Page 1

User’s Manual

Series F4S/D

96mm x 96mm Ramping Controller (1/4 DIN)

with Guided Setup and Programming

1241 Bundy Boulevard, Winona, Minnesota USA

Phone: +1 (507) 454-5300, Fax: +1 (507) 452-4507 http://www.watlow.com

Registered Company

Winona, Minnesota USA

0600-0032-0000 Rev H

*0600-0032-0000*

August 2011

Page 2

Watlow Winona is a division of Watlow Electric Mfg. Co., St. Louis, Missouri, a manufacturer of industrial

electric heating products since 1922. Watlow begins with a full set of specifications and completes an industrial product that is manufactured in-house, in the U.S.A. Watlow products include electric heaters, sensors,

controllers and switching devices. The Winona operation has been designing solid-state electronic control

devices since 1962, and has earned the reputation as an excellent supplier to original equipment manufacturers. These OEMs and end users depend upon Watlow Winona to provide compatibly engineered controls

that they can incorporate into their products with confidence. Watlow Winona resides in a 100,000-squarefoot marketing, engineering and manufacturing facility in Winona, Minnesota.

About Watlow Winona

About This Manual

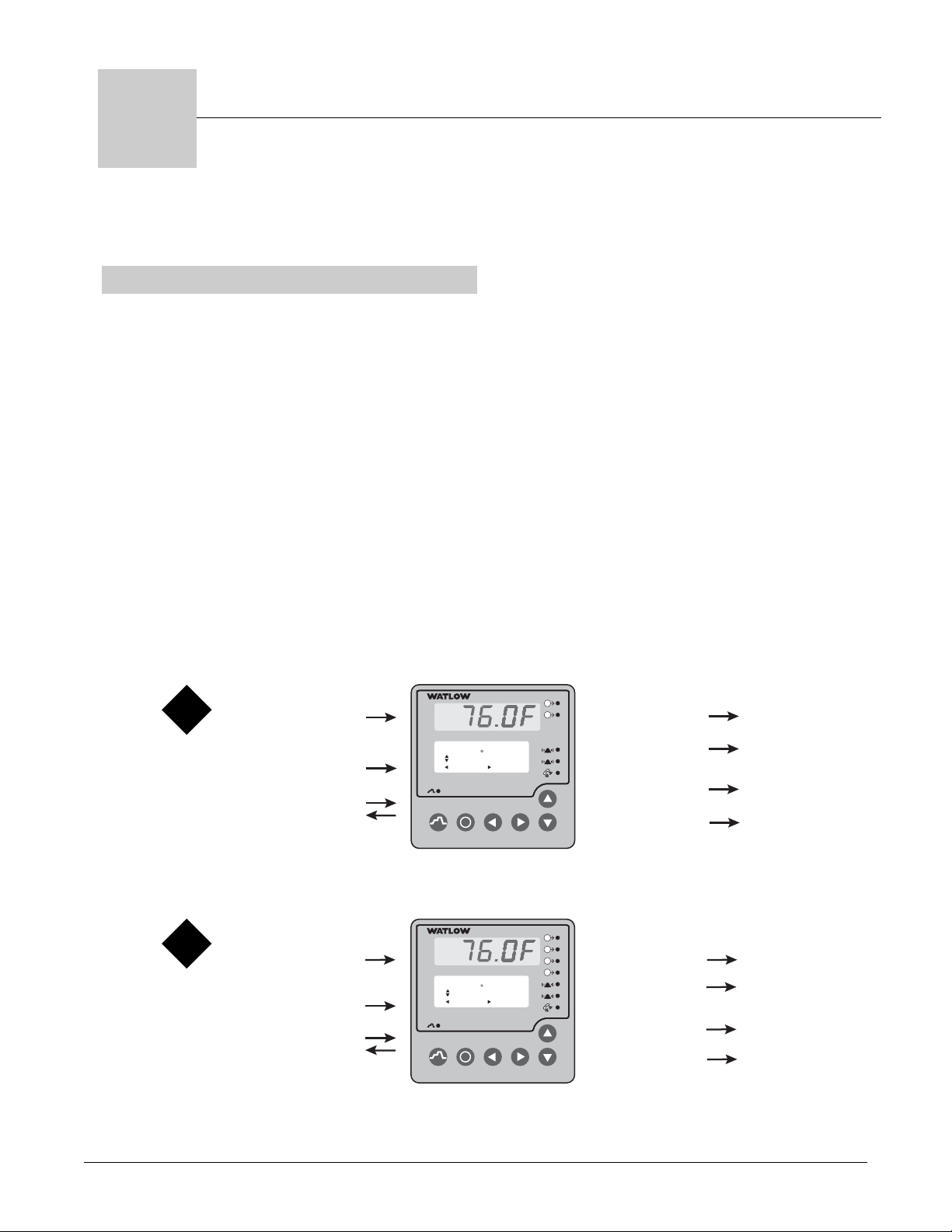

The Series F4 User’s Manual covers hardware and software in both the SingleChannel and Dual-Channel controllers. Instructions and illustrations pertain

to both unless otherwise specified. If a given feature or parameter operates on

only the Single or the Dual Channel controller, it will be identified by an icon in

the margin or nearby.

Your comments or suggestions on this manual are welcome. Please send them to the Technical Literature ,

Watlow Winona, 1241 Bundy Boulevard, P.O. Box 5580, Winona, Minnesota, 55987-5580 U.S.; Telephone:

+1 (507) 454-5300; fax: +1 (507) 452-4507.

Copyright July 2002 by Watlow, Inc., with all rights reserved. (2249)

Your Comments

1

Single

Channel

F4S

2

Dual

Channel

F4D

Page 3

Watlow Series F4S/D Table of Contents ■ i

Introduction

Chapter 1: Introduction . . . . . . . . . . . . . . . . . 1.1

Chapter 2: Keys, Displays and Navigation . . .2.1

Operations

Chapter 3: Operations . . . . . . . . . . . . . . . . . .3.1

Profiles

Chapter 4: Profile Programming . . . . . . . . . . .4.1

Setup

Chapter 5: Setup . . . . . . . . . . . . . . . . . . . . . .5.1

Chapter 6: Features . . . . . . . . . . . . . . . . . . . .6.1

Chapter 7: Communications . . . . . . . . . . . . . .7.1

Factory

Chapter 8: Security and Locks . . . . . . . . . . . .8.1

Chapter 9: Calibration . . . . . . . . . . . . . . . . . . .9.1

Chapter 10: Diagnostics . . . . . . . . . . . . . . . .10.1

Installation and Wiring

Chapter 11: Installation . . . . . . . . . . . . . . . . .11.1

Chapter 12: Wiring . . . . . . . . . . . . . . . . . . . .12.1

Appendix

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . .A.2

CE Declaration of Conformity . . . . . . . . . .A.5

Product Specifications . . . . . . . . . . . . . . .A.6

Ordering Information . . . . . . . . . . . . . . . . .A.7

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A.8

List of Figures . . . . . . . . . . . . . . . . . . . . . .A.13

Software Map . . . . . . . . . . . . . . . . . . . . . .A.16

Series F4S/D: Table of Contents

T

A downloadable electronic copy of this user manual is available free of charge through Watlow's web site:

http://www.watlow.com/prodtechinfo. Search on Series F4.

Page 4

ii ■ Table of Contents Watlow Series F4S/D

Safety Information in this Manual

Note, caution and warning symbols appear throughout this book to draw your attention to

important operational and safety information.

A “NOTE” marks a short message to alert you to an important detail.

A “CAUTION” safety alert appears with information that is important for protecting your

equipment and performance.

A“WARNING” safety alert appears with information that is important for protecting you,

others and equipment from damage. Pay very close attention to all warnings that apply to

your application.

The ç symbol (an exclamation point in a triangle) precedes a general CAUTION or

WARNING statement.

The Ó symbol (a lightning bolt in a lightning bolt in a triangle) precedes an electric shock

hazard CAUTION or WARNING safety statement.

Technical Assistance

If you encounter a problem with your Watlow controller, review all configuration

information to verify that your selections are consistent with your application: inputs;

outputs; alarms; limits; etc. If the problem persists after checking the above, you can get

technical assistance by calling your local Watlow representative (see back cover of this

manual), or in the U.S., dial +1 (507) 494-5656. For technical support, ask for an

Applications Engineer.

Please have the following information available when you call:

• Complete model number • All configuration information

• User’s Manual • Diagnostic menu readings

Warranty

The Watlow Series F4 is warranted to be free of defects in material and workmanship for

36 months after delivery to the first purchaser for use, providing that the units have not

been misapplied. Since Watlow has no control over their use, and sometimes misuse, we

cannot guarantee against failure. Watlow's obligations hereunder, at Watlow's option, are

limited to replacement, repair or refund of purchase price, and parts which upon

examination prove to be defective within the warranty period specified. This warranty

does not apply to damage resulting from transportation, alteration, misuse or abuse.

Returns

• Call or fax your distributor or the nearest Watlow sales office for best information

about returns. (See outside back cover.)

•To return directly to Watlow Winona in the U.S., first call or fax Customer Service for

a Return Material Authorization (RMA) number (telephone: +1 (507) 454-5300; fax: +1

(507) 452-4507).

• Put the RMA number on the shipping label, along with on a written description of the

problem.

•Arestocking charge of 20% of the net price is charged for all standard units returned

to stock. Returned units must be in like new condition and must be returned within

120 days of initial receipt of the product.

ç

Safety Alert

CAUTION or

WARNING

∫

Electrical Shock

Hazard

CAUTION or

WARNING

Page 5

Watlow Series F4S/D Introduction ■ 1.1

1

Chapter One: Introduction

Overview

Inputs and Outputs

Figure 1.1a — Single-Channel Series F4 (F4S_ - _ _ _ _ - ____ ) Inputs and Outputs.

Figure 1.1b — Dual-Channel Series F4 (F4D_ - _ _ _ _ - ____ ) Inputs and Outputs.

1B

2A

2B

1A

1B

1A

Watlow’s Series F4 1/4 DIN industrial ramping

controllers are easy to set up, program and operate

in the most demanding ramp-and-soak-processing

applications. The F4 includes:

• four-line, high resolution LCD display

• guided setup and programming software

• 16-bit microprocessor

• 256 possible ramp steps in as many as 40 variable-length, nameable profiles

• six step types

• eight programmable event outputs, compressor

control, boost heat/boost cool, power-out selections and a real-time clock.

• Note: the F4S has two less analog inputs and

two less control outputs than the F4D.

1 Universal

1

Single

Channel

F4S

1 Communication I/O

Analog Input

(2 optional)

4 Digital Inputs

…Alarm1 Lo Deviation

Adjusts Value

Back Next

–1

i

F

4

1A

1B

2 Control Outputs

1

F

2 Alarm Outputs

2

2 Retransmit Outputs

(optional)

8 Digital Outputs

F

4

1A

2

Dual

Channel

F4D

3 Universal

Analog Inputs

4 Digital Inputs

…Alarm2 Low SP_______

32 F

Adjusts Value

Back Next

1B

2A

4 Control Outputs

2B

1

2 Alarm Outputs

2

2 Retransmit Outputs

(optional)

