Page 1

W A T L O W

Tubular and

Process Assemblies

Flange Immersion Heaters

Watlow flange heaters are easy to

install and maintain. Designed for

heating liquids and gases in tanks

and pressure vessels, flange

immersion heaters are ideal for

applications requiring higher

kilowatts.

Watlow flange heaters are made

with WATROD or FIREBAR®tubular

elements brazed or welded to a

flange. Stock flange heaters are

equipped with a general purpose

(NEMA 1) terminal enclosure.

Flange heaters, with FIREBAR

elements, also answer the need for

liquid immersion applications

requiring high kilowatts in small

tanks. The FIREBAR element’s

unique flat surface geometry packs

more power in a smaller bundle,

with lower watt density, making it

especially well suited for petroleumbased liquid heating applications.

Performance Capabilities

• Watt densities to 100 W/in

(15.5 W/cm2)

• Wattages to one megawatt

®

•UL

and CSA component

recognition to 480VÅ(ac) and

600VÅ(ac) respectively

• Incoloy®sheath temperatures to

1600°F (870°C)

• Passivated 316 stainless steel

sheath temperatures to 1200°F

(650°C)

• 304 stainless steel sheath

temperatures to 1200°F (650°C)

• Steel sheath temperatures to

750°F (400°C)

• Copper sheath temperatures to

350°F (175°C)

2

Features and Benefits

• ANSI and ANSI compatible 2,

21⁄2

inch flanges provide appropriate

heater size-to-application and fit.

• Flange sizes up to 24 inches

available on made-to-order units.

• Element sheath and flange

materials to meet application

needs.

• Integral thermowells provide

convenient temperature sensor

insertion and replacement without

draining the fluid being heated.

• A standard, general purpose

(NEMA 1) terminal enclosure

offers easy access to wiring.

• Element support(s) provide

proper element spacing to

maximizing heater performance

and life.

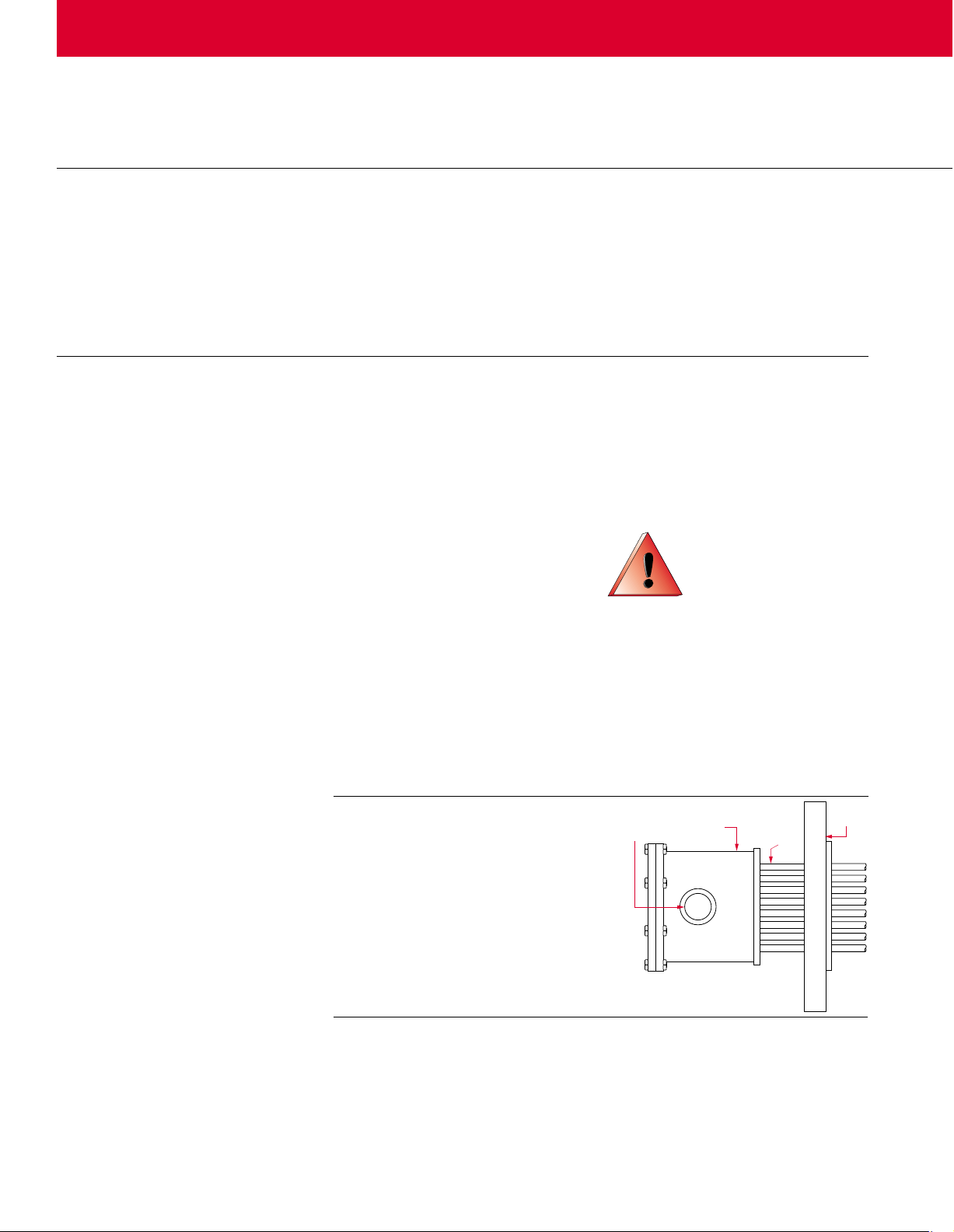

Conduit Opening

, 3, 4, 5, 6, 8, 10, 12 and 14

On stock chart units:

• Three to five working days on most heaters

• 10 working days on special voltages and/or

wattages

• 15 working days on special element lengths

Flange

Terminal Enclosure

Thermowell

FIREBAR

Heating Element

WATROD Heating Element

• To facilitate lifting, drilled and

tapped holes come supplied for

eye bolts on 10 inch and larger

flange heaters.

• All units are inspected and/or

tested to ensure element-toflange pressure seals do not leak.

• Four or six inch FIREBAR

flange heaters pack more

kilowatts in smaller bundles—in

liquid immersion applications, a

conventional 10 inch round

tubular element flange can be

replaced with a six inch FIREBAR

flange.

• WATROD hairpins are

repressed (recompacted) to

maintain MgO density, dielectric

strength, heat transfer and life.

• Branch circuits meet NEC with

48 amps per circuit maximum.

®

• UL

and CSA component

recognition under file numbers

E52951 and 31388 respectively.

See pages 268-271 for details.

Flange Heaters

Incoloy®is a registered trademark of

Special Metals Corporation.

UL®is a registered trademark of

Underwriter's Laboratories.

339

Page 2

Tubular and

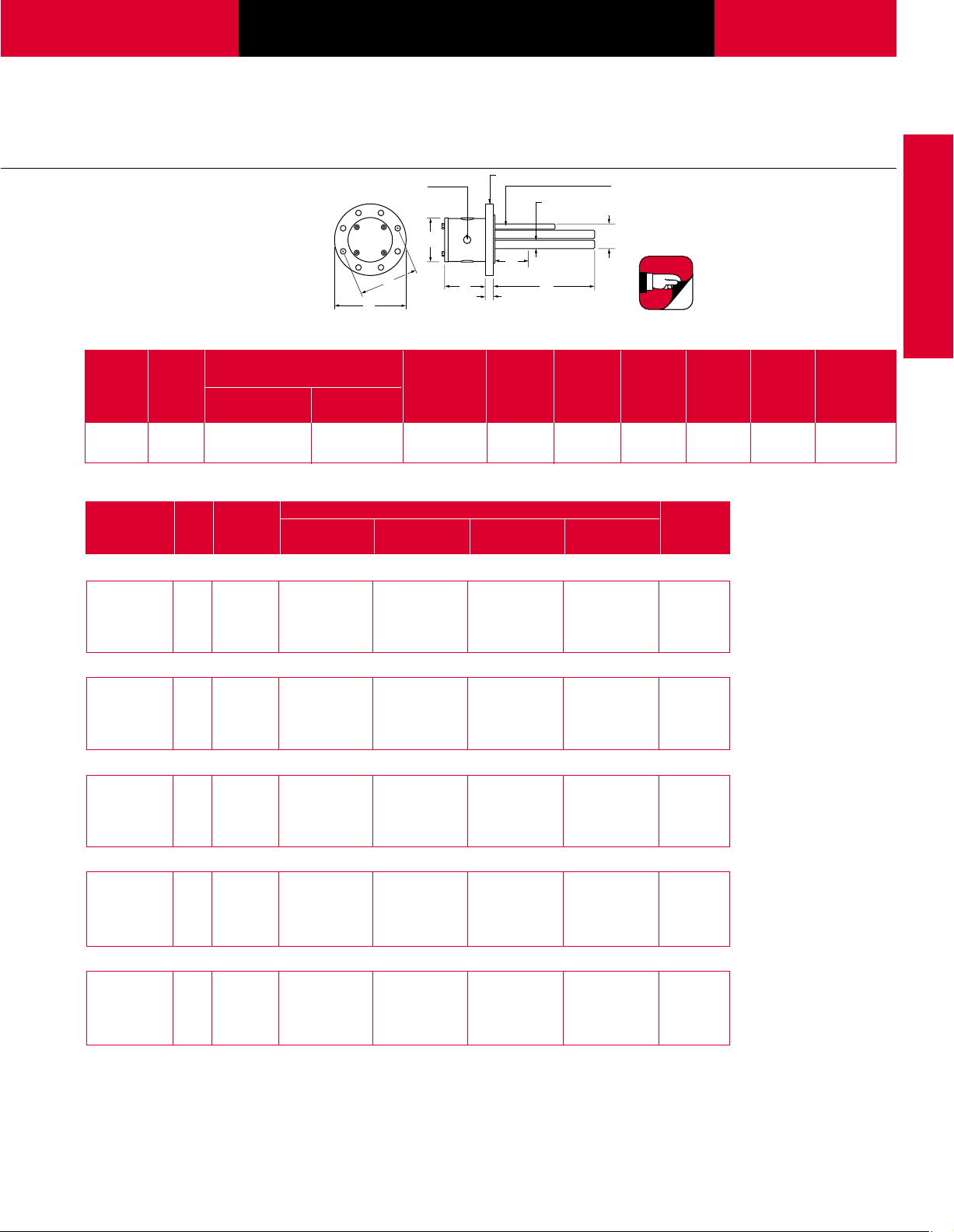

Stand-off

Terminal

Enclosure

Ref. 6"

(150 mm)

Stand-off

Height

ANSI

Flange

Conduit

Openings

Process Assemblies

Flange Immersion Heaters

Applications

• Water:

Deionized

Demineralized

Clean

Potable

Process

Options

Terminal Enclosures

General purpose terminal

enclosures, without thermostats, are

standard on all flange immersion

heaters. Optional terminal

enclosures include:

• General purpose (NEMA 1) with a

single or double pole thermostat.

• Moisture resistant (NEMA 4–

steel). Available with or without a

single or double pole thermostat.

• Corrosion resistant (NEMA 4X).

Available with or without a single

or double pole thermostat.

• Explosion resistant (NEMA 7)

class 1 groups C and D.

Available with or without a single

or double pole thermostat.

• Industrial water rinse tanks

• Vapor degreasers

• Hydraulic oil, crude, asphalt

• Lubricating oils at API specified

watt densities

• Air and gas flow

• Caustic solutions

• Explosion/moisture resistant

(NEMA 7/4) combinations.

Available with or without a single

or double pole thermostat.

• For class 1, group B enclosures,

consult your Watlow

representative.

Enclosure Enhancements

• Enclosure heater to solve

condensation and freeze

problems.

• Power distribution blocks to

facilitate power feed line wiring.

Prior to ordering, refer to the

terminal enclosure dimensions on

page 341. Order by adding the

appropriate suffix letter(s) to the

base flange heater code number, as

• Chemical baths

• Process air equipment

• Boiler equipment

• Freeze protection of any fluid

• Anti-freeze (glycol) solutions

• Paraffin

shown on the Build-a-Code chart.

Heater code numbers and suffix

letters are depicted on the Stock

and Options charts, pages 345 to

362. Specify class and group, if

applicable.

Caution

Explosion-resistant terminal

enclosures are intended to provide

explosion containment in the

electrical termination/wiring

enclosure only. No portion of the

assembly outside of this enclosure

is covered under this NEMA rating.

NEMA rating effectiveness may be

compromised by abuse or

misapplication.

Stand-off Terminal Enclosures

Stand-off terminal enclosures

provide an air-insulating barrier

between the flange and terminal

enclosure by mounting the

terminations and wiring away from

the flange. Stand-off terminal

enclosures are recommended

CSA Certified Enclosures

CSA certified moisture and/or

explosion resistant terminal

enclosures protect wiring in

hazardous gas environments.

These terminal enclosures, covered

under CSA file number 61707, are

340

whenever a process operating

temperature exceeds 400°F

(205°C). This helps minimize

terminal enclosure temperatures.

To order, specify stand-off terminal

enclosure.

available on all WATROD and

FIREBAR flange heaters. For

additional information, consult your

Watlow representative.

To order, specify CSA certified

enclosure, process temperature

(°F), maximum working pressure of

application (psig), media being

heated and heater mounting

orientation (horizontal or vertical)

and flange size.

