Water Worker WWDPC Installation Manual

INSTALLATION MANUAL FOR DIGITAL PRESSURE CONTROL

Model WWDPC

Your WWDPC has been carefully assembled and factory tested. To enjoy

the full service this unit can provide, you should read and follow all of the

instructions in this manual. When all installation steps have been completed,

make sure you also follow the enclosed post-installation and startup checklists

before using your WATER WORKER® product. You should also read carefully

the sections describing proper product maintenance and follow the required

procedures as you use your WWDPC. Keep this manual with the product. This

manual may become out-of-date by later amendments. Check our web site,

www.waterworkerDIY.com or ask your WATER WORKER® supplier for any

updates relating to your product. This product comes with a limited two (2)

year warranty. Visit www.waterworkerdiy.com for complete warranty details.

THIS IS THE SAFETY ALERT SYMBOL. IT IS USED TO ALERT YOU

TO POTENTIAL PERSONAL INJURY AND OTHER HAZARDS. OBEY

ALL SAFETY MESSAGES THAT FOLLOW THIS SYMBOL TO REDUCE

THE RISK OF POSSIBLE INJURY AS WELL AS PROPERTY DAMAGE.

INSTALLER: LEAVE THIS MANUAL WITH THE OWNER

Part # 9046-0002 (01/19)

1

Patent Pending

INSTALLATION INSTRUCTIONS

Unit is Recommended to be Installed by a Qualified Professional

PLUMBING CONNECTION (1/4" NPT FEMALE SYSTEM CONNECTION)

1. Select a location for the WWDPC. The WWDPC should be mounted near the

pressure tank or pump, depending upon the installation

LOCATE THE WWDPC FOLLOWING ALL LOCAL CODES. DO

NOT LOCATE THE UNIT WHERE IT CAN BE AFFECTED BY

FLOODING.

