Page 1

Using This Retrofit Guide

This document is best viewed with Adobe Reader 6.0. To obtain the latest version of Adobe Reader, visit

http://www.adobe.com

Specification sheets on Watlow product may be obtained at http://www.watlow.com/literature/specsheets/

User Manuals on Watlow product may be obtained at http://www.watlow.com/literature/prodtechinfo/

Additional information on other Watlow products may be obtained by visiting http://www.watlow.com/

To locate a controller, search on the part number such as 965A-1CD0-00RG. Use the Help feature in Adobe Reader on

how to search documents.

If there are multiple listings, then the retrofit is conditional upon field use. Select the appropriate selection. The User’s

Manual is included at the bottom of this document when availab le.

Before selecting a replacement controller:

1. Know the application.

• Temperature range

• Sensor type

• Is the sensor upgradable if required?

• Additional input requirements – remote set points, secondary sensor or events

• Output required – control, alarm, event

• Is the power-switching device upgradable?

• Operating voltage of controller

• Mounting requirements – panel space

• Is a safety limit device required?

2. Know the product.

• Inputs – type and number of

• Control function – direct (cool) or reverse (heat )

• Outputs – switched DC, SSR, or mechanical relay

• Communication requirements

• Which control features are required? (cascade, slidewire, differential, remote control, other)

3. Use your best judgment for selecting a replacement controller. All applications require close examination of input,

output and the control mode needs to have the controller function properly.

4. Safety: Remember to make sure all redundant safety equipment is in place and working when retrofitting equipment.

If a system has been retrofitted without the proper safety equipment, you could be liable if an accident occurs.

This is only a guide to replacement controllers. If you have doubts, please call (507) 454-5300

and ask for technical support or email wintechsupport@watlow.com. We’re here to help. The

suggested replacement will differ in fit and form. Please review the replacement controller

specifications for suitability. Carefully check the notes for additional information that may

apply.

Your comments or suggestions on the Retrofit Guide are welcome. Please send comments or corrections to: Technical

Writer, Watlow Controls, 1241 Bundy Boulevard, P.O. Box 5580, Winona, MN 55987-5580; phone (507) 454-5300; fax

(507) 452-4507.

This Retrofit Guide is copyrighted by Watlow Winona, Inc., © February 2004 with all rights reserved. (1455)

Page 2

Abbreviation & Terminology

(as used in this document)

0.5 – 0.5 amperes of current switching capability

2A – 2 amperes of current switching capability

5A - 5 amperes of current switching capability

10A – 10 amperes of current switching capability

15A – 15 amperes of current switching capability

12-24 – Supply voltage can be between 12 to 24 Volts

100-240 – Supply voltage can be between 100 to 240 Volts

100 ohm DIN – refers to 100-ohm platinum RTD that has a DIN curve.

100 ohm JIS – refers to 100-ohm platinum RTD that has a JIS curve.

1/32 DIN – Deutsche Industrial Norm standard for panel mounted controller, hole size is cut to 1.78”w x 0.88”h.

1/16 DIN – Deutsche Industrial Norm standard for panel mounted controller, hole size is cut to 1.78”w x 1.77”h.

1/8V DIN – Deutsche Industrial Norm standard for panel mounted controller, hole size is cut to 1.78”w x 3.63”h.

1/8H DIN – Deutsche Industrial Norm standard for panel mounted controller, hole size is cut to 3.63”w x 1.77”h”

1/8S DIN – Deutsche Industrial Norm standard for panel mounted controller, hole size is cut to 2.68”w x 2.68”h.

¼ DIN – Deutsche Industrial Norm standard for panel mounted controller, hole size is cut to 3.63”w x 3.63”h.

Action – determines the direction of control. Heat (reverse acting) or Cool (direct acting).

Auto Reset – the limit will automatically reset on a power cycle but requires manual reset on limit trip.

Cascade – a control algorithm in which the output of one control loop provides a set point for another loop. The second

loop, in turn, determines the control action.

Ch – Channel refers to an analog input. There are single and dual channel controllers.

Control Mode – the method that a controller uses to switch the outputs such as PID, ON/OFF, and Manual.

Differential - control algorithm in which the output is based on the difference of the inputs plus set point.

DIN – Deutsche Industrial Norm, a set of technical, scientific and dimensional standards developed in Germany. RTD

sensors with the DIN curve change resistance at a rate of 0.00385 ohms/ohms/C.

DIN Rail – standard DIN EN50022 mounting method for attaching devices onto a metal rail.

Fixed – refers to a set point that is fixed at one value.

High Limit - device will deactivate output on a temperature rise above set point.

Inductive Load – any device that has a wire winding such as solenoids, electromechanical relays or transformers.

Input – refers to the sensor types that may be connected.

Page 3

Integral – the set point in integral (on board) to the controller.

JIS – Joint Industrial Standards, a set of technical, scientific and dimensional standards developed in Japan. RTD sensors

with the JIS curve change resistance at a rate of 0.00396 ohms/ohms/C.

Line Voltage – the voltage required powering the electronics of the controller.

Low Limit - device will deactivate output on a temperature drop below set point.

On/Off – a method of control that turns the output full on until set point is reached and then off until the process error

exceeds the hysteresis.

Open Brd – the form factor of this controller is an open circuit board mounted on four standoffs.

Manual Reset – the limit must be reset on a power cycle and requires manual reset on limit trip.

Multi RSP – multiple remote set potentiometers were supported. Each allowed the set point to be selected and adjusted.

