Page 1

EZ-ZONE® RM Multi-Loop Controller

EZ-ZONE® RM High-Density

Modules Integrate

Temperature, Process,

Limit and Power Control

from 1 to 152 Loops Into

One System

SPECIFICATION SHEET

The EZ-ZONE® RM controller family simplifies thermal

system management. The EZ-ZONE RM controller family

is comprised of six module types: an integrated on-off

or PID control, monitoring and over/under temperature

limit module, a high-density on-off or PID control module,

a high-density limit only module, an input/output (I/O)

expansion module, a high-density monitor/scanner

module and a data logging and field communications

access module. A system is configured by connecting

any combination of module types to address specific

application needs. The EZ-ZONE RM is extremely flexible

and scalable allowing mixing and matching of I/O to

configure one to 152 control loops and up to 256 monitor

points.

Optional integrated controller functions can be

combined or ordered in different quantities:

• PID control loops

• Over/under temperature limit control loops

• 10 and 15 ampere power output/heater driver options

• On-board data logging

• Current measurement input

• Sequencer start up and control function

• Programmable timer and counter functions

• Programmable math and logic options

• Multiple communication protocol options

• Mobile configuration with removable secure digital

(SD) flash card

Benefits of using an integrated controller solution:

• Reduces wiring time and termination complexity

compared to connecting multiple discrete products

• Improves system reliability

• Reduces termination and installation cost

• Eliminates compatibility issues often encountered with

using various discrete components and brands

• Reduces troubleshooting time and downtime costs

because the system can specifically identify any

problems with a sensor, controller, solid state relay (SSR)

power output or heater load

• Complete thermal solution saves engineering time and

labor costs while shortening project schedules

Features and Benefits

Multiple inputs; from one to 152 PID loops of control or

monitor up to 256 analog inputs

• Mix and match I/O to fit any application; from one input

with two outputs to 152 analog inputs with 152 outputs,

or monitor up to as many as 256 analog inputs all in

one system

• Reduces cost because only required loops are purchased

• Allows a common controller platform across many

design applications as both loops and outputs can be

ordered in single increments

Advanced PID control algorithm

• Offers TRU-TUNE®+ adaptive control to provide tighter

control for demanding applications

• Enables auto-tune for fast, efficient start-up

Communication capabilities

• Provides a range of protocol options including universal

serial bus (USB) device port, Modbus® RTU, EtherNet/IP™,

Modbus® TCP, DeviceNet™ and PROFIBUS

USB Port

• Provides data log retrieval

SPLIT-RAIL control

• Allows modules mounted in separate high-voltage and

low-voltage cabinets to function as an integrated system

• Minimizes the length and cost of wire runs and improves

system reliability by locating inputs closer to sensors and

outputs closer to loads

AUTO CLONE

• Reduces time and configuration complexity by

automatically building a new module with the same

parameter settings as the replaced module

SENSOR GUARD

• Prevents unplanned process shutdowns and product

loss by switching to a backup sensor if the primary

sensor fails

Page 2

Additional Key Functions

• Configuration communication port (standard bus)

• Removable modules and connectors

• Ring lug and front-screw terminal options

• Profile ramp soak with 400 total steps

• Retransmit and remote set point input virtually inside

controller eliminating costs for input/output hardware

• User configuration settings can be stored and recalled

• Thermistor input

• Elevated operating range of 0 to 149°F (-18 to 65°C)

• UL® listed, CSA, CE, RoHS, W.E.E.E., FM, SEMI F47-0200,

Class 1, Div. 2 rating on selected models

Common Specifications (Applies to all modules)

Line Voltage/Power

• 20.4 to 30.8VAC/VDC, 50/60Hz ±5%

• Any external power supply used should comply with a

Class 2 or SELV rating (see specific module specification

listing for max. VA power consumption)

• Data retention upon power failure via non-volatile memory

• Compliant with Semi F47-0200, Figure R1-1 voltage sag

requirements

Environment

• 0 to 149°F (-18 to 65°C) operating temperature

• -40 to 185°F (-40 to 85°C) storage temperature

• 0 to 90% RH, non-condensing

Functional Operating Range for RMC, RMH, RML

and RMS

Type J: -346 to 2192°F (-210 to 1200°C)

Type K: -454 to 2500°F (-270 to 1371°C)

Type T: -454 to 750°F (-270 to 400°C)

Type E: -454 to 1832°F (-270 to 1000°C)

Type N: -454 to 2372°F (-270 to 1300°C)

Type C: 32 to 4200°F (0 to 2315°C)

Type D: 32 to 4200°F (0 to 2315°C)

Type F: 32 to 2449°F (0 to 1343°C)

Type R: -58 to 3214°F (-50 to 1767°C)

Type S: -58 to 3214°F (-50 to 1767°C)

Type B: 32 to 3300°F (0 to 1816°C)

RTD (DIN): -328 to 1472°F (-200 to 800°C)

Process: -1999 to 9999 units

Agency Approvals

• UL®/EN 61010 Listed, File E185611, C-UL® C22.2

#61010ANSI/ISA 12.12.01-2007 Class 1, Div. 2-Group A, B, C,

D temperature code T4 (optional)

• UL® 1604 Class 1, Div. 2 (optional)

• EN 60529 IP20

• UL® 50, NEMA 4X, EN 60529 IP66; 1/16 DIN remote user

interface (RUI)

• CSA 610110 CE

• RoHS by design, W.E.E.E.

• FM Class 3545 on limit control versions

• CE

Serial Communications

• All modules ship with standard bus protocol for

configuration and communication with all other

EZ-ZONE products

Implicit Messaging

Number of data members accessible through implicit

messaging

Protocol

Ethernet/IP™ 100 20 40 40 20 40 20

DeviceNet™ 200 20 40 40 20 40 20

RM

System

RMC RMH RML RME RMS RMA

User Interface

• Seven-segment LED, address/protocol indicator

programmed via push button switch

• Communication activity, 2 LEDs

• Error condition of each loop, 4 LEDs

• Output status indication, 16 LEDs

Maximum System Configuration

• One access module plus up to 16 additional control or

expansion modules (any combination), up to 152 loops

Mounting

• DIN-rail specification EN50022, 1.38 x 0.30 in.

