Page 1

SERIES F4 1⁄4 D I N

RAMPING CONTRO L L E R S

Ramping Control

Programming Made

Easy Through

Advanced Technology

The SERIES F4 1⁄4 DIN industrial ramping controllers

offer an easy to set up and operate solution for the

most demanding ramp and soak processing

applications.The features and performance of these

units make them ideally suited for environmental

chamber or furnace and oven applications. Single

and dual channel versions are available.

These competitively priced controllers feature a four

line, high definition LCD interface display that makes

profile programming and controller configuration

significantly faster and easier. A 16 bit microprocessor

supports all the accuracy and performance advantages

you have come to expect from a Watlow controller.

Up to 256 steps can be programmed into as many as

40 nameable profiles. Profiles can be programmed to

wait for events or for up to three different process

variables. A guaranteed soak feature allows you to

set how closely your process needs to be controlled.

The four digital event inputs can be programmed to

remotely start, pause or terminate any of your

preprogrammed process recipes. The eight event

outputs are segment programmable, or three of them

can be assigned to programmable compressor and

boost heat/boost cool control. A real time clock can

be used to start a profile at any time.

Serial communication and dual alarm relays are

included in the base unit.The SERIES F4 ramping

controllers are packaged with a NEMA 4X front face

to withstand harsh environments and a 101.6 mm

(4.0 in.) deep case with removable connectors for

wiring convenience.

The SERIES F4 controllers are manufactured by

ISO 9001 registered Watlow Controls and backed by

a three-year warranty.

Features and Benefits

Guided 256 step, 40 profile ramp and soak

programmable memory

• Supports a wide range of processing applications

High definition four line LCD controller interface

display

• Simplifies setup and operation

Menu customization

• Offers enhanced process monitoring

High performance 16 bit microprocessor

• Precise process control

Universal inputs

• Provides application versatility

Expandable modular construction

• Field upgradable

Enhanced environmental chamber control

• Supports humidity, compressor, boost heat/boost

cool control

Cascade control

• Provides precise two variable control

Real time clock with battery backup

• Offers operational flexibility

WIN-F4R-0203

1241 Bundy Boulevard, P.O. Box 5580

Winona, Minnesota 55987-5580 USA

Phone: +1 (507) 454-5300

Fax: +1 (507) 452-4507

Internet: www.watlow.com

e-mail: info@watlow.com

© 2003 Watlow Electric Manufacturing Company Printed in the USA on Recycled Paper, 15% Postconsumer Waste

Page 2

Set Point Ramp and Soak Programming

The enhanced programming features found in the

SERIES F4 ramping controllers are the result of listening

to our customers’demand for greater capabilities with

reduced programming complexity.

A profile guide leads the programmer through the

programming process by offering choices for step

configuration.For better operator recognition, profiles

and digital I/O used for events can be given names of

up to 10 characters in length.

Five step types including ramp, soak, jump, auto start

and end offer the programmer complete flexibility.

