Watlow LV Operating Manual

Registered Company

Winona, Minnesota USA

ISO 9001

Series L

User’s Manual

0600-0044-0001

Series L - Temperature Limit

TOTAL

CUSTOMER

SATISFACTION

3 Year Warranty

1241 Bundy Boulevard., Winona, Minnesota USA 55987

Phone: +1 (507) 454-5300, Fax: +1 (507) 452-4507 http://www.watlow.com

Rev. H Made in the U.S.A.

February 2015

ç

CAUTION or

WARNING

Safety Information

We use note, caution and warning symbols throughout this book to draw your attention to

important operational and safety information.

A “NOTE” marks a short message to alert you to an important detail.

A “CAUTION” safety alert appears with information that is important for protecting your

equipment and performance. Be especially careful to read and follow all cautions that apply to

your application.

A “WARNING” safety alert appears with information that is important for protecting you, others and equipment from damage. Pay very close attention to all warnings that apply to your

application.

The safety alert symbol, ç (an exclamation point in a triangle) precedes a general CAUTION

or WARNING statement.

The electrical hazard symbol, Ó (a lightning bolt in a triangle) precedes an electric shock hazard CAUTION or WARNING safety statement.

Ó

Electrical

Shock Hazard

CAUTION or WARNING

Technical Assistance

If you encounter a problem with your Watlow controller, review your configuration information to verify that your selections are consistent with your application: inputs, outputs, alarms,

limits, etc. If the problem persists, you can get technical assistance from your local Watlow representative (see back cover), by e-mailing your questions to wintechsupport@watlow.com or by

dialing +1 (507) 494-5656 between 7 a.m. and 5 p.m., Central Standard Time (CST). Ask for for

an Applications Engineer. Please have the following information available when calling:

• Complete model number • System wiring information

• Series L Limit User’s Manual

Warranty

These controllers are manufactured by ISO 9001-registered processes and are backed by a

three-year warranty.

Return Material Authorization (RMA)

1. Call Watlow Customer Service, (507) 454-5300, for a Return Material Authorization (RMA)

number before returning any item for repair. We need this information:

• Ship to address • Bill to address

• Contact name • Phone number

• Method of return shipment • Your P.O. number

• Detailed description of the problem • Any special instructions

• Name and phone number of person returning the product.

2. Prior approval and an RMA number, from the Customer Service Department, is needed

when returning any unused product for credit. Make sure the RMA number is on the out

side of the carton, and on all paperwork returned. Ship on a Freight Prepaid basis.

3. After we receive your return, we will examine it and try to verify the reason for the return.

4. In cases of manufacturing defect, we will enter a repair order, replacement order or issue

credit for material returned.

5. To return products that are not defective, goods must be be in new condition, in the origi nal boxes and they must be returned within 120 days of receipt. A 20 percent restocking

charge is applied for all returned stock controls and accessories.

6. If the unit is not repairable, it will be returned to you with a letter of explanation.

7. Watlow reserves the right to charge for no trouble found (NTF) returns.

The Series L Limit user’s manual is copyrighted by Watlow Electric Manufacturing, © February

2015 with all rights reserved.

1

Overview

Series LF and LV

Watlow's temperature limit controllers* provide an

economical limit controller solution for applications

where thermal system protection is needed.

A limit controller is added to applications to prevent

over or under temperature conditions. The limit provides safety assurances against instances where a

thermal runaway condition occurs as a result of a

failed sensor, controller or output device.

The LF and LV limit controllers are recommended for

any application where thermal system runaway could

result in large product scrap costs, damage to system

equipment, potential fire hazard or risk to personnel.

Both controllers are Factory Mutual and CSA approved.

The LF and LV controllers are available with or without an operator interface and can be ordered in square

1/8th DIN panel mount, din rail mount, open board or

potted module design configurations. Push-on, quick

connect spade terminal or removable screw clamp style

terminal block ordering options provide the electrical

connections.

The microprocessor design platform provides improvements in the performance, repeatability, and accuracy

offered by Watlow's current line of basic control products.

The Series LV includes an operator interface to allow

viewing and selection of the limit set point. A red four

character, seven-segment LED displays the limit set

point. The limit set point selection is made with a continuous turn, velocity-sensitive rotary encoder. Push-toSet operation reduces accidental limit set point adjustments. Limit set point operating range temperature

values are customer definable in the product configuration part number.