(35 x 7.5 mm)

• DIN-rail mounted or chassis mounted with customer

supplied screws

Wiring Termination—Touch-Safe Terminals

• Right angle and front screw type terminal blocks

(slots A, B, D, E)

• Input, power and controller output terminals, touch safe,

removable, 12 to 30 AWG

Programmable Application Blocks

Compare

• Greater than, less than, equal, not equal, greater than or

equal, less than or equal

Counters

• Counts up or down, loads predetermined value on the load

signal. Output is active when the count value equals or

exceeds predetermined target value

Linearization

• Interpolated or stepped relationship

Logic

• And, nand, or, nor, equal, not equal, latch, flip flop

Math

• Average, process scale, deviation scale, differential

(subtraction), ratio (divide), add, multiply, absolute

difference, min., max., square root, sample and

hold, altitude and dew point

Process Value

• Sensor backup, average, crossover, wet/dry bulb,

switch over, differential (subtraction), ratio (divide), add,

multiply, absolute difference, min., max., square root,

altitude, visala and dew point

Special Output Function

• Compressor – turns on-off compressor for one or two

loops (cool and dehumidify with single compressor)

• Motorized valve – turns on-off motor open/closed

outputs causing valve to represent desired power level

• Sequencer – turns on-off up to four outputs to

distribute a single power across all outputs with linear

and progressive load wearing

Timers

• On pulse – produces an output of fixed time on the active

edge of timer run signal

• Delay – output is a delayed start of timer run and off at

same time

• One shot – oven timer

• Retentive – measures timer run signal and output on when

accumulated time exceeds target

Variable

• User value for digital or analog variable

Page 3

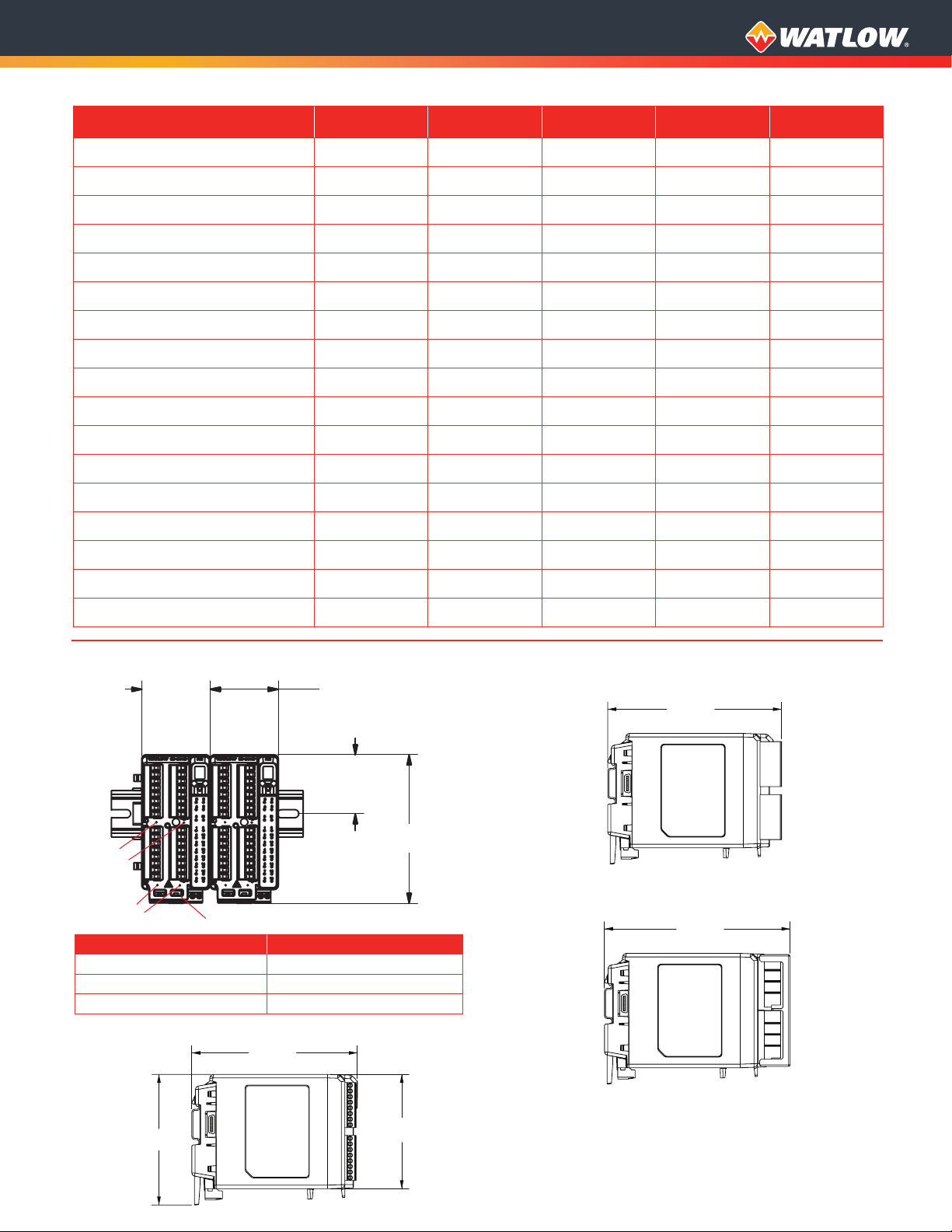

EZ-ZONE RM Family Comparison

Standard Connectors

Standard Connectors

Straight Connectors

5.8 in.

(147.1 mm)

4.57 in.

(116.08 mm)

4 in.

(102 mm)

Standard Connectors

Straight Connectors

Ring Terminal Connectors

5.8 in.

(147.1 mm)

4.57 in.

(116.08 mm)

4 in.

(102 mm)

6.1 in.

(154.4 mm)

Control

Module

Number of modules per system 1 to 16 1 to 16 1 to 16 1 to 16 1 to 16

Number of PID loops per module 1 to 4 4, 8, 12 or 16 0 0 0

Number of limit loops per module 1 to 4 0 4, 8 or 12 0 0

Number of monitoring points per module 1 to 3 0 0 0 4, 8, 12 or 16

Mechanical relays per module 1 to 8 4 or 8 4, 6 or 8 4, 8 or 12 4 or 8

Digital I/O points per module 6 6 or 12 6 or 7 6, 12, 18 or 24 6, 7 or 12

Actions (events) per module 8 24 16 8 16

Alarms per module 8 24 16 8 16

Compare per module 4 24 16 8 24

Counters per module 4 24 16 8 24

Linearization per module 4 24 16 8 24

Logic per module 16 24 16 16 24

High-Density

Control Module

High-Density

Limit Module

Expansion

Module

High-Density

Scanner Module

Math per module 8 24 16 8 24

Process value per module 1 to 4 4, 8, 12 or 16 4, 8 or 12 0 4, 8, 12 or 16

Special output function per module 4 0 0 4 0

Timers per module 4 24 16 8 24

Variable per module 16 24 16 16 24

Dimensional Drawings

2.03 in.

