Water Tech REIONATOR Classic Series Care And Use Manual

Care and Use Guide

REIONATOR

™

Classic Series

with Triton Electronic Control Valve

WQA Gold Seal certifi ed to NSF/ANSI Standards 42 and

44 for meeting or exceeding industry standards of

aesthetic chlorine reduction and softening effi ciency.

Water Tech Industries Residential REIONATOR

™

LIMITED LIFETIME WARRANTY

Applicable to REIONATOR™ Classic Models:

RC32-TM, RC40-TM, RC48-TM, RC64-TM, RC80-TM

Water Tech Industries (WTI) hereby warrants said equipment, only to the original purchaser at the original

installation location.

THIS WARRANTY PERIOD BEGINS at the time of initial installation and use. The warranty becomes valid upon

registration of the equipment.

LIMITED LIFETIME WARRANTY ON CONDITIONER AND BRINE TANK – Water Tech Industries will replace or repair (at WTI option) any conditioner tank that becomes unusable because of leakage, corrosion or rupture.

All internal mechanical components are warranted for a period of fi ve years from date of installation.

LIMITED LIFETIME WARRANTY ON RESIN – The REIONATOR has been equipped with the highest quality NSF

certifi ed water treatment media. If, upon factory inspection, the resin is found to be defective, Water Tech

Industries will furnish replacement resin. The resin warranty does not cover resins subjected to water containing greater than 3.0-ppm of free chlorine or chloramines or containing greater than 1.0-ppm total Iron

and/or Manganese. Resin which has been fouled by iron, manganese, organics (or other contaminants not

designed for treatment by the REIONATOR) is not covered.

LIMITED LIFETIME WARRANTY ON CONTROL VALVE - The REIONATOR has been equipped with the highest

quality water conditioning control valves available. If, upon factory inspection, the control valve body or PC

board is found to be defective, WaterTech Industries will furnish repair or replacement (at WTI option) of

the control valve body and/or the PC board. All internal mechanical components are warranted for a period

of fi ve years from the date of installation

EXCLUSIONS AND LIMITATION OF LIABILITY – Water Tech Industries' liability for special, incidental, or

consequential damages is expressly disclaimed. In no event shall Water Tech Industries' liability exceed

the obligation of repairing or replacing any part that becomes defective under valid warranty coverage as

described above. Cosmetic damage that does not affect the process functionality of the equipment is not

covered. Water Tech Industries makes every effort to ensure that all illustrations and specifi cations are

correct. However, these do not imply a warranty that the product is merchantable or fi t for a particular

purpose, or that the product may not vary from the illustrations and specifi cations. The warranty contained

herein is in lieu of all other warranties, expressed or inferred, including any implied warranty of fi tness

for a particular purpose. Labor and transportation costs incidental to the delivery or replacement of parts

other than WTI factory repairs are not covered under this warranty. In the event of a warranty replacement

or repair, WTI will cover the cost of shipping the covered components. This warranty expressly excludes any

system which has been damaged by accident, fi re, fl ood, Act of God, abuse, neglect, freezing, excessive

temperature (below 40° F or above 110° F.), inappropriate pressure (below 20psi or above 100psi), misuse,

alteration, product identifi cation tampering, misapplication, installation or operation not consistent with

WTI instructions and installation outside of applicable plumbing codes and local regulations. Fulfi llment

of the warranty coverage by WTI is contingent on proper execution of the procedures set forth in the WTI

Warranty RMA policy. No person or representative is authorized to assume for Water Tech Industries any

liability on its behalf, or in its name, except to refer the purchaser to this warranty. This warranty gives you

specifi c legal rights, you may also have other rights which vary from state to state.

WHAT MUST YOU DO TO OBTAIN WARRANTY SERVICE - The warranty registration card must be fi lled out

completely and returned to Water Tech Industries within thirty days of installation to validate the REIONATOR Limited Lifetime Warranty. Units that have not been registered will be covered under the Standard

Product Warranty rather than the Limited Lifetime Warranty. Repair work should be performed by an authorized Water Tech Dealer. In the event that authorized dealer service is not available, defective components

may be returned directly to Water Tech Industries for warranty service. The registered owner must return

the defective component, freight prepaid, with proof-of-purchase, within the applicable warranty period.