The Series LF offers fixed limit set points. These units

are supplied without an operator interface. Limit set

point temperature values are customer definable in

the product configuration part number.

The features and performance of the LF and LV controllers make them ideally suited for a wide range of

industrial limit control applications in the food preparation, industrial machinery, packaging and plastic

markets.

II with Class B Software review. It provides increased

safety due to the use of Factory fixed set point, Factory

fixed hysteresis and the use of redundant temperature sensors to protect against a single point sensor

failure. Either sensor can initiate an over temperature

limit condition along with a deviation between sensors

greater than the process comparison value. The unit

cannot be reset until both sensors are below the Limit

Temperature minus the hysteresis value. A power cycle

is then needed to reset the control.

Definitions under UL/EN 60730-1 , 60730-2-9

Protective - Intended to provide safety or protective

functionality. A control the operation of which is intended to prevent a hazardous situation during abnormal operation of the equipment

Type 2 Action - Calibration Verification Testing or

Functionality Verification testing conducted.

A Type ".B" control has been investigated for "microdisconnection" applications. Disconnection of any pole

(ungrounded conductor is not specified) for functional

purposes.

A Type ".K" control is designed that in the event

of a break in the SENSING ELEMENT, or in any

other part between the SENSING ELEMENT and

the SWITCH HEAD, the declared disconnection is

provided before the declared OPERATING VALUE ,

OPERATING TIME or OPERATING SEQUENCE is

exceeded.

THERMAL CUT-OUT - UL60730 Par 2.2.8. A Temperature Cut-out in accordance with UL60730 is defined as temperature sensing control intended to keep

a temperature below or above one particular value

during abnormal operating conditions and which has

no provision for setting by the user. A UL60730 THERMAL CUT-OUT is similar to a UL873 Temperature

Limiting control.

Class B - software that includes code intended to prevent unsafe state in appliance.

All Watlow Series L limit controllers include industryleading service, support and a 3-year warranty.

*Also available, Series C, an on-off temperature controller version.

Series LS

This control meets the newest safety standard requirements for the food service industry UL/EN 60335

equipment. It is approved to UL/EN 60730-1 and

60730-2-9 Electronic Control Thermal Cut-out Class

Watlow Series L • 1 • Chapter 1: Overview

LV and LF Features and Benefits

Four-Character LED Display

• Improves limit set point adjustment accuracy.

Fixed or Adjustable Limit Set Points

• Tamper proof operation.

• Control flexibility.

Set Point Adjustment Opetions

• Rotary encoder.

• Tactile increment and decrement keys.

Push to Set

• Reduce accidental limit set point adjustments.

Multiple Mounting Options

• Minimizes installation time.

High or Low Limit Operation

• Application flexibility.

Fahrenheit or Celsius Operation with Indication

• Application flexibility.

Sensor Break Protection

• Provides positive system shutdown.

Agency Approvals

• Meets requirements for agency certification.

• NEMA 4X/IP65 seal panel mount versions avail-

able.

• W.E.E.E.; CE; RoHS

Micro Processor Based Technology

• Accurate and repeatable protection.