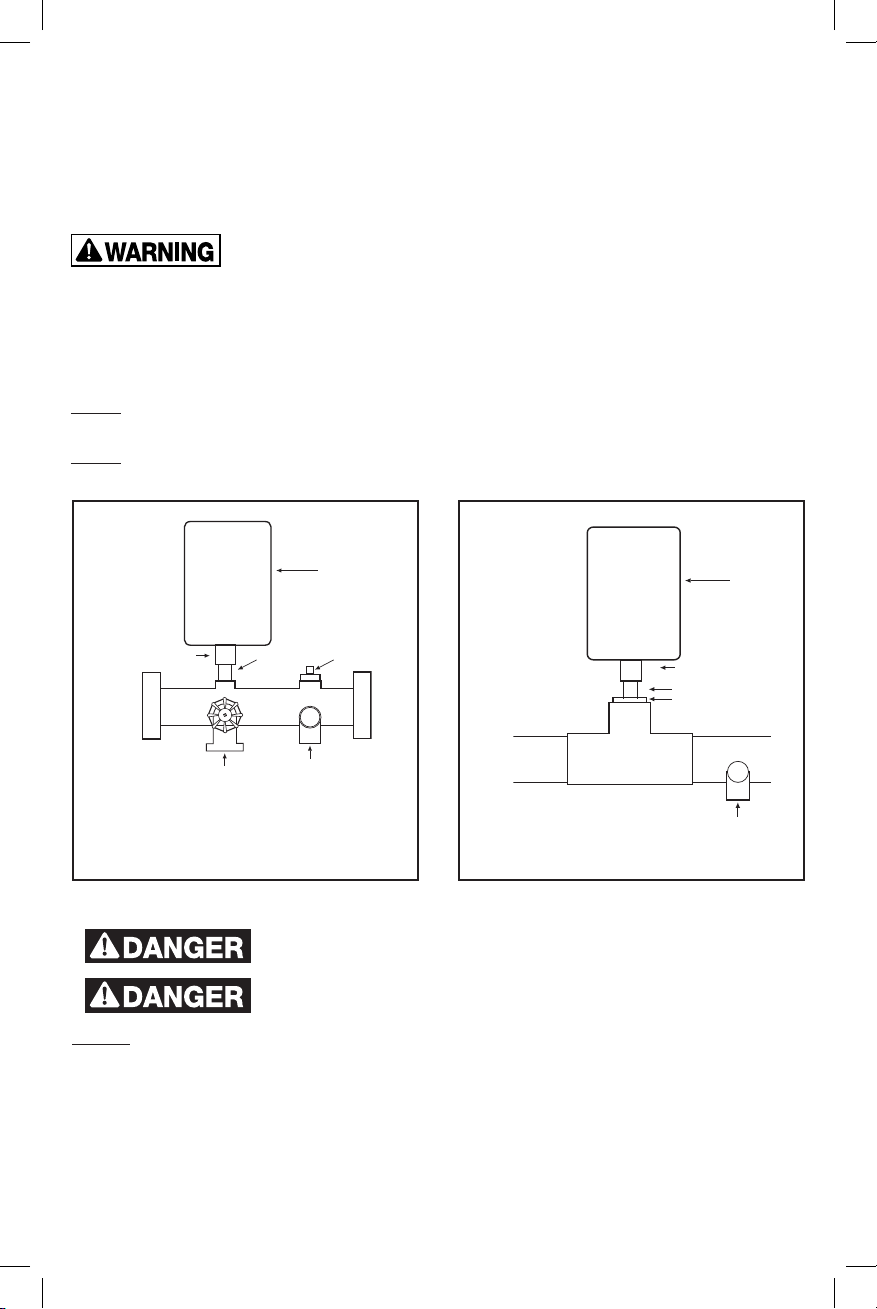

2. You may assemble the WWDPC to a “Tank Tee” or “Tank Cross” (Figure

1) or adapt the unit to an in-line pipe fitting (Figure 2). Use Teflon® sealing

tape or pipe sealant. Tighten the WWDPC using the wrench flats provided

on the bottom connection. DO NOT EXCEED 15LB./FT. of torque.

Note: Do not allow pipe sealant or other contaminants to enter the small port in

the WWDPC connection.

Note: A mechanical pressure gauge is not required. Use the appropriate plug to

block any unused ports.

1/4" NPT Female

System Connection

Drain

Valve

INSTALLATION ON TYPICAL TANK TEE

Fig. 1

WWDPC

Pipe Nipple Plug

Relief Valve

Tee

GENERAL IN-LINE INSTALLATION

Fig. 2

WWDPC

1/4" NPT Female

System Connection

Pipe Nipple

Adapt as necessary

Relief Valve

ELECTRICAL CONNECTION

ELECTROCUTION HAZARD. FIRST DISCONNECT ALL

ELECTRICAL POWER BEFORE SERVICING.

ELECTROCUTION HAZARD. THE WWDPC MUST BE

ELECTRICALLY GROUNDED.

NOTE: The WWDPC will operate on 115 VAC & 230 VAC systems. Its ambient air

temperature rating is 122°F / 50°C.

1. Disconnect power and verify with a volt meter.

2. Determine the pump electrical requirements. If unknown, contact the pump

manufacturer.

3.

Select the appropriate wire gauge per local codes and the pump manufacturer’s

recommendation.

2

4. Loosen the screw on the cover of the controller and remove the plastic cover,

LINE IN

3-WIRE, SINGLE PHASE CONTROL BOX

TO MOTOR

TYPICAL 3-PHASE CONTROL BOX

exposing the wiring pigtails. (When reassembling cover, do not over-tighten

screw.)

5. The wire conduit hub is to be connected to the conduit before the hub is

connected to the enclosure. The maximum hub diameter cannot exceed 1.15".

Larger hub will interfere with cover closure.

6. The opening of the enclosure shall be closed with hubs rated 3, 3S, 3SX, 3X, 4, 4X,

6 or 6P.

NOTE: Steps 5 and 6 are required for outdoor installations only.