1 Communication I/O

i

8 Digital Outputs

Page 6

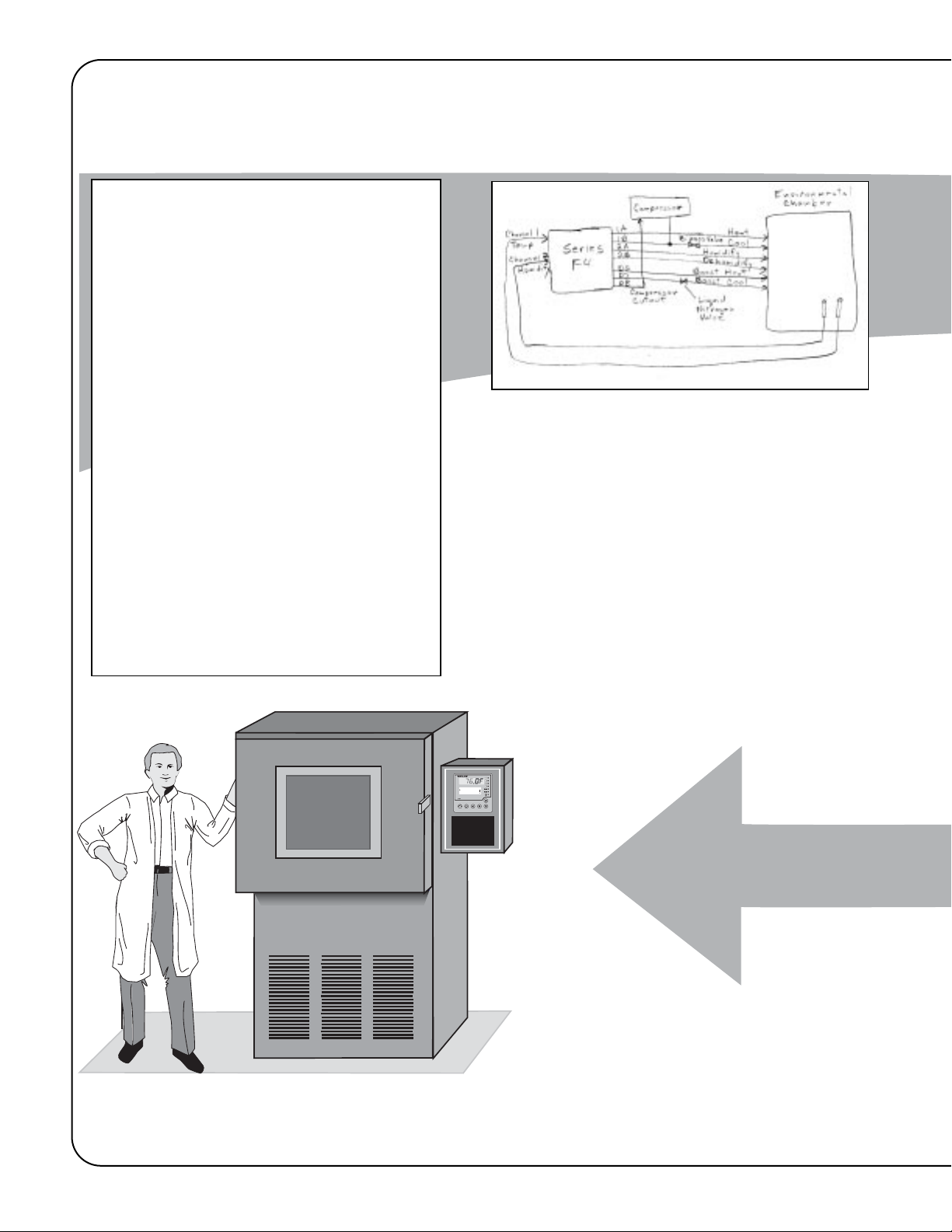

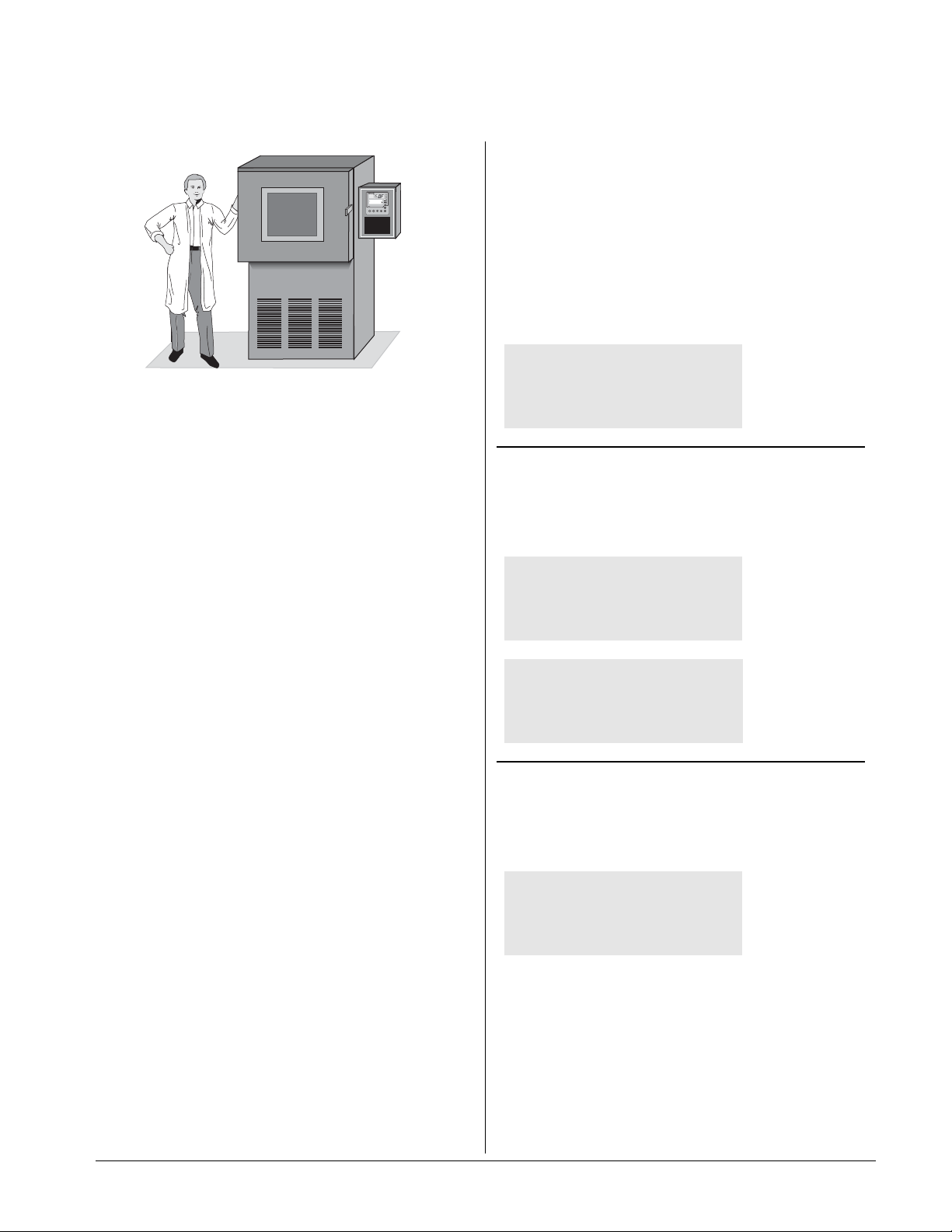

Sample Application: Environmental Testing

with a Dual Channel F4 Using Multiple Inputs and Outputs

Figure 1.2 — Sample Application 1: Series F4 Dual Channel Using Multiple Inputs and Outputs.

F

4

1

2

i

1B1B

2A2A

2B2B

1A1A

Main Page___________

Go to Profiles

Go to Setup

Go to Factory

Overview

Andy, an engineer with the Ajax

Testing Company, is running temperature and humidity tests on navigational equipment. He wants to be able to

control temperature and humidity in

the environmental chamber, and monitor the temperature of the equipment

itself. With the Watlow Series F4 ramping controller, he can:

•program the test as a ramping profile

and control it remotely;

•use boost heat and cool to maintain

precise temperatures;

•record the equipment temperature on

a chart recorder;

•notify the operator with a bell if process temperatures do not follow the

profile;

•pause the profile if someone opens the

chamber door during the test;

•set up communications with a PC

later.

5. Run the Profile

Andy pressed the Profile Key and

selected the test profile. He monitored

the progress of the test on the display

and the equipment temperature on the

chart recorder.

See the Operations Chapter.

1. Wire

Following diagrams in the user manual, Andy

connected the analog input terminals to temperature and humidity sensors, channel 1 output

terminals to the heater and cooler, channel 2

outputs to the humidifier/dehumidifier, alarm

output 1 to an alarm bell and retransmit output

1 to a chart recorder to track the equipment

temperature. Digital output 6 and 7 controlled

the boost heater and cooler, and 8 controlled the

mechanical refrigeration compressor.

See the Wiring Chapter.

1.2 ■ Introduction Watlow Series F4S/D

Page 7

Watlow Series F4S/D Introduction ■ 1.3

This sample application is continued in the Operations, Profile Programming and Setup Chapters.

Main Page___________

3. Customize and Name

Andy customized the Main Page so he could

tell the status of the digital outputs by glancing at the controller's Lower Display (Setup

Page > Custom Main Page Menu).

He also named one of the Alarms "TEMP

DEV", which will make it easy to identify the

alarm condition (Setup Page > Alarm Output

1 Menu). Three digital inputs, two alarms

and eight digital outputs can be given 10character names.

See the Setup Chapter.

4. Program the Profile

Andy programmed the test as a ramping profile of 21 steps. To make sure the equipment

is at the ambient chamber temperature, he

put a Wait condition on Step 2. Step 20 is a

Jump step that puts the equipment through

the same heat and humidity cycle 21 times.

See the Profile Programming Chapter.

✔ NOTE:

The profile in this sample application is embedded

in the Series F4 software for use as a teaching tool

or a template. It is the first profile, MILSTD810D,

located in the Profiles Page > Edit Profile Menu.

You can change or delete this profile and later

recall it through factory defaults. If you have a

single-channel controller, you will see only the temperature on Channel 1. This is not the true

Military Standard Test 810D.

1B

2A

2B

1A

Step 1: Ramp Time

Step 2: Ramp Time

Step 3: Soak

Step 4: Jump

2. Set up the F4

After checking the navigation instructions

in the user manual, Andy went to the

Setup Page of the software to configure the

controller for the equipment and the ramping profiles. He named the alarm to make

it easier to identify an alarm condition. The

alarm message will appear on the Lower

Display, which also informs about the

progress of the test.

See the Keys, Displays and Navigation Chapter.

See the Setup Chapter.

Go to Profiles

Go to Setup

Go to Factory

Choose to Setup:____

Digital Output8

Communications

Custom Main Page

F

4

1A

1B

2A

Main Page___________

Go to Profiles

Go to Setup

Go to Factory

i

2B

1

2

Page 8

1.4 ■ Introduction Watlow Series F4S/D

Setup Steps

The ˆ Key

During all these steps, the Information Key

will summon helpful definitions and setup tips.

Just position the cursor next to the item you

want to know more about, then press the key.

Press it again to return to your task.

See Chapter 3, Operations.

7

Run the profile (or establish a set point

for static set point control).

See Chapter 4, Profile Programming.

6

Program a profile.

See Chapter 7, Communications.

5

Set up serial communications.

See Chapter 3, Operations.

4

Tune the system and set alarm set points.

Learn to navigate the software in Chapter 2,

Keys, Displays and Navigation, and then go to

Chapter 5, Setup. For background, you may also

want to refer to Chapter 6, Features. (This step

may not be necessary if the Series F4 is already

installed in the equipment.)

3

Set up the controller to suit your basic

application.

See Chapter 12, Wiring. (This step will not be

necessary if the Series F4 is already installed in

equipment.)

2

Wire the controller.

See Chapter 11, Installation. (This step will not

be necessary if the Series F4 is already installed

in equipment.)

1

Install the controller.

How to do itWhat to do

• If the Series F4 is an independent unit, start

with Step 1 below.

• If the Series F4 is already installed in and set

up for a piece of equipment, proceed to Steps 4,

5, 6 and 7 below.

• If the Series F4 is already installed in a piece

of equipment and the setup and profile programming functions are locked, proceed directly to Step 5 or 7.

Page 9

Watlow Series F4S/D Keys, Displays and Navigation ■ 2.1

Chapter Two: Keys, Displays &

Navigation

Displays and Indicator Lights . . . . . . . . . . . . . . . . .2.2

Custom Main Page . . . . . . . . . . . . . . . . . . . . . . . . .2.3

Keys and Navigation . . . . . . . . . . . . . . . . . . . . . . . .2.4

Guided Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.5

How to Enter Numbers and Names . . . . . . . . . . . .2.6

ˆ Information Key Answers Your Questions . . . . .2.7

Main Page Parameter Table . . . . . . . . . . . . . . . . . .2.8

Overview

This chapter introduces the user interface of the

Series F4S/D controller — the displays, keys and

indicator lights, and the principles of navigating

the software to program profiles and change setup

settings. The Series F4 is designed with userfriendly features to facilitate setup, programming

and operation of the Series F4.

The four-line LCD display facilitates setup and

programming, and presents informative messages

about status, error and alarm conditions.

Digital inputs, digital outputs, profiles and alarms

can be named for easy reference.

The Information Key summons information about

the pages, menus, parameters and values, as well

as error and alarm conditions if they occur.

The software is organized into five pages of menus.