Page 3

W A T L O W

K

E

K

E

K

E

E

K

Tubular and

Process Assemblies

Flange Immersion Heaters

Options

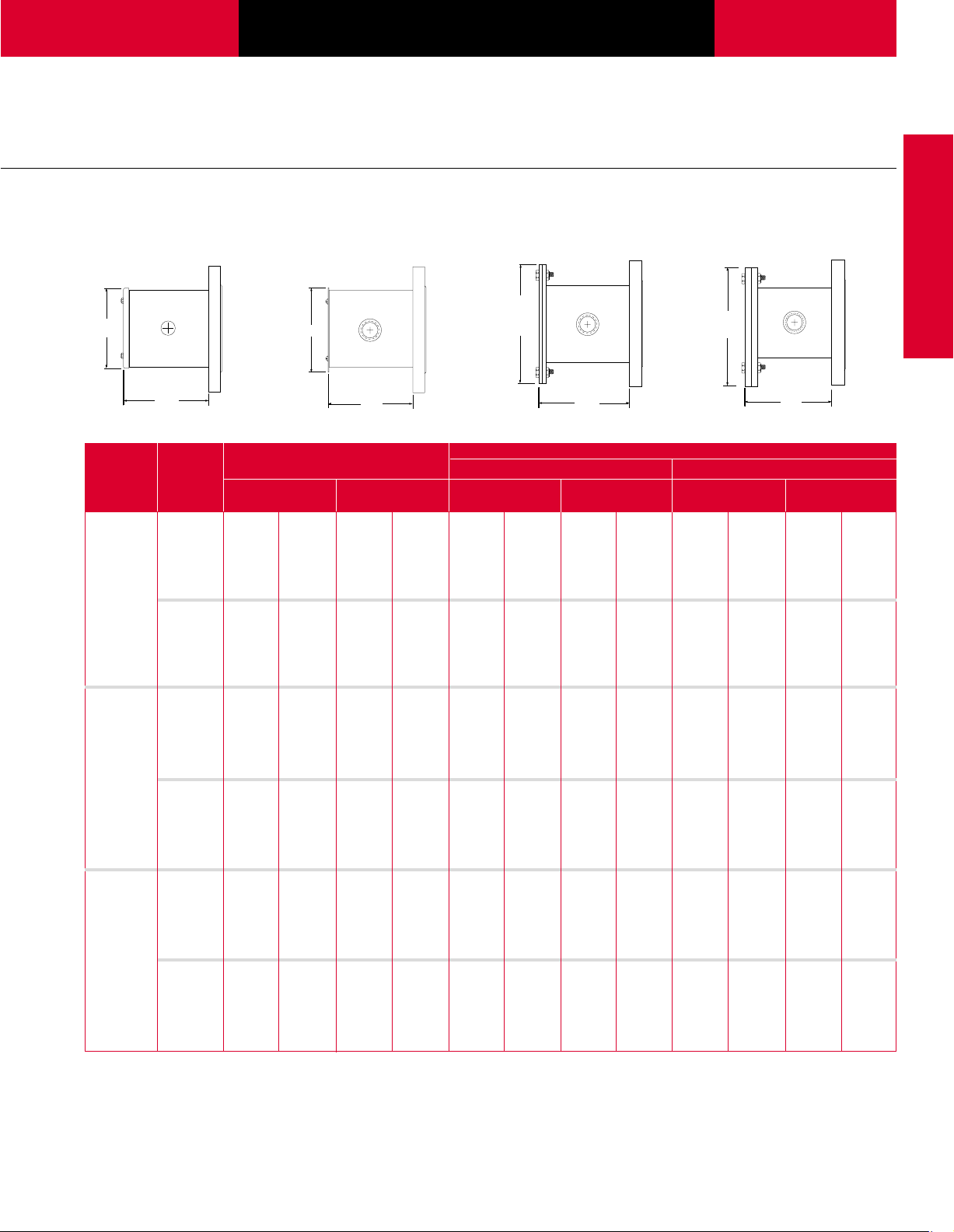

4-8 inches NEMA 1

and NEMA 4

10-14 inches

NEMA 1

10-14 inches

NEMA 4

Terminal Enclosure Dimensions

Without Thermostat With Thermostat

Enclosure Flange Single Pole Double Pole

Type Size E Dimension K Dimension E Dimension K Dimension E Dimension K Dimension

General 2➀ 1 1⁄2 (38) 3 3⁄8 (86) — — — — — — — —

Purpose 21⁄2➀ 2 1⁄8 (54) 4 (102) — — — — — — — —

(NEMA 1) 3 3 13⁄

Moisture 22

Resistant 2 1⁄2 2 5⁄8 (67) 3 1⁄2 (89) — — — — — — — —

(NEMA 4) 3 2

Explosion 23

Resistant 2

(NEMA 7) 3 7

Class 1, 4 7 1⁄8 (181) 5 3⁄4 (146) 7 1⁄8 (181) 5 3⁄4 (146) 7 1⁄8 (181) 5 3⁄4 (146)

Groups 5 7

C and D 6 7

Consult 8 7 7⁄8 (200) 12 1⁄8 (308) 7 7⁄8 (200) 12 1⁄8 (308) 7 7⁄8 (200) 12 1⁄8 (308)

Factory 10 7

for 12 7

Group B) 14 7 7⁄8 (200) 19 3⁄8 (492) 7 7⁄8 (200) 19 3⁄8 (492) 7 7⁄8 (200) 19 3⁄8 (492)

➀ Terminal enclosure is octagonal, not round.

inch inch (mm) inch (mm) inch (mm) inch (mm) inch (mm) inch (mm)

16 (97) 4

49

57

67

87

3

⁄8 (238) 7 (178) 9 3⁄8 (238) 7 (178) 9 3⁄8 (238) 7 (178)

1

⁄16 (179) 7 (178) 7 1⁄16 (179) 7 (178) 7 1⁄16 (179) 7 (178)

1

16 (179) 8 (203) 7

⁄

1

⁄16 (179) 10 1⁄32 (255) 7 1⁄16 (179) 10 1⁄32 (255) 7 1⁄16 (179) 10 1⁄32 (255)

5

8 (117) 9

⁄

3

8 (238) 7 (178) 9

⁄

1

16 (179) 8 (203) 7

⁄

10 7 1⁄16 (179) 11 5⁄8 (295) 7 1⁄16 (179) 11 5⁄8 (295) 7 1⁄16 (179) 11 5⁄8 (295)

12 7 1⁄

14 7

49

57

67

87

16 (179) 13

1

⁄16 (179) 15 1⁄8 (384) 7 1⁄16 (179) 15 1⁄8 (384) 7 1⁄16 (179) 15 1⁄8 (384)

5

⁄8 (67) 3 1⁄2 (89) — — — — — — — —

1

⁄8

3

⁄8 (238) 7 (178) 9 3⁄8 (238) 7 (178) 9 3⁄8 (238) 7 (178)

1

⁄16 (179) 7 (178) 7 1⁄16 (179) 7 (178) 7 1⁄16 (179) 7 (178)

1

⁄16

1

⁄16 (179) 10 1⁄32 (255) 7 1⁄16 (179) 10 1⁄32 (255) 7 1⁄16 (179) 10 1⁄32 (255)

1

2 (343) 7

⁄

(54) 4 (102) 9

(179) 8 (203) 7

1

16 (179) 13

⁄

3

(238) 7 (178) 9

⁄8

1

(179) 8 (203) 7

⁄16

1

2 (343) 7

⁄

10 7 3⁄4 (197) 13 3⁄4 (349) 7 3⁄4 (197) 13 3⁄4 (349) 7 3⁄4 (197) 13 3⁄4 (349)

12 7

14 7

1

⁄2

3

(197) 15

⁄4

3

⁄4 (197) 17 1⁄4 (438) 7 3⁄4 (197) 17 1⁄4 (438) 7 3⁄4 (197) 17 1⁄4 (438)

1

⁄16 (78) 3 3⁄4 (95) — — — — — — — —

1

3

⁄16

1

⁄8 (181) 5 3⁄4 (146) 7 1⁄8 (181) 5 3⁄4 (146) 7 1⁄8 (181) 5 3⁄4 (146)

7

⁄8

7

⁄8 (200) 9 7⁄8 (251) 7 7⁄8 (200) 9 7⁄8 (251) 7 7⁄8 (200) 9 7⁄8 (251)

7

⁄8 (200) 14 5⁄8 (371) 7 7⁄8 (200) 14 5⁄8 (371) 7 7⁄8 (200) 14 5⁄8 (371)

7

⁄8 (200) 15 7⁄8 (403) 7 7⁄8 (200) 15 7⁄8 (403) 7 7⁄8 (200) 15 7⁄8 (403)

(78) 3

(200) 8

7

⁄8

3

⁄4

7

⁄8

(403) 7

3

⁄4

(197) 15

7

⁄8

(403) 7

(95) — — — — — — — —

(225) 7

7

⁄8

(200) 8

7

⁄8

(225) 7

4-14 inches

NEMA 7

3

8 (238) 7 (178)

⁄

1

16 (179) 8 (203)

⁄

1

16 (179) 13

⁄

3

(238) 7 (178)

⁄8

1

(179) 8 (203)

⁄16

3

(197) 15

⁄4

7

(200) 8

⁄8

1

2 (343)

⁄

7

⁄8

7

⁄8

Flange Heaters

(403)

(225)

341

Page 4

Tubular and

Process Assemblies

Flange Immersion Heaters

Options

Thermocouples

ASTM Type J or K thermocouples

offer more accurate sensing of

process and/or sheath temperatures. A thermocouple may be

inserted into the thermowell or

attached to the heater’s sheath.

Thermocouples are supplied with

120 inch (3050 mm) leads (longer

lead lengths available). Unless

otherwise specified, thermocouples

are supplied with temperature

ranges detailed on the

Thermocouple Types chart.

Using a thermocouple requires an

appropriate temperature and power

control. These must be purchased

separately. Watlow offers a wide

variety of temperature and power

controls to meet virtually all

applications. Temperature controls

can be configured to accept

process variable inputs, too.

Thermostats

To provide process temperature

control, Watlow offers optional

single pole, single throw (SPST) and

double pole, single throw (DPST)

thermostats.

Unless otherwise specified,

Consult your Watlow representative

for details.

To order, specify Type J or K

thermocouple and lead length.

Indicate if the thermocouple is for

process temperature sensing or

heater sheath high-limit protection.

Please specify if the flange heater

will be mounted vertical or horizon-

tal in the tank. If vertical, specify if

the housing is on top or bottom.

thermostats are mounted inside the

terminal enclosure. For details

and ordering information, refer to

Thermostats on pages 423 to 425.

Please verify that the thermostat’s

sensing bulb O.D. is compatible with

the flange heater’s thermowell I.D.

If the flange heater is part of an

in-line circulation heating

application, indicate flow direction

relative to the heater’s enclosure.

RTDs

If your process requires greater

temperature sensing accuracy than

is possible with thermocouples,

Watlow can also supply RTDs in DIN

or JIS calibrations. Consult Watlow

for details.

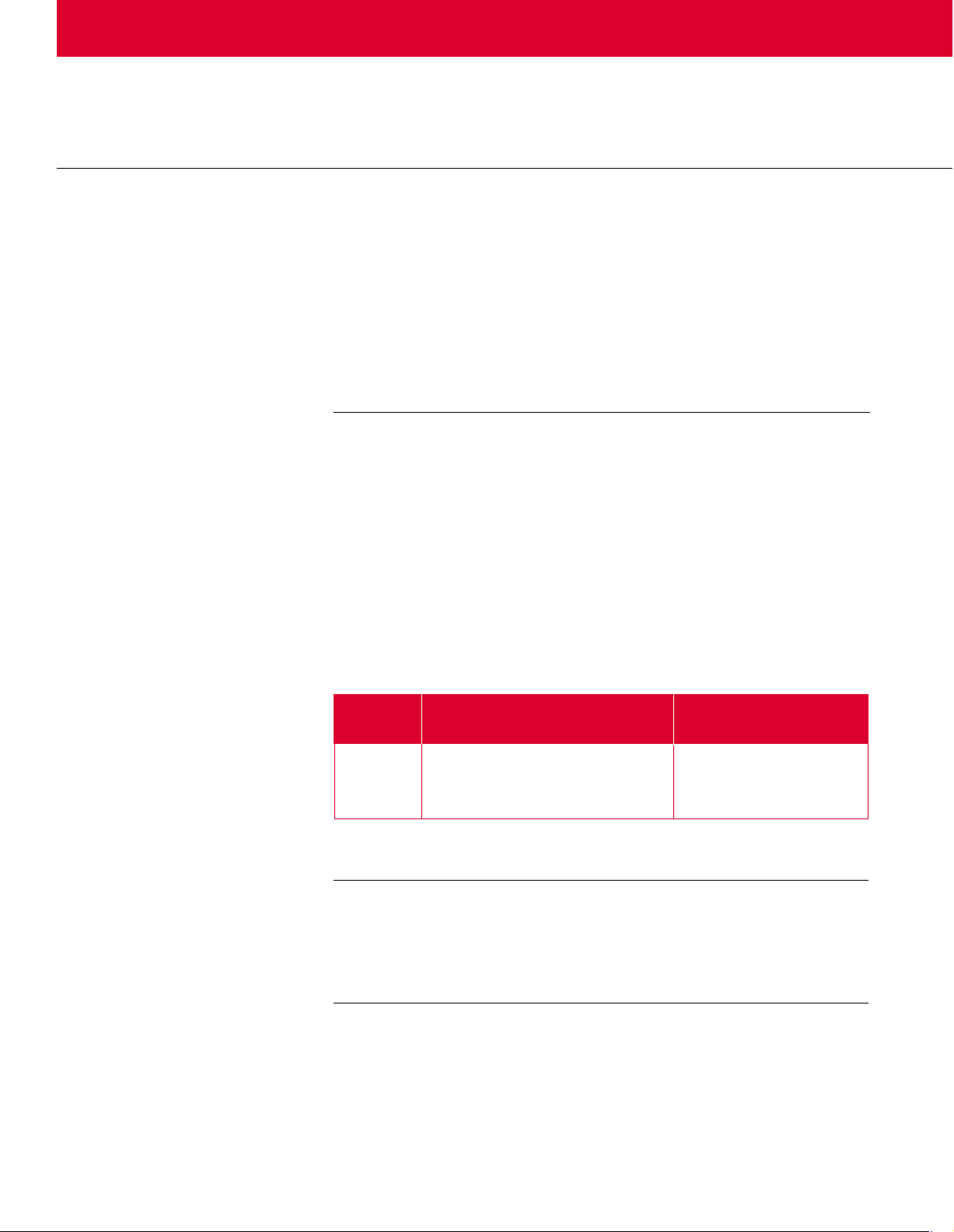

Thermocouple Types

Recommended

ASTM Conductor Characteristics Temperature Range

Type Positive Negative °F (°C)

J Iron Constantan 0 to 1000 (-20 to 540)

(Magnetic) (Non-magnetic)

K Chromel

(Non-magnetic) (Magnetic)

➀

Type J and Type K thermocouples are rated 32 to 1382°F and 32 to 2282°F (0-750°C and

0-1250°C), respectively. Watlow does not recommend exceeding temperature ranges

shown on this chart for the tubular product line.

®

Alumel

®

0 to 2000 (-20 to 1100)

➀

Wattages and Voltages

Watlow routinely supplies flange

immersion heaters with 240 to

480VÅ(ac) as well as wattages from

150 watts to one megawatt. If

®

and Chromel®are registered trademarks

Alumel

of the Hoskins Manufacturing Company.

342

required, Watlow will make heaters

with voltage up to 600VÅ(ac) and

wattage beyond one megawatt. For

more information on special voltage

Branch Circuits

Branch circuits are subdivided by

National Electrical Code (NEC)

requirements to a maximum of

and wattage configurations, consult

your Watlow representative.

48 amps per circuit. Consult factory

for circuit requirements other than

those listed in the stock charts.

Page 5

W A T L O W

Direction of Flow

Tubular and

Process Assemblies

Flange Immersion Heaters

Options

Sheath Materials

The following sheath materials are

available on WATROD and FIREBAR

flange heaters:

External Finishing

Passivation

During the manufacturing process,

particles of iron or tool steel may

become embedded in the stainless

steel or alloy sheath. If not removed,

these particles may

Standard Sheath Materials

WATROD Incoloy

FIREBAR Incoloy

corrode, produce rust spots and/or

contaminate the process. For

critical sheath applications,

passivation will remove free iron

from the sheath. To order, specify

passivation.