Stock to Four-Day Delivery

LS Features and Benefits

Dual channel sensors

• Detects sensor faults

• Fault tolerant design

• Firmware review

• Sensor deviation error, sensor placement errors

Fail Safe Design

• Internal or external faults cause product to shutdown in a safe manner

Watlow Series L • 2 • Chapter 1: Overview

61.7 mm

2

Designation

Installation

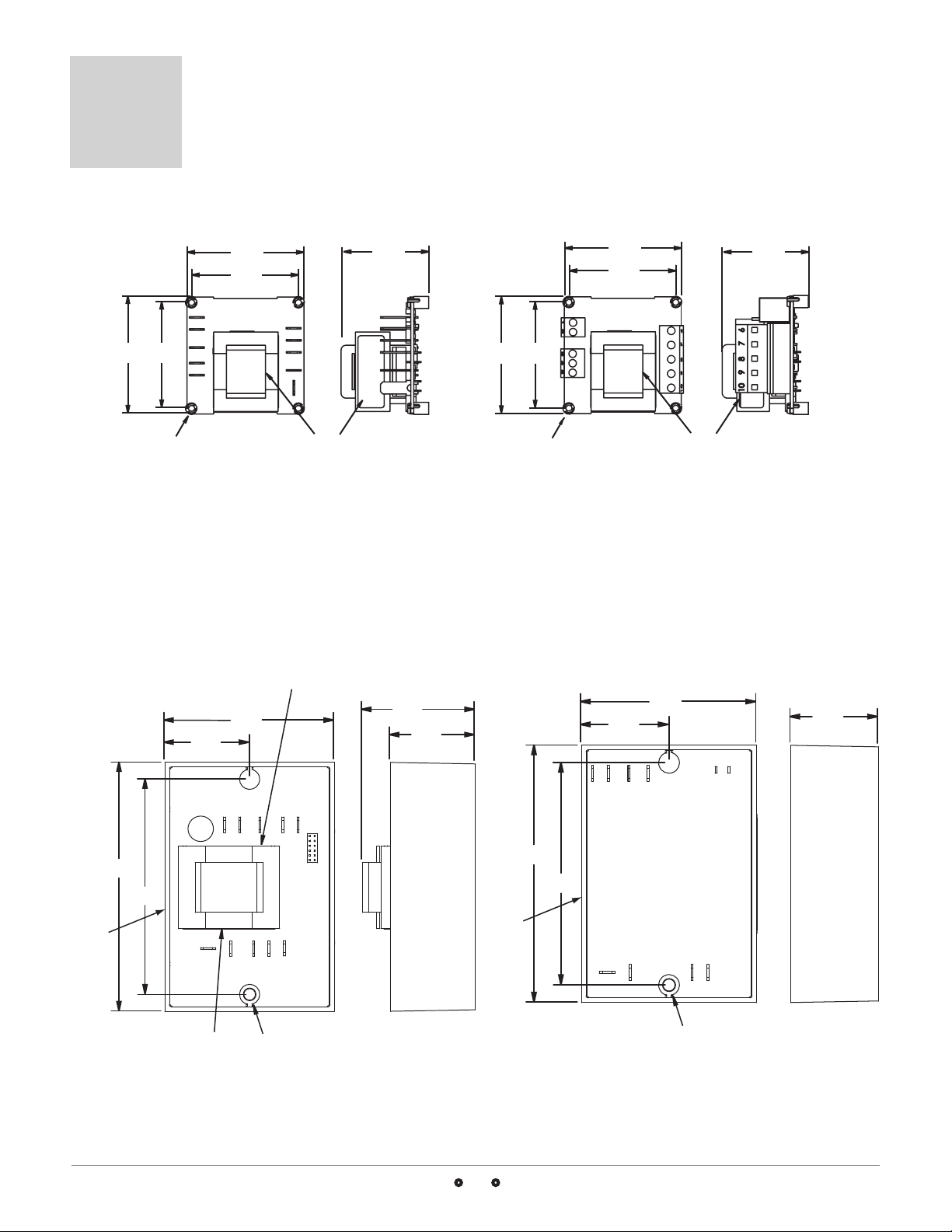

Installing the Open Board Controller (LF and LV)

61.7 mm

(2.43 in)

Use M2.5 (#4) mounting

hardware, not included

55.9 mm

(2.20 in)

61.7 mm

(2.43 in)

56.3 mm

(2.22 in)

Terminal Designation Sticker

Spade Terminal Model

SWDC+

SWDC-

COM

.6

N.O.

.7

.8

N.C.

.9

L2

.10

L1

45.07 mm

(1.775 in)

61.7 mm

55.9 mm

(2.43 in)

(2.20 in)

Use M2.5 (#4) mounting

hardware, not included

(2.43 in)

56.3 mm

(2.22 in)

Screw Terminal Model

Figure 3a

1. Locate and drill four 3.2 mm (0.125 in) holes in the desired panel location.

See Figure 3a for hole locations.

2. Mount the controller using four M2.5 (#4) screws.

Installing the Potted Controller

(LF, LV) (LS)

35.1 mm

(1.38 in)

70.1 mm

(2.76 in)

Terminal Designation Sticker

46.6 mm

(1.84 in)

35.1 mm

(1.38 in)

35.1 mm

(1.38 in)

70.1 mm

(2.76 in)

Terminal Designation Sticker

LED

45.07 mm

(1.775 in)

35.1 mm

(1.38 in)

Limit

Range

102.9 mm

Te rminal

Sticker

(4.05 in)

88.9 mm

(3.50 in)

Use [3.5M] #6 hardware,

not included

102.9 mm

(4.05 in)

