Page 1

Band/Barrel Heaters

Max. Operating Typical Max.

Temperatures Watt Densities

Band/Barrel Heaters Sheath Materials °F °C W/in2 W/cm

Mineral Insulated (MI) Stainless steel 1400 760 100 15.5 493

2

Page

Band/Barrel Heaters

WATLOW

®

491

Page 2

492

WATLOW

®

Page 3

Band/Barrel Heaters

Mineral Insulated (MI) Band Heaters

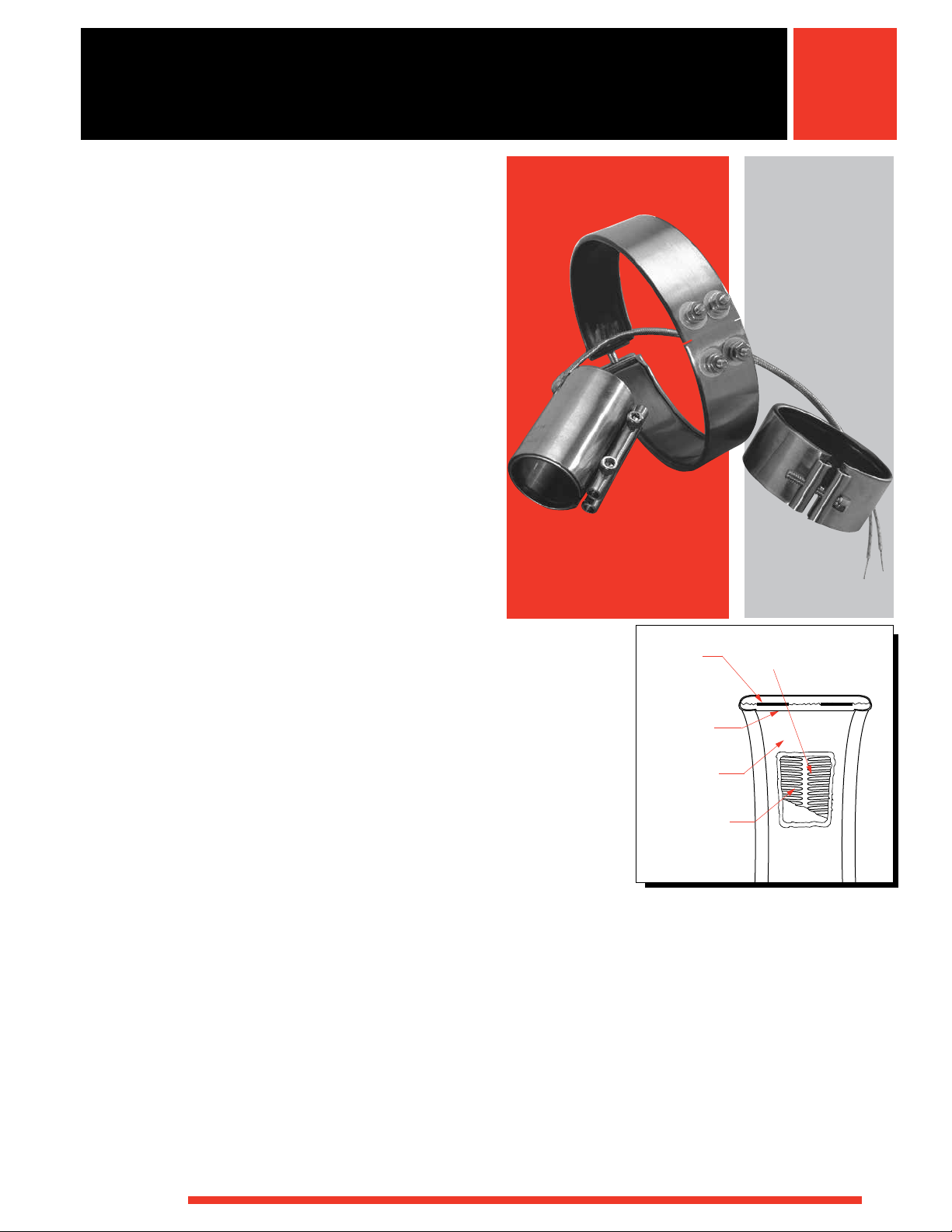

The mineral insulated (MI) band heater from Watlow® is

a high-performance heater that incorporates Watlow’s

exclusive mineral insulation. This material offers much

higher thermal conductivity than mica and hard ceramic

insulators that are used in conventional heaters.

A thin layer of the “high” thermally conductive MI material

electrically insulates the element wire from the inside

diameter of the heater sheath. A thicker, low thermally

conductivity layer backs up the element wire directing the

heat inward toward the part being heated. The result is

more efficient heat transfer, which lowers element wire

temperatures and increases heater life.

Performance Capabilities

• Heater operating temperatures up to 1400°F (760°C)

• Watt densities up to 100 W/in

on large diameter barrel bands

• Maximum voltage to 480V

2

(15.5 W/cm2) available

Features and Benefits

High thermal conductivity of MI and low mass

construction

• Provides an almost instant response to temperature

control

• Eliminates thermal lag and temperature overshoot

associated with ceramic insulated heaters

Operating temperatures up to 1400°F (760°C)

