Page 1

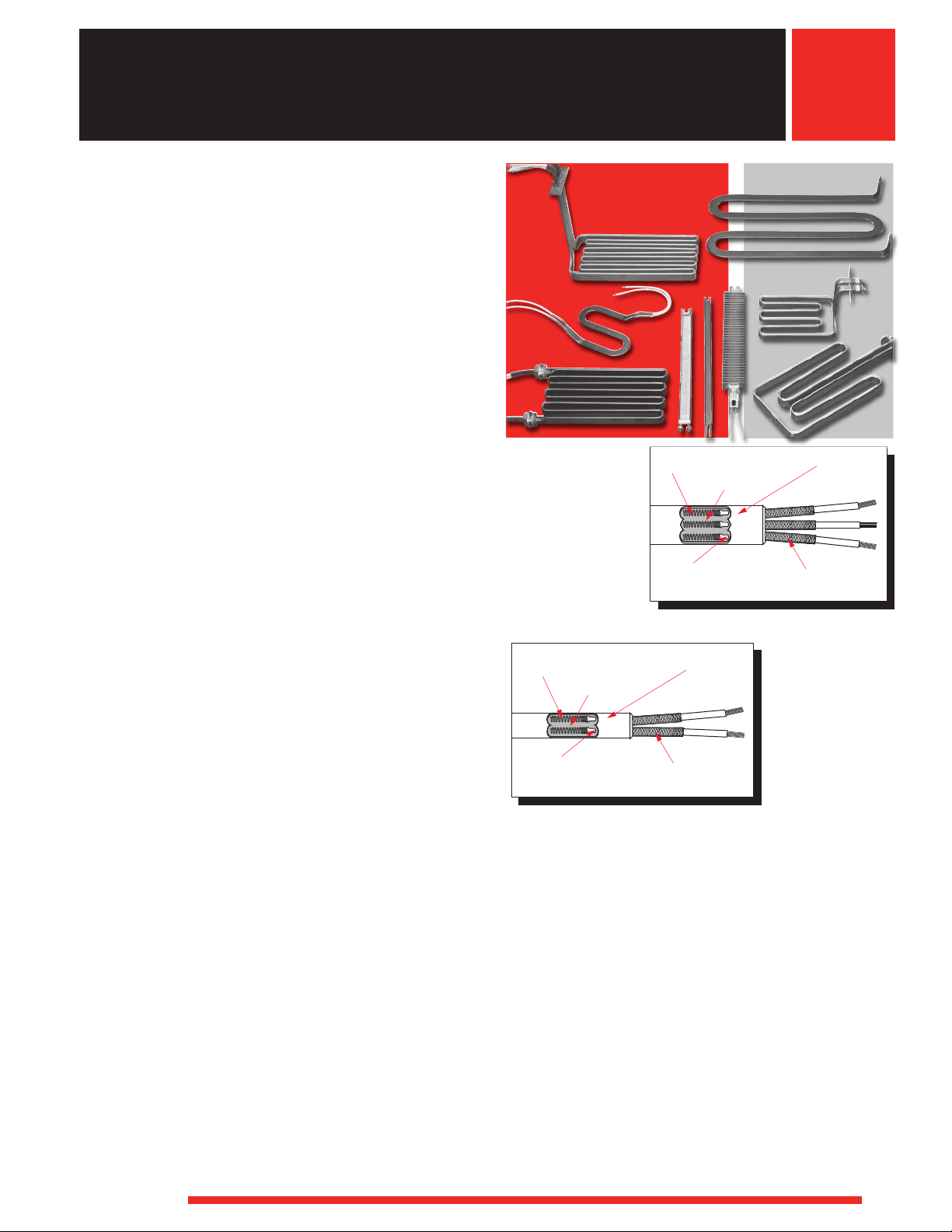

Tubular Heaters

Nickel-Chromium

Resistance Wire

Wire to Pin 360˚

Fusion Weld

Metal Sheath

MgO Insulation

Flexible Lead Wires

Nickel-Chromium

Resistance Wire

Wire to Pin 360°

Fusion Weld

Metal Sheath

MgO Insulation

Flexible Lead Wires

FIREBAR®Single/Double-Ended Heaters

FIREBAR®heating elements provide added heating

performance over standard round tubular heating

elements—especially for immersion applications in

petroleum based liquids requiring high kilowatts.

The FIREBAR’s unique flat surface geometry packs more

power in shorter elements and assemblies, along with a

host of other performance improvements. These include:

• Minimizing coking and fluid degrading

• Enhancing the flow of fluid past the element’s surface

• Improving heat transfer with a significantly larger

FIREBAR elements are available in single- and

double-ended constructions with one inch or

5

⁄8 inch heights. These two configuration variables make

it possible to use FIREBAR elements instead of round

tubular elements in virtually all applications.

FINBAR™ is a special version of the one inch,

single-ended FIREBAR. FINBAR is specially modified

with fins to further increase surface area for air and

gas heating applications. Details are contained in the

FINBAR section, starting on page 110.

Double-Ended Performance Capabilities

One Inch

• Watt densities to 120 W/in2(18.6 W/cm2)

• Incoloy®sheath temperatures to 1400°F (760°C)

• 304 stainless steel sheath temperatures to

• Voltages to 240VAC

• Amperages to 48 amperes per heater or 16 amperes

5

⁄8 Inch

• Watt densities to 90 W/in2(13.9 W/cm2)

• Incoloy®sheath temperatures to 1400°F (760°C)

• Voltages to 240VAC

• Amperages to 32 amperes per heater or 16 amperes

to carry heat from the sheath

boundary layer allowing much more liquid to flow up

and across the sheath’s surface

1200°F (650°C)

per coil

per coil

One Inch Double-Ended FIREBAR Element and

5

⁄8 Inch Double-Ended FIREBAR Element and

Lead Configurations

Lead Configurations

Single-Ended Performance Capabilities

One Inch

• Watt densities to 60 W/in2(9.3 W/cm2)

• Incoloy®sheath temperatures to 1400°F (760°C)

• 304 stainless steel sheath temperatures to

1200°F (650°C)

• Voltages to 240VAC

• Amperages to 48 amperes per heater or 16 amperes

per coil

5

⁄8 Inch

• Watt densities to 80 W/in2(12.4 W/cm2)

• Incoloy®sheath temperatures to 1400°F (760°C)

• Voltages to 240VAC

• Amperages to 16 amperes per heater

WATLOW

®

91

Page 2

Tubular Heaters

FIREBAR Double-Ended Heaters

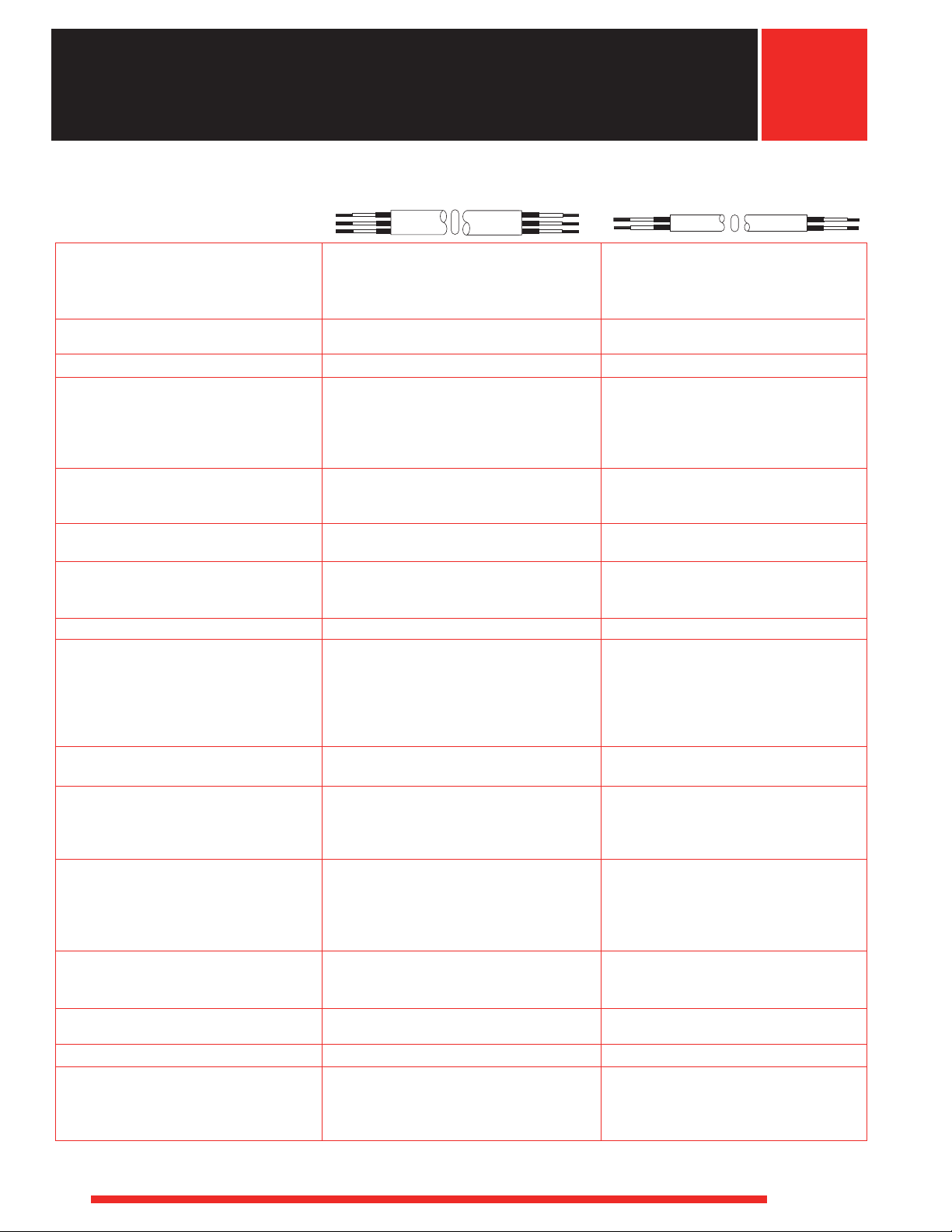

Specifications

Applications Direct immersion; water, oils, etc. Direct immersion; water, oils, etc.

