Page 1

WATLOW

FIREROD®CARTRIDGE HEATERS

PROVIDE QUALITY

AND

ENGINEERING

EXPERTISE FOR YOUR

MOST DEMANDING

APPLICA TIONS

Page 2

Selecting cartridge heaters for

industrial applications should involve

more than just specifying temperature

and power requirements. Today’s users

benefit when their cartridge heater

supplier can provide:

•

Custom design for specific

applications

•

On-time delivery

•

A quality product for maximum

performance

•

Expert technical assistance

Watlow began answering these

cartridge heater needs in 1954, when

we designed and manufactured the

first swaged cartridge heater — the

FIREROD

®

—and revolutionized the

heating element industry.

We have continued to meet our

customer’s most challenging needs

with ongoing research and

technological improvements; solving

your toughest heating problems

through quality products, engineering

assistance and fast delivery.

..........................

FOUR QUESTIONS TO ASK

WHEN SELECTING YOUR

CARTRIDGE HEATER SUPPLIER

1.

2.

3.

4.

1. Does my cartridge heater supplier

provide a complete product and

service package?

2. Can I be sure I’ll get the products

I need, when I need them?

3. Is my cartridge heater supplier

building the best product possible?

4. Does my cartridge heater supplier

provide application assistance to

solve my heating problems?

Page 3

2.

1.

1. Does my cartridge

heater supplier provide

a complete product

and service package?

Watlow does.

•

Watlow is the only designer and

manufacturer to offer single source

thermal system capability with our

complete line of heaters, sensors and

controllers. Y ou are assured of Watlow

quality in each system component.

•

Continuous product testing is one

way we ensure quality at Watlow. Our

commitment to Total Quality and

World-Class Manufacturing programs

also leads to continual product

improvements for the FIREROD heater.

•

Prototype testing is often performed

for special customer applications, such

as unusual zoning, temperature

response and special life requirements.

Based on test results, Watlow can

recommend the proper operating

conditions to ensure long heater life

while providing optimal performance.

•

Watlow is a certified cartridge

heater supplier for many major

industrial manufacturers, having

passed stringent quality and

delivery tests.

•

Watlow’s worldwide sales and

distributor networks provide instant

access to expert technical advice,

application assistance and after-thesale service.

our customers send us their production

usage schedules and we ensure that

the required number of heaters are in

their plant, on time.

Watlow offers ship-to-stock delivery

as required by many vendor

certification programs. We’ve

established partnerships with a

number of customers requiring the

quality levels and reliability necessary

for these programs to succeed. This

has led to instituting specific in-line

inspection and test fixtures that

duplicate those used by our

customers.

Our in-house quality control teams

are well equipped to handle your

inspection needs.

Ordering a special or customdesigned cartridge heater doesn’t

mean you’ll have to wait months.

Because of our flexible World Class

Manufacturing “work cells” for the

FIREROD heater line, custom sizes can

often be designed and manufactured

in three to five working days.

2. Can I be sure I’ll get

the products I need

when I need them?

Watlow says yes.

Product availability is recognized as

industry’s single biggest problem in

maintaining demanding production

schedules.

Watlow offers several delivery

programs, such as Same Day

Shipment, Just-In-Time and Ship-ToStock, that allow you to reduce heater

inventories as well as costly downtime.

Watlow’s unique LA —or Lead

Adaptor —modification method

utilizes a patented lead connection

technique permitting same day

shipment on more than 150,000

configurations of stock FIREROD

heaters and lead combinations. Many

orders received by 4 p.m. local time

can be shipped same day.

The LA modification begins with a

standard FIREROD unit. The heater is

stocked on the shelf prior to lead

attachment. When the order is

received, the stock unit undergoes a

patented process and a specially

designed cap is swaged onto the

FIREROD heater to permanently

secure the leads.

Watlow has taken a leadership role

concerning your JIT programs. We

have special account coordinators

who can work closely with your

purchasing department to assure that

both release and ship dates are

closely monitored and met to avoid

costly shut downs or delays. Some of

SAME DAY SHIPMENT

...........................

JUST-IN-TIME DELIVERY

SHIP-TO-STOCK

EMERGENCY DELIVERY OPTION

(EDO)

Page 4

3.

