Page 1

Series EHG SL10

Integrated Temperature Controller

User’s Guide

The Series EHG SL10 is a powerful instrument that integrates a temperature process controller, high-low temperature alert, and power switching with a safety high

limit that meets UL® 1998 and CE 60730 requirements.

The optional display and communications modules can

be easily upgraded in the field to provide a digital display, adjustable control parameters, RS-485 MODBUS

communications and other interface features. The compact design, inherent reliability and integrated safety

limit functions make this control a tremendous value.

The control is designed for easy integration with Watlow heaters providing additional value to simplify the

engineering and component count on new equipment.

CE compliance and UL recognition will reduce time and

costs necessary for global agency testing and validation

for OEMs.

Features

Standard Base Module

• Two, type K thermocouple inputs: process temperature

controller and safety limit

• Process temperature output: 10 amp “NO ARC” relay

• Safety limit: 10 amp relay

• High-low temperature alert: 2 amp, 30Vı (ac/dc), Form

A relay

• On-off and PID temperature control algorithm: Upgraded via communications to PID algorithm (minimum

cycle time 5 seconds)

0600-0050-0000 Rev. D

February 2011

Integrated Temperature Control

• Standard Molex Connectors

• Dimensions

Configuration Width Depth Height

basic unit 88.8 mm

with mounting bracket 88.8 mm

with communicatons-display module & mounting

bracket

Optional Communications Module

• Field adjustable set point

• Access to PID parameters

• Modbus RTU Communications

• RS-485

• 3-character, 7-segment LED display

• User Interface Software

The Series EHG SL10 User’s Guide is copyrighted by

Watlow Winona, Inc., © February 2011, with all rights

reserved.

Patent Pending

1241 Bundy Boulevard

Phone: (507) 454-5300; Fax: (507) 452-4507

http://www.watlow.com

(3.496 in)

(3.496 in)

88.8 mm

(3.496 in)

Watlow Winona

Winona, MN 55987

40.2 mm

(1.582 in)

48.4 mm

(1.907 in)

63.6 mm

(2.503)

55.8 mm

(2.196 in)

55.8 mm

(2.196 in)

55.8 mm

(2.196 in)

Page 2

Navigating the Series EHG SL10 with the Front Panel

The three-character display normally shows the process

temperature. To view and change the existing Set Point

value follow the steps below:

1. Press the Mode Key once. The right decimal point

will illuminate when viewing the Set Point value.

2. Press the Up-Arrow or Down-Arrow Key to change

the Set Point.

3. Press the Mode Key again to return to the process

temperature display.

The display will automatically return to showing the

process temperature after three seconds.

To view or change parameter values follow the steps

below:

1. Hold down both the Up-Arrow and Down-Arrow Keys

for five seconds.

This will display the Set Point High Limit prompt.

2. Press the Mode Key to view the other parameter

prompts.

3. Press the Up-Arrow or Down-Arrow Key once to view

a parameter’s value.

4. Press the Up-Arrow or Down-Arrow Key to increase

or decrease that value.

5. Press the Mode Key to again display the prompt and

again to display the next prompt.

6. Press the Mode Key at the Display Build Number

prompt to return to the process value display.