Clamp-on; hoppers, griddles Clamp-on; hoppers, griddles

Forced air heating (Also see FINBAR, page 110) Forced air heating

Radiant heating Radiant heating

Watt Density Stock: up to 90 (13.9) Stock: up to 90 (13.9)

W/in2(W/cm2) Made-to-Order (M-t-O): up to 120 (18.6) Made-to-Order (M-t-O) up to 90 (13.9)

Surface Area Per Linear In. (cm) 2.3 in2(14.8 cm2) 1.52 in2(9.80 cm2)

Cross Section

Height 1.010 (25.7) 0.650 (16.5)

± 0.015/0.010 in. (0.381/0.254 mm)

Thickness 0.235 (5.9) 0.235 (5.9)

± 0.005/0.001 in. (0.127/0.025 mm)

Sheath Material—Max. Stock: Incoloy

Operating temperature M-t-O: Incoloy

Sheath Length Stock: 15 to 114 (381 to 2896) Stock: 15 to 51 (381 to 1295)

in. (mm) M-t-O: 11 to 180 (280 to 4572) M-t-O: 11 to 115 (280 to 2920)

Straightness Tolerance

Major axis in./ft (cm/m): 0.062 (0.52) 0.062 (0.52)

Minor axis in./ft (cm/m): 0.062 (0.52) 0.062 (0.52)

No-Heat Length (Refer to page 105) 1 in. min., 12 in. max. (25/305 mm) 1 in. min., 12 in. max. (25/305 mm)

Max. Voltage—Amperage 240VAC—48A 240VAC—32A

Max. Hipotential 1480VAC 1480VAC

Max. Current Leakage Per Coil (cold) 3mA 3mA

Max. Amperage Per Coil 16A 16A

Phase(s) 1-ph parallel/series, 3-ph delta/wye 1-ph parallel/series

Resistance Coils 3 or 2 2

Ohms/In./Unita 0.270Ω min.—2.833Ω max. 0.040Ω min.—4.250Ω max.

Ohms/In./Coila 0.080Ω min.—8.500Ω max. per coil 0.080Ω min.—8.500Ω max. per coil

Terminations Flexible lead wires Flexible lead wires

Quick connect (spade) Quick connect (spade)

Screw lug (plate) Screw lug (plate)

Threaded stud Threaded stud

Seals Stock: Lavacone 221°F (105°C) Stock: Lavacone 221°F (105°C)

M-t-O: Ceramic base 2800°F (1535°C) M-t-O: Ceramic base 2800°F (1535°C)

Min. Axis Bending Radius Major: 1 (25) Major:3⁄4 (19)

in. (mm) (Do not field bend) Minor:1⁄2 (13)

Minor:5⁄32 (4) 180° bend Minor:5⁄32 (4) 180° bend

Mounting Options Brackets (Type 1, 2 and 3) Brackets (Type 1, 2 and 3)

Threaded bulkhead or fitting Threaded bulkhead or fitting

Surface Finish Options Bright anneal, passivation Bright anneal, passivation

Agency Recognition UL®Component recognition to 240VAC UL®Component recognition to 240VAC

CSA Component recognition to 240VAC CSA Component recognition to 240VAC

a

Resistance values valid for three coil 1 in. (25 mm) FIREBAR only.

One Inch FIREBAR

®

1400°F (760°C) Stock: Incoloy

®

1400°F (760°C) M-t-O: Incoloy

304 SS 1200°F (650°C) 304 SS 1200°F (650°C)

Silicone rubber 392°F (200°C) Silicone rubber 392°F (200°C)

Lavacone 221°F (105°C) Lavacone 221°F (105°C)

Epoxy resin 266/356°F (130/180°C) Epoxy resin 266/356°F(130/180°C)

090° bend Minor:1⁄2 (13) 090° bend

(File # E52951) (File # E52951)

(File # 31388) (File # 31388)

5

⁄8 Inch FIREBAR

®

1400°F (760°C)

®

1400°F (760°C)

92

WATLOW

®

Page 3

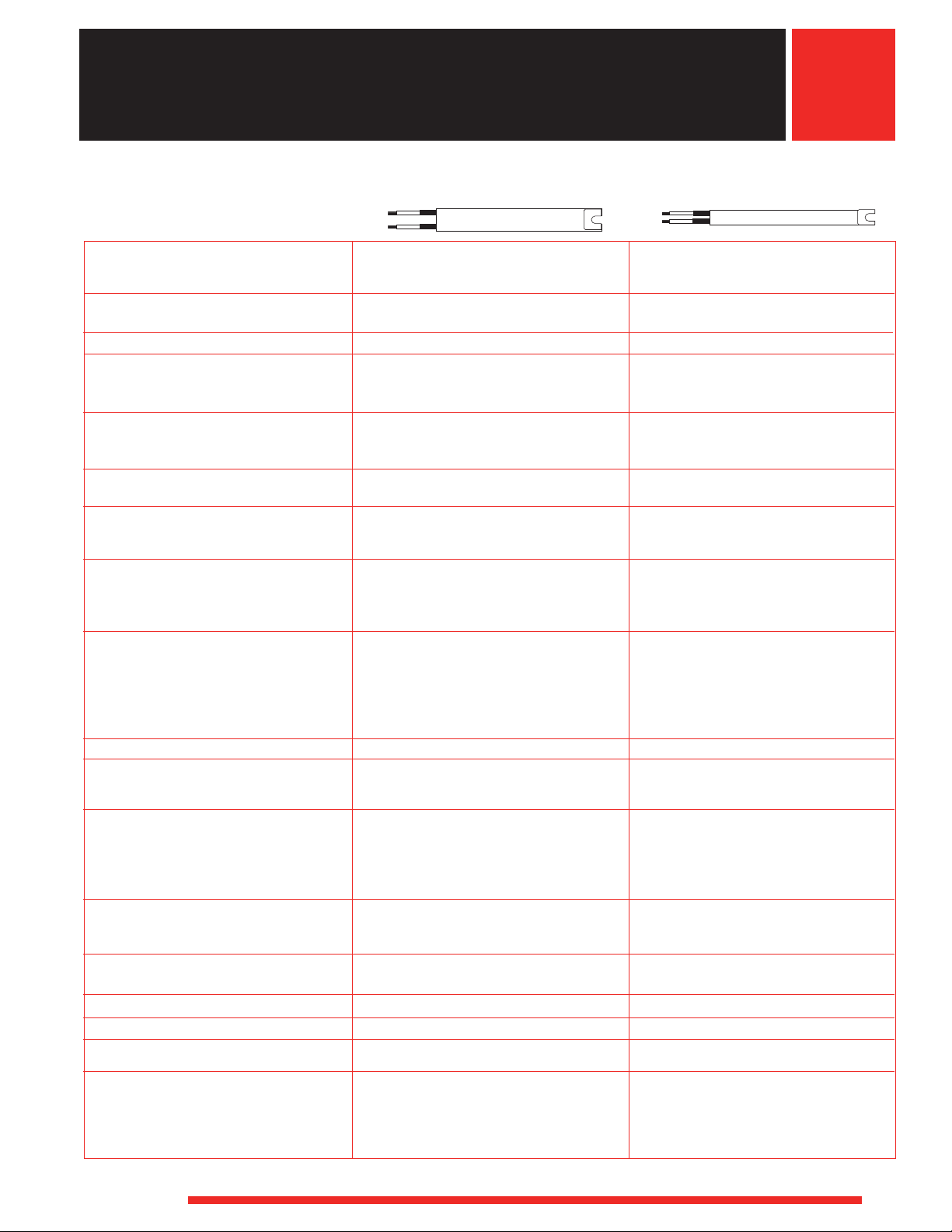

Tubular Heaters

FIREBAR Single-Ended Heaters

One Inch Single-Ended FIREBAR

5

⁄8 Inch Single-Ended FIREBAR

Specifications (Continued)

Applications Clamp-on; hoppers, griddles Clamp-on; hoppers, griddles

Forced or convection air heating Forced or convection air heating

(Also see FINBAR, page 110)

Watt Density Stock: up to 40 (6.2) Stock: up to 20 (3.1)

W/in2(W/cm2) M-t-O: up to 60 (9.3) M-t-O: up to 60 (12.4)

Surface Area Per Linear In. (cm) 2.3 in2(14.8 cm2) 1.52 in2(9.80 cm2)

Cross Section

Height ± 0.015/0.010 in. (0.381/0.254 mm) 1.010 (25.7) 0.650 (16.5)

Thickness ± 0.005/0.001 in. (0.127/0.025 mm) 0.235 (5.9) 0.235 (5.9)

Sheath Material—Max. Stock: 304 SS 1200°F (650°C) Stock: Incoloy

Operating temperature M-t-O: Incoloy

Sheath Length Stock: 11 to 461⁄4 (280 to 1175) Stock: 111⁄2 to 52 (280 to 1321)

in. (mm) M-t-O: 11 to 120 (280 to 3048) M-t-O: 11 to 116 (280 to 2946)

Straightness Tolerance

Major axis in./foot (cm/m): 0.062 (0.52) 0.062 (0.52)

Minor axis in./foot (cm/m): 0.062 (0.52) 0.062 (0.52)

No-Heat Length (Refer to page 105)

Top Cold End 1 in. min., 12 in. max. (25/305 mm) 1 in. min., 12 in. max. (25/305 mm)

Bottom (blunt end) Cold End 1 ph- 0.5 min., 2 in. max. (13/51 mm) Only available at 1.25 in.

