Page 1

MINICHEFTM2000

97

Registered Company

Winona, Minnesota USA

ISO 9001

TOTAL

CUSTOMER

SATISFACTION

Applications 24 & 25

Timer

Applications Guide

Programming & Operating Steps

Watlow Controls

1241 Bundy Blvd.

P.O. Box 5580

Winona, Minnesota U.S.A. 55987-5580

(507) 454-5300, Fax (507) 452-4507

WMC2-XAGN-0005-Rev A

May 1997

$5.00

Made in the U.S.A.

Page 2

Table of Contents

Application 24

Automatic Timer . . . . . . . . . . . . . . . . . . . . . . . 1

Application 25

Manual Timer. . . . . . . . . . . . . . . . . . . . . . . . . 7

Ordering Information . . . . . . . . . . . . . . . . . . . 14

© The Watlow MINICHEF 2000™ Timer Applications Guide is copyrighted by Watlow Winona, Inc., May

1997, with all rights reserved. (1011)

Page 3

24

Application 24

Automatic Timer

Introduction to Application 24 . . . . . . . . . . . . . . 1

Configuration Mode Quick Reference . . . . . . . . . 3

Program Mode Quick Reference . . . . . . . . . . . . 4

Step 7 Design a Faceplate Overlay. . . . . . . . . . . 5

Step 8 Operate the Controller . . . . . . . . . . . . . . 6

Application 24 allows you to program six concurrent timers.

Overview of Key Steps

1. Install the MINICHEF 2000.

2. Wire the controller.

3. Configure the controller.

4. Program the menus.

5. Set the controller security.

6. Set the Real-time Clock.

For instructions on Steps 1, 2, 3, 4, 5 and 6, see the Hardware & Software Setup Guide.

7. Design, manufacture and apply faceplate overlay for end-users. (For a suggested design

to suit this application, see this section. For overlay dimensions and guidelines, see the

Hardware & Software Setup Guide.)