Slot D

Slot E

Slot A

Slot B

(51.56 mm)

Slot C

Add 2.03 in.

(51.56 mm) per module

Connector Type Module Depth in. (mm)

Standard (Right Angle) 5.8 (148)

Straight (Front Screw) 6.1 (155)

Ring Terminal 6.5 (166)

Standard Connectors

5.8 in.

(147.1 mm)

1.75 in.

(44.45 mm)

4.41 in.

(112.04 mm)

Front-Screw Connectors

Ring Terminal Connectors

6.1 in.

(154.4 mm)

6.5 in.

(164.9 mm)

4.57 in.

(116.08 mm)

4 in.

(102 mm)

Page 4

Control Module Specifications (RMC)

(Select an RMC module for 1 to 4 loops of control.)

Line Voltage/Power

• Power consumption: 7 W, 14VA

• Any external power supply used should comply with a

Class 2 or SELV rating

Controller

• User-selectable heat/cool, on-off, P, PI, PD, PID or alarm

action, not valid for limit controllers

Process PID or Over-temperature Limit Mode Options

• Auto-tune with TRU-TUNE+ adaptive control

• Control sampling rates: input = 10Hz, output = 10Hz

(non-divisional)

Isolated Serial Communications

• All modules ship with standard bus protocol for

configuration and communication with all other EZ-ZONE

controllers

• Optional EIA 485, Modbus® RTU

Profile Ramp and Soak (RMC only, not available with

high-density controller)

• Profile engine affects one to four loops

• 25 profiles and 15 sub-routines, 400 steps total

• Option for battery backup and real time clock is via the

access module

Calibration Accuracy

• ±0.1% of span, ±1°C. See user manual for details.

Universal Input

• Thermocouple, grounded or ungrounded sensors

• >20MΩ input impedance

• Max. of 2kΩ source resistance

• RTD 2- or 3-wire, platinum, 100Ω and 1000Ω @ 32°F (0°C)

calibration to DIN curve (0.00385Ω/Ω/°C)

• Process, 0-20mA @100Ω, or 0-10VDC @ 20kΩ input

impedance; scalable, 0-50mV

• Potentiometer: 0 to 1,200Ω

• Inverse scaling

• Current: input range is 0 to 50mA, 100Ω input impedance

Response time: 1 second max., accuracy ±1mA typical

Thermistor Input

• 0 to 40kΩ, 0 to 20kΩ, 0 to 10kΩ, 0 to 5kΩ

• 2.252kΩ and 10kΩ base at 77°F (25°C)

Digital Input

• Update rate 10Hz

• Max. input 36VDC at 3mA

• Min. high state 3VDC at 0.25mA

• Max. low state 2V

Dry Contact Input

• Update rate 10Hz

• Min. open resistance 10kΩ, max. closed resistance 50Ω

Current Measurement Input

• Accepts 0-50mA signal (user programmable range)

• Displayed operating range and resolution can be scaled

and are user programmable

Output Hardware

• Switched dc:

• Max. 32VDC open circuit

• Max. current 30mA per single output

• Max. current 40mA per paired outputs (1 & 2, 3 & 4,

5 & 6, 7 & 8)

• Open collector:

• Max. 30VDC @ 100mA

• 6 digital inputs/outputs:

• Switched dc, max. 20VDC @ 40mA, 12VDC @ 80mA

• Open collector, max. 32VDC @ 1.5A, max. 8A per 6

outputs combined

• SSR, Form A, 1A at 50°F (10°C) to 0.5A at 149°F (65°C), 0.5A

@ 24VAC min., 264VAC max., opto-isolated, without contact

suppression

• Electromechanical relay, Form C, 5A, 24 to 240VAC or

30VDC max., resistive load, 100,000 cycles at rated load,

requires a min. load of 20mA at 24V, 125VA pilot duty

• Electromechanical relay, Form A, 5A, 24 to 240VAC or

30VDC max., resistive load, 100,000 cycles at rated load,

requires a min. load of 20mA at 24V, 125VA pilot duty

• NO-ARC relay, Form A, 15A @ 122°F (50°C),

85 to 264VAC, no VDC, resistive load, 2 million

cycles at rated load

• Universal process/retransmit, output range selectable:

• 0 to 10VDC ±15mV into a min. 1,000Ω load with 2.5mV

nominal resolution

• 0 to 20mA ±30µA into max. 800Ω load with 5µA

nominal resolution

• Temperature stability is 100ppm/°C

Page 5

Control Module Ordering Information

Requires 24 to 28VDC power supply, includes communication port for configuration with EZ-ZONE configurator and PC.

Part Number

① ②

EZ-ZONE

Rail

Mount

RM

④

1 =

2 =

3 = Ramp/Soak control with universal input (R/S applies to all loops in module)

4 = Ramp/Soak control with thermistor input (R/S applies to all loops in module)

5 =

6 =

7 =

9 =

⑤

A =

B =

U =

D =

E =

F =

G =

H =

J =

K =

L =

M =

N =

P =

R =

S =

T = None

Y =

Z =

⑥

A = None

1 = Control with universal input

2 = Control with thermistor input

5 = Limit with universal input (only valid Output 3 and 4, options will be B, F, L)

6 =

7 =

R = Auxiliary 2nd input (universal input)

P = Auxiliary 2nd input (thermistor input)

⑦

A =

B =

U =

D =

E =

F =

G =

H =

J =

K =

L =

M =

N =

P =

R =

S =

T = None

Y =

Z =

⑧

A = None

1 = Control with universal input

2 = Control with thermistor input

5 =

6 =

7 =

R = Auxiliary 2nd input (universal input)

P = Auxiliary 2nd input (thermistor input)

③

④

Input 1

Control

Module

Primary

Function

C

Control with universal input

Control with thermistor input

Limit with universal input (only valid Output 1 and 2, options will be

B, F, L)

Limit with thermistor input

B, F, L)

Current transformer input (not valid Output 1 and 2, options are A, B,

N, P, R, S, T)

