Page 1

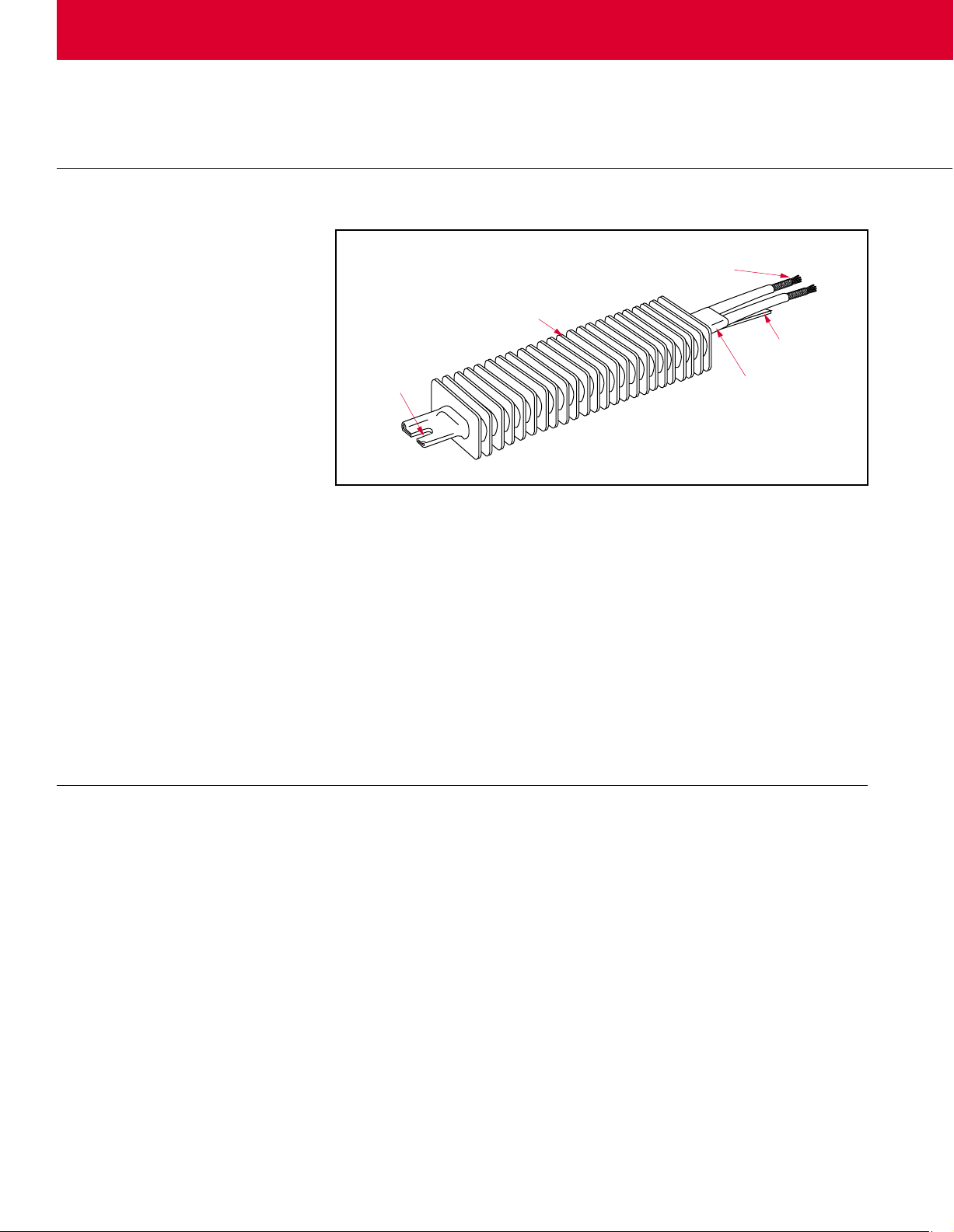

Tubular and

Slotted End

Aluminized Steel Fins

Flexible Lead Wires

304 Stainless Steel Sheath

Stainless Steel

Mounting Bracket

Process Assemblies

FIREBAR Heating

Elements

FINBAR

Composed of aluminized steel fins

press fitted to a one inch singleended FIREBAR element. The

FINBAR is designed to improve

heat transfer to the air and permits

putting more power in tighter

spaces—like forced air ducts,

dryers, ovens and load bank

resistors.