P: 888-254-8412 • F: 503-261-9118 • 13110-3 NE Airport Way, Portland, OR 97230 • watertech.com

R 10/12/07

Dealer Name:

Dealer Phone Number Installation Date:

Model Number: Serial Number

CUSTOMER CHECKLIST

After installation, installer should make sure of the following:

F Customer has a Care and Use Guide and warranty card

F Customer knows how to restart system if power goes out

F Customer knows how to put the system in bypass in case of an emergency

F Customer knows what kinds of regenerant to use in brine tank

F Customer knows where to purchase regenerant salt or potassium chloride

F Customer knows how often to check regenerant salt/potassium level

F Customer knows how much salt or potassium chloride to put in brine tank

F Customer knows how to contact dealer in case of service needs

F Customer is aware the warranty card must be fi lled out and mailed in or

submitted online to activate warranty coverage

Dear REIONATOR Customer:

Congratulations on your purchase of a Water Tech REIONATOR water conditioner

equipped with the Triton control valve. This is a premium quality system that is only

available through authorized Water Tech Dealers.

With minimal care, your system is designed to serve you for many years. I hope you

enjoy your new REIONATOR.

Sincerely,

Mark Russell

President

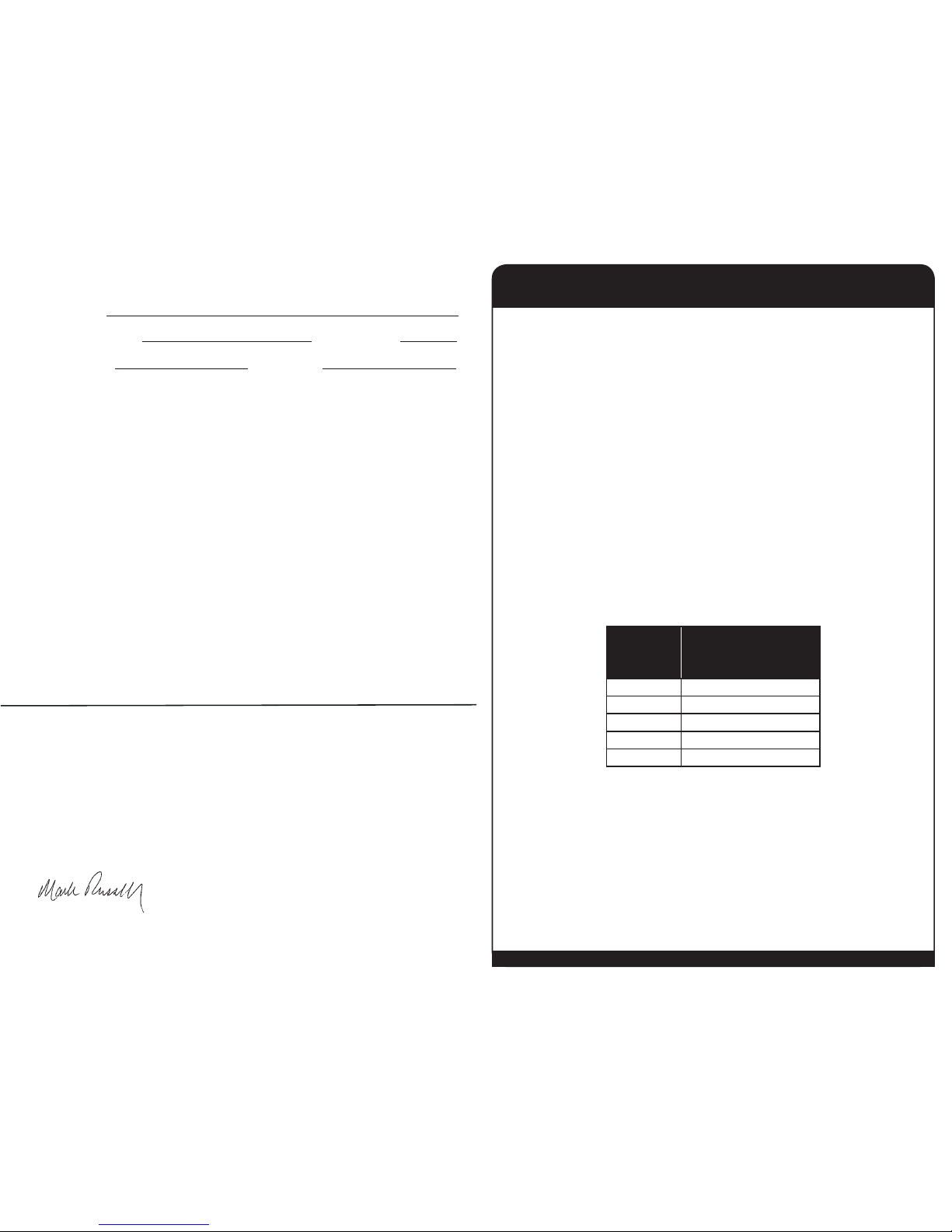

DEALER CONTACT AND PRODUCT INFORMATION

14

Specifi cations

The REIONATOR™ is a DIR (demand initiated regeneration) softener which complies

with specifi c performance specifi cations intended to minimize the use of regenerant

brine in its operation.

