Installation

WaterWorks _

Premier Demand

with high-flow 1" valve

AUTOMATIC WATER CON DITION ER

Model WS 2000

Operation

IF YOU HAVE QUESTIONS WHEN

INSTALLING, OPERATING AND

MAINTAINING YOUR CONDITIONER,

AND WHEN SETTING THE TIMER. o.

CALL TOLL FREE

1-800-86 WATER

Maintenance

Repair Parts

Manufactured by EcoWater Systems, Inc. PO BOX 64420, ST. PAUL, MN 55164 Part No. 721 3840 (10/99)

WaterWorks TM..... •AUTOMATIC WATERCONDITIONER

IIIIIII I I IIIII IIII lllll '111 II I IIIIIII Jl

WaterWorks RESIDENTIAL WATER SOFTENER WARRANTY

FULL ONE YEAR WARRANTY ON WATER SOFTENER

For one year from the date of purchase, when this water softener is installed and maintained in accordance with

our instructions, Sears will repair, free of charge, defects in material or workmanship in this water softener.

FULL TEN YEAR WARRANTY AGAINST LEAKS

For ten years from the date of purchase, Sears witl furnish and install a new current model water softener tank or

salt storage drum, free of charge, if either the tank or drum develop a leak.

TO OBTAIN WARRANTY SERVICE, SIMPLY CONTACT THE NEAREST SEARS SERVICE CENTER

THROUGHOUT THE UNITED STATES. This warranty applies only while this product is in use in the United States.

This warranty gives you specific legal rights, and you may have other rights which vary from state to state.

Sears, Roebuck end Co., D/817 WA, Hoffman Estates, IL 60179

IIIIIIII'¸ II I II IIII II Jill II1'1I

If you want your water softener professionally installed, contact Sears Installation. They wil! arrange for a prompt, quality

installation by Sears Authorized Installers.

SEARS INSTALLATION POLICY

All installation labor arranged by Sears shall be performed

in t_neat, workmanlike manner in accordance with gener-

ally accepted trade practices. Further, all installations

shall comply with all local laws, codes, regulations, and or-

dinances. Customer shall also be protected, during instal-

lation, by insurance relating to Property Damage, Work-

man's Compensation and Public Liability.

In addition to any warranty extended to you on the Water-

Works merchandise involved, which warranty becomes

effective the date the merchandise is installed, should the

workmanship of any Sears arranged installation prove

faulty within one year, Sears will, upon notice from you,

cause such faults to be corrected at no additional cost to

you.

SEARS INSTALLATION WARRANTY

SAFETY GUIDES

FOLLOW THE INSTALLATION INSTRUCTIONS CAREFULLY. FAILURE TO INSTALL THE SOFTENER PROPERLY

VOIDS THE WARRANTY.

BEFORE YOU BEGIN INSTALLATION, READ THIS ENTIRE MANUAL. THEN, OBTAIN ALL THE MATERIALS AND

TOOLS YOU WILL NEED TO MAKE THE INSTALLATION.

CHECK LOCAL PLUMBING AND ELECTRICAL CODES. THE INSTALLATION MUST CONFORM TO THEM.

PLUMBING CODES OF MASSACHUSETTS SHALL BE ADHERED TO. CONSULT WITH YOUR LICENSED PLUMB-

ER.

USE ONLY LEAD-FREE SOLDER AND FLUX FOR ALL SWEAT-SOLDER CONNECTIONS, AS REQUIRED BY

STATE AND FEDERAL CODES.

USE CARE WHEN HANDLING THE SOFTENER. DO NOT TURN UPSIDE DOWN, DROP, OR SET ON SHARP PRO-

TRUSIONS.

DO NOT LOCATE THE SOFTENER WHERE FREEZING TEMPERATURES OCCUR. DO NOT ATTEMPT TO TREAT

WATER OVER 120°F. FREEZING, OR HOT WATER DAMAGE VOIDS THE WARRANTY.

AVOID INSTALLING IN DIRECT SUNLIGHT. EXCESSIVE SUN HEAT MAY CAUSE DISTORTION OR OTHER DAM-

AGE TO NON-METALLIC PARTS.

THE SOFTENER REQUIRES A MINIMUM WATER FLOW OF 3 GALLONS PER MINUTE AT THE INLET. MAXIMUM

ALLOWABLE INLET WATER PRESSURE IS 125 PSI. IF DAYTIME PRESSURE IS OVER 80 PSt, NIGHTTIME PRES-

SURE MAY EXCEED THE MAXIMUM. USE A PRESSURE REDUCING VALVE IF NECESSARY. (ADDING A PRES-

SURE REDUCING VALVE MAY REDUCE THE FLOW.)

THE SOFTENER WORKS ON 24 VOLT-60 Hz ELECTRICAL POWER ONLY. BE SURE TO USE THE INCLUDED

TRANSFORMER.

THIS SYSTEM IS NOT INTENDED TO BE USED FOR TREATING WATER THAT IS MICROBIOLOGICALLY UNSAFE

OR OF UNKNOWN QUALITY WITHOUT ADEQUATE DISINFECTION BEFORE OR AFTER THE SYSTEM.

2

WaterWorks ...... AUTOMATIC WATER CONDITIONER

UNPACKING / INSPECTION

The softener is shipped in 1 carton. It is completely

assembled at the factory, except as required at

installation.

