Page 1

FLUENT® Product Guide

Product Guide

FLUENT® Product Guide

General

The purpose of this product guide (the “Guide”) is for Watlow Electric Manufacturing Company (“Watlow®”) to convey

certain recommendations, advisories and requirements regarding your purchase and use of the product(s) described

below (the “Product”). This guide is not intended to be an exhaustive list of recommendations, advisories or

requirements for the use of the product. Please visit Watlow’s website (http://www.watlow.com/) or contact Watlow

customer service (1-800-WATLOW2) for more information regarding Watlow’s products. To ensure the proper use

of the product, each user of the product should carefully review this guide. FAILURE TO COMPLY WITH THE

INFORMATION PROVIDED HEREIN SHALL CAUSE YOU TO ASSUME ALL RISK AND LIABILITY ARISING OUT

OF SUCH FAILURE.

Product Description

This guide applies to Watlow FLUENT® in-line heaters. The product can be distinguished via marking on the outer

metal sheath.

FLUENT® model number

Nominal operating voltage and total power

product serial number

patent site

Safety

The following markers utilized throughout this guide shall have the meanings set forth below:

DANGER – This is a danger statement that is related to the use of this product. Failure to heed these

messages will result in serious personal injury or death.

WARNING – This is a warning statement that is related to the use of this product. These statements warn

of actions that may result in physical injury or death.

WARNING – Risk of Electric Shock – This is a warning statement that warns of the presence of electrical

voltages, which can cause physical injury or death.

CAUTION – This is a caution statement that is related to the use of this product. These statements caution

against actions, which may damage the product or associated equipment.

DANGER – Care should be taken to read and completely understand this guide before installing and wiring

the product. The product is designed to become hot while in operational use. The end user must conduct

their own risk assessment to identify if there is any residual risk pertaining to direct contact with hot

surfaces. There is potential risk of rupture or other malfunction of the product if it is not installed in

accordance with this guide or other installation instructions provided by Watlow. It is the end user’s

responsibility to ensure that the product is properly selected and installed in accordance with applicable

recommendations given within this guide. Note: this guide does not cover all foreseeable end-use

applications, therefore, consult your local Watlow representative with any additional questions or concerns.

© 2019 Watlow Electric Manufacturing Company.

1

10-25338-05FEB19

Page 2

FLUENT® Product Guide

FLUENT® Product Guide

WARNING – Risk of Electric Shock – Any installation and maintenance performed on this product shall

be performed by a qualified electrician in accordance with applicable national and local electrical codes.

It is the end user’s responsibility to ensure that proper precautions are taken to ensure that necessary

personal protective equipment is utilized by persons installing and maintaining any equipment.

Pre Installation

The following sets forth general safety instructions and requirements relating to the use of the product.

CAUTION – Watlow products are built to comply with UL® and CSA dielectric requirements. However, due

to atmospheric conditions, it may be necessary to validate by performing a dielectric test prior to startup.

(Refer to megohm test under the Installation section.)

1. Upon receipt of the product, inspect for any damage occurring during shipment. If you have any concerns about

the condition of the product, do not install such product and contact your Watlow representative prior to taking

further action with the product.

2. Upon receipt of the product, confirm that the product received is the same as the product that was ordered. In the

event of a discrepancy, please contact your Watlow representative prior to taking further action with the product.

Installation

Proper product selection and installation will help to ensure heat transfer efficiency, safety and increased product life.

The following sets forth instructions and requirements relating to the installation of the product.

1. Megohm pre-check

WARNING – Risk of Electric Shock – The bake-out procedures listed below should only be performed

by qualified personnel. If the procedure calls for connecting electric power to the product, this shall

only be performed by a qualified electrician, in accordance with applicable national and local electrical

codes.

During shipping and/or storage, the possibility of moisture absorption by the insulation material within a heater

element is possible. To determine if the proper megohm value is present, use a 500VDC (minimum) megohm meter

to measure the insulation resistance between the product power terminals and the product’s outer protection tube.

This value should be greater than 200 megohms when the unit is at room temperature.

If a low megohm value exists, bake the product in an oven at 177°C (350°F) ± 27°C (50°F) for a duration of 12 to 24

hours. After baking, repeat the megohm insulation resistance test to verify that 200 megohms insulation resistance

has been achieved. If the product fails a second insulation resistance test, contact your Watlow representative or

customer service at the phone number indicated in this guide.