• Allows safe melting of resins such as PEEK™,

Teflon®, Ultem® and Zytel®

Higher watt densities

• Contributes to faster heat-up and throughput for

increased productivity

Stainless steel cover and side fold design

• Resists contamination from overflow of plastic or other

free-flowing materials

Attached clamp bars

• Eliminates cumbersome clamping straps to ease

installation

Typical Applications

• Extruders

• Blown film dies

• Injection molding machines

• Other cylinder heating applications

Thick Low

Conductivity

MI Backing

Thin High

Conductivity

MI Insulation

430 Stainless

Steel Sheath

Element Wire in

Mineral Insulation

Coiled or Sinuated

Wire Element

WATLOW

®

493

Page 4

Band/Barrel Heaters

Mineral Insulated (MI) Band Heaters

Applications and Technical Data

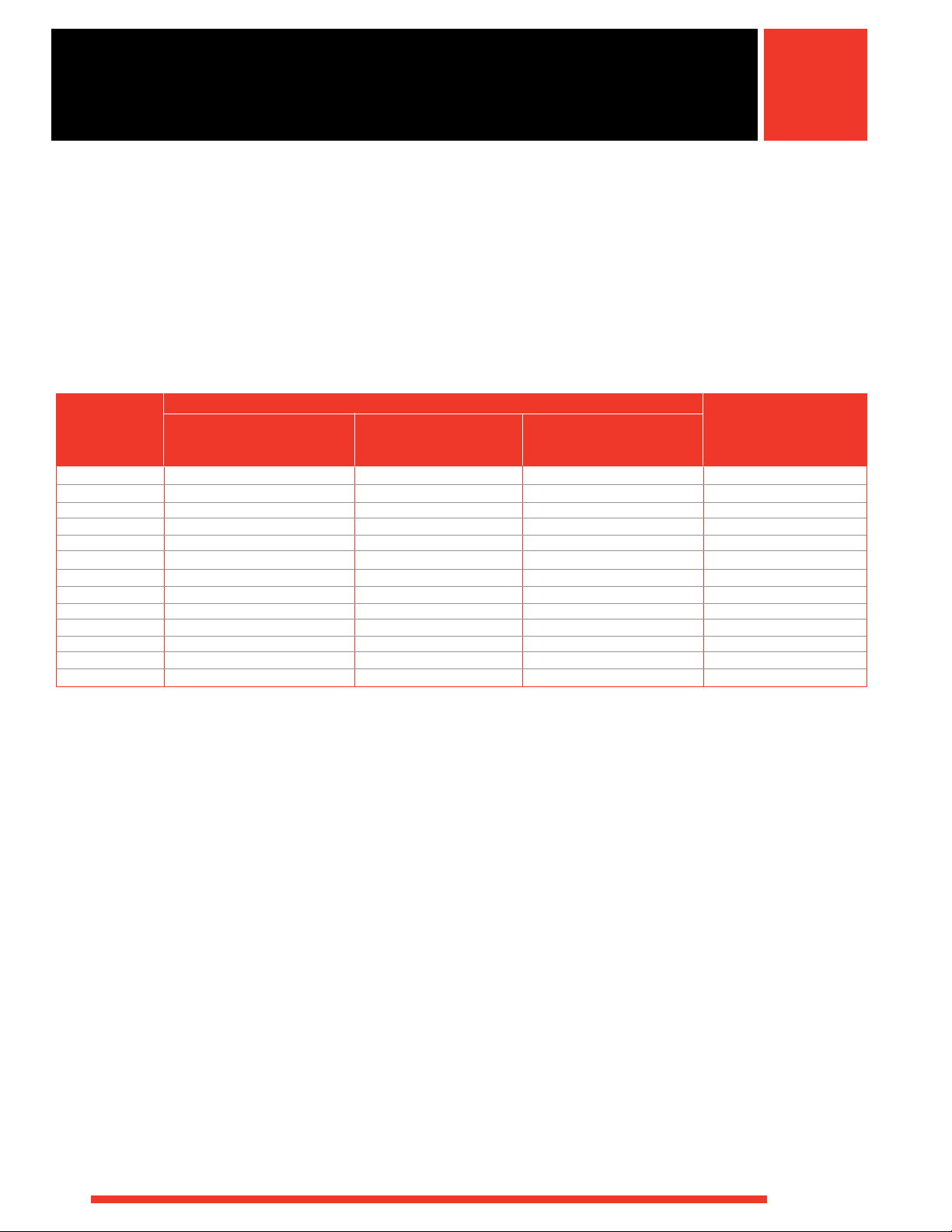

The Physical Limitations of Variations table shows the

availability of widths, inside diameters and terminations

If the application requires a heater exceeding limitations

shown, contact your Watlow representative.

for Watlow’s MI band, barrel and nozzle heaters. To

ensure available terminations meet application needs,

refer to the termination variation illustrations in this

section.

Physical Limitations of Variations

I.D. Available—in. (mm)

1 pc. Construction Expandable 2 pc. Construction

Width Min. Max. Min. Max. Min. Max.

in. (mm) in. (mm) in. (mm) in. (mm) in. (mm) in. (mm) in. (mm) Available Terminations

1 (25) 1 (25) – 6 (152) 3 (76) – 12 (305) 3 (76) – 12 (305) All

3

1

/8 (35) 1 (25) – 3 (76) 3 (76) – 6 (152) 3 (76) – 6 (152) All - Except SLE

1

1

/2 (38) 1 (25) – 14 (356) 3 (76) – 14 (356) 3 (76) – 28 (711) All

2 (51) 1

1

2

/2 (64) 11/4 (32) – 14 (356) 3 (76) – 14 (356) 3 (76) – 28 (711) All

3 (76) 1

1

3

/2 (89) 13/4 (45) – 14 (356) 3 (76) – 14 (356) 3 (76) – 28 (711) All - Except 90° “B” Leads

4 (102) 2 (51) – 14 (356) 3 (76) – 14 (356) 3 (76) – 28 (711) All

1

4

/2 (114) 21/4 (57) – 14 (356) 3 (76) – 14 (356) 3 (76) – 28 (711) All

5 (127) 2

1

5

/2 (140) 23/4 (70) – 14 (356) 3 (76) – 14 (356) 4 (102) – 28 (711) Post Terminals, SLE only