3 ph- 0.75 min., 2 in. max. (19/51 mm) N/A

Max. Voltage—Amperage 240VAC—48A 240VAC—16A

Max. Hipotential 1480VAC 1480VAC

Max. Current Leakage (cold) 3mA 3mA

Max. Amperage Per Coil 16A 16A

Phase(s) 1-ph, 3-ph wye 1-ph

Resistance Coils 3 or 1 1

Ohms/In./Unit 0.200Ω min.—14.00Ω max.

Terminations Flexible lead wires Threaded stud Flexible lead wires

Quick connect (spade) Quick connect (spade)

Screw lug (plate) Screw lug (plate)

Seals Stock: Lavacone 221°F (105°C) Stock: Lavacone 221°F (105°C)

M-t-O: Ceramic base 2800°F (1535°C) M-t-O: Ceramic base 2800°F (1535°C)

Min. Axis Bending Radius Major: 1 (25) Major:3⁄4 (19)

in. (mm) (Do Not Field Bend) Minor:1⁄2 (13)

Minor:5⁄32 (4) 180° bend Minor:5⁄32 (4) 180° bend

Mounting Options Bracket (Type 2) Bracket (Type 2)

Threaded bulkhead Threaded bulkhead

Surface Finish Options Bright anneal Bright anneal

Optional Internal Thermocouple — —

Single-end Configuration Stock: Slotted Stock: Slotted

M-t-O: Slotted, sealed or welded M-t-O: Slotted, sealed or welded

Agency Recognition UL®Component recognition to 240VAC UL®Component recognition to 240VAC

CSA Component recognition to 240VAC CSA Component recognition to 240VAC

®

1400°F (760°C) M-t-O: Incoloy

304 SS 1200°F (650°C) 304 SS 1200°F (650°C)

➀

Silicone rubber 392°F (200°C) Silicone rubber 392°F (200°C)

Lavacone 221°F (105°C) Lavacone 221°F (105°C)

Epoxy resin

(File # E52951) (File # E52951)

(File # 31388) (File # 31388)

266/356°F (130/180°C)

090° bend Minor:1⁄2 (13) 090° bend

0.200Ω min.—14.00Ω max.

®

®

Epoxy resin

1400°F (760°C)

1400°F (760°C)

➀

266/356°F (130/180°C)

➀

Based on 1-phase, single voltage heater.

WATLOW

®

93

Page 4

Tubular Heaters

FIREBAR Single/Double-Ended Heater

Features and Benefits

One Inch Features and Benefits

Double-Ended

Streamline, 0.235 x 1.010 in. (5.9 x 25.6 mm) normal

to flow dimension

• Reduces drag

70 percent greater surface area per linear inch

compared to a 0.430 in. (11 mm) diameter round

tubular heater

• Reduces watt density or packs more kilowatts in

smaller bundles

Compacted MgO insulation

• Maximizes thermal conductivity and dielectric strength

Nickel-chromium resistance wires

• Precision wound

0.040 in. (1 mm) thick MgO walls

• Transfers heat more efficiently away from the

resistance wire to the sheath and media—conducts

heat out of the element faster

Three resistance coil design

• Configurable to either one- or three-phase power,

readily adapts to a variety of electrical sources and

wattage outputs

Lavacone seals

• Provides protection against humid storage conditions,

moisture retardant to 221°F (105°C)

Single-Ended

Single-ended termination

• Simplifies wiring and installation

Streamline, 0.235 x 1.010 in. (5.9 x 25.6 mm) normal

to flow dimension

• Reduces drag

70 percent greater surface area per linear inch

• Reduces watt density from that of the 0.430 in.

(11 mm) diameter round tubular

Slotted end

• Provides installation ease in clamp-on applications

Lavacone seals

• Provides protection against humid storage conditions,

moisture retardant to 221°F (105°C)

s

5

⁄8 inch Features and Benefits

Double-Ended

Special sheath dimensions, 0.235 x 0.650 in.

(5.9 x 16.5 mm)

• Results in a lower profile heater

10 percent greater surface area per linear inch

• Reduces watt density from that of the 0.430 in.

(11 mm) diameter round tubular heater

0.040 in. (1 mm) thick MgO walls

• Transfers heat efficiently away from the resistance

wire to the heated media—conducts heat out of the

element faster

Lavacone seals

• Provides protection against humid storage conditions,

moisture retardant to 221°F (105°C)

Single-Ended

Single-ended termination

• Simplifies wiring and installation

Special sheath dimensions, 0.235 x 0.650 in.

(5.9 x 16.5 mm)

• Results in a lower profile heater for more wattage in

a smaller package

Slotted end

• Provides installation ease in clamp-on applications

Lavacone seals

• Provides protection against humid storage conditions,

moisture retardant to 221°F (105°C)

94

WATLOW

®

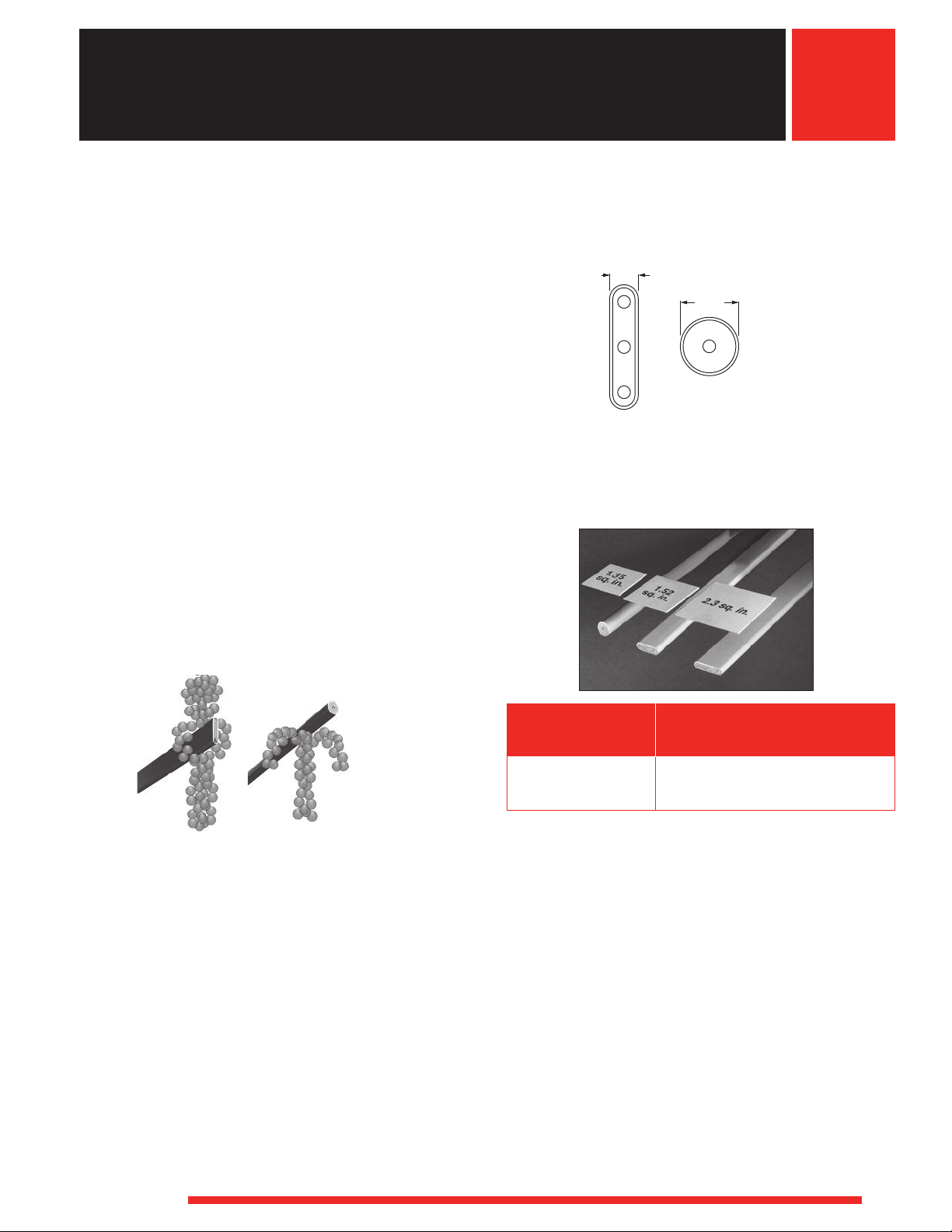

Page 5

Tubular Heaters

0.430 in.

