Page 1

WW AA TT LL OO W

Cartridge Heaters

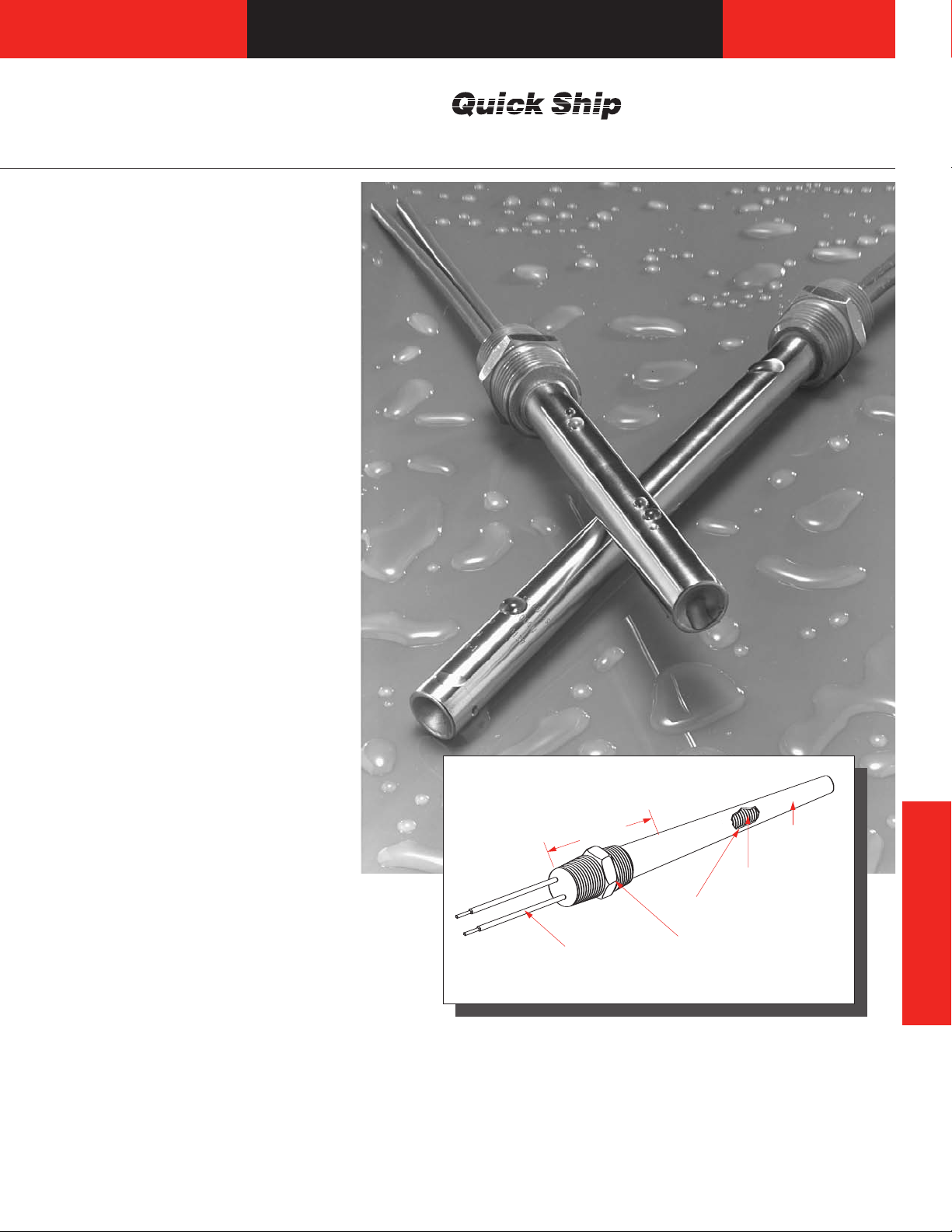

FIREROD®Immersion

FIREROD®immersion heaters

package to 300 W/in2(46.5 W/cm2)

in a compact unit, giving you greater

versatility in designing your heating

system. This design solution is ideal

for replacing large screw-plug

immersion heaters.

Aside from its versatile design, these

heaters come complete with a brass

3

⁄4 inch NPT double threaded screw

plug, which allows you to add

conduit boxes. Also, FIREROD

immersion heaters are sealed at the

lead end with a silicone rubber seal.

