Page 1

Electric Heaters

7

W A T L O W

Application Guide

Electric Heaters

Product Overview

This section of the Application Guide

is devoted to electric heaters; their

different types, methods of use and

general calculations for determining

specifications. If you’re unable to find

or determine which type of Watlow

heater will best suit your needs, call

your nearest Watlow sales representative. Sales offices are listed on the

back cover of this Application Guide.

Heaters

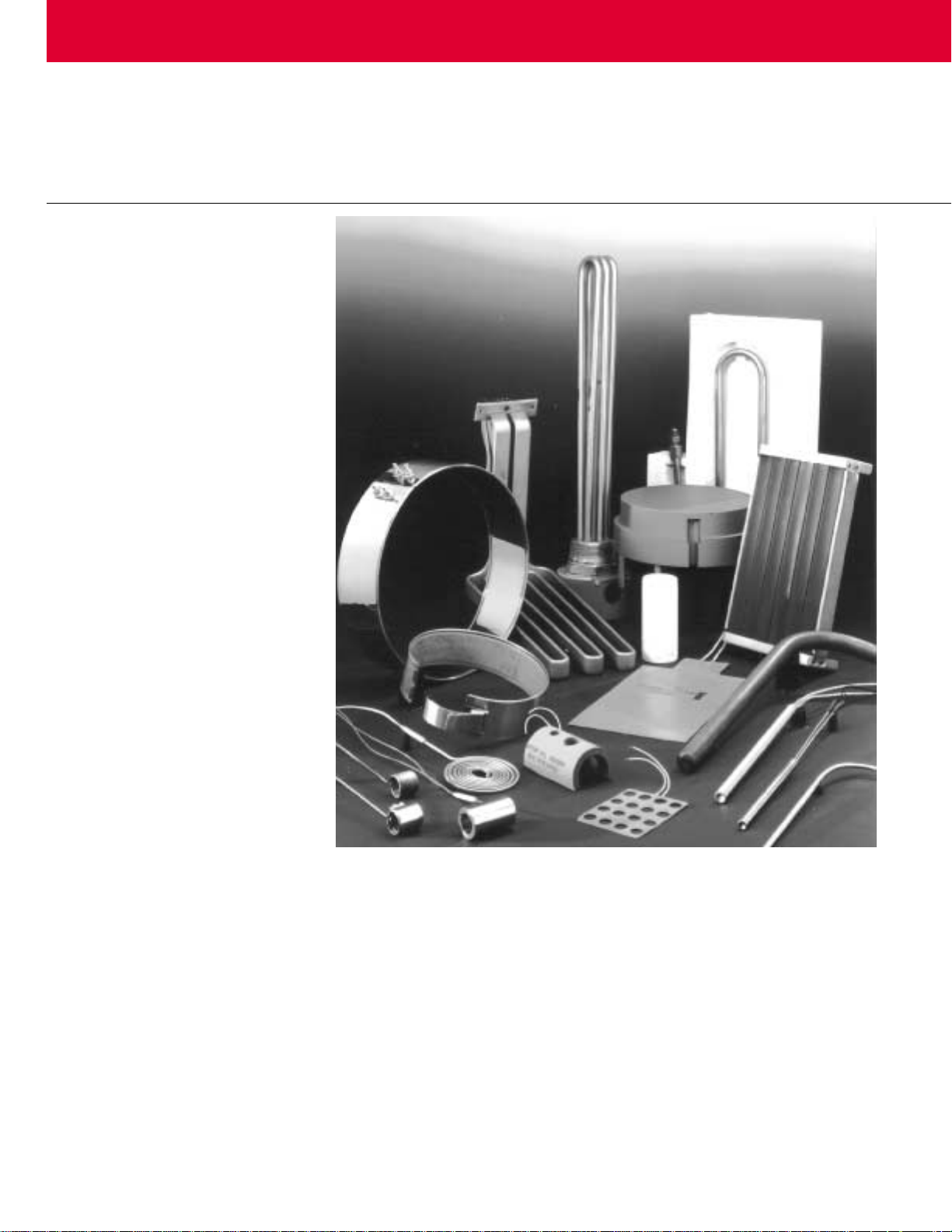

Band and Nozzle Heaters

Led by the high performance MI Band heater, the patented, flexible

THINBAND®heater and the standard mica band heater for specialized

constructions, Watlow’s band and nozzle heaters are ideal for every type of

plastic processing equipment.

Sheath materials available include stainless steel with mica insulation, stainless

steel with mineral insulation and aluminized or zinc steel with mica insulation.

Performance Capabilities

• Maximum operating temperatures

to 760°C (1400°F)

• Typical maximum watt densities from

8.5 W/cm2(55 W/in2) to

35.7 W/cm2(230 W/in2)

Applications

• Extruders

• Blown film dies

• Injection molding machines

• Other cylinder heating applications

Cable Heaters

The versatile Watlow cable heater can be formed to a variety of shapes as

dictated by its many applications. These small diameter, high performance units

are fully annealed and readily bent to your desired configuration.

Sheath materials available include Inconel®and stainless steel.

Performance Capabilities

• Typical maximum watt densities to

4.6 W/cm2(30 W/in2)

• Maximum operating temperatures

to 650°C (1200°F)

Applications

• Plastic injection molding nozzles

• Semiconductor manufacturing and

wafer processing

• Hot metal forming dies and punches

• Sealing and cutting bars

• Restaurant and food processing

equipment

• Cast-in heaters

• Laminating and printing presses

• Air heating

• Heating in a vacuum environment

• Textile manufacturing

Inconel®is a registered trademark of the

Special Metals Corporation.

Page 2

8

Application Guide

Electric Heaters

Product Overview

Continued

Cartridge Heaters

The Watlow FIREROD

®

heater enters its 50th year of industry leading expertise

as the premier choice in swaged cartridge heating. With premium materials

and tight manufacturing controls, the FIREROD heater continues to provide

superior heat transfer, uniform temperatures and resistance to oxidation and

corrosion in demanding applications and high temperatures.

Sheath materials available are Incoloy®and stainless steel.

Performance Capabilities

• Typical maximum watt densities up

to 62 W/cm2(400 W/in2)

• Maximum operating temperatures

to 760°C (1400°F)

Applications

• Molds • Life sciences

• Dies • Aerospace

• Platens • Semiconductor

• Hot plates • Foodservice

• Sealings

• Fluid heating

Cast-in Heaters

When Watlow creates a custom-engineered cast-in product, the result is more

than just a heater. It’s a “heated part” that becomes a functional component of

your equipment, designed in the exact shape and size you need. The IFC

heated part consists of a Watlow heater element built into custom metal shapes

designed specifically for your application.

Sheath materials available are 319 and 356 aluminum, pure aluminum and

IFC (stainless, nickel, Inconel®, aluminum, copper and bronze).

Performance Capabilities

• Typical maximum watt densities to

15.5 W/cm2(100 W/in2)

• Maximum operating temperatures

to 400°C (752°F) to 760°C (1400°F)

depending on material

Applications

• Semiconductor manufacturing

• Foodservice equipment

• Plastics processing

• Medical equipment

• Hot glue melt

• Circulation heating

Incoloy®and Inconel®are registered

trademarks of the Special Metals Corporation.

equipment

Page 3

Electric Heaters

9

W A T L O W

Application Guide

Electric Heaters

Product Overview

Continued

Circulation and Process Heaters

Watlow’s circulation heaters are compact heating solutions for fluids such as

purified and inert gases, supercritical fluids and liquids like de-ionized water

for use in semiconductor and electronics industries as well as for general liquid

and gas heating applications. Watlow’s industrial process heater lines of

immersion, circulation and duct heaters are used to heat a myriad of high and

low viscosity fluids ranging from de-ionized and process water, oils, solvents,

rinse agents, caustic solutions, etc. to process gases like air, nitrogen, purified

and inert gases as well.