®

316 stainless steel

Steel

Copper

®

Made-to-Order Sheath Materials

WATROD 304 stainless steel

FIREBAR 304 stainless steel

Monel

®

Exotic Sheath Materials

Consult your Watlow representative

for details and availability.

Other Finishes

Simple belt polishing and glass

beading are available to meet

cosmetic demands. Consult factory

for details.

Flange Heaters

Flanges

Flange Sizes and Styles

Standard: 2➀, 21⁄2➀, 3, 4, 5, 6, 8, 10,

12 and 14 inch ANSI raised

face/blind flanges.

Made-to-Order: 16, 18, 20 and 24

inch in any recognized

configuration, as well as customer

specified. Over 24 inch, consult

Watlow Process Systems.

Gaskets

Rubber, asbestos-free and spiral

wound gaskets are available for all

flange sizes. Order by specifying

gasket type, flange size/rating,

process operating temperature and

pressure.

To make the correct selection, see

the Gasket Selection chart.

Baffles

For forced circulation applications,

baffles can be arranged on the

heating element bundle to enhance

and/or modify fluid or gas flow for

better heat transfer.

Flange Materials

Standard Carbon steel

316 stainless steel

304 stainless steel

Made-to-Order Exotic materials to

meet specific

application needs➁

It provides a recommended gasket

type and effective temperature

rating.

To use this chart, multiply operating

temperature by the operating

pressure to arrive at “Maximum

PSIG X °F.” This is listed in the

chart’s first column.

For open tank or convection heating

applications, standard element

supports will be supplied.

To order, specify baffles.

Pressure Classes

Standard 150 lb

Made-to-Order 300 lb

600 lb

Over 600 lb

➁

Gasket Selection

Maximum Temperature

PSIG X °F °F Gasket Type

Up to 15,000 300 Rubber

Over 250,000 700 Asbestos-Free

Over 250,000 ➂ Spiral Wound

➂ Depends on metal gasket material.

Gasket

➀ ANSI compatible only.

➁ Consult Watlow Process Systems in

Troy, Missouri.

®

is a registered trademark of

Monel

Special Metals Corporation.

343

Page 6

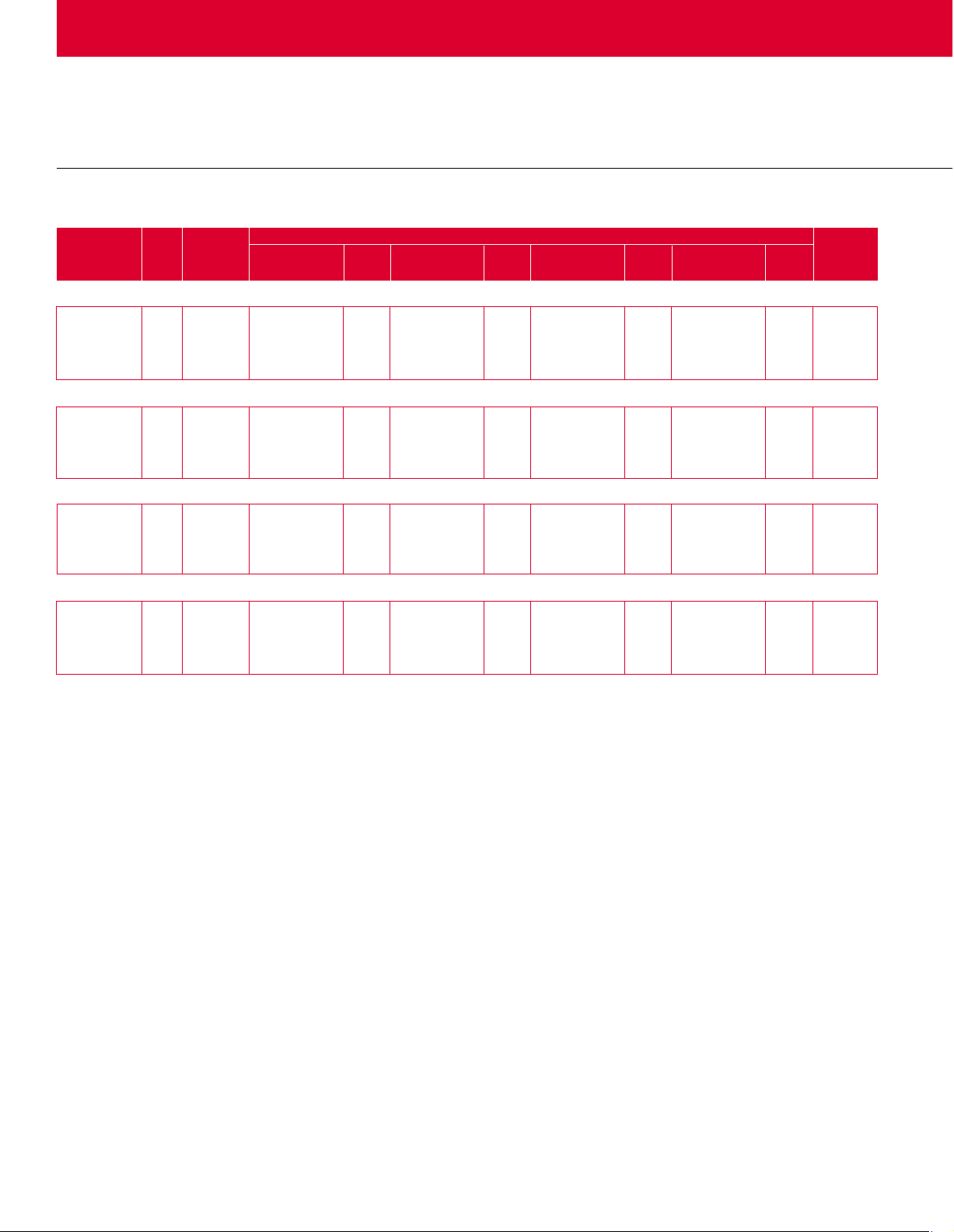

Tubular and

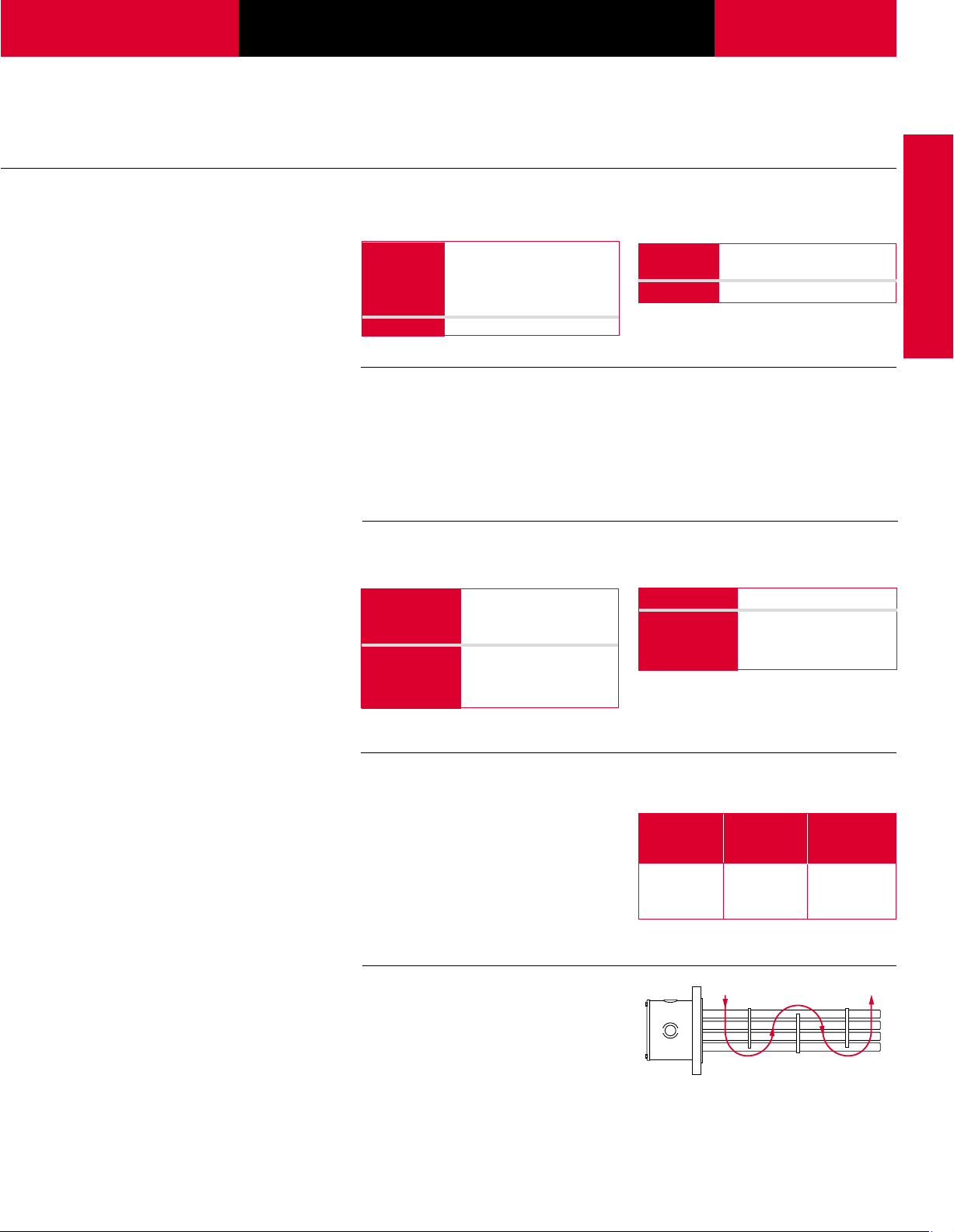

C

D

E

F

A

No-Heat Section

K

B

Immersed Length ± 1%

H

Bundle

150 lb Flange

Conduit Opening

WATROD Element

Thermowell for 0.375"

(10 mm) Diameter Bulb

No-Heat

Section

Process Assemblies

Flange Immersion Heaters

Application Hints

• Select the recommended heating

element sheath material and watt

density for the substance being

heated. Use the Supplemental

Applications Chart on pages

263 to 266. If unable to

determine the correct heating

element sheath material and type,

consult your Watlow

representative.

• Extend the element no-heat

section completely into the fluid

being heated to help prevent

premature heater failure. See

accompanying illustration for

proper no-heat section

placement.

• Locate flange heater low in the

tank, but above the sludge level.

• Choose a FIREBAR element when

your application requires a

smaller system package or lower

watt density.

• Ensure wiring integrity by keeping

terminal enclosure temperature

below 400°F (205°C).

• Keep electrical connections

clean, dry and tight.

• Minimize problems associated

with low liquid level conditions by

using low liquid level sensor or

sheath temperature high-limit

control.

• Periodically remove the flange

assembly to inspect and clean

the heating element(s). This

preventive maintenance will

reduce premature failure and

optimize heater performance.

• Refer to the Installation and

Maintenance Instructions for

correct orientation of FIREBAR

elements. This is important in air

applications with customer

supplied circulation tanks.

Correct element orientation to

flow minimizes pressure drop,

increases buoyancy force and

heater performance.

Flange Immersion Heater

➁

➀

For terminal enclosure

dimensions (K and E) see

page 341.

Flange Immersion Heater Dimensions

Flange

Element Flange

Type Size Siz e Number Length A Dimension C Dimension D Dimension F Dimension H Dimension Elements

WATROD 2➀

WATROD 2

WATROD 3

WATROD 4

WATROD 5

WATROD 6

WATROD 8

WATROD 10 1 (25) 12 18 (457) 6 (152) 14

WATROD 12 1 (25) 12 18 (457) 6 (152) 17 (432) 19 (483) 11⁄4 (32) 113⁄4 (298) 36 54

WATROD 14 1

➀ Thermowells are not provided on two and 21⁄2 inch units. 150 lb rating is not available on two and 21⁄2 inch stock units.

Note: The number and size of conduit openings will comply with the National Electrical Code standards.

344

Mounting Hole

in in (mm) in (mm) in (mm) in (mm) in (mm) in (mm) in (mm) Std Max

3

(19) 4 — — 2 (51) 4

⁄4

1

⁄2➀3⁄4 (19) 4 — — 3 (76) 51⁄2 (140) 7 (178)

3

⁄4 (19) 4 12 (305) 4 (102) 6 (152) 71⁄2 (191)

3

(19) 8 12 (305) 4 (102) 7

⁄4

7

⁄8 (22) 8 12 (305) 4 (102) 81⁄2 (216) 10 (254)

7

⁄8 (22) 8 12 (305) 4 (102) 91⁄2 (241) 11 (279) 1 (25) 6 (152) 12 15

7

(22) 8 18 (457) 6 (152) 11

⁄8

1

(29) 12 18 (457) 6 (152) 18

⁄8

Thermowell Number of

3

(121) 6 (152)

⁄4

1

(191) 9 (229)

⁄2

3

(298) 13

⁄4

1

⁄4 (362) 16 (406) 13⁄16 (30) 93⁄4 (248) 27 36

3

(476) 21 (533) 1

⁄4

1

(343) 1

⁄2

9

(14) 2 (51) 3 3

⁄16

3

⁄8 (10) 21⁄4 (57) 3 3

15

⁄16 (24) 23⁄4 (70) 3 6

15

(24) 3

⁄16

15

⁄16 (24) 5 (127) 6 9

1

(29) 7

⁄8

3

(35) 12

⁄8

7

(98) 6 6

⁄8

13

(198) 18 24

⁄16

3

(324) 45 72

⁄4

Page 7

W A T L O W

C

D

E

F

A

No-Heat Section

K

H

Bundle

1" (25 mm)

FIREBAR Element

B

Immersed Length ± 1%

150 lb Flange

1" (25 mm)

Conduit Openings

Thermowell for 0.375"

(10 mm) Diameter Bulb

Tubular and

Process Assemblies

Flange Immersion Heaters

Flange Immersion Heater Dimensions

Flange

Element Flang e Mounting Hole Thermowell

Type Size Size Number Length

in in (mm) in (mm) in (mm) in (mm) in (mm) in (mm) in (mm) Standard

3

FIREBAR 4

FIREBAR 6

⁄4 (19) 8 12 (305) 4 (102) 71⁄2 (191) 9 (229)15⁄16 (24) 37⁄8 (98) 6

7

⁄8 (22) 8 12 (305) 4 (102) 91⁄2 (241) 11 (279) 1 (25) 6 (152) 15

6" O.D. Plate Flange—WATROD Element

WATROD Immersed Code No. Est. Ship.