Relay – refers to an electromechanical relay.

Remote – set point is adjusted using a remote potentiometer.

Panel – the form factor of this controller is mounted through a hole cut in the panel.

PI – Proportional and Integral, a control mode with two functions: proportional action dampens the systems response,

and integral corrects for droop.

PID – Proportional, Integral, and Derivative, a control mode with three functions: proportional action dampens the

systems response, integral corrects for droop, and derivative prevents overshoot and undershoot.

Potted – the circuit board and electronics are encased in epoxy.

Proc – Process input may accept 0-5, 1-5, 0-10 volts or 0-20 and 4-20 mA.

Profiling – Controller will perform a sequence of programmed steps.

Programmable – The feature is changeable in the field through jumpers and/or parameter selection.

RTD – Resistance Temperature Detector, a sensor that is 100 ohms at 0 degrees C and made of platinum material.

SSR – Solid State Relay, these devices will switch AC voltage only and require a load to latch on.

Sw DC – Switched DC, a time proportioning DC output used to drive DC input solid state relays.

t/c – Thermocouple sensor device made by joining two dissimilar metals whose standards is identified by a letter.

Temp Range – the range over which the controller could have the set point adjustment.

Thermistor – a sensor that changes resistance as the temperature changes. Similar but not the same as an RTD.

Universal – Input can be a thermocouple, 100 ohm DIN RTD or process (volts or milliamperes)

VAC – Volts Alternating Current

VAC/DC- Volts Alternating Current or Direct Current

VDC – Volts Direct Current

Page 4

VTB Sw DC – Variable Time Base Switched Direct Current, a time proportioning DC output where the cycle time is

variable.

Page 5

These notes are used to signify areas of concern in changing to a retrofit choice. These notes are also printed at the end

of the retrofit listing.

Note 1: Retrofit controller requires a substitution of a 100 Ohm RTD sensor for the thermistor.

Note 2: Mounting and dimensions of retrofit controller are different. Verify that sufficient panel space and depth is

available.

Note 3: Retrofit controller outputs are different. Add external interposing mechanical or solid state relay if applicable.

Note 4: Retrofit controller has a programmable, not fixed set point. Lock set point using controller's lockout parameter.

Note 5: For DIN rail mounting or sub-panel mounting, purchase DIN rail adapter p/n 0822-0586-P001 for 1/32 DIN or

p/n 0822-0586-P002 for 1/16 DIN.

Note 6: Add a suppressor, Watlow p/n 0804-0147-0000, for inductive loads.

Note 7: Retrofit does not have equivalent action (as example, no manual reset)

Note 8: Retrofit controller does not have dual dial scale.

Note 9: Hardware lockout is not available on retrofit.

Note 10:Retrofit controller does not have user selectable line voltage.

Note 11:Retrofit does not support remote set point or retransmit. Check if pins 13, 14, 15 or 16 have termination. If

wires are on these pins, select a different retrofit.

Note 12:Retrofit co ntroller does not have user selectable control action.

Note 13:Solid state sensor required for humidity. See http://www.vaisala.com

Note 14:Retrofit co ntroller does not have user selectable control mode.

Note 15:Use auxiliary event board A007-1732-F4B8

Note 16:Retrofit communications are different, consult specifications.

Note 17:Verify retrofit input range matches application.

Page 6

HG Series Watlow Part

2

1

)

)

)

)

)

)

)

)

2

1

)

)

)

)

)

)

)

)

2

1

)

)

)

)

)

)

)

)

0

)

0

)

)

)

0

)

)

