

flow

Valve Actuator

gas

valve

this dead band, a change in output greater

than half the hunt parameter is required to

trigger action. Output 1 responds to “close”

commands and output 2 responds to “open”

commands.

Requirements

A slidewire configuration uses at least two

inputs and two control outputs. Input 2 must

be a slidewire input. Outputs must be compatible with the slidewire valve actuators.

Gas-fired Furnace

limit

limit

sensor

cut-off

valve

temperature

sensor

slidewire input

Sample Application

The 988 controls the gas valve for a gas-fired furnace to heat treat large metal

parts. First the 988 must be “married” to the slidewire feedback from the

valve actuator. To do this, first set the input 2 prompt

Advance to the learn low resistance value prompt

to slidewire .

. Close the valve

manually to the minimum resistance reading from the slidewire. Select

in the upper display and press the MODE key to advance to the learn high

resistance value prompt

resistance). Select

. Manually open the valve (maximum slidewire

in the upper display and press the MODE key. At this

point both the high and low resistance values have been learned and stored in

the range low 2

and range high 2 prompts.

You can also manually set the range low and range high values. From the

slidewire specifications, determine the low and high resistance values and

enter these at the range low

Once the control is operating, adjust the hunt

valve oscillations. The hunt parameter sets up a dead band on both sides of

the current valve position. The desired valve position is then compared to the

and range high prompts.

parameter, to minimize

actual position. If the difference is greater than the one-half of the hunt value,

the 988 repositions the valve to achieve the temperature set point. Once repositioning is complete, the dead band is recalculated for the new valve position.

3.13Optimizing Your Process System with the WATLOW Series 988

Page 34

Enhanced Software Features

Chapter Four

Enhanced Software Features

Cascade 4.2

Differential 4.4

Dual PID sets 4.5

Duplex 4.6

Ratio 4.7

How to use this chapter:

This chapter describes the software

features that are available in the 988

family of Watlow controllers equipped

with the enhanced software option.

4.1Optimizing Your Process System with the WATLOW Series 988

Page 35

Enhanced Software Features

Cascade

Overview

Cascade control can handle a difficult process

with minimal overshoot, while reaching the set

point quickly. This minimizes damage to

system components and allows for oversizing

heaters for optimal heat-up rates.

Systems with long lag times between the energy

source (heater, steam, etc.) and the measured

process value cannot be controlled accurately

or efficiently with a single control loop, because

a lot of energy can build up before a response

is detected. This can cause the system to

overshoot the set point, which could damage

the heater, product or heat transfer medium,

such as a heat transfer fluid.