Heat transfer, lower sheath

temperature and element life are all

maximized by its finned

construction.

Installation is simplified by

terminations exiting at one end and

mounting accommodations on both

ends.

Performance Capabilities

• Watt densities to 50 W/in

(7.7 W/cm2)

• 304 stainless steel sheath

temperatures to 1200°F (650°C)

• Voltages to 480VÅ(ac)

• Amperages to 48 amps per

heater or 16 amps per coil

2

Features and Benefits

• Rugged aluminized steel fins

effectively increase surface area

to approximately 16 square

inches for every linear inch of

element length. Fins press fitted

to the heating element improve

heat transfer to the air.

• Single-ended termination simplifies wiring and installation.

• Stainless steel mounting

bracket, welded to the terminal

end, is supplied with a slotted

end for ease of installation.

• Lavacone seals provide

protection against humid storage

conditions. Moisture retardant to

392°F (200°C).

Applications

• Forced air heating for dryers,

ovens, ducts

• Still air heating for ovens,

comfort heating

• Incubators

• Ink drying

• Load bank resistors

Construction Features

Construction features are detailed

for assembly stock products only.

Optional materials, sizes,

terminations and ratings may be

available at additional cost. For

availability and ordering information

on options, see pages 307 to 312.

Watt Density: Stock; up to 40 W/in

(6.2 W/cm2), made-to-order; up to

50 W/in2(7.7 W/cm2)

Fin Surface Area: 16 in2/linear inch

(40.5 cm2/linear cm)

Fin Cross Section: 2 X 1 inch (50 X

25 mm)

318

Maximum Operating Temperature:

Sheath material: 304 Stainless Steel,

1200°F (650°C), Fin material;

Aluminized Steel; 1100°F (600°C)

Heater Length: Stock; 10 to 48

inches (260 to 1210 mm),

made-to-order; 6 to 120 inches

2

(150 to 3050 mm)

No-Heat Length: 1 inch minimum,

12 inch maximum (25/305 mm)

Voltages: Up to 480VÅ(ac)

Phase: Stock; 1-phase parallel

made-to-order; 1-phase parallel or

3-phase wye

Resistance Coils: Stock; 1

made-to-order 1 or 3

Terminations: Flexible lead wires,

quick connect (spade), screw lug

(plate) and threaded stud

Seal Material: Lavacone, rated to

392°F (200°C)

Optional Internal Thermocouple:

made-to-order only; ASTM Type K

Single-End Configuration: Stock:

slotted, made-to-order; slotted,

no-slot or sealed

Agency Recognition: refer to

FIREBAR UL file # E52951 and CSA

file # 31388 under Agency

Recognition on pages 268 to 271.