Applications

• Oil and gas field equipment

• Refineries & petrochemical plants

• Chemical and industrial gas plants

• HVAC duct heating

• Open tanks and heat treat baths

• Textile drying

• Heat transfer and lube oil systems

• Semiconductor processing equipment

• Precision cleaning equipment

• Power generation systems

• Emissions control systems

• Supercritical fluid heating

• In-line water boilers

Ceramic Fiber Heaters

Ceramic fiber heaters integrate a high temperature iron-chrome-aluminum

(ICA) heating element wire with ceramic fiber insulation. Numerous stock,

standard and/or custom shapes can be provided, achieving the “heated

insulation” concept for your high temperature, non-contact applications. The

ceramic fiber insulation isolates the high temperatures inside the heated

chamber from the outside. The heaters are low mass, fast heating, with high

insulation values and the self-supported heating elements that offer some of

the highest temperature heating capabilities within the Watlow family of heater

designs.

The sheath material available is molded ceramic fiber.

Performance Capabilities

• Typical maximum watt densities to

1.8 W/cm

2

(11.5 W/in2)

• Maximum operating temperatures

to 1205°C (2200°F)

Applications

• High temperature furnaces

• Metal melting, holding and transfer

• Semiconductor processing

• Glass, ceramic and wire processing

• Analytical instrumentation

• Fluidized beds

• Laboratory and R&D

• Other high temperature process

applications

Page 4

10

Multicell Heaters

The multicell heater from Watlow offers independent zone control for precise

temperature uniformity, loose fit design for easy insertion in and removal from

the equipment and extreme process temperature capability. The heaters are

available with up to eight independently controllable zones and one to three

internal thermowells for removable sensors. Custom assemblies are available.

Incoloy®sheath material is available.

Performance Capabilities

• Typical maximum watt densities to

6.2 W/cm2(40 W/in2)

• Maximum operating temperatures

to 1230°C (2250°F)

Applications

• Super plastic forming and diffusion

bonding

• Hot forging dies

• Heated platens

• Furnace applications

• Superheating of air and other gases

• Fluidized beds for heat treating

• Glass forming, bending and tempering

• Long heater needs (1219 cm (40 foot))

• Soil remediation

• Aluminum processing

Application Guide

Electric Heaters

Product Overview

Continued

Flexible Heaters

Flexible heaters from Watlow are just what the name implies: thin, bendable and

shaped to fit your equipment. You can use your imagination to apply heat to the

most complex shapes and geometries conceivable without sacrificing efficiency

or dependability.

Sheath materials available include silicone rubber, Kapton®, HT foil and neoprene.

Performance Capabilities

• Typical maximum watt densities from

1.7 W/cm2(11 W/in2) to 17.0 W/cm

2

(110 W/in2)

• Maximum operating temperatures

to 595°C (1100°F)

Applications

• Medical equipment such as blood

analyzers, respiratory therapy units and

hydrotherapy baths

• Freeze protection for military hardware,

aircraft instrumentation and hydraulic

equipment

• Battery heating

• Foodservice equipment

• Factory bonding / subassemblies

• Any application requiring a flexible shape

or design

Kapton®is a registered trademark of

E.I. du Pont de Nemours & Company.

Page 5

Electric Heaters

11

W A T L O W

Application Guide

Electric Heaters

Product Overview

Continued

Radiant Heaters

With Watlow’s diverse RAYMAX

®

heater line, we have a solution for almost any

application requiring radiant heat. Our capabilities cover a wide range of

needs, from contamination-resistant panel heaters to fast-responding quartz

tubes to rugged tubular elements and high temperature ceramic panels.

Incoloy®tubular, molded ceramic fiber, quartz tube and stainless steel emitter

strip sheath materials are available.

Performance Capabilities

• Typical maximum watt densities from

4.6 W/cm2(30 W/in2) to 7.0 W/cm

2

(45 W/in2)

• Maximum operating temperatures to

1095°C (2000°F)

Applications

• Thermoforming

• Food warming

• Paint and epoxy curing

• Heat treating

• High temperature furnaces

• Tempering and annealing processes

Polymer Heaters

For the latest in heating technology from Watlow, specify a heated plastic part

in your next product. Watlow’s heated plastic parts combine resistive heating

elements with a wide range of thermoplastic compounds to yield a part that is

both heater and structure. Watlow utilizes typical injection molding techniques

and patented resistive element construction methods to produce heated plastic

parts that are durable, safe and cost-effective.

Performance Capabilities

• Typical maximum open watt densities

from 0.08 W/cm2(0.5 W/in2) to

0.59 W/cm2(3.8 W/in2)

• Typical maximum immersion watt

densities from 0.62 W/cm2(4.0 W/in2)

to 9.30 W/cm2(60 W/in2)

• Maximum operating temperatures to

220°C (428°F)

Applications

• Medical • Battery heating

• Analytical • Foodservice

• Aerospace • Transportation

• Freeze protection • Semiconductor

• Any heated part application requiring a

flexible shape

Alcryn®is a registered trademark of

Ferro Corporation.

Santoprene®is a registered trademark of

Advanced Elastomer Systems.

Page 6

12

Strip Heaters

Watlow’s mica and 375 strip heaters are the versatile solution for a number of

applications. They can be bolted or clamped to a solid surface for freeze and

moisture protection, food warming and other applications or utilized as a noncontact radiant heater. The 375 finned strip heaters are commonly used for air

heating, drying ovens and space heaters.

Performance Capabilities

• Typical maximum watt densities from

7.8 W/cm2(50 W/in2) to 15.5 W/cm

2

(100 W/in2)

• Maximum operating temperatures to

760°C (1400°F)

Applications

• Dies and molds

• Tank and platen heating

• Thermoforming

• Packaging and sealing equipment

• Ovens

• Food warming equipment

• Vulcanizing presses

• Duct, space and air heaters

• Incubators

• Autoclaves

• Freeze and moisture protection

Application Guide

Electric Heaters

Product Overview

Continued

Thick Film Heaters

Watlow layers thick film resistor and dielectric materials on quartz, stainless steel

and ceramic substrates to produce high performance industrial heaters. The

thick film heaters provide very fast temperature response and uniformity on a

low-profile heater. Thick film heaters are ideal for applications where space is

limited, where conventional heaters can’t be used, when heat output needs vary

across the surface, or in ultra-clean or aggressive chemical applications.

430 stainless steel (open air), 430 stainless

steel (immersion), aluminum nitride, quartz

(open air) and quartz (clamp-on) sheath

materials are available.

Performance Capabilities

• Typical maximum watt densities from

3 W/cm2(20 W/in2) to 27 W/cm

2

(175 W/in2)

• Maximum operating temperatures to

550°C (1022°F)

Applications

• Ultra pure aggressive chemicals

• Large panel processing

• Analytical equipment

• Foodservice equipment

• Packaging sealing equipment

• Life sciences sterilizers and GC/mass

spectroscopy

• Semiconductor wafer process equipment

• Plastics hot runners nozzles and

manifolds

Page 7

Electric Heaters

13

W A T L O W

Tubular and Process Assemblies

Watlow’s WATROD tubular heater elements and flat FIREBAR elements are

designed primarily for direct immersion in liquids such as water, oils, solvents

and process solutions, molten materials as well as air and gases. By generating

all the heat within the liquid or process, these heaters are virtually 100 percent

energy efficient. These versatile heaters can also be formed and shaped into

various geometries for radiant heating and contact surface heating applications.