While many cartridge heater

manufacturers now swage their

products, Watlow has developed its

own unique swaging process. This

assures consistent heater compaction

for longer heater life and uniform

temperatures. It also allows us to

manufacturer higher watt density

heaters.

Due to our tight manufacturing

controls, Watlow can provide the

smallest “no heat” section - on both

ends of the heater - of any cartridge

heater manufacturer. This is true of our

stock FIREROD heaters as well.

FIREROD cartridge heaters are

available in 1⁄8-inch to 1-inch

diameters and various lengths to

cover different applications. Watlow is

one of the only companies to offer

such a variety of specifications.

..........................

resistance, two factors that will reduce

lead wire failure and makes installation

easier.

•

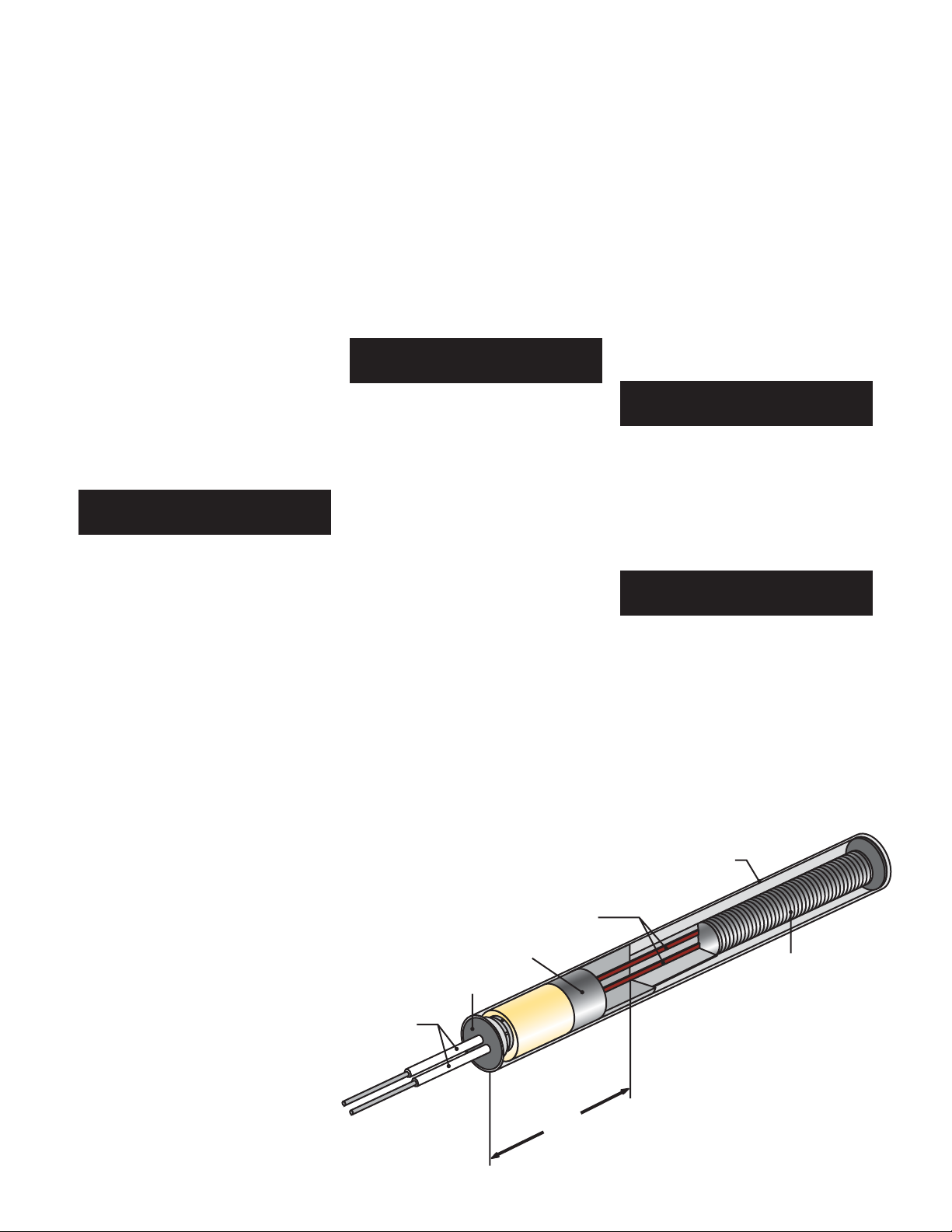

The Pins: High-grade nickel pins

assure resistance to corrosion at high

temperatures and minimize the

chances of embrittlement.

