Page 1

W A T L O W

Flexible Heaters

Flexible Shapes

and Geometries

Flexible heaters from Watlow are

just what the name implies: thin,

bendable and shaped to fit your

equipment. You can use your

imagination to apply heat to the

most complex shapes and

geometries, without sacrificing

efficiency or dependability. With

Watlow’s customization capabilities,

you have the maximum amount of

freedom when designing your

equipment.

Excellent heat transfer results from

the heater’s thin design and its

direct bonding to the application.

Flexible heaters also provide fast

heatup and cool down rates,

uniform heat distribution and high

watt densities.

Features and Benefits

• Flat geometry permits holes,

notches and unusual shapes.

• Four material types and two

element styles are available for

wider flexibility in meeting your

requirements. See next page for

performance capabilities.

• Lightweight construction and

low thermal mass permit use in

applications that have limited

space or weight requirements.

• Heating elements as close as

0.003 inches (0.08 mm) from the

heated part respond to controls

with faster heat up and cool down.

• Uniformly spaced element

paths, placed within

(6 mm) of the heater perimeter,

distribute heat more evenly.

1

⁄4 inch

Wire-Wound

Element

• Same day shipment on stock units with orders

received by 11:00 a.m.CST.

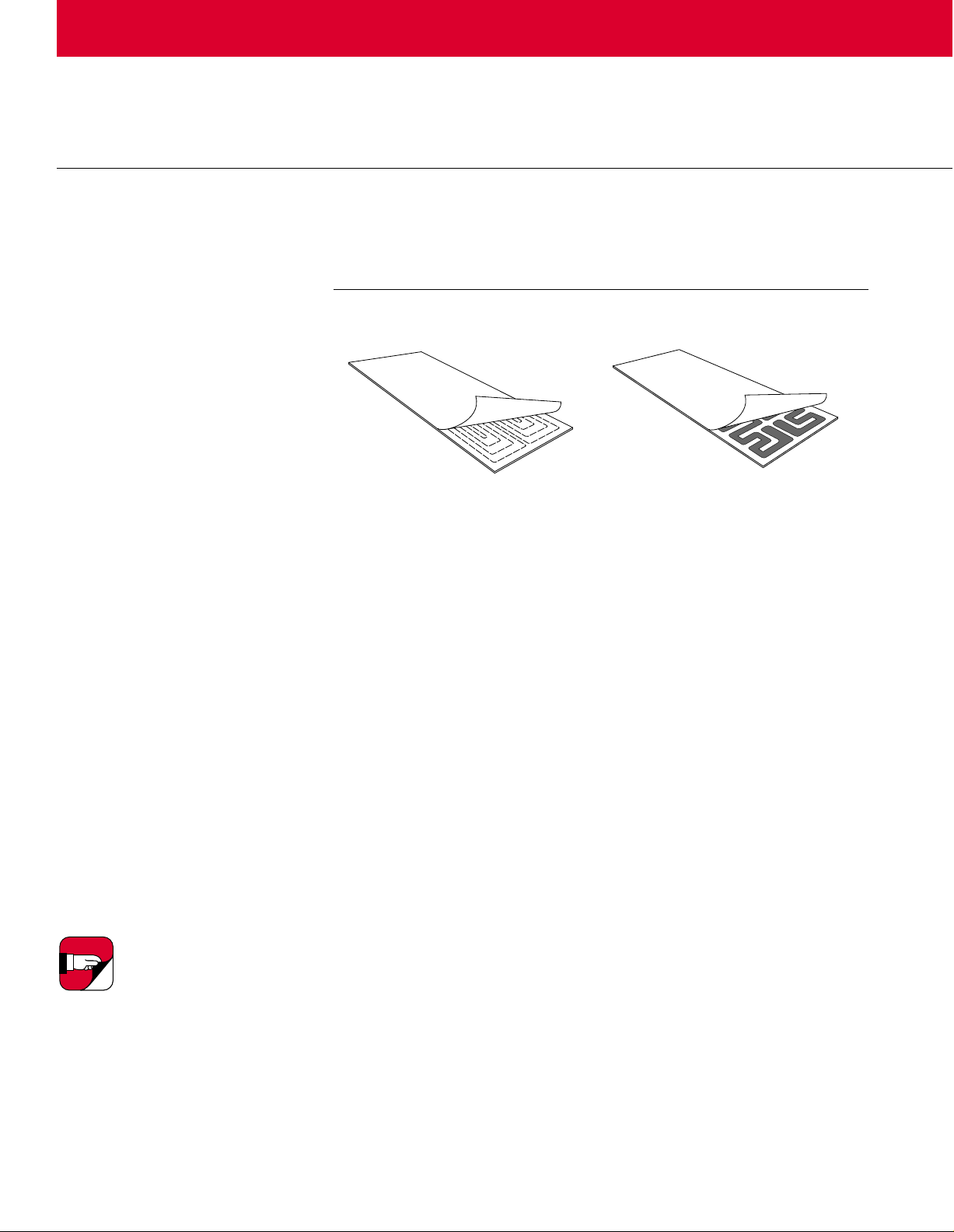

Top Layer of Insulation

Sheath Material

Bottom Layer of Insulation

Sheath Material

Flexible Heaters

Etched Foil

Element

Applications

• Medical equipment such as blood

analyzers, respiratory therapy

units and hydrotherapy baths

• Satellite and communication

equipment

• Freeze protection for military

hardware, aircraft instrumentation,

hydraulic equipment, etc.

• Battery heating

• Semiconductor equipment

• Foodservice equipment

• Any application requiring a flexible

shape or design

163

Page 2

Flexible Heaters

Flexible Shapes

and Geometries

Applications and

Technical Data

Four Material Types

Silicone Rubber:

This rugged, moisture- and chemicalresistant material is easily bonded or

cemented to parts. Watlow silicone

rubber heaters can handle temperatures up to 500°F (260°C). Many

styles of these heaters are available

with UR®, cUR®and VDE

recognition. See page 171 for details.

Kapton®:

A thin, lightweight transparent

material from du Pont, Kapton®is

designed for extremely precise

heating requirements ranging from

-319° to 392°F (-195° to 200°C). It is

ideal for applications requiring low

outgassing in a vacuum, or

resistance to radiation, fungus and

chemicals. Many custom heaters can

be UR®and cUR®recognized.

Neoprene:

Neoprene resists weathering,

abrasion and chemicals. It can be

used economically in applications to

