30119-33 Rev. 1.8/04-14

TOTALIZER-TRANSMITTER

MODEL TR15

INDICATOR-TOTALIZER

TRANSMITTER

MODEL TR16

OPERATION AND MAINTENANCE MANUAL

PARTS LIST

FEATURING:

*P/C CARD MOUNTED OPTIC SWITCH

*SOLID STATE CONSTRUCTION

*CURRENT OUTPUT SIGNAL

*CUB TYPE ACTUATOR

*SEALED HOUSING OUTPUT SIGNAL

*CUP TYPE ACTUATOR

*SEALED HOUSING

3255 WEST STETSON AVENUE

HEMET, CALIFORNIA 92545 U.S.A.

PHONE:

FAX:

VISIT OUR WEBSITE:

951-652-6811

951-652-3078

www.mccrometer.com

30119-33 Rev. 1.8/04-14

2

Copyright © 2001-2007 McCrometer. All written material should not be changed or altered without permission of McCrometer.

The published technical data and instructions is subject to change without notice. Contact your McCrometer representative for current technical data and instructions.

WARRANTY

This Warranty shall apply to and be limited to the original purchaser consumer of any McCrometer product. Meters or instruments defective because of

faulty material or workmanship will be repaired or replaced, at the option of McCrometer, free of charge, FOB the factory in Hemet, California, within a

period of one (1) year from the date of delivery.

Repairs or modications by others than McCrometer or their authorized representatives shall render this Warranty null and void in the event that factory

examination reveals that such repair or modication was detrimental to the meter or instrument. Any deviations from the factory calibration require

notication in writing to McCrometer of such recalibrations or this Warranty shall be voided.

In case of a claim under this Warranty, the claimant is instructed to contact McCrometer, 3255 W. Stetson Ave., Hemet, California 92545, and to provide

an identication or description of the meter or instrument, the date of delivery, and the nature of the problem.

The Warranty provided above is the only Warranty made by McCrometer with respect to its products or any parts thereof and is made expressly in lieu

of any other warranties, by course of dealing, usages of trade or otherwise, expressed or implied, including but not limited to any implied warranties

of tness for any particular purpose or of merchantability under the uniform commercial code. It is agreed this Warranty is in lieu of and buyer hereby

waives all other warranties, guarantees or liabilities arising by law or otherwise. Seller shall not incur any other obligations or liabilities or be liable

to buyer, or any customer of buyer for any anticipated or lost prots, incidental or consequential damages, or any other losses or expenses incurred by

reason of the purchase, installation, repair, use or misuse by buyer or third parties of its products (including any parts repaired or replaced); and seller

does not authorize any person to assume for seller any other liability in connection with the products or parts thereof. This Warranty cannot be extended,

altered or varied except by a written instrument signed by seller and buyer.

This Warranty gives you specic legal rights, and you may also have other rights which vary from state to state.

McCrometer reserves the right to make improvements and repairs on product components which are beyond the Warranty period at the manufacturer’s

option and expense, without obligation to renew the expired Warranty on the components or on the entire unit. Due to the rapid advancement of meter

design technology, McCrometer reserves the right to make improvements in design and material without prior notice to the trade.

All sales and all agreements in relation to sales shall be deemed made at the manufacturer’s place of business in Hemet, California and any dispute

arising from any sale or agreement shall be interpreted under the laws of the State of California.

