Page 1

CLS200, MLS300,

and CAS200

Communications

Specification

Watlow Anafaze

Repairs and Returns:

1241 Bundy Blvd.

Winona, MN 55987

Customer Service:

Phone.....800-414-4299

Fax..........800-445-8992

Technical Support:

Phone.......507-494-5656

Fax.............507-452-4507

Email.........wintechsupport@watlow.com

Part No. 0600-1015-5100. Revision 3.0

November 2003

Page 2

Copyright © 1996, 1997, 2003

Watlow Anafaze

Information in this manual is subject to change without notice. No part of this publication may be

reproduced, stored in a retrieval system, or transmitted in any form without written permission

from Watlow Anafaze.

Warranty

Watlow Anafaze, Incorporated warrants that the products furnished under this Agreement will be

free from defects in material and workmanship for a period of three years from the date of shipment. The customer shall provide notice of any defect to Watlow Anafaze, Incorporated within one

week after the Customer's discovery of such defect. The sole obligation and liability of Watlow

Anafaze, Incorporated under this warranty shall be to repair or replace, at its option and without

cost to the Customer, the defective product or part.

Upon request by Watlow Anafaze, Incorporated, the product or part claimed to be defective shall

immediately be returned at the Customer's expense to Watlow Anafaze, Incorporated. Replaced or

repaired products or parts will be shipped to the Customer at the expense of Watlow Anafaze,

Incorporated.

There shall be no warranty or liability for any products or parts that have been subject to misuse,

accident, negligence, failure of electric power or modification by the Customer without the written

approval of Watlow Anafaze, Incorporated. Final determination of warranty eligibility shall be

made by Watlow Anafaze, Incorporated. If a warranty claim is considered invalid for any reason,

the Customer will be charged for services performed and expenses incurred by Watlow Anafaze,

Incorporated in handling and shipping the returned unit.

If replacement parts are supplied or repairs made during the original warranty period, the warranty

period for the replacement or repaired part shall terminate with the termination of the warranty

period of the original product or part.

The foregoing warranty constitutes the sole liability of Watlow Anafaze, Incorporated and the customer's sole remedy with respect to the products. It is in lieu of all other warranties, liabilities, and

remedies. Except as thus provided, Watlow Anafaze, Inc. disclaims all warranties, express or

implied, including any warranty of merchantability or fitness for a particular purpose.

Please Note:

External safety devices must be used with this equipment.

Page 3

Contents

Contents

Overview........................................................................ 1

In This Manual ............................................................ 1

Chapter 1: ANAFAZE/AB Protocol............................. 3

Protocol Syntax

Control Codes.............................................................. 3

Transaction Sequence.................................................. 4

Packet Format.............................................................. 6

Codes in a Packet ........................................................ 6

Error Checking

Block Check Character (BCC).................................... 8

Cyclic Redundancy Check (CRC)............................... 9

.................................................................3

..................................................................8

Examples ...........................................................................10

Block Read .................................................................. 10

Block Write ................................................................. 13

Message Data ....................................................................14

Data for a Read Command.......................................... 14

Data for a Write Command ......................................... 15

Two-Byte Data Types ................................................. 15

Figuring Block Size..................................................... 15

Anafaze/AB Data Table Summary ....................................16

Ordering of Heat and Cool Channel Parameters......... 17

Ordering of Ramp-Soak Profile Parameters................ 17

Anafaze/AB Protocol Data Table................................ 17

Chapter 2: Modbus-RTU Protocol............................... 21

Overview ...........................................................................21

Transactions on Modbus-RTU Networks ................... 21

The Query-Response Cycle......................................... 22

Serial Transmission..................................................... 22

Message Framing ........................................................ 23

CRC Error Checking ................................................... 25

Function Codes............................................................ 26

Writing Data................................................................ 30

Reading Data............................................................... 30

Examples ...........................................................................31

Read Examples............................................................ 31

Write Examples........................................................... 32

Modbus-RTU Data Table Summary ..................................33

Ordering of Heat and Cool Channel Parameters......... 34

Ordering of Ramp-Soak Profile Parameters................ 34

Relative and Absolute Modbus Addresses.................. 35

Modbus-RTU Protocol Data Table ............................. 35

Communications Specification i

Page 4

Contents

Chapter 3: Controller Parameter Descriptions ........... 39

Correlating Menu Items with Parameters .........................39

Parameters (by number) ....................................................45

Proportional Band/Gain (0)......................................... 45

Derivative Term (1)..................................................... 45

Integral Term (2) ......................................................... 45

Input Type (3).............................................................. 46

Output Type (4)........................................................... 47

Setpoint (5).................................................................. 48

Process Variable (6) .................................................... 48

Output Filter (7) .......................................................... 48

Output Value (8).......................................................... 49

High Process Alarm Setpoint (9) ................................ 49

Low Process Alarm Setpoint (10) ............................... 49

Deviation Alarm Band Value (11) .............................. 49

Alarm Deadband (12).................................................. 49

Alarm_Status (13) ....................................................... 50

Ambient Sensor Readings (15) ................................... 52

Pulse Sample Time (16) .............................................. 52

High Process Variable (17) ......................................... 52

Low Process Variable (18).......................................... 52

Precision (19) .............................................................. 53

Cycle Time (20) .......................................................... 54

Zero Calibration (21)................................................... 54

Full Scale Calibration (22) .......................................... 54

Digital Inputs (25) ....................................................... 54

Digital Outputs (26) .................................................... 55

Override Digital Input (28) ......................................... 55

Override Polarity (29) ................................................. 55

System Status (30)....................................................... 56

System Command Register (31) ................................. 56

Data Changed Register (32) ........................................ 57

Input Units (33) ........................................................... 57

EPROM Version Code (34) ........................................ 58

Options Register (35) .................................................. 58

Process Power Digital Input (36) ................................ 59

High Reading (37)....................................................... 59

Low Reading (38)........................................................ 59

Heat/Cool Spread (39)................................................. 59

Startup Alarm Delay (40)............................................ 60

High Process Alarm Output Number (41)................... 60

Low Process Alarm Output Number (42) ................... 60

High Deviation Alarm Output Number (43)............... 60

Low Deviation Alarm Output Number (44)................ 60

Channel Profile and Status (46) .................................. 61

Current Segment (47).................................................. 62

Segment Time Remaining (48) ................................... 62

Current Cycle Number (49)......................................... 62

Tolerance Alarm Time (50)......................................... 62

Communications Specification ii

Page 5

Contents

Last Segment (51) ....................................................... 62

Number of Cycles (52)................................................ 63

Ready Setpoint (53)..................................................... 63

Ready Event States (54) .............................................. 63

Segment Setpoint (55)................................................. 64

Triggers and Trigger States (56) ................................. 64

Segment Events and Event States (57)........................ 65

Segment Time (58)...................................................... 66

Tolerance (59) ............................................................. 66

Ramp/Soak Flags (60)................................................. 66

Output Limit (61) ........................................................ 67

Output Limit Time (62)............................................... 67

Alarm_Control (63)..................................................... 68

Alarm_Acknowledge (64)........................................... 68

Alarm_Mask (65) ........................................................ 68

Alarm_Enable (66)...................................................... 68

Output Override Percentage (67) ................................ 69

AIM Fail Output (68) .................................................. 69

Output Linearity Curve (69)........................................ 70

SDAC Mode (70) ........................................................ 70

SDAC Low Value (71)................................................ 70

SDAC High Value (72)............................................... 70

Save Setup to Job (73)................................................. 71

Input Filter (74) ........................................................... 71

Loop Alarm Delay (75)............................................... 71

Loop Names (77)......................................................... 71

T/C Failure Detection Flags (78) ................................ 72

Channel Name (78) ..................................................... 72

Restore PID Digital input (79) .................................... 72

Manufacturing Test (80).............................................. 72

PV Retransmit Primary Loop Number (81) ................ 73

PV Retransmit Maximum Input (82) .......................... 73

PV Retransmit Maximum Output (83)........................ 73

PV Retransmit Minimum Input (84) ........................... 73

PV Retransmit Minimum Output (85) ........................ 74

Cascade Primary Loop Number (86)........................... 74

Cascade Base Setpoint (87)......................................... 74

Cascade Minimum Setpoint (88)................................. 74

Cascade Maximum Setpoint (89)................................ 74

Cascade Heat/Cool Span (90) ..................................... 75

Ratio Control Master Loop Number (91).................... 75

Ratio Control Minimum Setpoint (92)........................ 75

Ratio Control Maximum Setpoint (93) ....................... 75

Ratio Control Control Ratio (94) ................................ 75

Ratio Control Setpoint Differential (95) ..................... 75

Loop Status (96).......................................................... 76

Output Type/Disable (97)............................................ 76

Output Reverse/Direct (98) ......................................... 76

Controller Type (99).................................................... 77

Ramp/Soak Profile Number (100)............................... 77

Communications Specification iii

Page 6

Contents

Controller Address (101)............................................. 77

Baud Rate (102) .......................................................... 77

Ready Events (103) ..................................................... 78

Appendix A: Communications Driver ......................... 79

Compiling and Linking ............................................... 79

Compatibility............................................................... 79

Commands................................................................... 79

Glossary ........................................................................ 83

Communications Specification iv

Page 7

Overview

Overview

This reference guide is designed to help applications software

programmers with the following tasks:

Interface to Watlow Anafaze MLS300, CLS200, MLS and CLS con-

•

trollers, and the CAS200 and CAS scanners via serial communications.

•

Modify the communications Anafaze protocol driver in the Watlow

Anafaze Communications Driver Kit. (If you have the communications driver kit, you don’t need to read this manual unless you want

to modify the communications driver.)

In This Manual

The following sections are included in this guide:

Chapter 1: Anafaze/AB Protocol . Gives an overview and explanation

of the Anafaze/Allen Bradley communications protocol.

Chapter 2: Modbus-RTU Protocol. Gives an overview and

explanation of the Modbus-RTU communications protocol

Chapters 1 and 2: Data Table Summary . Provides standard controller

data table maps for the parameters (one for each protocol).

Chapter 3: Parameters Description . Describes each parameter.

Appendix A : Communications driver.

Glossary: Explanation of commonly used terms and acronyms.

NOTE

This reference guide is not a tutorial. It does not explain

how to use the controller; it is not a programming reference; it also does not explain PID control, alarms, linear

scaling, or other topics that are explained in detail in the

controller manuals. If you need additional information

about a topic covered in this reference guide, consult the

documentation included with your controller.

Communications Specification 1

Page 8

Overview

2 Communications Specification

Page 9

Chapter 1: ANAFAZE/AB Protocol

Chapter 1: ANAFAZE/AB Protocol

This section explains the ANAFAZE/Allen Bradley protocol used in

Watlow Anafaze MLS, CLS, and CAS devices. These controllers

operate on serial communications links (EIA/TIA-232 or EIA-TIA-485)

at either 2400 or 9600 baud. They use 8 data bits, one or 2 stop bits, and

no parity.

Protocol Syntax

The controllers use a half-duplex (master-slave) protocol to interface to

high-level software. The host software is considered the “master” and

the controller is considered the “slave.” In other words, the software can

request information from the controller or download information to the

controller. The controller can only respond to communications

transactions initiated by the host software. The controller cannot initiate

communications.

The controller and host software communicate by sending and receiving

information in a “packet” format. A packet consists of a sequence of

bytes in a specific format; it can be as large as 256 bytes of data. (For

more information about packets, see the Packet Format section later in

this chapter.)

The numbers in the packet are sent in binary format. However, our

examples show bytes in hexadecimal format.

Control Codes

Watlow Anafaze abbreviates control codes this way:

Code Meaning

DLE

STX

ETX

ENQ

Escape code

Signals the start of the other control code character sequences.

Start Text

Begins a transmission.

End Te xt

Ends a transmission.

Request Resend

Tells the controller to resend its last ACK or NAK. Host software

sends this command, and the controller responds to it.

Decimal

Value

16 10

02 02

03 03

05 05

Hex

Value

Communications Specification 3

Page 10

Chapter 1: ANAFAZE/AB Protocol

Code Meaning

ACK

NAK

Acknowledged

Signals that a syntactically correct packet has been received.

Not Acknowledged

Signals that an incorrect, invalid packet has been received.