CAUTION – Do not exceed 204°C (400°F) if an oven bake-out is performed.

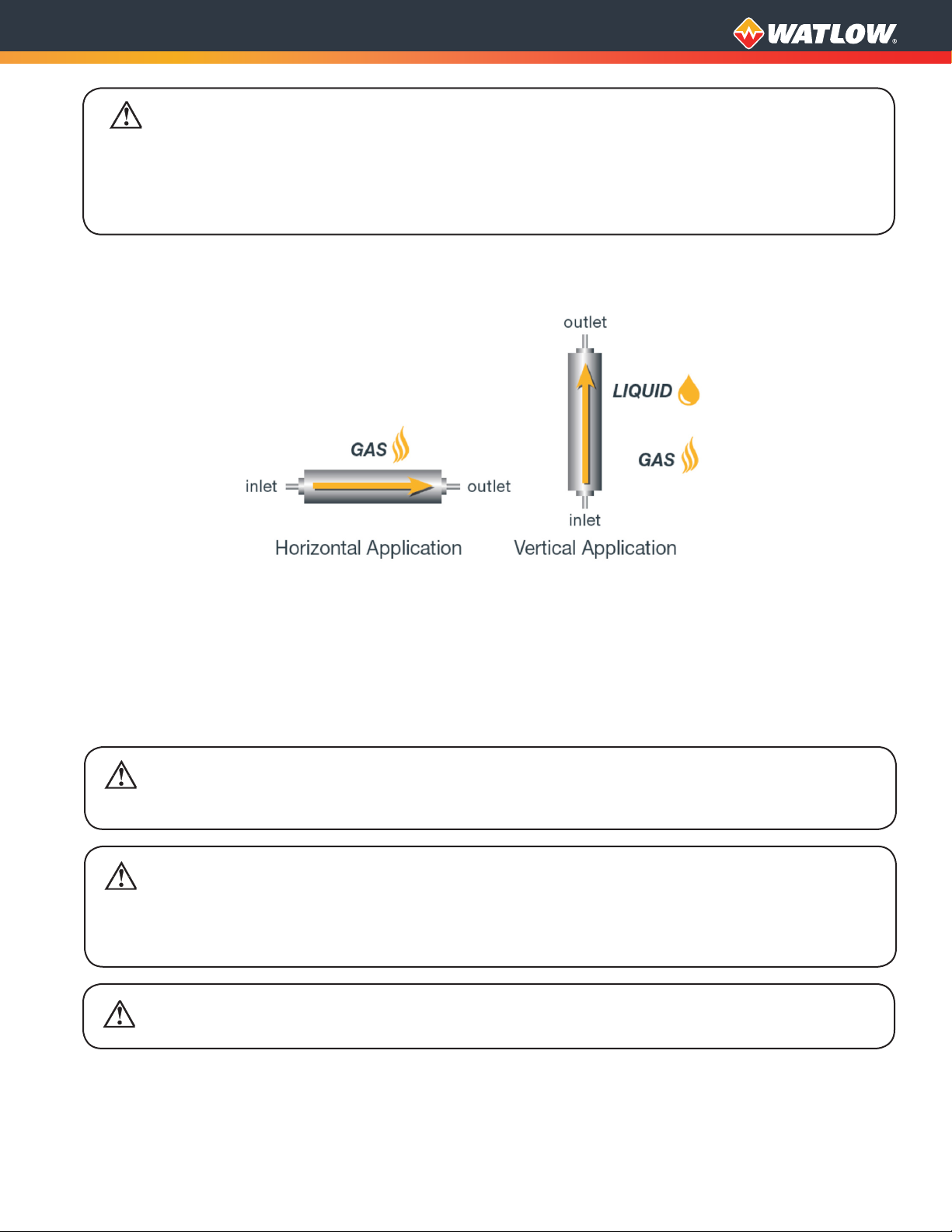

2. Heater orientation and mounting

When flowing liquids through the product, it should be mounted vertically with the inlet (side with the lead exits)

on bottom and the outlet on top. Failure to mount the product in this orientation can cause overheating and failure

of the product. For gaseous fluids, any product orientation is possible as long is it is not downwards. The direction

of the flow must go from inlet (lead exit) to outlet.