The Main Page gives access to the other four —

Operations, Profiles, Setup and Factory. The Main

Page can be customized to display user-chosen

information.

2

Page 10

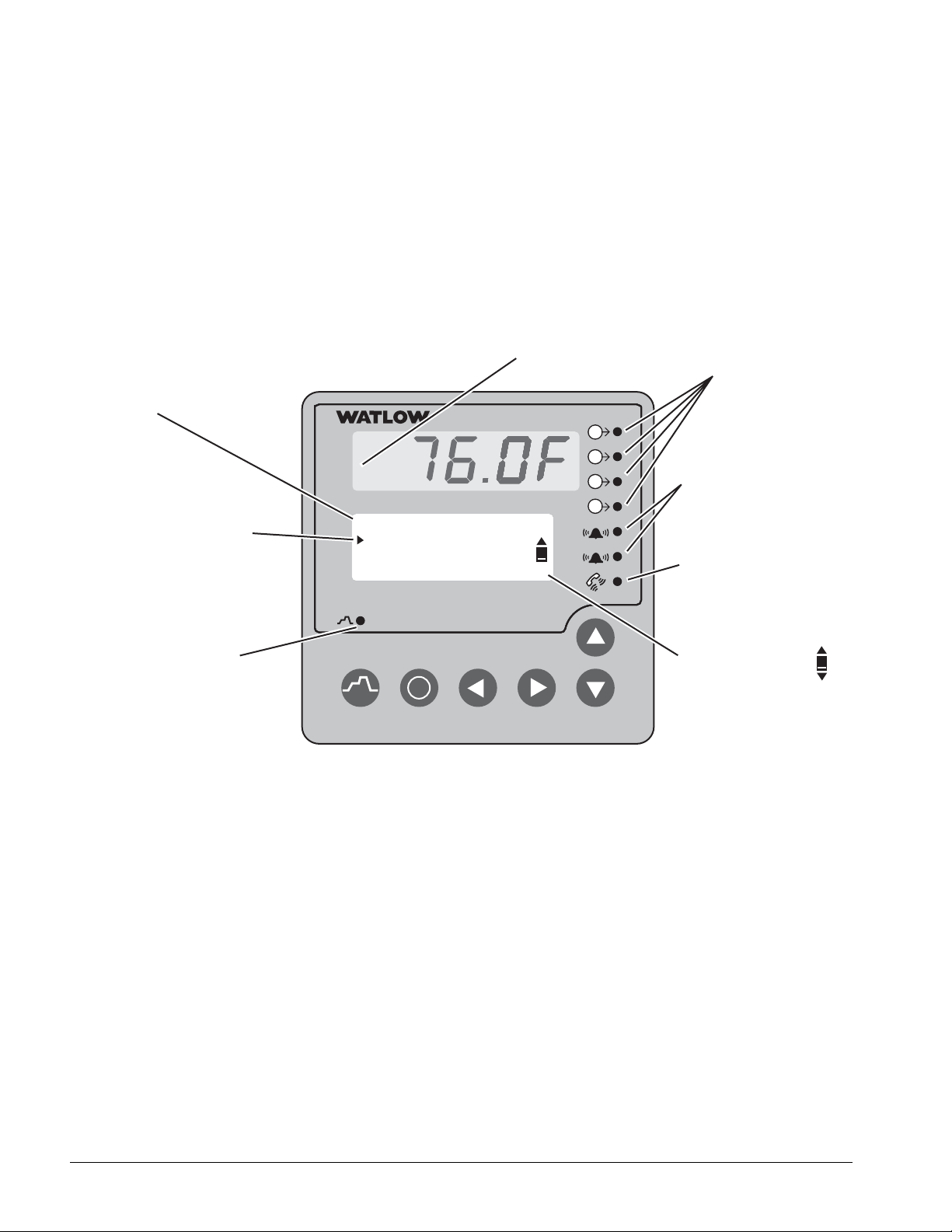

Displays and Indicator Lights

Figure 2.2 — Series F4S/D Displays and Indicator Lights. (F4D shown)

1B

2A

2B

1A

2.2 ■ Keys, Displays and Navigation Watlow Series F4S/D

Upper Display

Displays Channel 1 actual

process values during

operation. Displays error

information if errors occur.

Lower Display

Displays information about the setup,

operation and programming of the

controller.

Cursor

(>):

Indicates selected parameter

or present value in F4 memory. Moves via the four navigation keys.

Profile Indicator Light

(Run/Hold status):

• Lit when a ramping profile

runs.

• When blinking, the profile is

on hold.

• When not lit, the controller

operates as a static set

point controller.

Main Page___________

Go to Profiles

Go to Setup

Go to Factory

i

Active Output Indicator

Lights (Output status):

Lit when the corresponding

controller channel output is

active. (F4D shown)

F

4

1A

1B

2A

2B

1

2

Alarm Output Indicator

Lights

(Alarm status):

Lit during an alarm state.

Communications Indicator

Light

(Communication status):

Lit (pulsates) when the controller sends or receives valid

data.

Scroll Bar

(Scroll up or down):

Appears when the Up or

Down Keys can reveal more

information in the Lower

Display.

Page 11

Watlow Series F4S/D Keys, Displays and Navigation ■ 2.3

Custom Main Page

Figure 2.3 — Default Main Page Parameters.

The first and central page on the Lower Display is

the Main Page, which shows error messages, input,

output and profile status, and allows access to controller software (Go to Operations, Profiles, Setup

and Factory).

The Main Page can be customized to display cho-

sen information. (To do so, go to the Setup Page,

Custom Main Page Menu. See Chapter 5, Setup,

for instructions.)

The following parameters will appear by default on

the Main Page, unless the Main Page has been customized.

Main Page_____

Will always appear

if active:

Will appear if active

and if set up to appear:

Will appear if active and

selected to appear:

Will appear by default

(Profile information will

appear by default if a

profile is running.)

Will always appear

unless customized:

:

Input 1 Error

Input 2 Error

Input 3 Error

Alarm 1 Condition

Alarm 2 Condition

Autotuning Ch 1

Autotuning Ch 2

Current File

Current Step

Input2

Set Point 1

Set Point 2

Step Type

Target SP1

Target SP2

Wait for Status

Time Remaining

Digital Ins

Digital Outs

% Power1

% Power2

Date

Time

Press < to scroll

down the list.

Read-only information

Static set point control

Read-only information

>Go to Operations

Go to Profiles

Go to Setup

Go to Factory

Access to software

2

Dual

Channel

F4D

Page 12

2.4 ■ Keys, Displays and Navigation Watlow Series F4S/D

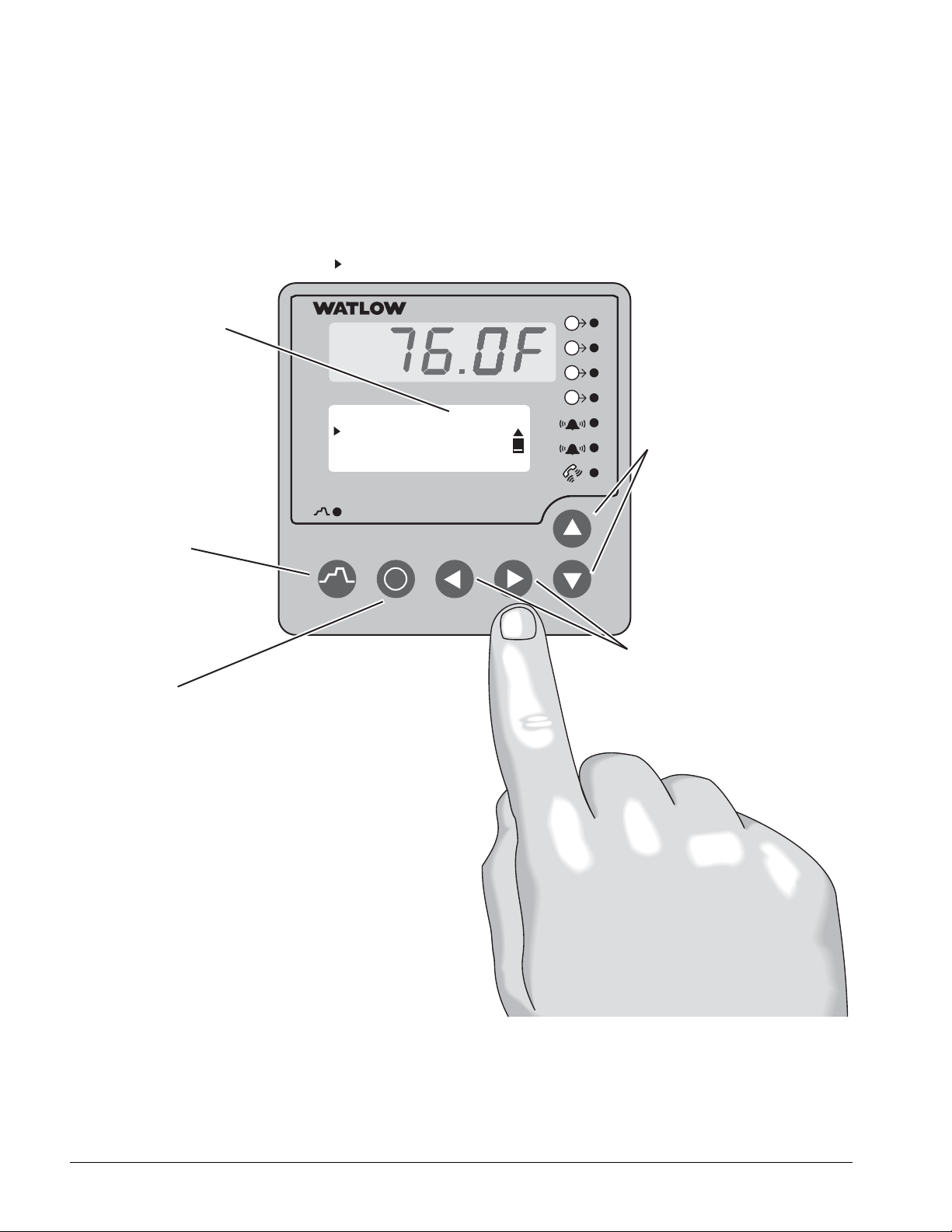

Keys and Navigation

Figure 2.4 — Series F4 Keys and Navigation.

1B

2A

2B

1A

T

f

Setup Page

Main>Setup

Choose to Setup

System

hink of this display as a window

into the software table. You move

around in the software using the

ollowing navigation keys:

> Move Up/Increase

, . < Move Down/Decrease

Back Next

Profile Key

(Profile Run/Hold):

Summons a menu that allows

you to start, hold, resume or

terminate a profile.

Information Key

(Toggle for more

information):

Provides information in the

Lower Display about the

cursor-selected parameter.

Another press toggles the

display back to the parameter.

Analog Input 1

Main Page___________

Go to Profiles

Go to Setup

Go to Factory

i

4-20mA

0-20mA

0-10V

0-5V

1-5V

0-50mV

Choose Units

Temperatur 2500 ft

%rh

PSI

units

Choose Decimal

0

0.0

0.00

0.000

F

4

1A

1B

2A

2B

1

2

Up and Down Keys

(Move Up/Increase and Move

Down/Decrease):

Move the cursor (>) position in the

Lower Display through the

software in the direction of the key

arrow. Increase or decrease a

value, or change a letter in a usernameable field, such as alarms,

events and profile names.

Left and Right Keys

(Back Out and Next):

Move right to select the choice to

the right of the cursor and proceed

to the next screen. Move left to exit.