Be sure to check the entire softener for any shipping

damage or parts loss. Also note any damage to the

TABLE OF CONTENTS

WARRANTY_, SAFETY GUIDES .................................................. 2

SPECIFICATIONS, DIMENSIONS ................................................ 4

BEFORE STARTING INSTALLATION ............................................. 5

TYPICAL INSTALLATION ILLUSTRATION ........................................ 6

INSTALLATION STEPS ...................................................... 7 - 10

PROGRAMMING THE PREMIUM DEMAND TIMER ........................... 10 -11

SANITIZING PROCEDURES ................................................... 12

WATER AND WATER CONDITIONING ...................................... 12 - 14

HOW THE WATER SOFTENER WORKS .................................... 14 - 15

GENERAL WATER SOFTENER MAINTENANCE/SERVICE CHECK LIST ....... 16 - 17

shipping cartons.

Small parts, needed to install the softener, are on a

skin-packed cardboard piece. To avoid loss of the

small parts, keep them on the skin-pack until you are

ready to use them.

PAGE NO.

PREMIER DEMAND TIMER FEATURES, SETTINGS, AND SERVICE

TIMER DISPLAYS ........................................................... 18

OPTIONAL RECHARGE CONTROLS / PROGRAM MEMORY ................... 19

RECHARGE (START) TIME, HEAVY DUTY BACKWASH ........................ 20

MODEL CODE, 12 OR 24 HOUR CLOCK, GALLONS OR LITERS MEASURE ...... 21

AUTO. ELECTRONIC DIAGNOSTICS ......................................... 22

SERVICE CHECKOUT PROCEDURES, WIRING SCHEMATIC ............... 22 - 24

WATER FLOW THROUGH VALVE ............................................ 25

REPAIR PARTS ........................................................... 26 - 29

WaterWorks TM...... AUTOMATIC WATERCONDITIONER

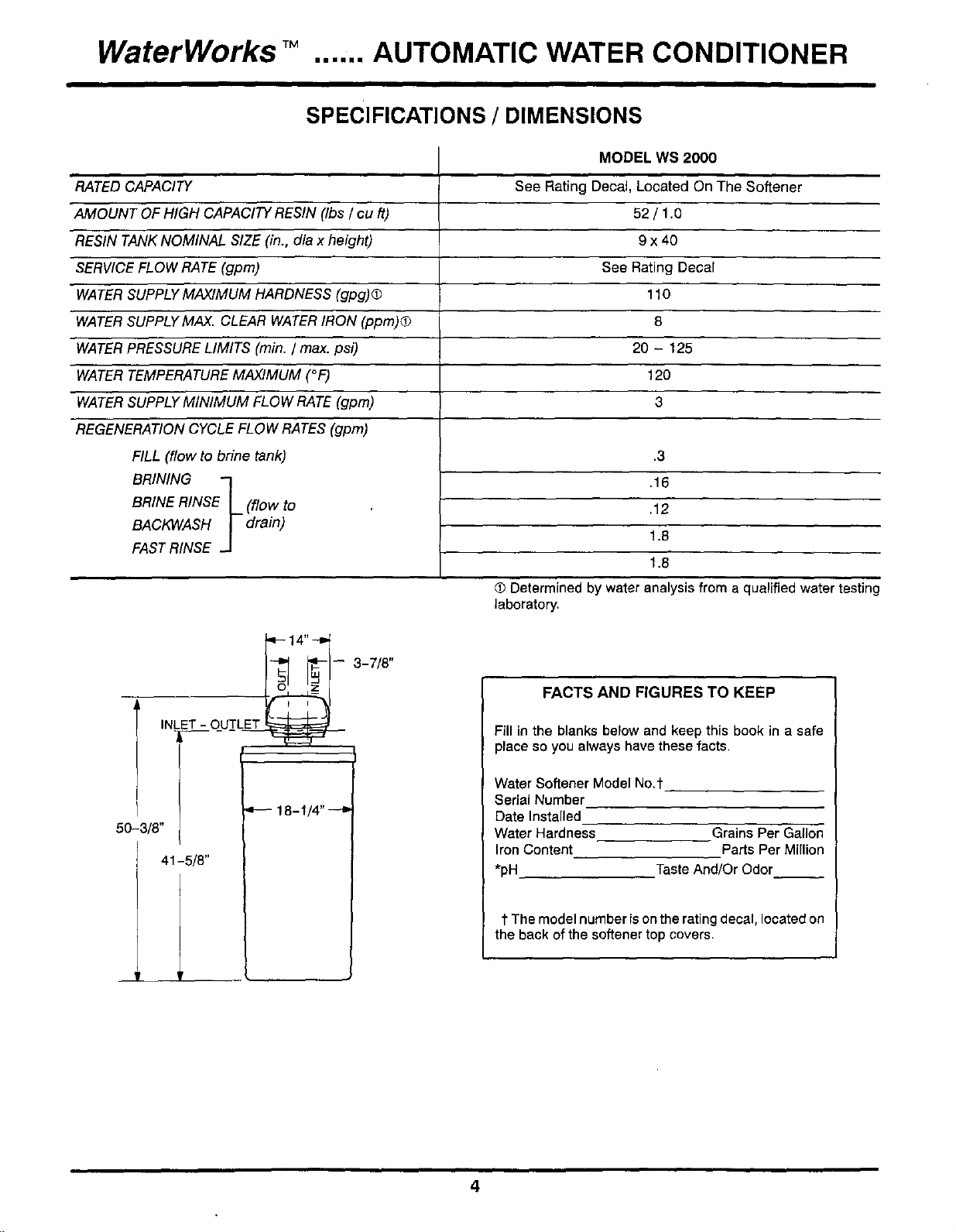

SPECIFICATIONS / DIMENSIONS

MODEL WS 2000

RATEDCAPACITY

AMOUNT OF HIGH CAPACITYRESIN (Ibs / cuft)

RESIN TANKNOMINAL SIZE (in., dia x height)

SERVICEFLOW RATE(gpm)

WATERSUPPLYMAXIMUM HARDNESS (gpg)_

WATERSUPPLYMAX. CLEAR WATERIRON (ppm)_

WATERPRESSURELIMITS (min. / max. psi)

WATERTEMPERATUREMAXIMUM (°F)

WATERSUPPLYMINIMUM FLOWRATE(gpm)

REGENERATION CYCLEFLOWRATES(gpm)

FILL (flow to brine tank)

BRINING 7

BRINE RINSEL (flow to

BACKWASH I drain)

FASTRINSE .J

See RatingDecal, Located On The Softener

52 / 1.0

9x40

See Rating Decal

110

8

20 - 125

120

3

.3

.16

.12

1.8

1.8

O Determined by water analysis from a qualified water testing

laboratory.