CAUTION – Failure to orient the product in the correct position or flow the fluid from the inlet (lead exit) to

the outlet can result in failure of the product.

2

Page 3

FLUENT® Product Guide

FLUENT® Product Guide

WARNING – Electric heaters are capable of developing high temperatures, so to minimize the risk of

fire extreme care should be taken to locate the product in a safe environment. Mounting products

in atmospheres containing combustible gases and vapors should be avoided. You must ensure that

combustible materials are maintained far enough away from the product to ensure that they are free of

the effects of high temperatures.

This product is not suitable for use in hazardous (classified) locations.

The best way to mount the product in place should be determined by the end user.

Application Orientation

3. Protection of heater elements from over temperature

The use of a temperature controller to regulate the heating process and prevent product failure is critical to

ensure safe operation. It is the end user’s responsibility to ensure safety of the installation. The maximum heater

engine operating temperature for the product is 350°C as measured by the integrated thermocouple. This thermocouple must be connected to a controller that provides a latching high limit at a maximum value of 350°C. The

high limit set point should be reduced if the normal operating conditions allow for it. The recommended high limit

temperature set point is the value of the integrated thermocouple during normal operating conditions plus 30°C.

WARNING – Install high temperature controller protection using the integrated thermocouple. The

high limit must be latching and the temperature set point should not exceed 350°C. Failure to install

temperature controller protection could result in damage to equipment, property and/or injury to personnel.

CAUTION – Failure of components in a temperature control loop, such as the sensor, heater control relay

or main temperature controller, can result in damage to a product in process, a product failure and/or

damaging fire. To protect against this possibility, over-temperature protection must be provided to interrupt

or remove power from the heater circuit during abnormal conditions. To limit this risk, perform a functional

test of all temperature limiting devices on a regular interval.

CAUTION – Certain heating applications may accompany volumetric expansion and/or phase change. In all

cases, ensure that appropriate safeguards against over-pressurization are included in system design.

All temperature limit devices must have appropriate third-party approval and be applied in the classification for which

it was tested and approved. The high temperature limiting device(s) should function independently from the process

temperature controller. This is a high performance product and requires a PID controller with a fast relay (refresh rate

of 10Hz or better) in order to be controlled effectively.

3

Page 4

Minimum High Limit Circuit Requirements

Thermocouple

FLUENT® Product Guide

NO

COM

NC

INLET OUTLET

FLOW DIRECTION

4. Mass flow conditions

This product should never be operated when there is no mass flow present. It is the responsibility of the end user

to ensure that there is mass flow through the product when it is operated. Operating the product without mass

flow can cause the product to fail.

CAUTION – Running the product without mass flow can result in product failure.

WARNING – This product is not designed for use with combustible or hazardous materials. Doing so

may have unintended consequences that may result in product failure, damage to equipment, or physical

injury or death. The end user is responsible for any unintended consequences due to combustible or

hazardous materials.

5. Termination

Do not handle the product by the lead wires or sensor wires!

Handling by the leads can compromise electrical and/or mechanical integrity of the product.

In order to maintain termination integrity, the termination area should be kept below 200°C (392°F). Do not allow

oil, moisture or other possible contaminants to come in contact with the heater lead wires. Mass flow through the

Product helps keep the termination area cool during operation.

WARNING – Risk of Electric Shock – The installation and wiring of this product shall only be done by

a qualified electrician, in accordance with applicable national and local electrical codes. It is the end

user’s responsibility to ensure that proper precautions are taken in reference to applicable personal

safety equipment needed by those installing and maintaining equipment.

Never interrupt the protective earth circuit/ground. Any interruption or disconnection of the protective

earth circuit used by this product will create a dangerous situation and could result in an electric shock

that in some situations could lead to serious injuries! It is the end user’s responsibility to properly size

the ground wire for the protective earth/safe ground and to assure that the impedance of this is low

enough to assure a person’s safety.

In some equipment or installations a GFI style breaker or circuit may need to be installed to ensure the

safe operation of the product. Determining if this is a requirement is the responsibility of the end user.

The mains/line voltage applied to the product must always be equal to or less than the voltage rating

marked on the heater’s outer tube. Some heaters are supplied as dual voltage (e.g. 120V/240V) units

and hence the end user needs to check the wiring diagram supplied with the product to ensure that the

product is wired correctly for their supply voltage.