Page 13

Watlow Series F4S/D Keys, Displays and Navigation ■ 2.5

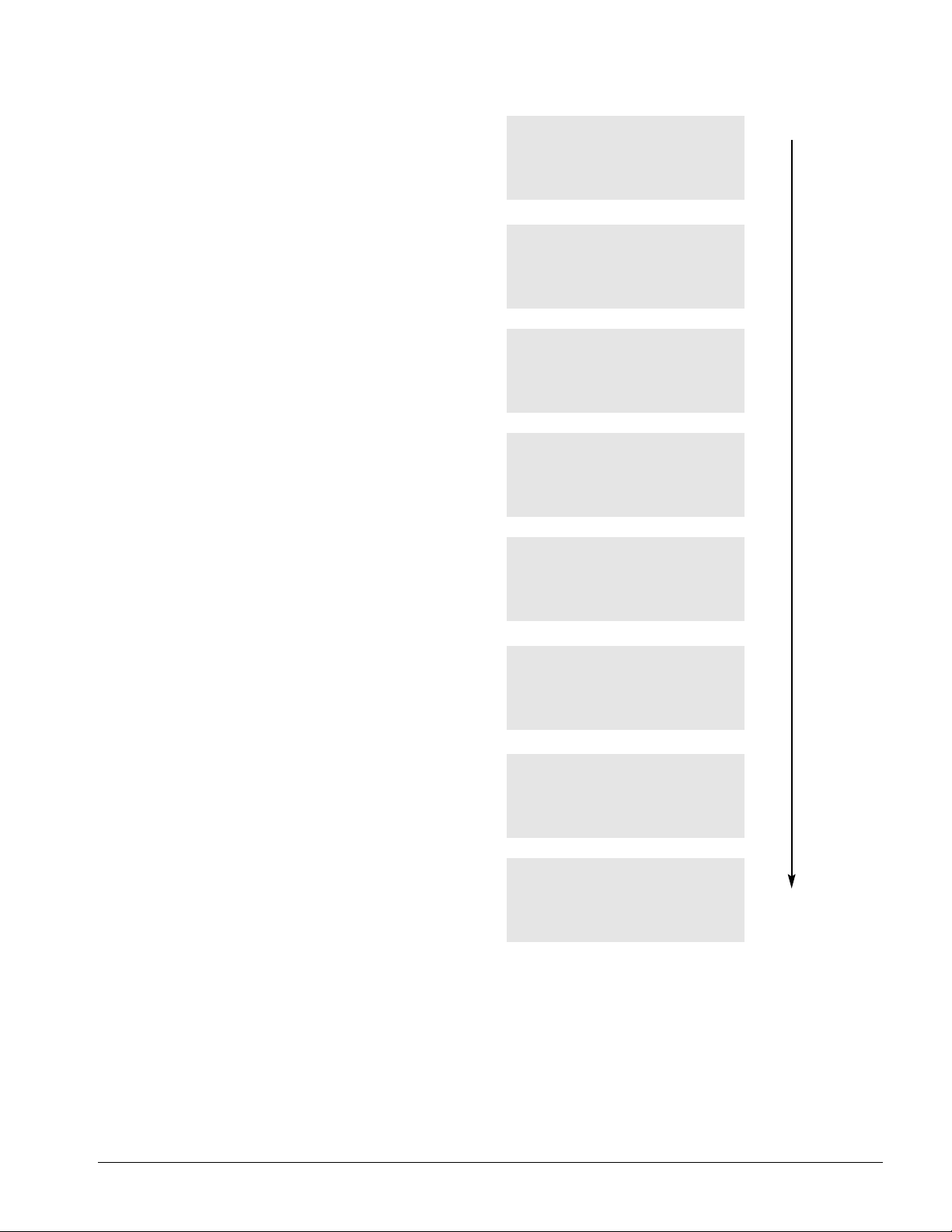

Guided Setup

In most F4 menus, setup and programming tasks

are guided. For example, once you select Analog

Input 1 on the Setup Page, all parameters necessary to configure that input are linked:

1. Use > < to move the cursor to select an

item in a list.

2. Press the Right Key ..

3. Enter the value and make a choice.

4. Press . again.

5. Repeat until you return to the original list.

. saves the value and proceeds to the next

parameter in the series.

, saves the value and backs out of the series, and

returns to the Main Page.

For initial setup and programming, we recommend

that you answer all the questions in the series,

entering values for all linked parameters and

pressing . until you return to your starting

point.

To edit a parameter, proceed through the series

without changing values until you find the parameter you want to change. After making the change,

you may back out or proceed to the end of the

series.

✔

NOTE:

The Edit PID Menu (Operations Page) presents lists of

parameters that can be entered and edited individually.

Press either

. or , to enter the value and return to

the list.

✔

NOTE:

Make sure your setup is complete before entering profiles.

Certain analog input setup changes will delete profiles.

.

.

.

.

.

.

,

Save setup changes

or restore values?

▼ Restore ▲Save

Choose to Setup:____

>Control Output 1A▲

Control Output 1B■

Control Output 2A▼

Enter Lo Power Limit

0%

▲▼ Adjusts Value

< Back > Next

Enter Hi Power Limit

100%

▲▼ Adjusts Value

< Back > Next

Choose Cycle Time:__

>Variable Burst

Fixed Time ■

▼

Choose Function:____

>Heat

Cool

Choose to Setup:____

>Control Output 1A▲

Control Output 1B■

Control Output 2A▼

Main Page___________

Go to Operations

Go to Profiles

>Go to Setup

Page 14

2.6 ■ Keys, Displays and Navigation Watlow Series F4S/D

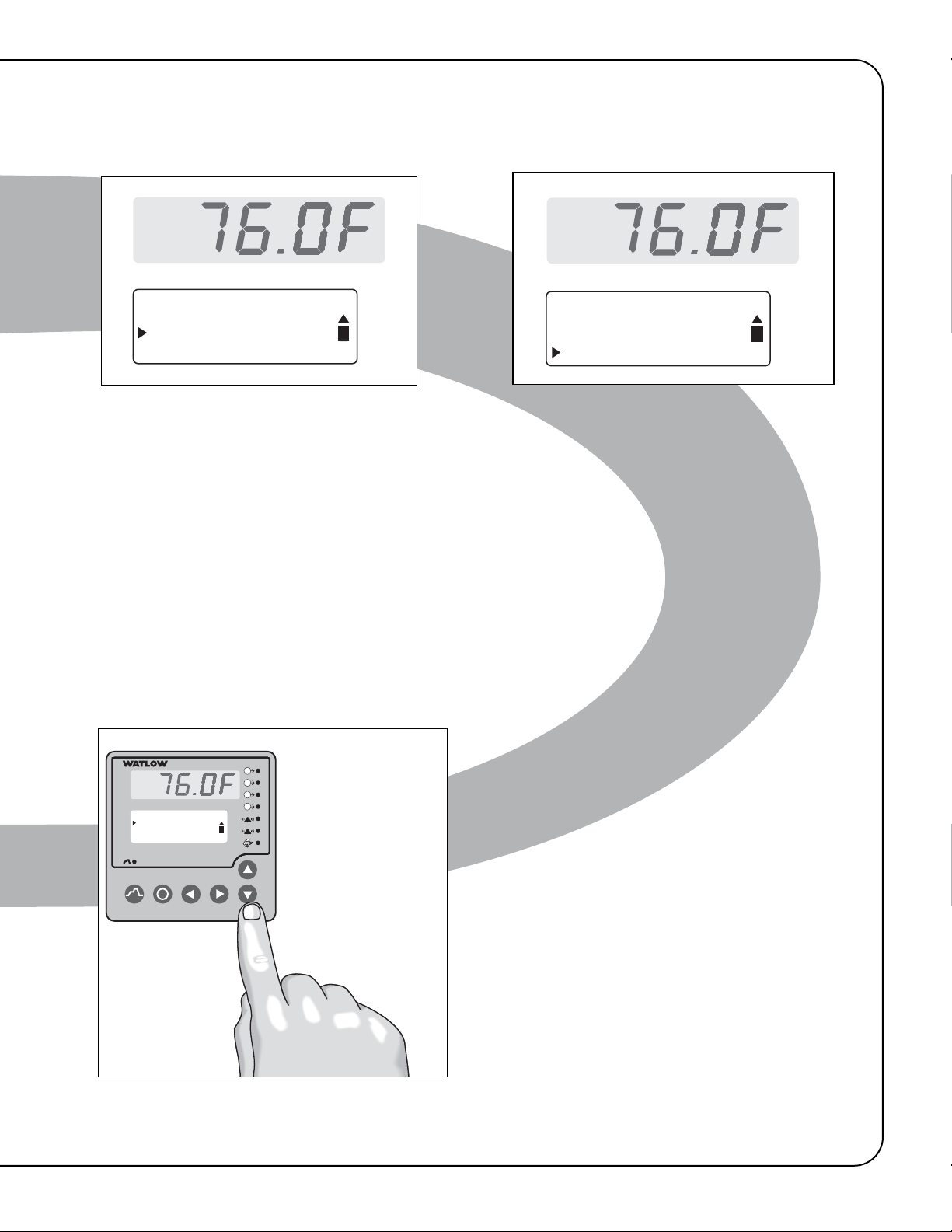

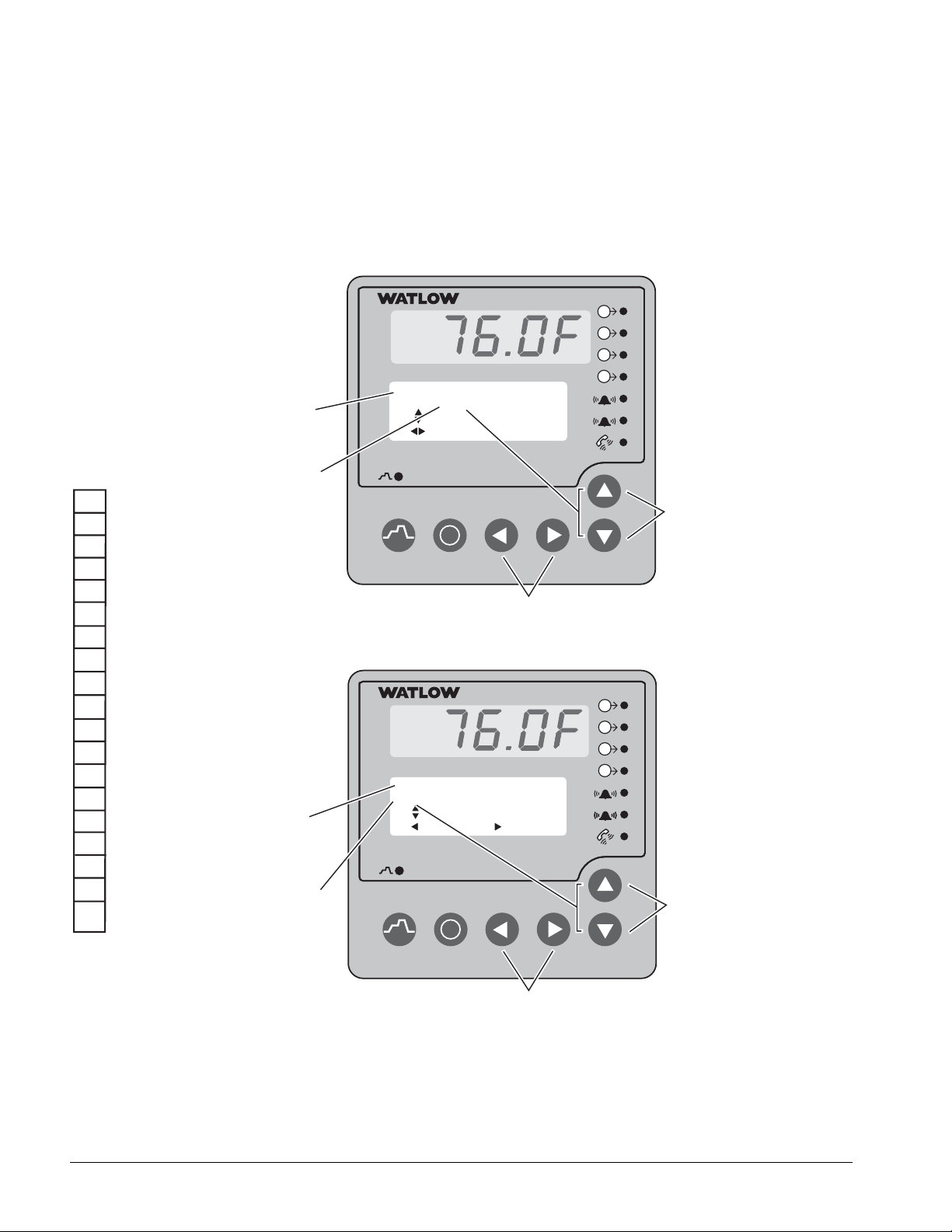

How to Enter Numbers and Names

Figure 2.6 — How to Enter Numbers and Names. (F4D shown)

1B

2A

2B

1A

1B

2A

2B

1A

Many parameters require users to enter a numerical value. Alarms, digital inputs, digital outputs

and profiles can be customized with easily recog-

nized names, such as TOO HOT for an alarm,

DOOR OPEN for a digital input and GLAZE 6 for

a profile.