Number

HG30-1KD1-0000 LF-701120AC

HG30-4KD1-0000 LF-70124AC

HG30-6KD1-0000 LF-70124DC

HG30-9KD1-0000 LF-701208ACDV

HG30-1KD2-0000 LF2-701120AC

HG30-4KD2-0000 LF2-70124AC

HG30-6KD2-0000 LF2-70124DC

HG30-9KD2-0000 LF2-701208ACDV

HG30-1KD3-0000 LF3-701120AC

HG30-4KD3-0000 LF3-70124AC

HG30-6KD3-0000 LF3-70124DC

HG30-9KD3-0000 LF3-701208ACDV

HG35-1LD1-0000 1035A120AC

HG35-4LD1-0000 1035A24AC

HG35-6LD1-0000 1035A24DC

HG35-9LD1-0000 1035A208ACDV

HG35-1LD2-0000 2035A120AC

HG35-4LD2-0000 2035A24AC

HG35-6LD2-0000 2035A24DC

HG35-9LD2-0000 2035A208ACDV

HG35-1LD3-0000 3035A120AC

HG35-4LD3-0000 3035A24AC

HG35-6LD3-0000 3035A24DC

HG35-9LD3-0000 3035A208ACDV

HG50-1MD1-0000 1050A120AC

HG50-4MD1-0000 1050A24AC

HG50-6MD1-0000 1050A24DC

HG50-9MD1-0000 1050A208ACDV

HG50-1MD2-0000 2050A120AC

HG50-4MD2-0000 2050A24AC

HG50-6MD2-0000 2050A24DC

HG50-9MD2-0000 2050A208ACDV

HG50-1MD3-0000 3050A120AC

HG50-4MD3-0000 3050A24AC

HG50-6MD3-0000 3050A24DC

HG50-9MD3-0000 3050A208ACDV

HG60-1PD1-0000 1060APS120AC

HG60-4PD1-0000 1060APS24AC

HG60-6PD1-0000 1060APS24DC

HG60-9PD1-0000 1060APS208ACDV

HG60-1PD2-0000 2060APS120AC

HG60-4PD2-0000 2060APS24AC

HG60-6PD2-0000 2060APS24DC

HG60-9PD2-0000 2060APS208ACDV

HG60-1PD3-0000 3060APS120AC

HG60-4PD3-0000 3060APS24AC

HG60-6PD3-0000 3060APS24DC

HG60-9PD3-0000 3060APS208ACDV

Durakool Equivalent Product Description Potential Solid State Alternatives

MDR to Solid State Alternatives Cross Reference

(30A NEW)(25A OLD), 1 POLE, 120VAC COIL DB10-60K2-0000, CZ34-A60V-AC1, SSR-480-50A-AC1

(30A NEW)(25A OLD), 1 POLE, 24VAC COIL DB10-60K1-0000, CZ34-A60V-AC

(30A NEW)(25A OLD), 1 POLE, 24VDC COIL DB10-60C0-0000, CZ34-A48V-DC1, SSR-480-50A-DC

(30A NEW)(25A OLD), 1 POLE, 208/240VAC COIL DB10-60K3-0000, SSR-480-50A-AC1

(30A NEW)(25A OLD), 2 POLE, 120VAC COIL DC20-60K2-0000, CZ34-A60V-AC1 (2PCS.), SSR-480-50A-AC1 (2 PCS.

(30A NEW)(25A OLD), 2 POLE, 24VAC COIL DC20-60K1-0000, CZ34-A60V-AC2 (2 PCS.

(30A NEW)(25A OLD), 2 POLE, 24VDC COIL DC20-60C0-0000, CZ34-A48V-DC1 (2PCS.), SSR-480-50A-DC1 (2 PCS

(30A NEW)(25A OLD), 2 POLE, 208/240VAC COIL DC20-60K3-0000, SSR-480-50A-AC1 (2pcs.

(30A NEW)(25A OLD), 3 POLE, 120VAC COIL DC30-60K2-0000, CZ34-A60V-AC1 (3PCS.), SSR-480-50A-AC1 (3 PCS.

(30A NEW)(25A OLD), 3 POLE, 24VAC COIL DC30-60K1-0000, CZ34-A60V-AC2 (3 PCS.

(30A NEW)(25A OLD), 3 POLE, 24VDC COIL DC20-60C0-0000, CZ34-A48V-DC1 (3 PCS.), SSR-480-50A-DC1 (3 PCS

(30A NEW)(25A OLD), 3 POLE, 208/240VAC COIL DC30-60K3-0000, SSR-480-50A-AC1 (3 pcs.

35A, 1 POLE, 120VAC COIL DB10-60K2-0000, CZ34-A60V-AC1, SSR-480-50A-AC1

35A, 1 POLE, 24VAC COIL DB10-60K1-0000, CZ34-A60V-AC

35A, 1 POLE, 24VDC COIL DB10-60C0-0000, CZ34-A48V-DC1, SSR-480-50A-DC

35A, 1 POLE, 208/240VAC COIL DB10-60K3-0000, SSR-480-50A-AC1

35A, 2 POLE, 120VAC COIL DC20-60K2-0000, CZ34-A60V-AC1 (2PCS.), SSR-480-50A-AC1 (2 PCS.

35A, 2 POLE, 24VAC COIL DC20-60K1-0000, CZ34-A60V-AC2 (2 PCS.

35A, 2 POLE, 24VDC COIL DC20-60C0-0000, CZ34-A48V-DC1 (2PCS.), SSR-480-50A-DC1 (2 PCS

35A, 2 POLE, 208/240VAC COIL DC20-60K3-0000, SSR-480-50A-AC1 (2pcs.

35A, 3 POLE, 120VAC COIL DC30-60K2-0000, CZ34-A60V-AC1 (3PCS.), SSR-480-50A-AC1 (3 PCS.

35A, 3 POLE, 24VAC COIL DC30-60K1-0000, CZ34-A60V-AC2 (3 PCS.

35A, 3 POLE, 24VDC COIL DC20-60C0-0000, CZ34-A48V-DC1 (3 PCS.), SSR-480-50A-DC1 (3 PCS

35A, 3 POLE, 208/240VAC COIL DC30-60K3-0000, SSR-480-50A-AC1 (3 pcs.

50A, 1 POLE, 120VAC COIL DC10-60K2-0000, CZ50-A48V-AC1, SSR-480-50A-AC1

50A, 1 POLE, 24VAC COIL DC10-60K1-0000, CZ50-A48V-AC

50A, 1 POLE, 24VDC COIL DC10-60C0-0000, CZ50-A48V-DC1, SSR-480-50A-DC

50A, 1 POLE, 208/240VAC COIL DC10-60K3-0000, SSR-480-50A-AC1

50A, 2 POLE, 120VAC COIL DC21-60K2-0000, CZ50-A48V-AC1 (2 PCS.),SSR-480-75A-AC1 (2 PCS.

50A, 2 POLE, 24VAC COIL DC21-60K1-0000, CZ50-A48V-AC2 (2 PCS.

50A, 2 POLE, 24VDC COIL DC21-60C0-0000, CZ50-A48V-DC1 (2 PCS.), SSR-480-75A-DC1 (2 PCS.

50A, 2 POLE, 208/240VAC COIL DC21-60K3-0000, SSR-480-75A-AC1 (2 PCS.

50A, 3 POLE, 120VAC COIL DC31-60K2-0000, CZ50-A48V-AC1 (3 PCS.),SSR-480-75A-AC1 (3 PCS.