Page 2

W A T L O W

51015202530354045505560

Watt Density—W/in

2

1600

1400

1200

1000

800

600

400

200

Sheath Temperature—°F

Maximum Heater Temperature

to Avoid Scaling of Fins

Maximum Heater Temperature

1 FPS

4 FPS

9 FPS

16 FPS

20 FPS

12 345678910

Watt Density—W/cm

2

800

700

600

500

400

300

200

100

Sheath Temperature—°C

Maximum Heater Temperature

to Avoid Scaling of Fins

Maximum Heater Temperature

900

1000

0.3 MPS

1.2 MPS

2.7 MPS

4.9 MPS

6.1 MPS

Temperature

Sensor

Tubular and

Process Assemblies

FIREBAR Heating

Elements

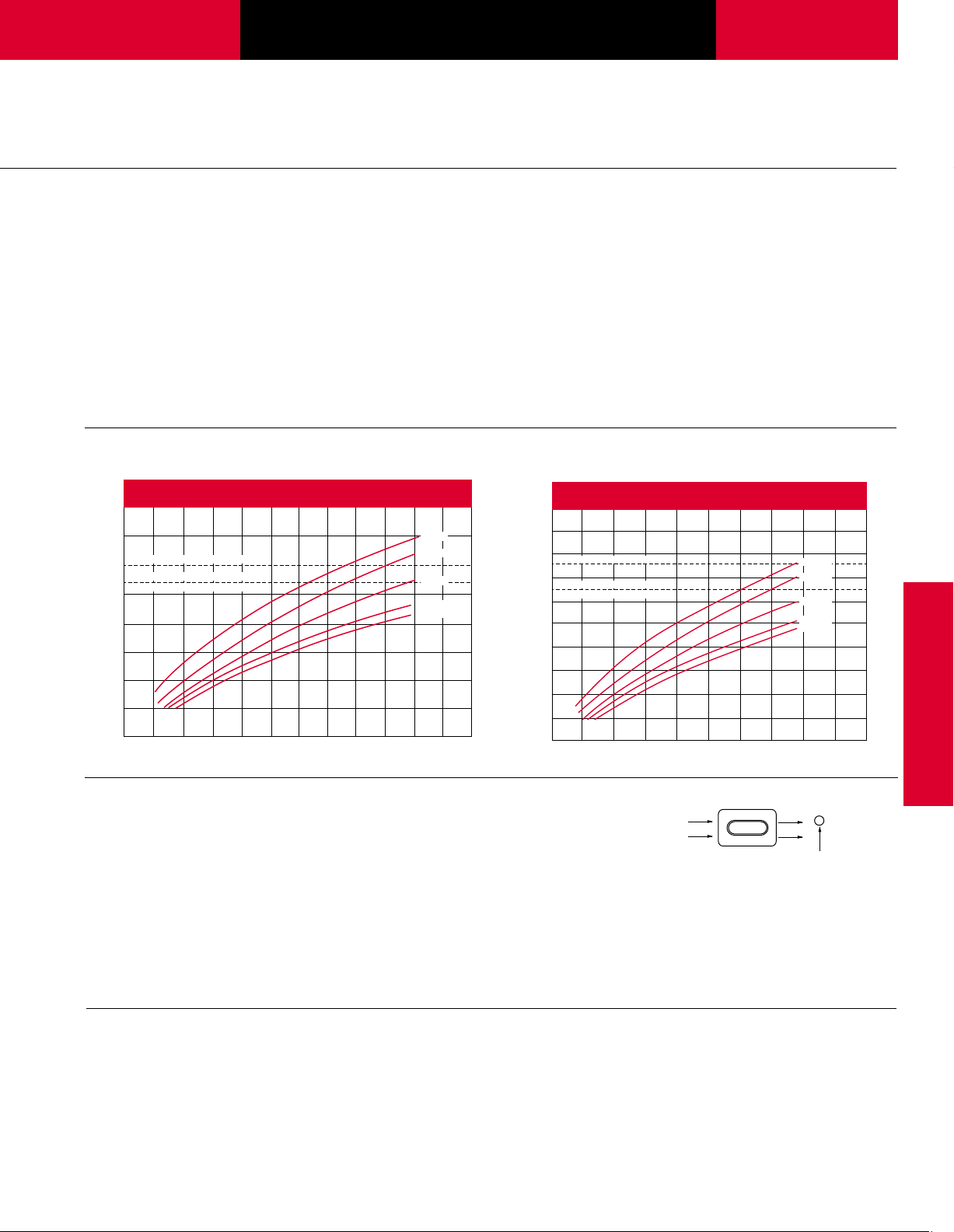

Air Heating

The Watt Density, Air Flow and

Sheath Temperature graph shows

the relationship between watt

density, air flow velocity and sheath

temperature, along with a

recommended temperature to avoid

deteriorating the fins. Be aware that

lower sheath temperature yields

longer heater life.