Swaging was introduced to the

cartridge heater field in 1954 with

Watlow’s FIREROD heater. This

mechanical procedure reduces the

diameter of the heater by

compacting the unit, directly

improving heat transfer efficiency.

Swaging compacts the MgO

insulation, which increases its thermal

conductivity and, also, enhances its

dielectric strength.

Swaging also provides these

advantages:

•

Permits the resistance wire to

operate at lower temperatures, a

critical factor in longer heater life

•

Enables users to achieve process

temperatures faster

•

Provides more uniform heating to

the application

•

Reduces energy costs through

better heating efficiency

•

Makes the heater more durable

and more resistant to shock and

vibration

3. Is my cartridge

heater supplier

building the best

product possible?

Watlow is.

FIREROD cartridge heaters from

Watlow are built using only the finest

materials and construction methods,

and are backed with extensive quality

assurance programs. The FIREROD’s

advantages:

Watlow refuses to take shortcuts.

Y ears of testing have proven certain

construction materials and

manufacturing methods to yield the

best performance for FIREROD

cartridge heaters. Following are the

standard materials we use.

•

The Sheath: Our standard Incoloy

®

800 provides high temperature

resistance to oxidation and corrosion,

proving far superior to 304 stainless

steel alloys used by other

manufacturers.

•

The Insulation: We use only high

purity MgO, compacted to a carefully

predetermined and closely monitored

density. This assures high dielectric

strength and efficient, fast heat

transfer.

•

The Resistance Wire: Our nickelchromium wire of computercalculated gauge, length and

spacing is wound on a supporting

core and precisely centered for

uniform temperatures.

•

The Lead Wire: Watlow purchases

only the finest high temperature wire

available from certified suppliers. This

ensures wire flexibility and fray

PREMIUM MATERIALS

SWAGING

SMALLER “NO HEAT” SECTION

VARIOUS SPECIFICATIONS

AVAILABLE

Incoloy® is a registered trademark of Special Metals Corporation.

MgO Insulator

Seal

Lead Wires

Sheath

Pins

Nickel-Chrome

Resistance Wire

No Heat

Section

Page 5

Instead of adapting our

manufacturing processes to the

equipment available, Watlow designs

and builds its own manufacturing

machinery. As with our customized

swaging equipment, this allows more

consistent quality and tighter

tolerances. It also gives us more

freedom when modifying or

developing products.

We developed our own MgO fill

density equipment, calibrated to our

exact needs and designed so that

humidity, temperature or other factory

conditions will have no effect on the

MgO.

Watlow’s fill machines are

designed to ensure uniform fill

thickness which results in better

dielectric strength. Our electronic

winding machines, engineered and

manufactured in-house, provide

extremely consistent windings for

uniform temperatures.

Consistent quality is also achieved

through our own certified supplier

programs, which ensure that the

materials received meet our standards

every time. These “partnerships” with

suppliers also allow us to take

advantage of advances in materials

technology.

4.

4. Does my

cartridge heater

supplier provide

application

assistance to solve

my heating

problems?

Watlow does.

Technical assistance from your

cartridge heater supplier can be

crucial to the success of your heating

application. Premature heater failure

often occurs because your supplier

doesn’t ask the right questions about

your application, such as your

temperature and watt density

requirements, temperature sensing

and control systems, even factory

environment considerations.

At Watlow, our engineers can help

you avoid many of the common

causes of cartridge heater failure. We

have developed innovative design

options to combat the four most

common culprits:

•

Contamination

•

Corrosion

•

Overtemperature

•

Lead wire failure

CONSISTENT QUALITY

STANDARDS

...........................

Page 6

Teflon®is a registered trademark of

E.I. du Pont de Nemours & Company.

Hexoloy

®

is a registered trademark of Carborundum Company.

1. Overtemperature: The

discolored portion indicates

part of the heater was

operated in open air, rather

than being fully inserted in the

application.