30119-33 Rev. 1.8/04-14

3

MODEL TR15

TOTALIZER-TRANSMITTER

MODEL TR16

INDICATOR-TOTALIZER-TRANSMITTER INDEX

I. DESCRIPTION

II. SPECIFICATIONS

III. UNPACKING

IV. INSTALLATION

1. Remove

2. Clean Meter Head

3. Totalizer Drive Magnet

4. Indicator Drive Gear

5. Transmitter Drive Gear

6. Vertical Shaft

7. Replacement Vertical Shaft

8. Adapter Plate

9. Transmitter Drive Clevis

10. Transmitter Base O-Ring

11. Position of Transmitter

12. Transmitter Wiring

V. SERVICE MANUAL

VI. WORKING AREA

VII. TOTALIZER ASSEMBLY

1. Bonnet Mounting Screws

2. Totalizer

3. Totalizer Change Gears

4. Totalizer Drive Magnet Assembly

‡VIII. INDICATOR-TOTALIZER

‡1. Bonnet Mounting Screws

‡2. Indicator Mounting Screws

‡3. Meter Change Gears

‡4. Indicator-Totalizer

‡5. Gears

IX. INSPECTION

X. REASSEMBLY

1. Totalizer Drive Magnet Assembly

2. Totalizer Base Cup

3. Bonnet Assembly

‡4. Change Gears

‡5. Indicator-Totalizer

‡6. Bonnet Assembly

XI. TROUBLE-SHOOTING

1. Trouble-Shooting Guide

2. Working Area

3. Totalizer or Indicator-Totalizer

4. Moisture

5. Driven Clevis Shaft

‡ For Indicator-Totalizers Only

6. Transmitter Base

7. Drive Clevis

8. Switch Actuator

9. Transmitter Communication Lines

10. Printed Circuit Card

11. Replacing Printed Circuit Card

XII. INSPECTION

XIII. REASSEMBLY

1. Before Return of Transmitter

XIV. INOPERATIVE INSTRUMENT EVALUATION

1. Check All Instruments and Transmitters

2. Check Your Instrument

3. Transmitter or Communication Line

4. Full Scale Output

5. Communication Problems

6. Separation of Signal and Power

I. DESCRIPTION

MODEL TR15 TOTALIZER-TRANSMITTERS provide a totalization

of ow volume and pulse output.

MODEL TR16 INDICATOR-TOTALIZER TRANSMITTERS provide

an instantaneous ow rate indication and totalization of ow

volume.

Both transmitters provide a pulse rate output signal proportional

to the rate of ow when mounted on our propeller meters.

II. SPECIFICATIONS

ACCURACY Current output: plus or minus .5% of full

scale of the instrument the transmitter is controlling. Accuracy of current

output can be increased but will cause

a slower response.

Pulse output: plus or minus 2.0% of

actual ow within the range specied

for each meter size.

TEMPERATURE RANGE 140° F Maximum. Consult factory for

special construction for higher temperatures.

POWER SUPPLY 24 VDC (as supplied by our power supply

Model IN36-1) wired in series with

mA output and instrument. The mA

output must be powered in order to use

the pulse output.

Note: Maximum current consumption of transmitter is 4-20 mA.

30119-33 Rev. 1.8/04-14

4

FLOW RANGE Acceptable for each transmitter unit is

the same as that for the meter to which

the unit mounts.

MATERIALS Used in construction are chosen for their

durability and immunity to the corrosive

eects of atmospheric moisture and the

liquids measured by the meter assembly.

OUTPUT SIGNAL Current signal: 4-20 mA sourcing type

(with loop impedance of 175Ω to

1075Ω), true two wire with external

power supply.

Pulse rate: two wire scaled pulse rate

output. (Customer specified pulse

rate, 600 PPM max.) The maximum

recommended distance for pulse output

transmission is 5000 feet.

Pulse Output Ratings

Maximums are for signals between P2

and P1

Voltage: 18 VDC

Current: 60 mA DC

Power dissipation: 100 mW

Note: Unit utilizes an open collector

transistor output. 35 VDC reverse voltage polarity protection.

SHIPPING WEIGHT 4 pounds

OPTIONAL EQUIPMENT Includes non-reversing ratchet, special

outputs (consult factory for special applications).

ORDERING INFO Must be specied by the customer and

includes: Serial number of meter unit

is to be mounted on, Maximum scale

range required for pulse output, Change

gears and type of dial on totalizer that is

going to be replaced.

III. UNPACKING. When unpacking the transmitter, any damage due

to rough or improper handling should be immediately reported to

the transportation rm and McCrometer. If for any reason, it is determined that the unit or parts of the unit should be returned to the

factory, please contact McCrometer for clearance prior to shipment.