This water softener conforms to NSF/ANSI Standard 42 for reduction of aesthetic chlorine and NSF/ANSI Standard 44 for softening effi ciency as verifi ed and substantiated

by test data. While testing was performed under laboratory conditions, due to varying

water conditions actual performance may vary.

The REIONATOR has been tested according to NSF/ANSI Standard 42 for the reduction

of the substances listed in the table below. The concentration of the substance in the

water entering the system was reduced to a concentration less than or equal to the

permissible limit for water leaving the system as specifi ed by NSF/ANSI Standard 42.

The REIONATOR is not intended for use in treating water that is microbiologically

unsafe or of unknown quality without adequate disinfection before and/or after

the system.

Usage of the REIONATOR in a manner other than prescribed in the manufacturer’s

warranty will void the REIONATOR limited lifetime warranty.

As with any appliance, proper operation and maintenance is required to ensure trouble-free operation. Please consult your local authorized Water Tech dealer for service.

MODEL

AESTHETIC CHLORINE

REDUCTION (GALLONS)

RC32-TM 810

RC40-TM 1000

RC48-TM 1180

RC64-TM 1580

RC80-TM 1960

Maintenance

This manual is applicable to one of the following model numbers:

RC32-TM, RC40-TM, RC48-TM, RC64-TM, RC80-TM

With minimal care, your system is designed to serve you for many years. While constant attention to your system is not necessary, the following suggestions will insure

your system’s performance and your convenience and satisfaction.

MAINTENANCE

• Salt in the brine tank is used as a resin ‘cleaner’ to remove contaminants during

the regeneration process. Check the salt level of the brine tank on a regular basis

to make sure your system is using salt. Your REIONATOR™ will function properly

whether the salt tank is near full or near empty, refi ll when necessary.

• Use only premium-grade regenerant salt that is designed specifi cally for use with

water softeners and conditioners. Sodium (NaCl) salt may be used. Potassium (KCl)

is recommended in most applications for superior taste, odor, aesthetic and environmental benefi ts.

SERVICE ISSUES

• If the Triton control valve system display does not appear, check to make sure the

system is plugged in and that there is power at the receptacle. If the unit does not

respond with power present, contact your Water Tech Dealer.

• The manual bypass valve (which is located at the rear of the unit) is designed to

isolate the unit from the plumbing for servicing or to shut off the water supply to

the unit in the event of a leak at the conditioner. Consult the operating diagram on

pages 11-12 of this manual for instructions to position your bypass valve for either

service or isolation.

• If you experience an extended power outage (over an hour in length), you may need

to reset the time of day on the Triton control valve. The internal battery is designed

to retain the time of day for up to 24 hours. There is no need to reset any other

part of the program as this is kept in non-volatile, permanent memory. Consult the

programming instructions on page 10 of this manual for instructions to set the electronic time clock of the Triton control valve.

• If you experience a change in water quality:

1. First check to see if your brine tank is empty (see above). If necessary,

add regenerant salt.

2. Check to see if your system has power (see above).

3. Check to see if the drain line has a kink that may be restricting fl ow during

regeneration. Correct, if necessary, or contact your Water Tech Dealer.