Description kW

B Dimension

inch (mm) 1-Phase 3-Phase 1-Phase 3-Phase lbs (kg)

Applications: Process Water, Ethylene Glycol (50%)

2

45 W/in

Steel Flange 9 29 (737) FKC29A10➁ FKC29A3 FKC29A11➁ FKC29A5 27 (13)

3-Copper

(7 W/cm2)

4.5 16 (406) FKC16A10➁ FKC16A3➁ FKC16A11➁ FKC16A5 22 (10)

Application: Process Water

2

45 W/in

Steel Flange

3-Incoloy

(7 W/cm2)

9 28 (711) FKN28A10➁ FKN28A3➁ FKN28A11➁ FKN28A5 27 (13)

®

Applications: Cooking Oils, Ethylene Glycol (100%)

2

30 W/in

Steel Flange

3-Steel

(4.7 W/cm2)

6 29 (737) FKS29A10➁ FKS29A3➁ FKS29A11➁ FKS29A5 27 (13)

Applications: Medium Weight Oils, Heat Transfer Oils, Liquid Paraffin

2

15 W/in

Steel Flange

3-Incoloy

(2.3 W/cm2)

➂

3 28 (711) FKN28A12➁ FKN28A13➁ 27 (13)

®

Applications: Medium Weight Oils, Heat Transfer Oils, Lube Oils, Liquid Paraffin

2

10 W/in

Steel Flange

3-Steel

(1.6 W/cm2)

All flange immersion heaters are Assembly

Stock unless otherwise noted.

Availability

Stock: Same day shipment

Assembly Stock: Five to seven working days

Standard: 10 working days, depending on

size

➂

2 29 (737) FKS29A12➁ FKS29A13➁ 27 (13)

240VÅ(ac) 240VÅ(ac) 480VÅ(ac) 480VÅ(ac) Weight

➁ Standard

➂ Must be operated 3-phase wye

A Dimension C Dimension D Dimension F Dimension H Dimension

Flange Heaters

For terminal enclosure

dimensions (K and E)

see page 341.

Elements

345

Page 8

Tubular and

Process Assemblies

Flange Immersion Heaters

7" O.D. Plate Flange— WA TR OD Element

WATROD Immersed Code No. Est. Ship.

Description kW

B Dimension

inch (mm) 1-Phase Circuits 3-Phase Circuits 1-Phase Circuits 3-Phase Circuits lbs (kg)

Applications: Clean and Potable Water

100 W/in

Steel Flange

3-304 SS

(15.5 W/cm2)

2

12 18 (457) FLN18A10➁ 2 FLN18A3➁ 1 FLN18A11

Applications: Clean and Potable Water

2

80 W/in

Steel Flange 18 30 (762) FLN30A10➁ 2 FLN30A3 1 FLN30A11➁ 1 FLN30A5➁ 1 27 (13)

3-304 SS

(12.4 W/cm

2

)

4 (451) FLN17N10➁ 1 FLN17N3 1 FLN17N11➁ 1 FLN17N5➁ 1 22 (10)

9173⁄

Application: Process Water

2

60 W/in

Steel Flange

3-Incoloy

(9.3 W/cm2)

4.5 121⁄2 (318) FLN12J10➁ 1 FLN12J3 1 FLN12J11➁ 1 FLN12J5➁ 1 21 (10)

®

Applications: Cooking Oils, Ethylene Glycol (100%)

30 W/in2➂ 3173⁄4 (451) FLN17N12➁ 1 FLN17N13➁ 1 22 (10)

Steel Flange 4 18 (457) FLN18A12➁ 1 FLN18A13 1 22 (10)

3-Incoloy

(4.7 W/cm2)

All flange immersion heaters are Assembly

Stock unless otherwise noted.

Availability

Stock: Same day shipment

Assembly Stock: Five to seven working days

Standard: 10 working days, depending on

size

®

6 30 (762) FLN30A12 1 FLN30A13 1 27 (13)

240VÅ(ac) No. of 240VÅ(ac) No. of 480VÅ(ac) No. of 480VÅ(ac) No. of Weight

➁

1 FLN18A5 1 22 (10)

➁

Standard

➂ Must be operated 3-phase wye

346

Page 9

W A T L O W

Tubular and

Process Assemblies

Flange Immersion Heaters

3" 150 lb ANSI Flange—WATROD Element

WATROD Immersed Code No. Est. Ship.

Description kW

Application: Clean Water

2

60 W/in

Steel Flange 9211⁄

3-Copper 12 27 (686) FMC727A3 1 FMC727A11 1 FMC727A5 1 27 (13)

(9.3 W/cm

2

)15321⁄

Application: Process Water

48 W/in2 ➄➅ 4.5 131⁄

Steel Flange 6 18 (457) FMN718A10 1 FMN718A3 1 FMN718A11 1 FMN718A5 1 23 (11)

3-Incoloy

(7.5 W/cm

®

2

)925

Applications: Forced Air and Gases, Caustic Solutions, Degreasing Solutions

23 W/in2 ➄➅ 3 18 (457) FMNA18A10 1 FMNA18A3 1 FMNA18A11 1 FMNA18A5 1 23 (11)

Steel Flange 4.5 251⁄2 (648) FMNA25J10 1 FMNA25J3 1 FMNA25J11 1 FMNA25J5 1 27 (13)

3-Incoloy

®

(3.6 W/cm2) 7.5 401⁄2 (1029) FMNA40J10 1 FMNA40J3 1 FMNA40J11 1 FMNA40J5 1 30 (14)

Applications: Lightweight Oils, Degreasing Solutions, Heat Transfer Oils

2

23 W/in

Steel Flange 4.5 25

3-Steel 6 33 (838) FMS733A10 1 FMS733A3 1 FMS733A11 1 FMS733A5 1 28 (13)

(3.6 W/cm

2

) 7.5 401⁄2 (1029) FMS740J10 1 FMS740J3 1 FMS740J11 1 FMS740J5 1 30 (14)

B Dimension

240VÅ(ac) No. of 240VÅ(ac) No. of 480VÅ(ac) No. of 480VÅ(ac) No. of Weight

inch (mm) 1-Phase Circuits 3-Phase Circuits 1-Phase Circuits 3-Phase Circuits lbs (kg)

6151⁄2 (394) FMC715J10 1 FMC715J3 1 FMC715J11 1 FMC715J5 1 22 (10)

2 (546) FMC721J10 1 FMC721J3 1 FMC721J11 1 FMC721J5 1 25 (12)

2 (826) FMC732J3 1 FMC732J11 1 FMC732J5 1 28 (13)

18 38 (965) FMC738A3 1 FMC738A11 1 FMC738A5 1 30 (14)

25 51 (1295) FMC751A11 1 FMC751A5 1 34 (16)

1

30 60

2 (1537) FMC760J11➁ 1 FMC760J5➁ 1 36 (17)

⁄

2 (343) FMN713J10 1 FMN713J3 1 FMN713J11 1 FMN713J5 1 22 (10)

2 (521) FMN720J10 1 FMN720J3 1 FMN720J11 1 FMN720J5 1 25 (12)

7.5 201⁄

1

2 (648) FMN725J10 1 FMN725J3 1 FMN725J11 1 FMN725J5 1 27 (13)

⁄

12 33 (838) FMN733A3 1 FMN733A11 1 FMN733A5 1 28 (13)

1

15 40

2 (1029) FMN740J3 1 FMN740J11 1 FMN740J5 1 30 (14)

⁄

18 48 (1219) FMN748A3 1 FMN748A11 1 FMN748A5 1 32 (15)

6 33 (838) FMNA33A10 1 FMNA33A3 1 FMNA33A11 1 FMNA33A5 1 28 (13)

9 48 (1219) FMNA48A10 1 FMNA48A3 1 FMNA48A11 1 FMNA48A5 1 32 (15)

12.5 641⁄2 (1638) FMNA64J3 1 FMNA64J11 1 FMNA64J5 1 37 (17)

15 77 (1956) FMNA77A3 1 FMNA77A11 1 FMNA77A5 1 42 (19)

3 18 (457) FMS718A10 1 FMS718A3 1 FMS718A11 1 FMS718A5 1 23 (11)

1

(648) FMS725J10 1 FMS725J3 1 FMS725J11 1 FMS725J5 1 27 (13)

⁄2

9 48 (1219) FMS748A10 1 FMS748A3 1 FMS748A11 1 FMS748A5 1 32 (15)

12.5 641⁄2 (1638) FMS764J3 1 FMS764J11 1 FMS764J5 1 37 (17)

15 77 (1956) FMS777A3 1 FMS777A11 1 FMS777A5 1 42 (19)

CONTINUED

Flange Heaters

All flange immersion heaters are Assembly

Stock unless otherwise noted.

Availability

Stock: Same day shipment

Assembly Stock: Five to seven working days

Standard: 10 working days, depending on

size

➁ Standard

➄ 240VÅ(ac) 3-phase can be rewired wye to

produce 1⁄3 more kW and watt density when

operated at 480VÅ(ac) 3-phase.

➅ Can be rewired wye to produce 1⁄3 of the

original kW and watt density (3-phase only).

347

Page 10

Tubular and

Process Assemblies

Flange Immersion Heaters

3" 150 lb ANSI Flange—WATROD Element

WATROD Immersed Code No. Est. Ship.

Description kW

Applications: Medium Weight Oils, Heat Transfer Oils, Liquid Paraffin

16 W/in2➂ 1.5 131⁄2 (343) FMN713J12 1 FMN713J13 1 22 (10)

Steel Flange 2 18 (457) FMN718A12 1 FMN718A13 1 23 (11)

3-Incoloy

(2.5 W/cm

®

2

)325

Applications: Bunker C and #6 Fuel Oils

8 W/in2➂ 2 33 (838) FMS733A12 1 FMS733A13 1 28 (13)

Steel Flange 3 48 (1219) FMS748A12 1 FMS748A13 1 32 (15)

3-Steel 4641⁄2 (1638) FMS764J12 1 FMS764J13 1 37 (17)

(1.3 W/cm2) 5 77 (1956) FMS777A12 1 FMS777A13 1 42 (19)

B Dimension

240VÅ(ac) No. of 240VÅ(ac) No. of 480VÅ(ac) No. of 480VÅ(ac) No. of Weight

inch (mm) 1-Phase Circuits 3-Phase Circuits 1-Phase Circuits 3-Phase Circuits lbs (kg)

2 (521) FMN720J12 1 FMN720J13 1 25 (12)

2.5 201⁄

1

⁄2 (648) FMN725J12 1 FMN725J13 1 27 (13)

4 33 (838) FMN733A12 1 FMN733A13 1 30 (14)

2 (1029) FMN740J12 1 FMN740J13 1 30 (14)

5401⁄

6 48 (1219) FMN748A12 1 FMN748A13 1 33 (15)

4" 150 Lb ANSI Flange—WATROD Element

WATROD Immersed Code No. Est. Ship.

Description kW

B Dimension

inch (mm) 1-Phase Circuits 3-Phase Circuits 1-Phase Circuits 3-Phase Circuits lbs (kg)

Application: Clean Water

2

60 W/in

Steel Flange 18 21

12 151⁄2(394) FOC715J10 2 FOC715J3 1 FOC715J11 1 FOC715J5 1 31 (14)

1

⁄2(546) FOC721J10 2 FOC721J3 1 FOC721J11 1 FOC721J5 1 34 (16)

6-Copper 24 27 (686) FOC727A10 2 FOC727A3 2 FOC727A11 1 FOC727A5 1 36 (17)

(9.3 W/cm

2

)3032

1

(826) FOC732J3 2 FOC732J11 2 FOC732J5 1 39 (18)

⁄

2

36 38 (965) FOC738A3 2 FOC738A11 2 FOC738A5 1 43 (20)

50 51 (1295) FOC751A5 2 48 (22)

1

(1537) FOC760J5

⁄

60 60

2

Application: Deionized Water , Demineralized Water

2

60 W/in

316 SS Flange 18 22 (559) FOR722A10 2 FOR722A3 1 FOR722A11 1 FOR722A5 1 34 (16)

6-316 SS 24 27

(9.3 W/cm

Passivated 36 38

All flange immersion heaters are Assembly

Stock unless otherwise noted.

Availability

Stock: Same day shipment

Assembly Stock: Five to seven working days

Standard: 10 working days, depending on

size

12 16 (406) FOR716A10 1 FOR716A3 1 FOR716A11 1 FOR716A5 1 31 (14)

1

2

) 30 33 (838) FOR733A3 2 FOR733A11 2 FOR733A5 1 39 (18)

⁄2(699) FOR727J10 2 FOR727J3 2 FOR727J11 1 FOR727J5 1 36 (17)

1

⁄2(978) FOR738J3 2 FOR738J11 2 FOR738J5 1 43 (20)

1

⁄2(1308) FOR751J5 2 53 (25)

50 51

60 61 (1549) FOR761A5 2 56 (26)

240VÅ(ac) No. of 240VÅ(ac) No. of 480VÅ(ac) No. of 480VÅ(ac) No. of Weight

➁

2 52 (24)

CONTINUED

➁ Standard

➂ Must be operated 3-phase wye

348

Page 11

W A T L O W

Tubular and

Process Assemblies

Flange Immersion Heaters

4" 150 lb ANSI Flange—WATROD Element

WATROD Immersed Code No. Est. Ship.

Description kW

Application: Process Water

2

48 W/in

➄

Steel Flange 12 18 (457) FON718A10 2 FON718A3 1 FON718A11 1 FON718A5 1 32 (15)

6-Incoloy

(7.5 W/cm

®

2

)1825

Applications: Forced Air and Gases, Caustic Solutions, Degreasing Solutions

2

23 W/in

➄➅

Steel Flange 925

6-Incoloy

(3.6 W/cm

®

2

)1540

Applications: Lightweight Oils, Degreasing Solutions, Heat Transfer Oils

2

23 W/in

Steel Flange 925

6-Steel 12 33 (838) FOS733A10 2 FOS733A3 1 FOS733A11 1 FOS733A5 1 39 (18)

2

(3.6 W/cm

)1540

Applications: Medium Weight Oils, Heat Transfer Oils, Liquid Paraffin

2

16 W/in

➂

Steel Flange 4 18 (457) FON718A12 1 FON718A13 1 32 (15)

6-Incoloy

(2.5 W/cm

®

2

)625

Applications: Bunker C and #6 Fuel Oils

2

8 W/in

➂

Steel Flange 6 48 (1219) FOS748A12 1 FOS748A13 1 48 (22)

6-Steel 864

(1.3 W/cm

All flange immersion heaters are Assembly

Stock unless otherwise noted.

