Page 1

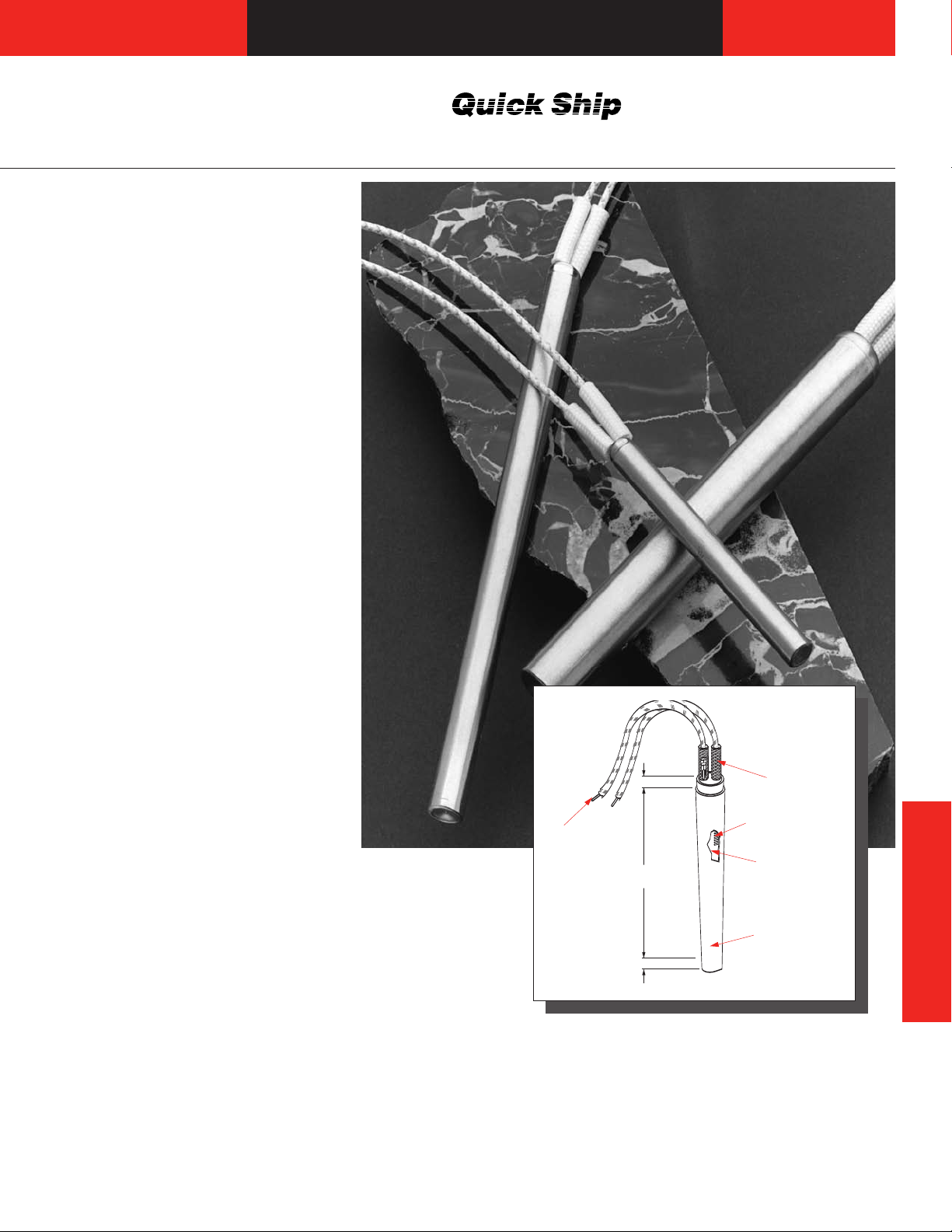

6 mm (

1

/

4

in.)

No-Heat

Heated

Length

6 mm (

1

/

4

in.)

No-Heat

WW AA TT LL OO W

Cartridge Heaters

Metric EB Cartridge

The Watlow EB cartridge heater is a

proven performer like the metric

FIREROD®. That’s because the

same quality materials go into its

construction; MgO insulation, nickelchromium resistance wire,

silicone-fiberglass insulated lead

wires. The only difference is that the

EB cartridge is packaged in a more

economical design. Instead of

having the high watt density

capabilities of a metric FIREROD,

it’s made for medium watt density

applications.

Performance Capabilities

• Part temperatures to 600°C

(1100°F)

• Maximum watt density to

2

30 W/cm

• Maximum voltage to 480VÅ(ac)

Features and Benefits

• Magnesium oxide insulation,

compacted to the proper density,

results in high dielectric strength

and contributes to faster heat-up.

• Nickel-chromium resistance

wire, precisely woundthrough the

heated length, assures even,

efficient distribution of heat to the

sheath.

• Metallurgically-bonded

conductor pins, crimpconnected to the resistance wires,

ensure trouble-free electrical

continuity. This process provides

lead flexibility just 8 mm (5⁄16 inch)

from the end of the heater.

• Flexible stranded wires, with

silicone-fiberglass sleeve, insulate

the wires to temperatures of

250°C (480°F).

• Optional lead end with silicone

rubber seal protects the leads

against moisture and other

contaminants.

(190 W/in2)

FFiibbeerrggllaassss

IInnssuullaatteedd

CCrriimmppeedd oonn

s

LLeeaadds

• VDE component recognition to

230VÅ(ac) according to VDE

0721 part 1/3.78 and part 2/3.78

Section E in connection with VDE

0720 part 1/11.74.