8. Operate the controller. (See this application guide.)

Page 4

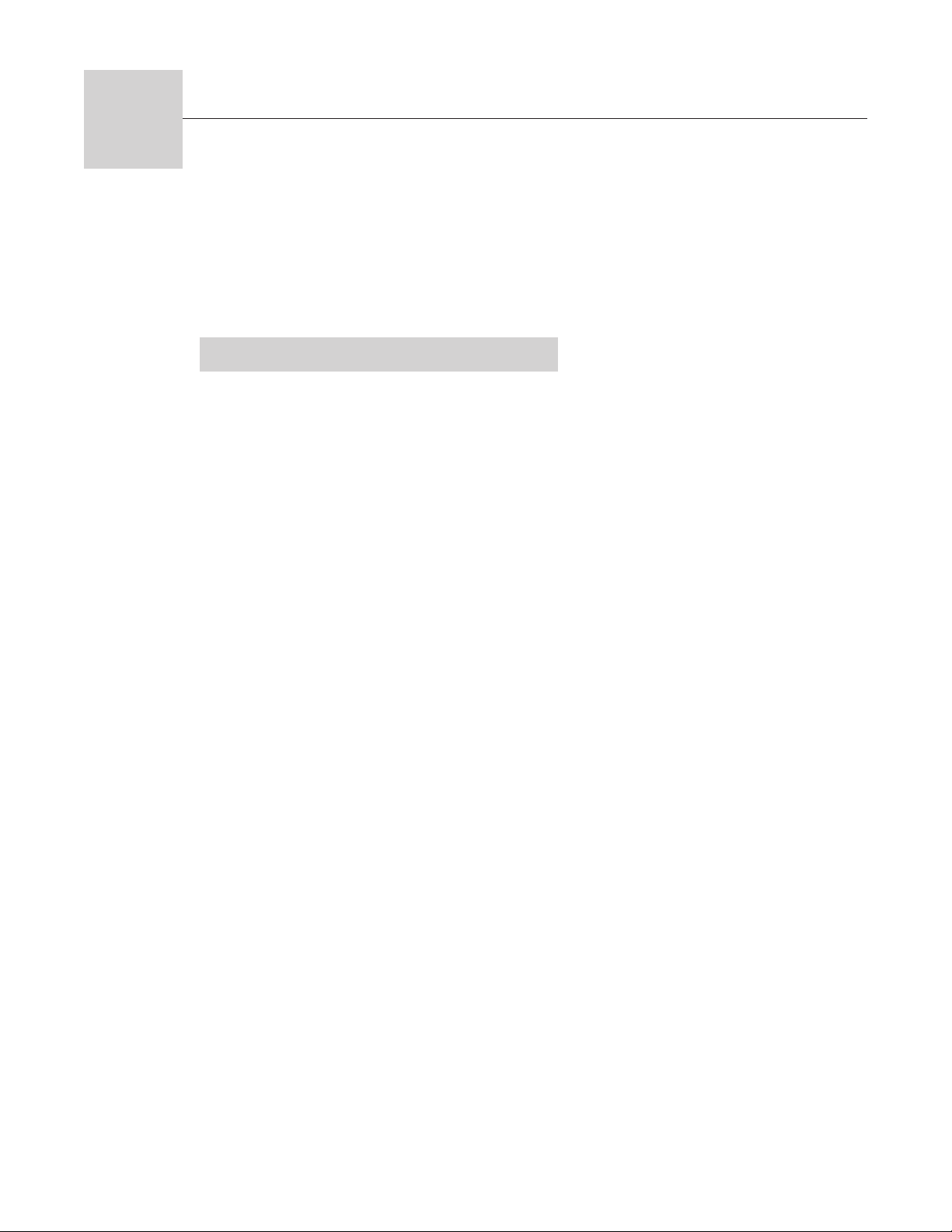

Key Functions in Configuration Mode

Input 1 not used →

Input 2 not used →

Event Input 1 not used →

Event Input 2 not used →

→ Output 1 not used

→ Output 2 not used

→ Event Output 1 not used

→ Event Output 2 not used

→ Output 5 Audible alarm

Time 1

Time 4

Time 3

Time 6

123

456

Your Company Logo

Time 2

Time 5

Time

Time

Time

Time

Time

Time

123

456

Your Company Logo

Timer Key Indicator

Lights

Lit...Timer running

Rapid flash...Done

Timer Keys Activate,

acknowledge,shut off and

cancel corresponding

timers.

AB

DE

GH

Enter

EscapeHome

Edit

C

F

MINICHEF 2000

Display five-digit, sevensegment numeric LED

display.

Indicator lights

(1 for each key, 2 for heat

channels).

Edit key (A) Access the

next level of parameters or

values.

Enter key (B) Enter the

value and return to

previous level.

Home key (D) Move to

Operation Mode with a

two-second key press.

Up key (C) Move up the

lists.

Escape key (E) Return to

original value when editing

a parameter value.

Down key (F) Move down

the lists.

Key Functions in Operation Mode

Summary of Input/Output Functions

Note: For details, see wiring instructions in the

2 ■ Watlow MINIC HEF 2000 Application 24

Hardware & Software Setup Guide.

Page 5

Configuration Mode Quick Reference

These are the functions, parameters and values included in the Configuration Mode for

this application. You must select Application 24 to access them. For directions, see the

Hardware & Software Setup Guide. The Appendix of that guide includes an explanation

of all parameters and values.

Function Parameter Value Your Settings

{Etype} Equipment-Type [appl`] Application Number 1 - 28 24

[a_Loc] Application Number Yes, No

Security Lock

[SEtUP] Setup [time] Time Display Format MMM:SS, HH:MM, H:MM:SS

[Chirp] Key Chirp On, Off

[loc``] Menu Security Lock Yes, No

[Cloc`] Real Time Clock Display Yes, No

[[`diag] WatHelp Used for equipment troubleshooting and testing. Not used when programming. See the Hardware

Diagnostics & Software Setup Guide.

Application 24 Watlow MINICHEF 2000 ■ 3

Page 6

Program Mode Quick Reference

These are the functions, parameters and values included in the Program Mode for this

application. You must select Application 24 to access them.. For menu programming

directions, see the Hardware & Software Setup Guide. The Appendix of that guide

includes a detailed explanation of all parameters and values.