50-3/8"

t

INLET - O_U_TL_

41-5/8"

_9--14"-_

,I--- 18_1/4" --_

3-7/8"

FACTS AND FIGURES TO KEEP

Fill in the blanks below and keep this book in a safe

place so you always have these facts.

Water Softener Model No.t

Serial Number

Date Installed

Water Hardness Grains Per Gallon

Iron Content Parts Per Million

*pH Taste And/Or Odor

?The model number is on the rating decal, located on

the back of the softener top covers.

4

WaterWorks. ..... AUTOMATIC WATER CONDITIONER

BEFORE STARTING INSTALLATION

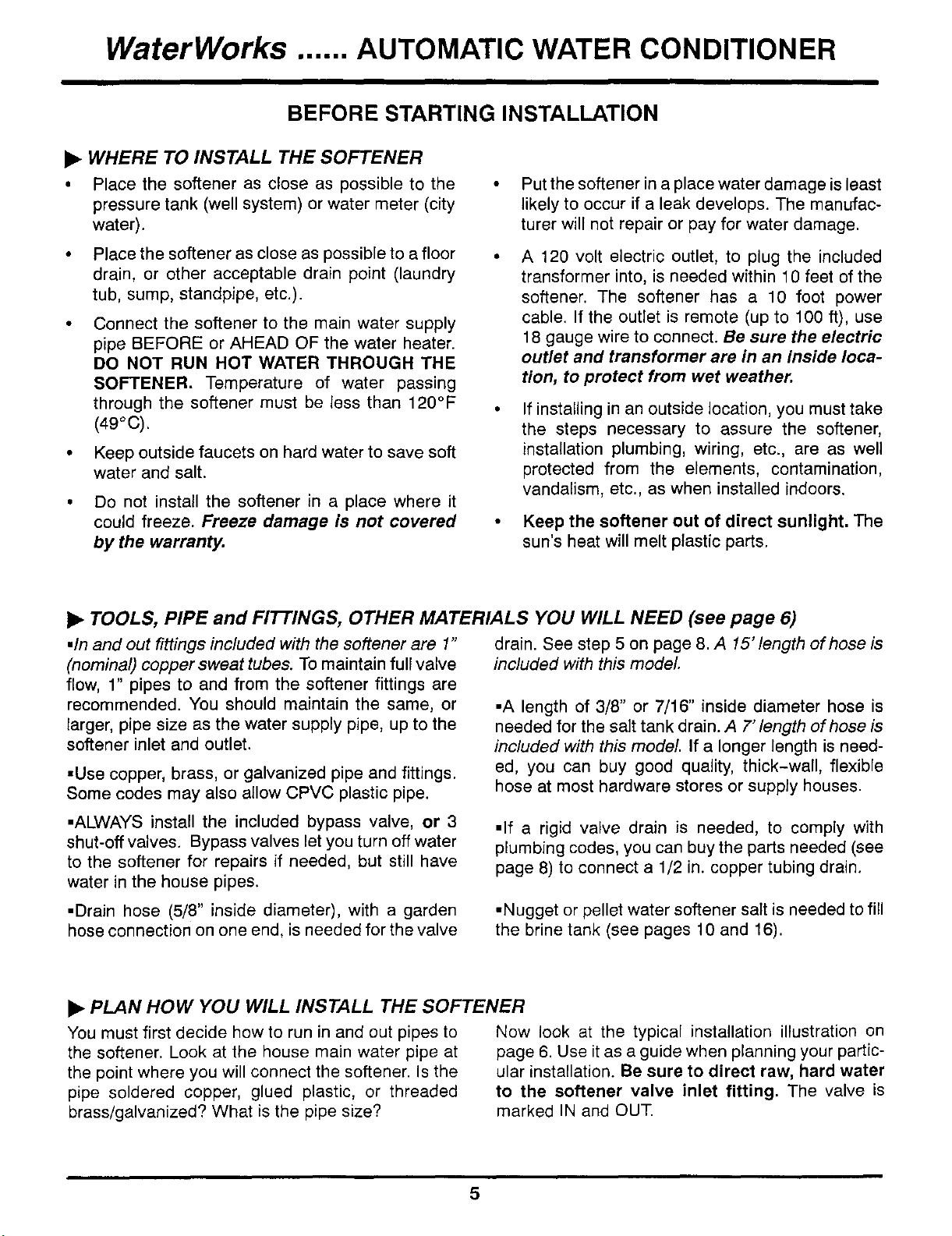

• WHERE TO INSTALL THE SOFTENER

• Place the softener as close as possible to the

pressure tank (well system) or water meter (city

water).

Put the softener in a place water damage is least

likely to occur if a leak develops. The manufac-

turer will not repair or pay for water damage.

• Place the softener as close as possible to a floor

drain, or other acceptable drain point (laundry

tub, sump, standpipe, etc.).

Connect the softener to the main water supply

pipe BEFORE or AHEAD OF the water heater.