Numbers

Z

Y

X

W

…

C

B

A

9

8

7

6

5

4

3

2

1

Ø

If the cursor

is at Z, press

< to go

down to A,

then from 9

to 0. Blank is

on the end.

Blank

1. Navigate

to the parameter

you want to

change.

You'll change

the value on

this line.

Names

1. Navigate

to the parameter

you want to

name.

You'll change

each letter on

this nameable

10-character

line.

Alarm Hysteresis:___

36 °F

Adjusts Value

Save Changes

Enter Alarm Name:___

ALARM1

Adjusts Char

Back Next

F

4

1A

1B

2A

2B

1

2

4. Press . to enter

the value.

i

3. Scroll to increase or

decrease the value of

the digit.

2. Move right or left, if necessary, to choose the digit to change.

(Some numbers increase or decrease as single units; others

digit by digit.) The active position is underlined.

F

4

1A

1B

2A

i

2B

1

2

4. Press . to move to the

end of the 10-character name

space and proceed to the

next screen. This enters the

name.

3. Scroll to choose the new

letter or a number.

2. Move right or left to choose the character to change.

(The position is underlined.)

Page 15

Watlow Series F4S/D Keys, Displays and Navigation ■ 2.7

ˆˆ

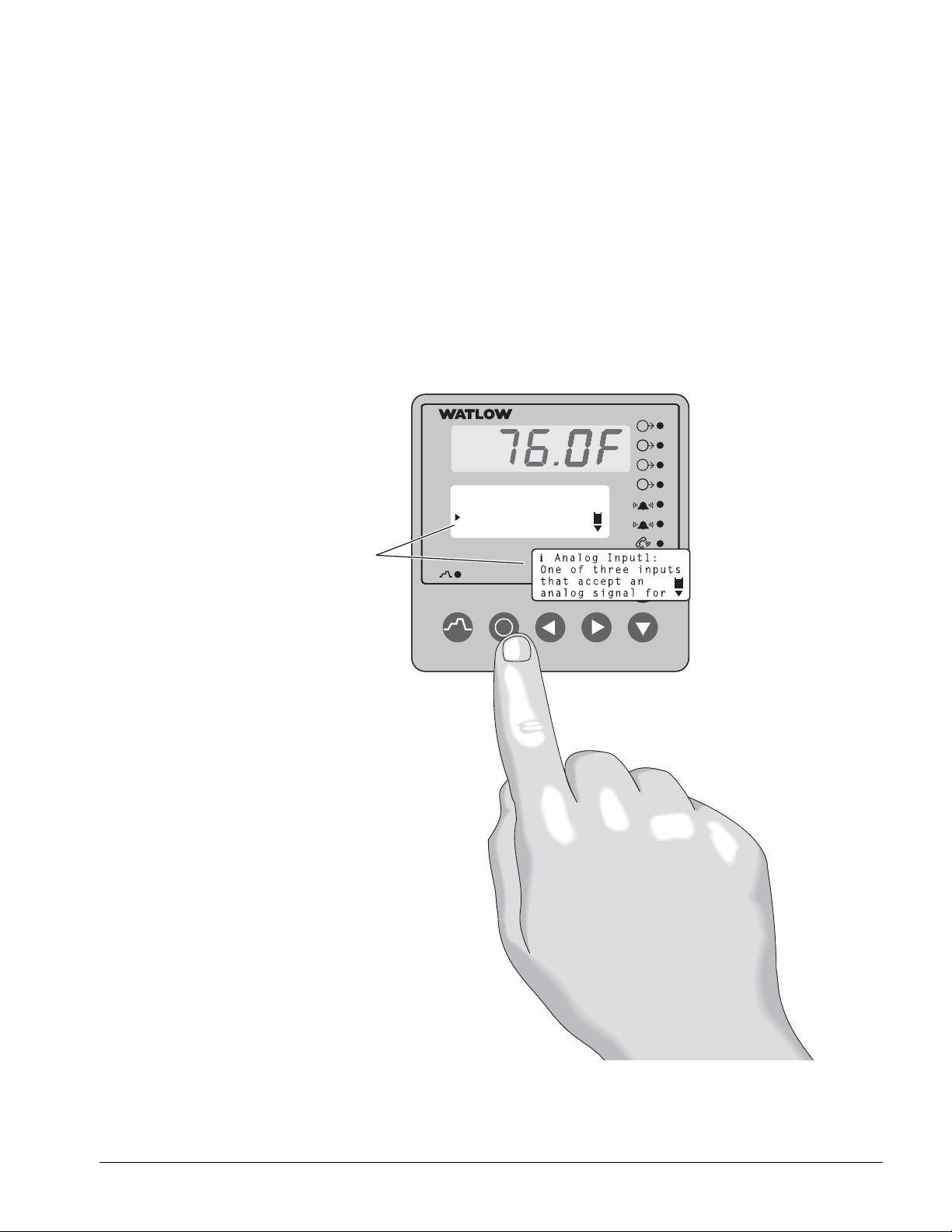

Information Key Answers Your Questions

Figure 2.7 — The Information Key. (F4D shown)

1B

2A

2B

1A

There’s a wealth of information about features and

parameters right in the Series F4 controller. Use

the Information Key to get this information.

1. Use the four navigation keys (< > , . )

to position the cursor ( >) next to the parameter

you want to know more about.

2. Press the ˆ key. The displayed information will

assist you during setup and operation. When

information takes more than four lines, the

scroll bar will be filled or weighted at the end,

directing you to press < or > to see the rest.

3. Press ˆ again to return to your task.

Toggle the Information Key

ˆ between the parameter

you need to know about and

its functional definition.

The second press takes you

back to where you were.

The scroll bar indicates

more information above or

below; use the

keys.

> and <

Choose to Setup:____

System

Analog Input 1

Analog Input 2

i

F

4

1A

1B

2A

2B

1

2

i

Page 16

Main Page Parameter Table Modbus

Register

Range read/write Conditions for

Parameter Description (Modbus Value) Default [I/O, Set, Ch] Parameters to Appear

Go to Factory

Set security settings,

and calibrate and restore factory settings.

Go to Setup

Set up inputs and

outputs, configure

the system and

design the Main

Page.

Go to Profiles

Create, edit, delete

and rename profiles.

Go to Operations

Auto-tune PID sets,

edit PID parameters

and select alarm set

points.

*Digital outputs configured as

events can be turned on/off in the

static set point mode or when a

running profile is on hold. The

event output status will remain as

set until reset by the profile or by

the operator.

Current File

Current Step

Input 2 value

Set Point 1

Set Point 2

Step Type

Target SP1

Target SP2

Wait for

Status

Time

Remaining

Digital Ins

Digital Outs*

% Power 1

% Power 2

Date

Time

None

Input 1 Value

Input 2 Value

Input 3 Value

Set Point 1

Set Point 2

% Power 1

% Power 2

Tune status 1

Tune status 2

Time

Date

Digital Ins

Digital Outs

Time Remaining

Current File

Current Step

Active Ch1 PID Set

Active Ch2 PID Set

Last Jump Step

Jump Count

WaitFor Status

Step Type

Target SP1

Target SP2

Inner Set Point

Custom Message 1

Custom Message 2

Custom Message 3

Custom Message 4

Input 1 Cal. Offset

Input 2 Cal. Offset

Input 3 Cal. Offset

Parameter x (1 to 16)

View customized

parameter list.

Autotuning Channel x (1 or 2)

Alarm x (1 to 2) Condition

Input x (1 to 3) Error

Main > Setup > Main Page

Main Page

2.8 ■ Keys, Displays and Navigation Watlow Series F4S/D

Page 17

Watlow Series F4S/D Operations ■ 3.1

3

Chapter Three: Operations

Static Set Point Control . . . . . . . . . . . . . . . . . . . . . .3.1

Profile Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.2

Alarm Set Points . . . . . . . . . . . . . . . . . . . . . . . . . . .3.4

Clearing Alarms and Errors . . . . . . . . . . . . . . . . . . .3.4

Auto-tune PID . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.4

Edit PID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.4

Multiple PID Sets . . . . . . . . . . . . . . . . . . . . . . . . . . .3.5

Cascade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.6

Sample Application . . . . . . . . . . . . . . . . . . . . . . . . .3.7

Troubleshooting Alarms and Errors . . . . . . . . . . . . .3.8

Operations Page Map . . . . . . . . . . . . . . . . . . . . . . .3.10

Operations Page Parameter Table . . . . . . . . . . . . .3.11

Operations Page Parameter Record . . . . . . . . . . . .3.15

Series F4S/D Operation

The Series F4S/D controller can function as either

a static set point controller or as a profile con-

troller. The information shown on the Lower Display during operation (the Main Page) is programmable and can be customized to support both

modes of operation. (See Setup Page.)

In either the static set point mode or the profile

mode, the Series F4 can only be operated in a

closed-loop configuration. Manual operation (openloop) mode is not allowed.

Static Set Point Control

The Series F4 is in static mode when it is not controlling a ramping profile. When in static mode:

• The Profile Indicator Light is off.

• The Upper Display shows the actual process

temperature of input 1, 2 or 3 depending upon

Setup Page configuration.

✔

NOTE:

All control activity stops when you enter the Setup Page,

Analog Input, Digital Input, Control Output, Alarm Output, Retransmit, and Digital Output menus.

• The Lower Display shows the default or user configured information set. See the Setup

Chapter for instructions in programming the

Main Page to display the information you want.

To operate the Series F4 as a static set point controller, use the navigation keys (><,.) to

select the preferred channel and adjust the set

point.

Limits may be placed on the set point in the Set

Point Low Limit and Set Point High Limit parameters (Setup Page > Analog Inputx).

Setting the set point to Set Point Low Limit minus

1 (-1) will turn control Output 1 off and display the

set point as off.

Static Set Point1___

OFF

▲▼ Adjusts Value

< Back > Next

Static Set Point1___

___ °F

▲▼ Adjusts Value

< Back > Next

Page 18

3.2 ■ Operations Watlow Series F4S/D

ç WARNING

Check the configuration of the controller on the Setup

Page before starting and running a profile (if the Setup

Page is not locked). Make sure the settings are appropriate to the profile: input sensor ranges and limits, digital

inputs and outputs as events, guaranteed soak band, response to power out and Celsius or Fahrenheit scales. If

the Setup Page is accessible, failure to check the configuration before running a profile could result in damage to

equipment and/or property, and/or injury or death to personnel.

Profile Control π

The main purpose of the Series F4 is to control profiles for ramp-and-soak-processing applications.

The instructions below explain how to use an existing profile. To program a profile, see Chapter 4,

Profile Programming.

>

Start a Profile? ■

■

▼ No ▲ Yes ■

■■■■■■■■■■■■■■■■

To Start/Run a Profile

To initiate the profile mode, press the Profile Key

π and answer the questions that follow.

While running a profile, the Profile Status message

on the lower display will keep you informed about

the progress of the profile. For example, it could

read like the screen at right:

✔

NOTE:

As a protective measure, all stored profiles will be cleared

if you enter the Setup Page and change values in the

Analog Input 1, 2, 3 menus —specifically, the Sensor,

Sensor Type, Decimal, Scale (for process inputs), and Set

Point High and Low Limits. Pop-up messages will warn

that the profiles will be erased from the controller’s memory.

✔

NOTE:

You must configure the software for your inputs and outputs before programming a profile. See the Setup Chapter.

✔

NOTE:

You must program a profile or use the pre-programmed

MILSTD810D profile before running it. See the Profile

Programming Chapter.

✔

NOTE:

While a profile is running, the controller will not recognize digital inputs that are programmed to start a profile.

Such digital inputs will be recognized only while the controller is in the static set point mode.

✔

NOTE:

While a profile is running, profiles can be either created

or renamed only while a profile is running. All other

pages and menus can be entered only during Static Set

Point Control mode.

Glaze 8 Running.

Step 2

Remain 00:10:30

.

Start:_______________

Step 1 Autostart

>Step 2 Ramp Time

Step 3 Ramp Time

.

Start Profile:_______

MILSTD810D..........

ALUMINUM

>Glaze 8

Page 19

Watlow Series F4S/D Operations ■ 3.3

π The Profile Key:

• initiates the ramping profile mode;

• initiates the Hold-profile state;

• initiates the Resume-profile command;

• initiates the Terminate-profile command.

The Profile Key functions only from the Main

Page. It will not function from any of the other

pages — Operations, Profile, Setup or Factory.