2. Overtemperature: Resulted

in breakdown of insulation,

and caused element to short

to ground and burn a hole in

the sheath.

3. Contamination: External

view. Molten plastic has

solidified on the heater and

the leads.

4. Contamination: Internal

view. Notice that more

reaction has occurred in the

element winding area, where

temperatures are highest.

5. Overtemperature of heater

and leads: Red insulation boot

turned white, and became

frayed, which can cause the

lead wires to short.

CONTAMINATION

..........................

Table 1

Seal Type Maximum

Continuous

Operating

Temperature

Silicone Rubber 176°C (350°F)

Teflon

®

204°C (400°F)

High Temperature Epoxy 260°C (500°F)

Glass Hermetic 315°C (600°F)

Ceramic to Metal Hermetic 537°C (1000°F)

FIREROD HT (high temp.) 593°C (1100°F)

Mineral Insulated Leads 815°C (1500°F)

Table 2

Sheath Material Typical Applications

Incoloy

®

800 Excellent for most general

(FIREROD standard) applications

304SS Food and medical;

deionized water

Titanium For highly corrosive

atmospheres

Hexoloy

®

protection tubes Liquid metals

heating/melting

1.

2.

3.

4.

5.

CONTAMINATION

Contamination occurs when

foreign materials enter the heater’s

internal area and cause a breakdown

of the element or insulation materials.

The contaminants are usually organic

and cause either a gross electrical

shorting to ground or an accelerated

deterioration of the heater’s internal

elements and/or power leads.

Heaters that are subject to large

temperature swings or cycling are

most susceptible to ingesting harmful

contaminants. When a heater heats

up and cools down, it “breathes” air in

and out from its surroundings due to

the thermal expansion and

contraction of the air inside it.

As application temperatures

increase, many materials normally

considered inert can become quite

destructive. Among these are

lubrication oils, cleaning solvents, antiseize lubricants, plastics, fumes,

electrical tape adhesives, gases

emitted from over-temped lead wire,

potting compounds and moisture.

Page 7

...........................

Corrosion occurs when the heater’s

outer sheath deteriorates, allowing

contaminants to enter the heater.

Watlow offers several sheath materials

to protect the FIREROD from corroding

in various environments. (See Table 2).

For certain applications, such as

medical and aerospace, Watlow can

provide passivated or electropolished

heater sheaths.

&

AND CORROSION

6. 7.

FIREROD heaters can be designed

with special seals to resist contaminants.

Watlow offers several seal types

to handle various application

temperatures. (See Table 1).

It is important to realize that the

seal or lead end of the heater will not

exceed the maximum operating

temperature of the seal material.

This can be accomplished in one of

two ways.

One way is to allow enough natural

or forced air convection to cool the

area. In other cases, it may be

necessary to specify a length of

no-heat zone between the heated

and the sealed areas of the heater.

Smaller diameter heaters drop in

temperature along a no-heat zone at a

faster rate than larger diameters. By

using Graph A, a good estimate for noheat zone length can be interpolated

for most temperature, seal and heater

diameter combinations.

Stored heaters can be protected

by keeping the heaters in sealed

containers or plastic bags.

6. Corrosion: The sheath deteriorated to

the extent that liquid entered the heater.

During subsequent heating cycles the

weakened sheath split open due to

pressure build-up.

7. Scale build-up on sheath:

Overtemperature occurred because

scale acts as an insulator, causing the

heater to compensate by operating at

temperatures much too high.

CORROSION

982°C

(1800°F)

871°C

(1600°F)

760°C

(1400°F)

649°C

(1200°F)

537°C

(1000°F)

426°C

(800°F)

315°C

(600°F)

204°C

(400°F)

93°C

(200°F)

0

0.25 in. FIREROD

0.5 in.

1 in. 1.5 in.

0.5 in. FIREROD

2 in.

0.75 in. FIREROD

2.5 in.

3 in.

3.5 in.

4 in.

Page 8

..........................

Color V ersus Temperature

The chart was created by recreating the colors of Incoloy® sheathed FIRERODs at specific temperatures. Several factors may

affect the color, but the chart is a handy reference of color vs. temperature for most metal objects. The power levels

indicated were calculated using the Stefan-Boltzman equation for a blackbody source at the temperatures listed.