DO NOT RUN HOT WATER THROUGH THE

SOFTENER. Temperature of water passing

through the softener must be less than 120°F

(49°C).

Keep outside faucets on hard water to save soft

water and salt.

Do not install the softener in a place where it

could freeze. Freeze damage is not covered

by the warranty.

A 120 volt electric outlet, to plug the included

transformer into, is needed within 10 feet of the

softener. The softener has a 10 foot power

cable. If the outlet is remote (up to 100 ft), use

18 gauge wire to connect. Be sure the electric

outlet and transformer are in an inside loca-

tion, to protect from wet weather.

If installing in an outside location, you must take

the steps necessary to assure the softener,

installation plumbing, wiring, etc., are as well

protected from the elements, contamination,

vandalism, etc., as when installed indoors.

Keep the softener out of direct sunlight. The

sun's heat will melt plastic parts.

• TOOLS, PIPE and FITTINGS, OTHER MATERIALS YOU WILL NEED (see page 6)

•In and out fittings included with the softener are 1"

(nominal) copper sweat tubes. To maintain full valve

flow, 1" pipes to and from the softener fittings are

recommended. You should maintain the same, or

larger, pipe size as the water supply pipe, up to the

softener inlet and outlet.

•Use copper, brass, or galvanized pipe and fittings.

Some codes may also allow CPVC plastic pipe.

drain. See step 5 on page 8. A 15'length ofhose is

included with this model.

•A length of 3/8" or 7/16" inside diameter hose is

needed for the salt tank drain. A 7' length of hose is

included with this model If a longer length is need-

ed, you can buy good quality, thick-wall, flexible

hose at most hardware stores or supply houses.

•ALWAYS install the included bypass valve, or 3

shut-off valves. Bypass valves let you turn off water

to the softener for repairs if needed, but still have

water in the house pipes.

•Drain hose (5/8" inside diameter), with a garden

hose connection on one end, is needed for the valve

• PLAN HOW YOU WILL INSTALL THE SOFTENER

You must first decide how to run in and out pipes to

the softener. Look at the house main water pipe at

the point where you will connect the softener. Is the

pipe soldered copper, glued plastic, or threaded

brass/galvanized? What is the pipe size?

5

•If a rigid valve drain is needed, to comply with

plumbing codes, you can buy the parts needed (see

page 8) to connect a 1/2 in. copper tubing drain.

• Nugget or pellet water softener salt is needed to fill

the brine tank (see pages 10 and 16).

Now look at the typical installation illustration on

page 6. Use it as a guide when planning your partic-

ular installation. Be sure to direct raw, hard water

to the softener valve inlet fitting. The valve is

marked IN and OUT.