The use of a disconnect switch or circuit breaker is highly recommended and will allow the isolation of

the product when maintenance is required.

4

Page 5

FLUENT® Product Guide

WARNING – It is the end user’s responsibility to properly size and install the feeder wires to the product.

Feeder wire should be properly selected based on amperage, electrical power rating, ambient temperature

and type of environment.

It is the end user’s responsibility to ensure that the bending radius of the lead wires provided with the

product are large enough to prevent any damage.

Minimum Circuit Requirements

Notes:

1) Above depictions represent the basic protection requirements in a simple circuit.

2) Heating elements considered “live” must be isolated from protective ground circuit.

Other wire configurations such as dual voltage or three phase are possible with this product. The end user should

check with their Watlow representative if there is any concern about the wire configuration. At a minimum, all wires

exiting the product must be terminated to prevent live wires.

The tables below list standard specifications for the standard lead wires used in various FLUENT heaters.

Wire Specifications

Lead Wire Specifications

Wire Insulation

PTFE Insulated (UL® 1199) 20 AWG (7/28), SPC, 600V 18 AWG (726), SPC 600V

Standard thermocouple wire specifications

Watlow PN K24-1-304, Type K, fiberglass insulated, solid 24 AWG wire. Other types of thermocouples may be

provided; please contact your Watlow representative or customer service for additional information.

Earthing/grounding

This product must be connected to an earth ground circuit. Earthing can be achieved through a connection to the

outer protection tube or the inlet/outlet fittings. It is the end user’s responsibility to ensure that there is an adequate

connection and all components are rated correctly.

Ø1.0 in. (25.4 mm) Outer Tube Ø1.625 in. (41.3 mm) Outer Tube

WARNING – Risk of Electric Shock – Never interrupt the protective earth circuit/ground. Any interruption

or disconnection of the protective earth circuit used by this product will create a dangerous situation and

could result in an electric shock that in some situations could lead to serious injuries! It is the end user’s

responsibility to properly size the ground wire for the protective earth ground.

5

Page 6

FLUENT® Product Guide

6. Miscellaneous

This product is not intended to be a pressure vessel. The maximum rated pressure of this product is 150 psi (10.3 bar).

WARNING – The maximum pressure rating of this product is 150 psi (10.3 bar). Exceeding this pressure

can cause the product to expand and rupture resulting in failure of the product. This can also lead to

damage to the equipment, physical injuries and/or death.

After installation of the product, it is strongly recommended that the end user ensure that their equipment fully

complies with all European New Approach Directives applicable to that equipment, this may include the EMC Directive.

This product is rated to IP63 and should not be submerged.

CAUTION – This product is not designed to be submersed in any fluid.

Freeze protection is required for this product if it will operate in environments below the fluid freezing temperature.

This expansion can cause the product to rupture and no longer operate as intended.

CAUTION – Operating this product without freeze protection in an environment below the fluid freezing

temperature can cause the product to fail and not function properly.

Do not modify the product in any way.

Ensure that any surrounding components or materials have an adequate temperature rating. Insulation around the

product may be required if placed in close proximity to heat sensitive components.

WARNING – The exterior components of this product may become hot during operation and may

exceed a touch safe temperature. The end user must ensure that all surrounding components have

adequate temperature rating and insulation. Failure to do so can lead to fire, personal injury and/or death.

Start Up

The following sets forth instructions and requirements relating to the initial startup of the product:

CAUTION – Before energizing the product, the following items should be checked with the main/line

voltage disconnected. Failure to do so could result in damage to the product, equipment and/or

operator injury when it is energized.

1. Electrical terminations are tight and wiring is per wiring diagram supplied (if applicable).

2. Proper disconnecting means and fusing have been installed.

3. The voltage rating of the product is the same as that being applied.

4. Leg to leg voltage is equal (for 3-phase units).

5. Megohm value of the heater elements are within acceptable limits.

6. Proper temperature controls and safety limiting devices are in place with proper set point(s).

7. The product is properly grounded.

8. Assure that the correct fluid flow has been started and is being maintained to ensure that heater.

elements do not overheat and fail once the product is energized.