UL®and CSA component recognized elements available.

Applications

• Furnaces and ovens

• Molten salt baths

• Foodservice equipment

• Semiconductor equipment

• Die casting equipment

• Metal melt and holding

• Fluidized beds

• Boilers

• Radiant heating

• Process air heating

• Drying and warming

Application Guide

Electric Heaters

Product Overview

Continued

Page 8

14

Application Guide

Electric Heaters

Most electrical heating problems

can be readily solved by determining the heat required to do the job.

To do this, the heat requirement must

be converted to electrical power and

the most practical heater can then

be selected for the job. Whether the

problem is heating solids, liquids or

gases, the method, or approach, to

determining the power requirement

is the same. All heating problems

involve the following steps to their

solution:

Define the Heating Problem

Calculate Power Requirements

System Start-up and Operating Power

Requirement

System Maintenance Power

Requirements

Operating Heat Losses

Power Evaluation

Review System Application Factors

Safe/Permissible Watt Densities

Mechanical Considerations

Operating Environment Factors

Safety Factor

Heater Life Requirements

Electrical Lead Considerations

Defining the Problem

Your heating problem must be clearly stated, paying careful attention to

defining operating parameters. Gather

this application information:

• Minimum start and finish

temperatures expected

• Maximum flow rate of material(s)

being heated

• Required time for start-up heating

and process cycle times

• Weights and dimensions of both

heated material(s) and containing

vessel(s)

• Effects of insulation and its thermal

properties

• Electrical requirements—voltage

• Temperature sensing methods and

location(s)

• Temperature controller type

• Power controller type

• Electrical limitations

And since the thermal system you’re

designing may not take into account

all the possible or unforeseen heating

requirements, don’t forget a safety

factor. A safety factor increases

heater capacity beyond calculated

requirements. For details on safety

factor, please see “Safety Factor

Calculation” under the portion of this

section dealing with “Review of Heater

Application Factors,” on page 20.

Page 9

Electric Heaters

15

W A T L O W

Short Method

Start-up watts = A + C + 2⁄3

L + Safety Factor

Operating watts = B + D + L + Safety Factor

Safety Factor is normally 10 percent to 35 percent based on application.

A = Watts required to raise the temperature of material and equipment

to the operating point, within the time desired

B = Watts required to raise temperature of the material during the

working cycle

Equation for A and B (Absorbed watts-raising temperature)

Specific heat

Weight of material (lbs)

•

of material • temperature rise (°F)

(Btu/lb • °F)

Start-up or cycle time (hrs) • 3.412

C = Watts required to melt or vaporize material during start-up period

D = Watts required to melt or vaporize material during working cycle

Equation for C and D (Absorbed watts-melting or vaporizing)

Weight of material (lbs) • heat of fusion or vaporization (Btu/lb)

Start-up or cycle time (hrs) • 3.412

L = Watts lost from surfaces by:

• Conduction-use equation below

• Radiation-use heat loss curves

• Convection-use heat loss curves

Equation for L (Lost conducted watts)

Thermal conductivity Temp. differential

of material or insulation Surface area to ambient

(Btu

•

in./ft

2

•

°F • hr) (ft2)(°F)

Thickness of material or insulation (in.) • 3.412

Application Guide

Electric Heaters

Power Calculations

Calculations for Required

Heat Energy

When performing your own calculations, refer to the Reference Data

section (begins on page 127) for

values of materials covered by

these equations.

The total heat energy (kWH or Btu)

required to satisfy the system needs

will be either of the two values shown

below depending on which calculated

result is larger.

A. Heat Required for Start-Up

B. Heat Required to Maintain the

Desired Temperature

The power required (kW) will be the

heat energy value (kWH) divided by

the required start-up or working cycle

time. The kW rating of the heater will

be the greater of these values plus a

safety factor.

The calculation of start-up and operating requirements consist of several

distinct parts that are best handled

separately. However, a short method

can also be used for a quick estimate

of heat energy required. Both methods

are defined and then evaluated using

the following formulas and methods:

Page 10

16

Equation 1

QA or QB=w •C

p

•

∆T

3.412

QA= Heat Required to Raise Temperature of Materials During

Heat-Up (Wh)

QB= Heat Required to Raise Temperature of Materials Processed

in Working Cycle (Wh)

w = Weight of Material (lb)

Cp= Specific Heat of Material (Btu/Ib •°F)

∆T = Temperature Rise of Material (T

Final

- T

Initial

)(°F)

This equation should be applied to all materials absorbing heat in the

application. Heated media, work being processed, vessels, racks, belts,

and ventilation air should be included.

Example: How much heat energy is needed to change the temperature

of 50 lbs of copper from 10°F to 70°F?

Q= w •C

p

•

∆T

= (50 lbs) •(0.10 Btu/Ib •°F) •(60°F) = 88 (Wh)

3.412

Application Guide

Electric Heaters

Power Calculations—

Conduction and Convection

Heating

Equation 1—Absorbed Energy,

Heat Required to Raise the

Temperature of a Material

Because substances all heat differently, different amounts of heat are

required in making a temperature

change. The specific heat capacity

of a substance is the quantity of heat

needed to raise the temperature of a

unit quantity of the substance by

one degree. Calling the amount of

heat added Q, which will cause a

change in temperature ∆T to a weight

of substance W, at a specific heat of

material Cp, then Q =w •C

p

•

∆T.

Since all calculations are in

watts, an additional conversion

of 3.412 Btu = 1 Wh is introduced

yielding:

Equation 2—Heat Required to

Melt or Vaporize a Material

In considering adding heat to a

substance, it is also necessary to

anticipate changes in state that might

occur during this heating such as

melting and vaporizing. The heat

needed to melt a material is known

as the latent heat of fusion and

represented by Hf. Another state

change is involved in vaporization

and condensation. The latent heat of

vaporization Hvof the substance is

the energy required to change a substance from a liquid to a vapor. This

same amount of energy is released as

the vapor condenses back to a liquid.

Equation 2

QCor QD=w •H

f

OR

w

•

H

v

3.412 3.412

QC= Heat Required to Melt/Vaporize Materials During Heat-Up (Wh)

QD= Heat Required to Melt/Vaporize Materials Processed in

Working Cycle (Wh)

w = Weight of Material (lb)

Hf= Latent Heat of Fusion (Btu/Ib)

Hv= Latent Heat of Vaporization (Btu/lb)

Example: How much energy is required to melt 50 lbs of lead?

Q = w •H

f

Q = (50 lbs) •(9.8 Btu/Ib) = 144 (Wh)

3.412 Btu/(Wh)

Changing state (melting and vaporizing) is a constant temperature process.

The Cpvalue (from Equation 1) of a material also changes with a change in

state. Separate calculations are thus required using Equation 1 for the material

below and above the phase change temperature.

Page 11

Electric Heaters

17

W A T L O W

Equation 3A—Heat Required to Replace Conduction Losses

Q

L1

=k •A • ∆T • t

e

3.412 • L

QL1= Conduction Heat Losses (Wh)

k = Thermal Conductivity

(Btu • in./ft

2

•

°F • hour)

A = Heat Transfer Surface Area (ft2)

L = Thickness of Material (in.)