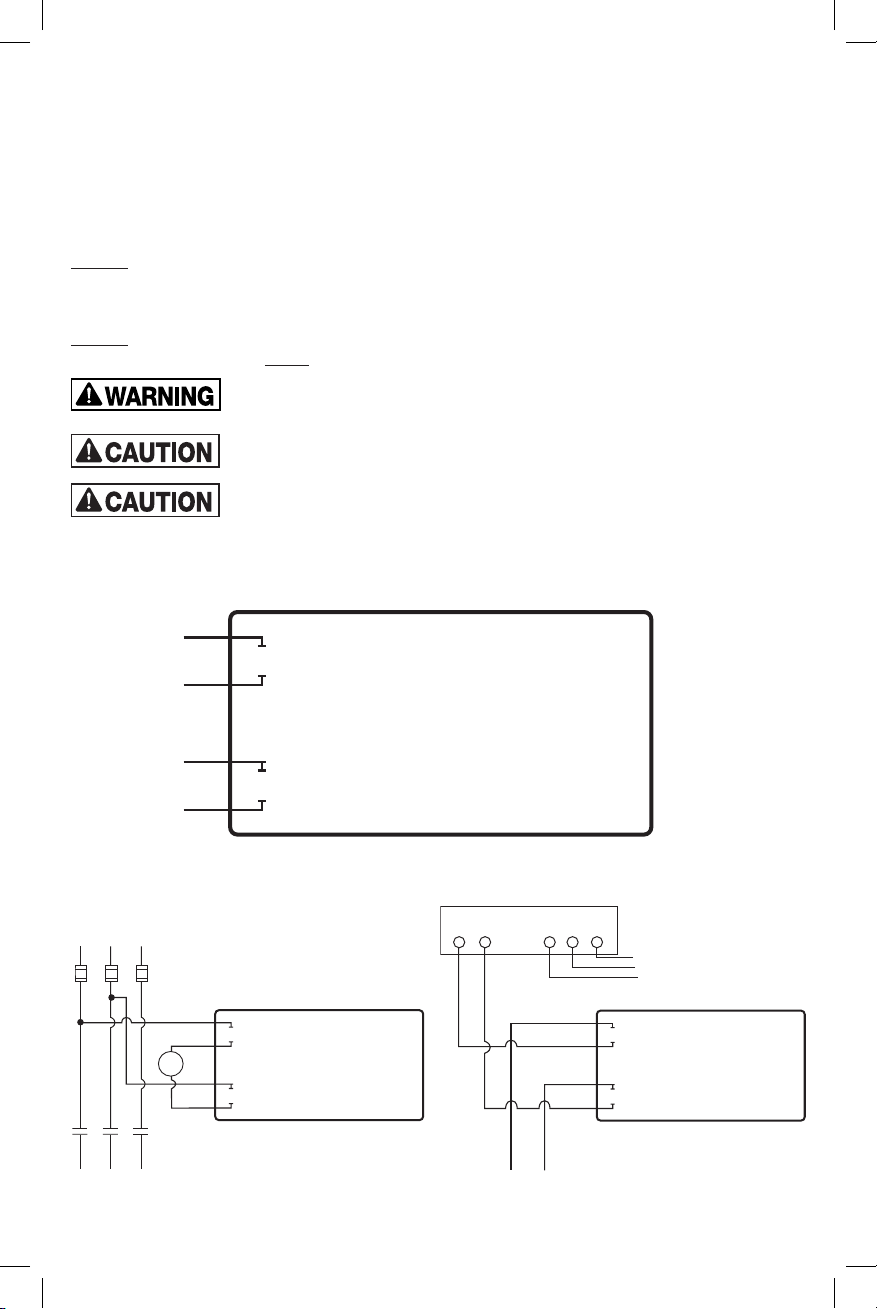

7. Following all electrical codes, wire the WWDPC using the wiring diagram below

(Figure 3).

NOTE: The WWDPC has openings to accept standard conduit terminations.

Outdoor installations must use watertight connections.

UNIT MUST NOT BE SUPPORTED SOLELY BY THE ELECTRICAL

CONDUIT.

WATERTIGHT CONDUIT CONNECTIONS MUST BE USED WHEN

EXPOSED TO DIRECT WEATHER, MOISTURE OR HIGH HUMIDITY.

ELECTRICAL BONDING BETWEEN CONDUIT CONNECTIONS IS

NOT AUTOMATIC AND MUST BE PROVIDED AS PART OF THE

INSTALLATION. BONDING KIT, PART #146-2350 CAN BE ORDERED SEPERATELY.

Fig. 3

®

Digital Pressure Control

LINE

Water Worker

Black

LINE

Blue

White

White

w/Black

FUSES

COIL

CONTACTS

Water Worker Digital Pressure Control

LOAD

LOAD

L1

L2 L3

Black

Blue

White

White

w/Black

L1

L2 YBR

3

TO

MOTOR

Water Worker Digital Pressure Control

Black

Blue

White

White

w/Black

Loading...

Loading...