250°F (120°C), where high watt

densities are not needed.

HT Foil:

This mica-insulated, high

temperature foil is a semi-rigid

heater. Operating temperatures up to

1100°F (595°C) can be achieved.

See pages 169 to 182 and

189 to 194 for information

on silicone rubber,

Kapton®, neoprene, and

HT foil heaters.

Two Element Types

Watlow offers both wire-wound and

etched foil resistance elements.

These element types are available in

Wire-Wound Elements

Available on silicone rubber and

neoprene heaters, this element

style is created by spiraling fine

resistance wires around a fiberglass

cord. The element is then laid out in

a pattern designed specifically for

your application. The benefits of

wire-wound elements include:

• Excellent physical strength and

flexibility; repeated flexing of the

heater has no harmful effects on

its performance

• Good economy for small

production runs

• Conforms readily to curved

surfaces, including small

radius bends

Drum heaters and conduit bender

heaters are typical examples of

applications that use the wirewound method. These heaters are

flexed repeatedly during use, but

due to their wiring, no internal

damage will occur.

most insulating materials, and

Watlow can recommend the type

best suited to your application.

Etched Foil Elements

This element type, created by acid

etching a circuit in nickel resistance

alloy foil, is available in silicone

rubber, Kapton

types. The etched foil element is

noted for its excellent circuit pattern

repeatability and superior heat

transfer, which results from greater

area coverage of the element. Other

benefits include:

• Delivers more heat and up to

twice the watt density of a wirewound element, providing longer

heater life

• Most economical for large

production runs

• Complex heat distribution

patterns can be provided

The etched foil element style is

usually recommended for

applications requiring high

temperatures or watt densities, or

multiple zoning.

®

and HT foil heater

Kapton®is a registered trademark of

E.I. du Pont de Nemours & Company.

®

and cUR®are registered trademarks of

UR

Underwriter's Laboratories, Inc.

164

Page 3

W A T L O W

Flexible Heaters

Flexible Shapes

and Geometries

Options

Note: PSAS maximum six months storage

life before heater installation.

Note: Not recommended for Kapton

heaters.

®

Mounting Methods

Watlow offers various attachment

techniques, all designed for fast

installation. These include: three

types of adhesives; Watlow’s special

factory vulcanization process; and

mechanical fasteners.

Pressure Sensitive Adhesive

Surface (PSAS)

For speed, convenience and

economy of installation, specify

PSAS. Simply peel off the protective

backing and roll the heater in place

for an even bond to a clean, smooth

surface.