0.235 in.

FIREBAR Single/Double-Ended Heate

Performance Features

FIREBAR’s flat tubular element geometry produces

performance features and benefits not possible with

traditional round tubular technology. The following

describes how and why the FIREBAR is functionally

superior for many applications—especially those

requiring large wattage with low watt density.

By using the FIREBAR element it will:

• Lower the element’s watt density

• Reduce element size and keep the same watt density

• Increase element life by reducing sheath temperature

Flat Shape Produces Lower Sheath Temperature

The FIREBAR element operates at a lower sheath

temperature than a round tubular element of equal

watt density because of three factors.

1. Flat Surface Geometry

FIREBAR’s flat, vertical geometry is streamline. The

liquid’s flow past the heating element’s surface is not

impaired by back eddies inherent in the round tubular

shape. The FIREBAR’s streamline shape results in fluids

flowing more freely with more heat carried away from

the sheath.

rs

Comparative Widths

Watt Density and Surface Area Advantages

The surface area per linear inch of a 1 in. FIREBAR is

70 percent greater than the 0.430 in. (11 mm) diameter

round tubular element. The5⁄8 in. FIREBAR is nearly

10 percent greater.

2. Normal to the Flow

The element’s width (thickness) of both 1 inch and

5

⁄8 inch FIREBAR elements is just 0.235 in. (5.9 mm).

Compared to a 0.430 in. (11 mm) round tubular

element, this relative thinness further reduces drag

on liquids or gases flowing past the heater.

3. Buoyancy Force

The FIREBAR element’s boundary layer, or vertical side,

is greater than virtually all round tubular elements. This

is 1.010 and 0.650 in. (25.6 and 16.5 mm) for the one

inch and5⁄8 in. FIREBARs respectively, compared to a

0.430 in. (11 mm) diameter on a round tubular

element. The FIREBAR element’s increased height,

relative to flow, increases the buoyancy force in

viscous liquids. This buoyancy force can be as much as

10 times greater depending on the FIREBAR element

and liquid used.

WATLOW

®

Surface Area Per

Linear inch (cm)

Element Type in

1 in. FIREBAR 2.30 in

5

⁄8 in. FIREBAR 1.52 in

0.430 in. Round 1.35 in

2

2

2

2

(cm2)

(5.84 cm2)

(3.86 cm2)

(3.43 cm2)

Flat vs. Round Geometry Comparisons

The unique flat surface geometry of the FIREBAR

element offers more versatility in solving heater problems

than the conventional round tubular element. The

following comparisons show how the FIREBAR element

consistently outperforms round tubular heaters.

FIREBAR elements can:

• Reduce coking and fluid degrading

• Increase heater power within application space

parameters

• Provide superior heat transfer in clamp-on applications

resulting from greater surface area contact

• Lower watt density

Reducing watt density or sheath temperature extends life.

The FIREBAR element allows you to do either, without

sacrificing equipment performance … as is proven by the

accompanying Heater Oil Test, Air Flow and Watt Density

vs. Sheath Temperature graphs.

95

Page 6

Tubular Heaters

Oil Temperature —°F

Sheath Temperature —°F

700

650

600

550

500

450

400

350

300

150 200 250 300 350 400 450 500

1 Inch FIREBAR Heater

0.430 Inch Round Tubular

350

325

300

275

250

225

200

175

150

75 100 125 150 175 200 225 250

Sheath Temperature —°C

Oil Temperature —°C

40 W/

i

n

2

(

6.2 W/

cm

2

)

30 W

/i

n

2

(4.7 W

/

cm

2

)

40 W/i

n

2

(6.2

W/

cm

2

)

30 W

/i

n

2

(

4.7 W/cm

2

)

FIREBAR Single/Double-Ended Heater

Technical Data

The FIREBAR Heater Oil Test graph compares sheath

temperatures of 40 W/in2(6.7 W/cm2) flat and round

tubular elements. The FIREBAR element consistently

operates at a lower sheath temperature than the round

tubular element, even when light oils are tested at

different temperatures. This reduces the chance that

coking and fluid degradation will occur.

In fact, the FIREBAR element’s sheath temperature

at 40 W/in2(6.7 W/cm2) is lower than a 30 W/in

(4.6 W/cm2) round tubular element.

2

s

FIREBAR Heater Oil Test

Heater Size and Power

The Heater Size Comparison chart shows, at the same

wattage and watt density, the FIREBAR element is

38 percent shorter than a 0.430 in. (11 mm) round

tubular element. The FIREBAR element requires less

space in application and equipment designs.

The Heater Power Comparison chart demonstrates equal

watt density, element length and increased total wattage

for the FIREBAR element. The power in the FIREBAR

element is 70 percent greater.

96

Heater Size Comparison

Heated Length

Element in. (mm) Wattage W/in2(W/cm2)

1 in. FIREBAR Element 197⁄8 (504.8) 1000 23 (3.6)

0.430 in. Round

Tubular Element 321⁄4 (819.0) 1000 23 (3.6)

Heater Power Comparison

Heated Length

Element in. (mm) Wattage W/in2(W/cm2)

1 in. FIREBAR Element 321⁄4 (819.0) 1700 23 (3.6)

0.430 in. Round

Tubular Element 321⁄4 (819.0) 1000 23 (3.6)

WATLOW

®

Page 7

Tubular Heaters

45

40

35

30

25

20

15

10

5

200 400 600 800 1000

Platen Temperature —°F

Watt Density —W/in

2

200°F

4

00

°F

6

00°F

8

00

°F

1

000°F

Sheath Temperature

Subtract 20% of Indicated Watt

Density for 2 Element FIREBAR

7

6

5

4

3

2

1

100 200 300 400 500

Platen Temperature —°C

1

00°C

2

00°C

30

0

°C

400°C

500°

C

600

Sheath Temperature

Subtract 20% of Indicated Watt

Density for 2 Element FIREBAR

1400

1200

1000

800

600

400

200

10 20 30 40 50

Watt Density—W/in

2

Sheath Temperature —°F

60

0

1600

1800

1 2 3 4

Watt Density—W/cm

2

9

800

700

600

500

400

300

200

Sheath Temperature —°C

0

900

1000

100

5 6 7 8

Air

SAE 3

0

C

o

ok

i

ng O

i

l

Wate

r

FIREBAR Single/Double-Ended Heater

Technical Data (Continued)

Clamp-On Applications

Direct immersion in the liquid may not always be

practical. In these instances the FIREBAR element can

be clamped to a tank wall. Heat from the FIREBAR is

conducted to the tank wall and into the media.

Platen Heating (˚F)

Allowable Watt Densities of FIREBARs in Clamp-on-Application

s

FIREBAR elements are also economical platen heaters.

The Platen Heating graph shows FIREBAR’s large, flat

surface area allows it to operate at twice the watt

density of round tubular elements … without sacrificing

heater life.

Clamps should be placed approximately 6 in. (150 mm)

apart and torqued down with 60 in-lbs (6.8 Newton

meters).

Platen Heating (˚C)