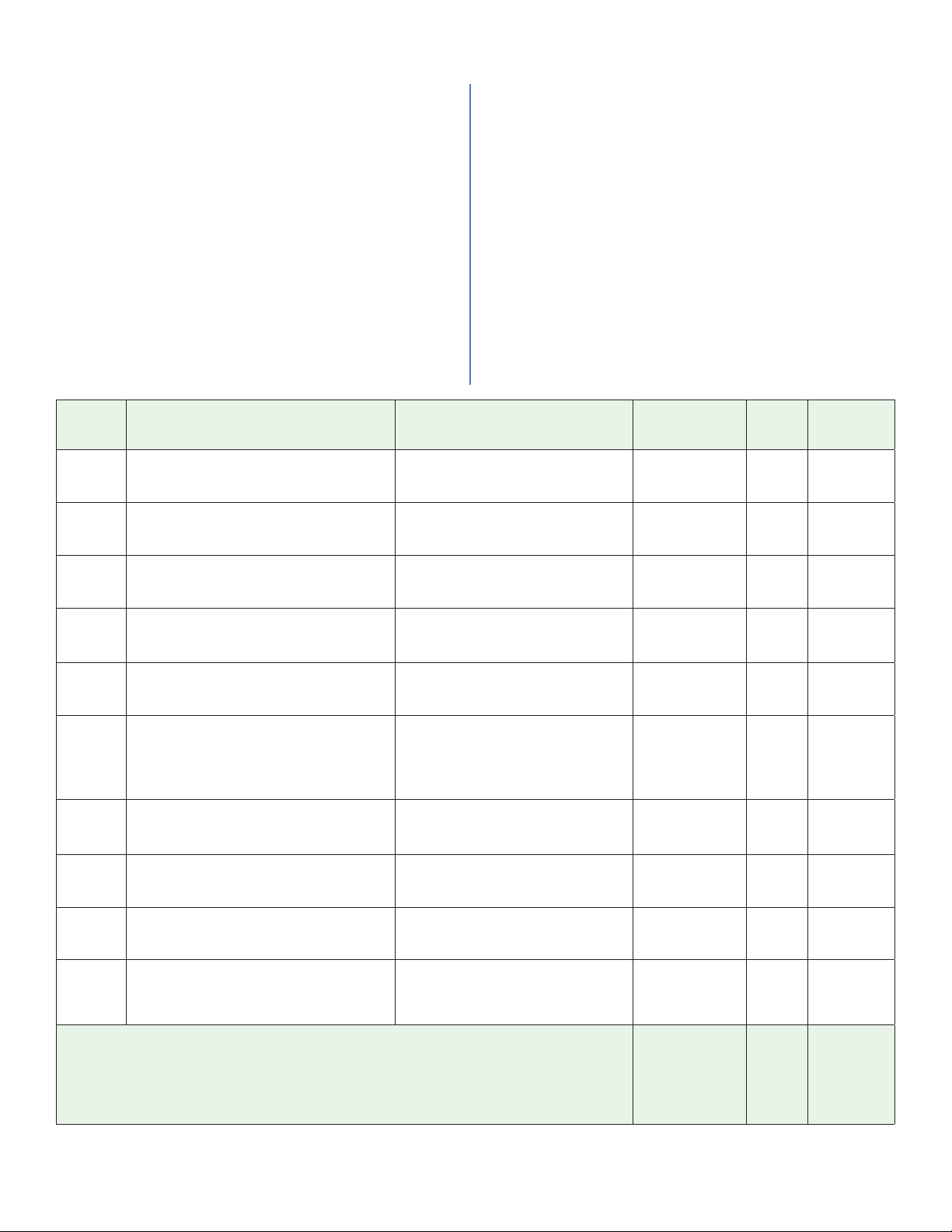

Display Parameter Name & Description Range Default

Process Value Controller

Numeric

Numeric

No Display

No Display

No Display

No Display

No Display

No Display

[SLA]

[SLA]

[HtA]

[HtA]

Note:

All values above 999 will be rounded off to fit in the three-character display. Full values can be

read with other interfaces.

Note:

The EHG SL10 does not support Modbus function code 16 (0x10) Write Multiple Registers. Parameter values must be written individually with function code 6 (0x06) Write Single Registers.

View the present Process Value.

Closed Loop Set Point

Set the set point that the controller will automatically control to.

Heat Output Power

Read (via Modbus communications) the

present heat output power level.

Alert Status

Read (via Modbus communications) the

present alert status.

Process Comparison Value

Set or read (via Modbus communications)

the Process Comparison Value.

Limit Status

Read (via Modbus communications) the

present condition of the limit.

Controller Sensor Status

Read (via Modbus communications) the

present status of the controller sensor.

Limit Sensor Value

View the present value of the limit sensor.

Limit High Set Point

Set the high process value that will trigger

the limit.

High Temperature Alert Value

The High Temperature Alert occurs when

the process variable exceeds the set point by

more than the value set here.

-18 to 400°C (0 to 752°F) 20°C (68°F)

0°C (32°F) to Set Point High Limit 150°C (302°F)

0 to 100% 0

Alert Low (7)

Alert High (8)

Alert None (6)

5 to 30°C (9 to 54°F) 20°C (68°F)

Bit 5 (0x0020)

0 = Not tripped (process value below

limit high set point)

1 = Tripped (process value exceeds

limit high set point)

Bit 2 (0x0004)

0 = Good

1 = Failure

-18 to 400°C (0 to 752°F) 20°C (68°F)

0 to 220°C (32 to 428°F) 200°C (392°F)

1 to 99°C (2 to 178°F) 20°C (36°F)