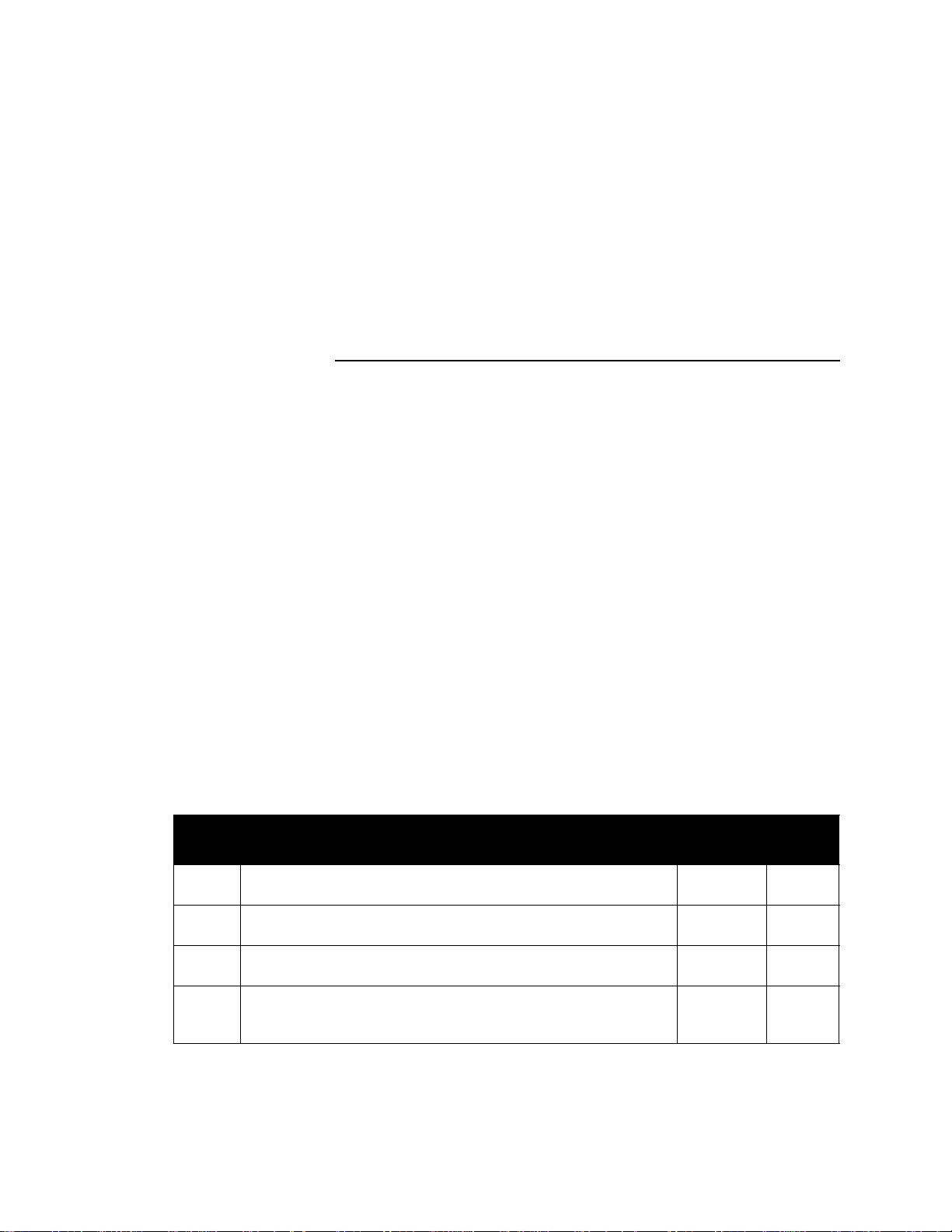

Transaction Sequence

Here are the four steps in a transaction between the host software and

the controller. The following example shows the transaction as an

exchange of packets. The example also assumes that there are no

communication errors in the exchange.

(1) The host software sends a packet that contains a read command or

write command.

(2) The controller sends a DLE ACK to the host software.

(3) The host software receives a reply packet from the controller.

(4) The host software sends a DLE ACK.