WaterWorks ...... AUTOMATIC WATER CONDITIONER

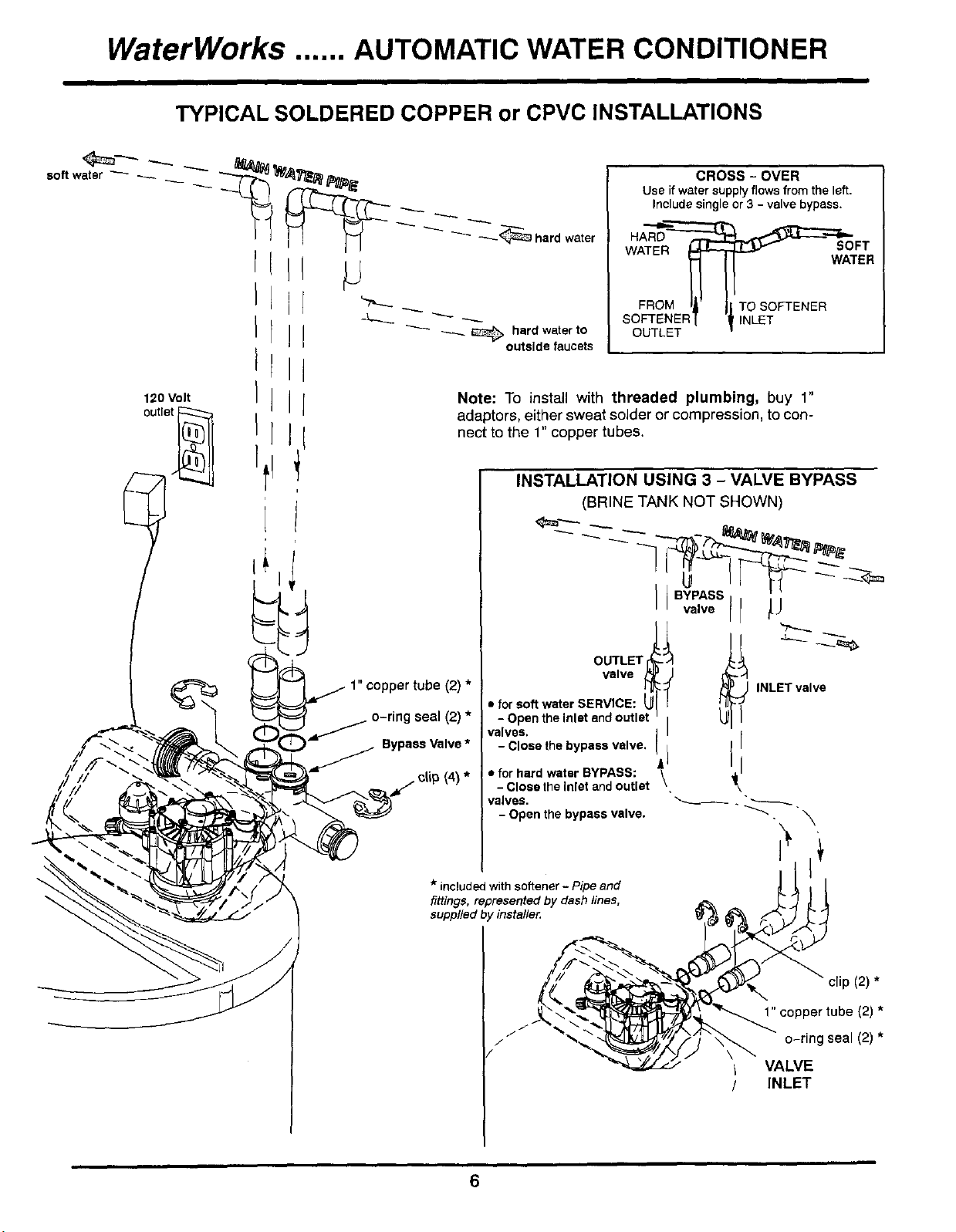

TYPICAL SOLDERED COPPER or CPVC INSTALLATIONS

soft water _ _

120 Volt

cutlet _

hardwater

I _ _ _ hard water to

outside faucets

I

Note: To install with threaded plumbing, buy 1"

adaptors, either sweat solder or compression, to con-

nect to the 1" copper tubes.

INSTALLATION USING 3 - VALVE BYPASS

CROSS - OVER

Use if water supply flows from the left.

Include single or 3 - valve bypass.

vHAATR_R- SOFT

W E_TER

FROM J| II TO SOFTENER

SOFTENER [ V INLET

OUTLET

(BRINE TANK NOT SHOWN)

[J I I 'rJ _==

BypASS,I !!

va,ver

1" copper tube (2) *

(2)*

Bypass Valve *

(4)*

* included with softener - Pipe and

fittings, represented by dash lines,

supplied L installer.

OUTLET

valve

• for soft water SERVICE:

- Open the inlet and outle

valves,

- Close the bypass valve.

• for hard water BYPASS:

- Close the Inlet and outlet

valves.

- Open the bypass valve.

/

INLET valve

I

clip (2) *

1" copper tube (2) *

o-ring seal (2) *

VALVE

INLET

6

WaterWorks ...... AUTOMATIC WATER CONDITIONER

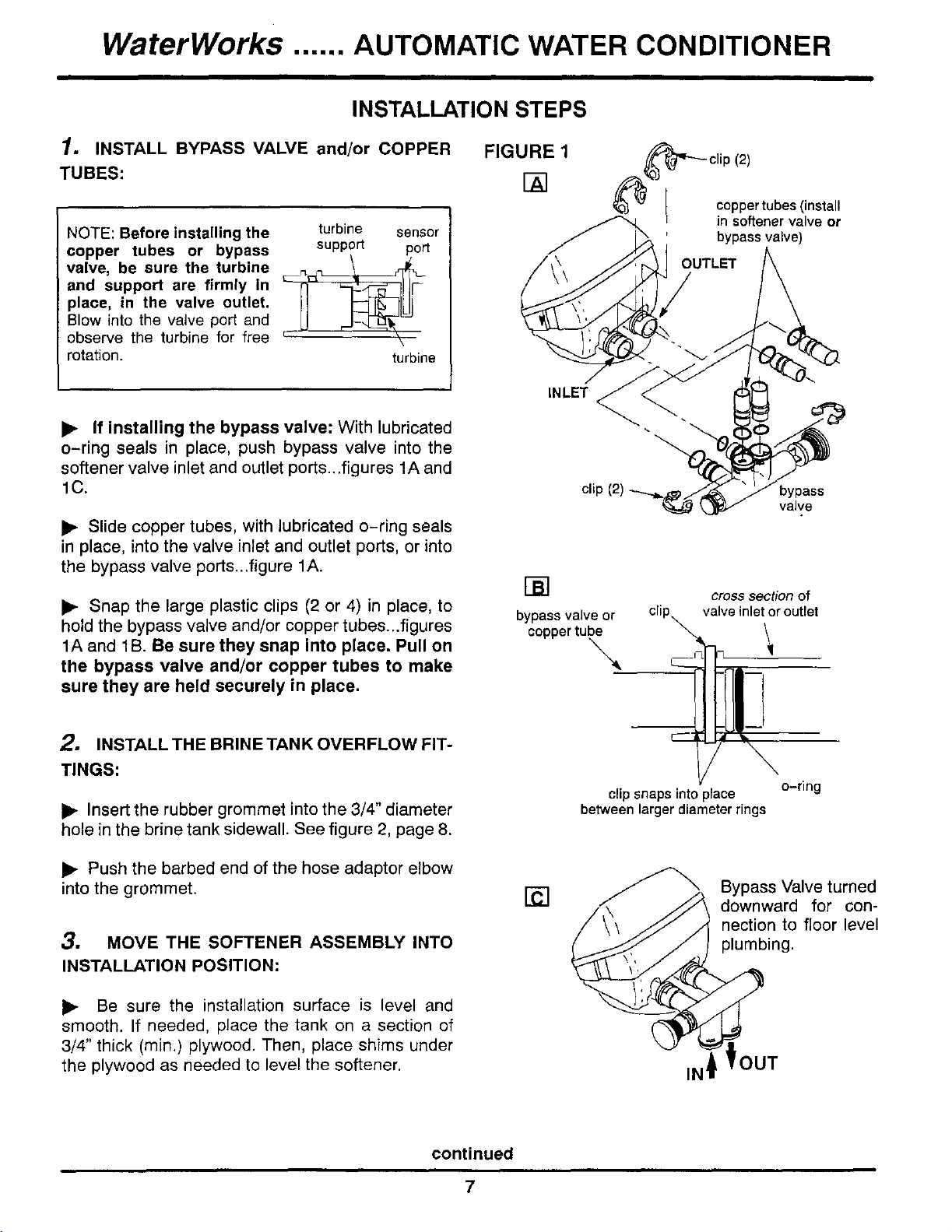

INSTALLATION STEPS

1. INSTALL BYPASS VALVE and/or COPPER

TUBES:

NOTE: Before installing the

copper tubes or bypass

valve, be sure the turbine

and support are firmly In

place, in the valve outlet.