6 (152) 3 (76) – 14 (356) 3 (76) – 14 (356) 4 (102) – 28 (711) All

7 (178) 4 (102) – 14 (356) Post Terminals, SLE only

1

/4 (32) – 14 (356) 3 (76) – 14 (356) 3 (76) – 28 (711) All

1

/2 (38) – 14 (356) 3 (76) – 14 (356) 3 (76) – 28 (711) All

1

/2 (64) – 14 (356) 3 (76) – 14 (356) 4 (102) – 28 (711) All - Except 90° “B” Leads

General Limitations

• Maximum width of 1 in. (25 mm) diameter heater:

11/2 in. (38 mm)

• Maximum heater width: 2x heater diameter

• Minimum I.D. for Type B, C, E and H leads:

1 in. (25 mm)

• Minimum I.D. for Type B—90° leads: 1

• Maximum lead amperes: 12.5A per pair

• SLE maximum: 17.0A

• Maximum amperes (post terminals): 30A per pair

• Minimum diameter and width for SLE: 4 in. x 1

(102 mm x 38 mm) width

• 90° leads not available over 250VAC

• Minimum I.D. for post terminals: 1

• Actual width for 7 in. (178 mm) wide heater:

7

6

/8 in. (175 mm)

1

/8 in. (29 mm)

1

/4 in. (32 mm)

1

/2 in.

Gaps

• ≤ 3 in. = 1/8 in. nomin al

• 3 in.

≤ 6 in. =

• 6 in.

≤14 in. =

• >14 in. =

1

/4 in. nominal ±1/8 in.

3

/8 in. nominal ±1/8 in.

1

/2 in. nominal ±1/4 in.

494

WATLOW

®

Page 5

Band/Barrel Heaters

03

Mineral Insulated (MI) Band Heaters

Applications and Technical Data (Continued)

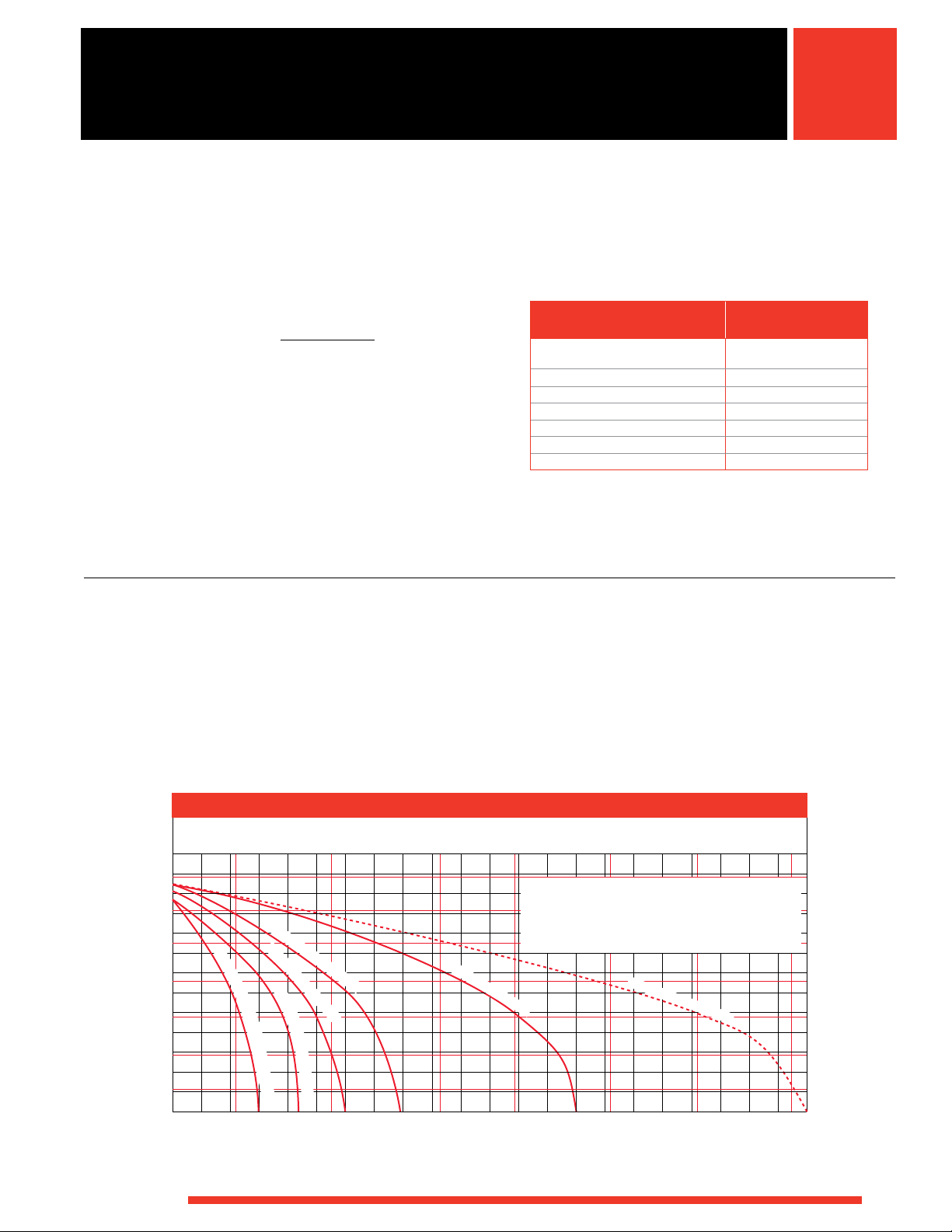

Calculating Watt Density

Watt density is the amount of wattage per square inch of

heated area. To determine watt density, divide the total

wattage by the heated area.

Watt Density =

Total Watts

Heated Area

To apply this equation, the term “heated area” must be

defined. Heated area is the total contact surface of the

heater less the areas of no-heat found around terminals,

mounting holes, etc.