WARNING – After applying power to the product, make sure that the system is being controlled properly

before leaving it to run unattended. Failure to do this could result in the product overheating in a “run away”

condition that could lead to damage to equipment, fire or personal injury.

6

Page 7

FLUENT® Product Guide

Troubleshooting

The information provided below contains potential causes and corrections for functional problems with the product.

This is a non-exhaustive list of potential problems and corrections and is not meant to cover all potential issues.

Please do not hesitate to contact your Watlow representative if you have any questions regarding the performance of

your product.

WARNING – Risk of Electric Shock – High voltage is present when the product is energized and hence

troubleshooting of this product shall only be done by qualified personnel.

It is the end user’s responsibility to ensure that proper precautions are taken in reference to applicable

personal safety equipment needed by those installing and maintaining equipment.

Problem Cause/Correction

No power available to product Check disconnect switch to ensure it is in the “ON”

position and that fuses are not blown. Replace fuses if they are

blown.

Fuses blowing Check heater electrical rating. Verify line voltage is within

specification.

Check fuse rating. Fuses should be at least 25 percent more

than full load amperage.

Disconnect product power source. Check the heater resistance

to ground. This should be no less than one megohm. Refer to

‘megohm pre-check’ in the Installation section of this guide.

Not enough power/application not heating to desired

temperature

Verify line voltage is within specification.

If voltage is correct, check full line current draw. If line

current is lower than designed, the heater circuit may be

wired incorrectly or the temperature controller and/or power

switching settings may need to be adjusted to deliver a greater

duty cycle percentage.

Heat losses to other system components and to the ambient

environment may be higher than initially calculated/estimated.

A higher wattage heater or additional thermal insulation in the

system may be required.

Preventative Maintenance

WARNING – Risk of Electric Shock – High voltage is present when the product is energized and hence

preventative maintenance of this product shall only be done by qualified personnel.

Turn all power off to the product and “lock out/tag out” the power disconnect switch(es) for the product

before preforming any preventative maintenance.

It is the end user’s responsibility to ensure that proper precautions are taken in reference to applicable

personal safety equipment needed by those installing and maintaining equipment.

WARNING – The product, vessel and system can remain hot for a long period of time after the power has

been removed, so make sure the equipment has cooled down to a safe temperature before preforming any

preventative maintenance.

Thermal cycling, corrosion and vibration can cause degradation of the thermal system and electrical interfaces.

Follow system designer’s guidelines for periodic checking of the condition of the installed product and the electrical

connections.

7

Page 8

FLUENT® Product Guide

Replacement Parts

When ordering replacement parts from your Watlow representative, please reference the part number(s) indicated on

the Watlow product(s).

If your Watlow representative is not known, please visit our website http://www.watlow.com and use the interactive

“Sales and Distributor Locater” tool to identify and contact your local Watlow distributor for ordering replacement

parts.

Patent Information

This Watlow product is protected by patents in the U.S. and elsewhere. Additional patents may be pending in the

U.S. and elsewhere.

U.S. Patent Numbers: 9,029,742

7,361,869

Disposal and Recycling

This product is classified under the RoHS and W.E.E.E. directives as electronic components with respect to disposal,

and as such, must be recycled as per the requirements of the national regulations of the end user.

Terms and Conditions and Product Returns

Unless otherwise expressly agreed to in writing by Watlow, Watlow’s standard terms and conditions shall apply

to your purchase and use of the product in all respects. Such terms and conditions include, but are not limited to,

applicable warranty obligations and payment terms. The terms and conditions may be found attached to any order

acceptance or bid prepared by Watlow. For a copy of such terms and conditions, please contact Watlow’s customer

service department or visit our website http://www.watlow.com.

In the event that you desire to make a warranty claim against any product because it does not comply with the

warranty provisions provided under the applicable terms and conditions, please contact Watlow customer service to

obtain a Return Material Authorization (RMA) number before returning any item for repair or replacement. The following information is needed to process a returned product:

• Customer name • Customer account number

• Contact name • Phone number

• Part number • Email address

• Quantity • P.O. number

• Reason for return • Application information

• MSDS sheet of material(s) that came in contact with product, if used

Watlow® and FLUENT® are registered trademarks of Watlow Electric Manufacturing Company.

UL® is a registered trademark of Underwriter’s Laboratories, Inc.

8

Loading...

Loading...