Function Parameter Value Your Settings

[M`__] Menu Numbers 1 - 6 [TiNe1] Time 1 Format varies based

Run time of menu. on configuration.

4 ■ Watlow MINIC HEF 2000 Application 24

Page 7

Step 7 Design a Faceplate Overlay

AB

DE

GH

Enter

EscapeHome

Edit

C

F

MINICHEF 2000

Time

Time

Time

Time

Time

Time

123

456

Your Company Logo

To complete the installation, you must apply a graphic membrane to the front panel of

the controller. The following artwork will help you design and create a membrane for

this application. For more dimensions and guidelines, see the Hardware & Software

Setup Guide.

Suggested End-user Overlay:

This Prototyping and Training Membrane Overlay will help you with the configuration and programming steps. To order it, see the Ordering Information

at the back of this guide.

Application 24 Watlow MINICHEF 2000 ■ 5

Page 8

Step 8 Operate the Controller

Summary of Key Functions in Operation Mode

Key Function

A Time 1

B Time 2

C Time 3

D Time 4

E Time 5

F Time 6

Startup

Apply power to the controller.

[`idle] will appear on the display.

If the Real-time Clock Display option is installed and [Setup] / [Cloc`] is set to

[``yes], the time of day will appear on the display.

Run a Timer

1. With [`idle] on the display, press the key for the timer that you want to run. If a

timer is currently running you may activate another timer by pressing the key for

that timer. Any combination of timers may be running simultaneously. When the

controller is running multiple timers the timer with shortest countdown time will be

displayed.

2. When a timer has completed [``end] will appear on the display, the timer key indicator light will flash rapidly, and an alarm will sound until the timer key is pressed

to acknowledge and shut off that timer.

3. To run another timer repeat steps 1 and 2.

Note: The controller will not respond if you select an invalid timer (one for which Time 1 is set to 0).

Cancel a Timer

Canceling a timer stops that timer only. The other running timers will continue to run.

• Press the active timer key for 2 seconds.

Restart Timer

Press the key(s) for the timer(s) you want to run at any time.

Errors

The controller will alert you to errors if they occur. Errors are critical problems that

shut down the unit. If an error occurs, an error message will appear on the display. You

should switch off the power and call for service.

See the Appendix in the Hardware & Software Setup Guide for a summary of errors.

6 ■ Watlow MINIC HEF 2000 Application 24

Page 9

25

Application 25

Manual Timer

Introduction to Application 25 . . . . . . . . . . . . . . 7

Configuration Mode Quick Reference . . . . . . . . . 9

Step 7 Design a Faceplate Overlay . . . . . . . . . . 10

Step 8 Operate the Controller . . . . . . . . . . . . . 11

Manual Timer

Application 25 is a timer, controlling no temperature zones, and controlling one timer.

Overview of Key Steps

1. Install the MINICHEF 2000.

2. Wire the controller.

3. Configure the controller.

4. Program the menu.

5. Set the controller security.

6. Set the Real-time Clock.

For instructions on Steps 1, 2, 3, 4, 5 and 6, see the Hardware & Software Setup Guide.

7. Design, manufacture and apply faceplate overlay for end-users. (For a suggested

design to suit this application, see this section. For overlay dimensions and guidelines, see the Hardware & Software Setup Guide.)