Alert None

0

0

Modbus

Relative

Address

20

34

22

31

68

63

23

60

43

35

Data Type

& Read/

Write

unsigned

integer

R

unsigned

integer

RWE

unsigned

integer

R

unsigned

integer

R

unsigned

integer

RWE

unsigned

integer

R

unsigned

integer

R

unsigned

integer

R

unsigned

integer

RWE

unsigned

integer

RWE

R: Read

W: Write

E: EEPROM

Watlow Controls 2 EHG SL10 User’s Guide

Page 3

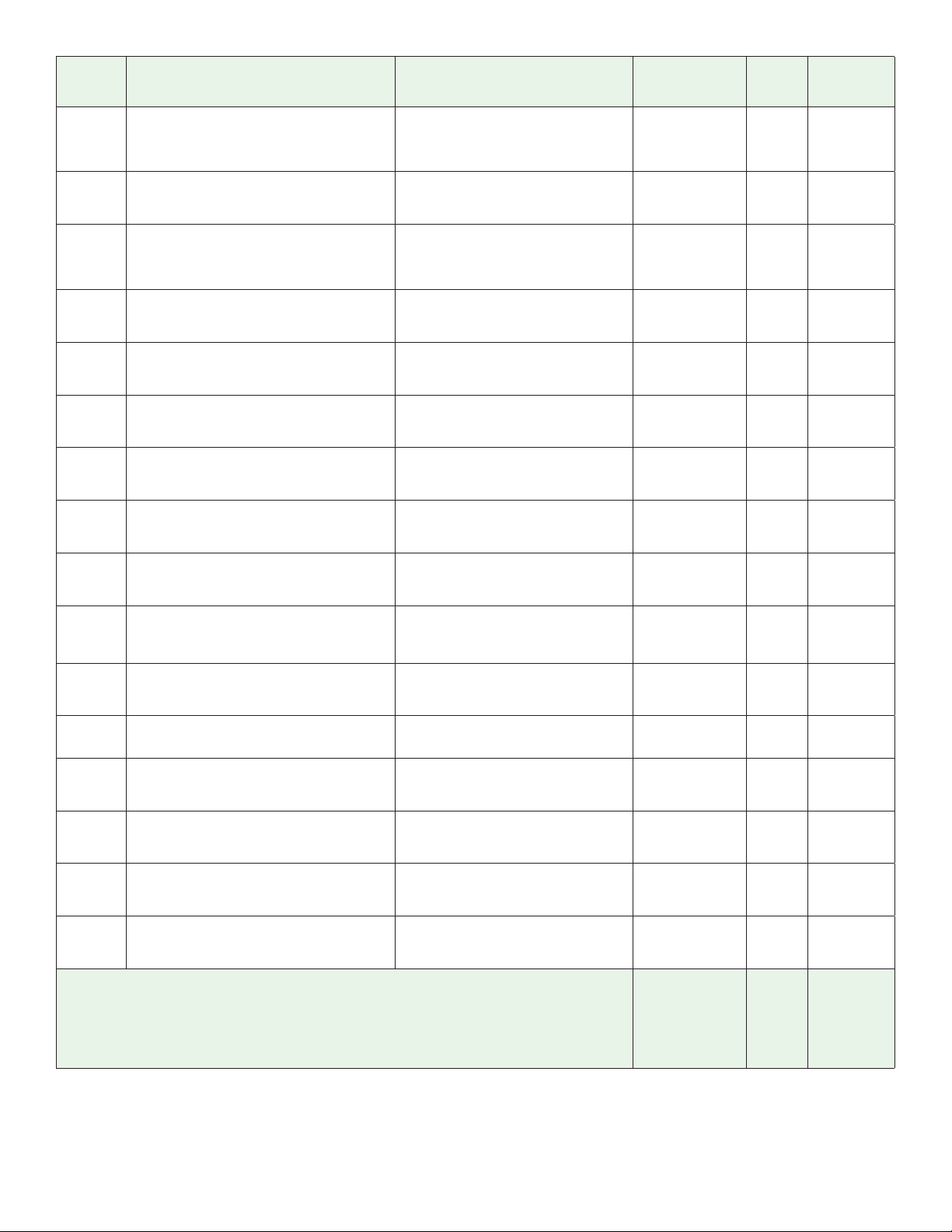

Display Parameter Name & Description Range Default

[ltA]

[LtA]

[Cnt]

[Cnt]

[HyS]

[HyS]

[`Pb]

[ Pb]

[Int]

[Int]

[dEu]

[dEv]

[`Ct]

[ Ct]

[Abt]

[Abt]

[Adr]

[Adr]

[bAU]

[bAU]

[tU`]

[tU ]

[rpp]

[rPP]

[bru]

[brv]

[bPu]

[bPv]

[bbu]

[bbu]

[dru]

[drv]

Note:

All values above 999 will be rounded off to fit in the three-character display. Full values can be

read with other interfaces.