Solid copper leads, with silicone

rubber sleeve, are provided for

unconfined wiring. These units are

recommended for immersion in

water or 90+ percent water soluble

solutions.

PPeerrffoorrmmaannccee CCaappaabbiilliittiiees

• Maximum operating temperature

in water to 100°C (212°F) at

atmospheric pressure

• Maximum watt density to

300 W/in2 (46.5 W/cm2)

• Maximum voltage to 480VÅ(ac)

FFeeaattuurreess aanndd BBeenneeffiitts

• Nickel-chromium resistance

wire, precisely centered in the

unit, assures even, efficient

distribution of heat to the sheath.

• Magnesium oxide insulation,

compacted to the proper density,

results in high dielectric strength

and contributes to faster heat-up.

• Incoloy®sheath resists corrosion

from water.

• Metallurgically-bonded

conductor pins overlap the

resistance wire inside the core,

ensuring trouble-free electrical

continuity.

• Lead end with silicone rubber

seal protects the heater against

moisture contamination.

• Optional stainless steel fittings

are available for use in corrosive

applications.

Incoloy®is a registered trademark of

Special Metals Corporation.

s

s

4 in. (100 mm)

No-Heat

6 in. (150 mm) Solid

Pins with Silicone

Rubber Boots

• Horizontal through the wall tank

mounting makes set-up faster.

• 240 and 480VÅ(ac) give

flexibility in wiring the heater for

use in your particular application.

W

Same day shipment on all stock units.

•

Incoloy

Sheath

Nickel-Chromium

Resistance Wire

Magnesium

Oxide Insulation

Double Threaded Brass

3

⁄4 in. NPT-13⁄8 in. long (35 mm)

AApppplliiccaattiioonns

• Plastic reclamation

Food preparation

•

Lab equipment

•

s

®

Cartridge Heaters

111

Page 2

Cartridge Heaters

FIREROD Immersion

AApppplliiccaattiioonnss aanndd

TTeecchhnniiccaall DDaattaa

The small size and big capacity

of FIREROD cartridge heating units

make them ideal immersion heaters

in cramped quarters. When heating

liquids of low viscosity, FIRERODs

have the high watt density to pack

more heat into tight spots. For water

heating applications a rating of 150

2

to 300 W/in

is recommended.

(Laboratory tests show that under

certain conditions ratings as high as

700 W/in2are safe.) For longer life at

high watt densities:

• The FIREROD unit should be in

the main body of the liquid and

not in a restricted space.

• The FIREROD heater should be

covered with liquid at all times.

• The heater should not be allowed

to cycle on and off too frequently.

• Scale should not form.

When heating viscous liquids, such

as oils, watt densities must be kept

low to prevent carbonization at the

heater sheath. FIREROD cartridges

offer advantages for heating viscous

materials where long life and high

quality outweigh the usual economic

considerations. As in all immersion

applications, scale build-up on the

sheath and sludge on the bottom of

the tank must be carefully controlled

to assure long heater life.

Equipped with smaller threaded

fittings than conventional immersion

heaters, FIRERODs leave room for

more units in the same space.

Replacement of single FIREROD

units in multiheater assemblies is

fast and easy, and avoids discarding

the complete assembly.

Moisture proof seals are available

to give protection from damp

atmospheres outside the tank.

Built for sustained operation at

high temperatures, the FIREROD is

especially valuable in heat-transfer

applications with liquid metals. This

factor alone has made the FIREROD

heater a widely used component in

the development of nuclear power

systems.

Threaded fittings are furnished in

either stainless steel or brass.

®

FIRERODs with Incoloy

or 304

stainless steel sheaths are standard,

but other sheath materials can be

provided. Headers and sheath

material should be suited to the

material being heated.

Consult FIREROD section,

pages 75 to 76 for more

information.

112

Sheath Material Compositions

Sheath Chemical Composition

Material

Stainless Steels

304 0.08

316 0.08

Nickel Alloys

Incoloy®800 0.15/0.6 0.1 19/23 0.75 Bal 1.5 30/35 0.015 1.0 0.15/0.6

➀ Maximum

See application guide for additional sheath material composition.