88.9 mm

(3.50 in)

Terminal

Designation

Sticker

Terminal Designation Sticker

Use [3.5M] #6 hardware,

not included

Figure 3b

1. Drill two 5 mm (0.187 in) diameter holes in the desired panel location. See Figure 3b for hole locations.

2. Mount the controller using two M3.5 (#6) screws.

Watlow Series L • 3 • Chapter 2: Installation

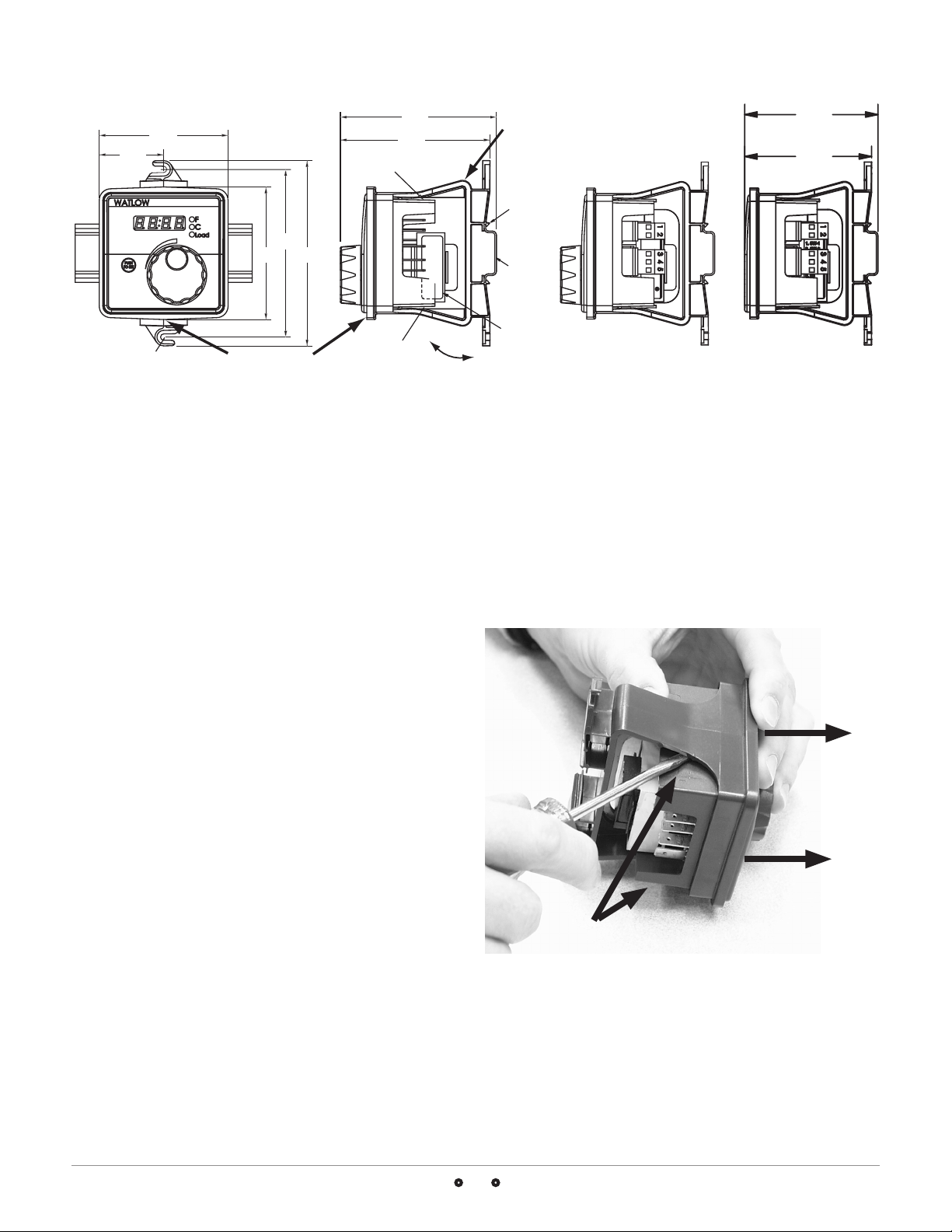

Installing the DIN Rail Mount Controller

94.7 mm

Agency Label

(3.73 in)

90.7 mm

(3.57 in)

1.

SW-1

2.

SW-2

3.

TC-/S1

4.