To Resume a Profile on Hold

1. Press the Profile Key π while a profile is

holding. The Resume Profile Menu appears.

2. Choose to Continue Holding, Resume or

Terminate the profile.

If you do not make a choice, the profile continues

holding and the Profile Indicator Light stays off.

✔

NOTE:

When a profile is resumed during a Ramp step, the controller uses the Static Set Point from the Main Page to

calculate the rate of change needed to get to the set point

at the end of the step. When a profile is resumed in a

soak step, the new set point value will be used as the soak

value for the time remaining in the step.

Resume Profile:_____

>Continue Holding

Resume

Terminate

To Terminate a Running/Holding Profile

1. Press the Profile Key π while a profile is

running. The Profile Action Menu appears.

2. Choose to Continue, Hold or Terminate the

profile. (Default is to Continue.) If you choose to

terminate, the profile ends with all outputs off.

The set point on the Main Page reads off.

If you do not make a choice when the Profile Action

Menu appears, the profile continues as it was —

running or holding.

✔

NOTE:

The Profile Status message takes precedence over all other information except errors, alarm messages and input

status. Errors and alarm messages always take precedence over Profile Status.

Hold Profile:_______

Don’t Hold

Hold

>Terminate

To Hold a Running Profile

1. Press the Profile Key π while running a pro-

file. The Profile Action Menu appears.

2. Choose to Don’t Hold, Hold or Terminate

the profile. (Default is to Don’t Hold.) If you

choose to hold the profile, the Main Page reappears, and the Profile Status message reads

“Profile X holding.” The Profile Indicator Light is

off.

If you do not make a choice when the Profile Action

Menu appears, the profile continues running and

the profile indicator light stays on.

✔

NOTE:

While profiles are on hold, the step set point value can be

adjusted using the Static Set Point parameter on the

Main Page.

Hold Profile:_______

Don’t Hold

>Hold

Terminate

Page 20

3.4 ■ Operations Watlow Series F4S/D

Alarm Set Points

The Series F4 includes two alarm outputs, which

can be programmed as process or deviation alarms.

Process alarms notify the operator when process

values exceed or fall below Alarm Low and Alarm

High Set Points. Deviation alarms notify the operator when the process has deviated from the set

point beyond the deviation limits. For more information, see the Features Chapter. To set up the

alarms, see the Setup Chapter.

Alarm set points are the points at which alarms

switch on or off, depending on the alarm setting.

Alarm set points can be viewed or changed in the

Alarm Set Point Menus (Operations Page).

The Alarm High Set Point defines the high temperature that, if exceeded, will trigger an alarm.

This temperature must be higher than the alarm

low set point and lower than the high limit of the

sensor range.

The Alarm Low Set Point defines the low temperature that, if exceeded, will trigger an alarm.

This temperature must be lower than the alarm

high set point and higher than the low limit of the

sensor range.

✔

TIP:

You may want to set up the alarms with names that will

identify the alarm conditions. See the Setup Page.

To Clear an Alarm or Error

In an alarm condition, an alarm message will appear on the Main Page (if this option has been selected on the Setup Page). To silence it, move the

cursor to the alarm message and press the Right

Key . . A pop-up message will confirm the silencing of the alarm, and the indicator light will go off.

When the condition causing the error or alarm is

corrected, return to the error or alarm message on

the Main Page, and press the Right Key again. A

pop-up message confirms the alarm is unlatched.

Auto-tune PID

In autotuning, the controller automatically selects

the PID parameters for optimal control, based on

the thermal response of the system. In the Series

F4, five sets of PID values are available for each

channel of the controller: sets 1 to 5 for channel 1,

and sets 6 to 10 for channel 2. Default PID values

exist for all PID sets, although these values typically do not provide optimal control. PID values

can be auto-tuned or adjusted manually. When autotuning is complete, the PID values will be stored

in the Edit PID Menu.

✔

NOTE:

PID Set 1 for Channel 1 and PID Set 6 for Channel 2

are used in the Static Set Point mode.

Autotuning Procedure

Autotuning cannot be initiated while a profile is

running. It can only be initiated in the static set

point control mode.

1. Before initiating auto-tune, go to the System

Menu (Setup Page), and set the Channel 1 or 2

Autotune Set Point to the percentage of set point

you choose to begin with. This percentage is

based on your knowledge of the system and how

much overshoot or undershoot there is likely to

be in on-off control.

In the Custom Main Page, select to display Tune

Status 1 and Tune Status 2. This displays Tune

Status in the Main Page.

2. Go to the Main Page and set the static set point.

3. Go to the Autotune PID Menu (Operations Page)

and choose the channel to auto-tune and the PID

set in which to store the settings. A message will

be displayed on the Main Page during the autotuning process. (Auto-tune cannot be initiated

when a profile is running. It can only be initiated

in the static set point mode.)

4. When autotuning is complete, the controller will

store the values for optimum control in the PID

set specified.

✔

NOTE:

While the controller is autotuning, profiles cannot be run

and only the Profiles Page and Operation Page of the

software can be entered.

ç

CAUTION: Choose an auto-tune set point value that will

protect your product from possible damage from overshoot

or undershoot during the autotuning oscillations. If the

product is sensitive, select the auto-tune set point very

carefully to prevent product damage.

For additional information about autotuning and proportional, integral and derivative control, see the Features Chapter.

Edit PID

Edit PID is useful when Auto-tune PID does not

provide adequate control. Each of the PID parameters can be adjusted manually:

Proportional Band: Define a band for PID control, entered in degrees or units. Lower values increase gain, which reduces droop but can cause oscillation. Increase the proportional band to eliminate oscillation.

Page 21

Watlow Series F4S/D Operations ■ 3.5

Integral (Reset): Define the integral time in minutes per repeat; define reset in repeats per minute.

Set repeats per minute if units are U.S.; minutes

per repeat if units are SI.

Derivative (Rate): Define the derivative (rate)

time in minutes. Large values prevent overshoot

but can cause sluggishness. Decrease if necessary.

Dead Band: Define the dead band in degrees or

units. Heating dead band shifts the set point down.

Cooling dead band shifts the set point up. For more

information, see the Features Chapter.

Manual Tuning Procedure

1. Apply power to the Series F4 and enter a set

point. Go to the Operations Page, Edit PID Menu

and begin with Proportional Band set to 5; Integral (Reset) set to 0; Derivative (Rate) set to 0;

and Autotune set to Tune Off.

2. Start manual tuning by entering the desired set

point and let the system stabilize. Once the system stabilizes, observe the value of Input 1 on

the Main Page. If the Input 1 value fluctuates,

increase the proportional band setting until it

stabilizes. Adjust the proportional band in 5º to

10º increments, allowing time between adjustments for the system to stabilize.

3. Once Input 1 has stabilized, observe the percent

power on the Main Page. It should be stable,

±2%. At this point, the process temperature

should also be stable, but it will exhibit droop

(stabilized below set point). The droop can be

eliminated with reset or integral.

4. Start with a reset setting of 0.01, and allow 10

minutes for the process temperature to come up

to set point. If it has not, increase the setting to

0.05 and wait another 10 minutes. After this,

double the reset setting and wait another 10

minutes until the process value equals the set

point. If the process becomes unstable, the reset

value is too large. Decrease the setting until the

process stabilizes.

5. Increase Derivative/Rate to 0.10 minute. Then

raise the set point by 20° to 30°F, or 11° to 17°C.

Observe the system's approach to the set point. If

the load process value overshoots the set point,

increase Derivative/Rate to 0.50 minute.

Raise the set point by 20° to 30°F, or 11° to 17°C

and watch the approach to the new set point. If

you increase Derivative/Rate too much, the approach to the set point will be very sluggish. Repeat as necessary until the system rises to the

new set point without overshooting or approaching the set point too slowly.

For additional information about manual tuning

and proportional, integral and derivative control,

see the Features Chapter.

Multiple PID Sets

Environmental chambers, ovens and furnaces typically have different thermal requirements when

they operate at high and low temperatures or pressures. To accommodate varying thermal requirements, the F4 is capable of storing five different

PID sets for each channel. One set for each channel

can be chosen in each profile step.

For example, a controller in an environmental

chamber with PID settings optimized for control at

subzero temperatures may not control well when

the set point is set to temperatures above the boiling point of water. With the F4, one PID set could

be used for subzero operation and another set for

temperatures above boiling.

Multiple Tuning Procedure

1. To auto-tune a single PID set, begin by setting

the static set point on the Main Page.

2. Go to the Autotune PID Menu (Operations Page),

and choose a channel and a set. Autotuning begins when you select the set. The Main Page displays information about the autotuning process

when Tune Status is selected in the Custom

Main Page.

3. When autotuning is finished, proceed with

another PID set.

In the example above, the user would first autotune a PID set for subzero operation, and then another for operation at boiling temperatures. When

programming a profile, the user could then select a

different PID set for each step, depending on the

thermal requirements.

✔

NOTE:

Autotuning cannot be done while running a profile. It can

only be initiated when the controller is in the Static Set

Point Control mode.

Page 22

3.6 ■ Operations Watlow Series F4S/D

Cascade

Cascade control is available on the Series F4 controllers. For background information about cascade

control, see the Features Chapter.

Select cascade control through the Analog Input 3

Menu (Setup Page) and choose Process Cascade or

Deviation Cascade. To set the range for the Process

Cascade Inner Loop set point, use Low and High

Range settings. These are independent of the Channel 1 set point. Deviation Cascade uses Deviation

Low and High settings that are referenced to the

Channel 1 set point.

Deviation Cascade is used in applications with large

set point ranges or where limiting heating or cooling

equipment temperatures is required.

When tuning a cascade system, the inner loop must

be tuned first. The inner loop comprises outputs 1A

and 1B and the Analog Input 1 sensor, which usually

measures the energy source temperature. The output

device controls a power switching device, which in

turn switches the heating and cooling. The set point

for the inner loop is generated by the outer loop. For

Process Cascade, this will have a range between the

Cascade Low Range and Cascade High Range.

Cascade Setup Procedure

1. First, configure Analog Input 3, Cascade Low

Range and Cascade High Range.

Go to the Analog Input 3 Menu (Setup Page).

Choose Process or Deviation Cascade. Deviation

Cascade references Channel 1 set point allowing a

range above and below the current control set

point. For Process Cascade control of a heat/cool or

cool only system, set the Cascade Low Range to a

value slightly lower than the lowest temperature

desired in the chamber. For heat-only systems, set

the Cascade Low Range to a value slightly lower

than the ambient temperature; otherwise the heat

output will never turn fully off.

For heat/cool or heat only systems , set the Cascade High Range to a value slightly higher than

the highest temperature desired in the chamber.

For cool-only systems, set the Cascade High Range

to a value slightly higher than the ambient temperature; otherwise the cooling will never fully

turn off.

2. Next, configure the controller to tune and display

data for the outer loop. To view Inner Loop Set

Point in the upper display, go to the Setup Page,

Custom Main Page Menu, select the Inner Set

point as one of the parameters, P1 to P16, to be

displayed in the Main Page.

To also view Analog Input 3 in the upper display,

go to the Setup Page, Process Display Menu, and

choose Alternating. Under Set Display Time,

choose a duration for the display of the Input 1 and

Input 3 variables.

Cascade Autotuning Procedure

1. Go to Setup Page, Custom Main Page Menu.

Choose Tune Status 1 and Tune Status 2 to appear as 2 of the 16 parameters that can be displayed on the Main Page. The Main Page will now

display the status of the autotuning process.

2. Autotune the inner loop. Go to the Autotune PID

Menu (Operations Page), and select Cascade Inner-loop. Choose Cascade Inner Loop PID Set 1 to

5, where PID values will be stored after autotuning. Autotuning begins when you choose the PID

set. While autotuning, the F4 controller will control the energy source in an on-off mode to a temperature equal to the Cascade High Range setting

x Channel 1 Autotune Set Point. For best results,

use proportional control only on the inner loop.

3. Next, autotune the outer loop. Go to the Autotune PID Menu (Operations Page). Choose

Cascade Outer Loop, then choose Outer Loop PID

set 1 to 5, where PID values will be stored after

autotuning. Autotuning begins when you choose

the PID set. While autotuning, the outer loop will

be controlled in an on-off mode at a set point

equal to static set point x Ch 1 Autotune Set

Point. In most cases, the autotuning feature will

tune for acceptable control. If not, manually tune

the outer loop (step 4 below). Before manually

tuning, record the values generated by the autotuning feature.