W

Next day shipment on all stock units.

•

d

SSoolliid

CCoonndduuccttoorrs

NNiicckkeell--CChhrroommiiuum

RReessiissttaannccee WWiirre

MMaaggnneessiiuum

OOxxiidde

IInnssuullaattiioon

SSttaaiinnlleesss

SStteeeell SShheeaatth

Applications

• Plastic injection molds, dies and

sealing jaws

Hot melt systems, labeling

•

Industrial and textile

•

manufacturing equipment

s

m

e

m

e

n

s

h

Cartridge Heaters

127

Page 2

Cartridge Heaters

0

Watt Density—W/cm

2

Fit in Hole—mm

1 2 3 4 5 10 15 20 30 40 50

2.5

2.0

1.0

0

.5

0.25

0.1

0.05

0.01

100°C

300°C

400°C

500°C

600°C

200°C

10 20 40 60 80 100 200 300

0.10

0.050

0.020

0.010

0.005

0.002

0.001

Watt Density—W/in

2

Fit in Hole—inches

1100°F

900°F

700°F

500°F

200°F

Metric EB Cartridge

Applications and Technical Data

Continued

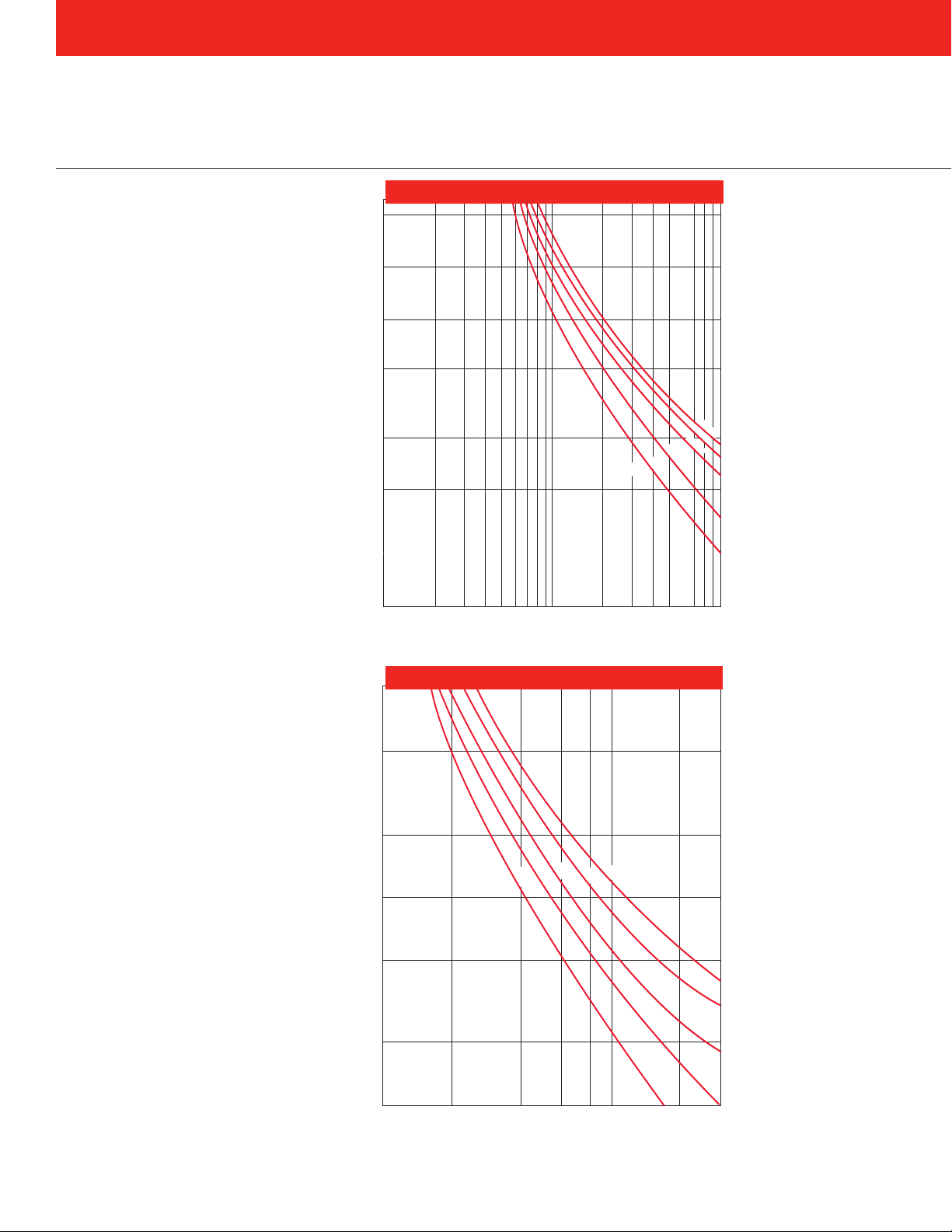

Maximum Allowable Watt Density

Both the Maximum Allowable Watt

Density metric and inch-base charts

will tell you either the hole fit or

recommended watt density in

relationship to part temperature.

Enter the chart with either known

variable, part fit in hole dimension or

watt density. Then find the part

temperature by reading up or over

on the chart. The part temperature

curves shown are measured

13 mm (

mild steel block. For stainless steel

blocks, enter the graph with a fit of

0.04 mm (0.0015 inch) larger than

actual. For aluminum and brass

blocks, enter the graph with a

temperature 55°C (100°F) above

actual block temperature.