Heated Area = Total Contact Area - No-Heat Area

Maximum Allowable Watt Density

The following derating factors apply to the Maximum

Allowable Watt Density chart, which are displayed in both

inches and millimeters. Review these factors and the

chart to determine the correct watt density curve for

the application.

Derating Factors:

• For units over 2 in. (51 mm) in width, multiply the watt

density by 0.80.

To calculate the heated area:

1. Locate the no-heat factor from the chart below that

corresponds to the type of heater being considered.

Type No-Heat Factor

in.

1 pc. lead unit Type B, C, H, E

or 90°B

1 pc. post terminal 1.60

1 pc. expandable post term 3.18

1 pc. expandable lead unit 3.00

True 2 pc. post term 3.20

True 2 pc. leads 2.74

SLE 3.68

1.37

2. To use the formula below, insert the no-heat factors,

diameter and width (in inches).

Heated Area =

(3.14 x Diameter - No-Heat Factor) x Width

• For applications where unusual operating conditions

are present, such as irregular mounting surfaces,

contact your Watlow representative for watt density

limitations.

• For two-piece units used in vertical applications, refer

to Clamping Matrix Application Guide on page 496.

• For applications where insulating blankets are used,

multiply watt density by 0.75.

1300

1200

1100

1000

900

800

700

600

500

Part Temperature — °F

400

300

200

WATLOW

Maximum Allowable Watt Density

Watt Density - W/cm

5101520253

6 in. (152 mm) I.D.

1

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200 210 220 230

®

10 in. (254 mm) I.D.

4

i

n

.

(

3

5

6

m

m

)

I

.

D

.

&

2

P

i

e

c

e

3 in. (76 mm) I.D.

1

2

i

n

.

(

3

0

5

m

m

)

I

.

D

.

Watt Density — W/in

2

Allowable watt density for 11⁄2 in. (38 mm) wide

MI band heaters:

• Moderate cycling

• Heaters properly clamped

• Heaters mounted on a smooth cylinder

1

1

/

2

in. (38 mm) I.D.

2

5

700

600

500

400

300

200

100

Part Temperature — °C

495

Page 6

Band/Barrel Heaters

Mineral Insulated (MI) Band Heaters

Applications and Technical Data (Continued)

• Review the Watt Density chart to ensure the

• Description of guideline letters are at the bottom of

application does not exceed the maximum watt

density at operating temperature after applying

• Note: Upward arrows are up to and not including

derating factors.

• Locate clamping guideline for unit diameter, width and

watt density.

MI Band Clamping Matrix Application Guide

Dia. 8 ≥ 10 10 ≥ 12 12 ≥ 14 14 ≥ 16 16 ≥ 18 18 ≥ 20 20 ≥ 22 22 ≥ 24 24 ≥ 26 26 ≥ 28

11/2 to

41/2 to

11/2 to

41/2 to

11/2 to

41/2 to

11/2 to

41/2 to

11/2 to

4 in.

7 in.

4 in.

7 in.

4 in.

7 in.

4 in.

Width

(38 to

(114

(38 to

(114

(38 to

102

to 178

102

mm)

mm)

80

75

70

2

65

60

55

50

45

40

35

Watt Density–W/in

30

25

20

15

10

0

Note: 1 in. (25 mm) wide heaters use welded barrel nuts rather than clamp bars.

B

B

A

A

A = Clamp bars, expandable or one piece construction Width Clamp Points at Each Gap

B = Spring clamps, expandable or one piece construction ≥ 5 in. (127 mm) 3

C = Spring clamps, at one gap, welded barrel nuts at other gap ≥ 3 in. (76 mm) 2

D = Spring clamps, spring clamps at both gaps < 3 in. (76 mm) 1

mm)

B

A

to 178

mm)

B

A

102

mm)

B

A

(114

to 178

mm)

B

A

(38 to

102

mm)

D

C

7 in.

(114

to 178

mm)

DCDCD

4 in.

(38 to

102

mm)

41/2 to

7 in.

(114

to 178

mm)

the MI Band Clamping Matrix Application Guide.

specified watt density. Downward arrows are greater

than or equal to specified watt density.

11/2 to

41/2 to

11/2 to

41/2 to

11/2 to

41/2 to

11/2 to

41/2 to

4 in.

7 in.

4 in.

7 in.

(38 to

(114

to 178

mm)

(38 to

102

mm)

C

102

mm)

Above Recommended Watt Densities

Contact your Watlow Representative

DCDCD

C

(114

to 178

mm)

D

C

4 in.

(38 to

102

mm)

D

C

7 in.

(114

to 178

mm)

D

C

4 in.

(38 to

102

mm)

D

C

7 in.

(114

to 178

mm)

D

C

11/2 to

4 in.

(38 to

102

mm)

DCD

41/2 to

7 in.

(114

to 178

mm)

C

496

WATLOW

®

Page 7

Band/Barrel Heaters

Mineral Insulated (MI) Band Heaters

Termination Variations

Post Terminals

Stock

0.625 in. (15.9 mm)

Nom.

0.75 in.

(19 mm)

0.16 in.

(4.1 mm)

Post terminals provide optimum connections. Screw

thread is 10-24. To order, specify post terminals

(metric threads available).

1.25 in.

(32 mm)

Width ±0.0625 in.

(1.6 mm)

Lead Wire

Heaters rated at less than 250VAC use UL® approved

lead insulation for operations to 480°F (250°C) as

standard. Lead insulation UL® rated for operation to 840°F

(450°C) is available for high-temperature applications

where the leads are shrouded or enclosed with the

heater. These leads are available in any of the Type

B with loose braid as well as Types E, F and H lead

configurations. All heaters rated at more than 250VAC

use this wire. When ordering, specify 850°F (450˚C) wire.