Blow into the valve port and

observe the turbine for free

rotation.

• If installing the bypass valve: With lubricated

o-ring seals in place, push bypass valve into the

softener valve inlet and outlet ports...figures 1A and

1C.

• Slide copper tubes, with lubricated o-ring seals

in place, into the valve inlet and outlet ports, or into

the bypass valve ports...figure 1A.

• Snap the large plastic clips (2 or 4) in place, to

hold the bypass valve and/or copper tubes...figures

1A and 1B. Be sure they snap into place. Pull on

the bypass valve and/or copper tubes to make

sure they are held securely in place.

turbine sensor

support port

turbine

FIGURE 1

[]

[]

bypass valve or

copper tube

_ clip (2)

copper tubes (install

in softener valve or

bypass valve)

OUTLET

clip (2) bypass

valve

cross section of

valve inlet or outlet

\

2. INSTALLTHE BRINETANKOVERFLOWFIT-

TINGS:

• Insert the rubber grommet into the 3/4" diameter

hole in the brine tank sidewall. See figure 2, page 8.

• Push the barbed end of the hose adaptor elbow

into the grommet.

3. MOVE THE SOFTENER ASSEMBLY INTO

INSTALLATION POSITION:

• Be sure the installation surface is level and

smooth. If needed, place the tank on a section of

3/4" thick (min.) plywood. Then, place shims under

the plywood as needed to level the softener.

continued

clip snaps into place o-ring

between larger diameter rings

[]

Bypass

/\ J/_ downward for con-

/_'\ JJ /_ nection to floor level

Valve turned

j.j p,umbin0

7

WaterWorks ...... AUTOMATIC WATER CONDITIONER

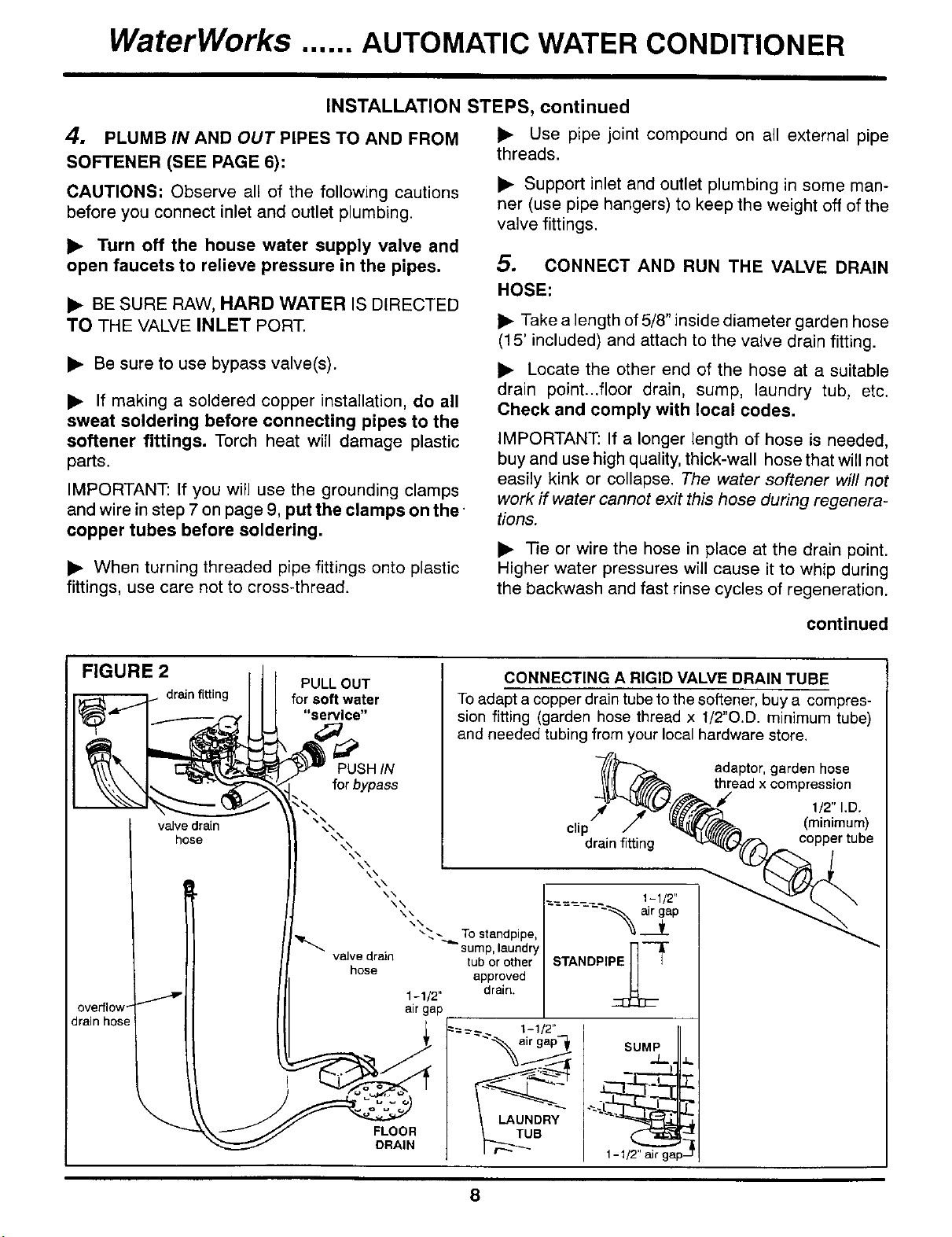

INSTALLATION STEPS, continued

4. PLUMB IN AND OUT PIPES TO AND FROM

SOFTENER (SEE PAGE 6):

CAUTIONS; Observe all of the following cautions

before you connect inlet and outlet plumbing.