Custom

Output 1 and 2 Hardware Options

None

None Mechanical relay 5A, Form A

Switched dc/open collector

Switched dc/open collector NO-ARC 15A power control

Switched dc/open collector Switched dc

Switched dc/open collector Mechanical relay 5A, Form A

Switched dc/open collector SSR Form A, 0.5A

Mechanical relay 5A, Form C

Mechanical relay 5A, Form C NO-ARC 15A power control

Mechanical relay 5A, Form C Switched dc

Mechanical relay 5A, Form C Mechanical relay 5A, Form A

Mechanical relay 5A, Form C SSR Form A, 0.5A

Universal process

Universal process Switched dc

Universal process Mechanical relay 5A, Form A

Universal process SSR Form A, 0.5A

SSR Form A, 0.5A NO-ARC 15A power control

SSR Form A, 0.5A SSR Form A, 0.5A

Limit with thermistor input (only valid Output 3 and 4, options will be B, F, L)

Current transformer input (not valid Output 3 and 4, options are N, P, R, S)

None

None Mechanical relay 5A, Form A

Switched dc/open collector

Switched dc/open collector NO-ARC 15A power control

Switched dc/open collector Switched dc

Switched dc/open collector Mechanical relay 5A, Form A

Switched dc/open collector SSR Form A, 0.5A

Mechanical relay 5A, Form C

Mechanical relay 5A, Form C NO-ARC 15A power control

Mechanical relay 5A, Form C Switched dc

Mechanical relay 5A, Form C Mechanical relay 5A, Form A

Mechanical relay 5A, Form C SSR Form A, 0.5A

Universal process

Universal process Switched dc

Universal process Mechanical relay 5A, Form A

Universal process SSR Form A, 0.5A

SSR Form A, 0.5A NO-ARC 15A power control

SSR Form A, 0.5A SSR Form A, 0.5A

Limit with universal input (only valid Output 5 and 6, options will be B, F, L)

Limit with thermistor input (only valid Output 5 and 6, options will be B, F, L)

Current transformer input (not valid Output 5 and 6, options are N, P, R, S)

Output 1 Output 2

Output 3 and 4 Hardware Options

Output 3 Output 4

⑤

Output 1 and

2 Hardware

Options

Input 1 Primary Function

(only valid Output 1 and 2, options will be

Input 2

Input 3

⑥

Input 2

None

None

None

None

SSR Form A, 0.5A

None

None

None

None

SSR Form A, 0.5A

⑦

Output 3 and

4 Hardware

Options

Input 3

⑧

⑨

Output 5 and

6 Hardware

Options

⑨

A =

None

B =

None Mechanical relay 5A, Form A

U =

Switched dc/open collector

D =

Switched dc/open collector NO-ARC 15A power control

E =

Switched dc/open collector Switched dc

F =

Switched dc/open collector Mechanical relay 5A, Form A

G =

Switched dc/open collector SSR Form A, 0.5A

H =

Mechanical relay 5A, Form C

J =

Mechanical relay 5A, Form C NO-ARC 15A power control

K =

Mechanical relay 5A, Form C Switched dc

L =

Mechanical relay 5A, Form C Mechanical relay 5A, Form A

M =

Mechanical relay 5A, Form C SSR Form A, 0.5A

N =

Universal process

P =

Universal process Switched dc

R =

Universal process Mechanical relay 5A, Form A

S =

Universal process SSR Form A, 0.5A

T = None

Y =

SSR Form A, 0.5A NO-ARC 15A power control

Z =

SSR Form A, 0.5A SSR Form A, 0.5A

⑩

A = None

1 = Control with universal input

2 = Control with thermistor input

5 = Limit with universal input (only valid Output 7 and 8, options will be B, F, L)

6 = Limit with thermistor input (only valid Output 7 and 8, options will be

B, F, L)

7 = Current transformer input (not valid Output 7 and 8, options are N, P, R, S)

R = Auxiliary 2nd input (universal input)

P = Auxiliary 2nd input (thermistor input)

⑪

A =

None

B =

None Mechanical relay 5A, Form A

U =

Switched dc/open collector

D =

Switched dc/open collector NO-ARC 15A power control

E =

Switched dc/open collector Switched dc

F =

Switched dc/open collector Mechanical relay 5A, Form A

G =

Switched dc/open collector SSR Form A, 0.5A

H =

Mechanical relay 5A, Form C

J =

Mechanical relay 5A, Form C NO-ARC 15A power control

K =

Mechanical relay 5A, Form C Switched dc

L =

Mechanical relay 5A, Form C Mechanical relay 5A, Form A

M =

Mechanical relay 5A, Form C SSR Form A, 0.5A

N =

Universal process

P =

Universal process Switched dc

R =

Universal process Mechanical relay 5A, Form A

S =

Universal process SSR Form A, 0.5A

T = None

Y =

SSR Form A, 0.5A NO-ARC 15A power control

Z =

SSR Form A, 0.5A SSR Form A, 0.5A

C =

6 digital inputs/outputs (valid option only if Input 4 selection =

⑫

A = Right angle screw connector (standard)

F = Front screw connector (slots A, B, D and E only)

⑬

A = Standard bus

1 =

Standard bus and Modbus® RTU 485 (selectable via dipswitch)

⑭

⑮

Firmware, Overlays, Parameter Settings

AA =

Standard

Replacement connectors hardware only for the entered part number.

AB =

Additional cost for the model can be disregarded as you are only

ordering replacement connectors.

12 =

Class 1, Div. 2 (not available with integrated limit controller or

mechanical relay options)

Custom

XX =

⑩

⑪

Output 7 and

Input 4

Options

Output 5 and 6 Hardware Options

Output 5 Output 6

Output 7 and 8 Hardware Options

Output 7 Output 8

8 Hardware

Connector

Input 4

Connector Style

Enhanced Options

Additional Options

⑫

⑬

Enhanced

Style

None

None

None

None

SSR Form A, 0.5A

None

None

None

None

SSR Form A, 0.5A

Options

⑭ ⑮

Additional

Options

A)

Page 6

High-Density Control Module Specifications (RMH)

(Select an RMH module for 4 to 16 loops of control.)

Line Voltage/Power

• Power consumption: 7 W, 14VA

• Any external power supply used should comply with a

Class 2 or SELV rating

Controller

• User-selectable heat/cool, on-off, P, PI, PD, PID or alarm

action, not valid for limit controllers

Process PID Options

• Auto-tune with TRU-TUNE+ adaptive control

• Control sampling rates: input = 10Hz, output = 10Hz

(non-divisional)

Isolated Serial Communications

• All modules ship with standard bus protocol for

configuration and communication with all other

EZ-ZONE controllers

• Optional EIA 485, Modbus® RTU

Calibration Accuracy

• ±0.1% of span, ±1°C. See user manual for details.