Leads Type B, Type B - 90° rotation, Type B - 180°

rotation or Type C: Two fiberglass-insulated lead wires

exit in a single metal braid for good abrasion protection,

lead flexibility and wiring convenience. Leads are 2 in.

(51 mm) longer than braid. Shipped with 12 in. (305 mm)

leads, unless longer length is specified. To order, specify

type and length.

Type B

Stock

0.36 in.

(9 mm)

12 in.

(305 mm)

0.81 in.

(21 mm)

Type B - 90° Rotation

Non-Stock

0.36 in.

(9 mm)

1.25 in.

(32 mm)

Type B - 180° Rotation

Stock

0.16 in.

(4.1 mm)

I.D.

0.625 in.

(15.9 mm)

Nom.

Width ±0.0625 in.

(1.6 mm)

WATLOW

I.D.

1.25 in.

(32 mm)

®

0.16 in.

(4.1 mm)

Width ±0.0625 in.

(1.6 mm)

1.25 in.

(32 mm)

Width ±0.0625 in.

(1.6 mm)

497

Page 8

Band/Barrel Heaters

Mineral Insulated (MI) Band Heaters

Termination Variations (Continued)

Lead Wire (Continued)

Type C

Stock

0.656 in.

(16.7 mm) Dia.

0.191 in.

(4.9 mm)

I.D.

0.557 in.

(14.1 mm)

0.75 in.

(19 mm) Nom.

Type F

Stock

0.191 in.

(4.9 mm)

I.D.

1.25 in.

(32 mm)

0.656 in.

(16.7 mm) Dia.

0.635 in.

(16.1 mm)

0.75 in.

(19 mm) Dia.

Width ±0.0625 in.

(1.6 mm)

1.25 in.

(32 mm)

Width ±0.0625 in.

(1.6 mm)

Type E

Stock

0.44 in.

(11.2 mm) Dia.

0.656 in.

0.191 in.

(4.9 mm)

I.D.

1.25 in.

(32 mm)

(16.7 mm) Dia.

0.635 in.

(16.1 mm)

Width ±0.0625 in.

(1.6 mm)

0.75 in.

(19 mm) Nom.

Type E: Loose metal braid encloses two fiberglass leads

for good abrasion protection, lead flexibility and wiring

convenience. Leads are 2 in. (51 mm) longer than the

braid. Shipped with 12 in. (305 mm) leads, unless longer

length is specified. To order, specify Type E and length.

Type F: Loose fiberglass sleeving encloses two fiberglass

leads for additional insulation protection where high

temperature or minor abrasion is present. Leads are

2 in. (51 mm) longer than the sleeving. To order, specify

Type F and length.

Type H

Stock

0.656 in.

(16.7 mm) Dia.

0.191 in.

(4.9 mm)

I.D.

1.25 in.

(32 mm)

0.635 in.

(16.1 mm)

0.75 in.

(19 mm) Nom.

Width ±0.0625 in.

(1.6 mm)

Type H: A flexible steel hose encloses the leads for

maximum abrasion protection. Leads are 2 in. (51 mm)

longer than hose. Shipped with 12 in. (305 mm) leads,

unless longer length is specified. To order, specify

Type H and length.

498

WATLOW

®

Page 9

Band/Barrel Heaters

f

Mineral Insulated (MI) Band Heaters

Termination Variations (Continued)

Lead Wire (Continued)

Type K

Stock

Type SLE

0.656 in.

0.191 in.

(4.9 mm)

I.D.

1.25 in.

(32 mm)

(16.7 mm) Dia.

0.557 in.

(14.1 mm)

0.75 in.

(19 mm) Nom.

Width ±0.0625 in.

(1.6 mm)

Type K: Flexible lead wires exit vertically from the heater.

These leads can be bent adjacent to the heater

for a quick and easy connection. To order, specify

Type K and length.

Variations

Thermocouple

0.4375 in.

(11.1 mm)

Strain Relie

Two fiberglass lead wires exit a single, tightly woven metal

braid at a right angle on the expandable construction vs.

two sets of leads. The minimum diameter capability is

4 in. (102 mm). Minimum width capability is 1

1

/2 in.

(38 mm). To order, specify Type SLE and length.

Heavy Duty Strain Relief

0.25 in.

(6 mm)

Spot Welded to

Heater Sheath

ASTM Type J or K thermocouples are available on lead

Type B with loose braid and fiberglass sleeving. They are

also available on E, F and H leads. The thermocouple

junction, spot-welded to the heater sheath, provides a

signal for measuring relative heater temperature.

A separate thermocouple is available.

WATLOW

®

Heavy duty strain relief is recommended for applications

where there is great stress or continued flexing of the

leads. The strain relief is available on Type B,

Type B - 90° and

Type B

-

180°

leads only. To order,

specify heavy-duty strain relief. Note: not available

with loose braid or fiberglass sleeving.

499

Page 10

Band/Barrel Heaters

Mineral Insulated (MI) Band Heaters

Variations (Continued)

Expandable Heaters With Post Terminals or Leads

Expandable heaters are two-piece units with a common

top metal allowing the heater to expand open to the

full diameter of the barrel. On expandable bands, each

half will be one half of the total wattage. Plus, on both

expandable and two-piece bands, each half will be rated

at full operating voltage, unless otherwise specified.

MI band heaters 11/2 in. (38 mm) wide or greater have

post terminals located next to the expansion joint. Leads

may be located anywhere along the circumference except

near the gap and at the expansion joint. Two sets of leads

required.

On 1 in. (25 mm) wide MI band heaters, post terminals

will be located 90° from the expansion joint. Leads may

be located anywhere along the circumference except

near the gap and at the expansion joint. Two sets of

leads are required. To order, specify expandable.

Expandable heaters are designed to be opened for

new installation only.

Metallic Terminal Box

3½ in. for 3½-5⁄ in. I.D.

