Page 1

How to Reach Us

To be automatically connected to the nearest North American

Technical and Sales Office call:

1-800-WATLOW2

International T echnical and Sales Offices:

Australia +61-3-9335-6449

China +86-21-3950-9510

France +33 (01) 3073-2425

Germany +49 (0) 7253-9400-0

Italy +39 (02) 458-8841

Japan +81-3-3518-6630

Korea +82-2-575-9804

Malaysia +60-3-7980-7741

Mexico +52 (442) 217-6235

Singapore +65-6777-1266

Spain +34 916 751 292

Sweden +46 35-27-11-66

Taiwan +886-7-288-5168

United Kingdom +44 (0) 115-964-0777

Your Authorized Watlow Distributor:

E-SAFE® II Hybrid Power Switch

User’s Manual

For other product information:

Watlow FAX REPLY: +1 (732) 885-6344, outside the U.S.; or +1 (800)

367-0430, inside the U.S.

About Watlow

Watlow Electric Mfg. Co., has been manufacturing industrial electric

heating products since 1922 and is located in St. Louis, Missouri. Watlow

products include electric heaters, sensors, controllers and switching

devices. Watlow's facility in Winona, Minnesota has been designing

solid-state electronic control devices since 1962, and has earned the

reputation as an excellent supplier to original equipment manufacturers.

These OEMs and end users depend upon Watlow to provide compatibly

engineered controls that they can incorporate into their products with

confidence. The controls operation resides in a 100,000-square-foot

marketing, engineering and manufacturing facility in Winona, Minnesota.

Warranty

The Watlow ESAFE® II Hybrid Power Switch is warranted to be free of

defects in material and workmanship for 24 months after delivery to the

first purchaser for use, providing that the units have not been misapplied.

Since Watlow has no control over their use, and sometimes misuse, we

cannot guarantee against failure. Watlow's obligations hereunder, at

Watlow's option, are limited to replacement, repair or refund of purchase

price, and parts which upon examination prove to be defective within

the warranty period specified. This warranty does not apply to damage

resulting from transportation, alteration, misuse, or abuse.

Returns

• Call or fax your distributor or the nearest Watlow sales office for best

information about returns. (See outside back cover.)

• To return directly to Watlow in the U.S., first call or fax Customer

Service for a Return Material Authorization (RMA) number

(telephone: +1 (507) 454-5300; fax: +1 (507) 452-4507).

• Put the RMA number on the shipping label, along with on a written

description of the problem.

• A restocking charge of 20% of the net price is charged for all standard

units returned to stock.

Quality and Mission Statement:

Watlow will be the world’s best supplier of superior thermal solutions by exceeding the expectations of our customers, shareholders, and employees.

1241 Bundy Boulevard, Winona, Minnesota USA 55987-5580

Phone: +1 (507) 454-5300 Fax: +1 (507) 452-4507

Internet: http://www.watlow.com

English

0600-0055-0001 Rev C

June 2008 Multiple U.S. and international patents pending.

Safety Information

We use note, caution and warning symbols throughout this

ç

CAUTION or

WARNING

Ó

Electrical

Shock Hazard

CAUTION or

WARNING

book to draw your attention to important operational and

safety information.

A “NOTE” marks a short message to alert you to an important

detail.

A “CAUTION” safety alert appears with information that is

important for protecting your equipment and performance. Be

especially careful to read and follow all cautions that apply to

your application.

A “WARNING” safety alert appears with information that

is important for protecting you, others and equipment from

damage. Pay very close attention to all warnings that apply to

your application.

The safety alert symbol, ç (an exclamation point in a triangle) precedes a general CAUTION or WARNING statement.

The electrical hazard symbol, Ó (a lightning bolt in a

triangle) precedes an electric shock hazard CAUTION or

WARNING safety statement.

Technical Assistance

If you encounter a problem with your Watlow controller,

review your configuration information to verify that your

selections are consistent with your application: inputs; outputs; alarms; limits; etc. If the problem persists after checking

the configuration of the controller, you can get technical assistance from your local Watlow representative (see back cover),

or in the U.S., dial +1 (507) 494-5656.

Please have the following information available when calling:

• Complete model number • User’s Manual

Your Comments

We welcome your comments or suggestions on this user’s

manual. Please send them to: Technical Writer, Watlow, 1241

Bundy Blvd., P.O. Box 5580, Winona, Minnesota, USA 559875580; telephone: +1 (507) 454-5300; fax: +1 (507) 452-4507. ©

Copyright 2007 by Watlow, Inc. All rights reserved.