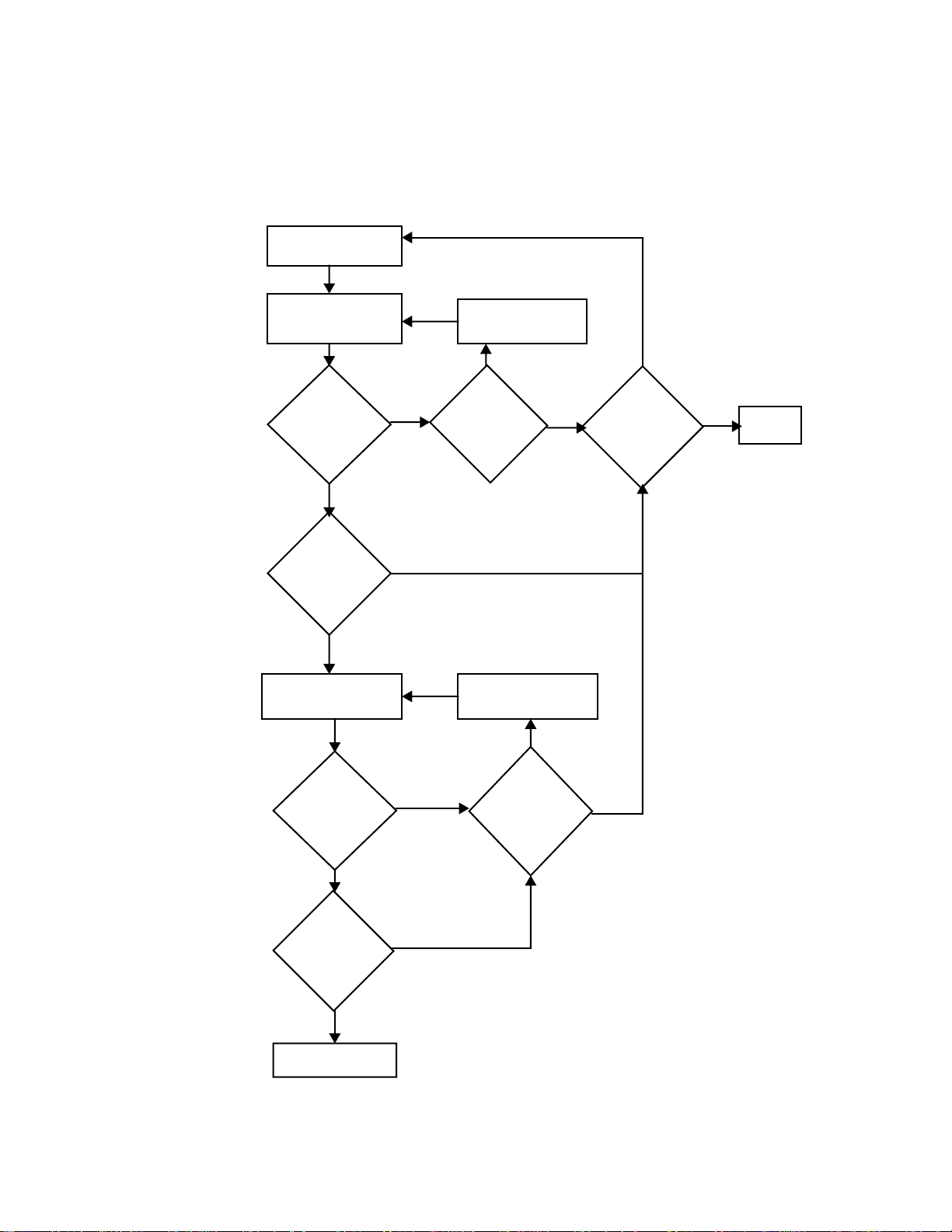

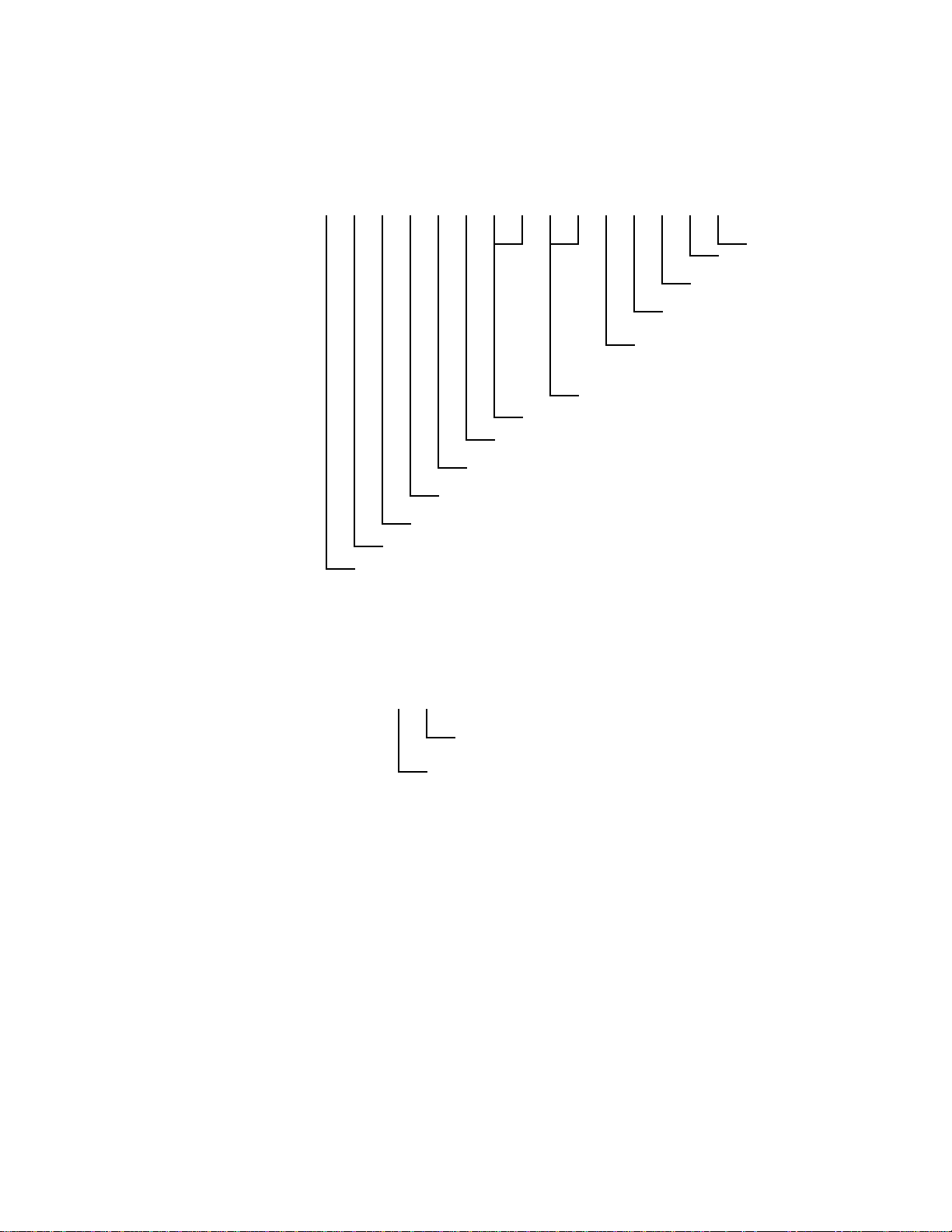

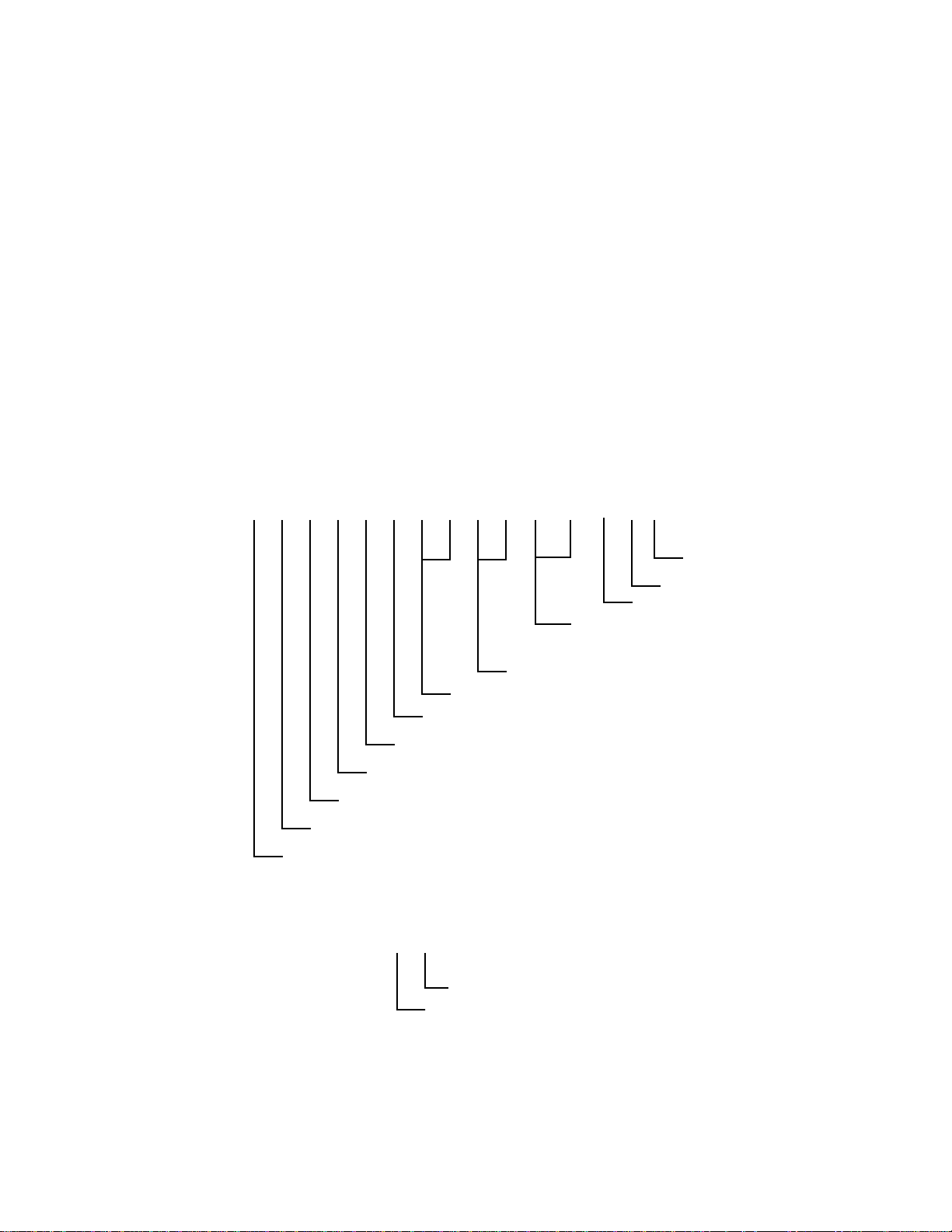

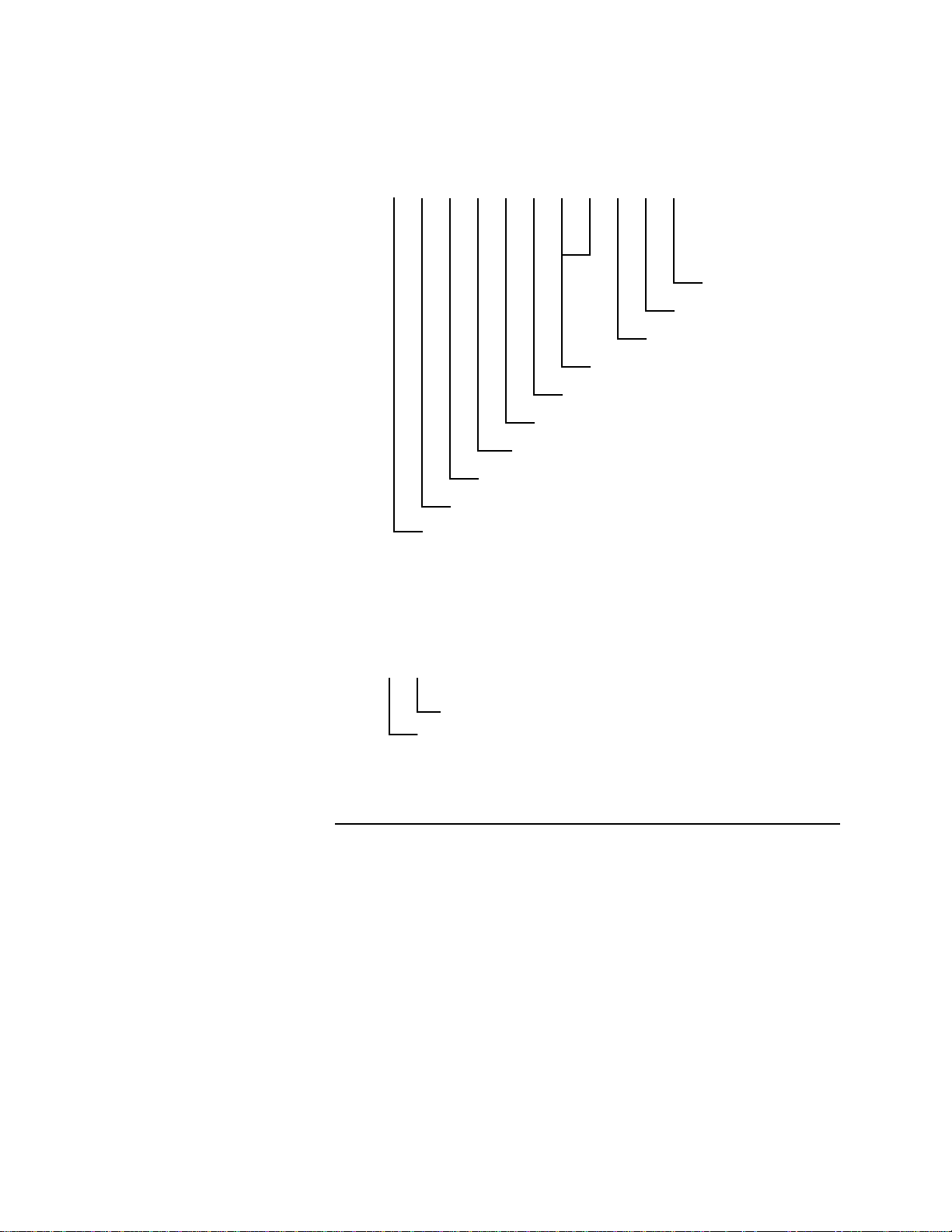

The following flowchart shows a transaction with no error handling.

Decimal

Value

06 06

21 15

Hex

Value

Send

command

packet

Receive

DLE ACK

Receive valid

reply packet

Send

DLE ACK

( continued on next page )

NOTE

Due to the difference between the processing speeds of the

controller and PCs, it may be necessary to delay the computer's acknowledgement (ACK) in order for the controller

to receive it. A delay of 200 ms should suffice.

4 Communications Specification

Page 11

Send command

packet

Chapter 1: ANAFAZE/AB Protocol

This flowchart shows one way for the host software to handle error

checking. (If you are writing simple software, you don't necessarily

need to use error handling routines as complete as these.)

Wait for DLE ACK

or DLE NAK

Timed out?

NO

Got ACK

or NAK?

ACK

Wait for reply

packet

YES

NAK

Send DLE ENQ

NO

Sent DLE

ENQ

3 times?

Send DLE NAK

YES

NO

NO

Sent packet

3 times?

YES

Done

Timed out?

NO

Packet valid?

YES

Send DLE ACK

NO

Sent DLE

NAK 3 times?

YESYES

Communications Specification 5

Page 12

Chapter 1: ANAFAZE/AB Protocol

Packet Format

Messages are transmitted in the form of packets. Command and reply

packets specify the source and destination addresses, whether to read or

write, the block of data to read or write, etc.

A packet contains a sequence of binary bytes formatted this way:

DLE STX DLE ETX BCC/CRC

DATA

DST

SRC CMD

STS

TNSL TNSH ADDL

ADDH

Sending Control Codes

To send a control code, send a DLE before the control code to

distinguish it from data.

Codes in a Packet

Sending a DLE as Data

When you send a byte with an x10, (a DLE), the controller and software

interpret it as a command. Therefore, to send a DLE as data, send

another DLE immediately before it (DLE DLE).

This section describes the sequence of bytes in a packet, in the order the

host software or controller sends them.

DLE STX

The DLE STX byte signals the beginning of a transmission. Every

•

packet of information starts with the control codes DLE STX.

DST

•

The DST byte is the address of the destination device (usually a con-

troller; the first Watlow Anafaze controller is at x08).

NOTE

When host software communicates with an MLS, a CLS, or

a CAS in ANAFAZE or AB protocol, it does not send the

controller’s actual address. Since the protocol reserves

device addresses 0 to 7, the host software sends the value

(controller address + 7), instead of the actual device

address.

6 Communications Specification

SRC

The SRC byte is the device address of the packet’s source. The host

•

software is usually designated address x00.

Page 13

Chapter 1: ANAFAZE/AB Protocol

CMD

The CMD byte indicates the command that the host software sends

•

to the controller. The software sends a read (x01) or write (x08).

When the controller replies, it returns the read or write command

with the 7th bit set—in other words, it sends an x41 or x48.

STS (The Status Byte)

The controller uses the status byte, or STS, to return general status

•

and error flags to the host software. (The controller ignores the status

byte in the host software's command packet.) The next table shows

status byte values and definitions.

An “x” in the status bytes below indicates that the associated nibble

•

may contain additional information. In most cases, the status byte is

composed of two independent nibbles. Each nibble is independent

so that two codes can return at once. For example, status code F1

indicates that data has changed (Fx) and the controller is being

updated through the front panel (x1).

Status

in Hex

00 The controller has nothing to report, or AB protocol is selected.

01 Access denied for editing. The controller is being updated through the

front panel.

02 AIM Comm failure.

A0 A controller reset occurred.

Cx The controller received a command that was not a block read or block

write. (Command Error)

Dx The block write command attempted to write beyond a particular parame-

ter block boundary, or the host software attempted to access a data table

block that does not exist. (Data Boundary Error)

Ex The Alarm_Status variable has changed. The software should query the

alarm status block to determine the particular alarm flag that changed.

Fx The controller altered shared data, either internally (from the firmware) or

externally (from the keyboard). The host software should read the Data

Changed Register to determine which data has been altered and update

its own run-time memory.

Description

TNSL

Least significant byte of the transaction number. This is the first half

•

of a “message stamp.”

The controller sends back the TNSL and TNSH exactly as it received

•

them, so host software can use the TNSL and TNSH bytes to keep

track of message packets.

TNSH

•

Most significant byte of the transaction number. This is the second

half of the “message stamp.”

Communications Specification 7

Page 14

Chapter 1: ANAFAZE/AB Protocol

ADDL

•

The low byte of the beginning data table address of the block of data

to read or write.

ADDH

The high byte of the beginning data table address of the block of data

•

to read or write.

DATA

•

The new values to be set with a write command, or the requested data

in a response to a read command.

DLE ETX

Every packet of information must end with the codes DLE ETX.

•

These codes signal the end of a transmission.

Error Checking

Block Check Character (BCC)

BCC or CRC

•

Communications packets include a one- or two-byte error check at

the end of the packet. There are two error check methods: Block

Check Character (BCC), which requires 1 byte, and Cyclic Redundancy Check (CRC), which requires 2 bytes.

Watlow Anafaze recommends that you use the default error check

method, BCC. It is easier to implement than CRC, and it is acceptable

for most applications.

Select one error check method and configure both software and

controller for that method, or they will be unable to communicate.

The error check methods work this way:

BCC checks the accuracy of each message packet transmission. It

provides a medium level of security. The BCC is the 2’s complement of

the 8-bit sum (modulo-256 arithmetic sum) of the data bytes between

the DLE STX and the DLE ETX. (1’s complement +1)

8 Communications Specification

BCC does not detect transposed bytes in a packet.

•

BCC cannot detect inserted or deleted 0 values in a packet.

•

If you have sent an x10 as data (by sending DLE x10) only one of the

•

DLE data bytes is included in the BCC’s sum (the DLE = x10 also).

Page 15

For instance, the block read example shown in the examples section,

adds x08 00 01 00 00 80 02 10. Note that the x10 representing DLE

has been left out of the calculation. The sum should come to x9B.

1001 1011 = x9B

0110 0100 = 1’s complement

+1 = 2’s complement

0110 0101 = x65

Cyclic Redundancy Check (CRC)

CRC is a more secure error check method than BCC. It provides a very

high level of data security. It can detect:

All single-bit and double-bit errors.

•

All errors of odd numbers of bits.

•

All burst errors of 16 bits or less.

•

•

99.997% of 17-bit error bursts.

•

99.998% of 18-bit and larger error bursts.

The CRC is calculated using the value of the data bytes and the ETX

byte. At the start of each message packet, the transmitter must clear a

16-bit CRC register.

Chapter 1: ANAFAZE/AB Protocol

When a byte is transmitted, it is exclusive-ORed with the right 8 bits of

the CRC register and the result is transferred to the right 8 bits of the

CRC register. The CRC register is then shifted right 8 times by inserting

0’s on the left.

Each time a 1 is shifted out on the right, the CRC register is ExclusiveORed with the constant value xA001. After the ETX value is

transmitted, the CRC value is sent, least significant byte (LSB) first.

Below is a structured English procedure from AB Manual:

data_byte = all application layer data, ETX

CLEAR CRC_REGISTER

FOR each data_byte

GET data_byte

XOR (data_byte, right eight bits of CRC_REGISTER)

PLACE RESULT in right eight bits of CRC_REGISTER

DO 8 times

Shift bit right, shift in 0 at left

IF bit shifted =1

XOR (CONSTANT, CRC_REGISTER)

PLACE RESULT in CRC_REGISTER

END IF

END DO

END FOR

TRANSMIT CRC_REGISTER as 2-byte CRC field

Communications Specification 9

Page 16

Chapter 1: ANAFAZE/AB Protocol

Examples

The host software sends two kinds of commands: block reads and block

writes. This section shows examples of both commands.

NOTE

If you read data from a loop set to SKIP, the controller will

send an empty packet for that loop.

This section does not show how to calculate the error check value

included with every packet. For help calculating the error check value,

see the section on BCC or CRC earlier in this chapter.

Block Read

This example shows the block read command the host software sends,

the controller’s responses, and the software's acknowledgment.

Situation: Read process variables for loops 1 to 8.

8 process variables 2 bytes each = 16 bytes from data table address

•

x0280.

•

Character values are represented in hex.

•

The sender is device address 0.

•

The destination is device address 8 (controller address 1).

•

The software sends transaction number 00.

10 Communications Specification

Page 17

Chapter 1: ANAFAZE/AB Protocol

The next picture shows the read command.

x10 02 08 00 01 00 00 00 80 02 10 10 10 03 65

DLE

Data (number of bytes

to upload)

DLE

Data table address (LSB first)

Transaction number

Placeholder for status byte

Command (block read)

SRC (Source Device Address)

BCC value

ETX

DST (Destination Device Address)

STX

DLE

The controller sends a DLE-ACK:

x10 06

ACK

DLE

Communications Specification 11

Page 18

Chapter 1: ANAFAZE/AB Protocol

Then the controller sends its reply:

x10 02 00 08 41 00 00 00 (DATA) 10 03 C3

BCC value

ETX

DLE

Data (see below)

Transaction number

Status (00 = nothing to report)

Command

Source Device Address (controller address + 7)

Destination Device Address

STX

DLE

DATA:

xE2 01 09 02 E4 01 09 02 F1 01 DF 01 28 3C E4 01

Data, transmitted LSB first. Assuming precision for loops is –1:

Loop 1 PV = x01E2 = 482, displayed as 48

Loop 2 PV = x0209 = 521, displayed as 52, etc.

Then the host software sends a DLE-ACK:

x10 06

ACK

DLE

12 Communications Specification

Page 19

Block Write

Chapter 1: ANAFAZE/AB Protocol

This section describes the block write command.