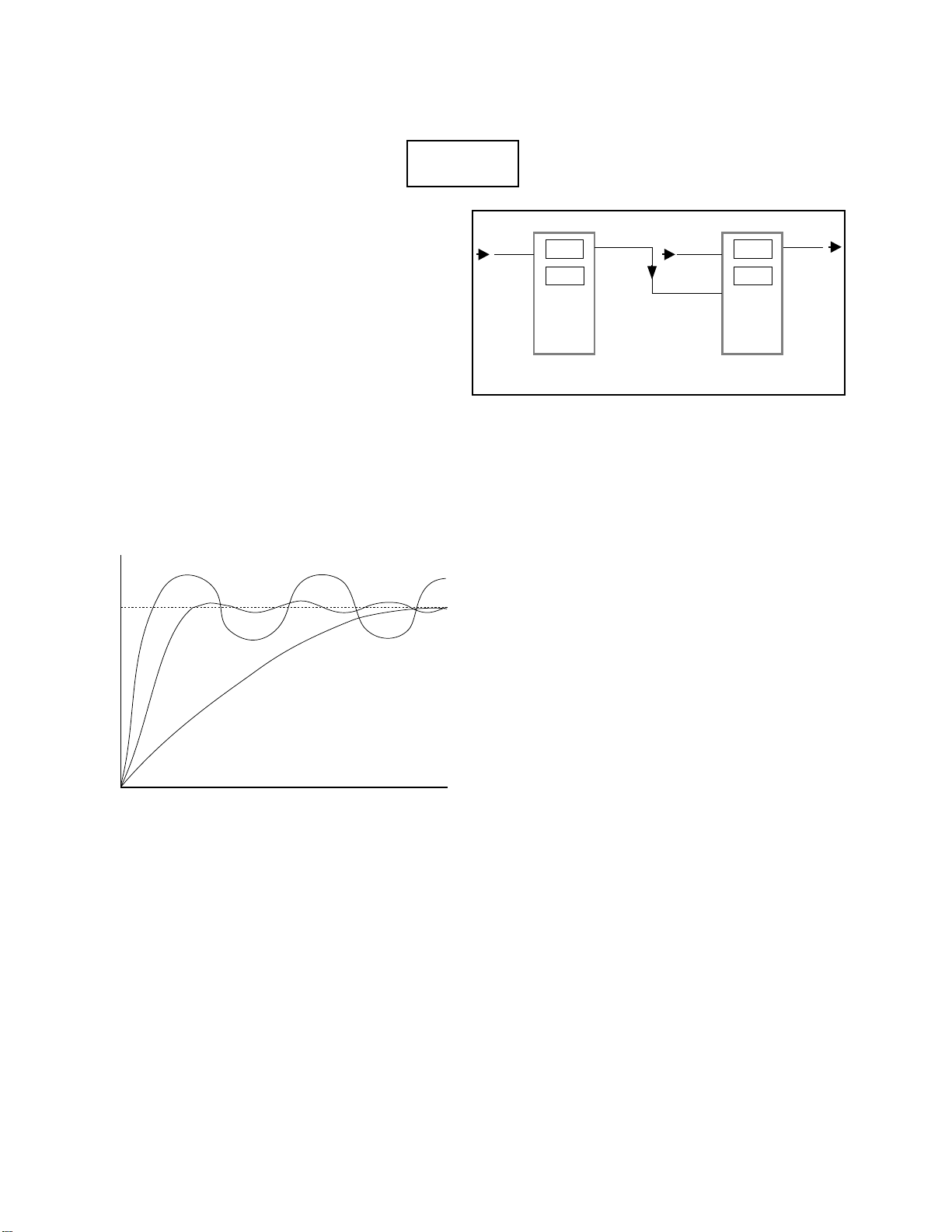

This graph illustrates a system with a long lag

time. Curve A represents a single-control

A

set point

B

C

Two controllers in one

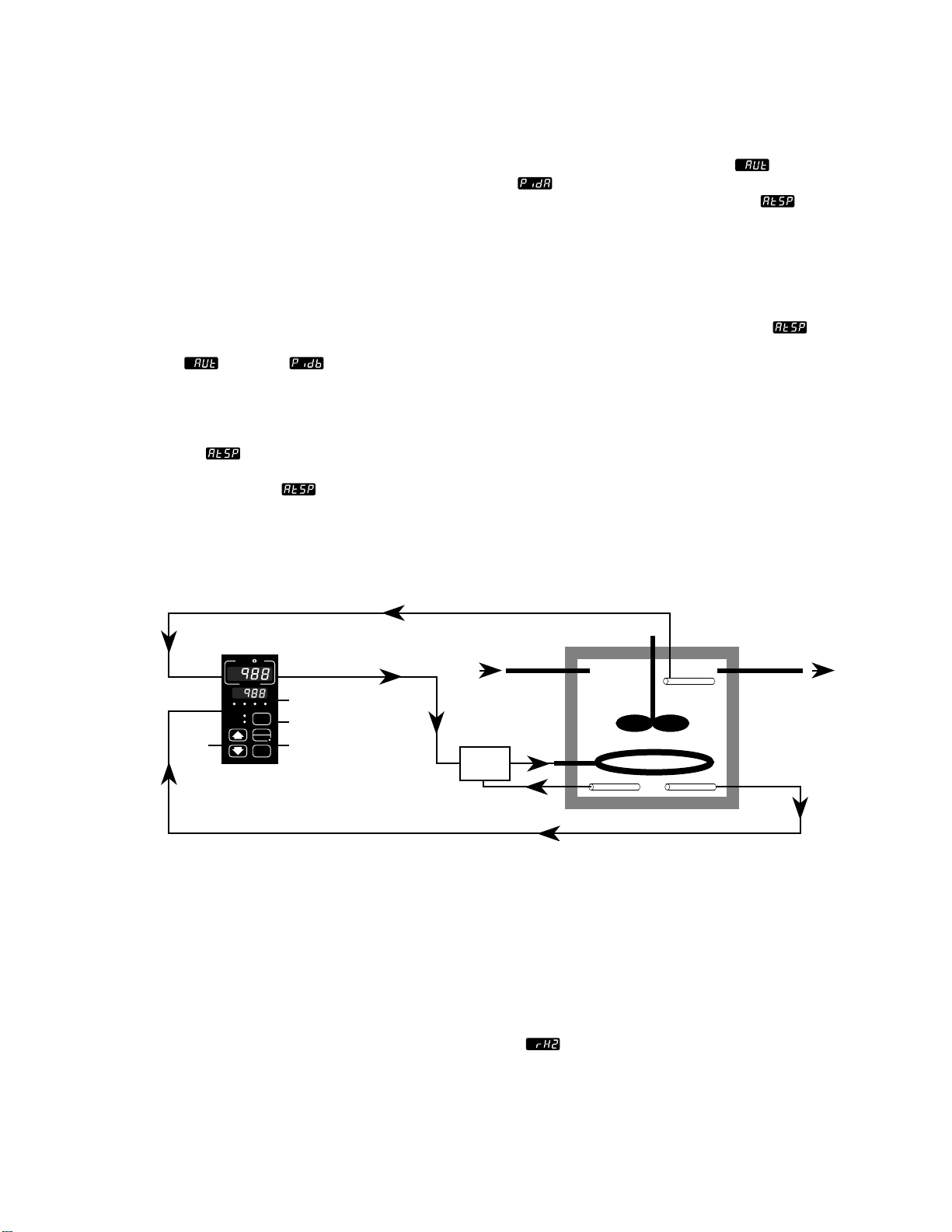

input 1 input 2

The cascade feature allows the Series 988 to internalize the functions of two controllers