• Turn off the house water supply valve and

open faucets to relieve pressure in the pipes.

• BE SURE RAW, HARD WATER IS DIRECTED

TO THE VALVE INLET PORT.

• Be sure to use bypass valve(s).

• If making a soldered copper installation, do all

sweat soldering before connecting pipes to the

softener fittings. Torch heat will damage plastic

parts.

IMPORTANT: If you will use the grounding clamps

and wire instep 7 on page 9, put the clamps on the'

copper tubes before soldering.

• When turning threaded pipe fittings onto plastic

fittings, use care not to cross-thread.

• Use pipe joint compound on all external pipe

threads.

• Support inlet and outlet plumbing in some man-

ner (use pipe hangers) to keep the weight off of the

valve fittings.

5. CONNECT AND RUN THE VALVE DRAIN

HOSE:

• Take a length of 5/8" inside diameter garden hose

(15' included) and attach to the valve drain fitting.

• Locate the other end of the hose at a suitable

drain point...floor drain, sump, laundry tub, etc.

Check and comply with local codes.

IMPORTANT: If a longer length of hose is needed,

buy and use high quality, thick-wall hose that will not

easily kink or collapse. The water softener will not

work if water cannot exit this hose during regenera-

tions.

• Tie or wire the hose in place at the drain point.

Higher water pressures will cause it to whip during

the backwash and fast rinse cycles of regeneration.

FIGURE 2

ove_low

drain hose

drain fitting

valve drain

hose

PULL OUT

for soft water

"service"

PUSH IN

for bypass

%\

\\

valve drain

hose

\\

\\

\\

\\

"_ _ TOstandpipe,

1-1/2"

air gap

continued

CONNECTING A RIGID VALVE DRAIN TUBE

To adapt a copper drain tube tothe softener, buy a compres-

sion fitting (garden hose thread x 1/2"O.D. minimum tube)

and needed tubing from your local hardware store.

adaptor, garden hose

thread x compression

2f 1/2" I.D.

clip (minimum)

drain fitting copper tube

1-1/2"

sump, laundry

tub or other

approved

drain.

1-1/2"

air gap-_

STANDPIP Z

SUMP

-L.. L

8

LAUNDRY

TUB

WaterWorks ...... AUTOMATIC WATER CONDITIONER

INSTALLATION STEPS, continued

Also provide an air gap of at least 1-1/2" between the

end of the hose and the drain point. An air gap pre-

vents possible siphoning of sewer water, into the

softener, if the sewer should "back-up".

• If raising the drain hose overhead is required to

get to the drain point, do not raise higher than 8'

above the floor. Elevating the hose may cause a

back-pressure that could reduce brine draw during

regenerations.

6o CONNECT AND RUN THE BRINE TANK

OVERFLOW HOSE: This drain is for safety only. If

the brine tank should over-fill with water, the excess

is carried to the drain.

• Attach a length of hose (7' included) to the drain

elbow, installed in step 2, page 7. Use a hose clamp

to hold it in place.

• Locate the other end'of the hose at the drain

point. Do not elevate this hose higher than the el-

bow on the brine tank. Do not tee this hose to the

valve drain hose.