A heater that is forced to operate

beyond its maximum operating

temperature is destined for premature

failure. Extreme overtemperature

conditions will cause the heater’s

internal conductors to melt. Less

severe overtemperature conditions will

accelerate a heater’s normal “aging”

process. In fact, operating a heater

37°C (100°F) beyond its maximum

recommended temperature can

reduce heater life by as much as

two-thirds.

Watlow designers optimize the

internal construction of your FIREROD

based on the wattage and operating

temperature you specify. Y et certain

conditions can cause the heater to

overtemp.

Overtemperature failure frequently

occurs when a heater is placed in a

hole that is too large, impeding heat

transfer from the heater to the part.

Watlow’s hole fit

graphs (B and

C) depict the

importance of

hole fit, and how

dramatically it

affects the temperature of the

heater’s internal components.

Allowing part of the heater’s heated

section to operate in open air can

cause the exposed section to rise

significantly in temperature, while the

part immersed or inserted into the

application is kept at the desired

temperature.

The solution is to be sure the heated

section is fully inserted into your heated

part or liquid.

A loose fit causes cartridge heaters to operate at temperatures that are much higher

than the part being heated. This is even more dramatic at higher watt densities. Using

a tighter hole fit and lowering the watt density will keep the heater’s internal

temperature low, prolonging life significantly.

Fit = I.D. Hole - O.D. FIREROD

This graph will help you

determine the maximum

allowable hole fit for your

application. Notice that

both the heated part

maximum temperature and

the surface watt density of

the heater affect the

recommended hole fit.

OVERTEMPERATURE OF THE HEATER

HOLE FIT

EXPOSED HEATER SECTION

1204°C (2200°F)

27.29 W/cm

2

(176.1 W/in2)

1093°C (2000°F)

19.96 W/cm2 (128.8 W/in2)

982°C (1800°F)

14.22 W/cm2 (91.8 W/in2)

NOTE: Maximum part temperature 760°C (1400°F), maximum watt density 69 W/cm2 (400 W/in2).

Hole Fit

Graph B: How Hole Fit & Watt Density Can Affect Internal Heater Temperature

Heater Operating

Temperature

(in block heated to 537°C (1000°F)

1204°C

(2200°F)

1093°C

(2000°F)

982°C

(1800°F)

871°C

(1600°F)

760°C

(1400°F)

649°C

(1200°F)

0.006

0.009

0.010

0.012

Hole Fit (inches)

0.015

0.0195

0.018 0.021

0.100

0.090

0.080

0.070

0.060

0.050

0.040

0.030

0.027

0.020

0.013

0.010

0.009

0.008

0.007

0.006

0.005

0.004

0.003

0.002

0.001

For stainless steel, enter

the graph with a fit 0.0015

larger than actual.

For aluminum and brass

enter the graph with a

temperature 37°C (100°F)

above actual temperature

760°C (1400°F)

649°C (1200°F)

537°C (1000°F)

426°C (800°F)

315°C (600°F)

204°C (400°F)

93°C (200°F)

Page 9

...........................

Poor temperature sensor location is

another common cause of

overtemperature heater failure. If the

controlling thermocouple is placed on

the edge of a heated part that runs

cooler due to “end effects” of heat

losses to atmosphere, the center

portions of the heated part can run

significantly higher in temperature,

forcing the heater to operate well

over its maximum recommended

temperature. The solution is to place

the temperature sensor in the hottest

part of the application.

When heating fluids or gases in

chambers, the process becomes

hotter as it flows through the chamber.

Thermocouples at the cooler end of

the chamber will be unable to

properly control heaters at the hot

end, causing early heater failure.

One solution is to relocate the

thermocouples to the hot end, or to

use lower watt density heaters at

that end.

Watlow can also design your

FIREROD heater with an internal

thermocouple to provide accurate

temperature readings. This is especially

beneficial for extremely sensitive,

zoned or uniform temperature

applications. Thermocouples can be

located at the disc end of the heater

or anywhere along the heater length.

Also, thermostats are available as a

high-limit temperature control.

Surprisingly, overtemperature failure

can occur in some low temperature

applications such as heating water.