∆T = Temperature Difference Across Material

(T2-T1) °F

te = Exposure Time (hr)

This expression can be used to calculate losses through insulated walls of

containers or other plane surfaces where the temperature of both surfaces

can be determined or estimated. Tabulated values of thermal conductivity are

included in the Reference Data section (begins on page 134).

Convection Heat Losses

Convection is a special case of

conduction. Convection is defined

as the transfer of heat from a high

temperature region in a gas or liquid

as a result of movement of the masses

of the fluid. The Reference Data

section (page 127) includes graphs

and charts showing natural and

forced convection losses under

various conditions.

Equation 3B—Convection Losses

Q

L2

= A • F

SL

•

C

F

QL2= Convection Heat Losses (Wh)

A = Surface Area (in2)

F

SL

= Vertical Surface Convection Loss Factor

(W/in2) Evaluated at Surface

Temperature (See Ref. 9, page 26)

CF = Surface Orientation Factor

Heated surface faces up horizontally = 1.29

Vertical = 1.00

Heated surface faces down horizontally = 0.63

Application Guide

Electric Heaters

Power Calculations

Continued

Conduction Heat Losses

Heat transfer by conduction is

the contact exchange of heat from

one body at a higher temperature to

another body at a lower temperature,

or between portions of the same body

at different temperatures.

Radiation Heat Losses

For the purposes of this section,

graphs are used to estimate radiation

losses. Charts in the Reference Data

section (page 127) give emissivity

values for various materials.

Radiation losses are not dependent

on orientation of the surface.

Emissivity is used to adjust for a

material’s ability to radiate heat

energy.

Equation 3C—Radiation Losses

Q

L3

=A • F

SL

•

e

QL3= Radiation Heat Losses (Wh)

A = Surface Area (in2)

FSL= Blackbody Radiation Loss Factor at Surface Temperature (W/in2)

e = Emissivity Correction Factor of Material Surface

Example:

Using Reference 139, page 155, we find that a blackbody radiator (perfect

radiator) at 500°F, has heat losses of 2.5 W/in2.

Polished aluminum, in contrast, (e = 0.09) only has heat losses of 0.22 W/in

2

at the same temperature (2.5 W/in

2

•

0.09 = 0.22 W/in2).

Page 12

18

Application Guide

Electric Heaters

Power Calculations

Continued

Combined Convection

and Radiation Heat Losses

Some curves in Reference 139

(page 155) combine both radiation

and convection losses. This saves

you from having to use both Equations

3B and 3C. If only the convection

component is required, then the

radiation component must be

determined separately and subtracted

from the combined curve.

Total Heat Losses

The total conduction, convection and

radiation heat losses are summed

together to allow for all losses in the

power equations. Depending on the

application, heat losses may make up

only a small fraction of total power

required... or it may be the largest

portion of the total. Therefore, do not

ignore heat losses unless previous

experience tells you it’s alright to do.

Equation 3E—Total Losses

Q

L

= QL1+ QL2+ Q

L3

If convection and radiation losses are calculated

separately. (Surfaces are not uniformly insulated

and losses must be calculated separately.)

OR

QL= QL1+ Q

L4

If combined radiation and convection curves are used.

(Pipes, ducts, uniformly insulated bodies.)

Equation 3D—Combined Convection and Radiation Heat Losses

QL4= A •F

SL

QL4= Surface Heat Losses Combined Convection and Radiation (Wh)

A = Surface Area (in2)

FSL= Combined Surface Loss Factor at Surface Temperature (W/in2)

This equation assumes a constant surface temperature.

Equation 5—Operating Power (Watts)

Po=

QB+ Q

D

+(QL)•(1 + S.F.)

t

c

QB= Heat Absorbed by Processed Materials in Working Cycle (Wh)

QD= Latent Heat Absorbed by Materials Heated in Working Cycle (Wh)

QL= Conduction, Convection, Radiation Losses (Wh)

S.F. = Safety Factor

tc= Cycle Time Required (hr)

Equation 4—Start-Up Power (Watts)

P

s

=

QA+ Q

C

+

2

(QL)

•

(1 + S.F.)

t

s

3

QA= Heat Absorbed by Materials During Heat-Up (Wh)

QC= Latent Heat Absorbed During Heat-Up (Wh)

QL= Conduction, Convection, Radiation Losses (Wh)

S.F. = Safety Factor

ts= Start-Up (Heat-Up) Time Required (hr)

During start-up of a system the losses are zero, and rise to 100 percent at

process temperature. A good approximation of actual losses is obtained when

heat losses (QL) are multiplied by 2⁄3 .

Equations 4 and 5 Start-Up

and Operating Power Required

Both of these equations estimate

required energy and convert it to

power. Since power (watts) specifies

an energy rate, we can use power to

select electric heater requirements.

Both the start-up power and the

operating power must be analyzed

before heater selection can take

place.

Page 13

Electric Heaters

19

W A T L O W

Application Guide

Electric Heaters

Power Calculations—

Radiant Heating

When the primary mode of heat transfer is radiation, we add a step after

Equation 5.

Equation 6 is used to calculate the net

radiant heat transfer between two

bodies. We use this to calculate either

the radiant heater temperature

required or (if we know the heater

temperature, but not the power

required) the maximum power which

can be transfered to the load.

Equation 6—Radiation Heat Transfer

Between Infinite Size Parallel Surfaces

P

R

=

S (T

4

- T4) F

A (144 in2/ft2) (3.412 Btu/Wh)

P

R

= Power Absorbed by the Load (watts) - from Equation 4 or 5

A = Area of Heater (in2) - known or assumed

S = Stephan Boltzman Constant

= 0.1714 • 10

-8

(Btu/Hr. Sq. Ft. °R4)

T1(°R) = Emitter Temperature (°F + 460)

T2(°R) = Load Temperature (°F + 460)

e

f

= Emissivity Correction Factor - see below

F = Shape Factor (0 to 1.0) - from Reference 139, page 155

(1)

e

f

1

2

Emissivity Correction Factor (ef)

Plane Surfaces

Concentric Cylinders

Inner Radiating Outward

Concentric Cylinders

Outer Radiating Inward

1 1

eSe

L

ef = - 1+

1

e

S

ef =

+

e

L

- 1

1

()

D

S

D

L

1

e

S

ef =

+

- 1

()

e

L

1

D

S

D

L

•

eS= Heater Emissivity (from Material

Emissivity Tables)

eL= Load Emissivity (from Material

Emissivity Tables)

DS= Heater Diameter

DL= Load Diameter

Power Evaluation

After calculating the start-up and

operating power requirements, a

comparison must be made and

various options evaluated.

Shown in Reference 1 are the start-up

and operating watts displayed in a

graphic format to help you see how

power requirements add up.

With this graphic aid in mind, the

following evaluations are possible:

• Compare start-up watts to

operating watts.

• Evaluate effects of lengthening

start-up time such that start-up

watts equals operating watts (use

timer to start system before shift).

Power (Watts)

Time (Hours)

Start-Up

7

Process

10% Safety Factor

Losses

2

/3 of

Conduction

Convection

Radiation

{

Initial Heat to

Melt or Vaporize

(Q

L)

(QC)

Initial Heat to

Raise Equipment

and Materials

(Q

A)

Operating Process Heat to

Raise Product from T

1

to T

2

Process Heat—Melting or Vaporizing

Operating Losses

Conduction

Convection

Radiation

10% Safety Factor

(Q

D)

(QB)

S.F.

(Q

L)

8

9

10

6

5

4

3

2

1

Comparison of Start-Up and Operating Power Requirements

Ref. 1

Page 14

20

• Recognize that more heating

capacity exists than is being

utilized. (A short start-up time

requirement needs more wattage

than the process in wattage.)