Universal Input

• Thermocouple, grounded or ungrounded sensors

• >20MΩ input impedance

• Max. of 2kΩ source resistance

• RTD 2-wire, platinum, 100Ω and 1000Ω @ 32°F (0°C)

calibration to DIN curve (0.00385Ω/Ω/°C)

• Process, 0-20mA @100Ω, or 0-10VDC @ 20kΩ input

impedance; scalable, 0-50mV

Thermistor Input

• 0 to 40kΩ, 0 to 20kΩ, 0 to 10kΩ, 0 to 5kΩ

• 2.252kΩ and 10kΩ base at 77°F (25°C)

Digital Input

• Update rate 10Hz

• Max. input 36VDC at 3mA

• Min. high state 3VDC at 0.25mA

Dry Contact Input

• Update rate 10Hz

• Min. open resistance 10kΩ, max. closed resistance 50Ω

Output Hardware

• 6 digital inputs/outputs:

• Switched dc, max. 20VDC @ 40mA, 12VDC @ 80mA

• Open collector, max. 32VDC @ 1.5A, max. 8A per

6 outputs combined

• Electromechanical relay, Form A, 5A, 24 to 240VAC or

30VDC max., resistive load, 100,000 cycles at rated load,

requires a min. load of 20mA at 24V, 125VA pilot duty

Tri-Process (Three universal process/retransmit outputs)

• Output range selections: 0 to 10VDC into a min. 4KΩ

load

• 0 to 20mA into max. 400Ω load

Quad SSR

• Four SSRs at 2A each. SSRs are grouped in 2-pairs with

each sharing a common. See table below.

Maximum Current Per Relay

Ambient Temp.

-18 to 20°C 2A 1.5A

20 to 65°C 1A 0.75A

1 Quad SSR Card

More than 1 Quad

SSR Card

High-Density Control Module Ordering Information

Requires 24 to 28VAC/VDC power supply, includes communication port for configuration with EZ-ZONE configurator and PC.

Part Number

① ②

EZ-ZONE

Rail

Mount

RM

④

A = Right angle screw connector (standard)

F = Front screw connector

S = Custom

⑤

1 = 4 universal inputs (T/C, RTD 2-wire, 0-10VDC, 0-20mA)

2 = 4 thermistor inputs with control loops

⑥

A = None

1 = 4 universal inputs (T/C, RTD 2-wire, 0-10VDC, 0-20mA)

2 = 4 thermistor inputs with control loops

⑦

A = None

1 =

2 = 4 thermistor inputs with control loops

C = 6 digital I/O

F = 3 universal process/retransmit outputs

J = 4 mechanical relay 5A, Form A

L = 4 SSR’s at 2A each. SSR’s grouped in 2-pairs with each pair

③

Control

Module

④

Connector

Style

H

Connector Style/Custom Product

with control loops

with control loops

4 universal inputs (T/C, RTD 2-wire, 0-10VDC, 0-20mA) with

control loops

sharing a common

⑤

Slot A

-

Slot A

Slot B

Slot D

⑥

Slot B⑦Slot D⑧Slot E

⑨

Future

Option

A

-

⑧

A = None

1 =

2 = 4 thermistor inputs with control loops

C = 6 digital I/O

F = 3 universal process/retransmit outputs

J = 4 mechanical relay 5A, Form A

L = 4 SSR’s at 2A each. SSR’s grouped in 2-pairs with each pair

⑩

A = Standard bus

1 =

⑪

Firmware, Overlays, Parameter Settings

AA =

AB = Replacement connectors hardware only for the entered

XX =

⑩

Enhanced

Options

4 universal inputs (T/C, RTD 2-wire, 0-10VDC, 0-20mA) with

control loops

sharing a common

Standard bus and Modbus® RTU 485 (user-selectable)

⑫

Standard

part number

Custom

⑪ ⑫

Additional

Options

Slot E

Enhanced Options

Additional Options

Page 7

High-Density Limit Module Specifications (RML)

(Select an RML module for 4 to 12 safety limits.)

Line Voltage/Power

• Power consumption: 7 W, 14VA

• Any external power supply used should comply with a

Class 2 or SELV rating

Isolated Serial Communications

• All modules ship with standard bus protocol for

configuration and communication with all other

EZ-ZONE controllers

• Optional EIA 485, Modbus® RTU

Calibration Accuracy

• ±0.1% of span, ±1°C. See user manual for details

Universal Input

• Thermocouple, grounded or ungrounded sensors

• >20MΩ input impedance

• Max. of 2kΩ source resistance

• RTD 2-wire, platinum, 100Ω and 1000Ω @ 32°F (0°C)

calibration to DIN curve (0.00385Ω/Ω/°C)

• Process, 0-20mA @100Ω, or 0-10VDC @ 20kΩ input

impedance; scalable, 0-50mV

Thermistor Input

• 0 to 40kΩ, 0 to 20kΩ, 0 to 10kΩ, 0 to 5kΩ

• 2.252kΩ and 10kΩ base at 77°F (25°C)

Digital Input

• Update rate 10Hz

• Max. input 36VDC at 3mA

• Min. high state 3VDC at 0.25mA

Dry Contact Input

• Update rate 10Hz

• Min. open resistance 10kΩ, max. closed resistance 50Ω

Output Hardware

• 6 digital inputs/outputs:

• Switched dc, max. 20VDC @ 40mA, 12VDC @ 80mA

• Open collector, max. 32VDC @ 1.5A, max. 8A per

6 outputs combined

• Electromechanical relay, Form A, 5A, 24 to 240VAC or

30VDC max., resistive load, 100,000 cycles at rated load,

requires a min. load of 20mA at 24V, 125VA pilot duty

High-Density Limit Module Ordering Information

Requires 24 to 28VAC/VDC power supply, includes communication port for configuration with EZ-ZONE configurator and PC.