Al

Co Cr Cu Fe Mn Mo Ni P S Si Ta Ti V W

C

➀

➀

18/20 Bal 2

16/18 Bal 2 ➀2/3 10/14 1

➀

8/12 1

➀

➀

Page 3

WW AA TT LL OO W

Cartridge Heaters

W

FIREROD Immersion

AApppplliiccaattiioonnss aanndd

TTeecchhnniiccaall DDaattaa

Continued

HHooww ttoo OOrrddeerr:

:

To order stock FIREROD immersion

heaters, specify Watlow code

number and quantity.

For

made-to-orderrunits, please

specify:

• Diameter

• Overall length

• Immersed length

• Heated length

• Watts

Ordering Example: Specify

FIREROD immersion heater 5⁄8 inch

iameter, six inches overall length,

d

immersed length of four inches, and

two inches heated length. The heater

is to be supplied with 1200 watts,

240 volts,

threaded brass fitting, silicone seal

and six inch pins, no leads.

Availability

Stock::Same day shipment

Made-to-Order: Consult Watlow

• Volts

• Threaded fitting material

Overall Approx

Diameter length Watt Density Fittings Net Wt.

in. in. (mm) Volts Watts W/in

5

⁄8 6 1⁄4 (159) 120 500 127 (19.7) Brass 0.58 (0.26) Stock

6 1⁄4 (159) 120 500 127 (19.7) SS 0.58 (0.26) Stock

6 1⁄4 (159) 240 500 127 (19.7) Brass 0.58 (0.26) Stock

6 1⁄4 (159) 240 500 127 (19.7) SS 0.58 (0.26) Stock

6 1⁄4 (159) 120 750 191 (29.6) Brass 0.58 (0.26) Stock

6 1⁄4 (159) 120 750 191 (29.6) SS 0.58 (0.26) Stock

6 1⁄4 (159) 240 750 191 (29.6) Brass 0.58 (0.26) Stock

6 1⁄4 (159) 240 750 191 (29.6) SS 0.58 (0.26) Stock

6 1⁄4 (159) 120 1000 254 (39.4) Brass 0.58 (0.26) Stock

6 1⁄4 (159) 120 1000 254 (39.4) SS 0.58 (0.26) Stock

6 1⁄4 (159) 240 1000 254 (39.4) Brass 0.58 (0.26) Stock

6 1⁄4 (159)

6 3⁄4 (159) 240 1500 300 (46.5) Brass 0.60 (0.27) Stock

6 3⁄4 (171) 240 1500 300 (46.5) SS 0.60 (0.27) Stock

6 3⁄4 (171)

6 3⁄4 (171) 480 1500 300 (46.5) SS 0.60 (0.27) Stock

7 3⁄4 (197)

7 3⁄4 (197) 240 2000 291 (45.1) SS 0.66 (0.30) Stock

7 3⁄4 (197) 480 2000 291 (45.1) Brass 0.66 (0.30) Stock

7 3⁄4 (197) 480 2000 291 (45.1) SS 0.66 (0.30) Stock

8 1⁄2 (216) 240 2500 300 (46.5) Brass 0.68 (0.31) Stock

8 1⁄2 (216)

8 1⁄2 (216) 480 2500 300 (46.5) Brass 0.68 (0.31) Stock

8 1⁄2 (216) 480 2500 300 (46.5) SS 0.68 (0.31) Stock

9 1⁄4 (235) 240 3000 300 (46.5) Brass 0.72 (0.33) Stock

9 1⁄4 (235) 240 3000 300 (46.5) SS 0.72 (0.33) Stock

9 1⁄4 (235) 480 3000 300 (46.5) Brass 0.72 (0.33) Stock

9 1⁄4 (235)

11 (279) 240 4000 300 (46.5) Brass 0.80 (0.36) Stock

(279)

11

11 (279) 480 4000 300 (46.5) Brass 0.80 (0.36) Stock

11 (279) 480 4000 300 (46.5) SS 0.80 (0.36) Stock

240

480

240

240

480

240

1000

1500 300 (46.5) Brass 0.60 (0.27) Stock

2000 291 (45.1) Brass 0.66 (0.30) Stock

2500

3000

4000

2

(W/cm2) Type lbs (kg) Availability Code No.