8. Operate the controller. (See this application guide.)

Page 10

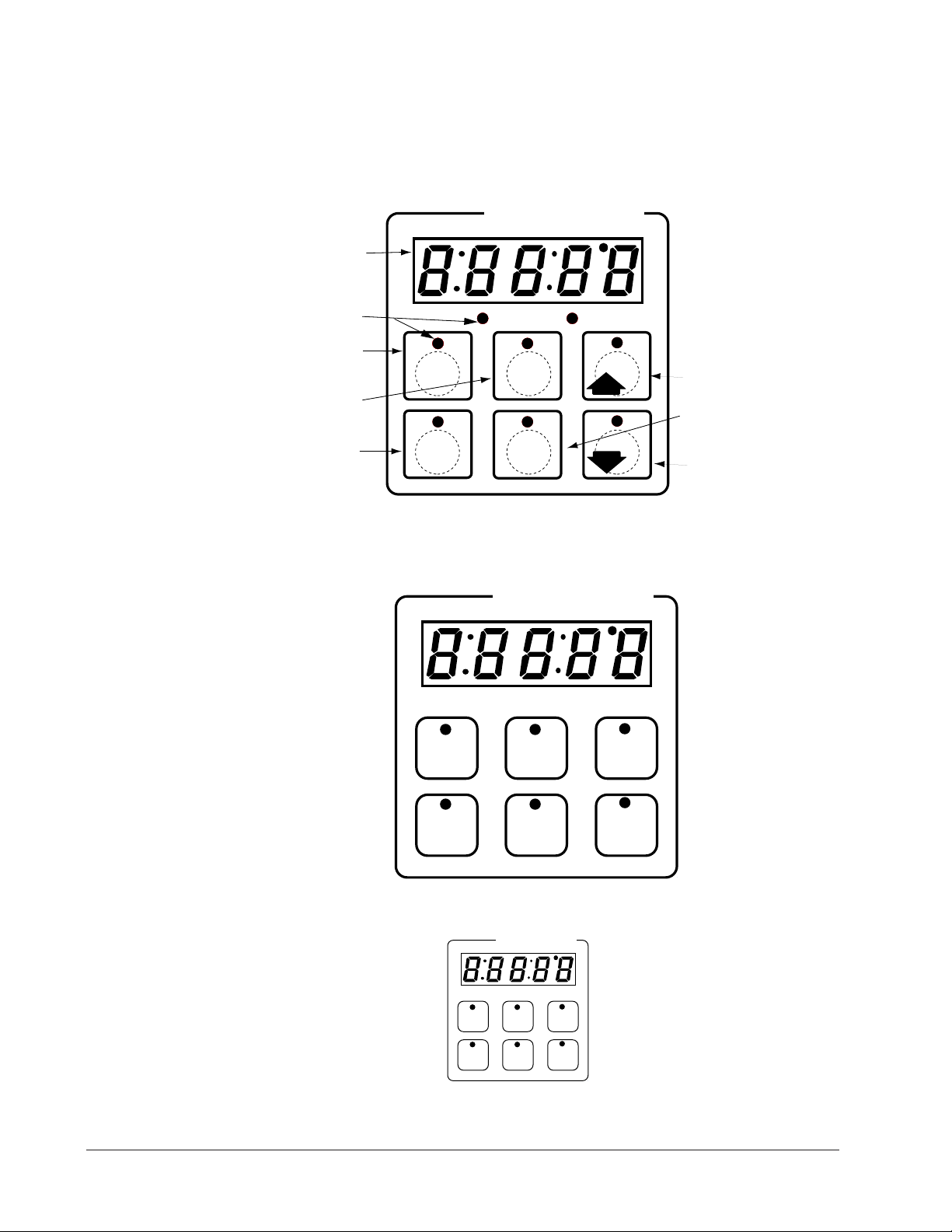

Key Functions in Configuration Mode

Heat

1

2

Time

4

Pause

5

Start/Stop

6

Down

Your Company Logo

3

Up

Input 1 not used →

Input 2 not used →

Event Input 1 not used →

Event Input 2 not used →

→Output 1 not used

→Output 2 not used

→Event Output 1 not used

→Event Output 2 Timer Output

→Output 5 Audible Alarm

Heat

1

2

Time

5

Start/Stop

6

Down

Your Company Logo

3

Up

4

Pause

Time Indicator Light Will

flash rapidly if editing the

parameter during menu

operation.

Not Used

Time Set time.

Pause Pause active

menu.

Increment

Start/Stop

Activate or cancel active

menu.

Decrement

Start/Stop Indicator Light

Rapid flash...Timer paused

Lit...Timer running

AB

DE

GH

Enter

EscapeHome

Edit

C

F

MINICHEF 2000

Display five-digit, sevensegment numeric LED

display.

Indicator lights

(1 for each key, 2 for heat

channels).

Edit key (A) Access the

next level of parameters or

values.

Enter key (B) Enter the

value and return to

previous level.

Home key (D) Move to

Operation Mode with a

two-second key press.

Up key (C) Move up the

lists.

Escape key (E) Return to

original value when editing

a parameter value.

