Watlow FIREBAR Flange Heater User Manual

WATLOW IND. FIREBAR

®

Flange Heater Installation & Maintenance Manual

I&M NUMBER: 316-42-2-1 Page: 1

Date: 6/11/2008 Rev: 2.00

________________________________________________________________________________________________________________________________________________________________________________________________________________________

Pre Installation

• Check to make sure that heater received is the same as that ordered.

• Elements may come in contact with each other during shipment. Minor adjustments to elements may be

required prior to installation to separate them. Extensive bending of elements should be avoided since

dielectric strength between coil and sheath may be compromised.

• Watlow heaters are built to comply with UL and CSA dielectric requirements, it may be necessary due to

atmospheric conditions / humidity, to perform a dielectric test prior to startup. (Refer to megohm test

under Installation section)

Safety

Electric heaters are inherently dangerous!! Care should be taken to read and completely understand the

Installation and Maintenance manual before installing and wiring the heater. Any installation and

maintenance performed on the heater shall be done by a qualified electrician, in accordance with the

"National Electric Code" and other electrical codes as they apply. It is the users responsibility to ensure that

the heater being used is properly selected and installed in the application.

!

The Caution Symbol (exclamation point) alerts you to a "CAUTION", a safety or

functional hazard which could affect your equipment or its performance.

The warning symbol (lightning bolt) alerts you to a "WARNING", a safety hazard which

Installation

Proper heater selection and installation will result in efficient heat transfer, safe operation, and long heater

life.

1. Megohm precheck

During shipping and/or storage, the possibility of moisture absorption by the insulation material within the

element is possible. To ensure proper megohm values a minimum 500 VDC megohm meter (Megger)

should be used to ensure that the megohm reading between the heater terminal and the heater sheath is

more than 10 megohms when the unit is at room temperature.

If several units are interconnected, the megohm of the heater is obtained by taking the reading and

dividing by the number of interconnected elements. This reading should be greater than 10 megohms.

If a low megohm value exists, two alternative methods can be used to remedy the situation. The best

method is to remove all terminal hardware including thermostat if provided, and bake out the heater at no

higher than 250°F (120°C) overnight or until an acceptable reading is reached. The second method is to

energize the unit at low voltage in air until the megohm is at an acceptable reading. Care should be

taken to prevent the heater sheath from exceeding 750°F (398°C) for Incoloy® and Stainless Steel

elements.

2. Protection of heater elements from over temperature

The use of temperature controls to regulate heating process and prevent heater over temperature is

highly recommended to ensure safe heater operation. It is the users responsibility to ensure safety of

the installation.

WARNING: Install high temperature control protection in systems where an over temperature

fault condition could present a fire hazard or other hazard. Failure to install temperature control

could affect you and the equipment

WATLOW IND.n # 6 INDUSTRIAL LOOP RD. n HANNIBAL MO, 63401n PHONE 573-221-2816 n FAX 573-221-3723

WATLOW IND. FIREBAR

®

Flange Heater Installation & Maintenance Manual

I&M NUMBER: 316-42-2-1 Page: 2

Date: 6/11/2008 Rev: 2.00

________________________________________________________________________________________________________________________________________________________________________________________________________________________

protection where a potential hazard exists could result in damage to equipment and property,

and injury to personnel.

Failure of components in a temperature control loop, such as the sensor, heater control relay or main

temperature control, can result in damage to a product in process, a melt down of a heater, and / or

damaging fire.

To protect against this possibility, over temperature protection must be provided to interrupt or remove

power from the heater circuit. A bulb and capillary thermostat is not recommended for this function

since it may not respond quickly enough to adequately protect the heater. In cases where the

thermostat bulb gets too hot before the system is turned off, the thermostat bulb could rupture.

This could result in the thermostat remaining in the "ON" condition since there is insufficient

fluid to move contacts apart. We recommend the temperature protection have appropriate third party

approval, and be applied in the classification for which it was tested and approved.

In order to help prevent premature failure and a potentially hazardous condition in cases where

consequences of failure may be severe, use an appropriate third party approved liquid level protection

device. The liquid level should be such that the entire heater is fully submerged with enough liquid above

the heater to adequately dissipate heat from itself as under normal operating conditions. Consult your

local authorized sales representative for specific recommendations for your application.

3. Terminal Enclosures

Terminal enclosures should be selected to be compatible with the environment in which the heater will

be located. It is the users responsibility to determine the need for correct rating of the electrical housing.

This should be based on appropriate national and local electrical codes. Failure to use a compatible

enclosure could result in heater damage and personnel danger.

Standard terminal enclosures are designed for general purpose use and are rated NEMA 1. These

enclosures should be applied where there will be no danger of spilled liquids, dampness, dirt, and

gaseous conditions. Enclosures for wet or hazardous locations are also available, but must be installed

at the factory.

Although enclosures are supplied over the terminals, units should be located in an area that will minimize

the chance of being hit by falling or moving objects. The terminals must be protected at all times from

moisture or vapor.

In hazardous locations, (as defined in NFPA 70 NEC, Article 501) explosion resistant housings must be

used.