4 in. for 6-28 in. I.D.

1⁄ in.

(46 mm)

1⁄ in.

(36.5 mm)

Metallic terminal boxes are available from stock on 31/2 in.

inside diameter x 11/2 in. wide (89 mm x 38 mm) or larger

heaters. Terminal boxes, which attach directly to the heater,

act as a safety feature by covering the terminals. Conduit

may be attached to the box through 7/8 in. (22 mm)

diameter holes in the ends of the box. Two-piece heaters

require two boxes. To order, specify terminal box.

MI Band Heater with Holes

Ceramic Terminal Cover

Ceramic covers, with openings for leads, are screwed

on to post terminals, providing a convenient, economical

insulator. To order, specify part number Z-4918 and

quantity. For metric sizes specify thread needed.

Note: Ceramic terminal covers will not fit on some stock

expandable MI bands or nozzles. Contact your Watlow

representative for more information.

500

MI band heaters with holes are available on all widths

except 1 in. (25 mm) wide. Contact your Watlow

representative for hole sizes and location constraints.

To order, specify hole size and location. The inside

diameter minimum is 3 in. (76 mm). Note: a minimum

charge per line item applies.

WATLOW

®

Page 11

Band/Barrel Heaters

Mineral Insulated (MI) Band Heaters

Clamping Variations

Tig-Welded Barrel Nuts with Spring Loaded Clamping

5⁄16 in. 18 Screw

5.8 in. (147 mm)

0.75 in.

(19 mm)

Welded barrel nuts with spring loaded clamping are

used to maintain a tight heater fit on large barrels during

start-up. This clamping variation is recommended for all

MI band heaters greater than 14 in. (356 mm) in diameter

and 11/2 in. (38 mm) or greater in width. Refer to MI Band

Clamping Matrix Application Guide. For smaller diameter

heaters, it is an option and must be ordered separately.

To order, specify spring loaded clamping.

Low-Profile Tig-Welded Barrel Nuts

Low-profile barrel nuts are available on all widths and

provide a clearance of 0.470 in. (12 mm). However, this

value can be higher depending on how far the clamp

screw extends past the barrel nut. To order, specify

low-profile tig-welded barrel nuts.

Tig-Welded Barrel Nuts

¼

in. 2 Screw

0.563 in.

(14.3 mm)

Tig Welded

Tig-welded barrel nuts can function like a hinge to allow

two-piece heaters to be more easily installed. If a large

gap is specified to provide access for instrumentation,

tig-welded barrel nuts can be situated in such a way

that the clamp screws do not interfere with the sensor.

To order, specify gap size and sensor location.

Note: a gap greater than 1 in. (25 mm) wide is

considered extended capability.

Options

Thermocouple Pocket

Low-Profile Clamp Bars

I.D.

0.45 in.

(11.4 mm)

Low-profile clamp bars are available on both

1 in. (25 mm) and 11/2 in. (38 mm) wide heaters, for

wider widths contact your Watlow representative. Watlow

recommends not using low-profile clamping on diameters

and widths greater than 3 in. (76 mm). The bars are

1

/4 in. (6 mm) diameter with an 8-32 screw. To order,

specify low-profile clamp bars.

WATLOW

®

8-32 Screw

A thermocouple pocket welded to the surface accepts a

0.063 in. (2 mm) diameter thermocouple (not included).

This option provides accurate temperature sensing of the

heater and easy thermocouple replacement.

501

Page 12

Band/Barrel Heaters

4 in.

2 in.

Extended Capabilities For

Mineral Insulated (MI) Band Heaters

Variations

xtEndEd

E

apability

C

High Temperature “Quick Disconnect”

European Style Plugs

(51 mm)

(102 mm)

15⁄8 in.

(41.3 mm)

2 7⁄8 in.

(73 mm)

2 ¼ in.

(57 mm)

15⁄16 in.

(33.3 mm)

Vertical Horizontal

They provide the simplest and safest way to apply power

to band heaters. The combination of high-temperature

male and female “quick disconnect” plug assemblies

eliminates all live exposed terminals and electrical wiring

that can be a potential hazard to employees or machine.

Maximum 15 amperes at 240VAC, maximum 240V.

To order, specify vertical or horizontal European plug.

Ground Wire

Insulated ground wire is available, contact your Watlow

representative.

Outside Diameter Heater

3 in. (76 mm) min. O.D,

14 in. (356 mm) max.

0.420 in.

(10.7 mm)

0.875 in.

(22.2 mm)

Two fiberglass-insulated lead wires rated to 840°F (450°C)

exit a metal braid 180° opposite from gap, Type B outside

diameter designed and constructed to mate with inside

diameter of cylinders. Maximum width for outside

diameter heaters is 6 in. (152 mm). To order, specify

outside diameter and width of heater.

502

WATLOW

®

Page 13

ww

RAPID SHIP

Band/Barrel Heaters

Mineral Insulated (MI) Band Heaters

Heater Part Numbers

Watt Approx.