2

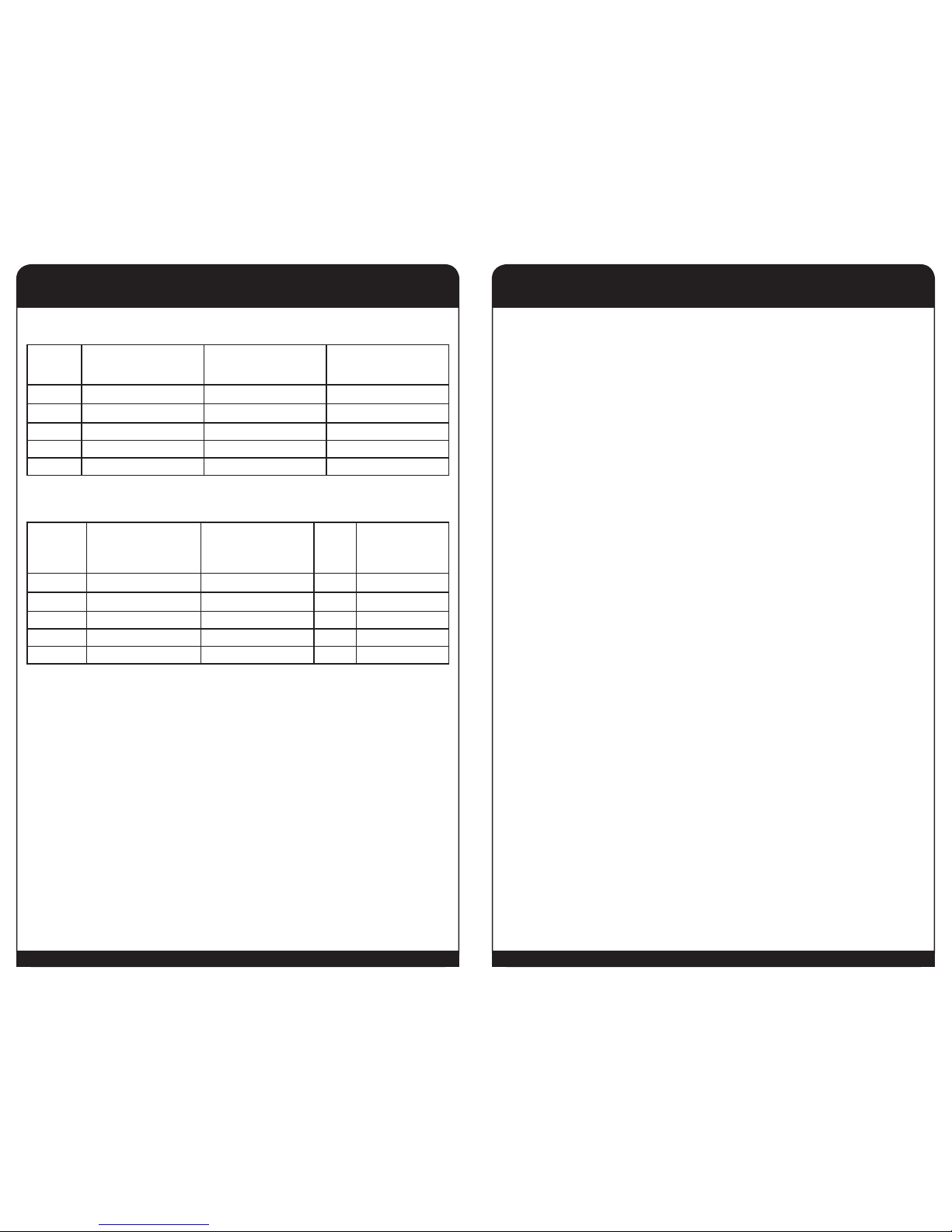

Specifi cations

Water Tech recommends the use of Potassium Chloride (KCl) as a regenerant salt.

* The effi ciency is only valid at the stated salt dosage and maximum service fl ow.

1

Softening effi ciency values based on NaCl as the regenerant salt.

2

Softening capacity values based on NaCl as the regenerant salt.

Effi ciency rated softeners shall have a rated salt effi ciency of not less than 3350 grains

of total hardness exchange per pound of salt, and shall not deliver more than its

listed rating.

MIN/MAX WORKING PRESSURE: 20-125 psi or 138-861 kPa

MIN/MAX OPERATING TEMPERATURE: 40°F-110°F or 4.4-43.3º C

MAX FLOW TO DRAIN DURING REGENERATION: 2.2 gpm or 8.3 l/min

INPUT VOLTAGE: 110-120VAC @ 60Hz

OPERATING VOLTAGE: 12VAC @ 60Hz

13

Model

*

1

Softening Effi ciency

@ Stated Salt Setting

(Grains Per Pound)

2

Softening Capacity

@ Stated Salt Setting

(Grains Per Gallon)

Max. Recommended

Hardness

(Grains Per Gallon)

RC32-TM

4400 @ 3 lbs. 15,000 @ 3 lbs. 35

RC40-TM

4400 @ 4lbs. 19,200 @ 4 lbs. 45

RC48-TM 4790 @ 5lbs. 22,600 @ 5 lbs. 55

RC64-TM 4790 @ 6lbs. 30,500 @ 6 lbs. 35

RC80-TM 4790 @ 8lbs. 37,400 @ 8 lbs. 45

Model

Max. Recommended

Flow Rate /

Service Flow Rate

(Gallons per minute)

Max. Flow to Drain

During

Regeneration

(Gallons per minute) @PSID

Total Bed Depth

(FT3)

RC32-TM

8.8 2.2 7 0.981

RC40-TM

11.0 2.2 9 1.199

RC48-TM 11.0 2.2 9 1.417

RC64-TM 15.8 3.2 13 1. 91 0

RC80-TM 17.4 4.2 15 2.350

Loading...

Loading...