This example shows the block write command the master sends, the

controller's responses, and the master's acknowledgment:

Situation: Write setpoint of 100 to loop 6.

• 1 setpoint 2 bytes per setpoint = 2 bytes to address x01CA (x01C0 +

xA, a 10-byte offset).

• Character values are represented in hexadecimal.

• The sender is device address 0.

• The destination is device address 8 (controller address 1).

• The software sends transaction number 00.

Here's a picture of the write command:

x10 02 08 00 08 00 00 00 CA 01 E8 03 10 03 3A

DLE

Data:

100 converts to 1000 = x03E8

(assuming the precision for loop 6 is –1)

Data table address

LSB first; x01CA = setpoint for loop

Transaction number

Placeholder for status byte

Command (block write)

SRC (Source Device Address)

DST (Destination Device Address)

STX

DLE

The controller sends a DLE-ACK:

x10 06

BCC value

ETX

DLE

ACK

Communications Specification 13

Page 20

Chapter 1: ANAFAZE/AB Protocol

Here’s a picture of the controller’s reply:

x10 02 00 08 48 00 00 00 10 03 B0

BCC value

ETX

DLE

Transaction number LSB/MSB

Status (00 = Nothing to report)

Command (block write)

Source device address

Destination device address

STX

DLE

Message Data

Data for a Read Command

Then the host software sends a DLE-ACK:

x10 06

ACK

DLE

Some messages contain data. What the data is and how much depends

on the command used and the purpose of the message.

For a block read command, the data block consists of one byte that

indicates the number of bytes to read (up to 244 bytes of data). The

controller sends back a packet with a data block that contains the

requested bytes.

14 Communications Specification

Page 21

Data for a Write Command

For a block write command, the block contains the bytes to write (up to

242 bytes of data). The controller sends back a message packet without

data.

Two-Byte Data Types

For two-byte data types, like process variable and setpoint, the

controller or host software sends the data in two-byte pairs with the least

significant byte first.

Figuring Block Size

In order to read parameter values, you must know how many bytes to

request. Parameter values are stored contiguously such that the setpoints

for all the loops are stored together and in loop number order. For

example, to read the deviation alarm deadband value for loops one to

five, you would read five bytes starting at x05A0. Some parameters,

such as setpoint, require two bytes of memory to store. So, for example,

if you want to read the setpoint for four loops, you must read eight

bytes.

Chapter 1: ANAFAZE/AB Protocol

Figure total block size in bytes for most loop parameters this way (do

not forget the pulse loop):

(Data Size) * (Number of Loops)

Some parameters have values for both heat and cool. Figure block size

for such a parameter this way:

2 * (Data Size) * (Number of Loops)

One exception is the units for each loop. Figure the data size for the

units this way:

3 * (Number of Loops)

Parameters that are not loop parameters (like system status, digital

inputs, or digital outputs) have specific data sizes. These data sizes are

listed in the data table in the next section.

Communications Specification 15

Page 22

Chapter 1: ANAFAZE/AB Protocol

Anafaze/AB Data Table Summary

Each address holds one byte of data. Each parameter value requires one

or two addresses to store depending on the type of data. The table below

indicates the number of bytes for each data type. The data type for each

parameter is indicated in the tables on the following pages.

Unsigned char (UC) 1 byte

Signed char (SC) 1 byte

Unsigned int (UI) 2 bytes

Signed int (SI) 2 bytes

Because each loop is individually configurable, the number of instances

of many parameters depends on the number of loops in the controller.

Therefore, the number of bytes for these parameters is listed in the

tables on the following pages in terms of the number of loops in the

controller.

Data Type and Symbol Data Size

The storage requirements for some parameters depend on the number of

digital inputs or digital outputs in the controller (MAX_DIGIN_BYTES

and MAX_DIGOUT_BYTES). The storage of ramp-soak profile

parameters depend on the number of profiles (MAX_RSP), the number

of segments per profile (MAX_SEG), the number of triggers per

segment (MAX_TRIG) and the number of events per segment

(MAX_EVENT).

The table below shows the values for each of these factors. Use them to

calculate the number of bytes for each parameter.

MAX_CH:

4CLS/CLS204 (4 loops + 1 pulse loop)

8CLS/CLS208 (8 loops + 1 pulse loop)

16CLS/CLS216/CAS200 (16 loops + 1 pulse loop)

16MLS/MLS316 (16 loops + 1 pulse loop)

32MLS/MLS332 (32 loops + 1 pulse loop)

MAX_DIGIN_BYTES 1

MAX_DIGOUT_BYTES 8

MAX_RSP 17

MAX_SEG 20

MAX_TRIG 2

MAX_EVENT 4

5

9

17

17

33

16 Communications Specification

Page 23

Ordering of Heat and Cool Channel Parameters

For parameters that have both heat and cool settings the heat values are

stored in the first registers and the cool values are stored in the registers

starting at the listed address plus MAX_CH.

NOTE

Data table parameters 46 to 60 and 100 are ramp-soak

parameters. They are only used in controllers with the

ramp-soak option. Parameters 81 to 95 are enhanced features and only available in controllers with the enhanced

features option.

Ordering of Ramp-Soak Profile Parameters

Ramp-soak profile parameters are ordered first by profile, then by

segment where applicable. So, for example, the first eight bytes of the

Ready Events parameter are the ready segment event states for the first

profile (profile A) and the next eight bytes are for profile B and so on. In

the case of the segment triggers, the first byte contains the first trigger

setting for the first segment of profile A, the second byte contains the

settings for the second trigger for the first segment of profile A, the third

byte contains the settings for the first trigger for the second segment of

profile A and so on.

Chapter 1: ANAFAZE/AB Protocol

Anafaze/AB Protocol Data Table

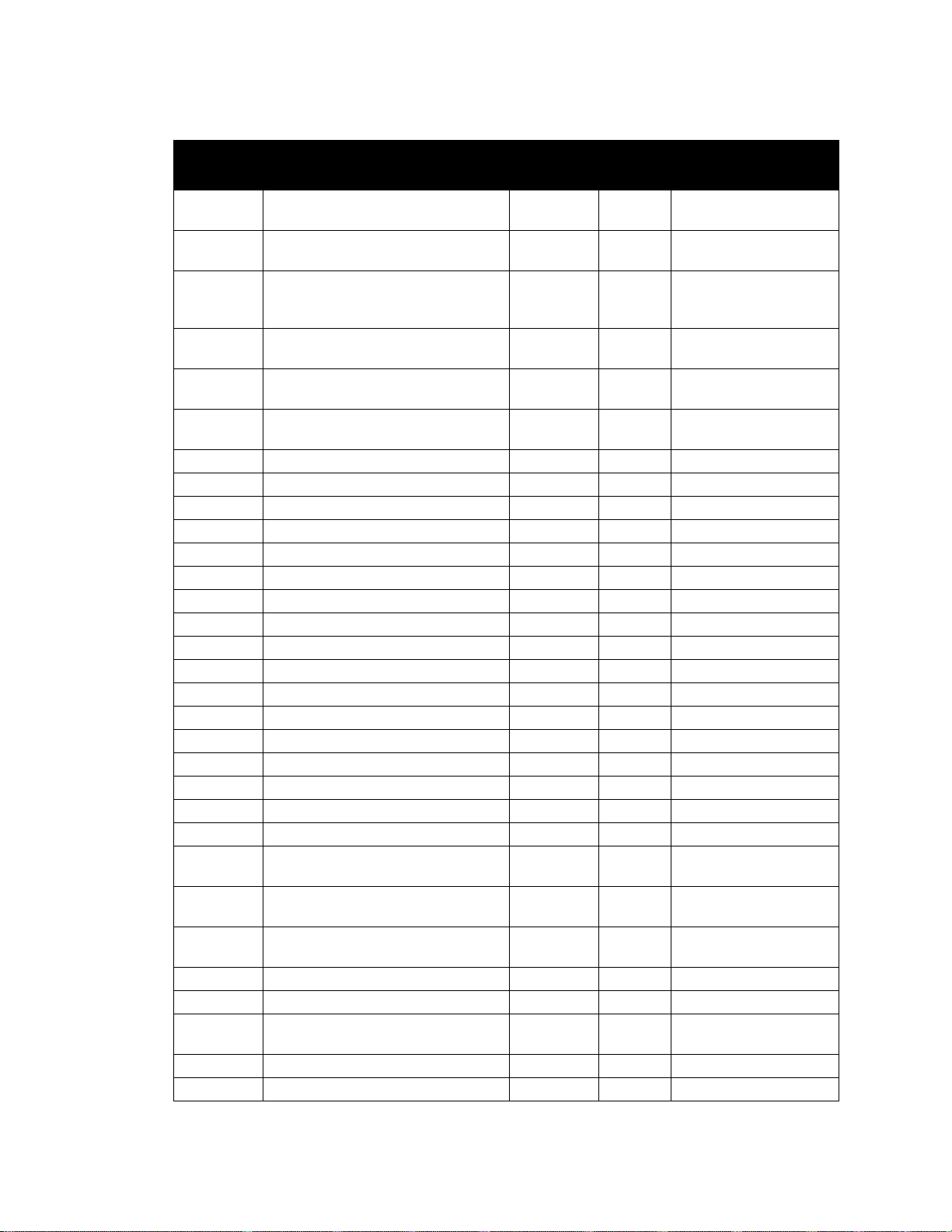

Number Description

0 Proportional Band/Gain 0020 UC MAX_CH * 2

1 Derivative Term 0060 UC MAX_CH * 2

2 Integral Term 00A0 UI MAX_CH * 4

3 Input T ype 0120 UC MAX_CH

4 Output Type 0180 UC MAX_CH * 2

5 Setpoint 01C0 SI MAX_CH * 2

6 Process Variable 0280 SI MAX_CH * 2

7 Output Filter 0340 UC MAX_CH * 2

8 Output Value 0380 UI MAX_CH * 4

9 High Process Alarm Setpoint 0400 SI MAX_CH * 2

10 Low Process Alarm Setpoint 04C0 SI MAX_CH * 2

11 Deviation Alarm Band Value 05A0 UC MAX_CH

12 Alarm Deadband 0600 UC MAX_CH

13 Alarm Status 0660 UI MAX_CH * 2

14 Not used 06A0 128

Address

in Hex

Type Number of Bytes

Communications Specification 17

Page 24

Chapter 1: ANAFAZE/AB Protocol

Number Description

15 Ambient Sensor Readings 0720 SI 2

16 Pulse Sample Time 0730 UC 1

17 High Process Variable 0790 SI MAX_CH * 2

18 Low Process Variable 0850 SI MAX_CH * 2

19 Precision 0910 SC MAX_CH

20 Cycle Time 09D0 UC MAX_CH * 2

21 Zero Calibration 0A10 UI 2

22 Full Scale Calibration 0A16 UI 2

23 Not used 0A1C 4

24 Not used 0A20 64

25 Digital Inputs 0A60 UC MAX_DIGIN_BYTES

26 Digital Outputs 0A70 UC MAX_DIGOUT_BYTES

27 Reserved 0A80 UC MAX_DIGOUT_BYTES

28 Override Digital Input 0AA0 UC 1

29 Override Polarity 0AC0 UC 1

30 System Status 0AC8 UC 4

31 System Command Register 0ACC UC 1

32 Data Changed Register 0ACE UC 1

33 Input Units 0AD0 UC MAX_CH * 3

34 EPROM V ersion Code 0BF0 UC 12

35 Options Register 0BFC UC 1

36 Process Power Digital Input 0C00 UC 1

37 High Reading 0C60 SI MAX_CH * 2

38 Low Reading 0D20 SI MAX_CH * 2

39 Heat/Cool Spread 0DE0 UC MAX_CH

40 Startup Alarm Delay 0E20 UC 1

41 High Process Alarm Output Number 0E30 UC MAX_CH

42 Low Process Alarm Output Number 0E90 UC MAX_CH

43 High Deviation Alarm Output

Number

44 Low Deviation Alarm Output Number 0F50 UC MAX_CH

45 Not used 0F60 MAX_CH

46 Channel Profile and Status 1000 UC MAX_CH

47 Current Segment 1020 UC MAX_CH

48 Segment Time Remaining 1040 UI MAX_CH * 2

49 Current Cycle Number 1080 UI MAX_CH * 2

50 Tolerance Alarm Time 10C0 UI MAX_CH * 2

51 Last Segment 1100 UC MAX_CH

52 Number Cycles 1120 UC MAX_CH

53 Ready Setpoint 1140 SI MAX_RSP * 2

Address

in Hex

0EF0 UC MAX_CH

Type Number of Bytes

18 Communications Specification

Page 25

Chapter 1: ANAFAZE/AB Protocol

Number Description

54 Ready Event States 1180 UC MAX_RSP *

55 Segment Setpoint 1280 SI MAX_RSP * 2 *

56 Triggers and Trigger States 1780 UC MAX_RSP*

57 Segment Events and Event States 1C80 UC MAX_RSP * MAX_SEG

58 Segment Time 2680 UI MAX_RSP * 2 *

59 Tolerance 2B80 SI MAX_RSP * 2 *

60 Ramp/Soak Flags 3080 UC MAX_CH

61 Output Limit 3200 SI MAX_CH * 4

62 Output Limit Time 3280 SI MAX_CH * 4

63 Alarm_Control 3300 UI MAX_CH * 2

64 Alarm_Acknowledge 33C0 UI MAX_CH * 2

65 Alarm_Mask 3480 UI MAX_CH * 2

66 Alarm_Enable 3540 UI MAX_CH * 2

67 Output Override Percentage 3600 SI MAX_CH * 4

68 AIM Failure Output 3690 UC 1

69 Output Linearity Curve 3700 UC MAX_CH * 2

70 SDAC Mode 3740 UC MAX_CH * 2

71 SDAC Low Value 3780 SI MAX_CH * 4

72 SDAC High Value 3800 SI MAX_CH * 4

73 Save Setup to Job 3880 UC 1

74 Input Filter 3890 UC MAX_CH

75 Loop Alarm Delay 38D0 UI MAX_CH * 2

76 Not used 3990 16

77 Loop Names

(CLS/CLS200 and MLS/MLS300)