4. To manually tune the outer loop, go to the Edit

PID Menu (Operations Page). Choose Cascade

Outer Loop, then choose Outer Loop PID set 1 to

5. Begin manual tuning by setting the Proportional Band to 5, Integral (Reset) to 0, and Rate

to 0. Establish the desired set point and let the

system stabilize. When the system stabilizes,

watch the Inner Loop Set Point on the Main

Page. If this value fluctuates, increase the proportional band until it stabilizes. Adjust the proportional band in 3° to 5° increments, allowing

time for the system to stabilize between adjustments.

5. When Input 1 has stabilized, watch the percent

power on the Main Page. It should be stable,

±2%. At this point, the process temperature

should also be stable, but it will exhibit droop

(stabilized below set point). The droop can be

eliminated with Integral (reset).

6. Start with an integral setting of 99.9 minutes,

and allow 10 minutes for the process temperature to come up to set point. If it has not,

decrease the setting by half and wait another 10

minutes. Then halve the setting again and wait

another 10 minutes until the process value

equals the set point. If the process becomes

unstable, the integral value is too small. Increase

it until the process stabilizes.

Page 23

Andy, an engineer with the Ajax Testing Company,

is running temperature and humidity tests on

navigational equipment. He runs the test profile,

Military Standard Test 810D, having already set

up the controller and programmed the profile.

In Step 4, the temperature in the chamber exceeded the Alarm 1 setting. This triggered the alarm,

causing the indicator light on the front panel (next

to the bell-shaped icon) to light up and a message

to appear on the lower display: "TEMP DEV

High."

Because Alarm 1 was set up as a latching alarm

(Setup Page), Andy had to clear it manually. First

he corrected the alarm condition by widening the

gap between low and high deviation alarm settings on the Operations Page. He then unlatched

the alarm by returning to the Main Page alarm

line and pressing the Right Key

. again.

If your Series F4 is a single-channel controller,

you will see only the temperature on Channel 1.

This is not the true Military Standard Test 810D.

✔

NOTE:

This profile is embedded in the Series F4 as a teaching

tool and a template. Go to the Edit Profile Menu (Profiles Page) and look for MILSTD810D.

RUN

Andy presses the Profile Key π , moves the cursor

to "MILSTD810D" on the Run Profile Menu, then

presses the Right Key .. He wants to begin at

Step 1, so he presses . to select that step. The

Profile Status Message (on the Lower Display)

now says: "MILSTD810D Running. Step 1 Remains: XX:XX."

π

HOLD

When the alarm occurred, Andy put the profile on

hold while he corrected the Alarm Set Points.

π

RESUME

After clearing the alarm, Andy entered the command to resume the profile.

π

Resume Profile:______

Continue Holding

>Resume

Terminate

.

MILSTD810D Holding.

Step 1

Remains 00:01:40

Hold Profile:_______

Don’t Hold

>Hold

Terminate

Start Profile:_______

>MILSTD810D..........

ALUMINUM

Glaze 8

1B

2A

2B

1A

Sample Application:

Environmental Testing, Running a Profile

Watlow Series F4S/D Operations ■ 3.7

F

4

1A

1B

2A

2B

Main Page___________

1

Go to Profiles

Go to Setup

2

Go to Factory

i

Page 24

3.8 ■ Operations Watlow Series F4S/D

Troubleshooting Alarms and Errors

• Configure output as an alarm.

• Check alarm set points.

• Check the alarm sides setting.

• Check the alarm type setting.

• Check the alarm logic for compatibility with

system peripherals and annunciators.

• Check the power limit setting.

• Check the operation mode.

• Check the alarm output function.

• Check the °C and °F setting.

• Check the calibration offset value. Set it to a

lower level.

• Alarm output may be off.

• Alarm set points may be incorrect.

• Alarm sides may be incorrect.

• Controller may be in diagnostics mode.

• Alarm may be latched. Move cursor to

alarm message. Press

.

.

• Alarm set points may be incorrect.

• Alarm hysteresis may be incorrect.

• Input may be in error condition.

Alarms

• Alarm won’t occur.

• Alarm won’t clear.

(To clear the alarm, cor-

rect the alarm condition. If the alarm is

latched, press

. with

the cursor at the alarm

message on the Main

Page.)

• Check Communications Setup Menu and set

to correct address.

• Check Communications Setup Menu and set

to correct baud rate.

• Look for a break in the daisy chain.

• Verify correct connections and test wiring

paths.

• Check converter box wiring and its documentation.

• Reconfigure computer’s communications port

setup and verify that communications are

okay.

• Check the communication card documentation

for setable variables and operational testing.

• Restart communications software and check

for settings agreement. Verify the communications bus is active.

• Verify operation with Watlow communications

tool.

• Address parameter may be incorrectly set.

• Baud rate parameter may be incorrectly

set.

• Unit-to-unit daisy chain may be disconnected.

•Communications wiring may be reversed,

short or open.

• EIA-485 converter box may be incorrectly

wired.

• Computer communications port may be incorrectly set up.

• Communications software setup or address

may be incorrect.

• Protocol or parity may be wrong, should be

8, n, 1.

• Application software not working properly.

• May need termination and pull-up and pulldown resistors.

Communications

• Unit will not

communicate.

• Check switches, fuses, breakers, interlocks,

limits, connectors, etc. for energized conditions and proper connection.

• Measure power upstream for required level.

Check part number for input power required.

• Check wire size.

• Check for bad connections.

• Power to unit may be off.

• Fuse may be blown.

• Breaker may be tripped.

• Safety Interlock door switch, etc., may be

activated.

• Separate system limit control may be

latched.

• Wiring may be open.

• Input power may be incorrect.

Power

• Displays are dead.

Corrective ActionProbable Cause(s)Indication

Page 25

Watlow Series F4S/D Operations ■ 3.9

• Turn the controller off, then on again.

• Turn the controller off, then on again.

• Turn the controller off, then on again.

• Call your Watlow distributor or representative.

• Call your Watlow distributor or representative.

• Loss of power during memory setup.

• Loss of power during memory setup.

• Loss of power during memory setup.

• Component failure.

• Component failure, loss of power

during download.

Fatal Errors (Controller shuts

down.)

• Checksum Error!, Parameter

memory.

• Checksum Error!, Unit config

memory.

• Checksum Error!, Profile memory.

• RAM Test Failed! Return controller to the Factory.

• Flash Memory Failed. Return

controller to the Factory.

• Move module to correct input slot.

• Move module to correct input slot.

• Replace incorrect module with retransmit

module.

• Replace incorrect module with retransmit

module.

• Remove the module just installed and

replace with a new module.

• Press any key. All parameters will

default.

• Wait until initialization is done.

• Wait until initialization is done.

• Input 2-3 module in input 1 slot.

• Input 1 module in input 2-3 slot.

• Wrong module in retransmit 1 slot.

• Wrong module in retransmit 2 slot.

• Component failure.

• Module changed.

• Firmware upgrade.

• Firmware upgrade.

•Input 1 Module Error! Only

single-channel modules

supported.

• Input 1 Module Error! Only

dual-channel modules

supported.

• Retransmit 1 Module Error!

Only process modules

supported.

• Retransmit 2 Module Error!

Only process modules

supported.

• Cannot identify: Modify: Replace module.

• Module change. Defaults will

occur. Accept with any key.

• First power-up. Parameters

are initializing.

• Firmware change. Parameters

are initializing.

• Check sensor connections.• Input is in error condition.

System Errors

(Upper Display shows error

numbers. Lower Display messages indicate cause and action to take.)

• Check sensor connections and sensor

wiring.

• Check the Sensor parameter to match the

sensor hardware.

• Measure power upstream for required

level. Check part number for power requirements.

• Check sensor function. The Open Loop

Detect parameter indicates it may be

broken.

• Check the Calibration Offset parameter

value. Set it to a lower level.

• Check sensor connections and sensor

wiring.

• Input type may be set to wrong sensor

or may not be calibrated.

• Power may be incorrect.

• The open loop detect feature shows a

broken sensor.

• The Calibration Offset parameter is set

much too high or low.

Upper [A-dLO]

Lower !Input x (1 to 3) AtoD -

Upper [A-dhi]

Lower !Input x (1 to 3) AtoD+

Upper [SEnLo]

Lower !Input x (1 to 3) Sensor -

Upper [SEnhi]

Lower !Input x (1 to 3) Sensor+

Upper [Atod`]

Lower !Timeout

• Check sensor connections.• Input is in error condition.

Input Errors

(Upper Display shows error code

for input 1 only. Lower Display

shows error message. Alarm

Output Indicator is lit.)

Corrective ActionProbable Cause(s)Indication

Page 26

Operations Page Map

✔

NOTE:

Some parameters may not appear, depending on the model and configuration of the controller.

3.10 ■ Operations Watlow Series F4S/D

Autotune PID

Channel 1 Autotune

Tune Off

PID Set 1

PID Set 2

PID Set 3

PID Set 4

PID Set 5

Channel 2 Autotune

Tune Off

PID Set 6

PID Set 7

PID Set 8

PID Set 9

PID Set 10

Channel 1 Outer Loop Autotune

PID Set C1

PID Set C2

PID Set C3

PID Set C4

PID Set C5

Edit PID

PID Set Channel 1

PID Set 1-5

Proportional Band A

IntegralA / ResetA

DerivativeA / RateA

Dead Band A

Hysteresis A

Proportional Band B

IntegralB / ResetB

DerivativeB / RateB

Dead Band B

Hysteresis B

PID Set Channel 2

PID Set 6-10

Proportional Band A

IntegralA / ResetA

DerivativeA / RateA

Dead Band A

Hysteresis A

Proportional Band B

IntegralB / ResetB

DerivativeB / RateB

Dead Band B

Hysteresis B

Cascade PID Set

Cascade Set 1-5

Proportional Band A

IntegralA / ResetA

DerivativeA / RateA

Dead Band A

Hysteresis A

Proportional Band B

IntegralB / ResetB

DerivativeB / RateB

Dead Band B

Hysteresis B

Alarm Set Points

Alarm1 Low SP

Alarm1 High SP

Alarm1 Lo Deviation

Alarm1 Hi Deviation

Alarm2 Low SP

Alarm2 High SP

Alarm2 Lo Deviation

Alarm2 Hi Deviation

Page 27

Watlow Series F4S/D Operations ■ 3.11

Operations Page Parameter Table Modbus

Register

Range read/write Conditions for

Parameter Description (Modbus Value) Default [I/O, Set, Ch] Parameters to Appear

*This section is also applicable for Cascade Inner Loop.

✔

NOTE: For more information about how parameter settings

affect the controller’s operation, see the Features Chapter.

Active if PID Units (Setup Page)

is set to SI and Proportional

Band is not set to 0.

1A 1B Set

503 553 [1]

513 563 [2]

523 573 [3]

533 583 [4]

543 593 [5]

r/w

0.00 minutes

(0)

0.00 to 9.99 minutes

(0 to 999)

Derivative x (A or B)

Set the derivative

time.

Active if PID Units (Setup Page)

is set to U.S. and Proportional

Band is not set to 0.

1A 1B Set

502 552 [1]

512 562 [2]

522 572 [3]

532 582 [4]

542 592 [5]

r/w

0 per minute

(0)

0.00 per minute to

99.99 per minute

(0 to 9999)

Reset x (A or B)

Set the reset time in

repeats per minute.

Active if PID Units (Setup Page)

is set to SI and Proportional

Band is not set to 0.

1A 1B Set

501 551 [1]

511 561 [2]

521 571 [3]

531 581 [4]

541 591 [5]

r/w

0 minutes

(0)

0.00 to 300.00 minutes

(0 to 30000)

Integral x (A or B)

Set the integral time

in minutes.

Active: Always (Channel 1).

°F Default for US

°C Default for SI

1A 1B Set

500 550 [1]

510 560 [2]

520 570 [3]

530 580 [4]

540 590 [5]

r/w

25°F (25)

14°C (14)

0 to 30000

(0 to 30000)

Proportional Band x (A or B)

Define the proportional band for PID

control.

Main > Operations > Edit PID > PID Set Channel 1 > PID Set x (1 to 5)

PID Set x (1 to 5)* (Optional Inner Loop)

Main > Operations > Edit PID

Edit PID

Active if Analog Input 3 Control

Type is set to Cascade.