Allowable Watt Densities of FIREBARs in Clamp-on-Application

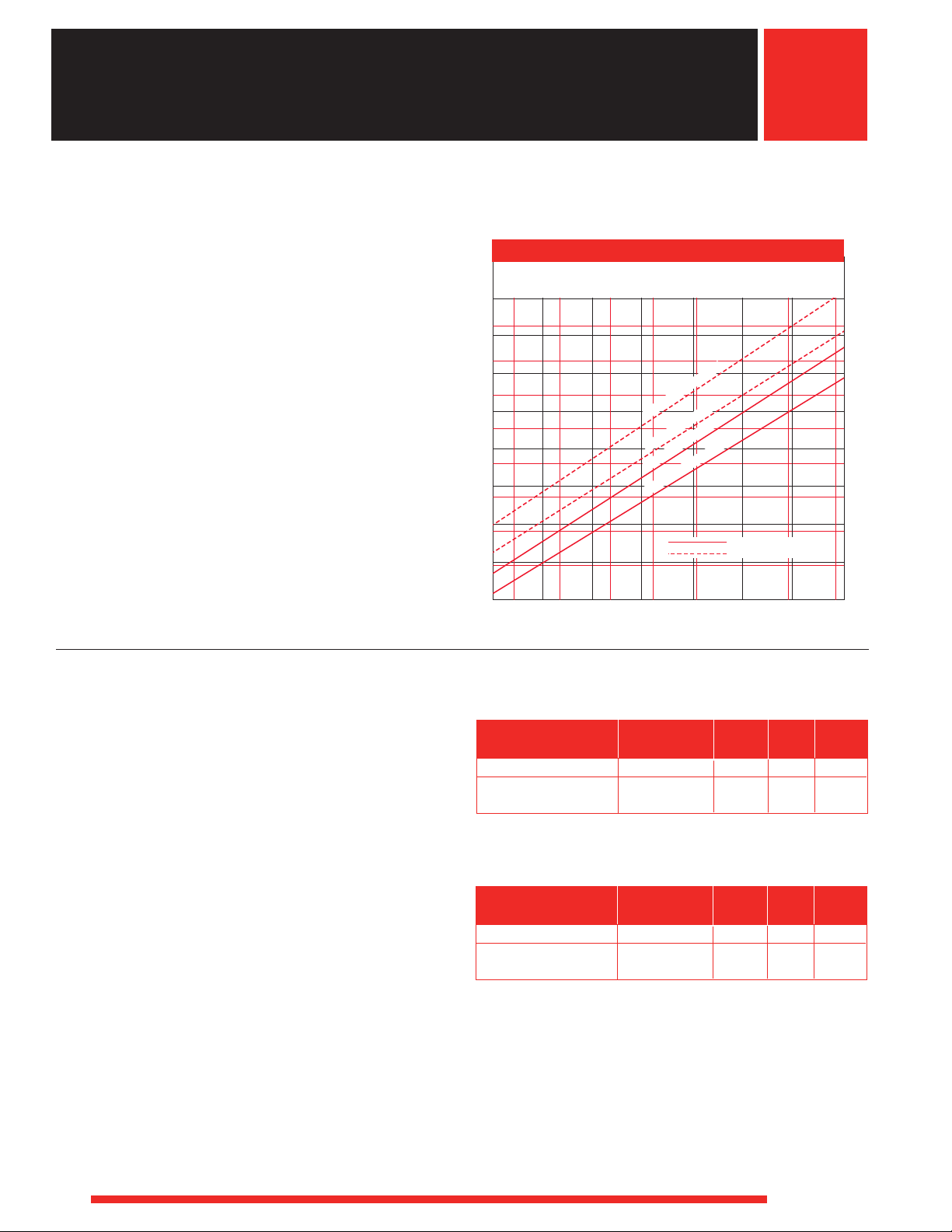

Watt Density vs. Sheath Temperature

The Watt Density vs. Sheath Temperature graph features

sheath temperature curves for commonly heated

substances. A FIREBAR element’s watt density will result

in the sheath temperature shown at the intersecting point

of its vertical watt density line and substance curve.

WATLOW

®

Watt Density vs. Sheath Temperature

97

Page 8

Tubular Heaters

1800

1600

1400

1200

1000

800

600

400

200

5 10 15 20 25 30 35 40 45 50 55 60

Watt Density —W/in

2

Sheath Temperature —°F

Max. Recommended Sheath Temperature

1 FPS

4 FPS

9 FPS

16 FPS

20 FPS

900

800

700

600

500

400

300

200

100

1 2 3 4 5 6 7 8 9 10

Watt Density—W/cm

2

Sheath Temperature—°C

0.3 MPS

1.2 MPS

2.7 MPS

4.9 MPS

6.1 MPS

1000

Max. Recommended

Sheath Temperature

FIREBAR Single/Double-Ended Heater

Technical Data (Continued)

Air Heating

The Air Flow/Watt Density/Sheath Temperature graph

shows the relationship between air flow, watt density and

sheath temperature. Keep in mind that lower sheath

temperature yields longer heater life.

To use the Air Flow graph,determine the air flow in feet

per second (or meters per second). Then follow the curve

to find the recommended sheath temperature and

watt density.

Air Flow/Watt Density/Sheath Temperature (°F)

Air Flow

s

Air Flow Normal to Sheath Geometry

Air Flow/Watt Density/Sheath Temperature (°C)

Air Flow

Moisture Resistant Seals

A lavacone seal is provided to prevent moisture and

contaminants from entering the heater. Upon request,

optional silicone rubber (RTV) and epoxy resin seals may

be ordered.

Silicone Rubber (RTV) Seal

Silicone rubber RTV seals are1⁄8 in. (3.2 mm) moisture

barriers surrounding the terminal pins at the end of the

sheath. Silicone rubber is effective to 392°F (200°C).

Epoxy Resin Seal

Epoxy resin seals are1⁄8 in. (3.2 mm) moisture barriers

surrounding the terminal pins at the end of the sheath.

Epoxy resin is effective to 194°F (90°C) or 356°F (180°C),

and recommended for water heating applications.

98

Application Hints

• Choose a FIREBAR heating element instead of an

assembly, when the application requires lower

wattages or smaller system packages.

• Keep terminations clean, dry and tight.

• Extend the heated section completely into the media

being heated at all times to maximize heat transfer and

heater life.

• Do not locate the end of the heated length within a

bend, unless the radius is 3 in. (76 mm) or larger.

• Ensure termination temperatures do not exceed 392°F

(200°C) or the maximum temperature rating of the end

seal, whichever is lower.

WATLOW

®

Page 9

Tubular Heaters

FIREBAR Single/Double-Ended Heater

All FIREBAR heaters are available with a variety of

s

termination options. Contact your Watlow representative

Technical Data (Continued)

Terminations

Code 1 in. FIREBAR

Number* Termination Phase Wiring Dual-Ended S. End/FINBAR Dual-Ended Single-Ended

Al

Sil-A-Blend™ 200°C lead wire

Sil-A-Blend™ 200°C lead wire

A2

A3

Sil-A-Blend™ 200°C lead wire

A4

Sil-A-Blend™ 200°C lead wire

B1 TGGT 250°C lead wire 1 Parallel Yes Yes Yes Yes

B2 TGGT 250°C lead wire 1 Series Yes No Yes No

B3 TGGT 250°C lead wire 3 Delta Yes No No No

B4 TGGT 250°C lead wire 3 Wye Yes Yes No No

C11⁄4 in. quick connect (spade) 1 Parallel Yes Yes Yes Yes

C21⁄4 in. quick connect (spade) 1 Series Yes No No No

D1 Screw lug (plate) terminal 1 Parallel Yes Yes Yes Yes

D2 Screw lug (plate) terminal 1 Series Yes No No No

D3 Screw lug (plate) terminal 3 Delta Yes No No No

E1 #10-32 stud terminal 1 Parallel Yes Yes Yes Yes

E2 #10-32 stud terminal 1 Series Yes No No No

E3 #10-32 stud terminal 3 Delta Yes No No No

Termination Code Number Legend*

A = Silicone rubber insulation (Sil-A-Blend™) with fiberglass oversleeves

Rated to 392°F (200°C)

B = High-temperature TGGT insulation with fiberglass oversleeves

Rated to 480°F (250°C)

C = Nickel-plated steel quick connect

1 Parallel Yes Yes Yes Yes

1 Series Yes No Yes No

3 Delta Yes No No No

3 Wye Yes Yes No No

for availability.

5

/8in. FIREBAR

D = Nickel-plated steel screw lug with ceramic insulator and plated

steel screw

E = #10-32 nickel-plated steel threaded stud with plated steel nuts and

washers

Electrical Configuration

1 = 1-phase parallel, 2 = 1-phase series, 3 = 3-phase delta,

4 = 3-phase wye

Double-End FIREBAR

Flexible Lead Wire

A, B

➀

Screw Lug (Plate)

D1

Screw Lug (Plate)

D3

Threaded Stud

E2

• Double-End 1 in. FIREBAR

• Single-End 1 in. FIREBAR

• FINBAR

Quick Connect (Spade)

C1

• Double-End 1 in. FIREBAR

Quick Connect (Spade)

C2

• Double-End 1 in. FIREBAR

Single-End FIREBAR

Flexible Lead Wire

A, B

• Single-End 1 in. FIREBAR

• Double-End

• Single-End5⁄8 in. FIREBAR

• FINBAR

WATLOW

5

⁄8 in. FIREBAR

®

➀

• Double-End 1 &

5

⁄8 in. FIREBAR

Screw Lug (Plate)

D2

• Double-End 1 in. FIREBAR

Quick Connect (Spade)

C3

• Single-End 1 FIREBAR

• FINBAR

5

• Double-End

• Single-End5⁄8 in. FIREBAR

⁄8 in. FIREBAR

• Double-End 1 in. FIREBAR

3-phase delta

wiring example

Threaded Stud

E1

5

• Double-End 1 &

⁄8 in. FIREBAR

Screw Lug (Plate)

D4

• Single-End 1 in. FIREBAR

• FINBAR

• Double-End

• Single-End5⁄8 in. FIREBAR

5

⁄8 in. FIREBAR

• Double-End 1 in. FIREBAR

Threaded Stud

E3

• Double-End 1 in. FIREBAR

3-phase delta

wiring example

➀

Flexible lead wires are 12 in. (305 mm)

long unless otherwise specified.

Threaded Stud

E4

• Single-End 1 in. FIREBAR

• FINBAR

➀

Flexible lead wires are 12 in. (305 mm)

long unless otherwise specified.

99

Page 10

Tubular Heaters

0.235 in.

(5.9 mm)

1 in.

(25 mm)

A

1 in.

(25 mm)

Min.

No-Heat

R

1 in.

(25 mm)

0.235 in.

(5.9 mm)

No-Heat

R

A

1 in. (25 mm) Min.

2.5 in. (64 mm)

Min.

No-Heat

R

A

B

1 in.

(25 mm)

Min.

R

A

B

No-Heat

3.5 in. (89 mm)

Min.

0.235 in.

(5.9 mm)

1 in.

(25 mm)

A

1 in. (25 mm) Min.

R

B

No-Heat

1 in. (25 mm)

Min.

1 in. (25 mm)

0.235

in.

(5.9 mm)

A

2 in. (51 mm) Min.

No-Heat

B

R

1 in. (25 mm)

Min.

FIREBAR Single/Double-Ended Heaters

Bending

Major and Minor Axis Bending Parameters

The following illustrations detail the recommended major

and minor axis bend parameters for FIREBAR

elements. These illustrations show the relationship

between the type of bend and the location of heat and

no-heat sections. See the next two pages for the

15 common bend formations.