50A, 3 POLE, 24VAC COIL DC31-60K1-0000, CZ50-A48V-AC2 (3 PCS.

50A, 3 POLE, 24VDC COIL DC31-60C0-0000, CZ50-A48V-DC1 (3 PCS.), SSR-480-75A-DC1 (3 PCS.

50A, 3 POLE, 208/240VAC COIL DC31-60K3-0000, SSR-480-75A-AC1 (3 PCS.

60A, 1 POLE, 120VAC COIL DC11-60K2-0000, SSR-480-75A-AC1

60A, 1 POLE, 24VAC COIL DC11-60K1-000

60A, 1 POLE, 24VDC COIL DC11-60C0-0000, SSR-480-75A-DC1

60A, 1 POLE, 208/240VAC COIL DC11-60K3-0000, SSR-480-75A-AC1

60A, 2 POLE, 120VAC COIL DC21-60K2-0000, SSR-480-75A-AC1 (2 PCS.

60A, 2 POLE, 24VAC COIL DC21-60K1-000

60A, 2 POLE, 24VDC COIL DC21-60C0-0000, SSR-480-75A-DC1 (2 PCS.

60A, 2 POLE, 208/240VAC COIL DC21-60K3-0000, SSR-480-75A-AC1 (2 PCS.

60A, 3 POLE, 120VAC COIL DC31-60K2-0000, SSR-480-75A-AC1 (3 PCS.

60A, 3 POLE, 24VAC COIL DC31-60K1-000

60A, 3 POLE, 24VDC COIL DC31-60C0-0000, SSR-480-75A-DC1 (3 PCS.

60A, 3 POLE, 208/240VAC COIL DC31-60K3-0000, SSR-480-75A-AC1 (3 PCS.

Watlow Controls 5/6/2004 Page 1

Page 7

HG Series Watlow Part

)

)

)

)

)

)

)

0

0

0

0

)

)

)

)

)

)

)

)

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

Number

HG30-1AA2-0000 2030APS120AC

HG30-4AA2-0000 2030APS24AC

HG30-6AA2-0000 2030APS24DC

HG30-9AA2-0000 2030APS208ACDV

HG30-1AA3-0000 3030APS120AC

HG30-4AA3-0000 3030APS24AC

HG30-6AA3-0000 3030APS24DC

HG30-9AA3-0000 3030APS208ACDV

HG80-1AB1-0000 CF-702

HG80-4AB1-0000 CF-701

HG80-6AB1-0000 CF-707

HG80-9AB1-0000 CF-713

HG80-1AB2-0000 CF2-702

HG80-4AB2-0000 CF2-701

HG80-6AB2-0000 CF2-708

HG80-9AB2-0000 CF2-713

HG80-1AB3-0000 CF3-702

HG80-4AB3-0000 CF3-701

HG80-6AB3-0000 CF3-708

HG80-9AB3-0000 CF3-713

HG1M-1AC1-0000 CFC-718

HG1M-4AC1-0000 CFC-717

HG1M-6AC1-0000 CFC-723

HG1M-9AC1-0000 CFC-734

HG1M-1AC2-0000 CFC2-727

HG1M-4AC2-0000 CFC2-726

HG1M-6AC2-0000 CFC2-733

HG1M-9AC2-0000 CFC2-734

HG1M-1AC3-0000 CFC3-708

HG1M-4AC3-0000 CFC3-707

HG1M-6AC3-0000 CFC3-721

HG1M-9AC3-0000 CFC3-734

HG2M-1AD1-0000 DFC-301

HG2M-4AD1-0000 DFC-307

HG2M-6AD1-0000 DFC-310

HG2M-9AD1-0000 DFC-311

HG2M-1AD2-0000 DFC2-301

HG2M-4AD2-0000 DFC2-307

HG2M-6AD2-0000 DFC2-310

HG2M-9AD2-0000 DFC2-311

HG2M-1AD3-0000 DFC3-301

HG2M-4AD3-0000 DFC3-307

HG2M-6AD3-0000 DFC3-310

HG2M-9AD3-0000 DFC3-311

Durakool Equivalent Product Description Potential Solid State Alternatives

MDR to Solid State Alternatives Cross Reference

30A, 2 POLE, 120VAC COIL DC20-60K2-0000, ES40-3120-AC00, SSR-480-50A-AC1 (2PCS.

30A, 2 POLE, 24VAC COIL DC20-60K1-0000, ES40-3024-AC00, CZ34-A48V-AC2 (2 PCS.

30A, 2 POLE, 24VDC COIL DC20-60C0-0000, CZ34-A60V-DC1 (2PCS.), SSR-480-50A-DC1 (2 PCS.

30A, 2 POLE, 208/240VAC COIL DC20-60K3-0000, ES40-3220-AC00, SSR-480-50A-AC1 (2 PCS.

30A, 3 POLE, 120VAC COIL

30A, 3 POLE, 24VAC COIL DC30-60K1-0000, ES40-3024-AC00, CZ34-A48V-AC2 (3 PCS.

30A, 3 POLE, 24VDC COIL DC30-60C0-0000, CZ34-A60V-DC1 (3 PCS.), SSR-480-50A-DC1 (3 PCS.

30A, 3 POLE, 208/240VAC COIL DC20-60K3-0000, ES40-3220-AC00, SSR-480-50A-AC1 (3 PCS.