Availability

Stock: Same day shipment

Assembly Stock: Five to seven working days

Standard: 10 working days, depending on

size

2

) 10 77 (1956) FOS777A12 1 FOS777A13 1 61 (28)

B Dimension

240VÅ(ac) No. of 240VÅ(ac) No. of 480VÅ(ac) No. of 480VÅ(ac) No. of Weight

inch (mm) 1-Phase Circuits 3-Phase Circuits 1-Phase Circuits 3-Phase Circuits lbs (kg)

9131⁄2(343) FON713J10 1 FON713J3 1 FON713J11 1 FON713J5 1 29 (14)

2

15 201⁄

(521) FON720J10 2 FON720J3 1 FON720J11 1 FON720J5 1 34 (16)

1

⁄2(648) FON725J10 2 FON725J3 1 FON725J11 1 FON725J5 1 36 (17)

24 33 (838) FON733A10 2 FON733A3 2 FON733A11 1 FON733A5 1 39 (18)

1

30 40

2

(1029) FON740J3 2 FON740J11 2 FON740J5 1 43 (20)

⁄

36 48 (1219) FON748A3 2 FON748A11 2 FON748A5 1 48 (22)

6 18 (457) FONA18A10 1 FONA18A3 1 FONA18A11 1 FONA18A5 1 32 (15)

1

2

(648) FONA25J10 1 FONA25J3 1 FONA25J11 1 FONA25J5 1 36 (17)

⁄

12 33 (838) FONA33A10 2 FONA33A3 1 FONA33A11 1 FONA33A5 1 39 (18)

1

2

(1029) FONA40J10 2 FONA40J3 1 FONA40J11 1 FONA40J5 1 43 (20)

⁄

18 48 (1219) FONA48A10 2 FONA48A3 1 FONA48A11 1 FONA48A5 1 48 (22)

1

25 64

⁄2(1638) FONA64J3 2 FONA64J11 2 FONA64J5 1 53 (24)

30 77 (1956) FONA77A3 2 FONA77A11 2 FONA77A5 1 61 (28)

6 18 (457) FOS718A10 1 FOS718A3 1 FOS718A11 1 FOS718A5 1 32 (15)

1

⁄2(648) FOS725J10 1 FOS725J3 1 FOS725J11 1 FOS725J5 1 36 (17)

1

2

(1029) FOS740J10 2 FOS740J3 1 FOS740J11 1 FOS740J5 1 43 (20)

⁄

18 48 (1219) FOS748A10 2 FOS748A3 1 FOS748A11 1 FOS748A5 1 48 (22)

1

25 64

⁄2(1638) FOS764J3 2 FOS764J11 2 FOS764J5 1 53 (24)

30 77 (1956) FOS777A3 2 FOS777A11 2 FOS777A5 1 61 (28)

3131⁄2(343) FON713J12 1 FON713J13 1 29 (14)

5201⁄

(521) FON720J12 1 FON720J13 1 34 (16)

2

1

⁄2(648) FON725J12 1 FON725J13 1 36 (17)

8 33 (838) FON733A12 1 FON733A13 1 39 (18)

1

10 40

(1029) FON740J12 1 FON740J13 1 43 (20)

⁄

2

12 48 (1219) FON748A12 1 FON748A13 1 48 (22)

5401⁄2(1029) FOS740J12 1 FOS740J13 1 43 (20)

1

⁄2(1638) FOS764J12 1 FOS764J13 1 53 (24)

➂

Must be operated 3-phase wye

➄ 240VÅ(ac) 3-phase can be rewired wye to

produce

1

⁄3 more kW and watt density when

➅ Can be rewired wye to produce

original kW and watt density

(3-phase only).

1

⁄3 of the

operated at 480VÅ(ac) 3-phase.

Flange Heaters

349

Page 12

Tubular and

Process Assemblies

Flange Immersion Heaters

4" 150 lb ANSI Flange—FIREBAR Element

FIREBAR Immersed Code No. Est. Ship.

Description kW B Dimension 240V

Å(ac)

No. of 480V

inch (mm) 3-Phase Circuits 3-Phase Circuits lbs (kg)

Applications: Process Water, Ethylene Glycol (50%)

2

45 W/in

304 SS Flange 15 16 (406) FONF16A27 1 35 (20)

6-Incoloy

2

(7 W/cm

)2422

12 133⁄8 (340) FONF13G27 1 32 (20)

®

18 183⁄

30 277⁄

36 32

48 42

60 51

8 (467) FONF18G27 1 38 (21)

7

⁄8 (581) FONF22R27 2 FONF22R28 1 41 (21)

8 (708) FONF27R27 2 FONF27R28 1 44 (20)

7

⁄8 (835) FONF32R27 2 FONF32R28 1 46 (21)

3

⁄8 (1076) FONF42G28 2 50 (23)

7

8 (1318) FONF51R28 2 54 (25)

⁄

Applications: Cooking Oils, Ethylene Glycol (100%)

30 W/in2➂ 10 161⁄

304 SS Flange 13 19

6-Incoloy

®

17 241⁄2 (622) FONF24J12 1 FONF24J13 1 41 (19)

(4.7 W/cm2) 21 30 (762) FONF30A12 2 FONF30A13 1 44 (20)

25.5 35 (889) FONF35A12 2 FONF35A13 1 46 (21)

34 451⁄2 (1156) FONF45J12 2 FONF45J13 1 50 (23)

43 56 (1422) FONF56A13 2 54 (25)

2 (420) FONF16J12 1 FONF16J13 1 35 (16)

1

2 (495) FONF19J12 1 FONF19J13 1 38 (17)

⁄

Applications: Heat Transfer Oils, Mineral Oils, Degreasing Solutions

23 W/in2➇

304 SS Flange 10 191⁄2 (495) FONF19J20 1 38 (18)

6-Incoloy

(3.6 W/cm

®

2

7.5 161⁄2 (419) FONF16J20 1 35 (16)

12.8 241⁄

2 (622) FONF24J20 1 FONF24J19 1 41 (19)

) 15.8 30 (762) FONF30A20 1 FONF30A19 1 44 (20)

19 35 (889) FONF35A20 1 FONF35A19 1 46 (21)

25 451⁄2 (1156) FONF45J20 2 FONF45J19 1 50 (23)

32.3 56 (1422) FONF56A20 2 FONF56A19 1 54 (25)

Applications: Medium Weight Oils, Heat Transfer Oils, Lube Oils, Liquid Paraffin

15 W/in2➂ 4133⁄8 (340) FONF13G29 1 32 (15)

304 SS Flange 5 16 (406) FONF16A29 1 35 (16)

6-Incoloy

(2.3 W/cm

®

2

6183⁄8

)822

7

⁄8 (581) FONF22R29 1 FONF22R30 1 41 (19)

(467) FONF18G29 1 38 (18)

10 277⁄8 (708) FONF27R29 1 FONF27R30 1 44 (20)

12 327⁄8 (835) FONF32R29 1 FONF32R30 1 46 (21)

16 42

20 51

3

(1076) FONF42G29 1 FONF42G30 1 50 (23)

⁄8

7

(1318) FONF51R29 1 FONF51R30 1 54 (25)

⁄8

Applications: Bunker C and #6 Fuel Oils, Asphalt

8 W/in2➂ 2.5 161⁄2 (419) FONF16J22 1 35 (16)

(495) FONF19J22 1 38 (17)

304 SS Flange 3.25 191⁄

6-Incoloy

®

(1.3 W/cm2) 5.25 30 (762) FONF30A22 1 FONF30A21 1 44 (20)

10.75 56 (1422) FONF56A22 1 FONF56A21 1 54 (25)

All flange immersion heaters are Assembly

Stock unless otherwise noted.

Availability

Stock: Same day shipment

Assembly Stock: Five to seven working days

Standard: 10 working days, depending on

size

2

4.25 241⁄2 (622) FONF24J22 1 FONF24J21 1 41 (19)

6.38 35 (889) FONF35A22 1 FONF35A21 1 46 (21)

8.5 451⁄2 (1156) FONF45J22 1 FONF45J21 1 50 (23)

➂ Must be operated 3-phase wye

➇ Can be rewired for 1-phase

Å(ac)

No. of Weight

350

Page 13

W A T L O W

Tubular and

Process Assemblies

Flange Immersion Heaters

5" 150 lb ANSI Flange—WATROD Element

WATROD Immersed Code No. Est. Ship.

Description kW

B Dimension

inch (mm) 1-Phase Circuits 3-Phase Circuits 1-Phase Circuits 3-Phase Circuits lbs (kg)

Application: Clean Water

2

60 W/in

12 151⁄

Steel Flange 18 21

6-Copper 24 27 (686) FNC727A10 3 FNC727A3 2 FNC727A11 3 FNC727A5 1 40 (19)

(9.3 W/cm2)30321⁄

36 38 (965) FNC738A3 2 FNC738A11 2 FNC738A5 1 47 (22)

50 51 (1295) FNC751A5 2 52 (24)

60 60

2

60 W/in

18 151⁄2 (394) FNC715J10X 3 FNC715J3X 1 FNC715J11X 1 FNC715J5X 1 38 (18)

Steel Flange 27 211⁄

9-Copper 36 27 (686) FNC727A3X 3 FNC727A11X 3 FNC727A5X 1 45 (21)

(9.3 W/cm

2

)45321⁄2 (826) FNC732J3X 3 FNC732J11X 3 FNC732J5X 3 48 (22)

54 38 (965) FNC738A3X 3 FNC738A11X 3 FNC738A5X 3 53 (24)

75 51 (1295) FNC751A5X 3 60 (28)

90 601⁄

2 (394) FNC715J10 2 FNC715J3 1 FNC715J11 1 FNC715J5 1 35 (16)

1

⁄2 (546) FNC721J10 2 FNC721J3 1 FNC721J11 1 FNC721J5 1 38 (18)

2 (826) FNC732J3 2 FNC732J11 2 FNC732J5 1 43 (20)

1

2 (1537) FNC760J5➁ 2 56 (26)

⁄

2 (546) FNC721J10X 3 FNC721J3X 3 FNC721J11X 3 FNC721J5X 1 42 (19)

2 (1537) FNC760J5X

Application: Process Water

48 W/in2➄ 9131⁄

Steel Flange 12 18 (457) FNN718A10 2 FNN718A3 1 FNN718A11 1 FNN718A5 1 36 (17)

6-Incoloy

®

15 201⁄2 (521) FNN720J10 2 FNN720J3 1 FNN720J11 1 FNN720J5 1 38 (18)

(7.5 W/cm2)18251⁄

24 33 (838) FNN733A10 3 FNN733A3 2 FNN733A11 3 FNN733A5 1 43 (20)

30 40

36 48 (1219) FNN748A3 2 FNN748A11 2 FNN748A5 1 52 (24)

2

48 W/in

14 131⁄

Steel Flange 18 18 (457) FNN718A10X 3 FNN718A3X 1 FNN718A11X 1 FNN718A5X 1 39 (18)

9-Incoloy

®

23 201⁄2 (521) FNN720J10X 3 FNN720J3X 3 FNN720J11X 1 FNN720J5X 1 42 (19)

(7.5 W/cm2)27251⁄2 (648) FNN725J10X 3 FNN725J3X 3 FNN725J11X 3 FNN725J5X 1 45 (21)

36 33 (838) FNN733A3X 3 FNN733A11X 3 FNN733A5X 1 48 (22)

45 401⁄2 (1029) FNN740J3X 3 FNN740J11X 3 FNN740J5X 3 53 (24)

54 48 (1219) FNN748A3X 3 FNN748A11X 3 FNN748A5X 3 60 (28)

2 (343) FNN713J10 1 FNN713J3 1 FNN713J11 1 FNN713J5 1 33 (15)

2 (648) FNN725J10 2 FNN725J3 1 FNN725J11 1 FNN725J5 1 40 (19)

1

⁄2 (1029) FNN740J3 2 FNN740J11 2 FNN740J5 1 47 (22)

2 (343) FNN713J10X 3 FNN713J3X 1 FNN713J11X 1 FNN713J5X 1 35 (16)

Applications: Forced Air and Gases, Caustic Solutions, Degreasing Solutions

23 W/in2➄➅ 6 18 (457) FNNA18A10 1 FNNA18A3 1 FNNA18A11 1 FNNA18A5 1 36 (17)

Steel Flange 925

6-Incoloy

®

12 33 (838) FNNA33A10 2 FNNA33A3 1 FNNA33A11 1 FNNA33A5 1 43 (20)

(3.6 W/cm2)15401⁄2 (1029) FNNA40J10 2 FNNA40J3 1 FNNA40J11 1 FNNA40J5 1 47 (22)

18 48 (1219) FNNA48A10 2 FNNA48A3 1 FNNA48A11 1 FNNA48A5 1 52 (24)

25 641⁄2 (1638) FNNA64J3 2 FNNA64J11 2 FNNA64J5 1 57 (26)

30 77 (1956) FNNA77A3 2 FNNA77A11 2 FNNA77A5 1 65 (28)

1

(648) FNNA25J10 1 FNNA25J3 1 FNNA25J11 1 FNNA25J5 1 40 (19)

⁄2

240VÅ(ac) No. of 240VÅ(ac) No. of 480VÅ(ac) No. of 480VÅ(ac) No. of Weight

➁

3 66 (30)

CONTINUED

Flange Heaters

All flange immersion heaters are Assembly

Stock unless otherwise noted.

Availability

Stock: Same day shipment

Assembly Stock: Five to seven working days

Standard: 10 working days, depending on size

➁ Standard

➄ 240VÅ(ac) 3-phase can be rewired wye to

1

3 more kW and watt density when

produce

⁄

operated at 480VÅ(ac) 3-phase.

➅

Can be rewired wye to produce 1⁄3 of the

original kW and watt density

(3-phase only).

351

Page 14

Tubular and

Process Assemblies

Flange Immersion Heaters

5" 150 lb ANSI Flange—WATROD Element

WATROD Immersed Code No. Est. Ship.