Part Number

① ②

EZ-ZONE

Rail

Mount

RM

④

A = Right angle screw connector (standard)

F = Front screw connector

S = Custom

⑤

5 = 4 universal inputs (T/C, RTD 2-wire, 0-10VDC, 0-20mA) with limit

6 = 4 thermistor inputs with limit control loops

⑥

A = None

5 = 4 universal inputs (T/C, RTD 2-wire, 0-10VDC, 0-20mA) with limit

6 = 4 thermistor inputs with limit control loops

⑦

A = None

5 = 4 universal inputs (T/C, RTD 2-wire, 0-10VDC, 0-20mA) with limit

6 = 4 thermistor inputs with limit control loops

J = 4 mechanical relay 5A, Form A

C = 6 digital I/O*

③

Limit

Module

L

control loops

control loops

control loops

④

Connector

Style

Connector Style/Custom Product

⑤

Slot A

- -

Slot A

Slot B

Slot D

⑥

Slot B⑦Slot D⑧Slot E

⑨

Future

Option

A

B =

A = Standard bus

Firmware, Overlays, Parameter Settings

AA =

* Reset limits via digital input, EZ key on RUI or communications commands

⑩

Enhanced

Options

⑧

J = 4 mechanical relay 5A, Form A

1 digital input and 2 mechanical relays, 5A (1 Form A and

1 Form C)*

⑩

1 =

Standard bus and Modbus® RTU 485* (user-selectable)

⑪

⑫

Standard

AB = Replacement connectors hardware only for the entered part

number.

XX =

Custom

⑪ ⑫

Additional

Options

Slot E

Enhanced Options

Additional Options

Page 8

Expansion Module Specifications (RME)

(Select an RME module for additional inputs and outputs

and higher amperage outputs.)

Line Voltage/Power

• Power consumption: 7 W, 14VA

• Any external power supply used should comply with a

Class 2 or SELV rating

Serial Communications

• All modules ship with standard bus protocol for

configuration and communication with all

other EZ-ZONE products

Wiring Termination—Touch Safe Terminals

• Right angle and front-screw type terminal blocks

(slots A, B, D, E)

• Input, power and controller output terminals, touch

safe, removable, 12 to 30 AWG

• Ring lug terminal blocks (slots A and D only)

• Input, power and controller output terminals are

touch safe and removable

Digital Input

• Update rate 10Hz

• Max. input 36VDC at 3mA

• Min. high state 3VDC at 0.25mA

Dry Contact

• Min. open resistance 100kΩ

• Max. closed resistance 50Ω

Output Hardware (6 digital inputs/outputs)

• Update rate 10Hz

• Switched dc

• Output voltage 20VDC max.

• Max. supply current source 40mA at 20VDC and 80mA

at 12VDC

• Open collector

• Switched voltage max. 32VDC

• Max. switched current per output 2.5A

• Max. switched current for all six outputs combined 10A

Dual Solid State Relay

• Two SSR board option, Form A, 10A max. each

SSRs combined @ 24VAC min., 264VAC max.,

opto-isolated, without contact suppression, max. resistive

load 10A per output at 240VAC, max. 20A per card at 122°F

(50°C), max. 12A per card at 149°F (65°C)

Four Mechanical Relay

• Four electro mechanical relays, Form A, 5A, 24 to

240VAC or 30VDC max., resistive load, 100,000 cycles at

rated load. Requires a min. load of 20mA at 24V, 125VA

pilot duty

Tri-Process (Three universal process/retransmit outputs)

• Output range selections: 0 to 10VDC into a min. 4KΩ load

• 0 to 20mA into max. 400Ω load

Quad SSR

• Four SSRs at 2A each. SSRs are grouped in 2-pairs with each

sharing a common.

Maximum Current Per Relay

Ambient Temp.

-18 to 20°C 2A 1.5A

20 to 65°C 1A 0.75A

1 Quad SSR Card

More than 1 Quad

SSR Card

Expansion Module Ordering Information

Requires 24 to 28VDC power supply, includes communication port for configuration with EZ-ZONE configurator and PC.

Part Number

① ②

EZ-ZONE

Rail

Mount

RM

④

A = Right angle screw connector (standard)

F = Front screw connector (slots A, B, D and E only)

R = Ring lug connector (if ordered then slots B and E must be =A)

S = Custom

⑤

A = None

C = 6 digital I/O

F = 3 universal process/retransmit outputs

J = 4 mechanical relay 5A, Form A

K =

2 SSRs, Form A, 10A max. each (if ordered, then slot B must

be =A)

L =

4 SSR’s at 2A each. SSR’s grouped in 2-pairs with each pair

sharing a common

T =

Quad inputs for external current transformers. Can do either

single-phase or three-phase system measurement for all

hardware outputs ordered within the expansion module.

⑥

A = None

C = 6 digital I/O

F = 3 universal process/retransmit outputs

J = 4 mechanical relay 5A, Form A

L = 4 SSR’s at 2A each. SSR’s grouped in 2-pairs with each pair

sharing a common

T = Quad inputs for external current transformers. Can do either

single-phase or three-phase system measurement for all

hardware outputs ordered within the expansion module.

③

Expansion

Module

E

④

Connector

Style

Connector Style/Custom Product

⑤

Slot A

-

Slot A

Slot B

⑥

Slot B⑦Slot D⑧Slot E

⑨ ⑩

Future

Options

AA

-

⑦

A = None

C = 6 digital I/O

F = 3 universal process/retransmit outputs

J = 4 mechanical relay 5A, Form A

K =

L = 4 SSR’s at 2A each. SSR’s grouped in 2-pairs with each pair

T = Quad inputs for external current transformers. Can do either

⑧

A = None

C = 6 digital I/O

F = 3 universal process/retransmit outputs

L =

T =

⑪

Firmware, Overlays, Parameter Settings

AA =

AB = Replacement connectors hardware only for the entered part

12 =

XX =

⑪ ⑫

Additional

Options

Slot D

2 SSRs, Form A, 10A max. each (if ordered, then slot E must

be = A)

sharing a common

single-phase or three-phase system measurement for all

hardware outputs ordered within the expansion module.

Slot E

4 SSR’s at 2A each. SSR’s grouped in 2-pairs with

each pair sharing a common

Quad inputs for external current transformers. Can do either

single-phase or three-phase system measurement for all

hardware outputs ordered within the expansion module.

⑫

Standard

number. Additional cost for the model can be disregarded as

you are only ordering replacement connectors.

Class 1, Div. 2 (not available with integrated limit controller or

mechanical relay options)

Custom

Additional Options

Page 9

High-Density Scanner Module Specifications (RMS)

(Select an RMS module for 4 to 16 auxiliary analog inputs.)

Line Voltage/Power

• Power consumption: 7 W, 14VA

• Any external power supply used should comply with a

Class 2 or SELV rating

Isolated Serial Communications

• All modules ship with standard bus protocol for

configuration and communication with all EZ-ZONE

controllers

• Optional EIA 485, Modbus® RTU

Calibration Accuracy

• ±0.1% of span, ±1°C. See user manual for details.