Each unit must be properly packaged to prevent any further damage. The factory assumes no responsibility for equipment damaged

in return shipment due to improper packaging. Proper paper work

must be enclosed with any returned material.

The shipping carton contains the following items:

Model TR15 or TR16 ......................................................................1

Base O-Ring 1

Mounting S crews 4

Vertical Shaft Clevis ......................................................................1

Clevis Coupling 1

Operation and Maintenance Manual .............................................1

IV. INSTALLATION of transmitters is normally done at the factory when

the meter is assembled, but may be made in the eld with the meter

stopped (i.e. no ow). Depending upon what situation exists, various

steps for installation apply and the procedures are outlined below.

1. REMOVE the existing totalizer or indicator or transmitter by

removing all the mounting screws and lifting the unit o the meter

head.

2. CLEAN METER HEAD of all dirt, glue, gaskets and other foreign

material.

3. TOTALIZER DRIVE MAGNET must be removed from the vertical

shaft tip of meters equipped with a totalizer so that the transmitter

drive clevis (#35) can be installed on the vertical shaft tip. The totalizer drive magnet can be removed by loosening the set screw in the

side of the magnet hub and sliding the assembly o the vertical shaft.

4. INDICATOR DRIVE GEAR must be removed from the vertical

shaft tip of meters equipped with indicator-totalizers so that the

transmitter drive clevis (#35) can be installed on the vertical shaft tip.

The indicator drive gear can be removed by loosening the set screw

in the side of the gear hub and sliding the assembly o the vertical

shaft.

5. TRANSMITTER DRIVE GEAR must be removed from the vertical

shaft of meters equipped with an old style McCrometer Model TR01

or TR06. The transmitter drive gear can be removed by loosening the

set screw in the side of the gear hub and sliding the assembly o the

vertical shaft.

6. VERTICAL SHAFT assembly must be removed from the meters

equipped with an old style McCrometer CN06 indicator, TR01 or TR06

transmitter (.100” dia. vertical shaft tip) and replaced with a vertical

shaft that has a 3/16” diameter tip. Vertical shaft removal can be accomplished by removing the two vertical shaft collar bearing mounting screws in the meter head and pulling the vertical shaft directly out

of the top of the meter. Remove the vertical shaft collar and bearing

assembly from the vertical shaft by loosening the set screw in the side

of the collar and sliding the assembly o the vertical shaft.

7. REPLACEMENT VERTICAL SHAFT for meters with

old style McCrometer models CN06 indicators, TR01 or TR06

transmitters, should be inspected to be sure it is not bent

or damaged. Install the vertical shaft collar and bearing

assembly on the new (3/16” diameter tip) vertical shaft,

30119-33 Rev. 1.8/04-14

5

but do not tighten the collar bearing set screw yet. Insert the vertical

shaft assembly, plastic tip rst, into the meter head and rotate the

shaft gently until it is engaged in the driven miter gear shaft of the

miter gear frame assembly. Set the collar and bearing assembly into

the hole in the meter head and replace and secure the two screws

that hold the collar bearing in place. Do not over tighten the screws

or the bearing can cock and cause drag. Turn the vertical shaft to

check for bind or drag. Note: If the meter is in a pipeline full of

water, then a slight drag will be created by the propeller moving

through the water. Should any bind or drag be apparent it can usually be corrected by adjusting the vertical shaft assembly. Slide the

vertical shaft down until it rests against the driven miter gear shaft,

then lift the vertical shaft up about 1/64 inch. Tighten the set screw

in the side of the collar bearing assembly.

8. ADAPTER PLATE part number A-2-4108, and gasket part

number 1558-3, must be attached to the top of the meter head on

the old style McCrometer LP21 (3 hole bolt circle) and all ML45, 47

and 49 meters. The adapter plate can be secured to the meter head

by three mounting screws (part number 1116-8-12) after the gasket

has been centered on the head. Throughout the rest of the instruction

manual, the top of the adapter ring will be referred to as the top of

the meter head.