Down key (F) Move down

the lists.

Key Functions in Operation Mode

Summary of Input/Output Functions

Note: For details, see wiring instructions in the

8 ■ Watlow MINIC HEF 2000 Application 25

Hardware & Software Setup Guide.

Page 11

Configuration Mode Quick Reference

These are the functions, parameters and values included in the Configuration Mode for

this application. You must select Application 25 to access them. For directions, see the

Hardware & Software Setup Guide. The Appendix of that guide includes an explanation

of all parameters and values.

Function Parameter Value Your Settings

{Etype} Equipment-Type [appl`] Application Number 1 - 28 25

[a_Loc] Application Number Yes, No

Security Lock

[t`OUt] Timer Output Yes, No

[SEtUP] Setup [time] Time Display Format MMM:SS, HH:MM, H:MM:SS

[Chirp] Key Chirp On, Off

[Cloc`] Real Time Clock Display Yes, No

[[`diag] WatHelp Used for equipment troubleshooting and testing. Not used when programming. See the Hardware

Diagnostics & Software Setup Guide.

Application 25 Watlow MINICHEF 2000 ■ 9

Page 12

Step 7 Design a Faceplate Overlay

AB

DE

GH

Enter

EscapeHome

Edit

C

F

MINICHEF 2000

1

2

Time

5

Start/Stop

6

Down

Your Company Logo

3

Up

4

Pause

To complete the installation, you must apply a graphic membrane to the front panel of

the controller. The following artwork will help you design and create a membrane for

this application. For more dimensions and guidelines, see the Hardware & Software

Setup Guide.

Suggested End-user Overlay:

This Prototyping and Training Membrane Overlay will help you with the configuration and programming steps. To order it, see the Ordering Information

at the back of this guide.

10 ■ Watlow MINIC HEF 2000 Application 25

Page 13

Step 8 Operate the Controller

Summary of Key Functions in Operation Mode

Key Function

A Not Used

B Time

C Increment

D Pause

E Start/Stop

F Decrement

Startup

Apply power to the controller.

[`idle] will appear on the display.

If the Real Time Clock Display option is installed and [Setup] / [Cloc`] is set to

[``yes], the time of day will appear on the display.

Set the Timer

1. Press the Time key [TiNe1] and then the time value will appear on the display.

2. Press the Up-arrow or Down-arrow key until the value you want appears on the display.

3. Press the Time key again.

The timer has been set.

[`idle] will appear on the display.

Five Second Timeout

When using the Up-arrow or Down-arrow keys to change a value, if you do not press

any key for 5 seconds, the timer will automatically be set to the last value on the display and return to [`idle].

Run the Timer

1. Set the timer as shown above in “Set the Timer”.

2. To run the timer settings, press the Start/Stop key. The timer will countdown. When

the timer is running the Start/Stop key indicator light will be solid on. While the

timer is running, its time can be adjusted by pressing the Time key [TiNe1] and

using the Up-arrow or Down-arrow keys to adjust its value, in five-second intervals.

The Time key indicator light will flash while adjustments are being made. Changing

the value of the Time while the timer is running will not change the settings of the

timer as set in “Set the Timer”.

Application 25 Watlow MINICHEF 2000 ■ 11

Page 14

3 When the timer has completed [``end] will appear on the display, the Start/Stop

key indicator light will flash rapidly, and an alarm will sound until the Start/Stop

key is pressed to acknowledge and shut off the timer.

4. To run the timer again repeat steps 1 thru 3.

Note: The controller will not respond if Time is set to 0.

Pause a Menu

While the timer is counting down you can pause it by pressing the Pause key. The

Pause key indicator light will flash rapidly until you press it again to resume the countdown.

Cancel a Menu

To cancel the active menu, press and hold the Start/Stop key for approximately 2 seconds.

Event Outputs

When [etype] / [t`OUt] in the Configuration Mode is set to [``yes], Event Output 2

is on during the countdown of the timer.

Errors

The controller will alert you to errors if they occur. Errors are critical problems that

shut down the unit. If an error occurs, an error message will appear on the display. You

should switch off the power and call for service.

See the Appendix in the Hardware & Software Setup Guide for a summary of errors.