Field Applied Adhesive (RTV)

For a stronger bond, or when long

storage is probable, a room

temperature vulcanizing (RTV)

silicone adhesive is available from

stock within two days. Watlow offers

red RTV for temperatures up to 500°F

(260°C). White RTV is available from

adhesive suppliers for temperatures

up to 400°F (205°C). Watlow’s one-

Complete installation instructions are

available from Watlow. Ask for

technical letter #2, silicone rubber

heaters.

Note: PSAS is not recommended

for curved surfaces or for heaters

rated above 10 W/in2(0.8 W/cm2). It

should not be used for applications

exceeding 400°F (205°C) on silicone

rubber, 300°F (150°C) on Kapton

or 200°F (93°C) for neoprene.

part RTV is self-priming and can be

ordered in either 3 oz (90 ml) or

12 oz (355 ml) tubes. For larger

heaters requiring longer adhesive

working time, two-part RTV kits can

be purchased from adhesive

suppliers. These kits require primer on

the surface prior to application of the

adhesive.

®

Flexible Heaters

Silicone Contact Cement Kit

This two-part adhesive consists of a

resin and catalyst which are easily

mixed together and applied with a

paintbrush. Recommended usage is

for field cementing of silicone rubber

heaters to customer parts. Available

Factory Bonding

This attachment technique provides

a strong, void-free bond for excellent

heat transfer and extended heater

life. Watlow’s expertise in bonding

heaters to customer parts has

proven extremely successful.

Mechanical Fasteners

When a wire-wound flexible heater

must be detachable, any type of

fastener normally used with fabrics

can usually be built into the sheath

material of Watlow flexible heaters.

The most common types are

latch fasteners, boot hooks and

from stock, the cement kit will handle

temperatures to 350°F (175°C).

The resin is available in pint or quart

containers. To order, specify silicone

contact cement, and container size.

Bonding is recommended for

applications that reach maximum

temperatures of 500°F (260°C) on

silicone rubber and 300°F (150°C)

on Kapton®.

grommets. Other styles include snap

fasteners, springs, velcro style

fastener strips and lacing cord. The

grommets and boot hooks are

commonly used with tension springs

to compensate for slight variations in

part size.

165

Page 4

Flexible Heaters

Flexible Shapes

and Geometries

Termination Styles

Watlow offers many types of leads

and terminations. Leads can project

from any position along the perimeter

of the unit. They will be centered

on the short side width of

rectangular heaters unless

specified otherwise.

Standard Leads —Type E Teflon

Leads shown exiting end of heater,

centered on short side.

®

Watlow’s standard leads are 12

inches (305 mm) long, white, Teflon

insulated, flexible, plated copper

wire. They are rated for 392°F

(200°C)/600 volts per MIL-W-16878,

Type E. The lead connections on or

at the heater are insulated with a

cap of sheath material, vulcanized to

the heater body. All custom flexible

heaters except HT foil will be

supplied with this lead type unless

otherwise specified.

®

HPN Cord and Plug Set

Molded leads are shown exiting edge of heater.

Capped leads are also available.

Silicone Insulated Leads

Leads shown exiting corner of heater.

®

Special Teflon

Leads shown exiting middle of heater.

Leads

For removable heaters, a six foot

(1.8 m) HPN (neoprene insulated)

cord and plug set provides convenience. It is rated for 194°F (90°C)/

300VÅ(ac). HPN cord without a plug

is also available in any length.

For a better moisture seal, specify

®

silicone insulated lead wires. This

UL

lead type is rated for 302°F (150°C)/

600VÅ(ac). Any lead length is available. Note: Silicone rubber heaters

are not designed to be waterproof.

Excess exposure to moisture may

facilitate premature heater failure.

Teflon®leads, UL®style 1180 and

cUR®approved, are rated for 392°F

(200°C)/300 volts. Any length is

available. UL®Teflon®leads are

standard on stock rectangles.

Construction

Teflon®is a registered trademark of

E.I. du Pont de Nemours & Company.

166

Formed Heaters

Holes, Cutouts and Notches

Many three-dimensional shapes,

such as cylinders, cones and boxes,

can be factory formed. Semi-rigid

shapes can be self-gripping to the

part. Special tooling may be

required for some designs.

Watlow can provide flexible heaters

with special holes, cutouts and notches in nearly any position required for

your design. The resistance element

can be brought to within

1

⁄8 inch (3 mm)

of all edges. Standard spacing is

1

inch (6 mm) from all edges.

⁄4

Page 5

W A T L O W

1

1

/

2

"

(38 mm)

1

3

/

4

"

(45 mm)

3

/

4

"

(19 mm )

Ref.