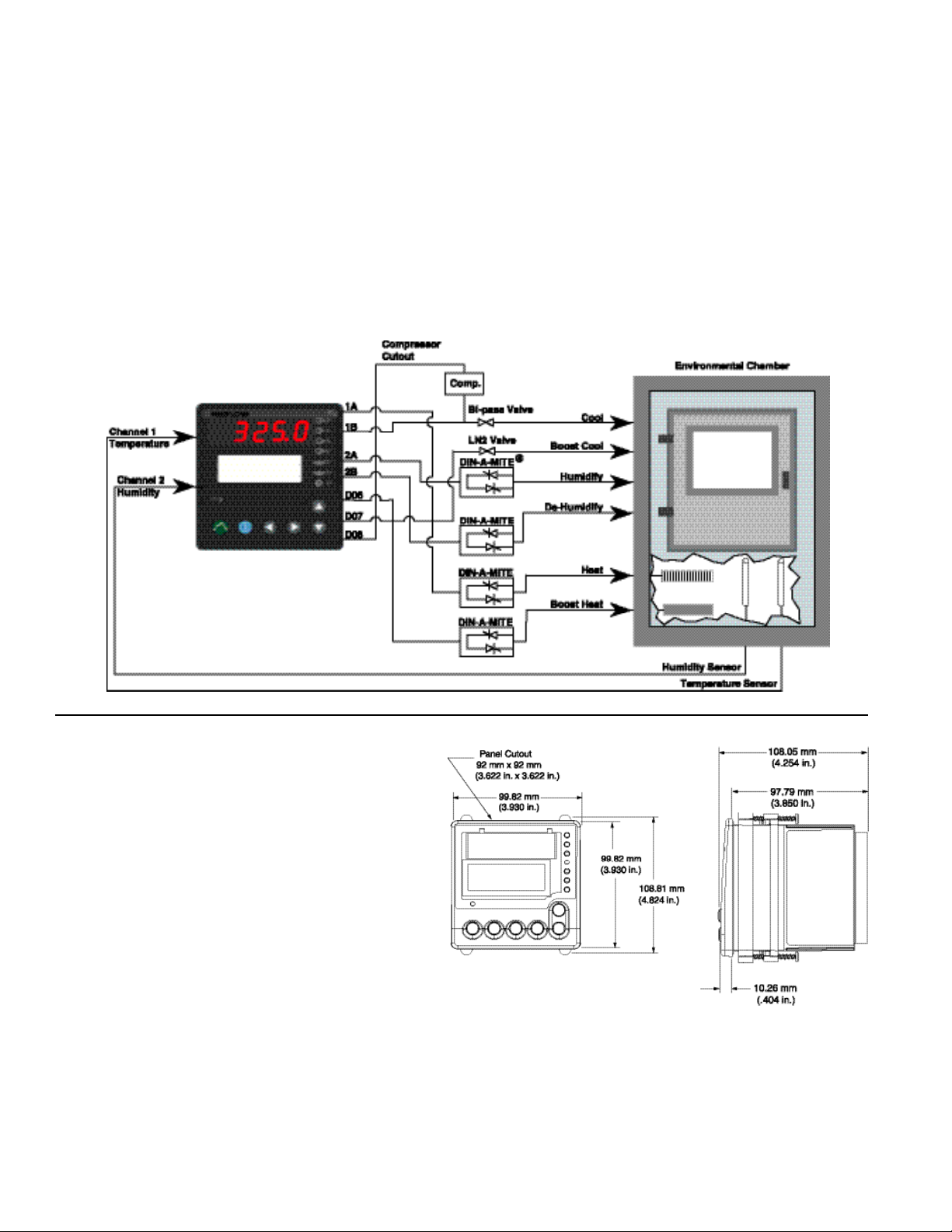

Temperature and Humidity Chamber Application

Ramp steps can be based on time or rate. Ramp and

soak steps can be programmed to wait for up to four event

inputs and three process variables. Up to eight eve n t

outputs are step selectabl e. Since your thermal systems

c h a ra c t e ristics may change over the operating range, up to

10 sets of PID heat/cool parameters are step selectable.

The auto start step can start a profile based on a set

date, a day of the week or daily, the choice is yours.

The jump step can be used to jump within a profile or to

another profile.The end step terminates a program with

the control outputs programmed to your process needs.

Serial Communication

EIA-232 and EIA-485 serial communication interfaces

are included in the base unit of both the SERIES F4S

(single channel) and the SERIES F4D (dual channel)

controllers.The baud rate is selectable as either 9600

or 19200 Kbaud.The protocol is Modbus™.

Alarms

Two Form “C” electromechanical alarm relays are

included in the base units.These alarms can be

programmed as either process or deviation alarms.

The alarms can be tied to up to three process variables.

Optional Retransmit

Optional retransmit capability is available to retransmit

one or two variables. These variables include up to

three process variables, control set points or percent

load power.

Specifications

Dimensions

• Width x height x depth

99 mm x 99 mm x 97 mm panel mount

(3.93 in. x 3.93 in. x 3.85 in.)

Modbus™ is a trademark of AEG Schneider Automation.