On-Off Cycling: On-off cycling

shortens heater life. If the heater

cycles more than once per hour,

multiply the watt density, shown on

the chart, by 0.8 to determine the

maximum allowable watt density for

the application. If the heater cycles

more than once a minute, multiply

by 0.7.

Tolerances

Diameter: -0.02 mm, -0.08 mm

Length: ±

Resistance: +5 percent, -10

Wattage: +10 percent, -5 percent.

1

⁄2 inch) from the heater in a

(-0.0008 inch, -0.0031 inch)

3 percent with

3

(±

⁄32 inch) minimum

percent. Resistance is measured

at room temperature following first

heater operation.

Wattage decreases approximately

5 percent with temperature.

Wattage tolerances are for

heaters at operating temperature.

2.4 mm

±

Maximum Allowable Watt Density

Maximum Allowable Watt Density

128

Page 3

WW AA TT LL OO W

6 mm

(

1

/

4

"

)

As

Specified

B

A

W

Cartridge Heaters

Metric EB Cartridge

Applications and

Technical Data

Continued

Dimensional & Electrical Data

Heater Diameter (mm) 6.5 8 10 12.5 16 20

Nominal Diameter (in) 0.256 0.315 0.394 0.492 0.630 0.787

Maximum Voltage 250 250 250 400 480 480

Crimped-on Leads

Maximum Amps 4.4 4.4 6.7 9.7 23 23

Maximum Wattage @ 230V 1010 1010 1540 2230 5290 5290

Maximum Wattage @ 400V

Swaged-in Leads

Maximum Amps 3.1/4.4

Maximum Wattage @ 230V 710/1010 710/1010 1010 1750/2875 1750/2875 2875

Maximum Wattage @ 400V

➀

— — — 3040/5000 3040/5000 5000

3.1/4.4

➀

4.4 7.6/12.5 ➁7.6/12.5 12.5

3880 9200 9200

➀ On certain lead construction, maximum amperage is 3.1. Please consult Watlow.

➁ On certain lead construction, maximum amperage is 7.6. Please consult Watlow.

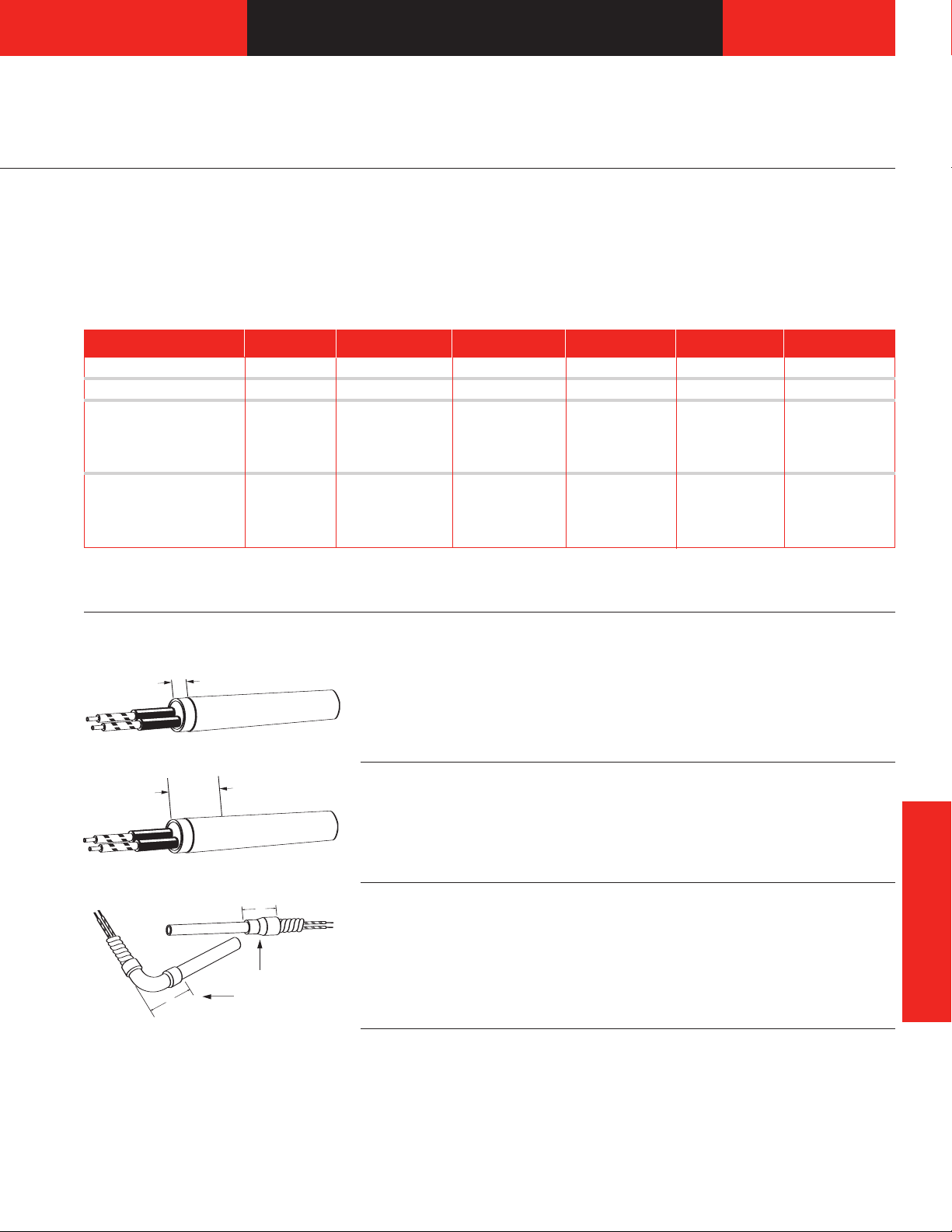

Termination Options

Crimped-on Lead

Crimped-on leads with a 6 mm

(1⁄4 inch) unheated section are

recommended for applications

where the lead wire temperature

does not exceed 250°C (480°F).