78 T/C Failure Detection Flags

(CLS/CLS200 and MLS/MLS300)

78 Channel Name

(CAS/CAS200)

79 Restore PID Digital Input 4130 UC MAX_CH

80 Manufacturing Test 4160 UI 1

81 PV Retransmit Primary Loop

Number

82 PV Retransmit Maximum Input 4250 UI MAX_CH * 4

83 PV Retransmit Maximum Output 42E0 UC MAX_CH * 2

Address

in Hex

39A0 UI MAX_CH * 2

3A30 UC MAX_CH

3994 UC MAX_CH * 8

4200 UC MAX_CH * 2

Type Number of Bytes

MAX_DIGOUT_BYTES

MAX_SEG

MAX_SEG*

MAX_TRIG

* MAX_EVENT

MAX_SEG

MAX_SEG

Communications Specification 19

Page 26

Chapter 1: ANAFAZE/AB Protocol

Number Description

84 PV Retransmit Minimum Input 4330 UI MAX_CH * 4

85 PV Retransmit Minimum Output 43C0 UC MAX_CH * 2

86 Cascade Primary Loop Number 4410 UC MAX_CH

87 Cacade Base Setpoint 4440 SI MAX_CH * 2

88 Cacade Minimum Setpoint 4490 SI MAX_CH * 2

89 Cascade Maximum Setpoint 44E0 SI MAX_CH * 2

90 Cascade Heat/Cool Span 4530 UI MAX_CH * 4

91 Ratio Control Master Loop Number 45C0 UC MAX_CH

92 Ratio Control Minimum Setpoint 45F0 SI MAX_CH * 2

93 Ratio Control Maximum Setpoint 4640 SI MAX_CH * 2

94 Ratio Control Control Ratio 4690 UI MAX_CH * 2

95 Ratio Control Setpoint Differential 46E0 SI MAX_CH * 2

96 Loop Status 4730 UC MAX_CH

97 Output Type/Disable 4760 UC MAX_CH * 2

98 Output Reverse/Direct 47B0 UC MAX_CH * 2

99 Controller T ype 47F0 UC 1

100 Ramp/Soak Profile Number 4800 UC MAX_CH

101 Controller Address 4830 UC 1

102 Baud Rate 4840 UC 1

Address

in Hex

Type Number of Bytes

20 Communications Specification

Page 27

Chapter 2: Modbus-RTU Protocol

Chapter 2: Modbus-RTU Protocol

Overview

Transactions on Modbus-RTU Networks

Standard Modbus-RTU ports use an EIA/TIA-232C- or EIA/TIA-485/

422-compatible serial interface that defines connector pinouts, cabling,

signal levels, transmission baud rates, and parity checking.

Controllers communicate using a master-slave technique, in which only

one device (the master) can initiate transactions (called “queries”). The

other devices (slaves) respond by supplying the requested data to the

master, or by taking the action requested in the query. Typical master

devices include host processors and programming panels.

The master can address individual slaves, or initiate a broadcast

message to all slaves. Slaves return a message (called a “response”) to

queries that are addressed to them individually. Responses are not

returned to broadcast queries from the master.

The Modbus-RTU protocol establishes the format for the master’s query

by placing into it the device (or broadcast) address, a function code

defining the requested action, any data to be sent, and an error-checking

field. The slave’s response message is also constructed using ModbusRTU protocol. It contains fields confirming the action taken, any data to

be returned, and an error-checking field. If an error occurred in receipt

of the message, or if the slave is unable to perform the requested action,

the slave will construct an error message and send it as its response.

Communications Specification 21

Page 28

Chapter 2: Modbus-RTU Protocol

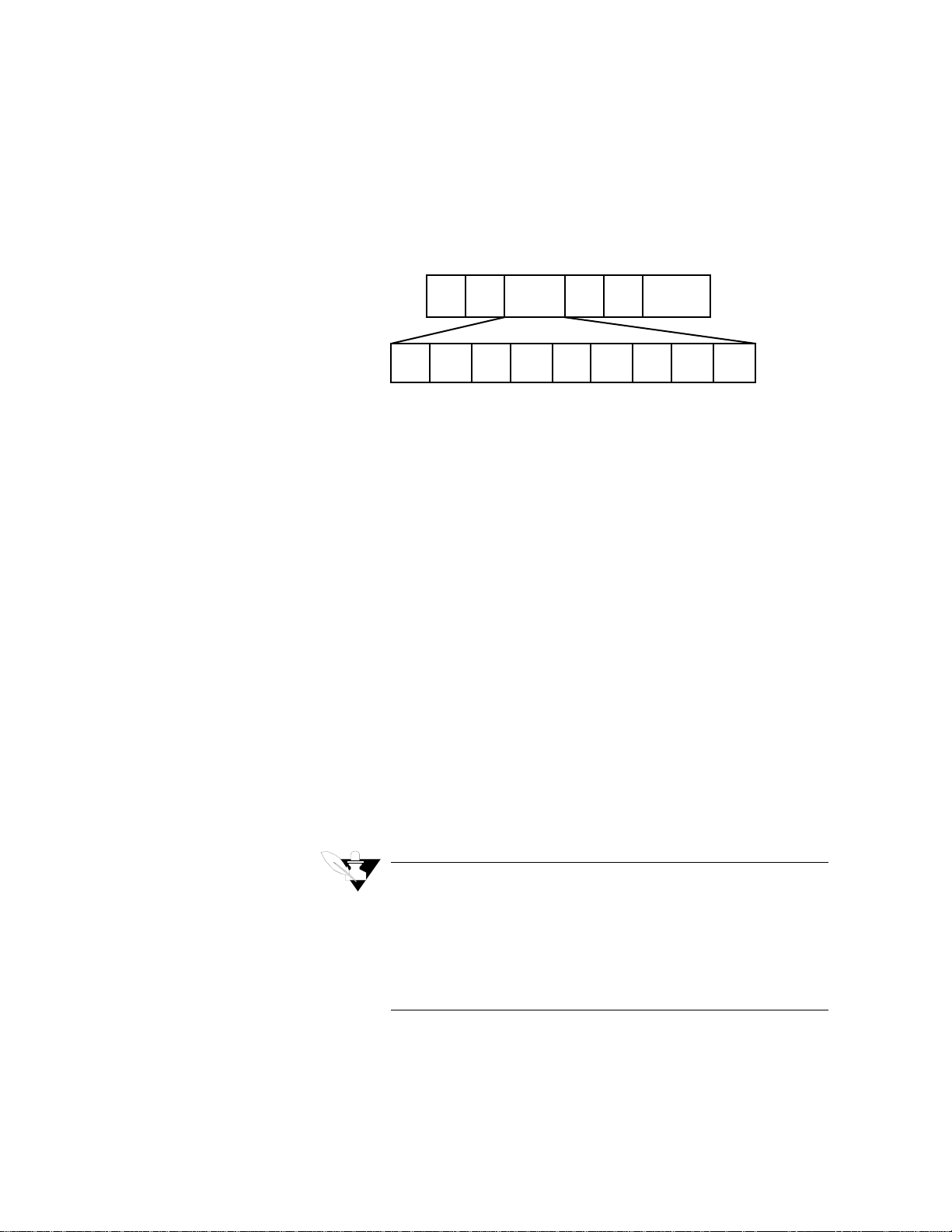

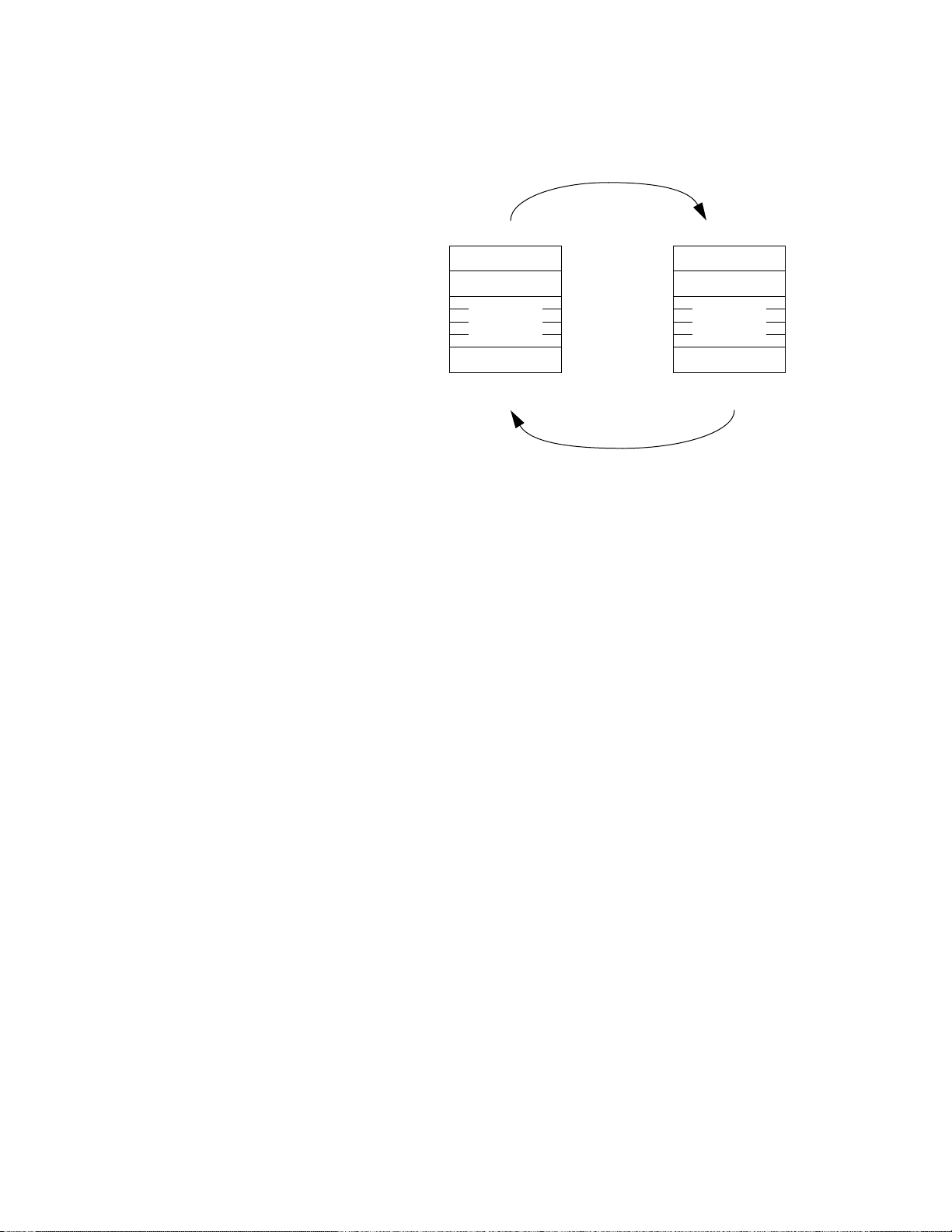

The Query-Response Cycle

Query Message from Master

Device Address

Function Code

8-Bit

Data Bytes

Error Check

Device Address

Function Code

8-Bit

Data Bytes

Error Check

Response Message from Slave

The Query

The function code in the query tells the addressed slave device what

kind of action to perform. The data bytes contain any additional

information that the slave will need to perform the function. For

example, function code 03 will query the slave to read holding registers

and respond with their contents. The data field must contain the

information telling the slave which register to start at and how many

registers to read. The error check field provides a method for the slave to

validate the integrity of the message contents.

The Response

If the slave makes a normal response, the function code in the response

is an echo of the function code in the query. The data bytes contain the

data collected by the slave, such as register values or status. If an error

occurs, the function code is modified to indicate that the response is an

error response, and the data bytes contain a code that describes the error.

The error check field allows the master to confirm that the message

contents are valid.

Serial Transmission

22 Communications Specification

Each 8-bit byte in a message contains two 4-bit hexadecimal characters.

This high character density allows better data throughput than ASCII for

the same baud rate. Each message must be transmitted in a continuous

stream.