I.D. Width Density Net Wt. Part

in. (mm) in. (mm) Construction Volts Watts W/in2 (W/cm2) Termination lbs (kg) Delivery Number

1 (25) 1 (25) 1 pc 120 150 92 (14.2) Type B,C,E, F or H 0.1 (0.05) RS MB1A1AN1

1 (25) 1 pc 120 100 61 (9.4) Type B,C,E, F or H 0.1 (0.05) RS MB1A1AN2

1 (25) 1 pc 120 200 122 (18.9) Type B,C,E, F or H 0.1 (0.05) RS MB1A1AN3

1 (25) 1 pc 240 200 122 (18.9) Type B,C,E, F or H 0.1 (0.05) RS MB1A1AN4

1 1/2 (38) 1 pc 240 300 106 (16.4) Type B,C,E, F or H 0.1 (0.05) RS MB1A1JN1

1 1/2 (38) 1 pc 120 300 106 (16.4) Type B,C,E, F or H 0.1 (0.05) RS MB1A1JN2

11/2 (38) 1 pc 240 200 70 (10.8) Type B,C,E, F or H 0.1 (0.05) RS MB1A1JN3

11/2 (38) 1 pc 120 200 70 (10.8) Type B,C,E, F or H 0.1 (0.05)

1 1/2 (38) 1 pc 240 400 141 (21.8) Type B,C,E, F or H 0.1 (0.05) RS MB1A1JN5

11/4 (32) 1 (25) 1 pc 240 250 104 (16.1) Type B,C,E, F or H 0.1 (0.05) RS MB1E1AN1

1 (25) 1 pc 120 250 104 (16.1) Type B,C,E, F or H 0.1 (0.05) RS MB1E1AN2

1 (25) 1 pc 240 300 124 (19.2) Type B,C,E, F or H 0.1 (0.05) M MB1E1AN3

1 1/2 (38) 1 pc 240 350 87 (13.5) Type B,C,E, F or H 0.2 (0.09) RS MB1E1JN1

1 1/2 (38) 1 pc 120 350 87 (13.5) Type B,C,E, F or H 0.2 (0.09) RS MB1E1JN2

1 1/2 (38) 1 pc 240 450 112 (17.3) Type B,C,E, F or H 0.2 (0.09) M MB1E1JN3

11/2 (38) 1 (25) 1 pc 240 300 93 (14.4) Type B,C,E, F or H 0.1 (0.05) M MB1J1AN1

1 (25) 1 pc 120 300 93 (14.4) Type B,C,E, F or H 0.1 (0.05) RS MB1J1AN2

1 (25) 1 pc 240 200 62 (9.6) Type B,C,E, F or H 0.1 (0.05) RS MB1J1AN3

1 (25) 1 pc 120 200 62 (9.6) Type B,C,E, F or H 0.1 (0.05) RS MB1J1AN4

1 (25) 1 pc 240 400 125 (19.3) Type B,C,E, F or H 0.1 (0.05) RS MB1J1AN5

11/2 (38) 1 pc 120 300 62 (9.6) Type B,C,E, F or H 0.2 (0.09) RS MB1J1JN1

1 1/2 (38) 1 pc 240 450 87 (13.5) Type B,C,E, F or H 0.2 (0.09) RS MB1J1JN2

1 1/2 (38) 1 pc 240 300 62 (9.6) Type B,C,E, F or H 0.2 (0.09) RS MB1J1JN3

1 1/2 (38) 1 pc 240 600 116 (17.9) Type B,C,E, F or H 0.2 (0.09) M MB1J1JN4

1 1/2 (38) 1 pc 240 300 62 (9.6) Post 0.2 (0.09) M MB1J1JP4

1 1/2 (38) 1 pc 240 450 96 (14.8) Post 0.2 (0.09) RS MB1J1JP6

2 (51) 1 pc 240 450 57 (8.8) Type B,C,E, F or H 0.3 (0.14) RS MB1J2AN1

2 (51) 1 pc 240 300 42 (6.5) Type B,C,E, F or H 0.3 (0.14) RS MB1J2AN2

2 (51) 1 pc 240 900 125 (19.3) Type B,C,E, F or H 0.3 (0.14) RS MB1J2AN3

3 (76) 1 pc 240 500 45 (7.0) Type B,C,E, F or H 0.4 (0.18) RS MB1J3AN1

3 (76) 1 pc 240 350 31 (4.8) Type B,C,E, F or H 0.4 (0.18) M MB1J3AN2

3 (76) 1 pc 240 1000 104 (16.1) Type B,C,E, F or H 0.4 (0.18) M MB1J3AN3

13/4 (45) 1 3/8 (35) 1 pc 240 450 83 (12.9) 36 in. 90° Type B 0.2 (0.09) RS

braid w/HD strain

relief

11/2 (38) 1 pc 240 300 47 (7.3) Type B,C,E, F or H 0.2 (0.09) RS MB1N1JN1

1 1/2 (38) 1 pc 120 300 50 (7.7) Type B,C,E, F or H 0.2 (0.09) RS MB1N1JN2

1 1/2 (38) 1 pc 240 700 110 (17.0) Type B,C,E, F or H 0.2 (0.09) RS MB1N1JN3

2 (51) 1 pc 240 750 86 (13.3) Type B,C,E, F or H 0.3 (0.14) M MB1N2AN1

2 (51) 1 (25) 1 pc 240 350 73 (11.3) Type B,C,E, F or H 0.2 (0.09) RS MB2A1AN1

1 (25) 1 pc 120 350 73 (11.3) Type B,C,E, F or H 0.2 (0.09) RS MB2A1AN2

1 (25) 1 pc 240 450 94 (14.5) Type B,C,E, F or H 0.2 (0.09) RS MB2A1AN3

1 (25) 1 pc 240 350 73 (10.3) 36 in. 90° Type B 0.2 (0.09) RS

braid w/HD strain

relief

M

MB1A1JN4

MB1N1GX3A

MB2A1AX6B

CONTINUED

• RS - Next day shipment

• M - Manufacturing lead times

WATLOW

®

Notes:

All lead units are available with any length Type B, C, E, F or Type H leads.

Type B 90° rotation not available as RAPID SHIP.

503

Page 14

Band/Barrel Heaters

RAPID SHIP

Mineral Insulated (MI) Band Heaters

Heater Part Numbers (Continued)

Watt Approx.