Conventional thinking suggests that a

heater immersed in liquid should never

greatly exceed the boiling

temperature of that liquid. But this isn’t

always the case. (See Graph D).

Placing power leads in a high

temperature environment can lead to

premature heater failure if the leads

aren’t properly rated for the

application. The binders in the lead

wire insulation will bake out and the

insulation becomes brittle. Any

amount of flexing after this usually

causes electrical shorting between the

lead wire conductors or a grounded

surface.

To combat this problem, W atlow

offers six types of insulation for lead

wire (see Table 3.)

Vibration is a frequent cause of lead

wire failure. Over-flexing can be

prevented by adjusting the lead wires

to withstand high vibration, as in a

moving or cycling platen or mold die.

To protect the leads, isolate any

relative movement of the heater and

leads by adding strain reliefs that

anchor back to the platen or heated

part. Y ou can also allow extra lead

length for flexing.

Watlow provides several lead wire

types that are ideal for applications

requiring abrasion assistance. These

include flexible stainless steel overbraid

and flexible metal conduit.

Graph D shows how water’s ability to

accept heat from a FIREROD heater

changes with watt density. A good rule of

thumb for water is to add 1˚F for every W/in

2

of heater surface to the boiling point of

water. (Example: On a 200 W/in2heater,

internal operating temperature =

200 W/in2+ 212˚ = 412˚F).

Heat flow between the heater sheath and

liquid can also be impeded by the buildup

of mineral deposits on the heater sheath.

The heat won’t be able to leave the heater,

causing its internal temperature to rise

dramatically.

SENSOR LOCATION

LOW TEMPERATURE

APPLICATIONS

LEAD WIRE FAILURE

OVERTEMPERATURE OVER-FLEXING

ABRASION

871°C (1600°F)

9.81 W/cm2 (63.3 W/in2)

760°C (1400°F)

6.52 W/cm2 (42.1 W/in2)

649°C (1200°F)

4.13 W/cm2 (26.7 W/in2)

Table 3

Insulation Material Maximum

Continuous

Operating

Temperature

Neoprene 93°C (200°F)

Silicone 176°C (350°F

Teflon

®

204°C (400°F)

Fiberglass/Silicone (GGS)

249°C (480°F)

Mica/Fiberglass/

Teflon®(MGT) 449°C (840°F)

Ceramic Beads 649°C (1200°F)

Mineral Insulated Leads 815°C (1500°F)

426°C

(800°F)

315°C

(600°F)

204°C

(400°F)

93°C

(200°F)

0

Sheath Watt Density (5/8 in. diameter FIREROD in water boiled in ambient conditions)

Page 10

✓

A gas analysis system required a heat

source capable of handling

temperatures above 649°C (1200°F)

and to provide heat to the analyzer

head from distances of up to 10 feet.

A 1⁄4-inch diameter, 10 -foot long

FIREROD heater was designed with a

unique heated zone that included an

internal thermocouple and a long noheat section.

A manufacturer of blood warming

equipment required a heat source

with an integral high limit cutoff device

as a protective measure for the

system. A FIREROD heater was

designed to meet UL®specifications for

medical equipment. An internal

thermostat provided the secondary

high limit necessary to prevent the

plastic reservoir from melting.

A food processing plant required

moisture-proof cartridge heaters that

could operate at temperatures higher

than Teflon

®

204°C (400°F) and potted

seals 60°C to 260°C (140°F to 500°F).

To eliminate the extra steps required

to protect heater leads from moisture

contamination during high-pressure

hose washdown, Watlow recommended the FIREROD with M.I. lead

temperature capability to 815°C

(1500°F).

A food packaging machine

manufacturer needed to apply heat

to an adhesive-backed paper lid and

seal it onto the mouth of a plastic

container. By concentrating the heat

only around the edge of the

container, none of the dairy product

inside the container would be

affected by the sealing process.

SOLUTION TO COMPLEX

HEATING PROBLEM

SOLUTION TO COMPLEX

MEDICAL STANDARD PROBLEM

SOLUTION TO COMPLEX

CONTAMINATION PROBLEM

SOLUTION TO RESPONSE

TIME PROBLEM

WATLOW SOLUTIONS TO

YOUR HEATING PROBLEMS

Watlow specializes in solving demanding heater

applications through customized engineering.