80A, 1 POLE, 120VAC COIL DD10-60K2-000

80A, 1 POLE, 24VAC COIL DD10-60K1-000

80A, 1 POLE, 24VDC COIL DD10-60C0-000

80A, 1 POLE, 208/240VAC COIL DD10-60K3-000

80A, 2 POLE, 120VAC COIL DD10-60K2-0000 (2 PCS.

80A, 2 POLE, 24VAC COIL DD10-60K1-0000 (2 PCS.

80A, 2 POLE, 24VDC COIL DD10-60C0-0000 (2 PCS.

80A, 2 POLE, 208/240VAC COIL DD10-60K3-0000 (2 PCS.

80A, 3 POLE, 120VAC COIL DD10-60K2-0000 (3PCS.

80A, 3 POLE, 24VAC COIL DD10-60K1-0000 (3 PCS.

80A, 3 POLE, 24VDC COIL DD10-60C0-0000 (3 PCS.

80A, 3 POLE, 208/240VAC COIL DD10-60K3-0000 (3 PCS.

100A, 1 POLE, 120VAC COIL N

100A, 1 POLE, 24VAC COIL N

100A, 1 POLE, 24VDC COIL N

100A, 1 POLE, 208/240VAC COIL N

100A, 2 POLE, 120VAC COIL N

100A, 2 POLE, 24VAC COIL N

100A, 2 POLE, 24VDC COIL N

100A, 2 POLE, 208/240VAC COIL N

100A, 3 POLE, 120VAC COIL N

100A, 3 POLE, 24VAC COIL N

100A, 3 POLE, 24VDC COIL N

100A, 3 POLE, 208/240VAC COIL N

150A, 1 POLE, 120VAC COIL N

150A, 1 POLE, 24VAC COIL N

150A, 1 POLE, 24VDC COIL N

150A, 1 POLE, 208/240VAC COIL N

150A, 2 POLE, 120VAC COIL N

150A, 2 POLE, 24VAC COIL N

150A, 2 POLE, 24VDC COIL N

150A, 2 POLE, 208/240VAC COIL N

150A, 3 POLE, 120VAC COIL N

150A, 3 POLE, 24VAC COIL N

150A, 3 POLE, 24VDC COIL N

150A, 3 POLE, 208/240VAC COIL N

DC30-60K2-0000, ES40-3120-AC00, SSR-480-50A-AC1 (3 PCS.), CZ34-A48V-AC1

(3 PCS.)

Watlow Controls 5/6/2004 Page 2

Page 8

HG Series

Mercury Displacement Relay

WMDR-XUMN-1097

June 1997

Supersedes: WMDR-XUMN Rev A00

Made in the U.S.A.

Printed on Recycled Paper 10% Postconsumer Waste

Power Controls

Watlow Controls, 1241 Bundy Blvd., P.O. Box 5580, Winona, MN, USA 55987-5580, Phone: (507) 454-5300, Fax: (507) 452-4507

Registered Company

Winona, Minnesota USA

ISO 9001

User’s Manual

Page 9

3.25

(83)

2.16

(55)

.25

Typ.

(6)

Up

3.14

(80)

Mounting

Slot

For #8 To

#10 Screw

3.75

(95)

#10-32

Binding

Head

Screw

Up To #10

A.W.G.

3.43

(87)

Dimensions

1.19

(30)

"A"

1.63

(41)

.20 (5)

Dia. Mtg.

Hole

2.25

(57)

1.94

(49)

Pressure

Connector

2.00

(51)

1 Pole

.21 (5)

Dia. Mtg.

Hole For

#10 Screw

.21 (5)

Wide Slot

For #10

Screw

Hole

3.13

(79)

2.65

(67)

1.94

(49)

40°

Typ.

4.00

(102)

2.62

(67)

"A"

Pressure

Connector

2 Pole

3.13

(79)

4.00

(102)

2.65

(67)

.21

(5)

Dia. Mtg.

Hole For

#10

Screw

.21 (5)

Wide Slot

For #10

Screw

Hole

40°

TYP.

3.75

(95)

"A"

Pressure

Connector

1.94

(49)

3 Pole

ÓÓ

WARNING: Mercury displacement relay must be

mounted vertically. Failure to do this will prevent the

contacts from turning off, which will supply full

voltage to the load. Failure to follow this guideline

could result in damage to equipment, and personal

injury or death.

ÓÓ

WARNING: Mercury displacement relay contacts

will switch ac current only. Not for use with dc

current. Failure to follow this guideline could result

in damage to equipment, and personal injury or

death.

2 Watlow Series HG Mercury Displacement Relay User’s Manual

.21 (5)

Dia.

Mounting

Hole

1.19

(30)

2.25

(57)

#8-32

Binding

Head

Screw

#10-#14

A.W.G.

1.63

(41)

3.58

(91)

2.00

(51)

Dia.

1.94

(49)

.21 (5)

Dia.

Mounting

Hole

3.13

(79)

4.00

(102)

#8-32 Binding

Head Screw

#10-#14 A.W.G.

2.62

(67)

2.65

(67)

1.94

(49)

.21 (5)

Wide Slot

For #10

Screw

Hole

40°

Typ.

4.00

(102)

2 Pole

.21 (5)

Dia.

Mounting

Hole

3.13

(79)

3.75

(95)

4.00

(102)

#8-32

Binding

Head Screw

#10-#14

A.W.G

4.00

(102)

1.94

(49)

.21 (5)

Wide

Slot

For#10

Screw

Hole

40°

Typ.