Coding System

• 8-bit binary, hexadecimal 0 to 9, A to F

• 2 hexadecimal characters contained in each 8-bit field of the message

Bits per Byte

• 1 start bit

Page 29

Message Framing

Chapter 2: Modbus-RTU Protocol

• 8 data bits, least significant bit sent first

• 2 stop bits

• No parity

Error Check Field

Cyclical Redundancy Check (CRC)

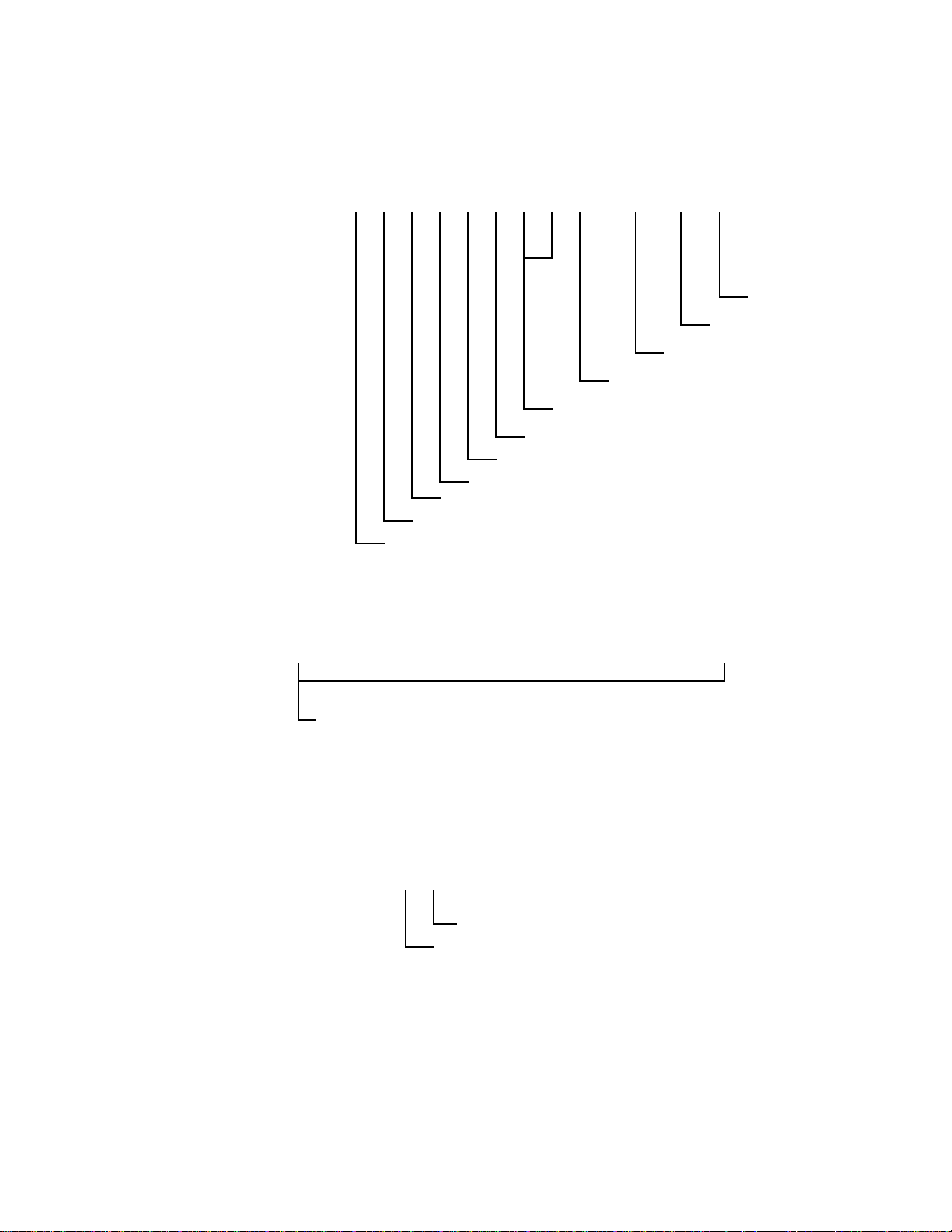

Messages start with a silent interval of at least 3.5 character times. This

is most easily implemented as a multiple of character times at the baud

rate that is being used on the network (shown as T1-T2-T3-T4 in the

figure below). The first field then transmitted is the device address.

The allowable characters transmitted for all fields are hexadecimal 0 to

9, A to F. Networked devices monitor the network bus continuously,

including during the silent intervals. When the first field (the address

field) is received, each device decodes it to find out if it is the addressed

device.

Following the last transmitted character, a similar interval of at least 3.5

character times marks the end of the message. A new message can begin

after this interval.

Similarly, if a new message begins earlier than 3.5 character times

following a previous message, the receiving device will consider it a

continuation of the previous message. This will set an error, as the value

in the final CRC field will not be valid for the combined messages. A

typical message frame is shown below.

START ADDRESS FUNCTION DATA CRC CHECK END

n

T1-T2-T3-T4 8 Bits 8 Bits

* 8 Bits 16 Bits T1-T2-T3-T4

Handling the Address Field

The address field of a message frame contains 8 bits. Valid slave device

addresses are in the range of 0 to 247 decimal. The individual slave

devices are assigned addresses in the range of 1 to 247 decimal. A

master addresses a slave by placing the slave address in the address field

of the message. When the slave sends its response, it places its own

address in this address field of the response to let the master know which

slave is responding.

Handling the Function Field

The function code field of a message frame contains 8 bits. Valid codes

are in the range of 1 to 255 decimal. Not all these codes are applicable to

all controllers. Current codes are described in the Function Codes

section.

Communications Specification 23

Page 30

Chapter 2: Modbus-RTU Protocol

When a message is sent from a master to a slave device, the function

code field tells the slave what kind of action to perform. Examples are to

read the On/Off states of a group of discrete coils or inputs; to read the

data contents of a group of registers; or to read the diagnostic status of a

slave.

When the slave responds to the master, it uses the function code field to

indicate either a normal (error-free) response or that some kind of error

occurred (called an exception response). For a normal response, the

slave simply echoes the original function code. For an exception

response, the slave returns a code that is equivalent to the original

function code with its most significant bit set to a logic 1.

For example, a message from the master to slave to read a group of

holding registers would have the following function code:

0000 0011 x3

If the slave device takes the requested action without error, it returns the

same code in its response. If an exception occurs, it returns:

1000 0011 x83

In addition to its modification of the function code for an exception

response, the slave places a unique code into the data field of the

response message. This tells the master what kind of error occurred, or

the reason for the exception.

The master device’s application program has the responsibility of

handling exception responses. Typical processes are to post subsequent

retries of the message, to try diagnostic messages to the slave, and to

notify operators.

Contents of the Data Field

The data field is constructed using sets of two hexadecimal numbers, in

the range of x00 to xFF.

The data field of messages sent from a master to slave devices contains

additional information that the slave must use to take the action defined

by the function code. This can include items like descrete and register

addresses, the quantity of items to be handled, and the count of actual

data bytes in the field.

For example, if the master requests a slave to read a group of holding

registers (function code 03), the data field specifies the starting register

and how many registers are to be read.

24 Communications Specification

If no error occurs, the data field of a response from a slave to a master

contained the data requested. If an error occurs, the field contains an

exception code that the master application can use to determine the next

action to be taken.

Page 31

Chapter 2: Modbus-RTU Protocol

The data field can be nonexistent (of zero length) in certain kinds of

messages, where the function code alone specifies the action.

Contents of the Error Checking Field

The error checking field contains a 16-bit value implemented as two 8bit bytes. The error check value is the result of a Cyclical Redundancy

Check (CRC) calculation performed on the message contents.

The CRC field is appended to the message as the last field in the

message. When this is done, the low-order byte of the field is appended

first, followed by the high-order byte. The CRC high-order byte is the

last byte to be sent in the message.

How Characters are Transmitted Serially

When messages are transmitted on standard Modbus-RTU serial

networks, each character or byte is sent in this order (left to right):

Least Significant Bit (LSB).............Most Significant Bit (MSB)

The bit sequence is:

Start 1 2 3 4 5 6 7 8 Stop Stop

CRC Error Checking

All messages include an error-checking field that is based on a Cyclical

Redundancy Check (CRC) method. The CRC field checks the contents

of the entire message. It is applied regardless of any parity check

method used for the individual characters of the message.

The CRC field is two bytes, containing a 16-bit binary value. The CRC

value is calculated by the transmitting device, which appends the CRC

to the message. The receiving device recalculates a CRC during receipt

of the message, and compares the calculated value to the actual value it

received in the CRC field. If the two values are not equal, an error

results.

The CRC is started by first preloading a 16-bit register to all 1’s. Then a

process begins of applying successive 8-bit bytes of the message to the

current contents of the register. Only the 8 bits of data in each character

are used for generating the CRC. Start and stop bits do not apply to the

CRC.

During generation of the CRC, each 8-bit character is exclusive ORed

with the register contents. Then the result is shifted in the direction of

the least significant bit (LSB), with a zero filled into the most significant

bit (MSB) position. The LSB is extracted and examined. If the LSB was

a 1, the register is then exclusive ORed with a preset, fixed xA001. If the

LSB was a 0, no exclusive OR takes place.

Communications Specification 25

Page 32

Chapter 2: Modbus-RTU Protocol

Function Codes

This process is repeated until eight shifts have been performed. After the

last shift, the next 8-bit byte is exclusive ORed with the register’s

current value, and the process repeats for eight more shifts as described

above. The final contents of the register, after all the bytes of the

message have been applied, is the CRC value.

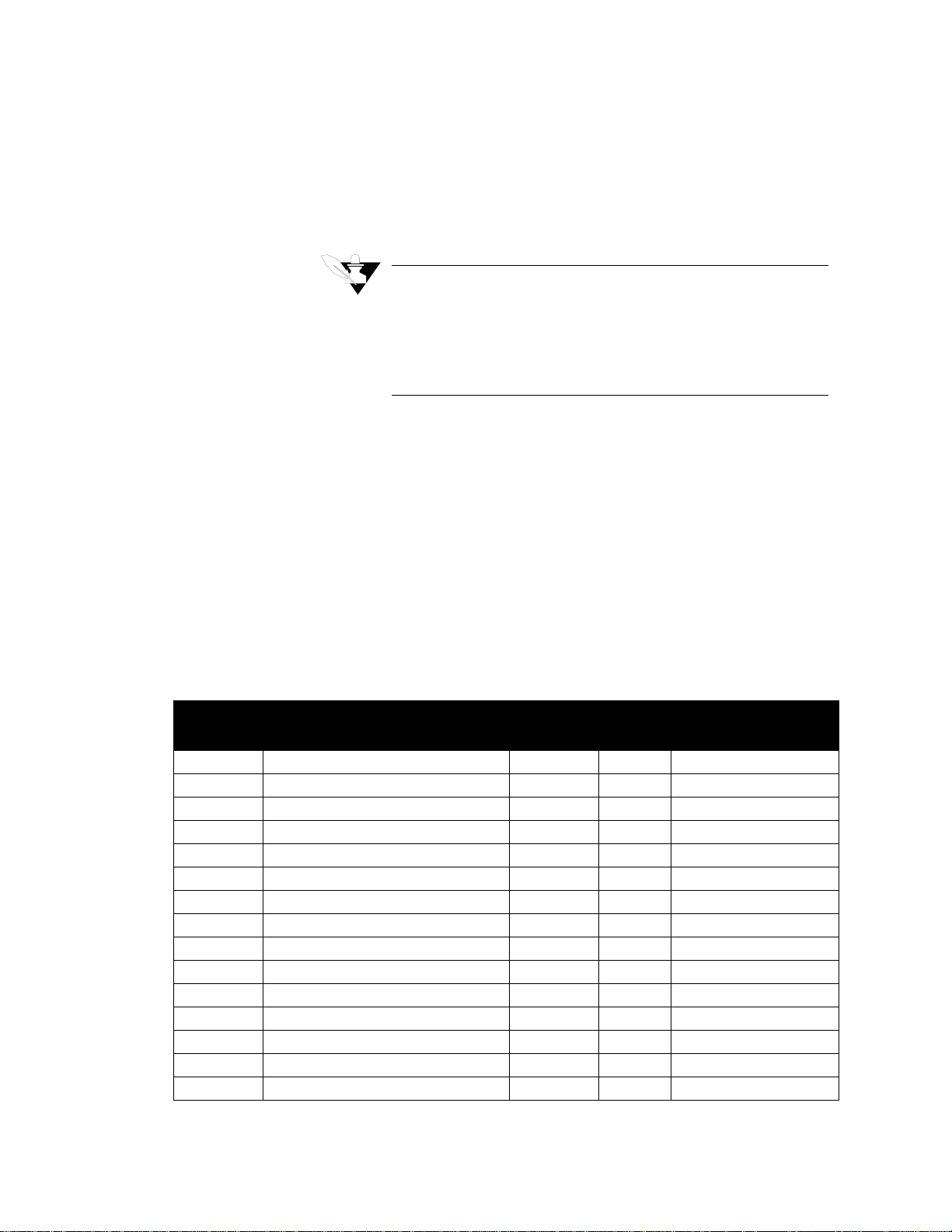

The listing below shows the function codes supported by the CLS

controllers. Codes are listed in decimal.

Code

in Hex

01 Read Coil Status

02 Read Input Status

03 Read Holding Registers

04 Read Input Registers

05 Force Single Coil

06 Preset Single Register

08 Diagnostics

0F Force Multiple Coils

10 Preset Multiple Registers

Name

x01 Read Coil Status

• Reads the On/Off status of discrete outputs (registers 00001 to

09999, the coils) in the slave. Broadcast is not supported.

x02 Read Input Status

• Reads the On/Off status of discrete inputs (registers 10001 to 19999)

in the slave. Broadcast is not supported.

x03 Read Holding Registers

• Reads the binary contents of holding registers (registers 40001 to

49999) in the slave. Broadcast is not supported.

26 Communications Specification

x04 Read Input Registers

• Reads the binary contents of input registers (registers 30001 to

39999) in the slave. Broadcast is not supported.

x05 Force Single Coil

• Forces a single coil (registers 00001 to 09999, the coils) to either On

or Off. When broadcast, the function forces the same coil reference

in all attached slaves.