Our experience is reflected in our design of over

250,000 different FIREROD heaters for such

industries as plastics processing, packaging,

medical equipment, aerospace, scientific

instruments, semiconductor, foodservice and

nuclear power generation.

..........................

UL®is a registered trademark of Underwriter’s Laboratories, Inc.

Page 11

An additional problem with the

application involved the high

throughput required for the machine,

making the duration of heater contact

less than one second. A FIREROD

heater was designed with a centerless

ground sheath for good hole fit and

heat transfer, and a special fill material

in the heater to greatly increase the

heater’s thermal conductivity.

A small, high watt density FIREROD

cartridge heater was designed to

provide freeze protection on a radar

guidance system used on missiles. The

application had space limitations, but

more importantly, the heat source had

to meet pages of military standards.

These specifications covered

everything from the type of nickel wire

to be used to complex test criteria.

A custom manufacturer of titanium

expanders for the aircraft/aerospace

industry required heat in order to form

thin walled titanium tubing into missile

nose cones. The application required

a uniform die temperature operating

at 760°C (1400°F). Multiple HT (high

temperature) FIREROD heaters with

zoned wattage were chosen because

of the die and the even higher internal

temperatures. Also, a special HT seal

reduced the amount of oxidation and

corrosion of the resistance wire thus

prolonging heater life.

Uniform temperature profile is critical

for the large sealing bars of vertical

and horizontal wrapping machines.

SOLUTION TO COMPLEX

MILITARY

STANDARD PROBLEM

SOLUTION TO HIGH TEMPERATURE

REQUIREMENT PROBLEM

SOLUTION TO TEMPERATURE

UNIFORMITY PROBLEM

Watlow conducted testing to

determine the proper heat zoning

needed to compensate for heat losses

at the ends and at the machinery

clamps. A FIREROD cartridge heater

with special distributed wattage was

designed, providing the extremely

tight profiles required by the

packaging equipment manufacturer.

A commercial sign producer needed

a means to apply heat to an

extremely small stylus used to cut vinyl.

Watlow engineers solved the

application using a 1⁄8-inch diameter

FIREROD with an internal

thermocouple for temperature

control.

A high-speed photographic film

processor required a heat source to

maintain stringent developer

temperatures, despite the highly

corrosive nature of these solutions. In

addition, the system design provided

limited space. Watlow engineering

designed a FIREROD heater with a

passivated 316 stainless steel sheath

and a unique flanged mounting

method.

A FIREROD heater with its high watt

density capabilities was designed for a

compact, mobile hyper/hypothermia

system. The heater was required to

meet UL®specifications for low current

leakage under the guidelines for

medical equipment.

SOLUTION TO LOW CURRENT

LEAKAGE SPECIFICATIONS

...........................

SOLUTION TO SPACE

LIMITATION PROBLEM

SOLUTION TO CORROSIVE

ENVIRONMENT PROBLEM

Page 12

12001 Lackland Road • St. Louis, Missouri 63146 USA

Phone: 314-878-4600 • FAX: 314-878-6814

e-mail: info@watlow.com • www.watlow.com

WATLOW

Worldwide Business

Centers

STL-FR-0706

Asian Technical Support &

Sales Offices

Australia +61-3-9335-6449

China +86-21-3950-9510

Japan +81-3-3518-6630

Korea +82-2-575-9804

Malaysia +60-3-7980-7741

Singapore +65-6777-1266

Taiwan +886-7-288-5168

European Technical Support &

Sales Offices

France +33 (01) 3073-2425

Germany +49 (0) 7253-9400-0

Italy +39 (02) 458-8841

Sweden +46 35 27 11 66

United Kingdom +44 (0) 115-964-0777

Spain +34 916 751 292

Latin American Technical Support &

Sales Office

Mexico +52-442-217-6235

Watlow Products and Technical Support Delivered Worldwide

North American Technical

Support & Sales Offices

Your Authorized Watlow Distributor is:

To be automatically connected to

the sales office nearest you call:

1-800-WATLOW2

©2006 Watlow Electric Manufacturing Company Printed in the USA on Recycled Paper, 15% Postconsumer Waste.

Loading...

Loading...