Note:

The EHG SL10 does not support Modbus function code 16 (0x10) Write Multiple Registers. Parameter values must be written individually with function code 6 (0x06) Write Single Registers.

Low Temperature Alert Value

The Low Temperature Alert occurs when the

process variable is below the set point by

more than the value set here.

Control Mode Select

Select a control method.

On-Off Hysteresis

Set the how far below the set point the temperature can drop before the heater turns

on.

Proportional Band

Set the proportional band in temperature

units.

Integral

Set the integral value in minutes per repeat.

Derivative

Set the derivative value in minutes.

Cycle Time

Set the cycle time in seconds.

Ambient Temperature

View the ambient temperature.

Modbus Device Address

View and or change the present Modbus

address.

Modbus Baud Rate

Select the communication speed.

Temperature Units

Select the temperature scale.

Restore Programmed Parameters

Restore factory default settings.

Base Release Version

View the controller’s base release version.

Base Prototype Version

View the controller’s base prototype version.

Base Build Version

View the controller’s base build number.

Display Release Version

View the interface’s release version.

5 to 99°C (9 to 178°F) 20°C (36°F)

[onF]

On-Off (2)

[PId]

PID (3)

3 to 28°C (5 to 50°F) 3°C (6°F)

0 to 68°C (0 to 122°F) 0°C or 0°F

0 to 999 0

0 to 999 0

5 to 60 10

0 to 106°C (0 to 190°F) 43°C (77°F)

1 to 247 1

[`96]

9,600 (15)

[192]

19,200 (16)

[384]

38,400 (17)

[``F]

°F (4)

[``C]

°C (5)

[yes] Yes

on-off

9,600

°C

No

[`no] No

0 to 9999

- - - - 48

0 to 9999

- - - - 49

0 to 9999

- - - - 50

0 to 9999

- - - - 11

Modbus

Relative

Address

36

42

41

37

38

39

40

24

15

16

17

- - - - - - - -

Data Type

& Read/

unsigned

integer

RWE

unsigned

integer

RWE

unsigned

integer

RWE

signed integer

RWE

signed integer

RWE

signed integer

RWE

unsigned

integer

RWE

unsigned

integer

R

unsigned

integer

RWE

unsigned

integer

RWE

unsigned

integer

RWE

unsigned

integer

R

unsigned

integer

R

unsigned

integer

R

unsigned

integer

R

R: Read

W: Write

E: EEPROM

Write

Watlow Controls 3 EHG SL10 User’s Guide

Page 4

Display Parameter Name & Description Range Default

[dPu]

[dPv]

[dbu]

[dbv]

Display Prototype Version

View the interface’s prototype version.

Display Build Version

View the interface’s build number.

0 to 9999

0 to 9999

Note:

All values above 999 will be rounded off to fit in the three-character display. Full values can be

read with other interfaces.

Note:

The EHG SL10 does not support Modbus function code 16 (0x10) Write Multiple Registers. Parameter values must be written individually with function code 6 (0x06) Write Single Registers.

Keys and Indicator Lights

Optional Communications

Connectors

Up-Arrow Key

Increases the

displayed value.

Optional Communications

Connectors

Mode Key

Toggles the display between

the set point and process

temperature. Enters edited

values and advances

to the next prompt.

Down-Arrow Key

Decreases the

displayed value.

Alarm (flashing red)

Indicates that the process

temperature is higher than the

Limit High Set Point.

Alert (solid red)

Indicates that the process

temperature is higher than the

Closed Loop Set Point plus the

High Temperature Alert

Value.

In Range (solid yellow)

Indicates that the process

temperature is in the normal

operating range (see figure at

right).

Output (green)

Indicates that the output is on.

Flashing

Alert/Alarm (red) and

In Range (yellow)

If they are flashing together, that

indicates an Ambient Alarm

(controller temperature higher

than 85°C).

If they are flashing alternately, that

indicates a Health Check Error.