Description kW

B Dimension

inch (mm) 1-Phase Circuits 3-Phase Circuits 1-Phase Circuits 3-Phase Circuits lbs (kg)

Applications: Forced Air and Gases, Caustic Solutions, Degreasing Solutions

2

23 W/in

Steel Flange 14 251⁄

9-Incoloy

9 18 (457) FNNA18A10X 1 FNNA18A3X 1 FNNA18A11X 1 FNNA18A5X 1 39 (18)

®

18 33 (838) FNNA33A10X 3 FNNA33A3X 1 FNNA33A11X 1 FNNA33A5X 1 48 (22)

2 (648) FNNA25J10X 3 FNNA25J3X 1 FNNA25J11X 1 FNNA25J5X 1 45 (21)

(3.6 W/cm2)23401⁄2 (1029) FNNA40J10X 3 FNNA40J3X 3 FNNA40J11X 1 FNNA40J5X 1 53 (24)

27 48 (1219) FNNA48A10X 3 FNNA48A3X 3 FNNA48A11X 3 FNNA48A5X 1 60 (28)

38 641⁄

2 (1638) FNNA64J3X 3 FNNA64J11X 3 FNNA64J5X 1 68 (31)

45 77 (1956) FNNA77A3X 3 FNNA77A11X 3 FNNA77A5X 3 78 (36)

Applications: Lightweight Oils, Degreasing Solutions, Heat Transfer Oils

2

23 W/in

Steel Flange 9251⁄

6 18 (457) FNS718A10 1 FNS718A3 1 FNS718A11 1 FNS718A5 1 36 (17)

2 (648) FNS725J10 1 FNS725J3 1 FNS725J11 1 FNS725J5 1 40 (18)

6-Steel 12 33 (838) FNS733A10 2 FNS733A3 1 FNS733A11 1 FNS733A5 1 43 (20)

(3.6 W/cm

2

)15401⁄

2 (1029) FNS740J10 2 FNS740J3 1 FNS740J11 1 FNS740J5 1 47 (22)

18 48 (1219) FNS748A10 2 FNS748A3 3 FNS748A11 1 FNS748A5➀ 1 52 (24)

25 64

1

⁄2 (1638) FNS764J3 2 FNS764J11 2 FNS764J5 1 57 (26)

30 77 (1956) FNS777A3 2 FNS777A11 2 FNS777A5 1 65 (30)

2

23 W/in

9 18 (457) FNS718A10X 1 FNS718A3X 1 FNS718A11X 1 FNS718A5X 1 39 (18)

Steel Flange 14 251⁄2 (648) FNS725J10X 3 FNS725J3X 1 FNS725J11X 1 FNS725J5X 1 45 (21)

9-Steel 18 33 (838) FNS733A10X 3 FNS733A3X 1 FNS733A11X 1 FNS733A5X 1 48 (22)

(3.6 W/cm2)23401⁄2 (1029) FNS740J10X 3 FNS740J3X 3 FNS740J11X 1 FNS740J5X 1 53 (24)

27 48 (1219) FNS748A10X 3 FNS748A3X 1 FNS748A11X 3 FNS748A5X 1 60 (28)

38 641⁄

2 (1638) FNS764J3X 3 FNS764J11X 3 FNS764J5X 1 68 (31)

45 77 (1956) FNS777A3X 3 FNS777A11X 3 FNS777A5X 3 78 (36)

Applications: Medium Weight Oils, Heat Transfer Oils, Liquid Paraffin

16 W/in2➂ 3131⁄2 (343) FNN713J12 1 FNN713J13 1 36 (17)

Steel Flange 4 18 (457) FNN718A12 1 FNN718A13 1 40 (18)

6-Incoloy

(2.5 W/cm2)625

16 W/in

Steel Flange 6 18 (457) FNN718A12X 1 FNN718A13X 1 45 (21)

9-Incoloy

(2.5 W/cm

®

5201⁄2 (521) FNN720J12 1 FNN720J13 1 43 (20)

1

⁄2 (648) FNN725J12 1 FNN725J13 1 47 (22)

8 33 (838) FNN733A12 1 FNN733A13 1 52 (24)

10 401⁄2 (1029) FNN740J12 1 FNN740J13 1 57 (26)

12 48 (1219) FNN748A12 1 FNN748A13 1 65 (30)

2

➂ 4.5 131⁄2 (343) FNN713J12X 1 FNN713J13X 1 39 (18)

®

7.5 201⁄2 (521) FNN720J12X 1 FNN720J13X 1 48 (22)

2

)925

1

⁄2 (648) FNN725J12X 1 FNN725J13X 1 53 (24)

12 33 (838) FNN733A12X 1 FNN733A13X 1 60 (28)

15 40

1

⁄2 (1029) FNN740J12X 1 FNN740J13X 1 68 (31)

18 48 (1219) FNN748A12X 1 FNN748A13X 1 78 (36)

240VÅ(ac) No. of 240VÅ(ac) No. of 480VÅ(ac) No. of 480VÅ(ac) No. of Weight

CONTINUED

All flange immersion heaters are Assembly

Stock unless otherwise noted.

Availability

Stock: Same day shipment

Assembly Stock: Five to seven working days

Standard: 10 working days, depending on

size

352

a Stock

c Must be operated 3-phase wye

Page 15

W A T L O W

Tubular and

Process Assemblies

Flange Immersion Heaters

5" 150 lb ANSI Flange—WATROD Element

WATROD Immersed Code No. Est. Ship.

Description kW

B Dimension

inch (mm) 1-Phase Circuits 3-Phase Circuits 1-Phase Circuits 3-Phase Circuits lbs (kg)

Applications: Bunker C and #6 Fuel Oils

8 W/in2➂ 5401⁄2 (1029) FNS740J12 1 FNS740J13 1 47 (22)

Steel Flange 6 48 (1219) FNS748A12 1 FNS748A13 1 52 (24)

6-Steel 8641⁄2 (1638) FNS764J12 1 FNS764J13 1 57 (26)

(1.3 W/cm2) 10 77 (1956) FNS777A12 1 FNS777A13 1 65 (30)

8 W/in2➂ 7.5 401⁄

2 (1029) FNS740J12X 1 FNS740J13X 1 53 (24)

Steel Flange 9 48 (1219) FNS748A12X 1 FNS748A13X 1 60 (28)

9-Steel 12 64

(1.3 W/cm

2

) 15 77 (1956) FNS777A12X 1 FNS777A13X 1 78 (36)

1

2 (1638) FNS764J12X 1 FNS764J13X 1 68 (31)

⁄

6" 150 lb ANSI Flange—WATROD Element

WATROD Immersed Code No. Est. Ship.

Description kW

B Dimension

inch (mm) 1-Phase Circuits 3-Phase Circuits 1-Phase Circuits 3-Phase Circuits lbs (kg)

240VÅ(ac) No. of 240VÅ(ac) No. of 480VÅ(ac) No. of 480VÅ(ac) No. of Weight

240VÅ(ac) No. of 240VÅ(ac) No. of 480VÅ(ac) No. of 480VÅ(ac) No. of Weight

Flange Heaters

Application: Clean Water

2

60 W/in

24 153⁄

Steel Flange 36 21

12-Copper 48 267⁄8 (683) FPC726R3 4 FPC726R11 3 FPC726R5 2 81 (37)

(9.3 W/cm2)6032

72 37

100 507⁄8 (1292) FPC750R5 4 100 (45)

120 603⁄8

2

60 W/in

30 153⁄8 (391) FPC715G10X 3 FPC715G3X 5 FPC715G11X 3 FPC715G5X 1 76 (35)

Steel Flange 45 213⁄8 (543) FPC721G10X 5 FPC721G3X 5 FPC721G11X 3 FPC721G5X 5 82 (38)

15-Copper 60 267⁄8 (683) FPC726R3X 5 FPC726R11X 3 FPC726R5X 5 85 (39)

(9.3 W/cm2)7532

90 37

125 50

150 603⁄8 (1534) FPC760G5X➁ 5 120 (55)

8 (391) FPC715G10 3 FPC715G3 2 FPC715G11 2 FPC715G5 1 73 (33)

3

⁄8 (543) FPC721G10 4 FPC721G3 2 FPC721G11 2 FPC721G5 1 78 (36)

3

8 (822) FPC732G3 4 FPC732G11 3 FPC732G5 2 85 (39)

⁄

7

⁄8 (962) FPC737R3 4 FPC737R5 2 92 (42)

(1534) FPC760G5➁ 4 110 (50)

3

⁄8 (822) FPC732G3X 5 FPC732G11X 5 FPC732G5X 5 90 (41)

7

⁄8 (962) FPC737R3X 5 FPC737R5X 5 98 (45)

7

⁄8 (1292) FPC750R5X 5 108 (49)

Application: Deionized Water , Demineralized Water

2

60 W/in

316 SS Flange 36 213⁄4 (552) FPR721N10 4 FPR721N3 2 FPR721N11 3 FPR721N5 1 78 (36)

12-316 SS 48 27

(9.3 W/cm

Passivated 72 381⁄4 (972) FPR738E3 4 FPR738E5 2 92 (42)

24 153⁄4 (400) FPR715N10 3 FPR715N3 2 FPR715N11 2 FPR715N5 1 73 (33)

1

(692) FPR727E3 4 FPR727E11 3 FPR727E5 2 81 (37)

2

)6032

100 51

120 60

⁄4

3

⁄4 (832) FPR732N3 4 FPR732N11 3 FPR732N5 2 85 (39)

1

(1302) FPR751E5 4 100 (46)

⁄4

3

⁄4 (1543) FPR760N5 4 110 (50)

CONTINUED

All flange immersion heaters are Assembly

Stock unless otherwise noted.

Availability

Stock: Same day shipment

Assembly Stock: Five to seven working days

Standard: 10 working days, depending on

size

➁ Standard

➂ Must be operated 3-phase wye

353

Page 16

Tubular and

Process Assemblies

Flange Immersion Heaters

6" 150 Lbs ANSI Flange—WATROD Element

WATROD Immersed Code No. Est. Ship.

Description kW

B Dimension

inch (mm) 1-Phase Circuits 3-Phase Circuits 1-Phase Circuits 3-Phase Circuits lbs (kg)

Application: Deionized Water , Demineralized Water

2

60 W/in

316 SS Flange 45 213⁄

15-316 SS 60 27

(9.3 W/cm

Passivated 90 381⁄

30 153⁄4 (400) FPR715N10X 3 FPR715N3X 5 FPR715N11X 3 FPR715N5X 1 76 (35)

4 (552) FPR721N10X 5 FPR721N3X 5 FPR721N11X 3 FPR721N5X 5 82 (38)

1

4 (692) FPR727E3X 5 FPR727E11X 3 FPR727E5X 5 85 (39)

2

)7532

125 51

150 60

⁄

3

⁄4 (832) FPR732N3X 5 FPR732N11X 5 FPR732N5X 5 90 (41)

4 (972) FPR738E3X 5 FPR738E5X 5 98 (45)

1

4 (1302) FPR751E5X 5 108 (49)

⁄

3

⁄4 (1543) FPR760N5X 5 120 (55)

Application: Process Water

48 W/in2➄ 18 133⁄8 (340) FPN713G10 2 FPN713G3 1 FPN713G11 1 FPN713G5 1 73 (33)

Steel Flange 24 177⁄

12-Incoloy

®

30 203⁄8 (518) FPN720G10 3 FPN720G3 2 FPN720G11 2 FPN720G5 1 78 (36)

(7.5 W/cm2)3625

48 32

60 40

72 477⁄

2

48 W/in

23 133⁄8 (340) FPN713G10X 3 FPN713G3X 5 FPN713G11X 1 FPN713G5X 1 76 (35)

8 (454) FPN717R10 3 FPN717R3 2 FPN717R11 2 FPN717R5 1 75 (34)

3

8 (645) FPN725G10 4 FPN725G3 2 FPN725G11 2 FPN725G5 1 81 (37)

⁄

7

8 (835) FPN732R3 4 FPN732R11 3 FPN732R5 2 85 (39)

⁄

3

⁄8 (1026) FPN740G3 4 FPN740G11 3 FPN740G5 2 92 (42)

8 (1216) FPN747R3 4 FPN747R5 2 100 (46)

Steel Flange 30 177⁄8 (454) FPN717R10X 3 FPN717R3X 5 FPN717R11X 3 FPN717R5X 1 78 (36)

15-Incoloy

(7.5 W/cm

®

38 203⁄

2

)4525

8 (518) FPN720G10X 5 FPN720G3X 5 FPN720G11X 3 FPN720G5X 1 82 (38)

3

⁄8 (645) FPN725G10X 5 FPN725G3X 5 FPN725G11X 3 FPN725G5X 5 85 (39)

60 327⁄8 (835) FPN732R3X 5 FPN732R11X 3 FPN732R5X 5 90 (41)

75 403⁄

90 47

8 (1026) FPN740G3X 5 FPN740G11X 5 FPN740G5X 5 98 (45)

7

(1216) FPN747R3X 5 FPN747R5X 5 108 (49)

⁄8

Applications: Forced Air and Gases, Caustic Solutions, Degreasing Solutions

23 W/in2➄➅ 12 177⁄8 (454) FPNA17R10 2 FPNA17R3 1 FPNA17R11 1 FPNA17R5 1 75 (34)

(645) FPNA25G10 2 FPNA25G3 1 FPNA25G11 1 FPNA25G5 1 81 (37)

Steel Flange 18 253⁄

12-Incoloy

®

24 327⁄8 (835) FPNA32R10 3 FPNA32R3 2 FPNA32R11 2 FPNA32R5 1 85 (39)

(3.6 W/cm2)3040

36 477⁄

50 64

60 767⁄8 (1953) FPNA76R3 4 FPNA76R11 3 FPNA76R5 2 118 (54)

2

23 W/in

15 177⁄

Steel Flange 23 25

15-Incoloy

®

30 327⁄8 (835) FPNA32R10X 3 FPNA32R3X 5 FPNA32R11X 3 FPNA32R5X 1 90 (41)

(3.6 W/cm2)3840

45 47

63 643⁄8 (1635) FPNA64G3X 5 FPNA64G11X 3 FPNA64G5X 5 120 (55)

75 767⁄

8

3

⁄8 (1026) FPNA40G10 3 FPNA40G3 2 FPNA40G11 1 FPNA40G5 1 92 (42)

(1216) FPNA47R10 4 FPNA47R3 2 FPNA47R11 2 FPNA47R5 1 100 (46)

8

3

⁄8 (1635) FPNA64G3 4 FPNA64G11 3 FPNA64G5 2 110 (50)

(454) FPNA17R10X 3 FPNA17R3X 1 FPNA17R11X 1 FPNA17R5X 1 78 (36)

8

3

⁄8 (645) FPNA25G10X 3 FPNA25G3X 5 FPNA25G11X 1 FPNA25G5X 1 85 (39)

3

8 (1026) FPNA40G10X 5 FPNA40G3X 5 FPNA40G11X 3 FPNA40G5X 1 98 (45)

⁄

7

⁄8 (1216) FPNA47R10X 5 FPNA47R3X 5 FPNA47R11X 3 FPNA47R5X 5 108 (49)

8 (1953) FPNA76R3X 5 FPNA76R11X 5 FPNA76R5X 5 131 (60)

240VÅ(ac) No. of 240VÅ(ac) No. of 480VÅ(ac) No. of 480VÅ(ac) No. of Weight

CONTINUED

All flange immersion heaters are Assembly

Stock unless otherwise noted.

Availability

Stock: Same day shipment

Assembly Stock: Five to seven working days

Standard: 10 working days, depending on

size

354

➄ 240VÅ(ac) 3-phase can be rewired wye to

produce

1

⁄3 more kW and watt density

when operated at 480VÅ(ac) 3-phase.

➅ Can be rewired wye to produce 1⁄3 of the

original kW and watt density

(3-phase only).

Page 17

W A T L O W

Tubular and

Process Assemblies

Flange Immersion Heaters

6" 150 lb ANSI Flange—WATROD Element

WATROD Immersed Code No. Est. Ship.