No-Heat Zone

An unheated section can be used to

extend the leads safely into a cool

zone in a high temperature

Galvanized Conduit

Flexible galvanized conduit can be

installed over the leads for abrasion

protection. It is attached with either a

Straight

Right Angle

straight or 90 degree elbow copper

coupler. The copper coupler

Unless a longer length is specified,

250 mm (10 inch) leads will be

supplied. To order, request

crimped-on leads and desired lead

length.

application. Leads should be kept

below 250°C (480°F) for maximum

service life. To order, specify no-

heat zone and length of unheated

section.

overlaps the heater sheath by

6 mm (1⁄4 inch). A no-heat section

is required. To order, specify

galvanized conduit, straight or

right angle.

Cartridge Heaters

Stainless Steel Hose

Stainless steel hose also protects

leads against abrasion. It is attached

with a straight or 90 degree elbow

copper coupler. The copper coupler

overlaps the heater sheath by

6 mm (1⁄4 inch).

It can also be swaged-in straight or

silver soldered to the heater sheath

at a right angle. A no-heat section is

required. To order, specify stainless

steel hose, straight or right angle

with copper coupler, straight

swaged-in or right angle silver

soldered.

129

Page 4

25 mm

(1")

Min

6 mm

(

1

/

4

"

)

No-Heat

B

A

Cartridge Heaters

No-Heat

Section

Minimum

No-Heat

Minimum

No-Heat

Metric EB Cartridge

Termination Options

Continued

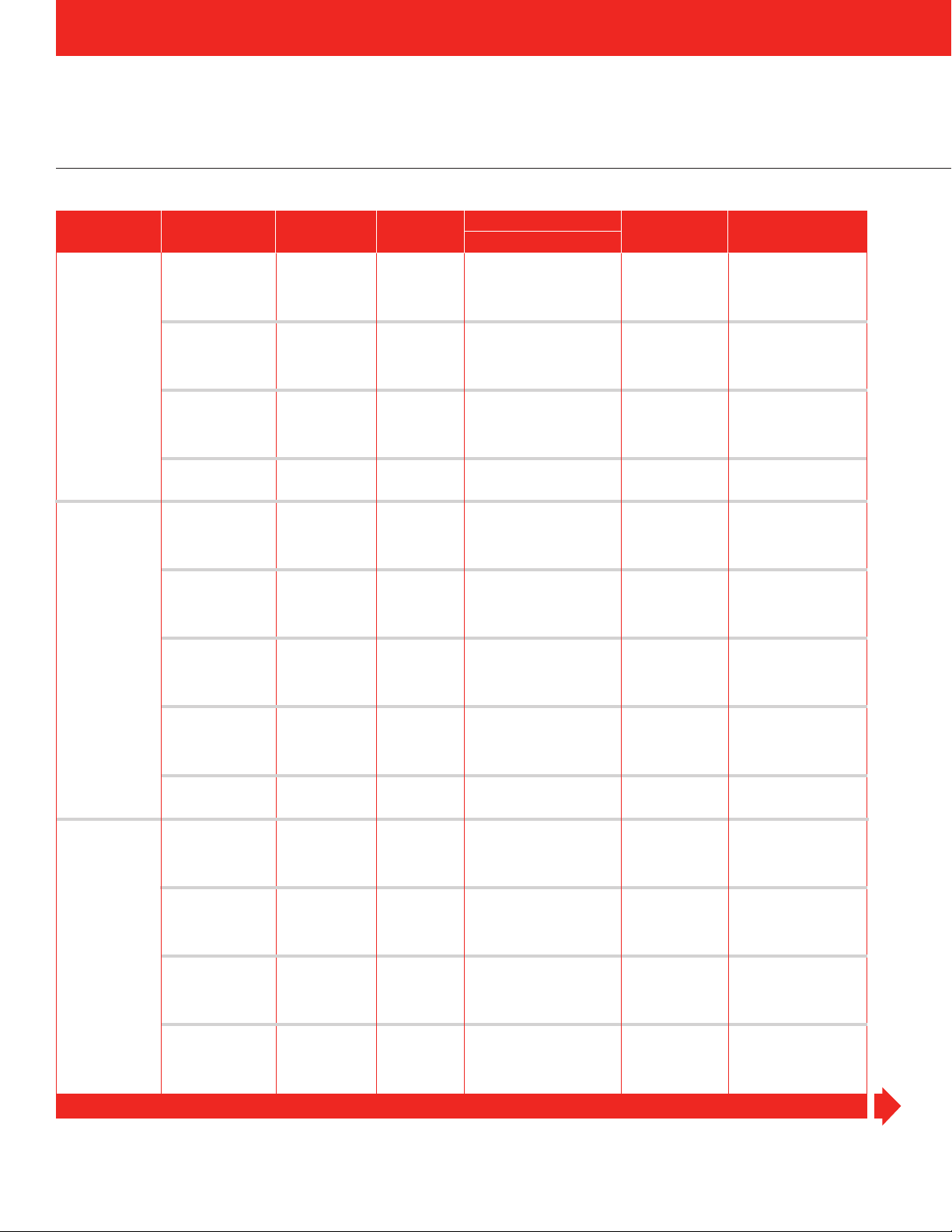

Galvanized Conduit and

Stainless Steel Hose Dimensions

Heater Minimum Dimension Dimension Galvanized Stainless Steel

Diameter No-Heat Length A B Conduit O.D. Hose O.D.