I.D. Width Density Net Wt. Part

in. (mm) in. (mm) Construction Volts Watts W/in2 (W/cm2) Termination lbs (kg) Delivery Number

2 (51) 11/2 (38) 1pc 240 400 53 (8.2) Type B,C,E, F or H 0.3 (0.14) RS MB2A1JN1

11/2 (38) 1pc 240 1000 132 (20.4) Type B,C,E, F or H 0.3 (0.14) M MB2A1JN2

2 (51) 1pc 240 750 75 (11.6) Type B,C,E, F or H 0.4 (0.18) M MB2A2AN1

2 (51) 1pc 240 1200 125 (19.3) Type B,C,E, F or H 0.4 (0.18) RS MB2A2AN2

2 (51) 1pc 240 750 75 (11.6) 36 in. 90° Type B 0.2 (0.09) RS

braid w/HD strain

relief

21/4 (57) 2 (51) 1pc 240 750 63 (9.7) 120 in. 180° Type B 0.2 (0.09) RS

braid w/HD strain

relief

21/2 (64) 1 pc 240 1000 72 (11.2) Type B,C,E, F or H 0.5 (0.23) RS MB2E2JN1

21/2 (64) 1 (25) 1 pc 240 400 63 (9.7) Type B,C,E, F or H 0.2 (0.09) RS MB2J1AN1

11/2 (38) 1 pc 240 500 50 (7.7) Type B,C,E, F or H 0.4 (0.18) RS MB2J1JN1

3 (76) 1 (25) 1 pc 240 400 54 (8.4) Post 0.3 (0.14) M MB3A1AP1

11/2 (38) 1 pc 240 500 40 (6.2) Post 0.4 (0.18) RS MB3A1JP1

11/2 (38) 2 pc exp 230/460 525 53 (8.2) Post 0.4 (0.18) M ME3A1JP10

31/2 (89) 2 (51) 1 pc 240 800 42 (6.5) Post 0.7 (0.32) RS MB3J2AP2

35/8 (92) 11/2 (38) 2 pc exp 230/460 650 51 (7.9) Post 0.5 (0.23) M ME3L1JP5

4 (102) 1 (25) 1 pc 240 700 62 (9.6) Post 0.4 (0.18) RS MB4A1AP1

11/2 (38) 1 pc 240 800 48 (7.4) Post 0.6 (0.27) RS MB4A1JP2

11/2 (38) 2 pc exp 230/460 625 43 (6.7) Post 0.6 (0.27) RS ME4A1JP11

11/2 (38) 2 pc exp 230/460 725 50 (7.8) Post 0.6 (0.27) RS ME4A1JP12

41/2 (114) 21/2 (64) 1pc 240 1250 40 (6.2) Post 1.0 (0.45) RS MB4J2JP1

5 (127) 11/2 (38) 2 pc exp 240/480 1000 52 (8.1) Post 0.8 (0.36) RS ME5A1JP8

51/4 (133) 11/2 (38) 2 pc exp 240/480 1000 48 (7.4) Post 0.8 (0.36) M ME5E1JP1

11/2 (38) 2 pc exp 230/460 600 29 (4.5) Post 0.7 (0.32) M ME5E1JP9

3 (76) 2 pc exp 230/460 1700 40 (6.2) Post 1.5 (0.68) RS ME5E3AP5

41/2 (114) 2 pc exp 230/460 2400 38 (5.9) Post 2.2 (1.00) RS ME5E4JP2

41/2 (114) 2 pc exp 230/460 2700 43 (6.6) Post 2.2 (1.00) M ME5E4JP3

51/2 (140) 11/2 (38) 2 pc exp 240/480 1000 46 (7.1) Post 0.9 (0.40) RS ME5J1JP1

6 (152) 11/2 (38) 2 pc exp 240/480 1000 41 (6.4) Post 0.9 (0.40) M ME6A1JP2

61/2 (165) 11/2 (38) 2 pc exp 240/480 1250 47 (7.3) Post 1.0 (0.45) RS ME6J1JP5

63/4 (171) 11/2 (38) 2 pc exp 230/460 815 29 (4.5) Post 0.9 (0.40) M ME6N1JP6

11/2 (38) 2 pc exp 230/460 1000 36 (5.6) Post 0.9 (0.40) M ME6N1JP7

4 (102) 2 pc exp 230/460 2600 35 (5.4) Post 2.5 (1.10) M ME6N4AP2

5 (127) 2 pc exp 230/460 3700 40 (6.2) Post 3.2 (1.50) M ME6N5AP3

6 (152) 2 pc exp 230/460 3750 33 (5.1) Post 3.8 (1.70) M ME6N6AP5

7 (178) 11/2 (38) 2 pc exp 240/480 1250 43 (6.6) Post 1.1 (0.50) M ME7A1JP4

71/2 (191) 11/2 (38) 2 pc exp 240/480 1500 47 (7.3) Post 1.1 (0.50) M ME7J1JP4

75/8 (194) 3 (76) 2 pc exp 230/460 1800 28 (4.3) Post 2.2 (1.00) M ME7L3AP1

8 (203) 11/2 (38) 2 pc exp 240/480 1250 37 (5.7) Post 1.2 (0.54) M ME8A1JP4

9 (229) 11/2 (38) 2 pc exp 240/480 1500 39 (6.0) Post 1.4 (0.64) M ME9A1JP1

91/2 (241) 3 (76) 2 pc exp 230/460 3000 37 (5.7) Post 2.6 (1.20) M ME9J3AP2

111/4 (286) 3 (76) 2 pc exp 230/460 2400 24 (3.7) Post 3.2 (1.50) M ME11E3AP2

5 (127) 2 pc exp 230/460 5100 31 (4.8) Post 5.2 (2.40) M ME11E5AP1

Notes:

All lead units are available with any length Type B, C, E, F or Type H leads.

• RS - Next day shipment

Type B 90° rotation not available as RAPID SHIP.

• M - Manufacturing lead times

MB2A2AX2A

MB2E2AX7

504

WATLOW

®

Loading...

Loading...