Description kW

Applications: Lightweight Oils, Degreasing Solutions, Heat Transfer Oils

2

23 W/in

Steel Flange 18 25

12-Steel 24 327⁄

(3.6 W/cm

23 W/in

2

)30403⁄

2

Steel Flange 23 253⁄

15-Steel 30 32

(3.6 W/cm

2

)38403⁄

Applications: Medium Weight Oils, Heat Transfer Oils, Liquid Paraffin

16 W/in2➂ 6133⁄

Steel Flange 817

12-Incoloy

®

(2.5 W/cm2)12253⁄

2

16 W/in

➂ 7.5 133⁄8 (340) FPN713G12X 1 FPN713G13X 1 76 (35)

Steel Flange 10 17

15-Incoloy

®

(2.5 W/cm2)15253⁄8 (645) FPN725G12X 1 FPN725G13X 1 85 (39)

Applications: Bunker C and #6 Fuel Oils

8 W/in2➂ 8327⁄8 (835) FPS732R12 1 FPS732R13 1 85 (39)

Steel Flange 10 40

12-Steel 12 47

(1.3 W/cm2)16.5643⁄8 (1635) FPS764G12 1 FPS764G13 1 110 (50)

2

8 W/in

➂ 10 327⁄8 (835) FPS732R12X 1 FPS732R13X 1 90 (41)

Steel Flange 12.5 403⁄8 (1026) FPS740G12X 1 FPS740G13X 1 98 (45)

15-Steel 15 47

(1.3 W/cm

All flange immersion heaters are Assembly

Stock unless otherwise noted.

Availability

Stock: Same day shipment

Assembly Stock: Five to seven working days

Standard: 10 working days, depending on

size

2

)21643⁄8 (1635) FPS764G12X 5 FPS764G13X 1 120 (55)

B Dimension

240VÅ(ac) No. of 240VÅ(ac) No. of 480VÅ(ac) No. of 480VÅ(ac) No. of Weight

inch (mm) 1-Phase Circuits 3-Phase Circuits 1-Phase Circuits 3-Phase Circuits lbs (kg)

12 177⁄

36 47

50 643⁄

60 76

8 (454) FPS717R10 2 FPS717R3 1 FPS717R11 1 FPS717R5 1 75 (34)

3

⁄8 (645) FPS725G10 2 FPS725G3 1 FPS725G11 1 FPS725G5 1 81 (37)

8 (835) FPS732R10 3 FPS732R3 2 FPS732R11 2 FPS732R5 1 85 (39)

8 (1026) FPS740G10 3 FPS740G3 2 FPS740G11 2 FPS740G5 1 92 (42)

7

⁄8 (1216) FPS747R10 4 FPS747R3 2 FPS747R11 2 FPS747R5 1 100 (46)

8 (1635) FPS764G3 4 FPS764G11 3 FPS764G5 2 110 (50)

7

8 (1953) FPS776R3 4 FPS776R11 3 FPS776R5 2 118 (54)

⁄

15 177⁄8 (454) FPS717R10X 3 FPS717R3X 1 FPS717R11X 1 FPS717R5X 1 78 (36)

8 (645) FPS725G10X 3 FPS725G3X 5 FPS725G11X 1 FPS725G5X 1 85 (39)

7

8 (835) FPS732R10X 3 FPS732R3X 5 FPS732R11X 3 FPS732R5X 1 90 (41)

⁄

8 (1026) FPS740G10X 5 FPS740G3X 5 FPS740G11X 3 FPS740G5X 1 98 (45)

45 47

63 64

75 767⁄

7

8 (1216) FPS747R10X 5 FPS747R3X 5 FPS747R11X 3 FPS747R5X 5 108 (49)

⁄

3

⁄8 (1635) FPS764G3X 5 FPS764G11X 3 FPS764G5X 5 120 (55)

8 (1953) FPS776R3X 5 FPS776R11X 5 FPS776R5X 5 131 (60)

8 (340) FPN713G12 1 FPN713G13 1 73 (33)

7

⁄8 (454) FPN717R12 1 FPN717R13 1 75 (34)

10 203⁄8 (518) FPN720G12 1 FPN720G13 1 78 (36)

8 (645) FPN725G12 1 FPN725G13 1 81 (37)

16 32

7

⁄8 (835) FPN732R12 1 FPN732R13 1 85 (39)

20 403⁄8 (1026) FPN740G12 2 FPN740G13 1 92 (42)

24 477⁄

8 (1216) FPN747R12 2 FPN747R13 1 100 (46)

7

(454) FPN717R12X 1 FPN717R13X 1 78 (36)

⁄8

12.5 203⁄8 (518) FPN720G12X 1 FPN720G13X 1 82 (38)

7

(835) FPN732R12X 5 FPN732R13X 1 90 (41)

20 32

25 40

⁄8

3

⁄8 (1026) FPN740G12X 5 FPN740G13X 1 98 (45)

30 477⁄8 (1216) FPN747R12X 5 FPN747R13X 1 108 (49)

3

⁄8 (1026) FPS740G12 1 FPS740G13 1 92 (42)

7

⁄8 (1216) FPS747R12 1 FPS747R13 1 100 (46)

7

20 76

⁄8 (1953) FPS776R12 2 FPS776R13 1 118 (54)

7

⁄8 (1216) FPS747R12X 1 FPS747R13X 1 108 (49)

25 767⁄8 (1953) FPS776R12X 5 FPS776R13X 1 131 (60)

➂ Must be operated 3-phase wye

Flange Heaters

355

Page 18

Tubular and

Process Assemblies

Flange Immersion Heaters

6" 150 lb ANSI Flange—FIREBAR Element

FIREBAR Immersed Code No. Est. Ship.

Description kW B Dimension 240V

inch (mm) 3-Phase Circuits 3-Phase Circuits lbs (kg)

Å(ac)

No. of 480V

Applications: Process Water, Ethylene Glycol (50%)

2

45 W/in

304 SS Flange 37.5 16 (406) FPNF16A27 5 81 (37)

15-Incoloy

(7 W/cm2)6022

30 133⁄8 (340) FPNF13G27 78 (36)

®

45 183⁄8 (467) FPNF18G27 5 84 (38)

7

⁄8 (581) FPNF22R27 5 FPNF22R28 5 87 (40)

75 277⁄8 (708) FPNF27R27 5 FPNF27R28 5 91 (42)

90 327⁄8 (835) FPNF32R27 5 FPNF32R28 5 95 (43)

120 423⁄8 (1076) FPNF42G28 5 106 (48)

150 517⁄8 (1318) FPNF51R28 5 116 (53)

Applications: Cooking Oils, Ethylene Glycol (100%)

30 W/in2➂ 25 161⁄2 (419) FPNF16J12 5 FPNF16J13 5 81 (37)

304 SS Flange 32 191⁄2 (495) FPNF19J12 5 FPNF19J13 5 84 (38)

15-Incoloy

(4.7 W/cm2) 52 30 (762) FPNF30A12 5 FPNF30A13 5 91 (42)

®

42 241⁄2 (622) FPNF24J12 5 FPNF24J13 5 87 (40)

64 35 (889) FPNF35A12 5 FPNF35A13 5 95 (43)

85 451⁄2 (1156) FPNF45J12 5 FPNF45J13 5 106 (48)

110 56 (1422) 5 FPNF56A13 5 116 (53)

Applications: Heat Transfer Oils, Mineral Oils, Degreasing Solutions

23 W/in2➃

304 SS Flange 24 191⁄2 (495) FPNF19J20 5 84 (38)

15-Incoloy

(3.6 W/cm2) 40 30 (762) FPNF30A20 5 FPNF30A19 5 91 (42)

19 161⁄2 (419) FPNF16J20 5 81 (37)

®

32 241⁄2 (622) FPNF24J20 5 FPNF24J19 5 87 (40)

48 35 (889) FPNF35A20 5 FPNF35A19 5 95 (43)

64 451⁄2 (1156) FPNF45J20 5 FPNF45J19 5 106 (48)

80 56 (1422) FPNF56A20 5 FPNF56A19 5 116 (53)

Applications: Medium Weight Oils, Heat Transfer Oils, Liquid Paraffin

15 W/in2➂ 10 133⁄8 (340) FPNF13G29 5 78 (36)

304 SS Flange 12.5 16 (406) FPNF16A29 5 81 (37)

15-Incoloy

(2.3 W/cm2)2022

®

15 183⁄8 (467) FPNF18G29 5 84 (38)

7

⁄8 (581) FPNF22R29 5 FPNF22R30 5 87 (40)

25 277⁄8 (708) FPNF27R29 5 FPNF27R30 5 91 (42)

30 327⁄8 (835) FPNF32R29 5 FPNF32R30 5 95 (43)

40 423⁄8 (1076) FPNF42G29 5 FPNF42G30 5 106 (48)

50 517⁄8 (1318) FPNF51R29 5 FPNF51R30 5 116 (53)

Applications: Bunker C and #6 Fuel Oils, Asphalt

8 W/in2➂ 6.3 161⁄2 (419) FPNF16J22 5 81 (37)

304 SS Flange 8.1 191⁄2 (495) FPNF19J22 5 84 (38)

15-Incoloy

(1.3 W/cm2) 13.1 30 (762) FPNF30A22 5 FPNF30A21 5 91 (42)

All flange immersion heaters are Assembly

Stock unless otherwise noted.

Availability

Stock: Same day shipment

Assembly Stock: Five to seven working days

Standard: 10 working days, depending on

size

®

10.6 241⁄2 (622) FPNF24J22 5 FPNF24J21 5 87 (40)

16 35 (889) FPNF35A22 5 FPNF35A21 5 95 (43)

21.3 451⁄2 (1156) FPNF45J22 5 FPNF45J21 5 106 (48)

26 56 (1422) FPNF56A22 5 FPNF56A21 5 116 (53)

➂ Must be operated 3-phase wye.

➃ Can be rewired for 1-phase.

Å(ac)

No. of Weight

356

Page 19

W A T L O W

Tubular and

Process Assemblies

Flange Immersion Heaters

8" 150 lb ANSI Flange—WATROD Element

WATROD Immersed Code No. Est. Ship.

Description kW

B Dimension

inch (mm) 1-Phase Circuits 3-Phase Circuits 1-Phase Circuits 3-Phase Circuits lbs (kg)

Application: Clean Water

2

60 W/in

50 213⁄4 (553) FRC721N3➁ 3 FRC721N11 3 FRC721N5 2 118 (54)

Steel Flange 75 293⁄4 (756) FRC729N3➁ 6 FRC729N5➁ 2 126 (58)

18-Copper 100 371⁄

(9.3 W/cm

2

) 125 451⁄4 (1149) FRC745E3➁ 6 FRC745E5➁ 6 132 (60)

150 523⁄

175 60

200 68

4 (946) FRC737E3➁ 6 FRC737E5 3 130 (59)

4 (1340) FRC752N5➁ 6 137 (63)

3

4 (1543) FRC760N5➁ 6 144 (66)

⁄

1

⁄4 (1734) FRC768E5➁ 6 149 (68)

Application: Process Water

48 W/in2➄ 50 253⁄4 (654) FRN725N3➁ 3 FRN725N11

Steel Flange 75 353⁄

18-Incoloy

®

100 441⁄4 (1124) FRN744E3 6 FRN744E5 3 132 (60)

(7.5 W/cm2) 125 5411⁄

150 63

175 73

200 8211⁄

2

48 W/in

4 (908) FRN735N3➁ 6 FRN735N5➁ 2 130 (59)

16 (1389) FRN754M3➁ 6 FRN754M5➁ 6 140 (64)

11

16 (1617) FRN763M5➁ 6 145 (66)

⁄

3

⁄16 (1859) FRN773D5 6 151 (69)

16 (2100) FRN782M5➁ 6 157 (72)

67 263⁄16 (665) FRN726D3X➁ 4 FRN726D11X➁ 3 FRN726D5X➁ 2 129 (59)

Steel Flange 100 363⁄16 (919) FRN736D3X➁ 8 FRN736D5X➁ 4 142 (65)

24-Incoloy®133 4411⁄

(7.5 W/cm

2

) 167 5411⁄16 (1389) FRN754M3X➁ 8 FRN754M5X➁ 8 158 (72)

16 (1135) FRN744M3X➁ 8 FRN744M5X➁ 4 147 (67)

200 6311⁄16 (1618) FRN763M5X➁ 8 166 (76)

233 733⁄

267 82

16 (1859) FRN773D5X 8 175 (80)

11

(2100) FRN782M5X➁ 8 184 (84)

⁄16

Application: Forced Air and Gases, Caustic Solutions, Degreasing Solutions

(832) FRNA32N10➁ 3 FRNA32N3➁ 2 FRNA32N11➁ 2 FRNA32N5➁ 1 130 (59)

23 W/in2➄➅ 30 323⁄

Steel Flange 40 43

18-Incoloy

®

(3.6 W/cm2)

2

23 W/in

Steel Flange 53 4311⁄16 (1110) FRNA43M3X➁ 4 FRNA43M11X➁ 3 FRNA43M5X➁ 2 147 (67)

24-Incoloy

(3.6 W/cm

®

2

)

4

1

⁄4 (1099) FRNA43E3➁ 3 FRNA43E11➁ 2 FRNA43E5➁ 2 132 (60)

50 5111⁄16 (1313) FRNA51M3 3 FRNA51M11 3 FRNA51M5 2 137 (63)

40 333⁄16 (843) FRNA33D10X➁ 4 FRNA33D3X➁ 4 FRNA33D11X➁ 2 FRNA33D5X➁ 2 142 (65)

(1313) FRNA51M3X➁ 4 FRNA51M11X➁ 3 FRNA51M5X➁ 2 154 (70)

16

67 5111⁄

240VÅ(ac) No. of 240VÅ(ac) No. of 480VÅ(ac) No. of 480VÅ(ac) No. of Weight

➁

3 FRN725N5➁ 2 121 (55)

CONTINUED

Flange Heaters

All flange immersion heaters are Assembly

Stock unless otherwise noted.

Availability

Stock: Same day shipment

Assembly Stock: Five to seven working days

Standard: 10 working days, depending on

size

Truck Shipment only

b Standard

e 240VÅ(ac) 3-phase can be rewired wye to

1

more kW and watt density when

produce

⁄3

operated at 480VÅ(ac) 3-phase.

➅ Can be rewired wye to produce 1⁄3 of the

original kW and watt density

(3-phase only).

357

Page 20

Tubular and

Process Assemblies

Flange Immersion Heaters

8" 150 lb ANSI Flange—WATROD Element

WATROD Immersed Code No. Est. Ship.