The graphic representation is based

on a a single-ended FINBAR,

various air velocities (at 68°F/20°C

inlet temperature) and different watt

densities.

To determine, from the graph, the

operating temperature of the

FINBAR’s sheath, identify the air

velocity curve that approximates

your application in feet per second

(meters per second). Then look at

the vertical line that most closely

approximates the FINBAR’s watt

density. From the intersecting point,

read over to the temperature

column to determine the sheath’s

operating temperature.

Watt Density, Air Flow and Sheath Temperature (°F)

Application Hints

• Avoid deteriorating the fins by

• Ensure proper air flow to prevent

• Locate the temperature sensor

Air Flow

not exceeding the recommended

maximum fin temperature of

1100°F (600°C).

premature heater failure.

downstream from heater(s) for

process temperature sensing.

Watt Density, Air Flow and Sheath Temperature (°C)

The following mounting parameters

are recommended:

• Air flow over element must be

parallel with the flat side.

• Element center line to element

center line spacing must be a

minimum of 11⁄2 inches (38 mm).

Dual Ended FINBAR

FINBAR elements are typically

terminated at one end. Upon

request, however, dual ended

Air Flow

FIREBAR

®

Proper air flow relative to the heater’s sheath

is parallel with the longer cross sectional axis.

FINBAR heaters can be ordered.

To order, specify dual ended

FINBAR and lead length.

319

Page 3

Tubular and

1

"

(25 mm)

5

/16

x

5

/8

" (8 x 16 mm) Slot

F

±

1

/4

" (6 mm)

1

"

(25 mm)

2

"

(51 mm)

B

A

3

/4

"

(19 mm)

1

/4

"

(6.5 mm)

1"

(25 mm)

2"

(51 mm)

1

1

/4

"

(32 mm)

1

/2

"

(13 mm)

12" (305 mm)

Standard Leads

2 Per Element

Lavacone Seal

Process Assemblies

FIREBAR Heating

Elements

FINBAR

FINBAR Overall Overall Mounting Est.Net

Description A Dimension F Dimension B Dimension Watts

Inch (mm) Inch (mm) Inch (mm) 120VÅ(ac) 240VÅ(ac) lbs (kg)

Application: Forced Air

2

20 W/in

304 SS 11

(3.1 W/cm

40 W/in

2

)133⁄

2

304 SS 11

2

(6.2 W/cm

)133⁄4 (349) 10 (254) 13 (330) 900 FSP121WKF FSP1210WKF 1.5 (0.7)

4 (260) 6

101⁄

3

⁄4 (298) 8 (203) 11 (279) 375 FSP101WMF 1.4 (0.7)

4 (349) 10 (254) 13 (330) 450 FSP121WMF 1.5 (0.7)

15 (381) 11

5

8 (447) 13

⁄

17

1

4 (489) 15

⁄

19

3

⁄4 (527) 17 (431) 20 (508) 800 FSP191WMF FSP1910WMF 1.7 (0.8)

20

1

2 (597) 19

⁄

23

1

⁄4 (641) 211⁄2 (546) 241⁄2 (622) 1000 FSP241WMF FSP2410WMF 1.9 (0.9)

25

1

⁄2 (673) 223⁄4 (577) 253⁄4 (654) 1050 FSP251WMF FSP2510WMF 1.9 (0.9)

26

1

8 (765) 26

⁄

30

1

⁄8 (841) 293⁄8 (746) 323⁄8 (822) 1350 FSP321WMF FSP3210WMF 2.2 (1.0)

33

5

8 (905) 31

⁄

35

3

⁄8 (975) 345⁄8 (879) 375⁄8 (955) 1600 FSP3710WMF 2.4 (1.1)

38

1

⁄8 (1070) 38 3⁄8 (974) 413⁄8 (1050) 1800 FSP4110WMF 2.5 (1.2)

42

3

4 (1213) 44 (1117) 47 (1193) 2000 FSP4610WMF 2.7 (1.3)