Page 3

Specifications

Universal Analog Inputs 1 (2 and 3 Optional)

• Updates rates, IN1 = 20Hz, IN2 and IN3 = 10HZ

Thermocouple

• Type J, K, T, N, E, C (W5), D (W3), PTII, R, S, B

• Input impedance 20MΩ

RTD

• 2- or 3-wire platinum, 100, 500 or 1000Ω

• JIS or DIN curves, 1.0 or 0.1 indication

Process

• Input resolution ≈50,000 bits at full scale

• Range selectable: 0-10VÎ(dc), 0-5VÎ(dc), 1-5VÎ(dc),

0-50mV, 0-20mA, 4-20mA

• Voltage input impedance 20KΩ

• Current input impedance 100Ω

Digital Inputs (4)

• Update rate = 10Hz

• Contact or dc voltage (36VÎ(dc) maximum)

• 10KΩ input impedance

Control Outputs (1A, 1B, 2A, 2B)

• Update rate = 20Hz

Open Collector/Switched dc

• Internal load switching (nominal):

Switched dc, 22 to 28VÎ(dc), limited @ 30mA

• External load switching (maximum):

Open collector 42VÎ (dc) @ 0.5A

Solid State Relay

• Zero switched, optically coupled, 0.5A @

24VÅ(ac) minimum, 253VÅ(ac) maximum

Process Outputs (Optional Retransmit)

• Update rate = 1Hz

• User selectable 0-10VÎ(dc), 0-5VÎ(dc), 1-5VÎ (dc) @

1KΩ min., 0-20mA, 4-20mA @ 800Ω max.

• Resolution:

dc ranges = 2.5mV nominal

mA ranges = 5µA nominal

• Calibration accuracy:

dc ranges = ±15mV

mA ranges = ±30µA

• Temperature stability 100ppm/°C

Alarm Outputs

• Output update rate 1Hz

• Electromechanical relay, Form C, 2A @

30VÎ(dc) or 240VÅ(ac) maximum

Digital Outputs (8)

• Update rate = 10Hz

• Open collector output

• Off = 42VÎ(dc) max @ 10µA

• On = 0.2VÎ(dc) max @ 50mA sink

• Internal supply: 5VÎ(dc), @ 80mA

Communications

EIA-232 and EIA-485 serial communications

with ModbusTMRTU protocol

Safety and Agency Approvals

• UL®/C-UL®916 listed, File # E185611

Process Control Equipment

• CE

• EN 61010-1

• EN 61326

• IP65 and NEMA 4X

Terminals

• Touch-safe removable terminal blocks, accepts

12 to 22 gauge wire

Power

• 100-240VÅ( a c ), -15 percent, +10 percent; 50/60Hz,

±5 percent

• 24-28Vı ( a c / d c ), -15 percent, +10 percent (order option)

• 39VA maximum power consumption

• Data retention upon power failure via nonvolatile

memory (seven years for battery backed RAM)

• Sensor input isolation from input to input to output to

communication circuitry is 500VÅ( a c )

Operating Environment

• 0 to 55°C (32 to 130°F)

• 0 to 90 percent RH, non-condensing

• Storage temperature: -40 to 70°C (-40 to 158°F)

Accuracy

• Calibration accuracy and sensor conformity:

±0.1 percent of span ±1°C @ 25°C ±3°C (77°F ±5°F)

ambient and rated line voltage ±10 percent with the

following exceptions:

Type T: 0.12 percent of span for -200°C to -50°C

(-328°F to -58°F)

Types R and S: 0.15 percent of span for 0°C to 100°C

(32°F to 212°F)

Type B: 0.24 percent of span for 870°C to 1700°C

(1598°F to 3092°F)

• Accuracy span: Less than or equal to operating ranges,

540°C/1000°F minimum.