Alert/Alarm

In Range

Output

Alert/Alarm

In Range

Output

Alert/Alarm

In Range

Output

Alert/Alarm

In Range

Output

Alert/Alarm

In Range

Output

Alert/Alarm

In Range

Output

Alert/Alarm

In Range

Output

flashing

flashing

alternate

flashing

Control

relay

LTA

HTA

relay

Safety

Alarm

relay

off off off

off off on

off on on

on on on

on off on

off off off Ambient Alarm

[Abt] 85°C

off off off Health Check Error

Modbus

Relative

Address

- - - - 12

- - - - 13

Limit High Set Point [SLA]

Closed Loop Set Point plus

High Temperature Alert

Value [HtA]

Alarm Hysteresis

Normal Operating Range

Closed Loop Set Point

On-Off Hysteresis [HyS]

Closed Loop Set Point minus

Low Temperature Alert

Value [LtA]

Data Type

& Read/

Write

unsigned

integer

R

unsigned

integer

R

R: Read

W: Write

E: EEPROM

Temperature

Alarm Hysteresis

Watlow Controls 4 EHG SL10 User’s Guide

Page 5

EHG SL10 Error Codes

Display Description Possible Cause Corrective Action

[SL1]

[SL2]

[Er3]

[Er4]

[Er5]

[Er6]

[ER9]

[Ahi]

[Alo]

[E91]

[E10]

[E11]

[E12]

[E13]

[E15]

[E16]

[E17]

Limit error Sensor has exceeded SLA value or

open thermocouple

Control error Sensor has exceeded SLA value or

open thermocouple

Limit Sensor Error Limit sensor reading out of range (<

-13 or > 640)

Control Sensor Error Control sensor reading out of range

(<-13 or > 640)

Limit Ambient Error Temperature at limit sensor cold junc-

tion (> 185 degrees)

Control Ambient Error Temperature at control cold junction

(> 185 degrees)

HMI Communications

Fault

Alarm High Process temp exceeds set point by

Alarm Low Process temp below set point by value

Communications Queue

Full

EEPROM Error EEPROM memory space fails CRC

CRC Error Flash memory space fails CRC check

CPU Clock Error Clock frequency is < 5 MHz or > 13.1

Stack Overfl ow Stack has overfl owed, return to factory • Contact Technical Support at

AI Function Error Analog reference is < 1.82 or > 2.06

Process Comparison

Error

Data Store Error Data store functions are not set up,

Loss of communication between base

and display communications module

value greater than alarm high setting

greater than alarm low setting

Communications buffer overfl ow, return to factory

check (checksum for parameter space),

return to factory

(checksum for program space), return

to factory

MHz, return to factory

volts, return to factory

Limit and control sensor readings

differ by value greater than process

comparison value

return to factory

• Set SLA to correct Safety

Limit Value

• Check wiring of sensor

• Check sensor confi guration

• Set SLA to correct Safety

Limit Value

• Check wiring of sensor

• Check sensor confi guration

• Check wiring of sensor

• Check sensor confi guration

• Check wiring of sensor

• Check sensor confi guration

• Check to be certain the EHG

SL10 is not in an ambient

condition greater than 185

degrees C

• Check to be certain the EHG

SL10 is not in an ambient

condition greater than 185

degrees C

• Check connection between

EHG SL10 and display/communications module

• Set HTA value to correct high

temperature alert value

• Set LTA value to correct Low

temperature alert value

• Contact Technical Support at

1-507-494-5656

• Contact Technical Support at

1-507-494-5656

• Contact Technical Support at

1-507-494-5656

• Contact Technical Support at

1-507-494-5656

1-507-494-5656

• Contact Technical Support at

1-507-494-5656

• Check setting of Proces Comparison Value

• Set Process Comparison Value

to correct value

• Check wiring of sensors

• Check setting of Proces Comparison Value

• Check wiring of sensors

Watlow Controls 5 EHG SL10 User’s Guide

Page 6

Proportional Control

Some processes need to maintain a temperature or

process value closer to the set point than on-off control can provide. Proportional control provides closer

control by adjusting the output when the temperature

or process value is within a proportional band. When

the value is in the band, the controller adjusts the output based on how close the process value is to the set

point.

The closer the process value is to the set point, the

lower the output power. This is similar to backing off

on the gas pedal of a car as you approach a stop sign.

It keeps the temperature or process value from swinging as widely as it would with simple on-off control.

However, when the system settles down, the temperature or process value tends to “droop” short of the set

point.

With proportional control the output power level

equals (set point minus process value) divided by the

proportional band value.

Adjust the proportional band with Proportional

[`Pb].