Universal Input

• Thermocouple, grounded or ungrounded sensors

• >20MΩ input impedance

• Max. of 2kΩ source resistance

• RTD 2-wire, platinum, 100Ω and 1000Ω @ 32°F (0°C)

calibration to DIN curve (0.00385Ω/Ω/°C)

• Process, 0-20mA @100Ω, or 0-10VDC @ 20kΩ input

impedance; scalable, 0-50mV

Thermistor Input

• 0 to 40kΩ, 0 to 20kΩ, 0 to 10kΩ, 0 to 5kΩ

• 2.252kΩ and 10kΩ base at 77°F (25°C)

Digital Input

• Update rate 10Hz

• Max. input 36VDC at 3mA

• Min. high state 3VDC at 0.25mA

Dry Contact Input

• Update rate 10Hz

• Min. open resistance 10kΩ, max. closed resistance 50Ω

Output Hardware

• 6 digital inputs/outputs:

• Switched dc, max. 20VDC @ 40mA, 12VDC @ 80mA

• Open collector, max. 32VDC @ 1.5A, max. 8A per

6 outputs combined

• Electromechanical relay, Form A, 5A, 24 to 240VAC or

30VDC max., resistive load, 100,000 cycles at rated load,

requires a min. load of 20mA at 24V, 125VA pilot duty

High-Density Scanner Module Ordering Information

Requires 24 to 28VAC/VDC power supply, includes communication port for configuration with EZ-ZONE configurator and PC.

Part Number

① ②

EZ-ZONE

Rail

Mount

RM

④

A = Right angle screw connector (standard)

F = Front screw connector

S = Custom

⑤

R =

P = 4 thermistor inputs without control loops

⑥

A =

R = 4 universal inputs (T/C RTD 2-wire, 0-10VDC, 0-20mA) without

P =

⑦

A = None

R =

P = 4 thermistor inputs without control loops

C = 6 digital I/O

F = 3 universal process/retransmit outputs

J = 4 mechanical relay 5A, Form A

L = 4 SSR’s at 2A each. SSR’s grouped in 2-pairs with each pair

③

Scanner

Module

④

Connector

Style

S

Connector Style/Custom Product

4 universal inputs (T/C, RTD 2-wire, 0-10VDC, 0-20mA) without

control loops

None

control loops

4 thermistor inputs without control loops

4 universal inputs (T/C RTD 2-wire, 0-10VDC, 0-20mA) without

control loops

sharing a common

⑤

Slot A

- -

Slot A

Slot B

Slot D

⑥

Slot B⑦Slot D⑧Slot E

⑨

Future

Option

A

⑧

A = None

R =

P = 4 thermistor inputs without control loops

B = 1 digital input and 2 mechanical relays, 4A

C = 6 digital I/O

F = 3 universal process/retransmit outputs

J = 4 mechanical relay 5A, Form A

L = 4 SSR’s at 2A each. SSR’s grouped in 2-pairs with

⑩

A = Standard bus

1 =

⑪

Firmware, Overlays, Parameter Settings

AA =

AB = Replacement connectors hardware only for the entered

XX =

⑩

Enhanced

Options

4 universal inputs (T/C RTD 2-wire, 0-10VDC, 0-20mA) without

control loops

each pair sharing a common

Standard bus and Modbus® RTU 485 (user-selectable)

⑫

Standard

part number

Custom

⑪ ⑫

Additional

Options

Slot E

Enhanced Options

Additional Options

Page 10

Access Module Specifications (RMA)

(Select an RMA module for communication protocol

options, datalogging and automatic configuration backup.)

Line Voltage/Power

• Power consumption: 4 W, 9VA

• Any external power supply used should comply with a

Class 2 or SELV rating

Isolated Serial Communications

• All modules ship with standard bus protocol for

configuration and communication connection to all

EZ-ZONE products

Additional Communication Options

• EIA 232/485, Modbus® RTU

• EtherNet/IP™, Modbus® TCP, 10 BASE-T/100 BASE-TX

• DeviceNet™

• PROFIBUS DP (future option, contact factory)

• USB, controller recognized as a device

Note: If an access module is present, all other modules must

have Modbus® disabled in order to achieve communications

with all of the modules.

USB

• USB 1.1 device only

• Mini USB connector type

• Recognized as a mass storage device

Real Time Clock with Battery Backup

• Accuracy (typical): +/- 30ppm at 77°F (25°C)

• +30/-100ppm overtemperature operating range

• Battery type and typical lifetime rating: 10 years at

77°F (25°C)

• Lithium battery used, recycle properly

Data Logging

• 200 points

• File storage on-board module

• Comma separated value (CSV) file type

• Export files via removable SD micro memory card or

USB communications port

Memory Card

• Removable SD micro card

• 2G SD memory card provided, also accepts other storage

space amounts

• -4 to 185°F (-20 to 85°C) ambient rating, non-volatile

memory

• Information access to configuration files and the ability to

store module auto-configuration settings and datalog files

if options have been ordered

Auto-configuration File Backup

• Limited memory can support up to four modules

• Limited memory is fixed on board

• Unlimited memory can support up to 16 modules

• Unlimited memory utilizes removable SD micro

card option

Note: All module parameters are backed up in memory

except for USER SET 1 and USER SET 2 parameter settings and

address.

Access Module Ordering Information

Requires 24 to 28VDC power supply, includes communication port for configuration with EZ-ZONE configurator and PC.

Part Number

① ②

EZ-ZONE

Rail

Mount

RM

④

A = Right angle screw connector (standard)

F = Front screw connector (slots B, and E only)

S = Custom

⑤

A = Standard

⑥

A = None

2 = Modbus® RTU 232/485

3 = EtherNet/IP™, Modbus®/TCP

5 = DeviceNet™

6 = PROFIBUS DP

⑦

A = None

B = Battery backup and real time clock for profile ramp and soak

⑧ System Configuration and Data Logging Options

Order

Option

A

B

Y

D

③

Access

Module

④

Connector

Style

A

Communications Options

Ramp/Soak Functions

Limited Auto-

Configuration

USB “Device”

Communication

✓

✓ ✓

File Backup for

Up to

4 Modules

✓

⑤

Future

Option

A

-

Connector Style

Future Option

Unlimited Auto-

Configuration

File Backup

for Up to

16 Modules

✓

✓

⑥

Comms.

Options

On-Board Data

✓ ✓

Ramp/

Functions

Logging

⑦

Soak

System Config.