9. TRANSMITTER DRIVE CLEVIS (#35) must now be installed on

the meter vertical shaft. Place the drive clevis (#35) on the vertical

shaft with the forked end up. Position the drive clevis so that the

top of the clevis is 1/8” below the top surface of the meter head (on

non-reversing models the entire ratchet assembly should be placed

on the vertical shaft and the measurement taken from the top of the

forked portion). Place the plastic drive clevis coupling (#36) on top

of the drive clevis (#35) with the forked portion of the drive clevis

fully engaged in the slot in the clevis coupling (#36) and the larger

diameter hole in the coupling (#36) facing up.

10. TRANSMITTER BASE O-RING (#38) should be covered with

a thin coat of silicone grease and placed in the o-ring groove in the

bottom of the transmitter base (#11).

11. POSITION OF TRANSMITTER on top of the meter head can be

made in one of four directions for the easiest possible reading. Normally the units are attached so that they can be read when looking

upstream. Be sure the drive clevis (#35) is in proper alignment and

makes a positive engagement with the clevis coupling (#36). Set the

transmitter on the meter head and position the driven clevis shaft

(#28) so that the slot in the clevis coupling (#36) is properly engaged

with the cross pin in the driven clevis shaft (#28). Secure the four

mounting screws (#37) .

12. TRANSMIT TER WIRING can be accomplished by following the

applicable wiring diagram on pages 13 and 14.

TRANSMITTER

OPERATION AND MAINTENANCE MANUAL

V. MCCROMETER products have been carefully designed to be as main-

tenance free as possible. Periodic preventive maintenance, however,

is highly recommended and should be practiced according to schedule

to assure continuous accuracy and trouble free performance of your

transmitter. The maintenance and inspection procedure can also be

used as a guide to locating a problem in the unit that may be the

cause of abnormal operation.

VI. WORKING AREA chosen for cleaning and inspection of the internal

components should be clean to reduce the chance of dust or dirt

particles being introduced into the transmitter mechanism.

VII. TOTALIZER ASSEMBLY (#4) service procedure should include

cleaning and inspection of the unit noting any excessive wear on the

change gears (#7 & #8) that may lead to operational problems in the

unit.

1. BONNET MOUNTING SCREWS (#3) should be removed and

the entire bonnet (#1) lifted o of the meter.

2. TOTALIZER is contained within the totalizer bonnet (#1) and

held in place by a base cup (#5). It should not be necessary to remove

the totalizer (#4) during inspection; however, removal of the base cup

(#5) is necessary for inspection of the totalizer change gears (#7 &

#8). Removal of the base cup (#5) can be accomplished by inserting

a small screwdriver into the two cutouts and prying upward under the

edge.

3. TOTALIZER CHANGE GEARS (#7 & #8) should be inspected

for any sign of wear. Both the A-(drive) gear and B-(driven) gear are

attached to the lower portion of the totalizer assembly (#4). Spin the

oating totalizer driven magnet in the center of the totalizer bottom

(#4) to make certain it spins freely without bind or drag. The bottom

of the totalizer has the letter “A” molded next to the A-drive gear

shaft, and the letter “B” next to the B-driven gear shaft.

4. TOTALIZER DRIVE MAGNET ASSEMBLY (#9) located in the

transmitter base (#10) at the top of the driven clevis shaft (#28)

should be checked and adjusted if necessary to position it 1/16 inch

below the top surface of the transmitter base (#10). Adjustments

can be made by loosening the socket head set screw in the side of

the totalizer drive magnet assembly (#9), and sliding it up or down

the driven clevis shaft (#28) as desired. Always be sure the set screw

is tightened into the at on the driven clevis shaft (#28).

‡VIII. INDICATOR-TOTALIZER service procedure should be practiced yearly

and should include removal, cleaning and inspection of the unit noting any excessive wear on the gears and other wear points that may

lead to operational problems in the unit.

‡ For Indicator-Totalizers Only

30119-33 Rev. 1.8/04-14

‡ For Indicator-Totalizers Only

‡ For Indicator-Totalizers Only

‡1. BONNET MOUNTING SCREWS (#2) located beneath the

indicator-totalizer bonnet lid, should be removed and the entire bonnet (#1) lifted o of the transmitter. Replace the o-ring seals around

each of the four screws (#3) and at the bottom of the bonnet (#4) and

cover each of the new o-rings with a thin coat of silicone grease.