⁄

47

101⁄4 (260) 61⁄2 (158) 91⁄2 (241) 600 FSP91WKF 1.4 (0.7)

3

4 (298) 8 (203) 11 (279) 750 FSP101WKF 1.4 (0.7)

⁄

15 (381) 11

5

(447) 13

8

⁄

17

1

⁄4 (489) 151⁄2 (393) 181⁄2 (469) 1450 FSP181WKF FSP1810WKF 1.7 (0.8)

19

3

⁄4 (527) 17 (431) 20 (508) 1600 FSP1910WKF 1.7 (0.8)

20

1

⁄2 (597) 193⁄4 (501) 223⁄4 (577) 1800 FSP2210WKF 1.8 (0.9)

23

1

25

4 (641) 21

⁄

1

⁄2 (673) 223⁄4 (577) 253⁄4 (654) 2100 FSP2510WKF 1.9 (0.9)

26

1

⁄8 (765) 263⁄8 (669) 293⁄8 (746) 2500 FSP2910WKF 2.1 (1.0)

30

1

33

8 (841) 29

⁄

5

⁄8 (905) 317⁄8 (809) 347⁄8 (885) 3000 FSP3410WKF 2.3 (1.1)

35

3

38

8 (975) 34

⁄

1

⁄8 (1070) 383⁄8 (974) 413⁄8 (1050) 3600 FSP4110WKF 2.5 (1.2)

42

3

⁄4 (1213) 44 (1117) 47 (1193) 4000 FSP4610WKF 2.7 (1.3)

47

1

2 (158) 9

⁄

1

4 (285) 14

⁄

7

8 (352) 16

⁄

1

2 (393) 18

⁄

3

4 (501) 22

⁄

3

8 (669) 29

⁄

7

8 (809) 34

⁄

1

⁄4 (285) 141⁄4 (362) 1000 FSP131WKF FSP1310WKF 1.5 (0.7)

7

(352) 16

8

⁄

1

2 (546) 24

⁄

3

8 (746) 32

⁄

5

8 (879) 37

⁄

1

2 (241) 300 FSP91WMF 1.4 (0.7)

⁄

1

4 (362) 500 FSP141WMF 1.5 (0.7)

⁄

7

8 (428) 650 FSP161WMF FSP1610WMF 1.6 (0.8)

⁄

1

2 (469) 725 FSP181WMF FSP1810WMF 1.7 (0.8)

⁄

3

4 (577) 900 FSP221WMF FSP2210WMF 1.8 (0.9)

⁄

3

8 (746) 1250 FSP291WMF FSP2910WMF 2.1 (1.0)

⁄

7

8 (885) 1500 FSP3410WMF 2.3 (1.1)

⁄

7

(428) 1300 FSP161WKF FSP1610WKF 1.6 (0.8)

8

⁄

1

2 (622) 2000 FSP2410WKF 1.9 (0.9)

⁄

3

8 (822) 2700 FSP3210WKF 2.2 (1.0)

⁄

5

8 (955) 3200 FSP3710WKF 2.4 (1.1)

⁄

All stock units are Assembly stock.

Availability

Assembly Stock: Three working days

How to Order

To order a stock FINBAR heating

element, specify:

• Watlow Code number

• Volts/watts

• Termination options

• Options

• Quantity

For made-to-order FINBAR heating

elements, specify:

320

• Type of application, including air

flow velocity, volume, etc.

• Single- or double-ended element

• Volts/watts

• Heated length

• No-heat length

• Terminal pin length or ter mination

options, including moisture seal

type

• Quantity

Code Number

F.O.B.: Hannibal, Missouri

• Options, including thermocouple,

sealed end, no mounting

bracket, etc.

Availability

Assembly Stock: Three working days

Modified Stock➀: Five to seven working

days

Made-to-Order: Four to five weeks

Options, complexity and quantity may

affect availability and lead times. Consult

factory.

➀ Assembly Stock units with catalog options.

Weight

Loading...

Loading...