2.65

(67)

3 Pole

30 Amp Models

HG30-XKDX-0000

Definite Purpose Relay Foot Print

HG30-XAAX-0000

1 Pole

NOTE:

Watlow recommends that ring terminal lugs be used

with stranded wire

on all binding head

screw terminals.

All 35, 50, and 60 Amp Models

“A” Pressure

Dimensions Connectors

HG35-XLDX-0000 4.62 (117) #4-14 A.W.G.

HG50-XMDX-0000 4.62 (117) #4-14 A.W.G.

HG60-XPDX-0000 5.12 (130) #1 - 8 A.W.G.

Page 10

2.62

(67)

Pressure

Connector

"A"

2.18

(55)

1.88

(48)

(5)

.20 Dia.

Mtg Hole

2.13

(54)

2.50

(64)

1 Pole

(7)

.27 Dia.

Mtg. Hole

5.70

(145)

4.70

(119)

2.79

(71)

.27

(7)

Wide Mtg.

Slot

40°

Typ.

3.25

(83)

3.78

(96)

"A"

Pressure

Connector

2 Pole

(7)

.27 Dia.

Mtg. Hole

(7)

.27 Dia.

Mtg. Slot

40°

Typ.

5.70

(145)

2.79

(71)

4.70

(119)

5.00

(127)

Pressure

Connector

"A"

3.78

(96)

3 Pole

All 80, 100, and 150 Amp Models

Dimensions

Watlow Series HG Mercury Displacement Relay User’s Manual 3

1 Pole Wiring Example

2 Pole Wiring Example

3 Pole Wiring Example

Wiring

120V~(ac)

Fuse

Fuse

1 Pole

120V~(ac)

Coil

Control

Heater

L2

Neutral

L1

Control

Fuse

Fuse

Fuse

Heater

2 Pole

240V~(ac)

Single

Phase

L1

L2

240V~(ac)

Single

Phase

}

Fuse

Fuses

Fuse

3 Pole

120V~(ac)

Coil

Control

N

3-Phase

Wye Heater

208V~ (ac)

3 Phase

Wye

L1

L2

L3

{

“A” Pressure

Dimensions Connectors:

HG80-XABX-0000 5.77 (147) #1-8 A.W.G.

HG1M-XACX-0000 5.77 (147) #1-8 A.W.G.

HG2M-XADX-0000 6.40 (163) #1/0 - #2 A.W.G.

∑∑

WARNING: Wiring must conform to

National Electric Code (NEC) safety

standards, as well as locally applicable

codes. Failure to do so could result in

personal injury or death. See page 6 for

fusing recommendations.

çç

Use copper conductors only.