• Temperature stability: ±0.1°C/°C (±0.1°F/°F) rise in

ambient for thermocouples

±0.05°C/°C (±0.05°F/°F) rise in ambient for RTD

sensors

Displays

• Process: 5, seven segment LED red

• Control interface display: high definition LCD green

Sensor Operating Ranges:

Type J: 0 to 815°C or 32 to 1500°F

Type K: -200 to 1370°C or -328 to 2500°F

Type T: -200 to 400°C or -328 to 750°F

Type N: 0 to 1300°C or 32 to 2372°F

Type E: -200 to 800°C or -32 to 1470°F

Type C: (W5) 0 to 2315°C or 32 to 4200°F

Type D: (W3) 0 to 2400°C or 32 to 4352°F

Type PTII: 0 to 1395°C or 32 to 2543°F

Type R: 0 to 1760°C or 32 to 3200°F

Type S: 0 to 1760°C or 32 to 3200°F

Type B: 0 to 1816°C or 32 to 3300°F

RTD (DIN): -200 to 800°C or -328 to 1472°F

RTD (JIS): -200 to 800°C or -328 to 1166°F

Process: -19,999 to 30,000 units

Sensor Accuracy Ranges:

Input ranges

Type J: 0 to 750°C or 32 to 1382°F

Type K: -200 to 1250°C or -328 to 2282°F

Type T: -200 to 350°C or -328 to 662°F

Type N: 0 to 1250°C or 32 to 2282°F

Type E: -200 to 800°C or -328 to 1470°F

Type C(W5): 0 to 2315°C or 32 to 4200°F

Type D(W3): 0 to 2400°C or 32 to 4352°F

Type PTII: 0 to 1393°C or 32 to 2540°F

Type R: 0 to 1450°C or 32 to 2642°F

Type S: 0 to 1450°C or 32 to 2642°F

Type B: 870 to 1700°C or 1598 to 3092°F

RTD (DIN): -200 to 800°C or -328 to 1472°F

RTD (JIS): -200 to 630°C or -328 to 1166°F

Process: -19,999 to 30,000 units

UL®and C-UL®are registered trademarks of Underwriter’s

Laboratories, Inc.

Note: Specifications subject to change without notice.

Page 4

Ordering Information

1

⁄4 DIN Single Channel Ramping Controller

Ordering Information

1

⁄4 DIN Dual Channel Ramping Controller

SERIES F4 F4 S - A -

1

⁄4 DIN, Single Channel

Ramping Controller

Single Channel

Ramping Controller

1 universal analog input, 4-digital

inputs, 8-digital outputs, 2 alarms,

EIA-232/485 comms

Power Supply

H = 100-240Vı ( a c / d c )

L = 24-28Vı ( a c / d c )

Output 1A

C = Open collector/switched dc

F = Process, 0-5, 1-5, 0-10VÎ(dc),

0-20mA, 4-20mA

K = Solid state Form A 0.5 amp relay

Output 1B

A = None

C = Open collector/switched dc

F = Process, 0-5, 1-5, 0-10VÎ(dc),

0-20mA, 4-20mA

K = Solid state Form A 0.5 amp relay

Auxiliary Input Module

0 = None

6 = Dual universal inputs

Auxiliary Retransmit Module

0 = None

1 = Single retransmit output

0-5, 1-5, 0-10VÎ (dc), 0-20mA, 4-20mA

2 = Dual retransmit outputs

0-5, 1-5, 0-10VÎ (dc), 0-20mA, 4-20mA

Language and RTD Option

1 = English with 100Ω RTD

2 = German with 100Ω RTD

3 = French with 100Ω RTD

4 = Spanish with 100Ω RTD

5 = English with 500 and 1KΩ RTD

6 = German with 500 and 1KΩ RTD

7 = French with 500 and 1KΩ RTD

8 = Spanish with 500 and 1KΩ RTD

D i s p l ay and Custom Options

RG = Standard display (Red/Green display only)

XX = Custom options: software, setting parameters,

overlay

SERIES F4 F4 D - -

1

⁄4 DIN, Dual Channel

Ramping Controller

Dual Channel

Ramping Controller

3 universal analog inputs, 4-digital

i n p u t s, 8-digital o u t p u t s, 2 alarm s,

EIA-232/485 comms

Power Supply

H = 1 0 0 - 2 4 0Vı ( a c / d c )