Note: Watlow does not recommend field bending

FIREBAR elements. If the element must be bent in the

field, please contact your Watlow representative for

assistance.

180° Minor Axis Heated Bend

90° Minor Axis Heated Bend

180° Major Axis Heated Bend

90° Major Axis Heated Bend

90° Minor Axis Un-Heated Bend

100

180° Major Axis Bends

FIREBAR Size Radius

in. (mm) in. (mm) Arc Length

5

1

⁄8 (15.9)

5

1

⁄8 (15.9) 1 (25.0) 3.900

5

⁄8 (15.9) 11⁄4 (32.0) 4.620

1

5

1

⁄8 (15.9) 11⁄2 (38.0) 5.600

1 (25.0) 1 (25.0) 4.335

1 (25.0) 11⁄4 (32.0) 5.121

1 (25.0) 11⁄2 (38.0) 5.906

3

1

⁄4 (19.0) 3.125

WATLOW

®

Page 11

Tubular Heaters

A

H

R

1

R

1

R

2

H

A

C

L

A

C

L

H

R

1

R

2

H

R

1

A

<°

(Angle)

F

R

2

R

1

A

H

R

2

K

A

H

R

1

R

2

K

A

H

R

1

H

A

R

1

R

1

H

R

2

A

<°

(Angle)

F

R

1

R

2

H

K

A

H

R

1

R

2

K

A

A

H

R

1

R

1

R

2

R

1

H

A

L

R

3

K

A

R

1

R

2

R

1

H

L

R

3

K

A

R

1

R

1

R

2

L

H

FIREBAR Single/Double-Ended Heaters

Bend Formations

FIREBAR elements can be formed into spirals,

compounds, multi-axis and multi-plane configurations

from 15 common bends. Custom bending with

tighter tolerances can be made to meet specific

application needs.

Formation is limited by bending parameters specified in

the illustrations of major and minor axis bends on the

previous page. On these illustrations, please note the

no-heat end location.

Minor Axis Major Axis Major AxisMinor Axis

Figure 1B

Figure 1A

Figure 3A

The no-heat end junction must be located a minimum of

1 in. (25 mm) from any bend. If these parameters are not

followed, the heater may fail prematurely.

Illustrated below are the common bends that can be

ordered for all FIREBAR heating elements.

To order a common bend, specify the figure number

and critical dimensions.

Note: The alpha characters and symbols are used to

designate specific dimensions within each illustration.

Figure 2A

Figure 2B

Figure 4BFigure 4AFigure 3B

Figure 5A

Figure 7A

WATLOW

Figure 5B

R

1

R

2

R

1

L

A

®

H

Figure 7B

Figure 6A

Figure 8A

Figure 6B

Figure 8B

101

Page 12

Tubular Heaters

L

R

1

R

2

H

A

K

B

R

1

R

1

R

3

R

4

R

2

X Hairpins

<°

(Angle)

R

1

L

B

H

K

R

1

A

R

2

H

K

R

1

R

2

L

B

A

L

R

1

R

2

A

H

R

1

R

1

R

2

X Hairpins

R

3

K

L

A

H

R

1

R

1

R

1

R

2

R

2

X Hairpins

R

3

K

L

R

1

R

2

A

H

R

1

R

1

R

2

X Hairpins

A

H

L

R

1

R

1

R

1

R

2

R

2

X Hairpins

L

H

A

K

B

R

1

R

1

R

1

R

3

R

4

R

2

R

2

X Hairpins

R

1

K

H

A

G

K

A

R

1

H

L

R

1

R

2

A

H

L

K

R

1

R

1

R

2

FIREBAR Single/Double-Ended Heaters

Bend Formation (Continued)

Minor Axis Major Axis Major AxisMinor Axis

Figure 9A

Figure 9B

Bend Figure

11B

Not Available

On Major Axis

Figure 10A

Bend Figure

10B

Not Available

On Major Axis

Figure 12BFigure 12AFigure 11A

Figure 15A

102

Figure 13BFigure 13A

Figure 15B

Figure 14A Figure 14B

WATLOW

®

Page 13

Tubular Heaters

1

5

/8 in. -

10 UNC

0.753 in.

(19 mm)

0.940 in.

(23.9 mm)

0.187 in.

(4.8 mm)

2.25 in.

(57 mm)

0.125 in. Max.

No Threads

9

/16 in.

(14.3 mm)

Wall

Washer

Nut

Gasket

2.625 in.

(66.7 mm)

(2) 0.25 in.

(6 mm) Dia.

1.5 in.

(38 mm)

3.25 in.

(83 mm)

1.75 in.

(45 mm)

4.875 in.

(123.8 mm)

1.75 in.

(45 mm)

3 in.

(76 mm)

5.5 in.

(140 mm)

(2) 0.25 in.

(6 mm) Dia.

(2) 0.25 in.

(6 mm) Dia.

1.75 in.

(45 mm)

1.125 in.

(28.6 mm)

1.75 in.

(45 mm)

FIREBAR Single/Double-Ended Heaters

Mounting Brackets

Steel brackets provide element mounting in

non-pressurized applications. In air heating applications,

an 18-gauge aluminized steel bracket is press fitted to

the element. A1⁄4 in. (6 mm) thick steel bracket is brazed

or welded liquid-tight to the element for liquid heating.

Upon request, stainless steel brackets can be provided.

Special sizes also available.

The bracket is located1⁄2 in. (13 mm) from the sheath’s

end,1⁄16 in. (1.6 mm) if welded. Available on5⁄8 in.

(15.9 mm) FIREBAR as made-to-order only.

To order, specify mounting bracket as well as type,

location, material and size.

Type 1

Water-Tight Double-Leg Threaded Fitting

5

A threaded 1

flange on the heater sheath provides rigid, leak-proof

mounting through tank walls. This fitting allows both legs

of the heater to pass through the same opening. A

gasket, plated steel washer and hex nut are included.

The threaded end of the bulkhead is mounted flush with

the sheath’s end, unless otherwise specified. Available

on 1 inch FIREBAR only (brazed only, available).

To order, specify water-tight double-leg threaded

fitting.

⁄8 in.-10 UNC stainless steel fitting with

Type 2

Type 3

WATLOW

®

Surface Finish

Bright Annealing

Bright annealing is a process that produces a smooth,

metallic finish. It is a special annealed finish created in a

non-oxidizing atmosphere. This finish is popular in the

pharmaceutical and foodservice/beverage markets.

To order, specify bright annealing.

Passivation

During manufacturing, particles of iron or tool steel may

be embedded in the stainless steel or alloy sheath. If not

removed, these particles may corrode and produce rust

spots. For critical sheath applications, passivation will

remove free iron from the sheath.

To order, specify passivation.

103

Page 14

Tubular Heaters

15

/16 in. (23.8 mm)

3

/4 in.

(19 mm)

3

/16 in.

(4.8 mm)

Wall

Washer

Nut

Gasket

11/4 in.

(32 mm)

Extended Capabilities For

FIREBAR Single/Double-Ended Heaters

XTE

E

APABILITY

C

NDED

Internal Thermocouples

To provide protection against element over-temperature

conditions, 1 in. (25 mm) double-ended FIREBAR

elements can be ordered with ASTM Type K

thermocouples. This is accomplished by eliminating the

center resistance coil and embedding the thermocouple

junction inside the sheath. Thus, thermocouples are

available only on two resistance coil, 1 in. (25 mm)

FIREBAR elements.

To order, specify:

• Type K thermocouple

• Distance the junction is to be located from the

element’s end

• Lead length

Thermocouple Types

Recommended

®

Temp. Range

°F (°C)

0 to 2000

(-20 to 1100)

ASTM

Type

K Chromel

➀ Type K thermocouples are rated 32 to 2282°F (0 to 1250°C).

Watlow does not recommend exceeding the temperature range

shown on this chart.

Conductor

Positive

®

(Non-magnetic)

Characteristics

Negative

Alumel

(Magnetic)

Options for5⁄8-Inch FIREBAR

• Electropolished finish

• Custom formations

• Cordset

• Termination overmolds (silicone or neoprene)

• Terminal enclosures (general purpose, moisture

resistant, moisture/explosion resistant and explosion

resistant)

• Internal thermocouple (dual end only, single or dual coil

• Custom wattage tolerance (±5%)

Options for One-Inch FIREBAR

• Electropolished finish

• Bulkhead, single leg

• Custom formations

• Cordset

• Termination overmolds (silicone or neoprene)

• Terminal enclosures (general purpose, moisture

resistant, moisture/explosion resistant and explosion

resistant)

• Internal thermocouple (dual end only, single or dual coil

• Custom wattage tolerance (±5%)

Mounting Brackets

Threaded Bulkheads

A threaded stainless steel bushing with flange on the

heater sheath provides rigid, leak-proof mounting

through tank walls. A gasket, plated steel washer and

hex nut are included (brazed only, available).

To order, specify threaded bulkheads.

Illustration for5⁄8-inch FIREBAR

Illustration for 1-inch FIREBAR

1

1

(32 mm)

/4 in.