Page 11

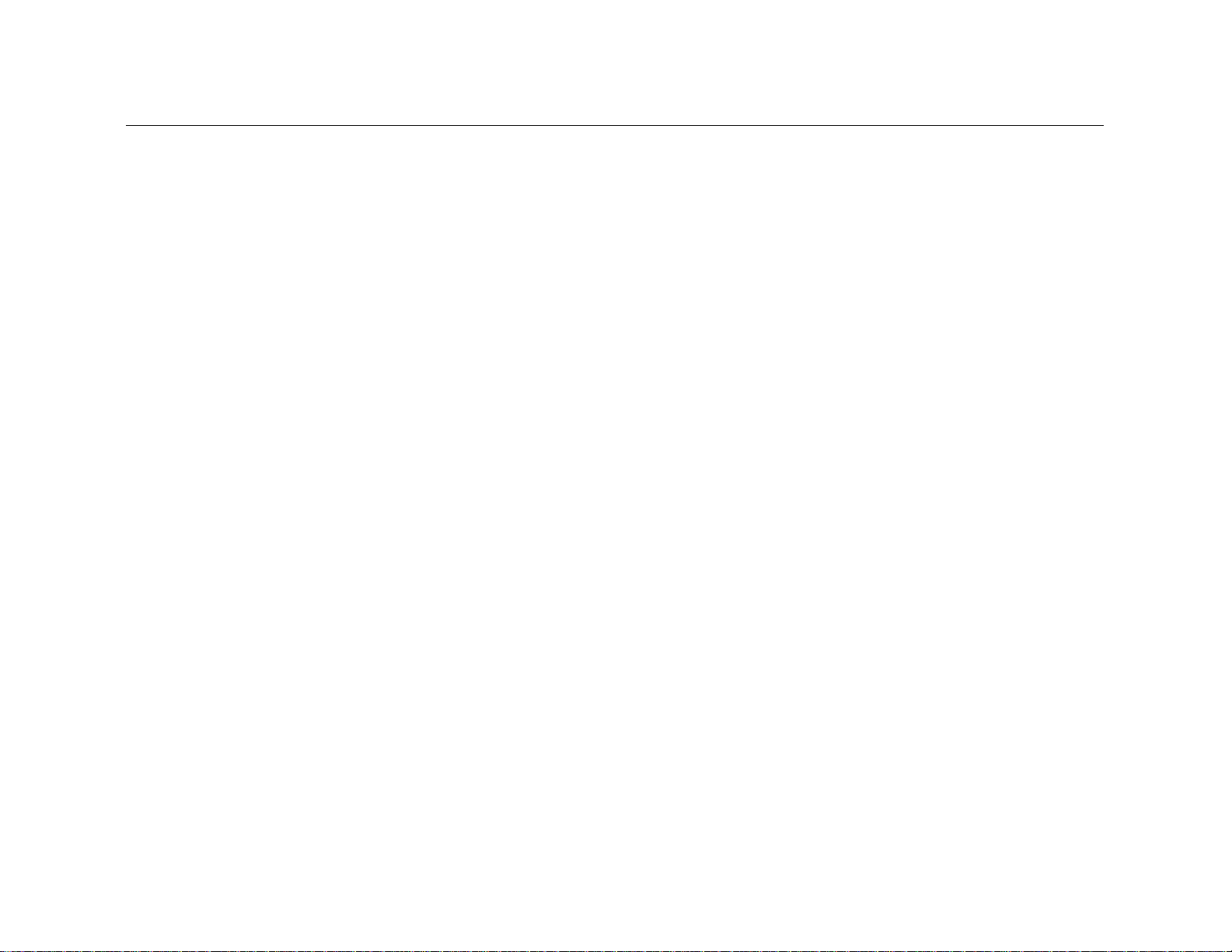

Temperature Control Output to MDR Coil Input

Please refer to the Field Coil Power Requirements when selecting the correct temperature control output.

Example: An HG35-1LD3-X000 requires 224mA to energize the coil and could be used with Watlow

temperature control output options ‘B’ or ‘K’ (i.e. 988A-XXBB-XXXX or 988A-XXKK-XXXX) models. The

best selection is the ‘B’ output option because it includes an RC snubber across the output. If you select

the ‘K’ option, it is recommended that you also purchase a Quencharc® snubber separately (Watlow part

number 0804-0147-0000). Place the snubber across the MDR coil terminals to protect the temperature

control solid state output. When placing the snubber across the coil of a 2 and 3 pole relay, you may have

to add some lead wire to the snubber. The MDR coil is an inductive load and the snubber will reduce the

flyback voltage produced by the MDR coil when it de-energizes. See below.

Note: Watlow temperature control solid state outputs will not drive VDC coils directly. Refer to the coil

current specifications above and any temperature control output specifications as required by the

application.

Quencharc

Snubber

(Purchase

Separately)

HG30-XAAX-0000

1 Pole 2 Pole 3 Pole

Voltage Current Power Current Power Current Power

24V~ (ac) NA NA 0.456A 10.9VA 0.510A 12.2VA

120V~ (ac) NA NA 0.121A 14.5VA 0.106A 12.7VA

208V~ (ac) NA NA 0.055A 11.4VA 0.055A 11.4VA

240V~ (ac) NA NA 0.063A 15.1VA 0.062A 14.9VA

24VÎ (dc) NA NA 0.240A 5.8W 0.250A 6.0W

HG30-XKDX-0000

HG35-XLDX-0000

HG50-XMDX-0000

HG60-XPDX-0000

1 Pole 2 Pole 3 Pole

Voltage Current Power Current Power Current Power

24V~ (ac) 0.235A 5.6VA 0.529A 12.7VA 1.270A 30.5VA

120V~ (ac) 0.057A 6.8VA 0.133A 16.0VA 0.224A 26.9VA

208V~ (ac) 0.030A 6.2VA 0.075A 15.6VA 0.111A 23.1VA

240V~ (ac) 0.035A 8.4VA 0.087A 20.9VA 0.128A 30.7VA

24VÎ (dc) 0.146A 3.5W 0.266A 6.4W 0.470A 11.3W

HG80-XABX-0000

HG1M-XACX-0000

HG2M-XADX-0000

1 Pole 2 Pole 3 Pole

Voltage Current Power Current Power Current Power

24V~ (ac) 0.930A 22.3VA 2.310A 55.4VA 5.060A 121.4VA

120V~ (ac) 0.195A 23.4VA 0.448A 53.8VA 0.968A 116.2VA

208V~ (ac) 0.097A 20.2VA 0.280A 58.2VA 0.482A 100.3VA

240V~ (ac) 0.112A 26.9VA 0.323A 77.5VA 0.563A 135.1VA

24VÎ (dc) 0.219A 5.2W 0.572A 13.7W 0.555A 13.3W

Field Coil Power Requirements

Watlow Series HG Mercury Displacement Relay User’s Manual 4

Page 12

HG _ _ - _ _ _ _ - 0 0 _ _

Amperage

30 = 30 Amp

35 = 35 Amp

50 = 50 Amp

60 = 60 Amp

80 = 80 Amp

1M = 100 Amp

2M = 150 Amp

Coil Voltage

1 = 120V~ (ac)

4 = 24V~ (ac)

6 = 24VÎ (dc)

9 = 208/240V~ (ac)

Option

KD = 30 Amp (Standard)

LD = 35 Amp

MD = 50 Amp

PD = 60 Amp

AA = 30 Amp (Definite Purpose

Relay Footprint)

AB = 80 Amp

AC = 100 Amp

AD = 150 Amp

Poles

1 = 1 Pole (Not For Option “AA”)

2 = 2 Pole

3 = 3 Pole

Type

00 = Standard

(Includes Definite Purpose Relay Footprint)

XX = Custom

Ordering Information WMDR-XMNN-1099

1. Call Customer Service: 507-454-5300, or

fax: 507-452-4507, for a Return Material

Authorization (RMA) number before returning any

item for repair.

2. Make sure the RMA number is on the outside of the

carton, and on all paperwork returned. Ship on a

freight prepaid basis.

3. A restocking charge of 20% of the net price applies

for all returned stock controls and accessories in like

new condition and within 120 days after shipment.

Non-stock and modified stock items are not

returnable.