TC+/S2

5.

S3

78.1 mm

(3.08 in)

39.1 mm

(1.54 in)

Panel mounting the bracket requires

two M3.5 (#6) screws, not included

Part Number Label

101.6 mm

(4.00 in)

80.3 mm

112.3 mm

(3.16 in)

(4.42 in)

To install, press in here.

To remove, pull out here.

See Mounting/Removing the

DIN Rail Controller procedures below.

Spade Terminal Model

Figure 4a

Sub-Panel Mounting

1. Using the controller as a location template, mark

both mounting holes.

2. Drill and tap two 2.7 mm (0.106 in) diameter

holes in the desired panel location. See Figure

4a above for hole locations.

3. Mount the controller using two M3.5 (#6) screws.

81.8 mm

To install or remove,

press down here.

See Installing/ Removing

the DIN Rail Controller

procedures below.

DIN rail, upper

mounting clip

35 mm x 7.5 mm

DIN rail is not included

with the assembly

Terminal Designation Sticker

Screw Terminal Model

(3.22 in)

80.0 mm

(3.07 in)

Tactile Key Model

3. Remove the DIN rail bracket from the DIN rail.

4. Insert a flat blade screwdriver between the DIN

rail bracket and the case. Rotate the screwdriver

to release the DIN rail bracket hooks from the

ridges on the case, while firmly pushing the controller out the front of the DIN rail bracket. Alternate back and forth between the top and then

the bottom. Be sure to support the controller as it

comes out of the bracket. See Figure 4b.

DIN Rail Mounting

1. Place the DIN rail upper mounting clip on the top

edge of the DIN rail. See Figure 4a. DIN rail

spec, DIN 50022, 35 mm x 7.5 mm (1.38 in x 0.30

in).

2. Press down firmly on the top back edge of the DIN

rail bracket and push in on the bottom, front edge

of the bracket. The controller snaps securely onto

the rail. See Figure 4a. If the controller does

not snap on, check to see if the DIN rail is bent.

Minimum clipping distance is 34.8 mm (1.37 in),

the maximum is 35.3 mm (1.39 in).

Removing the DIN Rail Controller

1. Remove power from the system.

2. Remove all the wiring connections from the back

of the controller.

3. While pressing down on the top, back edge of the

DIN rail bracket, pull forward on the bottom, front

edge of the DIN rail bracket. See Figure 4a.

Removing the Controller from the DIN

Rail Bracket

1. Remove power from the system.

2. Remove all the wiring connections from the back

of the controller.

Press forward

with thumb.

Insert at blade screwdriver here.

Figure 4b

ç Caution: FM approval requires limit switches to be suit-

ably enclosed to restrict casual user adjustment.