‡2. INDICATOR MOUNTING SCREWS (#6) and shake-proof wash-

ers (#7) holding the indicator-totalizer unit (#5) to the transmitter

base (#10) should be removed and the unit lifted o, exposing the

A-drive gear (#8) attached to the top of the driven clevis shaft (#28).

‡3. METER CHANGE GEARS (#8 & #9) should be inspected for

any sign of wear. The A-(drive) gear (#8) is attached to the top of

the driven clevis shaft (#28), and the B-(driven) gear (#9) is attached

to the bottom of the indicator (#5). The position of the A-drive gear

should be checked and adjusted if necessary to position the top face

of the gear 1/8 inch below the top surface of the transmitter base

(#10). The position of the B-driven gear top face should be 1/8 inch

below the bottom of the indicator-totalizer.

‡4. INDICATOR-TOTALIZER unit (#5) should be cleaned thoroughly

using a mild soap and a soft brush. Under no circumstances should

the entire unit be immersed in the soap or should any metal object be

used when cleaning and inspecting the internal parts of the indicatortotalizer unit.

‡5. GEARS within the indicator-totalizer unit (#5) should be

inspected carefully. If any excessive wear is visible on the gear teeth,

and other wear points, the unit must be returned to McCrometer for

repair.

IX. INSPECTION of all internal parts that may be replaced in the eld

has been accomplished at this point. Should any of the parts upon

inspection, appear to be damaged or excessively worn, they must be

replaced to assure proper operation and prevent further damage.

X. REASSEMBLY is necessary at this point. Before reassembling, make

certain that the unit is cleaned of any dust or dirt. Cost for replacement parts not covered by warranty are available from current parts

and price list. If it is determined that the unit should be returned for

repair, please notify McCrometer prior to shipment. Each unit must

be properly packaged to prevent damage to the unit in shipment.

1. TOTALIZER DRIVE MAGNET ASSEMBLY (9) should be checked

again to make certain it is properly set to drive the totalizer (#4). (See

step VII- 4).

2. TOTALIZER BASE CUP (#5) can be placed back in the totalizer

bonnet (#1) on the totalizer assembly (#4) after the desiccant capsule

and the base cup o-ring (#6) are replaced and the new o-ring (#6) has

been covered with a thick coat of silicone grease. Be sure o-ring (#6)

is on base cup (#5) properly. When reinstalling the cup (#5), put two

drops of super glue on the inside edge of the bonnet 180° apart and

push cup rmly into the bonnet and hold for 30 seconds.

3. BONNET ASSEMBLY (#1) should be cleaned and replaced on

the transmitter (#10). Bonnet o-ring (#2) should be replaced and the

new o-ring (#2) covered with a thin coat of silicone grease. Secure

four screws (#3).

‡4. CHANGE GEARS (#8 & #9) should be checked again to make

certain they are in proper alignment (see section VIII-3). The gear

teeth should be lubricated with a light grease to assure longer life.

‡5. INDICATOR TOTALIZER mechanism (#5) should be placed on

the transmitter base (#10) with the mounting screws and shakeproof

washers (#6 & #7). Do not tighten mounting screws (#6) until the

gear mesh has been properly adjusted. To adjust gear mesh, slide

the indicator-totalizer mechanism (#5) towards the A-drive gear

(#8) until the unit stops because of full gear mesh. Now back o the

indicator totalizer mechanism 1/64 inch and tighten mounting screws

(#6).

‡6. BONNET ASSEMBLY (#1) should be cleaned and replaced over

the indicator-totalizer unit (#5) after replacing the desiccant bag.

Secure four screws (#2) beneath the bonnet lid. Do not over tighten

the mounting screws (#2) as this will result in damage to the screw

o-rings (#3).