Set Point

Temperature

Overshoot

Proportional Band

Droop

Reduced Overshoot

Proportional Band

Proportional Band x 2

Time

PID Control

Temperature

Set Point

Heating Slows

On-Off Control

On-off control switches the output either full on or full

off, depending on the input, set point and hysteresis

values. The hysteresis value indicates the amount the

process value must deviate from the set point to turn on

the output. Increasing the value decreases the number

of times the output will cycle. Decreasing hysteresis improves controllability. With hysteresis set to the lowest

value of 3°C or 5°F, the process value would stay closer

to the set point, but the output would switch on and off

more frequently, and may result in the output “ chattering.” Both the control mode ([Cnt] prompt) and hysteresis ([Hys] prompt) values can be changed either using

the front panel or via Modbus communications.

The heating action switches off when the process

temperature rises above the set point.

Proportional Control

Time

Proportional plus Integral (PI) Control

The droop caused by proportional control can be corrected by adding integral control. When the system

settles down, the integral value is tuned to bring the

temperature or process value closer to the set point.

Integral determines the speed of the correction, but

this may increase the overshoot at startup or when

the set point is changed. Too much integral action will

make the system unstable. Integral is cleared when

the process value is outside of the proportional band.

Integral [Int] is measured in minutes per repeat. A

low integral value causes a fast integrating action.

Proportional plus Integral plus Derivative (PID)

Control

Use derivative control to minimize the overshoot in

a PI-controlled system. Derivative [dEu] adjusts the

output based on the rate of change in the temperature

or process value. Too much derivative will make the

system sluggish.

Set Point

Temperature

Process Temperature

The heating action switches on when the process temperature

The heating action

switches on at startup.

drops below the set point minus the hysteresis.

Time

On/Off System Cycles

Mounting the Series EHG SL10

88.8 mm

(3.496 in)

55.8 mm

(2.196 in)

Base Controlller

front

Hysteresis

48.4 mm

(1.907 in)

Base Controller

side

Watlow Controls 6 EHG SL10 User’s Guide

Page 7

81.5 mm

(3.210 in)

Interface

side

Wiring the Series EHG SL10 Power, Thermocouple

and Heater Connections

View looking at the top of the controller.

Interface

front

88.8 mm

(3.496 in)

Base Controller with Interface

front

Panel Mount Dimensions

45.72 mm

(1.800 in)

48.4 mm

(1.905 in)

55.8 mm

(2.196 in)

24.7 mm

(0.974 in)

63.6 mm

(2.503 in)

Base Controller with

Interface side

L2

(white)

5

1

L2

(white)

L1

(black)

6

2

L1

(black)

Power and relay connectors

Control Power Cord Coiled, Terminated Long

Part Number: 4800-0022

3.5” +/- 0.5”

6.0” +/-0.5” relaxed length

>= 18” extended length

Control Power Cord Coiled, Terminated Short

Part Number: 4800-0021

Alarm relay

N.O.

7

3

Control Power Cord Coiled, Jumpered Long

Control Power Cord Coiled, Jumpered Short

8

4

Alarm relay

Com.

Part Number: 4800-0012

12.0” +/- 1” Relaxed Length

>= 36” Extended Length

Part Number: 4800-0011

3.5” +/- 0.5”

drill and tap for #8-32

Mounting Bracket

The Series EHG SL10

mounting bracket lets

you mount the controller in any of four

angles. After disconnecting both wiring

connectors, gently

rotate the controller

counterclockwise until

it unlocks from the

mounting bracket.

Re-orient the controller on the mounting

bracket and gently rotate it clockwise until

it locks.

3.5” +/- 0.5”

3.5” +/- 0.5”

Relaxed Length

7.0” +/- 1” Relaxed Length

With the control facing you this connector is on the

right side.

Heater

Switched

L2

(white)

L1

(black)

– (red)

5

1

6

2

7

3

+ (yellow)

Thermocouple

8

4

Limit

– (red)

Process

Thermocouple

+ (yellow)

Thermocouple and heater connector

3.5” +/- 0.5”

Watlow Controls 7 EHG SL10 User’s Guide

Page 8

Wiring the Series EHG SL10 Communications Ports

The graphic below reflects the control being held upright with the display facing the holder. As shown, there

are two jacks on the top of the communications module

(RJ45 like, with 4 pins on each) which can accommodate

either a four or six 6 pin modular plug. Communications

from a PC to any EHG SL10 controller on the network

can be established by connecting it to either of the two

available jacks. The other jack can then be connected to

other EHG SL10 controllers on the network (32 maximum).

Looking at either of the jacks as shown in the graphic

pin identification is from left to right.