In1

SP

Outer-loop

Controller

%

int

Inner-loop

Controller

In2

SP

int

output 1

%

out

generates the internal set point. The Series 988

effectively combines both controllers into a

single package.

The primary controller measures the process in

the outer, or primary, loop with input 1 and

compares the value to the desired set point.

The difference between the set point and the

process temperature generates an internal

percent output value for the second controller.

This value cannot be seen by the operator. This

internal percent (%

) output generates the

int

internal set point for the secondary, or inner

loop. The secondary loop uses this set point

and the value of input 2 (typically attached to

the heater sheath) to control the heater temperature.

time →

system with PID parameters that allow a

maximum heat-up rate. Too much energy is

introduced and the set point is overshot. In

most long-lag-time systems the process value

may never settle out to an acceptable error.

Curve C represents a single-control system

tuned to minimize overshoot. This results in

unacceptable heat-up rates, with the final

value taking hours to reach. Curve B shows a

cascade system that limits the energy introduced into the system, allowing an optimal

heat-up rate with minimal overshoot.

This drawing shows two controllers configured

as a cascade system. The second controller

4.2

Optimizing Your Process System with the WATLOW Series 988

Algorithm

The following formulas show how the primary

control sends a set point (based on input 2

range-high and range-low values) to the secondary control. The secondary control uses this

set point (SP

(%

) to the heater.