• Identify where most energy is going and redesign or add insulation

to reduce wattage requirements.

Application Guide

Electric Heaters

Power Evaluation

Continued

Having considered the entire system,

a re-evaluation of start-up time,

production capacity, and insulating

methods should be made.

Review of Heater

Application Factors

Safe/Permissible Watt Densities

A heater’s watt density rating gives us

an indication of how hot a heater will

operate. We use this information to

establish limits on the application of

heaters at various temperatures and

under a variety of operating

conditions.

The maximum operating watt density

is based on applying a heater such

that heater life will exceed one year.

In conjunction with desired life, watt

density is used to calculate both the

required number of heaters and

their size.

Silicone Rubber Heater Example:

1000 watts are required for heating

a 150°C (300°F) block.

From the silicone rubber heater watt

density chart in the flexible heater

section of the Watlow Heaters catalog,

page 170.

Maximum Watt Density =

16 W/in2 for wirewound on-off

(2.5 W/in2) or 38 W/in2 (6 W/cm2) for

etched foil

This means 63 in2 of wirewound

(five 3 inch • 5 inch heaters) or 27 in

2

of etched foil (two 3 inch • 5 inch

heaters) are required.

Mechanical Considerations

Full access must be provided (in the

design process) for ease of heater

replacement. This is usually done with

shrouds or guards over the heaters.

These guards also serve a secondary

purpose in that they may minimize

convective heat losses from the back

of heaters and increase efficiency of

the system.

In all applications where the heater

must be attached to a surface, it is

extremely important to maintain as

intimate a contact as possible to aid

heat transfer. Heaters mounted on the

exterior of a part should have

clamping bands or bolts to facilitate

this contact. Heaters inserted in holes

should have hole fits as tight as

possible. Whenever possible, the

holes should exit through the opposite

side of the material to facilitate

removal of the heater.

choice of the external sheath material is very important to heater

life. A corrosion guide is provided,

page 144, and should be consulted

in order to avoid using materials

that are not compatible with a

particular environment.

• Explosive environments generally

require that the heater be completely isolated from potentially

dangerous areas. This is accomplished by inserting the heater in protective wells and routing the wiring

through sealed passage-ways out

of the hazardous area. Very close

fusing is recommended in these

cases to minimize the magnitude of

the failure, should it occur.

Operating Environment Factors

• Contaminants are the primary

cause of shortened heater life.

Decomposed oils and plastics

(hydrocarbons in general), conductive pastes used as anti-seize

materials, and molten metals and

metal vapors can all create situations that affect heater life. Some

heater constructions are better

sealed against contaminants than

others. In analyzing applications,

all possible contaminants must be

listed in order to be able to fully

evaluate the proposed heater.

Example: Heat is required to maintain molten zinc in the passageways

of a zinc die casting machine. The

possible contaminants for this application are as follows:

a. molten zinc metal

b. zinc vapor

c. hydraulic oils

d. high temperature anti-seize

materials

e. moisture, if die cooling is aided

by water circulation

All of these factors indicate that a

highly sealed heater construction

is required.

• The corrosiveness of the materials

heated, or the materials that will

contact the heater must also be

taken into consideration. Even if

a heater is completely sealed, the

Page 15

Electric Heaters

21

W A T L O W

Application Guide

Electric Heaters

Review of Heater

Application Factors

Continued

Below are the estimated life expectancies for mineral insulated heater

types: FIREROD

®

, FIREBAR®,

Tubular, MI Cable, MI Strip, MI Band.

815 (1500) 3

1

⁄2 yrs.

870* (1600)* 1 yr. (2000 hrs.)

925 (1700) 4 mos.

980 (1800) 1 1⁄2 mos.

1040 (1900) 2 wks.

1095 (2000) 1 wk.

1150 (2100) 2 days

* Application charts and operating recommen-

dations use maximum 870°C (1600°F) internal

temperature to insure expected heater life

greater than one year.

Internal Element

Temperature Approximate

°C (°F) Life

Heater Life Requirements

Temperature

The higher the temperature, the

shorter a heater’s service life. Mineral

insulated heaters using traditional

alloys for resistance elements are

subject to the life limiting factor of

wire oxidation. The winding wire

oxidizes at a rate proportional to the

element temperature. If the element

temperature is known it is possible to

project a heater life as shown on the

table in Reference 2.

Heaters utilizing lower temperature

insulating materials (silicone rubber

and mica) have life limiting factors

associated with exceeding the

temperature limits of the insulation

and with thermal cycling. Flexible

heaters and mica strip and band

heaters must be properly sized and

controlled to minimize the temperature

swings during thermal cycling of the

elements.

Thermal Cycling

Excessive thermal cycling will

accelerate heater failure. The worst

cycle rate is one which allows full

expansion and full contraction of the

heater at a high frequency

(approximately 30 to 60 seconds on

and off).

Prevent excessive cycling by using

solid state relays (SSRs) or SCR

power controllers. If using SSRs, set

the temperature controller’s cycle time

to one second. If using SCR power

controllers (like Watlow’s DIN-AMITE®), be sure to use the variable

time base, burst-firing version.

For Immersion Heaters

Use the Corrosion Guide, page 144,

and the Selection Guides in the

Tubular Elements and Assemblies

Ref. 2

Safety Factor Calculation

Heaters should always be sized for a

higher value than the calculated

figure, often referred to as adding in a

safety factor.

Generally speaking, the fewer

variables and outside influences—the

smaller the safety factor.

Here are some general guidelines:

• 10 percent safety factor for large

heating systems or when there are

very few unknown variables.

• 20 percent safety factor for small to

medium heating systems where

you are not 100 percent sure you

have accurate information.

• 20 to 35 percent for heating

systems where you are making

many assumptions.

section of the Watlow Heaters catalog,

page 262, to ensure that the sheath

material and watt density ratings are

compatible with the liquid being

heated.

Immersion heaters used in tanks

should be mounted horizontally near

the tank bottom to maximize convective circulation. However, locate the

heater high enough to be above any

sludge build-up in the bottom of the

tank. Vertical mounting is not

recommended.

The entire heated length of the

heater should be immersed at all

times. Do not locate the heater in a

restricted space where free boiling or

a steam trap could occur.

Scale build-up on the sheath and

sludge on the bottom of the tank must

be minimized. If not controlled they

will inhibit heat transfer to the liquid

and possibly cause overheating and

failure.

Extreme caution should be taken not

to get silicone lubricant on the heated

section of the heater. The silicone will

prevent the “wetting” of the sheath by

the liquid, act as an insulator, and

possibly cause the heater to fail.

Page 16

22

Application Guide

Electric Heaters

Review of Heater

Application Factors

Continued

Electrical Lead Considerations

General considerations in selecting

various lead types are:

• Temperature of lead area

• Contaminants in the lead

area

• Flexibility required

• Abrasion resistance

required

• Relative cost

Temperatures listed indicate actual

physical operating limits of various

wire types. Wires are sometimes rated

by CSA, UL®and other agencies for

operating at much lower temperatures. In this case, the rating agency

temperature limit is the maximum level

at which this wire has been tested. If

agency approvals are required, don’t

exceed their temperature limits.