- Left most pin, connects to ground terminal of converter

- Second pin from left, no connection

- Third pin from left, connects to converter A or T- / R-

- Right most pin connects to converter B or T+ / R+

2

1

456

3

Gnd terminal of converter

No connection

A or T- / R-

B or T+ / R+

Watlow Controls 8 EHG SL10 User’s Guide

Page 9

Specifications

Power

• Isolated Universal Power Supply: 85 to 264VÅ (ac)

50/60Hz

• Up to 2400 W with 10A switching capability

NO-ARC Relay

• 10A switching

• 4.5 million cycles

Environmental

• Ambient operating temperature range 0 to 70 °C (32 to

158 °F)

Agency Approvals

• UL® 1998/C-UL

• CE 60730

• SEMI-S2

®

Ordering Information

Series EHG SL10 Integrated Temperature Controller

EHG2- CNTL-_ _ _ _

0000 basic control (purchased only as part of a heater assembly)

EHG2- MODU-_ _ _ _

DISP with display module

COMS with communications module

DSCM with display & communications module

Additional Power Cables

4800-0012: jumpered long cable

4800-0022: terminated long cable

4800-0011: jumpered short cable

4800-0021: terminated short cable

EN 61010-1 2001 Safety Requirements of electrical equipment for measurement, control and laboratory use. Part 1: General

requirements

EN 60730-1 2001 + A1-A4 Automatic electrical controls for household and similar

use

EN 60730-2-9 2002 + A1 - Temperature Sensing Controls

UL 1998 ED.2 Software in programmable components.

Raymond D. Feller III Winona, Minnesota, USA

Name of Authorized Representative Place of Issue

General Manager February 2009

Title of Authorized Representative Date of Issue

Signature of Authorized Representative

2006/95/EC Low-Voltage Directive

Warranty

The Series EHG SL10 is warranted to be free of defects in material

and workmanship for 24 months after delivery to the first purchaser

for use, providing that the units have not been misapplied. Since

Watlow has no control over their use, and sometimes misuse, we

cannot guarantee against failure. Watlow’s obligations hereunder, at

Watlow’s option, are limited to replacement, repair or refund of purchase price, and parts which upon examination prove to be defective

within the warranty period specified. This warranty does not apply to

damage resulting from transportation, alteration, misuse or abuse.

WARNING: To avoid damage to property and equipment, and/or

injury or loss of life, use National Electric Code (NEC) standard

wiring practices to install and operate the Series EHG SL10. Failure to do so could result in such damage, and/or injury or death.

Series EHG SL10

Declaration of Conformity

Watlow Winona, Inc.

1241 Bundy Blvd.

Winona, MN 55987 USA

Declares that the following product:

Designation: Series EHG SL10

Model Numbers: EHG2-CNTL-(0000, DISP, COMS, DSCM)

Classi cation: Electronic Thermostat with Integrated Temperature Limiter Protective

Control, Control Relay = 2CK, Limit Relay = 2JK, TA Relay = 2B

Installation Category II, Pollution degree 2, Software Class B

Rated Supply Source: 100 to 240 V~ (ac), 50 or 60 Hz

IP Code IP20

Rated Power: 5 VA Unit power, 10 A Resistive Heater Load

Meets the essential requirements of the following European Union Directives by using the relevant

standards show below to indicate compliance.

EN 60730-1 2001 + A1-A4 Automatic electrical controls for household and similar

use

EN 60730-2-9 2002 + A1 - Temperature Sensing Controls, Class B Emissions

EN 61000-4-2 1996 + A1, A2 Electrostatic Discharge Immunity

EN 61000-4-3 2006 Radiated Field Immunity

EN 61000-4-4 2004 Electrical Fast-Transient / Burst Immunity

EN 61000-4-5 2006 Surge Immunity

EN 61000-4-6 1996 + A1, A2, A3 Conducted Immunity

EN 61000-4-8 1994 + A1 Power frequency magnetic eld immunity

EN 61000-4-11 2004 Voltage Dips, Short Interruptions and Voltage

Variations Immunity

EN 61000-4-28 2000 Variation of power frequency immunity – Level 2

EN 61000-3-2 2006 Harmonic Current Emissions

EN 61000-3-3 2005 Voltage Fluctuations and Flicker

SEMI F47 2000 Speci cation for Semiconductor Processing Equipment

Voltage Sag Immunity – Figure R1-1

89/336/EEC Electromagnetic Compatibility Directive

Watlow Controls 9 EHG SL10 User’s Guide

Page 10

How to Reach Us

ER

TISFFAACTCTIIOONN

Corporate Headquarters

Watlow Electric Manufacturing Company

12001 Lackland Road

St. Louis, MO 63146

Sales: 1-800-WATLOW2

Manufacturing Support: 1-800-4WATLOW

Email: info@watlow.com

Website:

From outside the USA and Canada:

Tel: +1 (314) 878-4600

Fax: +1 (314) 878-6814

Latin America

Watlow de México S.A. de C.V.