343

r/w

Tune Off (0)Tune Off (0)

Outer Loop PID Set 1 (1)

Outer Loop PID Set 2 (2)

Outer Loop PID Set 3 (3)

Outer Loop PID Set 4 (4)

Outer Loop PID Set 5 (5)

Cascade Outer Loop

Select which PID parameters will be automatically tuned.

Active if Analog Input 3 Control

Type is set to Cascade.

305

r/w

Tune Off (0)Tune Off (0)

Inner Loop PID Set 1 (1)

Inner Loop PID Set 2 (2)

Inner Loop PID Set 3 (3)

Inner Loop PID Set 4 (4)

Inner Loop PID Set 5 (5)

Cascade Inner Loop

Select which PID parameters will be automatically tuned.

Main > Operations > Autotune PID > Cascade

Autotune PID Cascade

Active: Always (Channel 1).

Active if controller is set to Dual

Channel Ramping (Channel 2).

Channel

305 [1]

324 [2]

r/w

Tune Off (0)Tune Off (0)

Ch1 PID Set 1 (1)

Ch1 PID Set 2 (2)

Ch1 PID Set 3 (3)

Ch1 PID Set 4 (4)

Ch1 PID Set 5 (5)

Ch2 PID Set 6 (1)

Ch2 PID Set 7 (2)

Ch2 PID Set 8 (3)

Ch2 PID Set 9 (4)

Ch2 PID Set 10 (5)

Channel x (1 to 2) Autotune

Select whether PID

parameters will be

automatically

selected.

Main > Operations > Autotune PID

Autotune PID

Page 28

3.12 ■ Operations Watlow Series F4S/D

Operations Page Parameter Table Modbus

Register

Range read/write Conditions for

Parameter Description (Modbus Value) Default [I/O, Set, Ch] Parameters to Appear

✔

NOTE: Press the Information Key ˆ for more task-related tips.

Active if PID Units (Setup Page)

is set to U.S. and Proportional

Band is not set to 0.

2A 2B Set

2504 2554 [6]

2514 2564 [7]

2524 2574 [8]

2534 2584 [9]

2544 2594 [10]

r/w

0.00 minutes

(0)

0.00 to 9.99 minutes

(0 to 999)

Rate x (A or B)

Set the rate time.

Active if PID Units (Setup Page)

is set to SI and Proportional

Band is not set to 0.

2A 2B Set

2503 2553 [6]

2513 2563 [7]

2523 2573 [8]

2533 2583 [9]

2543 2593 [10]

r/w

0.00 minutes

(0)

0.00 to 9.99 minutes

(0 to 999)

Derivative x (A or B)

Set the derivative

time.

Active if PID Units (Setup Page)

is set to U.S. and Proportional

Band is not set to 0.

2A 2B Set

2502 2552 [6]

2512 2562 [7]

2522 2572 [8]

2532 2582 [9]

2542 2592 [10]

r/w

0 per minute

(0)

0.00 per minute to

99.99 per minute

(0 to 9999)

Reset x (A or B)

Set the reset time in

repeats per minute.

Active if PID Units (Setup Page)

is set to SI and Proportional

Band is not set to 0.

2A 2B Set

2501 2551 [6]

2511 2561 [7]

2521 2571 [8]

2531 2581 [9]

2541 2591 [10]

r/w

0 minutes

(0)

0.00 to 99.99 minutes

(0 to 9999)

Integral x (A or B)

Set the integral time

in minutes.

Active: Always (Channel 1).

2A 2B Set

2500 2550 [6]

2510 2560 [7]

2520 2570 [8]

2530 2580 [9]

2540 2590 [10]

r/w

25°F (25)

14°C (14)

0 to 30000

(1 to 30000)

Proportional Band x (A or B)

Set the proportional

band.

Main > Operations > Edit PID > PID Set Channel 2 > PID Set x (6 to 10)

PID Set x (6 to 10)

Active if Proportional Band is set

to 0 and one channel is set to

heat and the other to cool

(Setup Page).

1A 1B Set

507 557 [1]

517 567 [2]

527 577 [3]

537 587 [4]

547 597 [5]

r/w

3 (3)1 to 30000

(1 to 30000)

Hysteresis x (A or B)

Define the process

variable change from

the set point required to re-energize

the output (in on-off

mode).

Active if Proportional Band is not

set to 0 and one output is set to

heat and the other to cool

(Setup Page).

1A 1B Set

505 555 [1]

515 565 [2]

525 575 [3]

535 585 [4]

545 595 [5]

r/w

0

(0)

0 to 30000

(0 to 30000)

Dead Band x (A or B)

Define the effective

shift in the heating

and cooling set

points to prevent

conflict.

Active if PID Units (Setup Page)

is set to U.S. and Proportional

Band is not set to 0.

1A 1B Set

504 554 [1]

514 564 [2]

524 574 [3]

534 584 [4]

544 594 [5]

r/w

0.00 minutes

(0)

0.00 to 9.99 minutes

(0 to 999)

Rate x (A or B)

Set the rate time.

Page 29

Watlow Series F4S/D Operations ■ 3.13

Operations Page Parameter Table Modbus

Register

Range read/write Conditions for

Parameter Description (Modbus Value) Default [I/O, Set, Ch] Parameters to Appear

✔

NOTE: For more information about how parameter settings

affect the controller’s operation, see the Features Chapter.

Active if Proportional Band is not

set to 0 and one output is set to

heat and the other to cool

(Setup Page).

1A 1B Set

2605 2655 [1]

2615 2665 [2]

2625 2675 [3]

2635 2685 [4]

2645 2695 [5]

r/w

0

(0)

0 to 30000

(0 to 30000)

Dead Band x (A or B)

Define the effective

shift in the heating

and cooling set

points to prevent

conflict.

Active if PID Units (Setup Page)

is set to U.S. and Proportional

Band is not set to 0.

1A 1B Set

2604 2654 [1]

2614 2664 [2]

2624 2674 [3]

2634 2684 [4]

2644 2694 [5]

r/w

0.00 minutes

(0)

0.00 to 9.99 minutes

(0 to 999)

Rate x (A or B)

Set the rate time.

Active if PID Units (Setup Page)

is set to SI and Proportional

Band is not set to 0.

1A 1B Set

2603 2653 [1]

2613 2663 [2]

2623 2673 [3]

2633 2683 [4]

2643 2693 [5]

r/w

0.00 minutes

(0)

0.00 to 9.99 minutes

(0 to 999)

Derivative x (A or B)

Set the derivative

time.

Active if PID Units (Setup Page)

is set to U.S. and Proportional

Band is not set to 0.

1A 1B Set

2602 2652 [1]

2612 2662 [2]

2622 2672 [3]

2632 2682 [4]

2642 2692 [5]

r/w

0 per minute

(0)

0.00 per minute to

99.99 per minute

(0 to 9999)

Reset x (A or B)

Set the reset time in

repeats per minute.

Active if PID Units (Setup Page)

is set to SI and Proportional

Band is not set to 0.

1A 1B Set

2601 2651 [1]

2611 2661 [2]

2621 2671 [3]

2631 2681 [4]

2641 2691 [5]

r/w

0 minutes

(0)

0.00 to 99.99 minutes

(0 to 9999)

Integral x (A or B)

Set the integral time

in minutes.

Active: Always (Channel 1).

°F Default for US

°C Default for SI

1A 1B Set

2600 2650 [1]

2610 2660 [2]

2620 2670 [3]

2630 2680 [4]

2640 2690 [5]

r/w

25°F (25)

14°C (14)

0 to 30000

(0 to 30000)

Proportional Band x (A or B)

Define the proportional band for PID

control.

Main > Operations > Edit PID > Cascade Outer Loop PID Set X (1 to 5)

Cascade Outer Loop PID Set x (1 to 5)

Active if Proportional Band is set

to 0 and one channel is set to

heat and the other to cool

(Setup Page).

2A 2B Set

2507 2557 [6]

2517 2567 [7]

2527 2577 [8]

2537 2587 [9]

2547 2597 [10]

r/w

3 (3)1 to 30000

(1 to 30000)

Hysteresis x (A or B)

Define the process

variable change from

the set point required to re-energize

the output (in on-off

mode).

Active if Proportional Band is not

set to 0 and one output is set to

heat and the other to cool

(Setup Page).

2A 2B Set

2505 2555 [6]

2515 2565 [7]

2525 2575 [8]

2535 2585 [9]

2545 2595 [10]

r/w

0 (0)0 to 30000

(1 to 30000)

Dead Band x (A or B)

Define the effective

shift in the heating

and cooling set

points to prevent

conflict.

Page 30

Active if Alarm 2 Type (Setup

Page) is set to Deviation.

322

r/w

999 (999)0 to 30000

(0 to 30000)

Alarm 2 High Deviation

Set the deviation

above set point 2

that will trigger an

alarm.

Active if Alarm 2 Type (Setup

Page) is set to Deviation.

Active if decimal is set to 0.0

321

r/w

-999 (-999)

-99.9 (-999)

-19999 to -1

(-1 to -19999)

-.1 to -1999.9

(-1 to -19999)

Alarm 2 Low Deviation

Set the deviation

below set point 2

that will trigger an

alarm.

Active if Alarm 2 Type (Setup

Page) is set to Process.

322

r/w

<per sensor><per sensor> to Alarm

2 Low Set Point

Alarm 2 High SP

Set high value at

which alarm is triggered.

Active if Alarm 2 Type (Setup

Page) is set to Process.

321

r/w

<per sensor><per sensor> to Alarm

2 High Set Point

Alarm 2 Low SP

Set low value at

which alarm is triggered.

Active if Alarm 1 Type (Setup

Page) is set to Deviation.

Active if decimal is set to 0.0

303

r/w

999 (999)

99.9 (999)

1 to 30000

(1 to 30000)

.1 to 3000.0

(1 to 30000)

Alarm 1 High Deviation

Set the deviation

above set point 1

that will trigger an

alarm.

Active if Alarm 1 Type (Setup

Page) is set to Deviation.

Active if decimal is set to 0.0.

302

r/w

-999 (-999)

-99.9 (999)

-19999 to -1

(-1 to 19999)

-.1 to -1999.9

(-1 to 19999)

Alarm 1 Low Deviation

Set the deviation

below set point 1

that will trigger an

alarm.

Active if Alarm 1 Type (Setup

Page) is set to Process.

303

r/w

<per sensor><per sensor> to Alarm

1 Low Set Point

Alarm 1 High SP

Set high value at

which alarm is triggered.

Active if Alarm 1 Type (Setup

Page) is set to Process.

302

r/w

<per sensor><per sensor> to Alarm

1 High Set Point

Alarm 1 Low SP

Set low value at

which alarm is triggered.

Main > Operations > Alarm Set Points

Alarm Set Points

Active if Proportional Band is set

to 0 and one channel is set to

heat and the other to cool

(Setup Page).

1A 1B Set

2607 2657 [1]

2617 2667 [2]

2627 2677 [3]

2637 2687 [4]

2647 2697 [5]

r/w

3 (3)1 to 30000

(1 to 30000)

Hysteresis x (A or B)

Define the process

variable change from

the set point required to re-energize

the output (in on-off

mode).

3.14 ■ Operations Watlow Series F4S/D

Operations Page Parameter Table Modbus

Register

Range read/write Conditions for

Parameter Description (Modbus Value) Default [I/O, Set, Ch] Parameters to Appear

Page 31

Watlow Series F4S/D Operations ■ 3.15

Operations Page Parameter Record

Make a photocopy of this page and enter your settings on that copy .

Name _________________________________________________

Date __________________________________________________

Operations Page

PID Set Chan 1 Menu

PID Set 1

PID Set 2

PID Set 3

PID Set 4

PID Set 5

Proportional Band A

IntegralA / ResetA

DerivativeA / RateA

Dead Band A

Hysteresis A

Proportional Band B

IntegralB / ResetB

DerivativeB / RateB

Dead Band B

Hysteresis B

PID Set Chan 2 Menu

PID Set 6

PID Set 7

PID Set 8

PID Set 9

PID Set 10

Proportional Band A

IntegralA / ResetA

DerivativeA / RateA

Dead Band A

Hysteresis A

Proportional Band B

IntegralB / ResetB

DerivativeB / RateB

Dead Band B

Hysteresis B

Cascade

Outer Loop

PID Set 1

PID Set 2

PID Set 3

PID Set 4

PID Set 5