Watlow Series L • 4 • Chapter 2: Installation

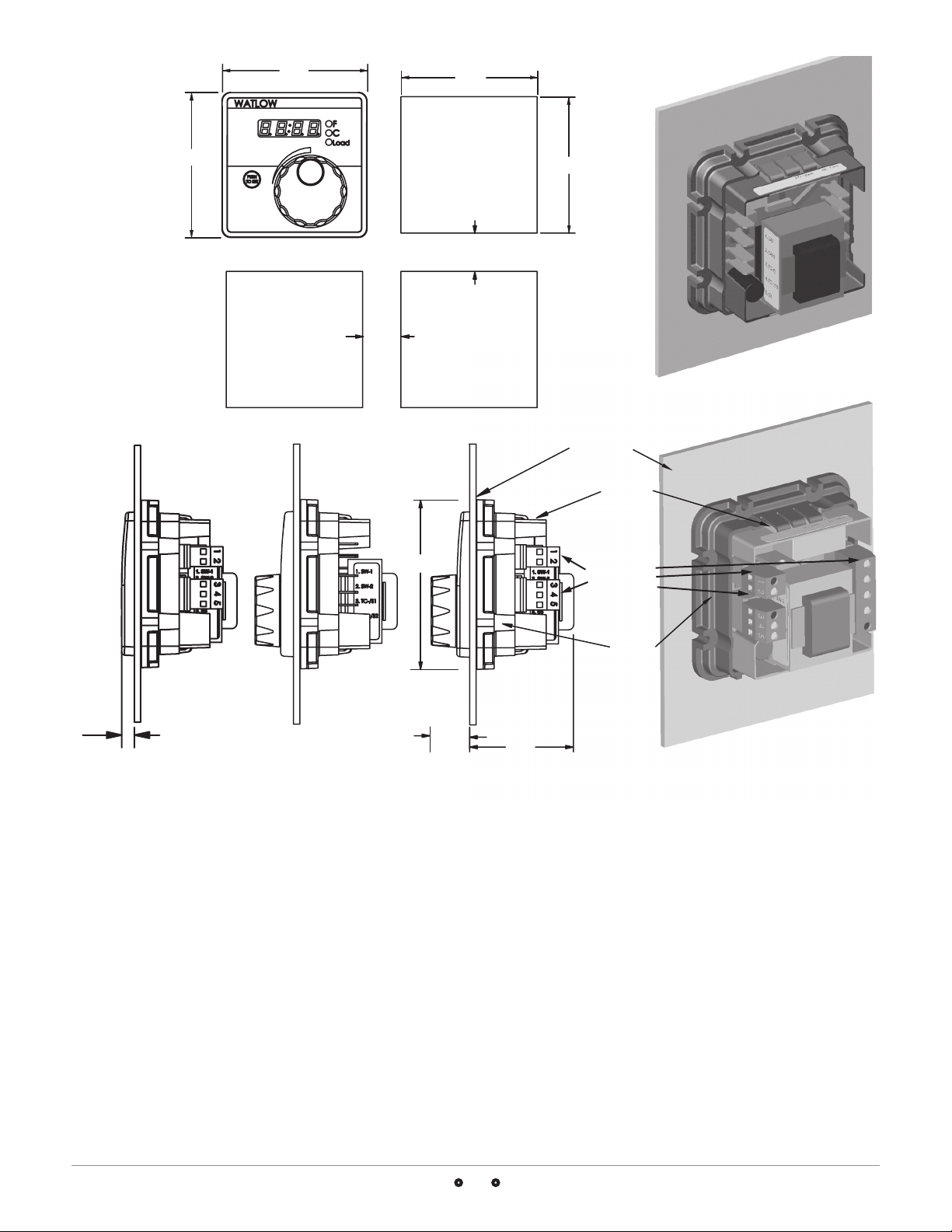

72.4 mm

(2.85 in)

68.0 mm

(2.68 in)

72.4 mm

(2.85 in)

19.1 mm

(0.75 in)

minimum

84.5 mm square

(3.33 in)

Panel Cutout

Panel Thickness

1.52 to 3.18 mm

(0.060 to 0.125 in)

19.1 mm

(0.75 in)

minimum

68.0 mm

(2.68 in)

Customer Front Panel

Terminal Blocks Locations

on Screw Terminal Models

Spade Terminal Model

Part Number Label

6.4 mm

(0.25 in)

Tactile Key,

Spade Terminal Model

19.2 mm

(0.76 in)

Screw Terminal Model

Figure 5

Installing the Square 1/8 DIN Panel

Mount Controller

1. Make the panel cutout using the mounting dimensions above.

2. Remove mounting bracket from the back of the

controller.

3. If your controller has a gasket, check to see that

the gasket is not twisted, and is seated within the

case bezel flush with the panel. Place the case in

the cutout. Make sure the gasket is between the

panel cutout and the case bezel.

4. While pressing the front of the case firmly against

the panel, slide the mounting collar over the back

of the control. The tabs on the collar must line up

with the mounting ridges on the case for secure

Mounting Bracket

51.7 mm

(2.04 in)

Contact your local Greenlee supplier for the appropriate

punch kit and cutout tool for rapid mounting.

Screw Terminal Models

installation. See Figure 4. Slide the collar firmly

against the back of the panel, getting it as tight

as possible. To ensure a tight seal, use your thumb

to lock the tabs into place while pressing the case

from side to side. Don’t be afraid to apply enough

pressure to install the controller. The tabs on

each side of the collar have teeth that latch into

the ridges. Each tooth is staggered at a different

height, so only one of the tabs on each side are

ever locked into the ridges at a time. Confirm that

the tabs on one side of the collar correspond with

those on the opposite side. Make sure the two corresponding tabs are the only ones locked in the

ridges at the same time. If the corresponding tabs

are not supporting the case at the same time, you

will not have a NEMA 4X seal.

5. Insert the control chassis into its case and press

the bezel to seat it. Make sure the inside gasket

Watlow Series L • 5 • Chapter 2: Installation

Loading...

Loading...