Lead Protection

Metal Overbraid Average Good Excellent Moderate

Flexible Conduit Good Average Excellent Moderate

Lead Insulation

Ceramic Beads 650 (1200) Poor Poor Average High

Mica-Glass Braid

(Silicone or Teflon

®

Impregnated) 540 (1000) Poor Good Average High

Glass Braid

(Silicone

Impregnated) 400 (750) Poor Good Average Low

Silicone Rubber 260 (500) Good Good Poor Low

Teflon

®

260 (500) Excellent Good Good Low

PVC 65 (150) Good Good Poor Low

Maximum

Lead Area Contamination Abrasion Relative

Lead Types Temperature Resistance Flexibility Resistance Cost

°C (°F)

Lead Characteristics—Ref. 3

Teflon®is a registered trademark of

E.I. du Pont de Nemours & Company.

UL®is a registered trademark of the

Underwriter’s Laboratories Inc.

——

——

Select Heater

Heater Costs

After calculating wattage required and

considering various heater attributes,

the scope of possible heater types

should be narrowed considerably.

Now, several factors not previously

examined must be considered before

final heater type selection: installation,

operation and replacement costs.

Initial Installation Cost

Each heater type has specific

installation costs to be considered.

• Machining required—

mill, drill, ream

• Materials required—

heater, brackets, wiring

• Labor to mount and wire

heating elements

Operating Cost

The total system operating cost is a

composite of two factors. It is usually

best to examine cost on an annual

basis:

• Total cost of energy

(kW Hours) ($/kWH)

Replacement Cost

The cost of a new heater, lost production time, removal and installation of

the new heater must be considered.

Generally, these costs are actually

much greater than expected. Heater

life must be such that replacement

can be scheduled and planned during off-peak production times to avoid

lost production.

• Removal of existing heater

• Equipment downtime cost

• Material cost—

heater, brackets, wiring

• Labor to remove and install

heating elements

• Additional purchasing costs

• Scrap products after heater failure

and during restart of process

• Frequency of burnouts

Page 17

Electric Heaters

23

W A T L O W

Case 2: Shrouded and Insulated = 2.38 kW/H

Annual Energy Cost:

2080 Hours •2.38 kW/H •$0.07/kWH = $346.00

Replacement Cost:

Same as Case 1 = 340.00

Total/Year = $686.00

Case 1: Shrouded and Uninsulated = 4.06 kW/H

Annual Energy Cost:

2080 Hours •4.06 kW/H •$0.07/kWH = $591.00

Replacement Cost:

5 Heaters •$12.00 Each = 60.00

4 Hours Labor to Install •$20.00/hr = 80.00

4 Hours Lost Production Time •$50.00/hr = 200.00

Total/Year = $931.00

Application Guide

Electric Heaters

Select Heater Type, Size

and Quantity

Example: A plastic extrusion barrel is operating 40 hours per week. Five

band heaters are utilized, 1000 watts each. Energy cost $0.07/kWH. Assume

one shift operation or 2080 hours per year Actual power usage is as follows:

Here, the cost of operation is much less when insulation is used.

Page 18

24

Application Guide

Electric Heaters

Reference Data

Ohm’s Law

Ref. 4

VI

WR

(Volts)

(Amps)

(Ohms)

(Watts)

WR

IR

I

2

R

VI

W

I

V

I

W

I

2

V

R

W

V

2V2

W

2V2

R

W

R

Volts

Volts = Watts x Ohms

Volts = Amperes x Ohms

Volts =

Watts

Amperes

Amperes

Amperes =

Watts

Volts

Amperes =

Watts

Ohms

Amperes =

Volts

Ohms

Watts

Watts =

Volts

2

Ohms

Watts = Amperes2 x Ohms

Watts = Volts x Amperes

Ohms

Ohms =

Volts

Amperes

Ohms =

Volts

2

Watts

Ohms =

Watts

Amperes

2

)

W2 = W1 x

V

2

2

V

1

(

3 Phase Amperes =

Total Watts

Volts x 1.732

Wattage varies directly as ratio of

voltages squared

Page 19

Electric Heaters

25

W A T L O W

3-Phase Open Delta

Ref. 8

3-Phase Delta (Balanced Load)

Ref. 7

3-Phase Wye (Balanced Load)

Ref. 5

3-Phase Open Wye (No Neutral)

Ref. 6

Application Guide

Electric Heaters

Reference Data

Continued

R

2

R

1

R

3

I

L

I

L

I

P

V

P

V

L

Equations For Delta Only

IP = IL/1.73

V

P

= V

L

W

DELTA

= 3(V

L

2

)/R

W

DELTA

= 1.73 VLI

L

R

1

R

3

I

L03

I

L01

I

P01

V

P

V

L

I

P03

I

L02

Equations For Open Delta Only

VP = V

L

I

PO1

= I

PO3

= I

LO2

I

LO3

= 1.73 I

PO1

W

0DELTA

= 2 (V

L

2

/R)

V

L

I

L

R

3

R

1

R

2

I

P

V

P

Equations For Wye Only

I

P

= I

L

V

P

= V

L

/1.73

W

WYE

= V

L

2

/R = 3(V

P

2

)/R

W

WYE

= 1.73 V

LIL

V

L

I

LO

R

1

R

2

I

PO

V

PO

Equations For Open Wye Only

(No Neutral)

I

PO

= I

LO

V

PO

= V

L

/2

W

0WYE

=

1

/2 (V

L

2

/R)

W

0WYE

= 2 (V

PO

2

/R)

Typical 3-Phase Wiring Diagrams and Equations for Resistive Heaters

Definitions

For Both Wye and Delta

(Balanced Loads)

VP= Phase Voltage

VL= Line Voltage

IP= Phase Current

IL= Line Current

R= R1= R2= R3=

= Resistance of each branch

W = Wattage

Wye and Delta Equivalents

W

DELTA

= 3 W

WYE

W

ODELTA

= 2⁄3 W

DELTA

W

OWYE

= 1⁄2 W

WYE

Page 20

26

26

Application Guide

Electric Heaters

Heat Loss Factors

and Graphs

Heat Losses at 70°F Ambient

How to use the graph for more

accurate calculations

Ref. 9—Convection curve

correction factors:

For losses from Multiply convection

top surfaces or curve value by

from horizontal 1.29

pipes

For side surfaces Use convection

and vertical curve directly

pipes

For bottom Multiply

surfaces convection curve

value by 0.63

Radiation Curve Correction Factors

The radiation curve shows losses

from a perfect blackbody and are not

dependent upon position. Commonly

used block materials lose less heat by

radiation than a blackbody, so correction factors are applied. These corrections are the emissivity (e) values

listed to the right:

Total Heat Losses =

Radiation losses (curve value times e)

+ Convection losses (top)

+ Convection losses (sides)

+ Convection losses (bottom)

= Conduction losses

(where applicable)

Ref. 9

Temperature of Surface—°F

Losses—W/in

2

2000

1800

1600

1400

1200

1000

800

600

400

200

0.1 0.2 0.3 0.4

0.6 0.8 1 2 3 4 5 6 7 8910 20 30 405060 80100

Convection—Vertical Surface

Combined Radiation and Convection—

Oxidized Aluminum

Radiation—Black Body

Combined Radiation and Convection—

Oxidized Steel

Heat Losses from Uninsulated Surfaces

Page 21

Electric Heaters

27

W A T L O W

Asbestos 0.25-0.2

Asphalt 0.40-0.2

Brickwork 0.22-0.2

Carbon 0.20-0.2 Most non-metals:

Glass 0.20-0.2 0.90

Paper 0.45-0.2

Plastic 0.2-0.5.-..2

Rubber 0.40-0.2

Silicon Carbide 0.20-0.230.-..