out

1.) %

2.) SP

3.) %

) to generate a percent output

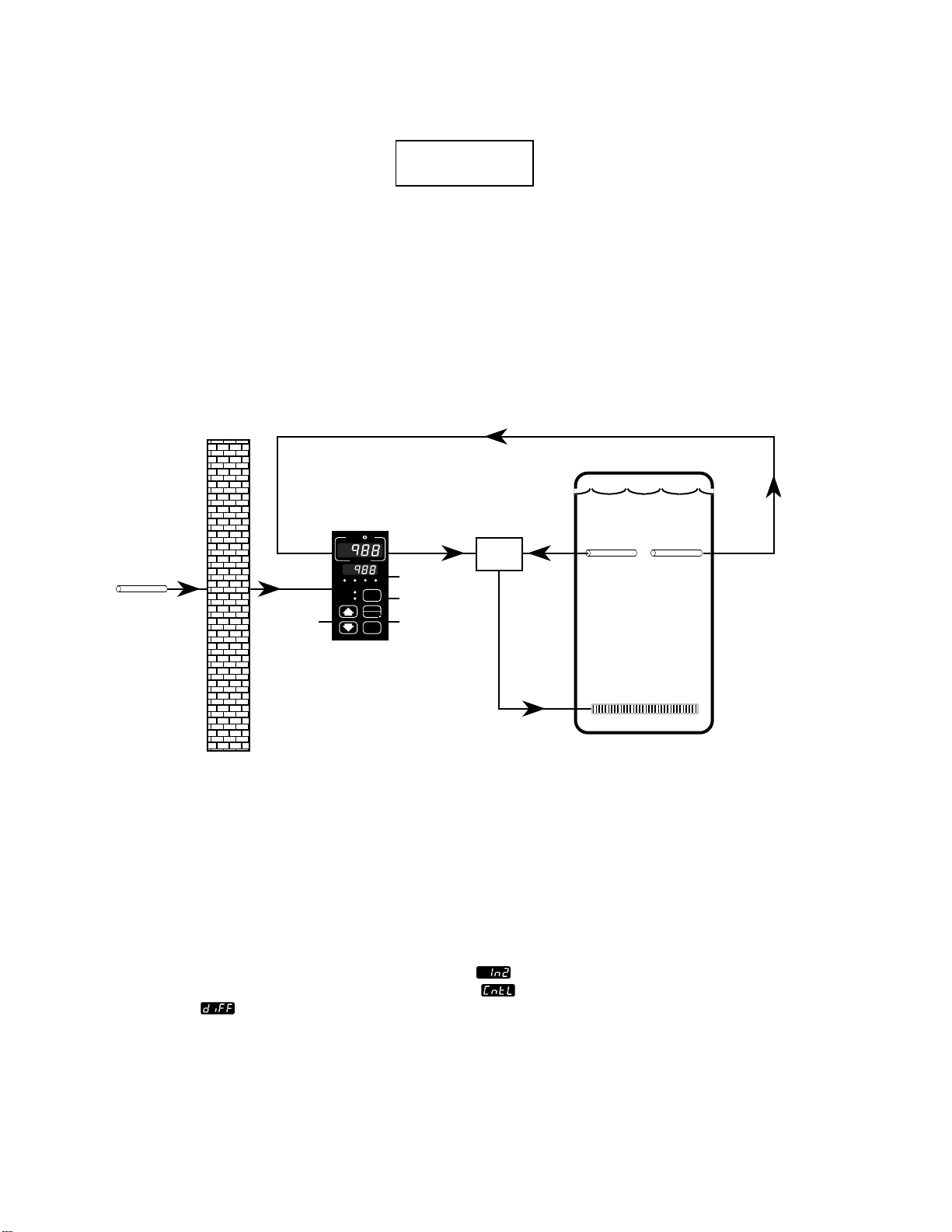

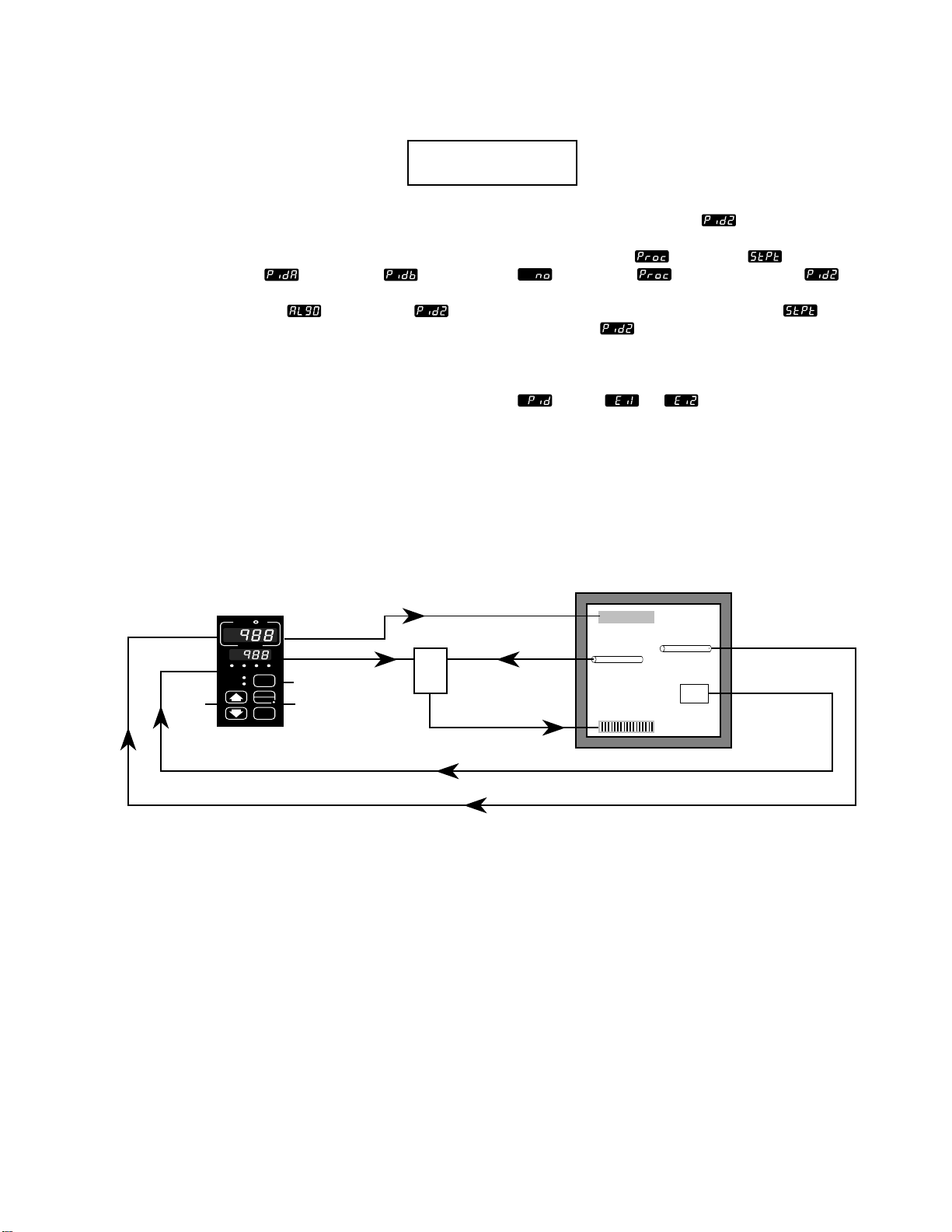

int