mm mm (inches) mm (inches) mm (inches) mm (inches) mm (inches)

6.5 12 (7⁄16)22(

812(

10 14 (

12.5 16 (

16 19 (

20 22 (

Dimensions are shown for designs with copper coupler only.

7

⁄16)22(

1

⁄2)22(

5

⁄8) 28 (1 1⁄8) 30 (1 3⁄16)14(

3

⁄4) 28 (1 1⁄8) 34 (1 3⁄8)14(

7

⁄8) 29 (1 1⁄8) 36 (1 7⁄16)16(

7

⁄8) 29 (1 1⁄8)10(

7

⁄8) 29 (1 1⁄8)10(

7

⁄8) 29 (1 1⁄8)10(

3

⁄8) 5.6 (3⁄16)

3

⁄8) 6.5 (1⁄4)

3

⁄8) 7.2 (5⁄16)

9

⁄16) 9.5 (3⁄8)

9

⁄16) 12.7 (1⁄2)

5

⁄8) 15.9 (5⁄8)

Brass Stainless Steel

Stainless Steel Braid

Like stainless steel hose, stainless

steel braid also protects against

abrasion. Stainless steel braid is

swaged-in straight or crimped-on to

the heater at a right angle. Metal

Swaged-in Flexible Lead

Swaged-in flexible leads, with a

silicone-fiberglass insulation, are

recommended for applications in

which the leads must be bent at the

exit point from the heater. Unless

longer length is specified, 250 mm

(10 inch) leads are supplied.

Moisture Resistant Seal

Silicone rubber moisture resistant

seals can be provided at the lead

end to virtually seal the heater. This

seal is rated to 230°C (450°F)

continuous operation.

A 25 mm (one inch) no-heat section

is required at the lead end. Solid pin

leads exit through the seal with

Threaded Fitting

Either brass or stainless steel threaded fittings for screw-in mounting can

be added to units that have moisture

resistant seals. Available dimensions

are shown on the Threaded Fittings

braid is recommended when

excellent flexibility with good

physical protection is needed.

A unheated section is required. To

order, specify stainless steel braid,

straight or right angle.

Heaters 140 mm (5 1⁄2 inches) or

shorter generally have a six mm

1

⁄4 inch) no-heat section. Heaters to

(

250 mm (10 inches) require a 25 mm

(one inch) no-heat section. Heaters

greater than 250 mm may require

more than a 25 mm no-heat section.

To order, please specify swaged-in

flexible leads.

crimped-on silicone rubber insulated

lead wires and silicone rubber

sleeves that extend into the seal.

Swaged-in leads are also an option

where flexibility at the lead exit is

required. To order specify, silicone

rubber moisture resistant seal and

either crimped-on or swaged-in

leads

.

charts. To order, please request

brass or stainless steel threaded

fittings and location on the heater.

Note: For liquid immersion

applications, please also specify

heavy weld end disc.

130

Page 5

WW AA TT LL OO W

13 mm (

1

/

2

in.)

No-Heat

W

Cartridge Heaters

Metric EB Cartridge

Termination Options

Continued

DIN Thread Size

Heater Minimum Dimension Dimension Length of

Diameter No-Heat Length Thread Size A B Threaded Section

mm mm (inches) DIN 13 mm (inches) mm (inches) mm (inches)

6.5 16 (5⁄8) M 10 X 1 10 (3⁄8)12(

816(

10 18 (

12.5 19 (

16 20 (

20 22 (

5

⁄8) M 12 X 1 10 (3⁄8)14(

11

⁄16) M 14 X 1.5 11 (7⁄16)17(

3

⁄4) M 16 X 1.5 12 (7⁄16)19(

3

⁄4) M 20 X 1.5 14 (9⁄16)24(

7

⁄8) M 26 X 1.5 15 (9⁄16) 30 (1 3⁄16)10(

NPT Thread Size

Heater Minimum Thread Size Dimension Dimension Length of

Diameter No-Heat Length NPT A B Threaded Section

mm mm (inches) inches mm (inches) mm (inches) mm (inches)

6.5 19 (3⁄4)

8 22 (

10 22 (

12.5 25 (1)

16 28 (1

20 32 (1

7

7

1

⁄8)

⁄8)

⁄8)

1

⁄4)

1

⁄8 13 (1⁄2) 11 (7⁄16) 10 (3⁄8)

1

⁄4 16 (5⁄8) 14 (1⁄2) 13 (1⁄2)

1

⁄4 16 (5⁄8) 14 (1⁄2) 13 (1⁄2)

3

⁄8 19 (3⁄4) 17.5 (11⁄16)15(

1

⁄2 22 (7⁄8) 22 (7⁄8) 16 (5⁄8)

3

⁄4 25 (1) 29 (1 1⁄8)19(

7

⁄16)6(

1

⁄2) 6.5 (1⁄4)

5

⁄8) 6.5 (1⁄4)

3

⁄4) 7.5 (5⁄16)

15

⁄16)9(

1

⁄4)

3

⁄8)

3

⁄8)

9

⁄16)

3

⁄4)

Style A

Style B

Style C

Thermocouple Types

ASTM Conductor Characteristics Temperature Range

Code

J Copper Constantan (Silver Color) -60 to 370 (-75 to 700)

K Chromel

For other ASTM types, contact Watlow.