Page 33

Chapter 2: Modbus-RTU Protocol

NOTE

The function will override the controller’s memory protect

state and the coil’s disable state. The forced state will

remain valid until the controller’s logic next solves the coil.

The coil will remain forced if it is not programmed in the

controller’s logic.

x06 Preset Single Register

• Presets a value into a single holding register (registers 40001 to

49999). When broadcast, the function presets the same register reference in all attached slaves.

NOTE

The function will override the controller’s memory protect

state. The preset value will remain valid in the register until

the controller’s logic next solves the register contents. The

register’s value will remain if it is not programmed in the

controller’s logic.

x08 Diagnostics

• This function provides a series of tests for checking the communica-

tion system between the master and slave, or for checking various

internal error conditions within the slave. Broadcast is not supported.

• The function uses a 2-byte subfunction code field in the query to

define the type of test to be performed. The slave echoes both the

function code and subfunction code in a normal response.

• Most of the diagnostic queries use a 2-byte data field to send diag-

nostic data or controller information to the slave. Some of the diagnostics cause data to be returned from the slave in a data field of a

normal response.

Diagnostic Subfunctions

x00 Return Query Data

• The data passed in the query data field is to be returned

(looped back) in the response. The entire response message

should be identical to the query.

Subfunction Data Field (Query) Data Field (Response)

x00 00 Any Echo Query Data

x01 Restart Communications Option

• The slave’s peripheral port is to be initialized and restarted,

and all of its communications event counters are to be

cleared. If the port is currently in Listen Only Mode, no

Communications Specification 27

Page 34

Chapter 2: Modbus-RTU Protocol

response is returned. This function is the only one that

brings the port out of Listen Only Mode. If the port is not

currently in Listen Only Mode, a normal response is

returned. This occurs before the restart is executed.

Subfunction Data Field (Query) Data Field (Response)

x00 01 x00 00 Echo Query Data

x00 01 xFF 00 Echo Query Data

x02 Return Diagnostic Register

• The contents of the slave’s 16-bit diagnostic register are

returned in the response.

Subfunction Data Field (Query) Data Field (Response)

x00 02 x00 00 Diagnostic Register

Contents

x04 Force Listen Only Mode

• Forces the addressed slave to its Listen Only Mode for

Modbus-RTU communications. This isolates it from the

other devices on the network, allowing them to continue

communicating without interruption from the addressed

slave. No response is returned.

• When the slave enters its Listen Only Mode, all active com-

munication controls are turned off. The ready watchdog

timer is allowed to expire, locking the controls off. While in

this mode, any Modbus-RTU messages addressed to the

salve or broadcast are monitored, but no actions will be

taken and no responses will be sent.

• The only function that will be processed after the mode is

entered will be the Restart Communications Option function (function code 8, subfunction 1).

Subfunction Data Field (Query) Data Field (Response)

x00 04 x00 00 No Response

Returned

28 Communications Specification

x0A Clear Counters

• Clears all Communication Event counters. Counters are

also cleared upon power-up.

Subfunction Data Field (Query) Data Field (Response)

x00 0A x00 00 Echo Query Data

x0B Return Bus Message Count

• The response data field returns the quantity of messages that

the slave has detected on the communications system since

its last restart, clear counters operations, or power-up.

Subfunction Data Field (Query) Data Field (Response)

x00 0B x00 00 Total Message Count

x0C Return Bus Communication Error Count

• The response data field returns the quantity of CRC errors

encountered by the slave since its last restart, clear counters

Page 35

Chapter 2: Modbus-RTU Protocol

operation, or power-up.

Subfunction Data Field (Query) Data Field (Response)

x00 0C x00 00 CRC Error Count

x0D Return Bus Exception Error Count

• The response data field returns the quantity of Modbus-RTU

exception responses returned by the slave since its last

restart, clear counters operation, or power-up.

Subfunction Data Field (Query) Data Field (Response)

x00 0D x00 00 Exception Error

Count

x0E Return Slave Message Count

• The response data field returns the quantity of messages

addressed to the slave, or broadcast, that the slave has processed since its last restart, clear counters operation, or

power-up.

Subfunction Data Field (Query) Data Field (Response)

x00 0E x00 00 Slave Message Count

x0F Return Slave No Response Count

• The response data field returns the quantity of messages

addressed to the slave for which it returned a no response

(neither a normal response nor an exception response),

since its last restart, clear counters operation, or power-up.

Subfunction Data Field (Query) Data Field (Response)

x00 0F x00 00 Slave No Response

Count

x0F Force Multiple Coils

• Forces each coil (registers 00001 to 09999, the coils) in a sequence

of coils to either ON or OFF. When broadcast, the function forces

the same coil references in all attached slaves.

x10 Preset Multiple registers

• Presets values into the sequence of holding registers (registers 40001

to 49999). When broadcast, the function presets the same register

references an all attached slaves.

NOTE

The function will override the controller’s memory protect

state. The preset values will remain valid in the registers

until the controller’s logic next solves the register contents.

The register values will remain if they are not programmed

in the controller’s logic.

Communications Specification 29

Page 36

Chapter 2: Modbus-RTU Protocol

Writing Data

Reading Data

Watlow Anafaze controller memory is divided into approximately 100

parameters with unique control functions, such as temperature, set

point, etc. Each parameter can have several Modbus-RTU addresses

associated with it. When a Modbus-RTU host writes data to a controller

parameter, the data sent may “command” controller firmware to perform

specific functions. While host writes to multiple registers are permitted

within a parameter, controller function hierarchies necessitate that only

one parameter may be written at a time. Any data written past a

parameter boundary is simply rejected.

The same parameter-based model is used for reading data from the

controller’s Modbus-RTU interface. Modbus-RTU allows multiple

register block reads for all types of registers. While Watlow Anafaze

Modbus-RTU allows this type of read function, unexpected results may

occur when reading registers that span across the boundaries of more

than one parameter. A query from a Modbus-RTU host starts specific

firmware processes that allow data to be formatted properly for the

Modbus-RTU host. The sequence proceeds as follows:

(1) A query for data comes in from a Modbus-RTU host.

(2) The controller determines what parameter among the hundred or so

is being queried.

(3) The data format from internal memory is converted for a Modbus-

RTU interface.

(a) Data for registers 40001 to 49999 and registers 30001 to

39999 are always two bytes in length. If the internal controller memory is in bit or byte size, the data is padded

appropriately.

(b) The byte order from internal memory is LSB to MSB (least

significant byte to most significant byte. For example, the

LSB first value for 550.0° would be x7C 15. The MSB first

value would be x15 7C.) while the Modbus-RTU is MSB to

LSB. Bytes are swapped as needed.

(4) Parameter data is sent to the Modbus-RTU interface.

When data from adjacent parameters is read and the parameters share

the same data type (bit, byte or integer), the information is formatted

correctly. However, if they do not share the same data type, host

software could be written to pad and/or swap bytes as necessary.

30 Communications Specification

Page 37

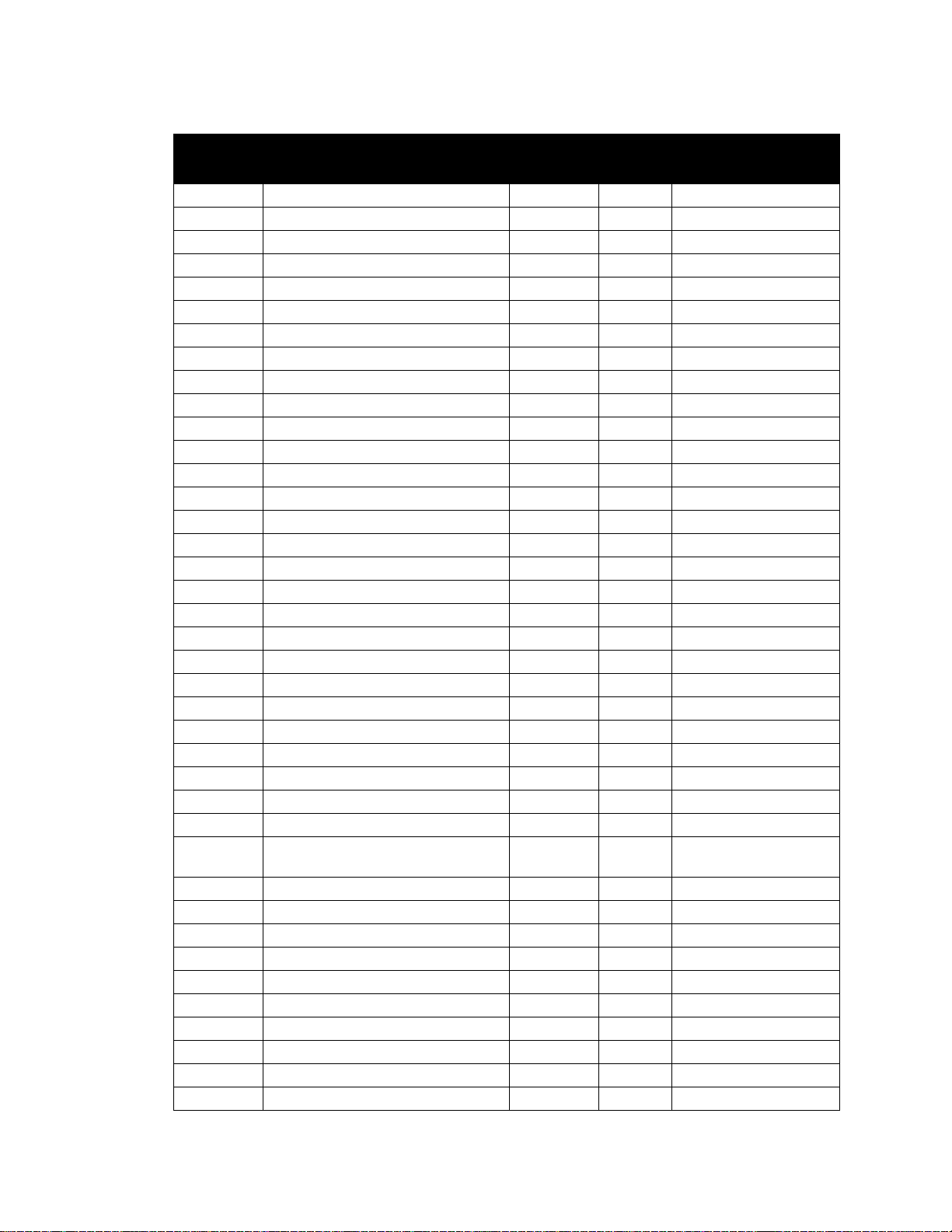

Examples

Chapter 2: Modbus-RTU Protocol

Read Examples

The data read must be sequentially located. If you’re reading a coil

rather than a register, you must offset the address by the location of the

bit you wish to read.

Sample Packet for Host Transmission

Slave

Example

1. Reading

Address

in Hex

01 03 01 6C 00 01 45 EB

PV of loop 2

(1600),

controller 1

(single-point

read)

2. Reading

03 03 01 D1 00 02 94 2C

loops 4 and 5

heat outputs,

of controller 3

(multipoint

read)

3. Reading

01 02 03 82 00 10 D9 AA

digital input

4, controller 1

(input status

read)

Example

1. Reading PV of loop 2 (1600),

controller 1 (single-point read)

2. Reading loops 4 and 5 (50%,

60%) outputs (heat), of controller 3

(multipoint read)

3. Reading digital input 4, controller

1 (input status read)

Function

in Hex

Start

Address

High

in Hex

Start

Address

Low

in Hex

Number

of Points

High

in Hex

Number

of Points

Low

in Hex

CRC

High

in Hex

Sample Packet for Slave Transmission

Slave

Address

in Hex

Function

in Hex

01 03 02 3E 80 84 1B

03 03 04 3F DE 4C 4A 2D 41

01 02 02 08 00 BE 78

Byte

Count

in Hex

Data

in Hex

CRC

High

in Hex

CRC

Low

in Hex

CRC

Low

in Hex

Communications Specification 31

Page 38

Chapter 2: Modbus-RTU Protocol

Write Examples

The data written is echoed back to the controller.

Sample Packet for Host Transmission, a Single-Point Write

Example

4. Writing loop 1

gain (20),

controller 4

(single-point

write)

5. Writing

digital output 30

(on), controller 2

(single coil

write)

Example

4. Writing loop 1

gain (20),

controller 4

(single-point

write)

5. Writing

digital output 30

(on), controller 2

(single coil

write)

Slave

Address

in Hex

Function

in Hex

Address

High

in Hex

Address

Low

in Hex

Data

High

in Hex

Data

Low

in Hex

CRC

High

in Hex

in Hex

04 06 00 00 00 14 89 90

02 05 03 A8 FF 00 0D AD

Sample Pac ket for Slave T ransmission, a Single-Point Write

Slave

Address

in Hex

Function

in Hex

04 06 00 00 00 14 89 90

02 05 03 A8 FF 00 OD AD

Address

High

in Hex

Address

Low

in Hex

Data

High

in Hex

Data

Low

in Hex

CRC

High

in Hex

in Hex

CRC

Low

CRC

Low

32 Communications Specification

Page 39

Chapter 2: Modbus-RTU Protocol

Sample Packet for Host Transmission, a Multipoint Write

The data must be written to sequential locations.

Helpful hint: The string is longer for multiple write; checking the

BYTE COUNT can help in determining if a command timeout is valid.

Example 6: Writing TI loops 3 (100) and 4 (150), controller

10.