12 ■ Watlow MINIC HEF 2000 Application 25

Page 15

Specifications (1032)

Control Mode

• Single and dual heat channels, PID or on/off.

• Microprocessor-based, programmable, reverse-acting

control outputs.

• User-selectable embedded application software defines

operation of display, keys, inputs, outputs, timing action.

• One-step auto-tuning, WatHelp diagnostics, WatCurve

temperature compensation.

Agency

• CE approved:

89/336/EEC Electromagnetic Compatibility Directive

-EN 50081-1: Emissions

-EN 50082-1: Immunity

73/23/EEC Low-Voltage Directive

-EN 60730-1 and EN 60730-2-9: Safety

• NSF Listed, Criteria 2.

5

• AGA: UL tested to AGA standard Z21.23, UL File

#E43684.

• UL and C-UL recognized, UL 197, 873, 991 and CSA

standard C22.2-24, File # E43684.

Operator Interface

• Membrane overlay, contamination and water resistant,

(supplied by customer).

• LED display, 5-digit, 0.56 in high, red.

• Displays times, temperatures, user prompts and

diagnostic codes.

• User-selectable time and temperature display formats.

• Temperature display formats

—˚F or ˚C.

• Time display formats—H:MM:SS, HH:MM, or MMM:SS.

• 8 discrete indicator LEDs, red.

• 6 tactile feedback keys.

• Menu-driven operation and manual modes available.

• WatHelp diagnostics.

• Real-time clock option displays time of day.

Accuracy

• Calibration accuracy and sensor conformity

for Type J thermocouple and RTD, ± 0.35% of span for

Type K and E thermocouples, ±1 LSD, 77°F ± 5°F

ambient and rated line voltage of ±10%.

• Accuracy span: 1000°F (540°C) minimum.

• Temperature stability: ± 0.15˚F/˚F (0.15˚C/˚C) change

in ambient typical.

Sensors/Inputs

• Contact inputs, TTL compatible with internal pull-up

resistor, two available.

• Thermocouple,

3

software selectable Type J, K or E,

32 to 1200°F. (Dual-channel applications require at

least one ungrounded thermocouple).

3

•RTD,

2- or 3-wire, platinum, 100, 500, 1000Ω, at 0°C,

software selectable DIN or JIS curves, 0 to 1200°F

(3-wire will function as 2-wire).

• Input A /D resolution: 15 bit.

Output Options

• Solid-state relay, 0.4A, with or without contact suppression.

• Switched dc signal, 4.5V to 5.25V, 30mAmaximum

output, minimum load resistance > 150Ω, non-isolated.

1

2

: ± 2.0°F

Audible Output Options

• Switched dc signal, 4.5V to 5.25V, 30mAmaximum

output, minimum load resistance > 150Ω, non-isolated.

• Internal audible alarm, 75dB at 10 cm.

Connectors

• Sensor Input Terminal Strip

quick-connect.

• Power Supply & Input/Output Terminal

4

: RIACON, 6-position,

4

: AMP,

15-position, quick-connect.

Power/Line Voltage

• 20.4 to 26.4VÅ (ac), 47 to 63Hz.

• 15VA maximum.

• For CE applications, input power must be limited to

15W external to the control.

• Program retention upon power failure via non-volatile

memory.

• Battery/real-time clock option: 6-year lithium battery,

provides power backup upon power failure, operation

resumption after power recovery, ability to display time

of day.

Operating Environment

• 32 to 176°F (0 to 80°C), 0 to 90% RH, non-condensing.

Storage Temperature

• -40 to 176°F (-40 to 80°C).

Mechanical

• Case: polycarbonate Lexan with adjustable mounting

collar (vertical or horizontal orientation), designed for

mounting on 16-, 18-, 20- and 22-gauge panels.

• Internal panel mounting requires a specified panel

cutout and four #6-32 studs or equivalent.

• Overall width x height x depth: horizontal - 4.13 in x

3.25 in x 2.00 in; vertical - 3.25 in x 4.13 in x 2.00 in

(Assumes mating connectors are attached. Does not

include wire bundle space requirements.).

• Vibration: 2g, 10 to 150Hz, applied in any one of three

axes.