Positive Negative

®

(Non-Magnetic) Alumel®(Magnetic) -20 to 1260 (0 to 2300)

How to Order

To order stock AB cartridge heaters,

please specify:

• Code number

• Termination options, and length

of leads

Alumel®and Chromel®are registered

trademarks of Hoskins Manufacturing Co.

Internal Thermocouple

Style A is used to evaluate heat

transfer efficiency of an application.

The junction is located in the heater

core to monitor the internal

temperature of the heater.

Style B approximates part

temperature, and is available in all

diameters. The thermocouple

junction can be in contact with the

inside of the heater sheath, located

in the 13 mm (1⁄2 inch) no-heat

For made-to-order units, please

specify:

Diameter

•

Overall length

•

• Watts

Termination options, and length of

•

leads

section anywhere along the heater

length.

Style C is useful in applications

where material flows past the end of

the heater. This junction is embedded

in a special end disc. Type C is

available only on 6.5, 8,10, 12.5 and

16 mm diameter units.

To order, specify internal

thermocouple, Style A, B or C and

thermocouple ASTM Type J, T, K or

E. If not specified, 250 mm (10 inch)

thermocouple leads are supplied.

°C (°F)

Availability

Stock: Next day shipment

Made-to-Order: Shipment within

three weeks

Cartridge Heaters

131

Page 6

Cartridge Heaters

Metric EB Cartridge

Made in Kronau, Germany

Diameter Sheath Length No-Heat Length Watt Density

mm mm (inches) mm Watts W/cm

2

(W/in2) Availability Code No.

6.5 40 (1 9⁄16) 50 9 (58) Stock KEBE0040C001A

40 (1 9⁄16) 75 14 (90) Stock KEBE0040C002A

40 (1 9⁄16) 100 19 (123) Stock KEBE0040C003A

40 (1 9⁄16) 125 24 (155) Stock KEBE0040C004A

40 (1 9⁄16) 150 28 (181) Stock KEBE0040C005A

60 (2 3⁄8) 50 5 (32) Stock KEBE0060C001A

60 (2 3⁄8) 100 11 (71) Stock KEBE0060C002A

60 (2 3⁄8) 150 16 (103) Stock KEBE0060C003A

60 (2 3⁄8) 200 21 (135) Stock KEBE0060C004A

60 (2 3⁄8) 250 27 (174) Stock KEBE0060C005A

80 (3 1⁄8) 100 7 (45) Stock KEBE0080C001A

80 (3 1⁄8) 150 11 (71) Stock KEBE0080C002A

80 (3 1⁄8) 200 15 (97) Stock KEBE0080C003A

80 (3 1⁄8) 300 22 (142) Stock KEBE0080C004A

80 (3 1⁄8) 450 33 (213) Stock KEBE0080C005A

100 (3 15⁄16) 100 6 (39) Stock KEBE0100C001A

100 (3 15⁄16) 200 11 (71) Stock KEBE0100C002A

100 (3

1

5

⁄16) 300 17 (110) Stock KEBE0100C003A

8.0 40 (1 9⁄16) 50 8 (52) Stock KEBF0040C001A

40 (1 9⁄16) 75 11 (71) Stock KEBF0040C002A

40 (1 9⁄16) 100 15 (97) Stock KEBF0040C003A

40 (1 9⁄16) 150 23 (148) Stock KEBF0040C004A

40 (1 9⁄16) 200 31 (200) Stock KEBF0040C005A

60 (2 3⁄8) 75 6 (39) Stock KEBF0060C001A

60 (2 3⁄8) 150 13 (84) Stock KEBF0060C002A

60 (2 3⁄8) 200 17 (110) Stock KEBF0060C003A

60 (2 3⁄8) 250 22 (142) Stock KEBF0060C004A

60 (2 3⁄8) 300 26 (168) Stock KEBF0060C005A

80 (3 1⁄8) 100 6 (39) Stock KEBF0080C001A

80 (3 1⁄8) 200 12 (77) Stock KEBF0080C002A

80 (3 1⁄8) 300 18 (116) Stock KEBF0080C003A

80 (3 1⁄8) 25 400 33 (213) Stock KEBF0080D001A

80 (3 1⁄8) 25 500 41 (265) Stock KEBF0080D002A

5

100 (3

100 (3 15⁄16) 250 12 (77) Stock KEBF0100C002A

100 (3

100 (3 15⁄16) 25 500 29 (187) Stock KEBF0100D002A

100

130

130

1

⁄16) 100 5 (32) Stock KEBF0100C001A

5

1

⁄16) 25 400 23 (148) Stock KEBF0100D001A

5

(3

(5

(5

1

⁄16)

1

⁄8)

1

⁄8)

25

25

25

600

200 8 (52) Stock

350

35

14

(226) Stock

(90)