Slave

Address

in Hex

Function

in Hex

Address

High

in Hex

Address

Low

in Hex

Number

of

Registers

High

in Hex

Number

of

Registers

Low

in Hex

Byte

Count

in Hex

Data

in Hex

CRC

High

in

Hex

in Hex

0A 10 00 86 00 02 04 00 64 00 96 9F 70

Sample Packet for Slave Transmission, a multipoint write.

Number

Slave

Address

in Hex

Function

in Hex

Address

High

in Hex

Address

Low

in Hex

of

Registers

High

in Hex

0A 10 00 86 00 02 A1 5A

Number of

Registers

Low

in Hex

CRC

High

in Hex

Modbus-RTU Data Table Summary

Each addressable register holds two bytes of data. Each parameter value

requires only one register to store any of these types of data. The data

type for each parameter is indicated in the tables on the following pages.

CRC

Low

CRC

Low

in

Hex

Data Type and Symbol Data Size

Unsigned char (UC) 1 byte

Signed char (SC) 1 byte

Unsigned int (UI) 2 bytes

Signed int (SI) 2 bytes

Because each loop is individually configurable, the number of instances

of many parameters depends on the number of loops in the controller.

Therefore, the number of registers for these parameters is listed in the

tables on the following pages in terms of the number of loops in the

controller.

Communications Specification 33

Page 40

Chapter 2: Modbus-RTU Protocol

The storage requirements for some parameters depend on the number of

digital inputs or digital outputs to the controller (MAX_DIGIN and

MAX_DIGOUT). The storage of ramp-soak profile parameters depend

on the number of profiles (MAX_RSP), the number of segments per

profile (MAX_SEG), the number of triggers per segment

(MAX_TRIG), and the number of events per segment (MAX_EVENT).

The table below shows the values for each of these factors. Use them to

calculate the number of registers for each parameter.

MAX_CH:

4CLS/CLS204 (4 loops + 1 pulse loop)

8CLS/CLS208 (8 loops + 1 pulse loop)

16CLS/CLS216/CAS200 (16 loops + 1 pulse loop)

16MLS/MLS316 (16 loops + 1 pulse loop)

32MLS/MLS332 (32 loops + 1 pulse loop

MAX_DIGIN 8

MAX_DIGOUT 35

MAX_RSP 17

MAX_SEG 20

MAX_TRIG 2

MAX_EVENT 4

5

9

17

17

33

NOTE

Data table parameters 46 to 60, 100 and 103 are ramp-soak

parameters. They are only used in controllers with the

ramp-soak option. Parameters 81 to 95 are enhanced features and are only available in controllers with the

enhanced features option.

Ordering of Heat and Cool Channel Parameters

For parameters that have both heat and cool settings, the heat values are

stored in the first registers and the cool values are stored in the registers

starting at the listed address plus MAX_CH.

Ordering of Ramp-Soak Profile Parameters

Ramp-soak profile parameters are ordered first by profile, then by

segment where applicable. So, for example, the first 35 registers of the

Ready Events parameter are the ready segment event states for the first

profile (profile A), the next 35 registers are for profile B, and so on. In

the case of the segment triggers, the first register contains the first

trigger setting for the first segment of profile A, the second register

contains the settings for the second trigger for the first segment of

profile A, the third register contains the settings for the first trigger for

the second segment of profile A, and so on.

34 Communications Specification

Page 41

Relative and Absolute Modbus Addresses

In the tables on the following pages, absolute addresses are in decimal

and relative addresses are in hexidecimal. Absolute addresses include

the type of register. Refer to the absolute address to determine which

function to use to read or write values (see the Function Codes on page

26).

Relative addresses indicate the register offset from the first register of

the particular type. For example, the first register for the Derivative

parameter is at 40067, which is offset 66 (x42) registers from the

beginning of the holding registers at 40001.

Modbus-RTU Protocol Data Table

Chapter 2: Modbus-RTU Protocol

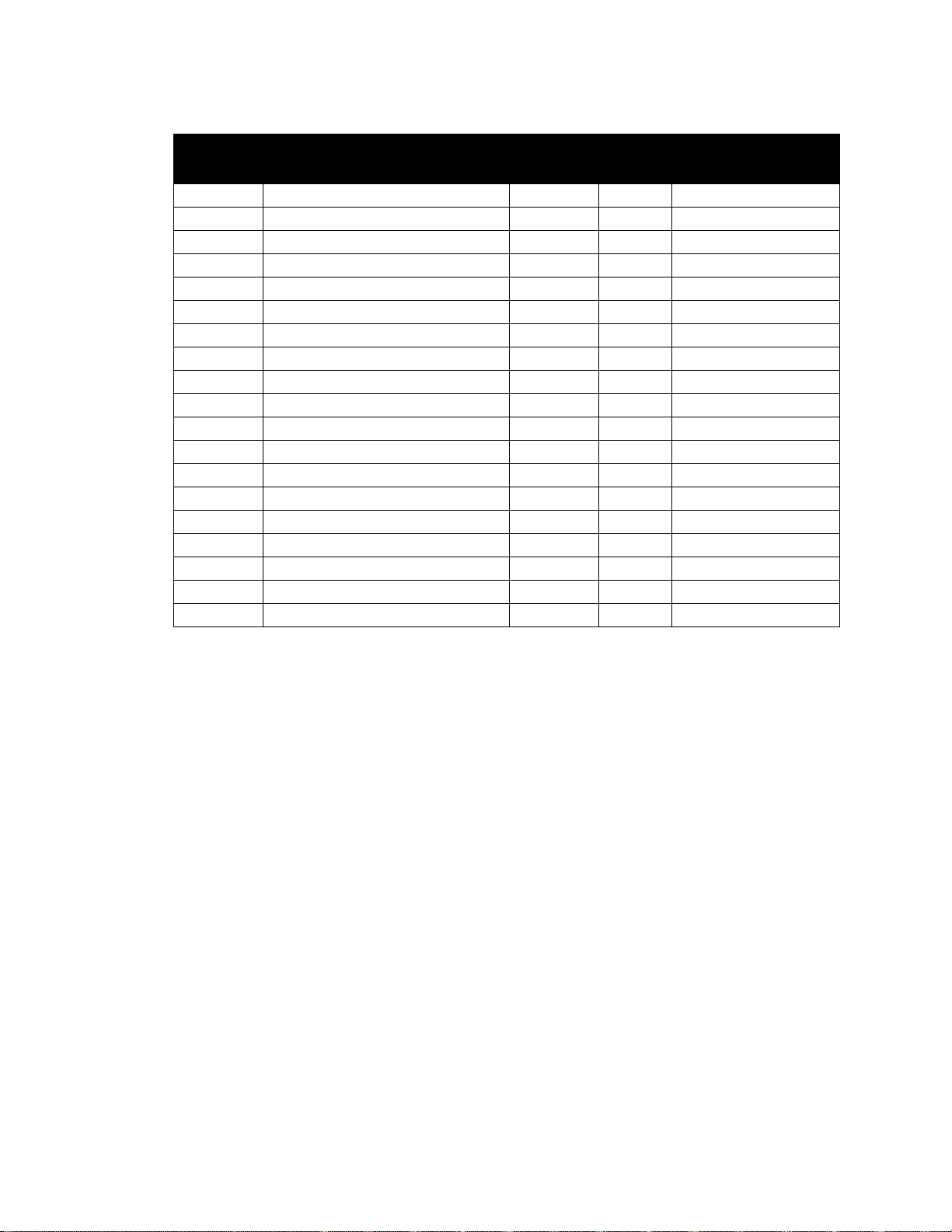

Number Description

0 Proportional Band/Gain 40001 0000 UC MAX_CH * 2

1 Derivative Term 40067 0042 UC MAX_CH * 2

2 Integral Term 40133 0084 UI MAX_CH * 2

3 Input T ype 40199 00C6 UC MAX_CH

4 Output Type 40265 0108 UC MAX_CH * 2

5 Setpoint 40331 014A SI MAX_CH

6 Process Variab le 40364 016B SI MAX_CH

7 Output Filter 40397 018C UC MAX_CH * 2

8 Output Value 40463 01CE UI MAX_CH * 2

9 High Process Alarm Setpoint 40529 0210 SI MAX_CH

10 Low Process Alarm Setpoint 40562 0231 SI MAX_CH

11 Deviation Alarm Band Value 40595 0252 UC MAX_CH

12 Alarm Deadband 40628 0273 UC MAX_CH

13 Alarm_Status 40661 0294 UI MAX_CH

14 Not used 40694 02B5 33

15 Ambient Sensor Readings 40727 02D6 SI 2

16 Pulse Sample Time 40729 02D8 UC 1

17 High Process Variable 40730 02D9 SI MAX_CH

18 Low Process Variable 40763 02FA SI MAX_CH

19 Precision 40796 031B SC MAX_CH

20 Cycle Time 40829 033C UC MAX_CH

21 Zero Calibration 40895 037E UI 2

22 Full Scale Calibration 40896 037F UI 2

23 Not used 40897 0380 1

24 Not used 40898 0381 1

25 Digital Inputs 10899 0382 Bit MAX_DIGIN

26 Digital Outputs 00907 038A Bit MAX_DIGOUT

Absolute

Address

Relative

Address in

Hex

Type

Number of

Registers

Communications Specification 35

Page 42

Chapter 2: Modbus-RTU Protocol

Number Description

27 Not used 40942 03AD UC 1

28 Override Digital Input 40943 03AE UC 1

29 Override Polarity 40944 03AF UC 1

30 System Status 40945 03B0 UC 4

31 System Command Register 40949 03B4 UC 1

32 Data Changed Register 40950 03B5 UC 1

33 Input Units 40951 03B6 UC MAX_CH * 3

34 EPROM V ersion Code 41050 0419 UC 1

35 Options Register 41062 0425 UC 1

36 Process Power Digital Input 41063 0426 UC 1

37 High Reading 41064 0427 SI MAX_CH

38 Low Reading 41097 0448 SI MAX_CH

39 Heat/Cool Spread 41130 0469 UC MAX_CH

40 Startup Alarm Delay 41163 048A UC 1

41 High Process Alarm Output

Number

42 Low Process Alarm Output

Number

43 High Deviation Alarm Output

Number

44 Low Deviation Alarm Output

Number

45 Not used 41296 050F 1

46 Channel Profile and Status 41297 0510 UC MAX_CH

47 Current Segment 41330 0531 UC MAX_CH

48 Segment Time Remaining 41363 0552 UI MAX_CH

49 Current Cycle Number 41924 0783 UI MAX_CH

50 Tolerance Alarm Time 41957 07A4 UI MAX_CH

51 Last Segment 41990 07C5 UC MAX_CH

52 Number of Cycles 42023 07E6 UC MAX_CH

53 Ready Setpoint 42056 0807 SI MAX_RSP

54 Ready Event States 42089 0828 UC MAX_RSP *

55 Segment Setpoint 42174 087D SI MAX_RSP * MAX_SEG

56 Triggers and Trigger States 42834 0B11 UC MAX_RSP * MAX_SEG

57 Segment Events and Event

States

58 Segment Time 46794 1A89 UI MAX_RSP * MAX_SEG

59 Tolerance 47454 1D1D SI MAX_RSP * MAX_SEG

60 Ramp/Soak Flags 48114 1FB1 UC MAX_CH

Absolute

Address

41164 048B UC MAX_CH

41197 04AC UC MAX_CH

41230 04CD UC MAX_CH

41263 04EE UC MAX_CH

44154 1039 UC MAX_RSP * MAX_SEG

Relative

Address in

Hex

Type

Number of

Registers

MAX_DIGOUT

* MAX_TRIG

* MAX_EVENT

36 Communications Specification

Page 43

Chapter 2: Modbus-RTU Protocol

Number Description

61 Output Limit 48147 1FD2 SI MAX_CH * 2

62 Output Limit Time 48213 2014 SI MAX_CH * 2

63 Alarm_Control 48279 2056 UI MAX_CH

64 Alarm_Acknowledge 48312 2077 UI MAX_CH

65 Alarm_Mask 48345 2098 UI MAX_CH

66 Alarm_Enable 48378 20B9 UI MAX_CH

67 Output Override Percentage 48411 20DA SI MAX_CH * 2

68 AIM Fail Output 48477 211C UC 1

69 Output Linearity Curve 48478 211D UC MAX_CH

70 SDAC Mode 48544 215F UC MAX_CH * 2

71 SDAC Low Value 48610 21A1 SI MAX_CH * 2

72 SDAC High Value 48676 21E3 SI MAX_CH * 2

73 Save Setup to Job 48742 2225 UC 1

74 Input Filter 48743 2226 UC MAX_CH

75 Loop Alarm Delay 48776 2247 UI MAX_CH

76 Not used 48809 2268 1

77 Loop Names

(CLS/CLS200 and MLS/

MLS300)

78 T/C Failure Detection Flags

(CLS/CLS200 and MLS/

MLS300)

78 Channel Name

(CAS/CAS200)

79 Restore PID Digital Input 48909 22CC UC MAX_CH

80 Manufacturing Test

(CLS/CLS200 and MLS/

MLS300)

80 Manufacturing Test

(CAS/CAS200)

81 PV Retransmit Primary Loop

Number

82 PV Retransmit Maximum

Input

83 PV Retransmit Maximum

Output

84 PV Retransmit Minimum

Input

85 PV Retransmit Minimum

Output

86 Cascade Primary Loop

Number

Absolute

Address

48810 2269 UI MAX_CH * 2

48876 22AB UC MAX_CH

48876 22AB UC MAX_CH * 8

48942 22ED UI 1

49014 2235 UI 1

48943 22EE UC MAX_CH * 2