In order to maintain termination integrity, the terminal enclosure should be kept below 400°F

(204°C).

4. Orientation / Mounting

Watlow flange immersion heaters incorporate a standard ANSI flange for universal mounting in tanks

equipped with the same size mounting flange. A suitable gasket and mounting bolts are required for

installation but are not provided with the heater. The correct gasket material should be based on the

material being heated and the process temperature.

Proper installation and orientation of the FIREBAR® flange heater is important to insure maximum

efficiency and minimum sheath temperatures. The unique shape of this flat element offers many

advantages, but they can only be realized if the heater is properly oriented. Every effort should be made

to position the heater as recommended.

WATLOW IND.n # 6 INDUSTRIAL LOOP RD. n HANNIBAL MO, 63401n PHONE 573-221-2816 n FAX 573-221-3723

WATLOW IND. FIREBAR

®

Flange Heater Installation & Maintenance Manual

I&M NUMBER: 316-42-2-1 Page: 3

Date: 6/11/2008 Rev: 2.00

________________________________________________________________________________________________________________________________________________________________________________________________________________________

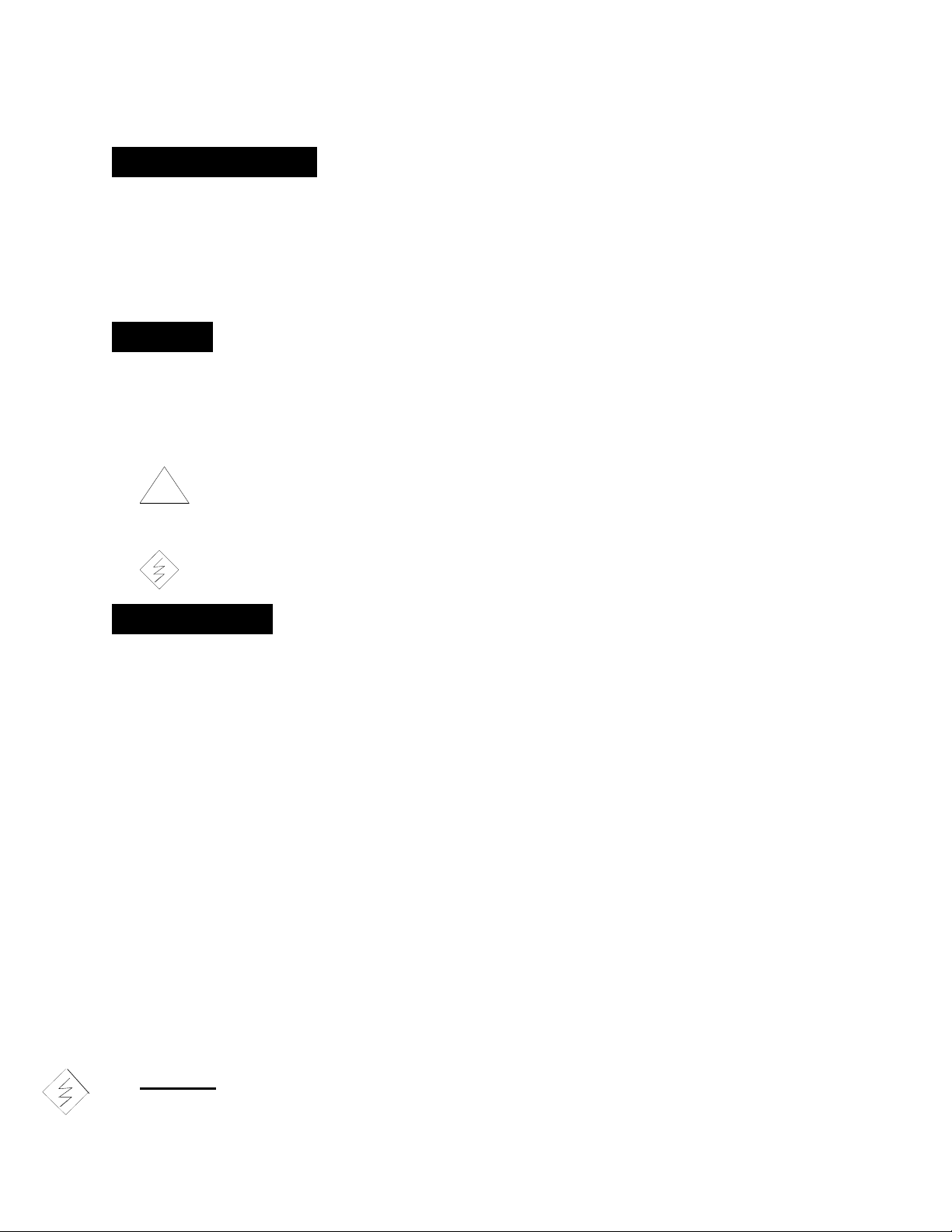

The recommended location for open tank heating is shown in Figure #1. The heater should be installed

as low as possible in the tank to take advantage of natural convection. Attention should be given to

sludge build-up and low liquid level. Location in either of these situations could cause premature failure.