4. If the unit is unrepairable, it will be returned to you

with a letter of explanation. Repair costs will not

exceed 50% of the original cost.

Recycle

To provide proper disposal, Watlow accepts used MDRs.

Phone (507) 454-5300 for an Return Materials

Authorization (RMA) number. Contact your Watlow

representative for details.

The Mercury Relay is warranted to be free of defects in

material and workmanship for 18 months after delivery to

the first purchaser for use, providing that the units have

not been misapplied. Since Watlow has no control over

their use, and sometimes misuse, we cannot guarantee

against failure. Watlow’s obligations hereunder, at

Watlow’s option, are limited to replacement, repair or

refund of purchase price, and parts which upon

examination prove to be defective within the warranty

period specified. This warranty does not apply to

damage resulting from transportation, alteration, misuse,

abuse or improper fusing.

Returns

Warranty

5

Watlow Series HG Mercury Displacement Relay User’s Manual

Page 13

Model Number HG30-XKDX HG30-XAAX HG35-XLDX HG50-XMDX HG60-XPDX HG80-XABX HG1M-XACX HG2M-XADX

Contact Type N.O. N.O. N.O. N.O. N.O. N.O. N.O. N.O.

Maximum Load See Table

Current ac 30A 30A 35A 50A 60A 80A 100A Below

(typ) Contact

Resistance 4mΩ 4mΩ 4mΩ 4mΩ 4mΩ 4mΩ 4mΩ 4mΩ

Load Wire 10-14AWG 10-14AWG 4-14AWG 4-14AWG 1-8AWG 1-8AWG 1-8AWG 1/0-2AWG

Terminations bhs bhs pc pc pc pc pc pc

Coil Wire #6-32bhs #6-32bhs #6-32bhs #6-32bhs #6-32bhs #6-32bhs #6-32bhs #6-32bhs

Terminations up to up to up to up to up to up to up to up to

#12AWG #16AWG #12AWG #12AWG #12AWG #12AWG #12AWG #12AWG

Load Type Resistive Resistive Resistive Resistive Resistive Resistive Resistive Resistive

Maximum Load

Voltage ac 480/600** 480/600** 600**** 600**** 480/600**** 480*** 480*** 480/600

Load Frequency 50/60 Hz. 50/60 Hz. 50/60 Hz. 50/60 Hz. 50/60 Hz. 50/60 Hz. 50/60 Hz. 50/60 Hz.

Pull-in Time 70 mS 50 mS 70 mS 70 mS 70 mS 90 mS 90 mS 90 mS

Drop-out Time 90 mS 70 mS 90 mS 90 mS 90 mS 140 mS 140 mS 140 mS

Operating

Ambient -35 to 55°C -35 to 55°C -35 to 55°C -35 to 55°C -35 to 55°C -35 to 55°C -35 to 55°C -35 to 55°C

Storage

Temperature -40 to 100°C -40 to 100°C -40 to 100°C -40 to 100°C -40 to 100°C -40 to 100°C -40 to 100°C -40 to 100°C

Hg - Mass/Contact 1.82 oz. 0.84 oz. 1.75 oz. 1.75 oz. 1.75 oz. 8.93 oz 8.93 oz. 9.46 oz.

Weight : 1 Pole 1.0 lbs. 1.0 lbs. 1.0 lbs. 1.0 lbs. 1.0 lbs. 2.0 lbs. 2.0 lbs. 2.5 lbs.

2 Pole 2.0 lbs. 2.0 lbs. 2.0 lbs. 2.0 lbs. 2.0 lbs. 3.5 lbs. 4.0 lbs. 4.5 lbs.

3 Pole 2.5 lbs. 2.0 lbs. 3.0 lbs. 3.0 lbs. 3.0 lbs. 4.5 lbs. 7.0 lbs. 7.0 lbs.

Note: pc = pressure connector

bhs = binding head screw

Note: Watlow recommends that you do not exceed 30

cycles per minute.

Note: Watlow recommends that ring terminal lugs be

used on all binding head screw terminals.

Note: When replacing Watlow MD style relays,

consider the HG60 model if larger gauge or

multiple wires are required. See the load

termination specification above.

Specifications WMDR-XSPN-1098

Note: The 150 Amp relay (HG2M-XADX) is not UL or

CSA approved.

** UL listed to 480V

ÅÅ

(ac); CSA certified to 600VÅÅ(ac)

*** UL listed to 480V

ÅÅ

(ac)

**** UL listed and CSA certified to 600V

ÅÅ

(ac)

Watlow Series HG Mercury Displacement Relay User’s Manual 6

Volts 120 208 240 277 480 600

Amps 150 140 135 130 120 120

HG2M-XADX Load Current Table

Fusing

To prevent the MDR from rupture in the event of a heater

short circuit, you should always fuse the MDR load circuit.

Watlow recommends a Bussmann type JJN or JJS (Class

T) fuse or equivalent. Select a fuse size 1.25 times the

connected load or the next size above, but do not exceed

1.6 times the MDR rating. To fuse the MDR field coil, you

can use Bussmann fuse number MDL-2 for coils up to

240V~ (ac). For coils up to 480V~ (ac), use Bussmann fuse

number JJS-1.

∑∑

WARNING: Install high or low temperature control

protection in systems where an overtemperature or

undertemperature fault condition could present a

fire hazard or other hazard. Failure to install

temperature control protection where a potential

hazard exists could result in damage to equipment

and property, and personal injury or death.

Agency Approvals

• UL, File #ULE177629

• CSA File #LR22416

Loading...

Loading...