L = 24-28Vı( a c / d c )

Output 1A

C = Open collector/switched dc

F = Process, 0-5, 1-5, 0 - 1 0VÎ(dc),

0 - 2 0 mA, 4-20mA

K = Solid state Fo rm A 0.5 amp relay

Output 1B

A = None

C = Open collector/switched dc

F = Process, 0-5, 1-5, 0 - 1 0VÎ(dc),

0 - 2 0 mA, 4-20mA

K = Solid state Fo rm A 0.5 amp relay

Output 2 A

C = Open collector/switched dc

F = Process, 0-5, 1-5, 0 - 1 0VÎ(dc), 0-20mA,

4 - 2 0 mA

K = Solid state Fo rm A 0.5 amp relay

Output 2 B

A = None

C = Open collector/switched dc

F = Process, 0-5, 1-5, 0 - 1 0VÎ(dc), 0-20mA, 4-20mA

K = Solid state Fo rm A 0.5 amp relay

Au x i l i a ry Retransmit Module

0 = None

1 = Single retransmit output 0-5, 1-5, 0 - 1 0VÎ(dc),

0 - 2 0 mA, 4-20mA

2 = Dual retransmit outputs 0-5, 1-5, 0 - 1 0VÎ (dc),

0 - 2 0 mA, 4-20mA

L a n g u age and RTD Option

1 = English with 100Ω RTD

2 = German with 100Ω RTD

3 = French with 100Ω RTD

4 = Spanish with 100Ω RTD

5 = English with 500 and 1KΩ RTD

6 = German with 500 and 1KΩ RTD

7 = French with 500 and 1KΩ RTD

8 = Spanish with 500 and 1KΩ RTD

D i s p l ay and Custom Options

RG = Standard display (Red/Green display only)

XX = Custom options: software, setting parameters, over

lay

North American Sales Offices: Atlanta, (770)972-4948 • Austin, (512)249-1900 • Birmingham, (205)678-2358 • Charlotte, (704)573-8446 •

Chicago, (847)458-1500 • Cincinnati, (513)398-5500 • Cleveland, (330)467-1423 • Dallas, (972)620-6030 • Denver, (303)798-7778 •

Detroit, (248)651-0500 • Eastern Canada, (450)433-1309 • Houston, (281)440-3074 • Indianapolis, (317)575-8932 • Kansas City, (913)897-3973 •

Los Angeles, (714)935-2999 • Louisiana, (318)864-2864 • Maryland/Virginia, (215)345-8130 • Minneapolis/Manitoba, (952)892-9222 •

Nashville, (615)264-6148 • New England, (603)882-1330 • NewYork/New Jersey/Philadelphia, (215)345-8130 • NewYork,Upstate, (716)438-0454 •

Ontario, (905)979-3507 • Orlando, (407)351-0737 • Phoenix, (602)289-6960 • Pittsburgh, (412)322-5004 • Portland, (503)245-9037 •

Raleigh/Greensboro, (336)766-9659 • St. Louis, (314)878-4600 • Sacramento, (707)425-1155 • San Diego, (714)935-2999 •

San Francisco, (408)434-1894 • Seattle, (425)222-4090 • Tampa/St. Petersburg, (407)647-9052 • Tulsa, (918)496-2826 •

Western Canada, (604)444-4881 • Wisconsin, North (920)993-2161 • Wisconsin, South (262)723-5990

Asian Sales Offices: Australia, +61 (3) 9335-6449 • China, +86 (21) 6277-2138 • Japan, +81 (03) 5403-4688 • Korea, +82 (02) 575-9804 •

Malaysia, +60 (4) 641-5977 • Singapore, +65 777-9488 • Taiwan, +886 (0) 7-288-5168 European Sales Offices: France, +33 (01) 3073-2425 •

Germany, +49 (0) 7253-9400-0 • Italy, +39 (02) 458-8841 • United Kingdom, +44 (0) 115-964-0777

Latin American Sales Office: Mexico, +52 (442) 217-6235

Loading...

Loading...