3

/

8

"

(10 mm)

T-10

1

1

/

2

"

(38 mm)

1

1

/

4

"

(32 mm)

3

/

4

"

(19 mm )

Ref.

11

/

16

"

(18 mm)

T-207

2

1

/

2

"

(64 mm)

3

/

4

"

(19 mm)

3

/

16

"

(5 mm)

Thermocouple

Flexible Heaters

Flexible Shapes

and Geometries

Temperature Sensors

Watlow offers several styles of

sensors for use with flexible heaters.

These sensors are available as

preset or adjustable thermostats,

thermocouples, thermistors, RTDs or

thermal fuses. They can be

integrally mounted (encapsulated

in silicone rubber) to sense the

temperature of either the part or the

heater sheath. The thermostats can

also be ordered separate from the

heater, allowing direct control of your

process temperature, if desired.

Pre-Set Thermostats

Several styles of non-adjustable,

pre-set thermostats are available

from Watlow. Thermostats separate

from the heater are encapsulated in

silicone rubber, and are available

with standard 12 inch (305 mm)

leads unless otherwise specified.

Note: Precise part temperature control with preset thermostats requires prototyping and

field testing.

Thermocouples, thermistors, RTDs

and thermal fuses are usually

mounted to the heater under a

vulcanized protective cap of

silicone rubber sheath material. This

drawing shows a typical mounting

style for a thermocouple.

Flexible Heaters

Pre-Set Thermostats (Non-Adjustable)

Thermostat Maximum Volts Temperature Settings

Model Watts AC Available °F (°C)

T-10 600/960 120/240 *125-300±10 (50-149±5) yes yes yes

T-207 1500 120/240 40/55±8 (4/13±4.4) yes yes yes

1500 120/240 60/75±8 (16/24±4.4) yes yes yes

1500 120/240 95/110±8 (35/43±4.4) yes yes yes

1500 120/240 145/160±8 (63/71±4.4) yes yes yes

Notes:

• When ordering a pre-set thermostat

separate from the heater, simply add the

prefix S to the model number.

(Example: ST-10) See next page.

• Snap action preset temperatures on the

T-207 are close/open settings.

• T-10 thermostats are manufactured for

specific preset temperatures. Available in

25˚F increments.

• Other temperature ranges and voltages

are available on special order. Minimum

quantities apply, so consult factory before

ordering.

Agency Approvals

UR cUR VDE

Adjustable Thermostats

The B-200 thermostat features a

maximum rating of 1500 watts at

120/240VÅ(ac). The following

temperature ranges are available:

• Model B-200-2:

100° to 500°F (40° to 260°C)

• Model B-200-3:

25° to 330°F (-5° to 165°C)

The B-200 thermostat can be

integrally mounted to the heater with

a bonded protective cap of

silicone rubber sheath material.

167

Page 6

Flexible Heaters

Ref.

0.50

(13 mm)

1

(25 mm)

2.25

(57 mm)

0.50

(13 mm)

0.34

(9 mm)

0.218

(6 mm)

Dia. Typ.

1.75

(44 mm)

1.25

(32 mm)

0.50

(13 mm)

Flexible Shapes

and Geometries

Temperature Sensors

Continued

ST-207

ST-10

ST-207E

Separate Heater Accessories

Available From Stock

Pre-Set Thermostats Separate

From Heater

These are offered to allow direct

control of your process temperature,

so you’re not limited to controlling

only the heater temperature when

using stock heaters. Pre-set thermostats are encapsulated in silicone

rubber with standard 12 inch leads.

The same temperature ranges,

ratings and sizes are available on

these thermostats. When ordering,

add “S” prefix to the model number

to indicate “separate” item.

(Examples: ST-10 and ST-207)

Standard leads are 12 inch (305

mm) 18 ga. UL1180 black leads.

Notes: For direct control of air temperature

as is required in enclosure heating

applications, specify thermostat model

number ST-207E. This is a modified ST-207

mounted on 1⁄32

with the thermostat’s metal cap exposed to

sense air temperature.

inch thick G-10 circuit board

11

⁄16"

27⁄8

"

B-200

5

⁄8"

1

1

⁄2"

Adjustable Thermostats Separate

From Heater

The Model B-200 adjustable

thermostat can be ordered as a

separate item. The same model

numbers and temperature ranges

indicated under Adjustable

Thermostats are available. When

ordering, simply note that you want

the B-200 separate from the heater.

168

Loading...

Loading...