Page 2

240VÅ

L3

L2

L1

1

Fuse

Reset

Breaker

Series SD

SD3_-_K_ _-_ _RG

234

56

Fuse

Series LV

LVC6KW-4542500A

1

2

3

4

5

Neutral

L3

480VÅ

L2

Fuse

8

9

1011

6

7

8

9

10

240VÅ

120VÅ

Fuse

Fuse

Input

120V

Fuse

CR1

Coil

7

A1

Å

CR1

L1

1

A2

T1

2

Thermocouple

Thermocouple

L2

3

T2

4

Control

High Limit

L3

5

T3

6

Connected

®

II

E-SAFE

Hybrid Power

Switch

ES2X-2XX0-0000

Delta

T3

Heater

T2 T1

4-Wire Wye

Connected Heater

T3

Wye

T2 T1

Connected

Heater

N

L1

1

Fuse

Reset

Breaker

Series SD

SD3_-_K_ _-_ _RG

234

56

Fuse

Series LV

LVC6KW-4542500A

1

2

3

4

5

Fuse

Fuse

480VÅ

120VÅ

8

9

1011

6

7

Fuse

8

9

10

Fuse

Input

120V

CR1

Coil

7

A1

Å

CR1

L1

1

A2

T1

2

Thermocouple

L2

3

T2

4

Control

L3

5

T3

6

Connected Heater

E-SAFE

Hybrid Power

Switch

ES2X-3XX0-0000

4-Wire Wye

High Limit

Thermocouple

®

II

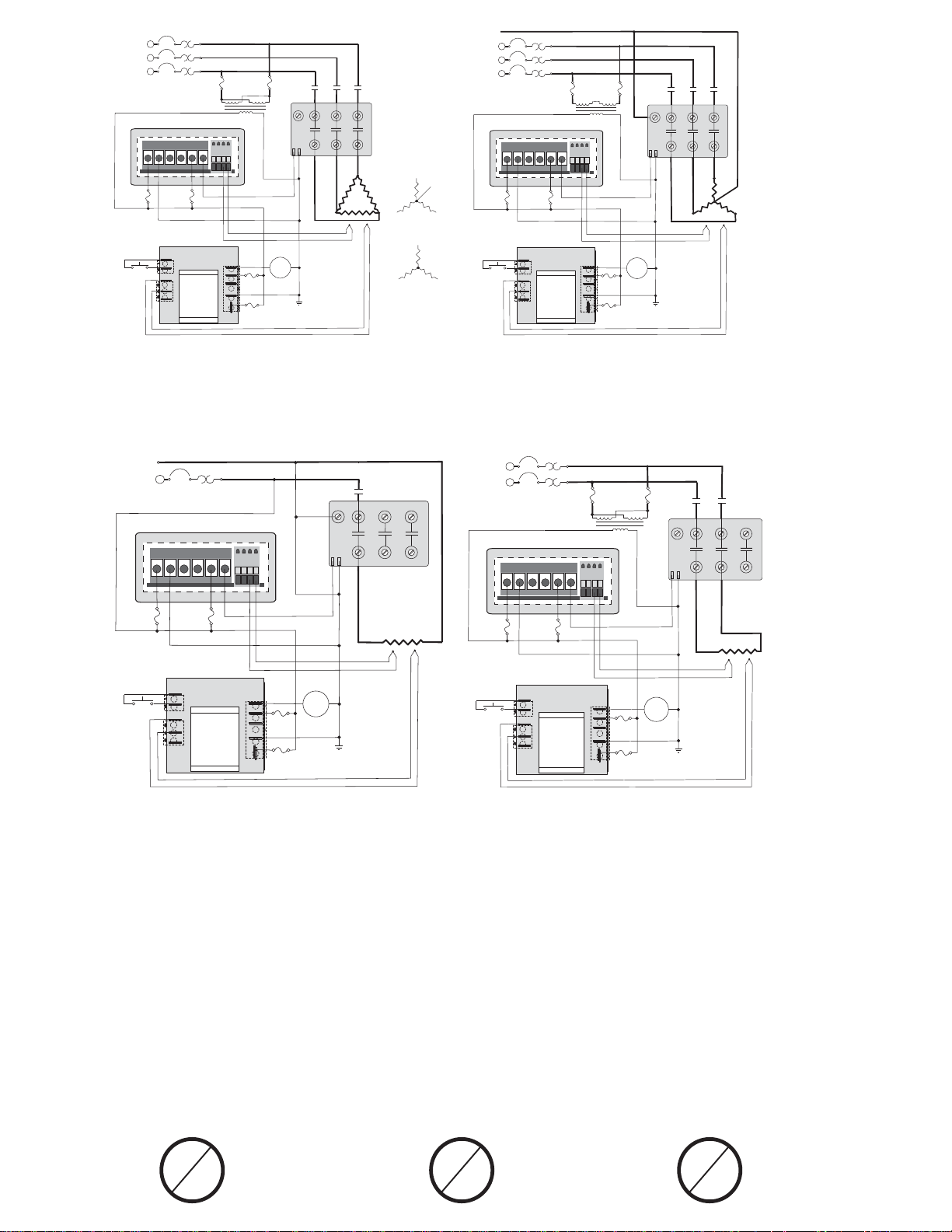

System Wiring Example 240 volt, 3-phase, 3 pole

with ac input control

Note:

ES2X-2XX0-0000 is powered via L1, L2

N

L1

120VÅ

1

Fuse

Reset

Breaker

Series SD

SD3_-_K_ _-_ _RG

234

56

Fuse

Series LV

LVC6KW-4542500A

1

2

3

4

5

CR1

L1

1

7

A1

A2

Input

8

9

1011

120V

T1

2

Å

Thermocouple

Fuse

Fuse

CR1

Coil

Thermocouple

6

7

8

9

10

L3

L2

5

3

T2

T3

4

6

®

E-SAFE

II

Hybrid Power

Switch

ES21-1HV0-0000

Control

High Limit

System Wiring Example 120 volt, single-phase, 1

pole with ac input control

System Wiring Example 277/480 volt, 3-phase, 3

pole with ac input control, 4-wire Wye connected

heater only

Note:

ES2X-3XX0-0000 is powered via terminal (7) and L1

L2

Å

240V

L1

1

Fuse

Reset

Breaker

Series SD

SD3_-_K_ _-_ _RG

234

Fuse

Series LV

LVC6KW-4542500A

1

2

3

4

5

56

Fuse

240V

89

1011

6

7

8

9

10

120V

Fuse

Fuse

Fuse

Å

CR1

L3

L2

L1

1

7

Å

A1

A2

Input

T1

120V

2

Å

Thermocouple

CR1

Coil

Thermocouple

3

T2

T3

4

6

E-SAFE

Hybrid Power

Switch

ES22-2HV0-0000

Control

High Limit

5

®

II

System Wiring Example 240 volt, single-phase, 2

pole with ac input control

ç∫

WARNING:

Wiring must conform to National Electric Code (NEC) safety standards, as well as locally applicable codes. Failure to do so could result in

personal injury or loss of life. See the product rating curve for wire gauge selection, ambient temperature and current restrictions.

∫

WARNING:

Only authorized and qualified personnel should install and service the E-SAFE II Hybrid Power Switch. Failure to comply with these recommendations may result in damage to equipment and property and injury to personnel.

Torque Guidelines:

Properly torque line and load terminals to 2.25 nm (20 in-lbs).

NOTE:

Do not use an RC snubber on the temperature control command signal output. The leakage current through

a snubber circuit can turn the E-SAFE II relay on, even when the command signal is off.

Snubbers Snubbers Snubbers

Page 3

These ratings apply to 3-phase units with cycle times of 30 seconds or more. Consult the factory for 1- and 2-phase unit ratings.

U.L. Conditions of Acceptability

Applications must be tested as described below for specific wire insulation or specific wire gauge sizes. Tests

shall be performed in the end application under worstcase operating conditions.

Test Procedure

A. Monitor the temperature of terminals, using

thermocouples between the ring terminal and

connectors L1, L2 or L3. The temperature must

not exceed 95

B. Monitor the temperatures of wire insulation,

using a thermocouple located 3 inches from the

connector. The temperature must not exceed the

insulation rating of the wire.

°C.

ç∫

WARNING: Thermocouples attached to terminals will be at load

voltage potential, measurements need to be taken with isolated

equipment or isolate the sensor from the terminal with suitable

insulation.

ç∫

WARNING: Wiring must conform to National Electric Code (NEC)

safety standards, as well as locally applicable codes. Failure to do

so could result in personal injury or loss of life.

See the product rating curve for wire gauge selection, ambient temperature and current restrictions.

∫

WARNING: Only authorized and qualified personnel should install

and service the E-SAFE II Hybrid Power Switch. Failure to comply

with these recommendations may result in damage to equipment

and property and injury to personnel.

Unit Dimensions

6.35 mm

(0.25 in)

Top

97.03 mm

(3.82 in)

82.55 mm

(3.25 in)

ç∫

WARNING: Do not use an ungrounded wye- or delta-wired heater

configuration at 400 or 480V

Failure to follow all specifications and wiring instructions may result

in property damage, personal injury and/or loss of life.

Å (ac).

ç

CAUTION: Provide proper enclosure ventilation to maintain an operating environment less than 70°C (158°F) maximum ambient rating.

Failure to do so could cause damage to equipment and property.

Torque Guidelines:

Properly torque line and load terminals to 2.25 nm (20

in-lbs).