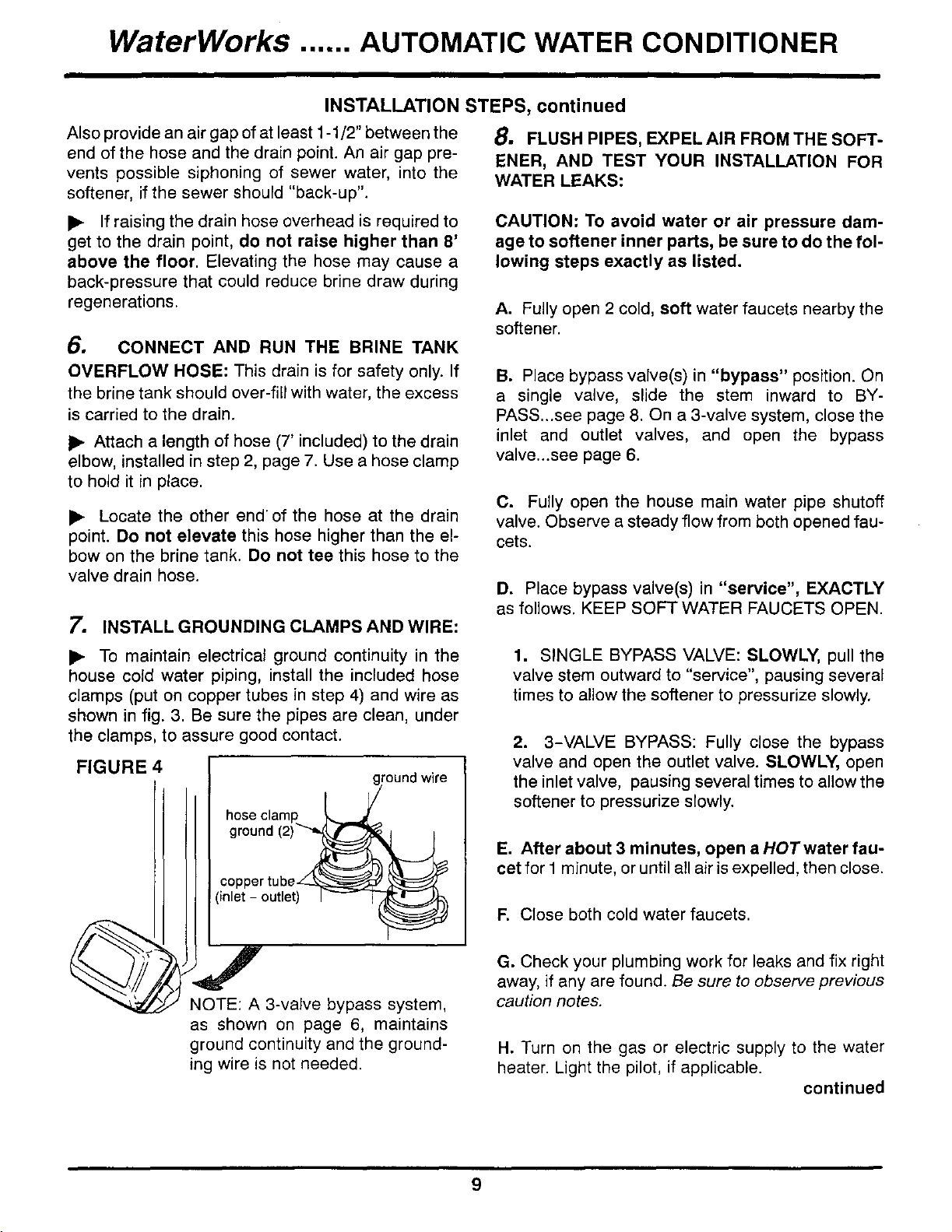

7. INSTALL GROUNDING CLAMPS AND WIRE:

8. FLUSH PIPES, EXPEL AIR FROM THE SOFT-

ENER, AND TEST YOUR INSTALLATION FOR

WATER LEAKS:

CAUTION: To avoid water or air pressure dam-

age to softener inner parts, be sure to do the fol-

lowing steps exactly as listed.

A. Fully open 2 cold, soft water faucets nearby the

softener.

B. Place bypass valve(s) in "bypass" position. On

a single valve, slide the stem inward to BY-

PASS...see page 8. On a 3-valve system, close the

inlet and outlet valves, and open the bypass

valve...see page 6.

C. Fully open the house main water pipe shutoff

valve. Observe a steady flow from both opened fau-

cets.

D. Place bypass valve(s) in "service", EXACTLY

as follows. KEEP SOFT WATER FAUCETS OPEN.

• To maintain electrical ground continuity in the

house cold water piping, install the included hose

clamps (put on copper tubes in step 4) and wire as

shown in fig. 3. Be sure the pipes are clean, under

the clamps, to assure good contact.

FIGURE 4

g/round wire

hose clamp_

ground (2)_

(Cn_PP_ertu be__

/

NOTE: A 3-valve bypass system,

as shown on page 6, maintains

ground continuity and the ground-

ing wire is not needed.

1. SINGLE BYPASS VALVE: SLOWLY, pull the

valve stem outward to "service", pausing several

times to allow the softener to pressurize slowly,

2. 3-VALVE BYPASS: Fully close the bypass

valve and open the outlet valve. SLOWLY, open

the inlet valve, pausing several times to allow the

softener to pressurize slowly.

E. After about 3 minutes, open a HOTwater fau-

cet for 1 minute, or until all air is expelled, then close.

F. Close both cold water faucets.

G. Check your plumbing work for leaks and fix right

away, if any are found. Be sure to observe previous

caution notes.

H. Turn on the gas or electric supply to the water

heater. Light the pilot, if applicable.

continued

9

WaterWorks ...... AUTOMATIC WATER CONDITIONER

INSTALLATION

9. ADD WATER AND SALT TO THE BRINE

TANK:

• Remove the salt storage area cover. Add about

3 gallons of water into the tank. Do not add into the

brinewell.

• Fill the tank with NUGGET, PELLET or coarse

SOLAR water softener salt. Do not use rock, block,

granulated, and ice cream making salts, or salt with

iron removing additives. Also see page 16. Salt

storage capacity is 200 Ibs or more.

Note: If the softener is installed in a humid basement

or other damp area, it is better to fill the tank with less

salt, more frequently (see salt bridging in the mainte-

nance section). Eighty to 100 Ibs of salt will last for

several months, depending on water hardness and

family size.

STEPS, continued

10. CONNECT TO ELECTRICAL POWER:

• The softener works on 24 volt, 60 Hz electric pow-

er. The included transformer changes standard 120

volt AC house power to 24 volts. Plug the trans-

former into a 120 volt outlet only. Be sure the out-

let is always "live" so it can not be switched off by

mistake.

Fasten the 2 power cable lugs to the 2 screws on the

transformer, and tighten the screws. Then, plug the

transformer into the electrical outlet.

11. PROGRAM THE PREMIER DEMAND TIMER,

below:

PROGRAMMING THE PREMIER DEMAND TIMER

. TOUCH-HOLD button

WATER CONDI T I_

0,s,_/ J ,, 0o°oo

WaterWorks TM

DATA button

• TIMER SETTINGS REQUIRED...upon installation, and after an extended power outage (see Program

Memory, page 19).

NOTES:

• WHEN THE TRANSFORMER IS PLUGGED INTO THE ELECTRICAL OUTLET (STEP 10, ABOVE),

12"00AM (flashing), and PRESENT TIME show in the upper display area. Program the timer as instructed

on page 11. If A- - - is flashing, please see Model Code setting on page 21.

continued

10

Loading...

Loading...