• Weight: 6.50oz maximum.

Program Storage

• All non-embedded user and factory programs are

stored in non-volatile memory. Can be changed by

reprogramming.

Sample/Update Rates

• 1 input: 4Hz.

• 2 inputs: 4Hz.

• PID: 1Hz.

• Control outputs: 100Hz.

• Display: 10Hz.

1

The MINICHEF 2000 controller is to be used in systems with an

external high temperature limiting device.

2

Thermocouple lead resistance of 200Ω causes < 1°C error. RTD, 22

gauge wire will not contribute more than 0.086°F error /ft.

3

Dual channel applications require either two thermocouple sensors or two identical RTD sensor types.

4

For mating connector information, see Ordering Information

Accessory section.

5

Certified for thermometer accuracy (oven and hot food holding

applications from 32°F to 60°F) when used with RTD or type J thermo

couple probes.

Specifications Watlow MINICHEF 2000 ■ 13

Page 16

Ordering Information

(1033)

F 2 H A - _ _ _ 1 - _ _ AA

INICHEF™ 2000

M

Cooking controller with numerous food

equipment application software sets,

single and dual channel on/off or PID

temperature regulation, timer and

machine-function control, microprocessorbased, programmable, auto-tuning,

WatCurve, WatHelp diagnostics,

24V

Å

(ac) power input, agency approved,

flush mounted (membrane faceplate

supplied by customer).

Inputs

1 = Dual thermocouple, Type J, K or E

2 = Dual RTD, platinum, 100Ω, curve

selectable

3 = Dual RTD, platinum, 500Ω, curve

selectable

4 = Dual RTD, platinum, 1000Ω, curve

selectable

(Note: All models include two event inputs,

switched dc logic signal, non-isolated.)

Output Number 1

1 = Switched dc, 5V nominal, 30mA,

non-isolated

2 = Solid-state relay, Form A, 0.4A,

without RC suppression

3 = Solid-state relay, Form A, 0.4A,

with RC suppression

Output Number 2

1 = Switched dc, 5V nominal, 30mA,

non-isolated

2 = Solid-state relay, Form A, 0.4A,

without RC suppression

3 = Solid-state relay, Form A, 0.4A,

with RC suppression

Event Outputs 1 and 2

1 = 2 event outputs, switched dc, 5V nominal,

30mA, non-isolated

Battery and Real-time Clock

0 = None

1 = Includes battery and real-time clock

Audible Alarm

0 = Alarm signal available at connector,

switched dc, 5V nominal, 30mA, non-isolated

1 = Internal alarm included

Software

AA = Standard Food Equipment Application

Software Set

XX =

Custom Set-up parameters or Made-To-Order

custom

Sales Engineer. Code number assigned by factory.

software. Consult your local Watlow

14 ■ Watlow MINIC HEF 2000 Ordering Information

Page 17

Ordering Information: Part Numbers & Accessories

MINICHEF 2000 Accessories

0836-0442-0000 Sensor Input Mating Connector,

(RIACON #31007106), 6-position,

quick-connect terminal, screw

connection for 28-14 AWG wires,

tighten to 7in/lb

A001-0298-0000 Power Supply and I/O Mating

Connector Kit. Includes:

– 1 AMP #1-640523-0, 15-position,

quick-connect terminal

– 15 AMP #641300-1 crimp pins

0238-0679-0000

0830-0479-0000 Prototyping EPROM Extraction Tool,

A001-0249-0001 120VÅ to 24VÅ (ac), stepdown

A001-0249-0002 208/240VÅ to 24VÅ (ac), step-

Prototyping & Training Membrane

Overlay, adhesive-backed,

4.75 in x 4.75 in

AMP #821980-1

transformer, class 2, quick-connect

terminals included

down transformer, class 2, quickconnect terminals included

Recommended Sources of Supply

for Miscellaneous Items

DURA-TECH, Inc. •

LaCrosse, WI

(608) 781-2570

Custom Membrane Faceplates

MINICHEF 2000 Documentation

WMC2-XUGN-0000 The Complete

2000 User Guide

WMC2-XADN-0000 The Complete

2000 User Guide on CD

M

WMC2-XTDN-0000

WMC2-XSGN-0000 Hardware & Software

WMC2-XAGN-0001 Cook-&-Hold Oven

WMC2-XAGN-0002 Convection Oven

WMC2-XAGN-0003 Deepfat Fryer Application

WMC2-XAGN-0004 Griddle Application Guide

WMC2-XAGN-0005 Timer Application Guide

WMC2-XAGN-0006 Shelf-Timer Application

WMC2-XAGN-0007 Rotisserie Oven

INICHEF

Disk

Setup Guide

Application Guide

Application Guide

Guide

Guide

Application Guide

M

INICHEF

M

INICHEF

2000 Tutorial

AMP, Inc. •

Harrisburg, PA

1-800-522-6752

RIA Electronic, Inc.

Eatontown, NJ

(908) 389-1300

Prototyping EPROM Extraction

Tool

Part No. 821980-1

•

Pin Crimping Hand Tools

Part No. 90325-1 or 58514-1

•

Pin Extraction Hand Tool

Part No. 455822-2

•

RIACON Connectors

Ordering Information Watlow MINICHEF 2000 ■ 15

Page 18

Watlow Controls

Watlow Controls is a division of Watlow Electric Mfg. Co., St. Louis, Missouri, a manufacturer of industrial electric heating products since 1922. Watlow begins with a full set

of specifications and completes an industrial product that is manufactured totally inhouse, in the U.S.A. Watlow products include electric heaters, sensors, controls and

switching devices. The Winona operation has been designing solid state electronic control devices since 1962, and has earned the reputation as an excellent supplier to original equipment manufacturers. These OEMs depend upon Watlow Controls to provide

compatibly engineered controls that they can incorporate into their products with confidence. Watlow Controls resides in a 100,000-square-foot marketing, engineering and

manufacturing facility in Winona, Minnesota.

Technical Assistance

If you encounter a problem with your Watlow controller, refer to the Troubleshooting

Chart in this guide. Also review all of your configuration information for each step of

the setup to verify that your selections are consistent with your applications.

If the problem persists after checking all the steps, you can get technical assistance by

calling Watlow Controls at (507) 454-5300, between 7 a.m. and 5 p.m. CST, and asking

for an applications engineer. When you call have the following information on hand: the

controller’s part number, date code, serial number, software revision number, and application number. Much of this information is available on the controller case. All of this

information is also available via the MINICHEF 2000 main display by accessing the

WatHelp Diagnostics Function under [`diag] in the Configuration Mode.

We Value Your Feedback

Your comments and suggestions on this manual are welcome. Please send them to,

Technical Writer, Watlow Controls, 1241 Bundy Blvd., P.O. Box 5580, Winona, MN

55987-5580 or call (507) 454-5300 or fax (507) 452-4507.

Contact

• Phone: (507) 454-5300.

• Fax: (507) 452-4507.

• For technical support, ask for an Applications Engineer.

• To place an order, ask for Customer Service.

• To discuss a custom option, ask for the MINICHEF 2000 Product Manager.

Warranty

The MINICHEF 2000 is warranted to be free of defects in material and workmanship for

36 months after delivery to the first purchaser for use, providing that the unit has not

been misapplied. Since Watlow has no control over its use, or misuse, we cannot guarantee against failure. Watlow's obligations hereunder, at Watlow's option, are limited to

replacement or refund of purchase price of a unit which upon examination proves to be

defective within the warranty period. This warranty does not apply to damage resulting

from transportation, alteration, misuse, or abuse.

Returns

• Call or fax Customer Service for a Return Material Authorization (RMA) number

before returning a control.

• Put the RMAnumber on the shipping label, and also on a description of the problem.

• 20% of net price restocking charge applies to all standard units returned to stock.

Note: All documentation of the MINICHEF 2000 is subject to change without notice.

16 ■ Watlow MINIC HEF 2000 Warranty and Returns

Page 19

Watlow MINICHEF™ 2000 Timer Applications Guide

Watlow Controls, 1241 Bundy Blvd., P.O. Box 5580, Winona, MN U.S.A. 55987-5580 Phone: (507) 454-5300, Fax: (507) 452-4507

Loading...

Loading...