Textiles —0.2

Wood, Oak 0.57-0.2

Additional information on emissivities is available

from Watlow.

Specific

Material Heat Emissivity

Btu/lb-°F

Some Material Emissivities/Non-Metals—Ref. 11

Application Guide

Electric Data

Heat Loss Factors

and Graphs

Continued

Helpful Hint: The graphs for losses

from uninsulated and insulated

surfaces are hard to read at low

temperatures close to ambient. Here

are two easy-to-use calculations that

are only rule-of-thumb approximations

when used within the limits noted.

Rule #1: Losses from an uninsulated

surface (with an emissivity close

to 1.0): (This applies only to temperatures between ambient and about

250°F)

Losses (W/in2) =

∆T (°F) rise above ambient

200

Rule #2: Losses from an insulated

surface: (This insulation is assumed

to be one inch thick and have a

K-value of about 0.5 Btu-in/hr - ft2-°F.

Use only for surfaces less than 800°F.)

Losses (W/in2) =

∆T (°F) rise above ambient

950

Blackbody 0.75 1.00

Aluminum 0.24 0.09 0.11 0.22

Brass 0.10 0.04 0.35 0.60

Copper 0.10 0.04 0.03 0.65

Incoloy®800 0.12 0.20 0.60 0.92

Inconel®600 0.11 0.20 0.60 0.92

Iron, Cast 0.12 — 0.80 0.85

Lead, solid 0.03 — 0.28 —

Magnesium 0.23 ———

Nickel 200 0.11 ———

Nichrome, 80-20 0.11 ———

Solder, 50-50 0.04 ———

Steel

mild 0.12 0.10 0.75 0.85

stainless 304 0.11 0.17 0.57 0.85

stainless 430 0.11 0.17 0.57 0.85

Tin 0.056 ———

Zinc 0.10 — 0.25 —

Some Material Emissivities/Metals—Ref. 10

Specific Emissivity

Material Heat Polished Medium Heavy

Btu/lb-°F Surface Oxide Oxide

Incoloy®and Inconel®are registered

trademarks of the Special Metals Corporation.

Page 22

28

Application Guide

Electric Heaters

Heat Loss Factors

and Graphs

Continued

1. Based upon combined natural convection

and radiation losses into 70°F environment.

2. Insulation characteristics

k = 0.67 @ 200°F

k = 0.83 @ 1000°F.

3. For molded ceramic fiber products and

packed or tightly packed insulation, losses

will be lower than values shown.

For 2 or 3 inches Insulation multiply by 0.84

For 4 or 5 inches Insulation multiply by 0.81

For 6 inches Insulation multiply by 0.79

Losses—W/in

2

123456789

10 11

12 13 14 15

16 17

18 19 20

Temperature of Surface—°F

1400

1300

1200

110 0

1000

900

800

700

600

500

Heat Losses from Horizontal Metal Surfaces

0

Losses—W/ft

2

100 200 300 400 500 600 700 800 900 1000 1100 1200 1300

Temperature of Surface—°F

210

19 0

17 0

15 0

13 0

110

90

70

60% Humidity

40% Humidity

Combined Convection and Radiation—Losses from Water Surfaces

0

0.1 0.2

0.3

0.4

0.5

0.6 0.7 0.8 0.9 1.0 1.1 1.2 1.3 1.4 1.5

1. 6

1.7 1. 8

Losses—W/in

2

2600

2400

2200

2000

1800

1600

1400

1200

1000

800

600

400

200

Temperature of Insulated Surface—°F

6" Insulation

5" Insulation

4" Insulation

3" Insulation

2" Insulation

1" Insulation

0" Insulation

Heat Losses from Vertical Insulated Surfaces

0

Ref. 14

Ref. 13

Ref. 12

* For losses of molten metal surfaces,

use the curve e=0.40.

0

2

.

0

=

e

n

o

i

t

a

i

n

o

i

t

c

e

v

n

o

C

l

a

r

u

t

a

N

n

i

b

m

o

C

t

c

e

v

n

o

C

d

e

n

i

b

m

o

C

o

C

d

a

R

d

n

a

n

o

i

n

o

C

d

e

e

n

i

b

m

n

a

n

o

i

t

c

e

v

t

c

e

v

n

o

C

d

o

i

t

a

i

d

a

R

d

R

d

n

a

n

o

i

*

0

4

.

0

=

e

n

0

.

1

=

e

n

o

i

t

a

i

d

a

Page 23

Electric Heaters

29

W A T L O W

Application Guide

Electric Heaters

Heat Loss Factors

and Graphs

Continued

Losses—W/ft

2

100 200 300 400 500 600 700 800 900 1000 1100 1200 1300

Temperature of Surface—°F

600

500

400

300

200

100

Combined Convection and Radiation—Losses from Oil or Paraffin Surfaces

0

0

Wind Velocity Correction Factor

3.5

3.0

2.5

2.0

1.5

1.0

100 200 300 400 500 600 700

Wind Velocity—MPH

2.5

5

10

15

20

25

30

35

Wind Velocity Effects on Exposed, Bare and Insulated Surfaces

Temperature Difference Between Exposed Surface and Air—°F (∆T)

Ref. 15

Ref. 16

How to Use:

1. Calculate surface heat losses at still air

conditions (ref. Equation #3, page 17)

2. Multiply result by proper wind correction

factor from the curves below to determine

total heat losses.

Page 24

30

For Steel: Use table or metric equation.

kW = Kilograms x Temperature Rise (°C)

5040 x Heat-up Time (hrs.)

kW = Pounds x Temperature Rise (°F)

20,000 x Heat-up Time (hrs.)

Application Guide

Electric Heaters

Quick Estimates of

Wattage Requirements

The following tables can be used

to make quick estimates of wattage

requirements.

25 0.06 0.12 0.25 .37 0.50 0.65 0.75

50 0.12 0.25 0.50 .75 1.00 1.25 1.50

100 0.25 0.50 1.00 1.50 2.00 2.50 3.00

150 0.37 0.75 1.50 2.25 3.00 3.75 4.50

200 0.50 1.00 2.00 3.00 4.00 5.00 6.00

250 0.65 1.25 2.50 3.75 5.00 6.25 7.50

300 0.75 1.50 3.00 4.50 6.00 7.50 9.00

400 1.00 2.00 4.00 6.00 8.00 10.00 12.00

500 1.25 2.50 5.00 7.50 10.00 12.50 15.00

600 1.50 3.00 6.00 9.00 12.00 15.00 18.00

700 1.75 3.50 7.00 10.50 14.00 17.50 21.00

800 2.00 4.00 8.00 12.00 16.00 20.00 24.00

900 2.25 4.50 9.00 13.50 18.00 22.50 27.00

1000 2.50 5.00 10.00 15.00 20.00 25.00 30.00

Amount

Temperature Rise °F

of Steel

50° 100° 200° 300° 400° 500° 600°

(lb.)

Kilowatts to Heat in One Hour

* Read across in table from nearest amount

in pounds of steel to desired temperature rise

column and note kilowatts to heat in one hour.

Includes a 40 percent safety factor to

compensate for high heat losses and/or low

power voltage.