Description kW

Applications: Lightweight Oils, Degreasing Solutions, Heat Transfer Oils

2

23 W/in

Steel Flange 40 43

18-Steel 50 5111⁄

(3.6 W/cm

23 W/in

2

)60623⁄

2

Steel Flange 53 43

24-Steel 67 5111⁄

(3.6 W/cm

2

)80623⁄

107 79

Applications: Medium Weight Oils, Heat Transfer Oils, Liquid Paraffin

16 W/in2➂ 17 253⁄

Steel Flange 25 35

18-Incoloy®33 441⁄

(2.5 W/cm

2

)425411⁄16 (1389) FRN754M12➁ 3 FRN754M13➁ 2 140 (64)

16 W/in2➂ 23 263⁄16 (665) FRN726D12X➁ 2 FRN726D13X➁ 1 129 (59)

Steel Flange 33 363⁄

24-Incoloy

(2.5 W/cm

®

2

)565411⁄16 (1389) FRN754M12X➁ 4 FRN754M13X➁ 2 158 (72)

Applications: Bunker C and #6 Fuel Oils

8 W/in2➂ 12.5 431⁄4

Steel Flange 16.5 51

18-Steel 20 623⁄16 (1580) FRS762D12➁ 2 FRS762D13➁ 1 145 (66)

(1.3 W/cm

8 W/in2➂ 17 4311⁄16 (1110) FRS743M12X➁ 1 FRS743M13X➁ 1 147 (67)

Steel Flange 22 51

24-Steel 27 62

(1.3 W/cm2)327011⁄16 (1796) FRS770M12X➁ 2 FRS770M13X

2

)247011⁄16 (1795) FRS770M12 2 FRS770M13 1 151 (69)

B Dimension

240VÅ(ac) No. of 240VÅ(ac) No. of 480VÅ(ac) No. of 480VÅ(ac) No. of Weight

inch (mm) 1-Phase Circuits 3-Phase Circuits 1-Phase Circuits 3-Phase Circuits lbs (kg)

30 323⁄

70 70

80 7911⁄

40 333⁄

93 70

4 (832) FRS732N10➁ 3 FRS732N3➁ 2 FRS732N11➁ 2 FRS732N5➁ 1 130 (59)

1

⁄4 (1099) FRS743E3➁ 3 FRS743E11➁ 2 FRS743E5 2 132 (60)

16 (1313) FRS751M3 3 FRS751M11 3 FRS751M5 2 137 (63)

16 (1580) FRS762D3➁ 6 FRS762D11➁ 3 FRS762D5➁ 2 154 (70)

11

⁄16 (1795) FRS770M3➁ 6 FRS770M11 6 FRS770M5 2 160 (73)

16 (2024) FRS779M3➁ 6 FRS779M5➁ 3 172 (78)

16 (843) FRS733D10X➁ 4 FRS733D3X➁ 4 FRS733D11X➁ 2 FRS733D5X➁ 2 142 (65)

11

⁄16 (1110) FRS743M3X➁ 4 FRS743M11X➁ 3 FRS743M5X➁ 2 147 (67)

16 (1313) FRS751M3X➁ 4 FRS751M11X➁ 3 FRS751M5X➁ 2 154 (70)

16 (1580) FRS762D3X➁ 8 FRS762D11X➁ 4 FRS762D5X➁ 4 166 (76)

11

16 (1796) FRS770M3X➁ 8 FRS770M11X➁ 6 FRS770M5X➁ 4 175 (80)

⁄

11

16 (2024) FRS779M3X➁ 8 FRS779M5X➁ 4 181 (82)

⁄

4 (654) FRN725N12➁ 1 FRN725N13➁ 1 121 (55)

3

⁄4 (908) FRN735N12➁ 2 FRN735N13➁ 1 130 (59)

4 (1124) FRN744E12➁ 2 FRN744E13 1 132 (60)

50 6311⁄16 (1618) FRN763M13➁ 2 145 (66)

58 733⁄

67 82

44 4411⁄

16 (1859) FRN773D13 2 151 (69)

11

⁄16 (2100) FRN782M13➁ 2 157 (72)

16 (919) FRN736D12X➁ 2 FRN736D13X➁ 1 142 (65)

16 (1135) FRN744M12X➁ 4 FRN744M13X➁ 2 147 (67)

67 6311⁄16 (1618) FRN763M13X➁ 2 166 (76)

77 733⁄16 (1859) FRN773D13X➁ 2 175 (80)

11

89 82

⁄16 (2100) FRN782M13X➁ 4 184 (84)

(1099) FRS743E12➁ 1 FRS743E13➁ 1 132 (60)

11

⁄16 (1313) FRS751M12 1 FRS751M13 1 137 (62)

27 79

36 79

11

⁄16 (2024) FRS779M12➁ 2 FRS779M13➁ 1 155 (71)

11

⁄16 (1313) FRS751M12X➁ 2 FRS751M13X➁ 1 154 (70)

3

⁄16 (1580) FRS762D12X➁ 2 FRS762D13X➁ 1 166 (76)

11

⁄16 (2024) FRS779M12X➁ 2 FRS779M13X

➁

➁

1 175 (80)

1 181 (82)

All flange immersion heaters are Assembly

Stock unless otherwise noted.

Availability

Stock: Same day shipment

Assembly Stock: Five to seven working days

Standard: 10 working days, depending on

size

Truck Shipment only

358

➁ Standard

➂ Must be operated 3-phase wye

Page 21

W A T L O W

Tubular and

Process Assemblies

Flange Immersion Heaters

10" 150 lb ANSI Flange—WATROD Element

WATROD Immersed Code No. Est. Ship.

Description kW B Dimension 240VÅ(ac) No. of 480VÅ(ac) No. of Weight

Application: Process Water

48 W/in2➄ 190 543⁄

Steel Flange 262 73

27-Incoloy

®

(7.5 W/cm2)

Applications: Forced Air and Gases, Caustic Solutions, Degreasing Solutions

23 W/in2➄➅ 45 331⁄

Steel Flange 60 43

27-Incoloy

(3.6 W/cm

®

2

)

Applications: Lightweight Oils, Degreasing Solutions, Heat Transfer Oils

2

23 W/in

Steel Flange 60 433⁄4 (1111) FSS743N3➁ 3 FSS743N5➁ 3 195 (89)

27-Steel 75 513⁄

(3.6 W/cm

2

)9062

Applications: Medium Weight Oils, Heat Transfer Oils, Liquid Paraffin

16 W/in2➂ 63 543⁄

Steel Flange 75 63

27-Incoloy

(2.5 W/cm

®

2

)

Applications: Bunker C and #6 Fuel Oils

8 W/in2➂ 25 513⁄

Steel Flange 30 621⁄4

27-Steel 35 70

(1.3 W/cm2)4078

All flange immersion heaters are Assembly

Stock unless otherwise noted.

Availability

Stock: Same day shipment

Assembly Stock: Five to seven working days

Standard: 10 working days, depending on

size

Truck Shipment only

inch (mm) 3-Phase Circuits 3-Phase Circuits lbs (kg)

4 (1391) FSN754N5➁ 9 240 (109)

1

⁄4 (1861) FSN773E5 9 260 (118)

4 (845) FSNA33E3➁ 3 FSNA33E5➁ 3 165 (75)

3

⁄4 (1111) FSNA43N3➁ 3 FSNA43N5➁ 3 195 (89)

4 (1314) FSNA51N3 9 FSNA51N5 3 230 (105)

75 513⁄

45 331⁄4 (845) FSS733E3➁ 3 FSS733E5➁ 3 165 (75)

4 (1314) FSS751N3 9 FSS751N5 3 230 (105)

1

⁄4 (1581) FSS762E5➁ 3 250 (114)

105 703⁄

120 78

4 (1797) FSS770N5 3 258 (117)

3

4 (2000) FSS778N5➁ 3 265 (121)

⁄

4 (1391) FSN754N13➁ 3 240 (109)

3

⁄4 (1619) FSN763N13➁ 3 250 (114)

4 (1861) FSN773E13 3 258 (117)

87 731⁄

4 (1314) FSS751N12 3 FSS751N13 1 230 (105)

(1581) FSS762E12➁ 3 FSS762E13➁ 1 250 (114)

3

⁄4 (1797) FSS770N12 3 FSS770N13 1 258 (117)

3

⁄4 (2000) FSS778N12➁ 3 FSS778N13➁ 1 265 (121)

➁ Standard

➂ Must be operated 3-phase wye.

➄ 240VÅ(ac) 3-phase can be rewired wye

to produce 1⁄3 more kW and watt density

when operated at 480VÅ(ac) 3-phase.

➅

Can be rewired wye to produce 1⁄3 of the

original kW and watt density

(3-phase only).

Flange Heaters

359

Page 22

Tubular and

Process Assemblies

Flange Immersion Heaters

12" 150 lb ANSI Flange—WATROD Element

WATROD Immersed Code No. Est. Ship.

Description kW B Dimension 240VÅ(ac) No. of 480VÅ(ac) No. of Weight

Application: Process Water

2

48 W/in

Steel Flange 350 73

36-Incoloy

®

(7.5 W/cm2)

Applications: Forced Air and Gases, Caustic Solutions, Degreasing Solutions

2

23 W/in

Steel Flange 80 43

36-Incoloy

(3.6 W/cm

®

2

)

Applications: Lightweight Oils, Degreasing Solutions, Heat Transfer Oils

2

23 W/in

Steel Flange 80 435⁄8 (1108) FTS743L5➁ 3 240 (109)

36-Steel 100 515⁄

(3.6 W/cm

2

) 120 621⁄8 (1578) FTS762C5➁ 3 285 (130)

Applications: Medium Weight Oils, Heat Transfer Oils, Liquid Paraffin

16 W/in2➂ 83 545⁄

Steel Flange 117 73

36-Incoloy

®

(2.5 W/cm2)

Applications: Bunker C and #6 Fuel Oils

8 W/in2➂ 34 515⁄8 (1311) FTS751L12➁ 2 FTS751L13 1 280 (127)

Steel Flange 40 62

36-Steel 47 70

(1.3 W/cm2)5478

All flange immersion heaters are Assembly

Stock unless otherwise noted.

Availability

Stock: Same day shipment

Assembly Stock: Five to seven working days

Standard: 10 working days, depending on

size

Truck Shipment only

inch (mm) 3-Phase Circuits 3-Phase Circuits lbs (kg)

250 545⁄

100 515⁄

8 (1387) FTN754L5➁ 6 280 (127)

1

⁄8 (1857) FTN773C5 12 291 (132)

8 (841) FTNA33C5➁ 3 205 (93)

60 331⁄

5

⁄8 (1108) FTNA43L5➁ 3 240 (109)

8 (1311) FTNA51L5 3 280 (127)

60 331⁄8 (841) FTS733C5➁ 3 205 (93)

8 (1311) FTS751L5 3 280 (127)

140 705⁄

160 78

8 (1794) FTS770L5 4 290 (132)

5

8 (1997) FTS778L5➁ 4 300 (136)

⁄

8 (1387) FTN754L13➁ 3 280 (127)

1

⁄8 (1857) FTN773C13➁ 3 291 (132)

1

(1578) FTS762C12➁ 2 FTS762C13➁ 1 285 (130)

⁄8

5

⁄8 (1794) FTS770L12➁ 3 FTS770L13 2 290 (132)

5

⁄8 (1997) FTS778L12➁ 3 FTS778L13➁ 2 300 (136)

➁ Standard

➂ Must be operated 3-phase wye.

360

Page 23

W A T L O W

Tubular and

Process Assemblies

Flange Immersion Heaters

14" 150 lb ANSI Flange—WATROD Element

WATROD Immersed Code No. Est. Ship.

Description kW B Dimension 240VÅ(ac) No. of 480VÅ(ac) No. of Weight

Application: Process Water

2

48 W/in

Steel Flange 375 63

45-Incoloy

®

(7.5 W/cm2)

Applications: Forced Air and Gases, Caustic Solutions, Degreasing Solutions

2

23 W/in

Steel Flange 100 431⁄2 (1105) FWNA43J5➁ 3 255 (116)

45-Incoloy

(3.6 W/cm

®

2

)

Applications: Lightweight Oils, Degreasing Solutions, Heat Transfer Oils

2

23 W/in

Steel Flange 100 431⁄2 (1105) FWS743J5➁ 3 255 (116)

45-Steel 125 511⁄

(3.6 W/cm

2

) 150 62 (1575) FWS762A5➁ 5 310 (141)

Applications: Medium Weight Oils, Heat Transfer Oils, Liquid Paraffin

16 W/in2➂ 105 541⁄

Steel Flange 125 63

45-Incoloy

®

(2.5 W/cm2)

Applications: Bunker C and #6 Fuel Oils

8 W/in2➂ 42 511⁄2 (1308) FWS751J12 3 FWS751J13 3 300 (136)

Steel Flange 50 62 (1575) FWS762A12➁ 3 FWS762A13➁ 3 310 (141)

45-Steel 60 70

(1.3 W/cm

All flange immersion heaters are Assembly

Stock unless otherwise noted.

Availability

Stock: Same day shipment

Assembly Stock: Five to seven working days

Standard: 10 working days, depending on

size

2

)6778

Truck Shipment only

inch (mm) 3-Phase Circuits 3-Phase Circuits lbs (kg)

315 541⁄

2 (1384) FWN754J5➁ 15 300 (136)

1

2 (1613) FWN763J5➁ 15 310 (141)

⁄

75 33 (838) FWNA33A5➁ 3 225 (102)

125 511⁄

2 (1308) FWNA51J5 5 300 (136)

75 33 (838) FWS733A5➁ 3 225 (102)

2 (1308) FWS751J5 5 300 (136)

175 701⁄2 (1791) FWS770J5 5 318 (145)

200 781⁄

2 (1994) FWS778J5➁ 5 330 (150)

2 (1384) FWN754J13➁ 3 300 (136)

1

⁄2 (1613) FWN763J13➁ 5 310 (141)

1

⁄2 (1791) FWS770J12 3 FWS770J13 3 318 (144)

1

⁄2 (1994) FWS778J12➁ 5 FWS778J13➁ 3 330 (150)

➁

Standard

➂

Must be operated 3-phase wye.

Flange Heaters

361

Page 24

Tubular and

Process Assemblies

Flange Immersion Heaters

Build-a-Code

Flange Immersion

Heater Base Code Number➀

(Includes general purpose enclosure without thermostat)

Terminal Enclosure Type

S = General purpose (NEMA 1)

W = Moisture resistant (NEMA 4)

E = Explosion resistant (NEMA 7)

E/W = Explosion/moisture resistant (NEMA 7/4)

Thermostatb

Thermocouplec

J = Type J

K = Type K

F.O.B.: Hannibal, Missouri

-

-

-

a Flange immersion heaters are supplied with a standard, general purpose (NEMA 1) terminal enclosure. A

thermostat will not fit the standard general purpose terminal enclosure on 2, 2

b Code numbers are shown on the Thermostat stock chart on page 425. Check the temperature sensing bulb

O.D. to be certain it will fit into the thermowell’s I.D.

c Specify Type J or K thermocouple. If overtemp thermocouple specify orientation horizontal, vertical up or

vertical down.

How to Order

To order a stock flange heater,

please specify:

• Watlow code number

• Flange size and material

• Volts/watts

• Phase

• Options

• Quantity

If the flange immersion heater is to

be configured with options, add the

suffix letter(s) to the base flange

heater code number, as indicated

on the Build-a-Code chart.

If our stock units do not meet your

application needs, Watlow will

make-to-order.

For made-to-order units please

specify:

• Application, including media

heated, flow rate, pressure, and

process operating temperatures

• Volts/watts

• Watt density

• Phase

• Number of circuits

• Number of heating elements

• Element diameter (WATROD only)

• Immersed (‘B’ dimension) length

• Flange size, rating and material

• No-heat section below the flange

• Ter minal enclosure type

• Options

• Quantity

1