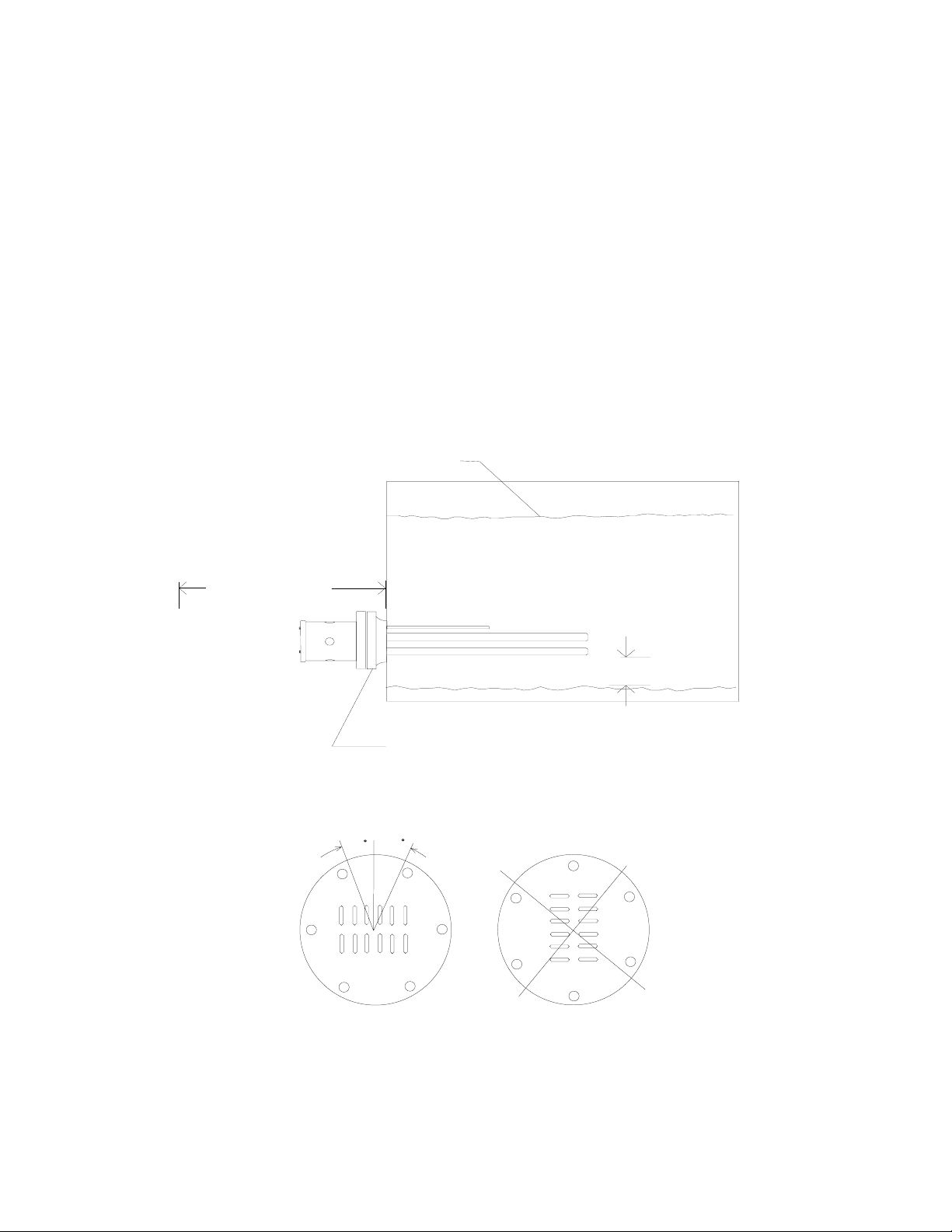

During installation of the heater it is important that special attention be given to the final orientation of the

element. The flat side of the element must be positioned vertically as shown in Figure #2. Maximum

advantages are realized when the element is within +/- 25° of vertical. Positions outside this range are

not recommended, and 90° from vertical should always be avoided.

Each flange is marked with "TOP" to help clarify the preferred orientation. For open tank heating, this

marking should normally be on top of the final plug position. If this is not practical, it may be positioned

on the bottom, which will also orient the flat element vertical.

If heater is being installed in customer supplied circulation tank, a FIREBAR® Flange Circulation I&M

manual should be obtained from the factory to ensure safe installation of heater in tank. Failure to do this

could result in premature heater failure due to improper fluid flow over elements

LIQUID LEVEL

ALLOWANCE FOR

HEATER REMOVAL

2" MIN

SLUDGE

ANSI WELD NECK FLANGE

TO MATCH HEATER FLANGE SIZE

Figure # 1

25

25

TOP

TOP

CORRECT ORIENTATION

Remove terminal enclosure to see element position

Figure # 2

WATLOW IND.n # 6 INDUSTRIAL LOOP RD. n HANNIBAL MO, 63401n PHONE 573-221-2816 n FAX 573-221-3723

INCORRECT ORIENTATION

Loading...

Loading...