Stock

KEBF0100D003A

KEBF0130D001A

KEBF0130D002A

130 (5 1⁄8) 25 500 20 (129) Stock KEBF0130D003A

10.0 40 (1 9⁄16) 50 6 (39) Stock KEBG0040C001A

40 (1 9⁄16) 100 12 (77) Stock KEBG0040C002A

40

(1

9

⁄16)

150

18 (116) Stock

KEBG0040C003A

40 (1 9⁄16) 200 24 (155) Stock KEBG0040C004A

40 (1 9⁄16) 250 31 (200) Stock KEBG0040C005A

60 (2 3⁄8) 100 7 (45) Stock KEBG0060C001A

60 (2 3⁄8) 150 10 (65) Stock KEBG0060C002A

60 (2 3⁄8) 200 14 (90) Stock KEBG0060C003A

60 (2 3⁄8) 300 21 (135) Stock KEBG0060C004A

60

80

80

(2

(3

(3

3

⁄8)

1

⁄8)

1

⁄8)

400

100

200

28

5

10

(181)

(32) Stock

(65)

Stock

Stock

KEBG0060C005A

KEBG0080C001A

KEBG0080C002A

80 (3 1⁄8) 300 14 (90) Stock KEBG0080C003A

80 (3 1⁄8) 400 19 (123) Stock KEBG0080C004A

80

100

100 (3

100 (3

100

1

(3

⁄8)

15

(3

⁄16)

5

1

⁄16) 300 11 (71) Stock KEBG0100C002A

5

1

⁄16) 400 15 (97) Stock KEBG0100C003A

15

(3

⁄16)

600

200

500 19 (123) Stock

29 (187) Stock

7

(45)

Stock

KEBG0080C005A

KEBG0100C001A

KEBG0100C004A

100 (3 15⁄16) 25 700 33 (213) Stock KEBG0100D001A

CONTINUED

Note: All stock EB cartridge heaters 230VÅ(ac) and 1000 mm fiberglass insulated swaged-in leads.

132

Page 7

WW AA TT LL OO W

W

Cartridge Heaters

Metric EB Cartridge

D

iameter Sheath Length No-Heat Length Watt Density

mm mm (inches) mm Watts W/cm

10.0 130 (5 1⁄8) 200 5 (32) Stock KEBG0130C001A

12.5 80 (3 1⁄8) 150 6 (39) Stock KEBJ0080C001A

16.0 80 (3 1⁄8) 200 6 (39) Stock KEBL0080C001A

130 (5 1⁄8) 400 11 (71) Stock KEBG0130C002A

130 (5 1⁄8) 25 600 19 (123) Stock KEBG0130D001A

130 (5 1⁄8) 25 800 26 (168) Stock KEBG0130D002A

1

30 (5

160 (6 5⁄16) 25 200 5 (32) Stock KEBG0160D001A

160 (6 5⁄16) 25 500 12 (77) Stock KEBG0160D002A

1

⁄8)

25 1000 32 (206) Stock

160 (6 5⁄16) 25 800 20 (129) Stock KEBG0160D003A

160 (6 5⁄16) 25 1000 25 (161) Stock KEBG0160D004A

160 (6 5⁄16) 25 1200 30 (194) Stock KEBG0160D005A

200 (7 7⁄8) 25 300 6 (39) Stock KEBG0200D001A

200 (7 7⁄8) 25 600 11 (71) Stock KEBG0200D002A

200 (7 7⁄8) 25 1000 19 (123) Stock KEBG0200D003A

200 (7 7⁄8) 25 1200 23 (148) Stock KEBG0200D004A

200 (7 7⁄8) 25 1400 27 (174) Stock KEBG0200D005A

250 (9 7⁄8) 25 400 6 (39) Stock KEBG0250D001A

250 (9 7⁄8) 25 700 10 (65) Stock KEBG0250D002A

250 (9 7⁄8) 25 1000 15 (97) Stock KEBG0250D003A

250 (9 7⁄8) 25 1400 20 (129) Stock KEBG0250D004A

300 (11 13⁄16) 30 500 6 (39) Stock KEBG0300D004A

300 (11 13⁄16) 30 1000 12 (77) Stock KEBG0300D002A

300 (11 13⁄16) 30 1500 18 (116) Stock KEBG0300D003A

80 (3 1⁄8) 300 12 (77) Stock KEBJ0080C003A

80 (3 1⁄8) 400 15 (97) Stock KEBJ0080C004A

80 (3 1⁄8) 500 19 (123) Stock KEBJ0080C002A

80 (3 1⁄8) 700 27 (174) Stock KEBJ0080C005A

100 (3 15⁄16) 200 6 (39) Stock KEBJ0100C001A

100 (3 15⁄16) 400 12 (77) Stock KEBJ0100C002A

100 (3 15⁄16) 600 18 (116) Stock KEBJ0100D003A

100 (3

5

1

⁄16) 800 24 (155) Stock KEBJ0100D004A

100 (3 15⁄16) 25 1000 37 (239) Stock KEBJ0100D001A

130 (5 1⁄8) 250 5 (32) Stock KEBJ0130C001A

130 (5 1⁄8) 500 11 (71) Stock KEBJ0130C002A

130 (5 1⁄8) 25 800 21 (135) Stock KEBJ0130D001A

130 (5 1⁄8) 25 1000 26 (168) Stock KEBJ0130D002A

130 (5 1⁄8) 25 1400 36 (232) Stock KEBJ0130D003A

5

160

160 (6 5⁄16) 25 600 12 (77) Stock KEBJ0160D002A

160

(6

(6

⁄16)