Heater Size Thread

in. (mm) Size

5

⁄8 (15.9)

1 (25.0)

7

⁄8-14 UNF-2A

3

⁄4-16 UNF-2A

104

WATLOW

®

Page 15

Tubular Heaters

No-Heat

Sheath Length

A

Heated Length

B

No-Heat

Lavacone Seal

Straight Length Annealed Incoloy

®

Sheath Permits

Factory Bending to Customer Requirements

12 in. (305 mm)

Standard Leads

6 Per Element

½ in.

(13 mm)

RAPID SHIP

FIREBAR Single/Double-Ended Heaters

One-Inch, Double-Ended FIREBAR

FIREBAR Sheath Heated Est. Net

Description A Dimension B Dimension Watts Code Number Wt.

Applications: Asphalt, Paraffin (Solid), Bunker Oil, Clamp-On

2

6 W/in

®

Incoloy

(1 W/cm

Applications: Griddles, Fuel Oil, Clamp-On

10 W/in

Incoloy

(1.6 W/cm

Applications: Clamp-On, Medium Weight Oils, Liquid Paraffin, Low-Temperature Ovens 400°F (205°C)

15 W/in2➀ 29 (736) 19 (482) 670 FBN2910WE 1.1 (0.5)

Incoloy

(2.3 W/cm

Applications: Radiant, Platens, Dies, Low-Temperature Ovens 300°F (150°C)

20 W/in

Incoloy

(3.1 W/cm

Applications: Degreasing Solutions, Heat Transfer Oils

23 W/in

Incoloy

(3.6 W/cm

WATLOW

2

) 51 (1295) 41 (1041) 530 FBN511WD FBN5110WD 1.9 (0.9)

2

®

®

2

®

2

®

in. (mm) in. (mm) 120VAC 240VAC 480VAC lbs (kg)

35 (889) 25 (635) 310 FBN351WD 1.3 (0.6)

41 (1041) 31 (787) 410 FBN411WD 1.5 (0.7)

62 (1574) 52 (1320) 650 FBN621WD FBN6210WD 2.3 (1.1)

72 (1828) 62 (1574) 800 FBN721WD FBN7210WD 2.6 (1.2)

93 (2362) 83 (2108) 1,060 FBN931WD FBN9310WD 3.4 (1.6)

114 (2895) 104 (2641) 1,350 FBN1141WD FBN11410WD 4.2 (1.9)

25 (635) 22 (558) 500 FBN251WL 0.9 (0.4)

35 (889) 32 (812) 750 FBN351WL FBN3510WL 1.3 (0.6)

2

) 47 (1193) 43 (1092) 1,000 FBN471WL FBN4710WL 1.7 (0.8)

69 (1752) 65 (1651) 1,500 FBN691WL FBN6910WL 2.5 (1.2)

90 (2286) 86 (2184) 2,000 FBN901WL FBN9010WL 3.3 (1.5)

34 (863) 24 (609) 830 FBN3410WE 1.3 (0.6)

2

) 39 (990) 29 (736) 1,000 FBN3910WE 1.4 (0.7)

48 (1219) 38 (965) 1,330 FBN4810WE FBN4811WE 1.8 (0.9)

58 (1473) 48 (1219) 1,670 FBN5810WE FBN5811WE 2.1 (1.0)

68 (1727) 58 (1473) 2,000 FBN6810WE FBN6811WE 2.5 (1.2)

87 (2209) 77 (1955) 2,670 FBN8710WE FBN8711WE 3.2 (1.5)

106 (2692) 96 (2438) 3,330 FBN10610WE FBN10611WE 3.9 (1.8)

15 (381) 11 (279) 500 FBN151WM 0.6 (0.3)

20 (508) 16 (406) 750 FBN201WM 0.8 (0.4)

2

) 26 (660) 22 (558) 1,000 FBN261WM FBN2610WM 1.0 (0.5)

36 (914) 32 (812) 1,500 FBN361WM FBN3610WM 1.3 (0.6)

48 (1219) 43 (1092) 2,000 FBN481WM FBN4810WM 1.8 (0.9)

70 (1778) 65 (1651) 3,000 FBN7010WM FBN7011WM 2.6 (1.2)

91 (2311) 85 (2159) 4,000 FBN9110WM FBN9111WM 3.3 (1.5)

35 (889) 25 (635) 1,250 FBN351WT FBN3510WT 1.3 (0.6)

41 (1041) 31 (787) 1,625 FBN411WT FBN4110WT 1.5 (0.7)

2

) 51 (1295) 41 (1041) 2,125 FBN511WT FBN5110WT FBN5111WT 1.9 (0.9)

62 (1574) 52 (1320) 2,625 FBN621WT FBN6210WT FBN6211WT 2.3 (1.1)

72 (1828) 62 (1574) 3,200 FBN721WT FBN7210WT FBN7211WT 2.6 (1.2)

93 (2362) 83 (2108) 4,250 FBN931WT FBN9310WT FBN9311WT 3.4 (1.6)

114 (2895) 104 (2641) 5,400 FBN1141WT FBN11410WT FBN11411WT 4.2 (1.9)

• Available on all elements unless otherwise noted

CONTINUED

• Same day shipment up to 15 pieces

®

➀ Delivery, 10 working days

Truck Shipment only

105

Page 16

Tubular Heaters

No-Heat

Sheath Length

A

Heated Length

B

No-Heat

Lavacone Seal

Straight Length Annealed Incoloy

®

Sheath Permits

Factory Bending to Customer Requirements

12 in. (305 mm)

Standard Leads

6 Per Element

½ in.

(13 mm)

RAPID SHIP

FIREBAR Single/Double-Ended Heaters

One-Inch, Double-Ended FIREBAR (Continued)

FIREBAR Sheath Heated Est. Net

Description A Dimension B Dimension Watts Code Number Wt.

in. (mm) in. (mm) 120VAC 240VAC 480VAC lbs (kg)

Applications: Cooking Oils, Mild Caustic Solution, Ethylene Glycol (100%)

2

30 W/in

®

Incoloy

(4.7 W/cm

Applications: Process Water, Ethylene Glycol (50%)

2

40 W/in

®

Incoloy

(6.2 W/cm

2

45 W/in

®

Incoloy

(7 W/cm

2

) 39 (990) 29 (736) 3000 FBN3910WP 1.4 (0.7)

Applications: Clean and Potable Water

2

80 W/in

®

Incoloy

(12.4 W/cm

2

90 W/in

®

Incoloy

(14 W/cm

2

16 (406) 10 (254) 750 FBN161WH 0.6 (0.3)

20 (508) 14 (355) 1000 FBN201WH 0.8 (0.4)

2

) 27 (685) 21 (533) 1500 FBN271WH FBN2710WH 1.0 (0.5)

34 (863) 28 (711) 2000 FBN341WH FBN3410WH 1.3 (0.6)

50 (1270) 43 (1092) 3000 FBN5010WH FBN5011WH 1.8 (0.9)

64 (1625) 57 (1447) 4000 FBN6410WH FBN6411WH 2.4 (1.1)

80 (2032) 72 (1828) 5000 FBN8010WH FBN8011WH 2.9 (1.4)

25 (635) 22 (558) 2000 FBN2510WK 0.9 (0.4)

35 (889) 32 (812) 3000 FBN3510WK FBN3511WK 1.3 (0.6)

2

) 47 (1193) 43 (1092) 4000 FBN4710WK FBN4711WK 1.7 (0.8)

69 (1752) 65 (1651) 6000 FBN6910WK FBN6911WK 2.5 (1.2)

90 (2286) 86 (2184) 8000 FBN9010WK FBN9011WK 3.3 (1.5)

29 (736) 19 (482) 2000 FBN2910WP 1.1 (0.5)

34 (863) 24 (609) 2500 FBN3410WP 1.3 (0.6)

48 (1219) 38 (965) 4000 FBN4810WP FBN4811WP 1.8 (0.9)

58 (1473) 48 (1219) 5000 FBN5810WP FBN5811WP 2.1 (1.0)

68 (1727) 58 (1473) 6000 FBN6810WP FBN6811WP 2.5 (1.2)

87 (2209) 77 (1955) 8000 FBN8710WP FBN8711WP 3.2 (1.5)

106 (2692) 96 (2438) 10,000 FBN10610WP FBN10611WP 3.9 (1.8)

15 (381) 11 (279) 2000 FBN1510WJ 0.6 (0.3)

20 (508) 16 (406) 3000 FBN2010WJ 0.8 (0.4)

2

) 26 (660) 22 (558) 4000 FBN2610WJ FBN2611WJ 1.0 (0.5)

36 (914) 32 (812) 6000 FBN3610WJ FBN3611WJ 1.3 (0.6)

48 (1219) 43 (1092) 8000 FBN4810WJ FBN4811WJ 1.8 (0.9)

70 (1778) 65 (1651) 12,000 FBN7011WJ 2.6 (1.2)

91 (2311) 85 (2159) 16,000 FBN9111WJ 3.3 (1.5)

35 (889) 25 (635) 5000 FBN351WG FBN3510WG FBN3511WG 1.3 (0.6)

41 (1041) 31 (787) 6500 FBN411WG

➀

FBN4110WG FBN4111WG 1.5 (0.7)

) 51 (1295) 41 (1041) 8500 FBN5110WG FBN5111WG 1.9 (0.9)

62 (1574) 52 (1320) 10,500 FBN6210WG FBN6211WG 2.3 (1.1)

72 (1828) 62 (1574) 12,750 FBN7210WG FBN7211WG 2.6 (1.2)

93 (2362) 83 (2108) 17,000 FBN931WG 3.4 (1.6)

114 (2895) 104 (2641) 21,500 FBN11411WG 3.4 (1.6)

• Available on all elements unless otherwise noted

• Same day shipment up to 15 pieces

➀ Delivery, 10 working days

Truck Shipment only

106

WATLOW

®

Page 17

Tubular Heaters

No-Heat

Sheath Length

A

Heated Length

B

No-Heat

Lavacone Seal

Straight Length Annealed Incoloy

®

Sheath Permits

Factory Bending to Customer Requirements

12 in. (305 mm)

Standard Leads

4 Per Element

1

/2 in.