Side

46.99 mm

(1.85 in)

23.88 mm

(0.94 in)

14.88 mm

(0.586 in)

48.51 mm

(1.910 in)

140.72 mm

(5.54 in)

1/4 x 0.032

male Q.D. (2x)

#10-32 (7x)

holes and slots for fit

with #10 screws

Page 4

Specifications

Output voltage

• 100/120VÅ (ac) +10/-15 percent, 50/60Hz

• 200/240VÅ (ac) +10/-15 percent, 50/60Hz

• 230/277VÅ (ac) +10/-15 percent, 50/60Hz

Output amperage

• Up to 35 amperes single, dual and three-phase

• 30 A @ 277VÅ (ac)

Operating environment

• 0 to 70°C (32 to 158°F) operating temperature

• 0 to 90 percent RH, non-condensing

• Operational life: Four million switching cycles

• Installation category III, Pollution degree 2

Control mode

• “No-arc” hybrid contactor

Input command signal

• 3 to 32VÎ (dc), 24VÅ (ac) +20/-20 percent

• 100 to 240VÅ (ac) +10/-15 percent, [85 to 264VÅ (ac)]

Input command signal terminals

• 1⁄4 inch fast on appliance

Line and load terminals

• No. 10 screw will accept ring terminals, locking fork terminals or block

fork terminals, 1⁄4 in. (6.35 mm) by 10-32

• Wire insulation temperature can be determined through testing

described in the U.L. Conditions of Acceptability.

Ordering Information

E S 2 _ - _ _ _ 0 - 0 _ _ _

Number of Poles

1 1 pole

2 2 poles controlled

3 3 poles controlled

Load Voltage

1 100 to 120VÅ (ac)

2 200 to 240VÅ (ac)

3 230/277VÅ (ac) (400/480VÅ (ac) with

wye/star, neutral connected to center

required)

Command Signal Voltage

LV Low voltage 3 to 24VÎ (dc) or 24VÅ (ac)

HV High voltage 100 to 240VÅ (ac) +10/-15

percent, [85 to 264VÅ (ac)]

Future Option

Future Option

Custom Parameters

000 Standard product

Mounting

• Back panel mount

• Horizontal or vertical mounting options with equal product

performance

NOTE:

Do not use an RC snubber on the temperature control

command signal output. The leakage current through

a snubber circuit can turn the E-SAFE II relay on, even

when the command signal is off.

Snubbers

Declaration of Conformity

Series Esafe II Relay

Watlow Winona, Inc.

1241 Bundy Blvd.

Winona, MN 55987 USA

Declares that the following product:

Designation:

Model Numbers: ES2 (1, 2 or 3) – (1, 2 or 3)(LV or HV)0 – 0 (any three letters or numbers)

Classification: AC51 Semiconductor Direct-on-line contactor,

Rated Voltage and Frequency: 100-120 Vac, 200-240 Vac, 230-277 Vac*

Rated Power Consumption: 35A Resistive Load Maximum

Meets the essential requirements of the following European Union Directives by using the relevant standards show

below to indicate compliance.

EN 60947-4-1

EN 60947-4-3

EN 61000-4-2 1996 A2, 2001 Electrostatic Discharge Immunity

EN 61000-4-3 2002 Radiated Field Immunity

EN 61000-4-4 2004 Electrical Fast-Transient / Burst Immunity

EN 61000-4-5 1995 A2, 2001 Surge Immunity

EN 61000-4-6 1996 A3, 2005 Conducted Immunity

EN 61000-4-8 1994 A1, 2001 Magnetic Field Immunity

EN 61000-4-11 2004 Voltage Dips, Short Interruptions and Voltage Variations Immunity

IEC 61000-3-12 2004 Harmonic Current Emissions > 16A < 75A

IEC 61000-3-11

2

NOTE 1: To comply with flicker requirements cycle time may need to be greater than 12 seconds if Load

Power is = 16A to comply with standard, or the maximum source impedance needs to be determined. Source

impedance shall meet EN 61000-3-11 requirements for load currents > 16A.

EN 60947-1

EN 60947-4-3

2004/108/EC Electromagnetic Compatibility Directive

2004

2000

2

2000 Voltage Fluctuations and Flicker > 16A < 75A

2004

2000

Compliant with 2002/95/EC RoHS Directive

2002/96/EC WEEE Directive

Series Esafe II Relay

Installation Category III, Pollution degree 2, IP00

*Star or Wye with Center connected Neutral required.

CRGD,

2005

2006-95-EC Low-Voltage Directive

CRGD,

2005

Low-Voltage switchgear and controlgear Part 4-3: Contactors and

motor-starters AC semiconductor controllers and contactors for

non-motor loads. Class B Emissions

Low-Voltage switchgear and controlgear Part 4-3: Contactors and

motor-starters AC semiconductor controllers and contactors for

non-motor loads.

Equipment Requires Recycling

Raymond D. Feller III Winona, Minnesota, USA

Name of Authorized Representative Place of Issue

General Manager February 2008

Title of Authorized Representative Date of Issue

Signature of Authorized Representative

Loading...

Loading...