5

⁄16)

25 300 6 (39) Stock

25

1000

160 (6 5⁄16) 25 1400 28 (181) Stock KEBJ0160D004A

160 (6 5⁄16) 25 1700 34 (219) Stock KEBJ0160D005A

200 (7 7⁄8) 25 400 6 (39) Stock KEBJ0200D002A

200 (7 7⁄8) 25 700 11 (71) Stock KEBJ0200D003A

200 (7 7⁄8) 25 1000 15 (97) Stock KEBJ0200D004A

200 (7 7⁄8) 25 1500 23 (148) Stock KEBJ0200D005A

200 (7 7⁄8) 25 2000 30 (194) Stock KEBJ0200D006A

250 (9 7⁄8) 25 500 6 (39) Stock KEBJ0250D001A

250 (9 7⁄8) 25 1000 12 (77) Stock KEBJ0250D002A

250 (9 7⁄8) 25 1500 18 (116) Stock KEBJ0250D003A

250 (9 7⁄8) 25 2000 23 (148) Stock KEBJ0250D004A

300 (11 13⁄16) 30 600 6 (39) Stock KEBJ0300D001A

300

80

80 (3 1⁄8) 600 18 (116) Stock KEBL0080C003A

80

100

100

(11

(3

(3

(3

(3

13

⁄16)

1

⁄8)

1

⁄8)

15

⁄16)

15

⁄16)

30

1500

400

800

300 7 (45) Stock

500

100 (3 15⁄16) 700 16 (103) Stock KEBL0100C003A

100 (3 15⁄16) 25 1000 29 (187) Stock KEBL0100D001A

2

(W/in2) Availability Code No.

20 (129) Stock

15

12

(97)

(77)

Stock

Stock

24 (155) Stock

12

(77) Stock

Made in Kronau, Germany

K

EBG0130D003A

KEBJ0160D001A

KEBJ0160D003A

KEBJ0300D002A

KEBL0080C002A

KEBL0080C004A

KEBL0100C001A

KEBL0100C002A

CONTINUED

Cartridge Heaters

Note: All stock EB cartridge heaters 230VÅ(ac) and 1000 mm fiberglass insulated swaged-in leads.

133

Page 8

Cartridge Heaters

Metric EB Cartridge

Made in Kronau, Germany

Diameter Sheath Length No-Heat Length Watt Density

mm mm (inches) mm Watts W/cm

16.0 130 (5 1⁄8) 25 400 8 (52) Stock KEBL0130D001A

130 (5 1⁄8) 25 600 12 (77) Stock KEBL0130D002A

2

(W/in2) Availability Code No.

130 (5 1⁄8) 25 800 16 (103) Stock KEBL0130D003A

130 (5 1⁄8) 25 1200 24 (155) Stock KEBL0130D004A

160 (6 5⁄16) 25 500 8 (52) Stock KEBL0160D001A

160 (6 5⁄16) 25 700 11 (71) Stock KEBL0160D002A

160 (6 5⁄16) 25 1000 16 (103) Stock KEBL0160D003A

160 (6 5⁄16) 25 1500 23 (148) Stock KEBL0160D004A

160 (6 5⁄16) 25 2000 31 (200) Stock KEBL0160D005A

200 (7 7⁄8) 25 600 7 (45) Stock KEBL0200D001A

200

(7

7

⁄8)

25 1000 12 (77) Stock

200 (7 7⁄8) 25 1500 18 (116) Stock KEBL0200D003A

200 (7 7⁄8) 25 2000 24 (155) Stock KEBL0200D004A

250 (9 7⁄8) 25 700 6 (39) Stock KEBL0250D001A

250

(9

7

⁄8)

25 1500 14 (90) Stock

250 (9 7⁄8) 25 2000 18 (116) Stock KEBL0250D003A

3

300 (11

1

⁄16) 30 1000 8 (52) Stock KEBL0300D001A

300 (11 13⁄16) 30 1500 11 (71) Stock KEBL0300D002A

300 (11 13⁄16) 30 2000 15 (97) Stock KEBL0300D003A

20.0 200 (7 7⁄8) 25 1000 9 (58) Stock KEBN0200D001A

200 (7 7⁄8) 25 1500 14 (90) Stock KEBN0200D002A

200 (7 7⁄8) 25 2000 19 (123) Stock KEBN0200D003A

300 (11 13⁄16) 30 1000 6 (39) Stock KEBN0300D001A

300 (11

3

1

⁄16) 30 1500 9 (58) Stock KEBN0300D002A

300 (11 13⁄16) 30 2500 15 (97) Stock KEBN0300D003A

400 (15 3⁄4) 40 1000 5 (32) Stock KEBN0400D001A

400 (15 3⁄4) 40 2500 11 (71) Stock KEBN0400D002A

400 (15 3⁄4) 40 4000 18 (116) Stock KEBN0400D003A

1

500 (19

500 (19 11⁄16) 50 2500 9 (58) Stock KEBN0500D002A

500 (19

1

⁄16) 50 1000 4 (26) Stock KEBN0500D001A

1

1

⁄16) 50 4000 14 (90) Stock KEBN0500D003A

Note: All stock EB cartridge heaters 230VÅ(ac) and 1000 mm fiberglass insulated swaged-in leads.

KEBL0200D002A

KEBL0250D002A

134

Loading...

Loading...