254 (39.4) SS 0.58 (0.26) Stock

300

300

300

(46.5)

(46.5)

(46.5)

SS 0.68 (0.31) Stock

SS

SS 0.80 (0.36) Stock

0.72 (0.33) Stock

3

⁄4 inch NPT double

F.O.B.: St. Louis, Missouri

LL66EEXX1122AA

LL66EEXX1122BB

LL66EEXX1133AA

LL66EEXX1133BB**

LL66EEXX1144AA

LL66EEXX1144BB

LL66EEXX1155AA

LL66EEXX1155BB

LL66EEXX1166AA

LL66EEXX1166BB

LL66EEXX1177AA

LL66EEXX1177BB

LL66NNXX77AA

LL66NNXX77BB

LL66NNXX88AA

LL66NNXX88BB

LL77NNXX55AA

LL77NNXX55BB

LL77NNXX66AA

LL77NNXX66BB

LL88JJXX1166AA

LL88JJXX1166BB

LL88JJXX1177AA

LL88JJXX1177BB**

LL99EEXX1111AA

LL99EEXX1111BB

LL99EEXX1122AA

LL99EEXX1122BB

LL1111AAXX5599AA

LL1111AAXX5599BB

LL1111AAXX6600AA

LL1111AAXX6600BB

CONTINUED

Cartridge Heaters

* Limited quantities available, consult factory for delivery.

113

Page 4

Cartridge Heaters

FIREROD Immersion

Overall Approx

Diameter length Watt Density Fittings Net Wt.

in. in. (mm) Volts Watts W/in

5

⁄8 12 3⁄4 (324) 240 5000 300 (46.5) Brass 0.89 (0.41) Stock

12 3⁄4 (324) 240 5000 300 (46.5) SS 0.89 (0.41) Stock

12 3⁄4 (324) 480 5000 300 (46.5) Brass 0.89 (0.41) Stock

12 3⁄4 (324) 480 5000 300 (46.5) SS 0.89 (0.41) Stock

14 1⁄2 (368) 240 6000 300 (46.5) Brass 0.95 (0.43) Stock

14 1⁄2 (368) 240 6000 300 (46.5) SS 0.95 (0.43) Stock

14 1⁄2 (368) 480 6000 300 (46.5) Brass 0.95 (0.43) Stock

14 1⁄2 (368) 480 6000 300 (46.5) SS 0.95 (0.43) Stock

18 (457) 240 8000 295 (45.7) Brass 1.14 (0.52) Stock

18 (457) 240 8000 295 (45.7) SS 1.14 (0.52) Stock

18 (457) 480 8000 295 (45.7) Brass 1.14 (0.52) Stock

18 (457) 480 8000 295 (45.7) SS 1.14 (0.52) Stock

21 1⁄4 (540) 240 10000 300 (46.5) Brass 1.3 (0.59) Stock

21 1⁄4 (540) 240 10000 300 (46.5) SS 1.3 (0.59) Stock

21 1⁄4 (540) 480 10000 300 (46.5) Brass 1.3 (0.59) Stock

21 1⁄4 (540) 480 10000 300 (46.5) SS 1.3 (0.59) Stock

24 3⁄4 (629) 480 12000 300 (46.5) Brass 1.5 (0.68) Stock

24 3⁄4 (629) 480 12000 300 (46.5) SS 1.5 (0.68) Stock

29 3⁄4 (756) 480 15000 300 (46.5) Brass 1.8 (0.82) Stock

29 3⁄4 (756) 480 15000 300 (46.5) SS 1.8 (0.82) Stock

35 (889) 480 18000 300 (46.5) Brass 2.0 (0.91) Stock

35 (889) 480 18000 300 (46.5) SS 2.0 (0.91) Stock

* Limited quantities available, consult factory for delivery.

2

(W/cm2) Type lbs (kg) Availability Code No.

F.O.B.: St. Louis, Missouri

LL1122NNXX44AA

LL1122NNXX44BB

LL1122NNXX55AA

LL1122NNXX55BB

LL1144JJXX88AA

LL1144JJXX88BB

LL1144JJXX99AA

LL1144JJXX99BB

LL1188AAXX4433AA

LL1188AAXX4433BB

LL1188AAXX4444AA

LL1188AAXX4444BB

LL2211EEXX11AA

LL2211EEXX11BB

LL2211EEXX22AA

LL2211EEXX22BB

LL2244NNXX11AA

LL2244NNXX11BB**

LL2299NNXX55AA

LL2299NNXX55BB**

LL3355AAXX55AA

LL3355AAXX55BB

114

Loading...

Loading...