& Data Logging

Options

Mobile Data

(2G SD Card)

✓

✓

⑧

⑨ ⑩

Future

Options

AA

-

USB Device Configuration: USB access to configuration files (and data log

files if data logging option is ordered) stored via on-board SD memory card.

PC access to product via standard bus protocol.

Auto-Configuration Backup: Limited fixed on board memory can support

backing up configuration files for a maximum of four modules. The unlimited

option utilizes a SD memory card to enable configuration file backup for up

to 16 modules. Feature can be used for cloning configuration files to multiple

modules or for easy field replacement to limit downtime.

Data Logging: Data log files stored on 2G SD memory card. Data files can

be exported via USB communication port transfer or removing SD card into

external card reader. Watlow reserves the right to ship a larger memory

amount at any point in time.

Mobile Data: Transfer configuration files (and data logging files

if data logging option is ordered) via removable SD memory card.

⑪

⑫

Firmware, Overlays, Parameter Settings

AA =

Standard

AB = Replacement connectors hardware only for the entered part

number. Additional cost for the model can be disregarded as

you are only ordering replacement connectors.

12 =

Class 1, Div. 2 (not available with integrated limit controller or

mechanical relay options)

XX =

Custom

⑪ ⑫

Additional

Options

Additional Options

Page 11

Compatible Accessories

Specifications for Basic Remote User Interface (RUI) EZKB

Operator Interface

• Dual 4 digit, 7 segment LED displays

• Forward, backward, up and down keys plus a customer

programmable function key - EZ key

• Typical display update rate: 1Hz

• Agency approved to IP65/NEMA 4X

• Standard bus ships with all units. Options: EIA 232/485

Modbus® RTU, EtherNet/IP™/TCP Modbus® or DeviceNet™,

PROFIBUS DP

Line Voltage/Power

• 100 to 240VAC, +10/-15%; (85-264VAC) 50/60Hz, ±5%

• 24VAC/VDC, +10/-15%; 50/60Hz, ±5%

2.05 in.

(52.07 mm)

2.05 in.

(52.07 mm)

EZ-ZONE Configurator Software

The EZ-ZONE configurator software is used to set up Watlow

EZ-ZONE products in one simple process. It works without

requiring the purchase of any communication options because

it uses the standard bus communications protocol that is

included with all EZ-ZONE products. EZ-ZONE configurator

can be used for on-line and off-line configurations and

downloading previously saved setups. It is available as a

FREE download at www.watlow.com.

SpecView

Basic RUI

Front View

Depth Dimensions for RUI: long case 4 in. (101.6 mm),

short case 2.33 in. (59.10 mm)

COMPOSER® with INTUITION®

COMPOSER® with INTUITION® is Watlow’s new software

for configuring F4T and EZ-ZONE RM controllers. It is used

to set up functions such as control loops, profiles and

alarms and link them to controller inputs and outputs.

COMPOSER can be used to edit and save configurations

while communicating with controllers and to download

previously saved setups. It works without requiring the

purchase of any communication options and is available

as a FREE download at www.watlow.com.

SpecView is designed for industrial users and includes

features such as data logging, trending and support for bar

code readers and touch screens. Errors are reduced for any

process by creating application-specific screens. The software

provides a historical replay option, easy-to-use recipe

features and remote access options, including LAN, internet

and modem.

Operator Interface Terminals (OIT)

Silver Series touchscreen operator interface terminals provide a

customizable user interface and log and graph data for Watlow

controllers and other devices. A Silver Series operator interface

terminal, paired with Watlow controllers, is the perfect solution

for industrial processes or machine control applications.

Page 12

Accessories (continued)

Power Supplies

• AC/DC power supply converter 90-264VAC to

24VDC volts.

• P/N 0847-0299-0000 – 31 W

• P/N 0847-0300-0000 – 60 W

• P/N 0847-0301-0000 – 91 W

EZ-ZONE RM Product Documentation

• User’s manual – electronic DVD P/N 0601-0001-0000

• Table of manuals in various languages (see below)

User Documentation RMC RMH RML RME RMS RMA

English 0600-0070-0000 0600-0074-0000 0600-0075-0000 0600-0073-0000 0600-0071-0000 0600-0072-0000

German 0600-0070-0001 0600-0074-0001 0600-0075-0001 0600-0073-0001 0600-0071-0001 0600-0072-0001

Japanese 0600-0070-0002 0600-0074-0002 0600-0075-0002 0600-0073-0002 0600-0071-0002 0600-0072-0002

Korean 0600-0070-0003 0600-0074-0003 0600-0075-0003 0600-0073-0003 0600-0071-0003 0600-0072-0003

French 0600-0070-0004 0600-0074-0004 0600-0075-0004 0600-0073-0004 0600-0071-0004 0600-0072-0004

Italian 0600-0070-0005 0600-0074-0005 0600-0075-0005 0600-0073-0005 0600-0071-0005 0600-0072-0005

Spanish 0600-0070-0006 0600-0074-0006 0600-0075-0006 0600-0073-0006 0600-0071-0006 0600-0072-0006

Chinese

0600-0070-0007 0600-0074-0007 0600-0075-0007 0600-0073-0007 0600-0071-0007 0600-0072-0007

Watlow®, EZ-ZONE®, TRU-TUNE®, COMPOSER®, and INTUITION® are registered

trademarks of Watlow Electric Manufacturing Company.

UL® is a registered trademark of Underwriter’s Laboratories, Inc.

Modbus® is a registered trademark of Schneider Automation Incorporated.

DeviceNet™ and EtherNet/IP™ are trademarks of Open DeviceNet Vendors

Association.

PROFIBUS is a registered trademark of PROFIBUS Nutzerorganisation e.V.

(PNO).

Powered by Possibility

To be automatically connected to the nearest

North American Technical Sales Oce:

1-800-WATLOW2 • www.watlow.com

inquiry@watlow.com

©2016 Watlow Electric Manufacturing Company all rights reserved.

International Technical Sales Offices:

Austria +43 6244 20129 0

Australia +61 3 9335 6449

China +86 21 3532 8532

France +33 (0) 1 41 32 79 70

Your Authorized Watlow Distributor Is:

India +91 40 6661 2700

Italy +39 02 4588841

Japan +81 3 3518 6630

Korea +82 2 2169 2600

Mexico +52 442 256 2200

Singapore +65 6773 9488

Spain +34 91 675 1292

Taiwan +886 7 288 5168

UK +44 (0) 115 964 0777

WIN-EZRM-0416

Loading...

Loading...