Av. Fundición No. 5

Col. Parques Industriales

Querétaro, Qro. CP-76130

Mexico

Tel: +52 442 217-6235

Fax: +52 442 217-6403

www.watlow.com

Europe

Watlow France

Tour d'Asnières.

4 Avenue Laurent Cély

92600 Asnières sur Seine

France

Tél: + 33 (0)1 41 32 79 70

Télécopie: + 33(0)1 47 33 36 57

Email: info@watlow.fr

Website:

Watlow GmbH

Postfach 11 65, Lauchwasenstr. 1

D-76709 Kronau

Germany

Tel: +49 (0) 7253 9400-0

Fax: +49 (0) 7253 9400-900

Email: info@watlow.de

Website: www.watlow.de

Watlow Italy S.r.l.

Viale Italia 52/54

20094 Corsico MI

Italy

Tel: +39 024588841

Fax: +39 0245869954

Email: italyinfo@watlow.com

Website:

www.watlow.fr

www.watlow.it

Watlow Ibérica, S.L.U.

C/Marte 12, Posterior, Local 9

E-28850 Torrejón de Ardoz

Madrid - Spain

T. +34 91 675 12 92

F. +34 91 648 73 80

Email: info@watlow.es

Website:

Watlow UK Ltd.

Linby Industrial Estate

Linby, Nottingham, NG15 8AA

United Kingdom

Telephone: (0) 115 964 0777

Fax: (0) 115 964 0071

Email: info@watlow.co.uk

Website: www.watlow.co.uk

From outside The United Kingdom:

Tel: +44 115 964 0777

Fax: +44 115 964 0071

www.watlow.es

Asia and Pacifi c

Watlow Singapore Pte Ltd.

16 Ayer Rajah Crescent,

#06-03/04,

Singapore 139965

Tel: +65 6773 9488 Fax: +65 6778 0323

Email: info@watlow.com.sg Website: www.watlow.com.sg

Watlow Australia Pty., Ltd.

4/57 Sharps Road

Tullamarine, VIC 3043

Australia

Tel: +61 3 9335 6449

Fax: +61 3 9330 3566

Website: www.watlow.com

Watlow Electric Manufacturing (Shanghai) Company

1118 Fangyuan Road, Anting Industrial Park, Jiading, Shanghai, PRC

201203

People’s Republic of China

Tel: +86 21 39509510

Fax: +86 21 5080-0906

Email: info@watlow.cn

Website: www.watlow.cn

ワトロー・ジャパン株式会社

〒101-0047 東京都千代田区内神田1-14-4

四国ビル別館9階

Tel: 03-3518-6630 Fax: 03-3518-6632

Email: infoj@watlow.com Website: www.watlow.co.jp

Watlow Japan Ltd.

1-14-4 Uchikanda, Chiyoda-Ku

Tokyo 101-0047

Japan

Tel: +81-3-3518-6630 Fax: +81-3-3518-6632

Email: infoj@watlow.com Website: www.watlow.co.jp

Watlow Korea Co., Ltd.

#1406, E&C Dream Tower, 46, Yangpyeongdong-3ga

Yeongdeungpo-gu, Seoul 150-103

Republic of Korea

Tel: +82 (2) 2628-5770 Fax: +82 (2) 2628-5771

Website: www.watlow.co.kr

Watlow Malaysia Sdn Bhd

No. 14-3 Jalan 2/114

Kuchai Business Centre

Jalan Kuchai Lama

58200 Kuala Lumpur

Malaysia

Tel: +60 3 7980 7741 Fax: +60 3 7980 7739

瓦特龍電機股份有限公司

80143 高雄市前金區七賢二路189號 10樓之一

電話: 07-2885168 傳真: 07-2885568

Watlow Electric Taiwan Corporation

10F-1 No.189 Chi-Shen 2nd Road Kaohsiung 80143

Taiwan

Tel: +886-7-2885168 Fax: +886-7-2885568

Your Authorized Watlow Distributor

TOT AL

CUCUSSTTOOMMER

SSAATIS

3 Y ear Warranty

Watlow Controls 10 EHG SL10 User’s Guide

Loading...

Loading...