(13 mm)

RAPID SHIP

FIREBAR Single/Double-Ended Heaters

5

⁄8-Inch Double-Ended FIREBAR

FIREBAR Sheath Heated Est. Net

Description A Dimension B Dimension Watts Code Number Wt.

in. (mm) in. (mm) 120VAC 240VAC 480VAC lbs (kg)

Applications: Degreasing Fluids, Heat Transfer Oils

23 W/in2➀ 19 (483) 11 (279) 375 FAN191WT 0.5 (0.3)

®

Incoloy

(3.6 W/cm2) 26 (660) 18 (457) 625 FAN261WT FAN2610WT 0.6 (0.3)

Applications: Clean and Potable Water

2

90 W/in

®

Incoloy

(14 W/cm2) 22 (559) 14 (356) 2000 FAN221WG FAN2210WG➀ FAN2211WG 0.5 (0.3)

22 (559) 14 (356) 500 FAN221WT FAN2210WT 0.5 (0.3)

30 (762) 22 (559) 750 FAN301WT FAN3010WT 0.7 (0.4)

37 (940) 29 (737) 1000 FAN371WT FAN3710WT 0.9 (0.5)

44 (1118) 36 (914) 1250 FAN441WT FAN4410WT 1.0 (0.5)

51 (1295) 43 (1092) 1500 FAN511WT FAN5110WT 1.2 (0.6)

15 (381) 7 (178) 1000 FAN151WG➀ FAN1510WG 0.4 (0.2)

19 (483) 11 (279) 1500 FAN191WG FAN1910WG➀ FAN1911WG 0.5 (0.3)

26 (660) 18 (457) 2500 FAN261WG FAN2610WG➀ FAN2611WG 0.6 (0.3)

30 (762) 22 (559) 3000 FAN301WG➀ FAN3010WG➀ FAN3011WG 0.7 (0.4)

37 (940) 29 (737) 4000 FAN3710WG➀ FAN3711WG 0.9 (0.5)

44 (1118) 36 (914) 5000 FAN4410WG➀ FAN4411WG 1.0 (0.5)

51 (1295) 43 (1092) 6000 FAN5110WG➀ FAN5111WG 1.2 (0.6)

• Available on all elements unless otherwise noted

• Same day shipment up to 15 pieces

➀ Delivery, 10 working days

WATLOW

®

107

Page 18

Tubular Heaters

1

1

/4 in.

(32 mm)

No-Heat

Sheath Length

A

Heated Length

B

1 in. (25 mm)

No-Heat

12 in. (305 mm) Standard Leads

2 per Element

1

in. (25 mm)

1

/4 in.

(6 mm)

5

/16 in.

(7.9 mm)

1

/2 in.

(13 mm)

0.235 in.

(5.9 mm)

Lavacone

Seal

RAPID SHIP

FIREBAR Single/Double-Ended Heaters

One-Inch, Single-Ended FIREBAR

FIREBAR Sheath Heated Est. Net

Description A Dimension B Dimension Watts Code Number Wt.

in. (mm) in. (mm) 120VAC 240VAC lbs (kg)

Applications: Radiant, Platens, Dies, Low-Temperature Ovens 300°F (150°C)

2

20 W/in

304 SS 101⁄4 (260.0) 71⁄2 (203.0) 375 FSP101WM 0.4 (0.2)

(3.1 W/cm2) 121⁄4 (311.0) 10 (254.0) 450 FSP121WM 0.5 (0.3)

Applications: Process Water, Ethylene Glycol (50%)

2

40 W/in

304 SS 101⁄4 (260.0) 71⁄2 (203.0) 750 FSP101WK 0.4 (0.2)

(6.2 W/cm2) 121⁄4 (311.0) 10 (254.0) 900 FSP121WK FSP1210WK 0.5 (0.3)

83⁄4 (222.0) 61⁄2 (165.0) 300 FSP91WM 0.4 (0.2)

131⁄2 (343.0) 111⁄4 (286.0) 500 FSP141WM 0.5 (0.3)

161⁄8 (408.6) 137⁄8 (352.4) 650 FSP161WM FSP1610WM 0.6 (0.3)

173⁄4 (451.0) 151⁄2 (393.0) 725 FSP181WM FSP1810WM 0.7 (0.4)

191⁄4 (489.0) 17 (431.0) 800 FSP191WM FSP1910WM 0.7 (0.4)

22 (558.0) 193⁄4 (502.0) 900 FSP221WM FSP2210WM 0.8 (0.4)

233⁄4 (603.0) 211⁄2 (546.0) 1,000 FSP241WM FSP2410WM 0.9 (0.4)

25 (635.0) 223⁄4 (578.0) 1,050 FSP251WM FSP2510WM 0.9 (0.4)

285⁄8 (727.1) 263⁄8 (670.0) 1,250 FSP291WM FSP2910WM 1.1 (0.5)

315⁄8 (803.3) 293⁄8 (746.1) 1,350 FSP321WM FSP3210WM 1.2 (0.6)

341⁄8 (866.8) 317⁄8 (809.6) 1,500 FSP3410WM 1.3 (0.6)

367⁄8 (936.6) 345⁄8 (879.5) 1,600 FSP3710WM 1.4 (0.7)

405⁄8 (1031.9) 383⁄8 (974.7) 1,800 FSP4110WM 1.5 (0.7)

461⁄4 (1175.0) 44 (1117.0) 2,000 FSP4610WM 1.7 (0.8)

83⁄4 (222.0) 61⁄2 (165.0) 600 FSP91WK 0.4 (0.2)

131⁄2 (343.0) 111⁄4 (286.0) 1,000 FSP131WK FSP1310WK 0.5 (0.3)

161⁄4 (413.0) 137⁄8 (352.4) 1,300 FSP161WK FSP1610WK 0.6 (0.3)

173⁄4 (451.0) 151⁄2 (393.0) 1,450 FSP181WK FSP1810WK 0.7 (0.4)

191⁄4 (489.0) 17 (431.0) 1,600 FSP1910WK 0.7 (0.4)

22 (558.0) 193⁄4 (502.0) 1,800 FSP2210WK 0.8 (0.4)

233⁄4 (603.0) 211⁄2 (546.0) 2,000 FSP2410WK 0.9 (0.4)

25 (635.0) 223⁄4 (578.0) 2,100 FSP2510WK 0.9 (0.4)

285⁄8 (727.1) 263⁄8 (669.9) 2,500 FSP2910WK 1.1 (0.5)

315⁄8 (803.2) 293⁄8 (746.1) 2,700 FSP3210WK 1.2 (0.6)

341⁄8 (866.8) 317⁄8 (809.6) 3,000 FSP3410WK 1.3 (0.6)

367⁄8 (936.6) 345⁄8 (879.5) 3,200 FSP3710WK 1.4 (0.7)

405⁄8 (1031.9) 383⁄8 (974.7) 3,600 FSP4110WK 1.5 (0.7)

461⁄4 (1175.0) 44 (1117.0) 4,000 FSP4610WK 1.7 (0.8)

• Available on all elements unless otherwise noted

• Same day shipment up to 15 pieces

108

WATLOW

®

Page 19

Tubular Heaters

1

1

/4 in.

(32 mm)

No-Heat

Sheath Length

A

Heated Length

B

1 in.

(25 mm)

Min. No-Heat

1

/2 in.

(13 mm)

5

/8

in.

(15.9 mm)

0.235 in.

(5.9 mm)

1

/4 in.

(6 mm)

5

/16 in.

(7.9 mm)

12 in. (305 mm)

Standard Leads

2 Per Element

Lavacone

Seal

RAPID SHIP

FIREBAR Single/Double-Ended Heaters

5

⁄8-Inch Single-Ended FIREBAR

FIREBAR Sheath Heated Est. Net

Description A Dimension B Dimension Watts Code Number Weight

in. (mm) in. (mm) 120VAC 240VAC lbs (kg)

Applications: Radiant, Platens, Dies, Low-Temperature Ovens 300°F (150°C)

2

20 W/in

®

Incoloy

(3.1 W/cm2) 191⁄2 (495) 16 (406) 500 FSA201WM FSA2010WM 0.5 (0.3)

111⁄2 (292) 8 (203) 250 FSA121WM 0.3 (0.2)

151⁄2 (394) 12 (304) 375 FSA161WM FSA1610WM 0.4 (0.2)

28 (711) 24 (609) 750 FSA281WM FSA2810WM 0.6 (0.3)

36 (914) 32 (812) 1,000 FSA361WM FSA3610WM 0.8 (0.4)

52 (1321) 48 (1219) 1,500 FSA521WM FSA5210WM 1.2 (0.6)

• Available on all elements unless otherwise noted

• Same day shipment up to 15 pieces

WATLOW

®

109

Loading...

Loading...