Kilowatt-Hours to Heat Steel*—Ref. 17

0.5 3.74 0.3 0.5 1 2 2 3

1.0 7.48 0.5 1.0 2 3 4 6

2.0 14.96 1.0 1.0 2 4 6 11

3.0 22.25 2.0 3.0 6 9 12 16

4.0 29.9 2.0 4.0 8 12 16 22

5.0 37.4 3.0 4.0 9 15 20 25

10.0 74.8 5.0 9.0 18 29 40 52

15.0 112.5 7.0 14.0 28 44 60 77

20.0 149.6 9.0 18.0 37 58 80 102

25.0 187 11.0 22.0 46 72 100 127

30.0 222.5 13.0 27.0 56 86 120 151

35.0 252 16.0 31.0 65 100 139 176

40.0 299 18.0 36.0 74 115 158 201

45.0 336.5 20.0 40.0 84 129 178 226

50.0 374 22.0 45.0 93 144 197 252

55.0 412 25.0 49.0 102 158 217 276

60.0 449 27.0 54.0 112 172 236 302

65.0 486 29.0 58.0 121 186 255 326

70.0 524 32.0 62.0 130 200 275 350

75.0 562 34.0 67.0 140 215 294 375

Kilowatt-Hours to Heat Oil*—Ref. 18

Temperature Rise °F

Amount of Oil

50°

Cubic

Feet

Gallons

100°

200°

300°

400°

500°

Add 5 percent for uninsulated tanks.* Read across in table from nearest amount

in gallons of liquids to desired temperature rise

column and note kilowatts to heat in one hour.

For Oil:

Use equation or table.

kW = Gallons x Temperature Rise (°F)

800 x Heat-up time (hrs.)

OR

kW = Liters x Temperature Rise (°C)

1680 x Heat-up time (hrs.)

1 cu. ft. = 7.49 gallons

Page 25

Electric Heaters

31

W A T L O W

Application Guide

Electric Heaters

Quick Estimates of

Wattage Requirements

Continued

0.66 5 0.3 0.5 0.8 1.1 1.3 1.6 1.9

1.3 10 0.5 1.1 1.6 2.1 2.7 3.2 3.7

2.0 13 0.8 1.6 2.4 3.2 4.0 4.8 5.6

2.7 20 1.1 2.2 3.2 4.3 5.3 6.4 7.5

3.3 25 1.3 2.7 4.0 5.3 6.7 8.0 9.3

4.0 30 1.6 3.2 4.8 6.4 8.0 9.6 12.0

5.3 40 2.1 4.0 6.4 8.5 11.0 13.0 15.0

6.7 50 2.7 5.4 8.0 10.7 13.0 16.0 19.0

8.0 60 3.3 6.4 9.6 12.8 16.0 19.0 22.0

9.4 70 3.7 7.5 11.2 15.0 19.0 22.0 26.0

10.7 80 4.3 8.5 13.0 17.0 21.0 26.0 30.0

12.0 90 5.0 10.0 14.5 19.0 24.0 29.0 34.0

13.4 100 5.5 11.0 16.0 21.0 27.0 32.0 37.0

16.7 125 7.0 13.0 20.0 27.0 33.0 40.0 47.0

20.0 150 8.0 16.0 24.0 32.0 40.0 48.0 56.0

23.4 175 9.0 18.0 28.0 37.0 47.0 56.0 65.0

26.7 200 11.0 21.0 32.0 43.0 53.0 64.0 75.0

33.7 250 13.0 27.0 40.0 53.0 67.0 80.0 93.0

40.0 300 16.0 32.0 47.0 64.0 80.0 96.0 112.0

53.4 400 21.0 43.0 64.0 85.0 107.0 128.0 149.0

66.8 500 27.0 53.0 80.0 107.0 133.0 160.0 187.0

* Read across in table from nearest amount in

gallons of liquid to desired temperature rise

column and note kilowatts to heat in one hour.

Kilowatt-Hours to Heat Water*—Ref. 19

Amount of Liquid

Temperature Rise °F

ft

3

Gallons

20°

40°

60°

80°

100°

120°

140°

Kilowatts to Heat in One Hour

For Heating Flowing Water:

kW = GPM x Temperature Rise (°F) x 0.16

OR

kW = Liters/min. x Temperature Rise (°C) x 0.076

For Heating Water in Tanks: Use equation or table.

kW = Gallons x Temperature Rise (°F)

375 x Heat-up Time (hrs)

OR

kW = Liters x Temperature Rise (°C)

790 x Heat-up Time (hrs)

1 cu. ft. = 7.49 gallons

Kilowatt-Hours to Superheat Steam

Ref. 20

1. Plot points on lines P, Q and S.

P represents the inlet temperature

(and saturation pressure) of the

system.

Q represents the liquid content of

the water vapor.

S indicates the outlet temperature

minus the saturated temperature.

W indicates the heat content of the

water vapor.

2. Draw a straight line from P through

Q to W. Read W1.

3. Draw a straight line from P through

S to W. Read W2.

4. Required watts = Weight (lbs.) of

steam/hour x (W2-W1)

Watt density is critical. Review temperature and velocity prior to heater

selection.

Reference is 80 percent quality at

20 psig.

Saturated Temperature—°F

Gauge Pressure—lbs/in

2

Heat Content—Watt–hour/lb

0

10

20

30

40

50

60

70

80

90

10 0

110

12 0

13 0

14 0

15 0

16 0

17 0

18 0

19 0

200

400

300

15 0

10 0

50

25

10

0

450

400

350

300

250

210

85

90

95

10 0

Quality

—% R.h.

P

W

Q

10 0

200

300

400

500

600

700

800

900

Degrees of Superheat

—°

F

S

Page 26

32

Application Guide

Electric Heaters

Quick Estimates of

Wattage Requirements

Continued

100 1.7 3.3 5.0 6.7 8.3 10.0 11.7 13.3 15.0 16.7 20.0

200 3.3 6.7 10.0 13.3 16.7 20.0 23.3 26.7 30.0 33.3 40.0

300 5.0 10.0 15.0 20.0 25.0 30.0 35.0 40.0 45.0 50.0 60.0

400 6.7 13.3 20.0 26.7 33.3 40.0 46.7 53.3 60.0 66.7 80.0

500 8.3 16.7 25.0 33.3 41.7 50.0 58.3 66.7 75.0 83.3 100.0

600 10.0 20.0 30.0 40.0 50.0 60.0 70.0 80.0 90.0 100.0 120.0

700 11.7 23.3 35.0 46.7 58.3 70.0 81.7 93.3 105.0 116.7 140.0

800 13.3 26.7 40.0 53.3 66.7 80.0 93.3 106.7 120.0 133.3 160.0

900 15.0 30.0 45.0 60.0 75.0 90.0 105.0 120.0 135.0 150.0 180.0

1000 16.7 33.3 50.0 66.7 83.3 100.0 116.7 133.3 150.0 166.7 200.0

1100 18.3 36.7 55.0 73.3 91.7 110.0 128.3 146.7 165.0 183.3 220.0

1200 20.0 40.0 60.0 80.0 100.0 120.0 140.0 160.0 180.0 200.0 240.0

Kilowatt-Hours to Heat Air—Ref. 21

Temperature Rise °F

Amt.

of

Air

CFM

50°

100°

150°

200°

250°

300°

350°

400°

450°

500°

600°

Use the maximum anticipated airflow. This equation assumes insulated duct (negligible heat loss).

70°F inlet air and 14.7 psia.

For Air:

Use equation or table.

kW = CFM* x Temperature Rise (°F)

3000

OR

kW = Cubic Meters/Min* x Temperature Rise (°C)

47

For Compressed Air:

kW = CFM** x Density** x Temperature Rise (°F)

228

OR

kW = Cubic Meters/Min** x Temperature Rise (°C) x Density (kg/m3)**

57.5

**Measured at normal temperature and pressure.

**Measured at heater system inlet temperature and pressure.

Loading...

Loading...