XI. TROUBLESHOOTING the transmitter is necessary if it is apparent that

the instrument being controlled by the transmitter is not receiving a

proper signal from the transmitter, and/or the totalizer or indicatortotalizer is not functioning. Before beginning, it is important to be

sure that the problem is with the transmitter, therefore, the following

checks should be made. 1) Check to be sure that water is owing

through the meter at ows above the minimum ow rate for the

given size meter. 2) Check the instrument to be sure it has the

required power being supplied to it. 3) Check the junction box to be

sure the communication lines from the transmitter to the instrument

are making good contact and that the transmitter is wired properly

to the instrument.

1. THE TROUBLESHOOTING GUIDE is provided to help isolate any

problem that may occur with the transmitter. Follow the instructions

and test procedures listed for each problem.

A. If the meter totalizer or indicator-totalizer does not work, but

the remote instrument does operate (receiving the proper signal),

then see section VI, VII-1 thru 4, IX and X-1 thru 3 for checking the

totalizer, or section VI, VIII-1 thru 5, IX and X-4 thru 6 for checking the

indicator-totalizer.

6

30119-33 Rev. 1.8/04-14

7

B. If the meter totalizer or indicator-totalizer does work but the

remote instrument does not operate (not receiving proper signal),

then use troubleshooting procedures #2 thru #4 and #8 thru #11.

C. If the meter totalizer or indicator-totalizer and remote instru-

ment do not operate, then use troubleshooting procedures #2 thru

#11.

2. WORKING AREA chosen for testing and inspection of the

internal components should be clean to reduce the chance of dust or

dirt particles being introduced into the transmitter mechanism.

3. TOTALIZER OR INDICATOR-TOTALIZER must be removed from

the transmitter base (#10) and inspected for damage (see section VII

for removal and inspection of the totalizer or section VIII for removal

and inspection of the indicator-totalizer).

4. MOISTURE should not be apparent within the transmitter base

(#11) chamber. All o-rings should be inspected for breaks or presence

of foreign materials that allow leakage to occur. Check to be sure

water is not coming up through the meter head. If water is coming

up through the meter head then the meter should be checked (see

meter service manual).

5. DRIVEN CLEVIS SHAFT (#28) should be turning if water is

owing (above minimum ow rates) through the line. If water is

not owing through the line, then the transmitter base assembly

(#10) must be removed from the meter head and the driven clevis

shaft (#28) turned by hand. If water is owing, but the driven clevis

shaft is not turning, then the transmitter base assembly (#10) must

be removed from the meter head and the drive clevis (#35) must be

checked.

6. TRANSMITTER BASE (#10) can be removed by removing the

four transmitter base mounting screws (#37). Lift the unit carefully

o the meter. (Sometimes the transmitter sticks to the meter so

it may be necessary to separate the joint by using a sharp knife or

putty knife as a pry.) Be sure not to damage the transmitter base

(#10) or the clevis (#35). Note: After the transmitter base (#10) has

been removed, the meter assembly should be inspected thoroughly

to be sure it is operating properly (vertical shaft turns when water is

owing through the line) and is not the cause of the problem (refer

to your meter service manual for instructions on inspection of the

meter).

7. DRIVE CLEVIS (#35) and the drive clevis coupling (#36) should

be checked for damage and checked to be sure they are at the proper

elevation and are engaging properly with the driven clevis shaft (#28)

(see section IV-9). If the clevis (#35) or coupling (#36) is damaged

then they are the likely cause of the problem and must be replaced

(see section IV-9 for installation of new clevis). If the clevis (#35) and

coupling (#36) are adjusted correctly and engaged properly with the

driven clevis shaft (#28) but the meter is not turning them, then the

meter is the likely cause of the problem.

8. SWITCH ACTUATOR (#23) is a black plastic slotted cup located

below the circuit card (#12). The actuator (#23) should be turning

(with water owing or driven clevis shaft turned by hand) when the

driven clevis shaft (#28) is turning. If the actuator (#23) does not

turn when the driven clevis shaft (#28) turns, then the transmitter

gear train is damaged and must be returned to the factory for repair

(see section XIII for return of transmitter to factory). If the actuator

cam (#23) is turning then the communication lines (#39) and printed

circuit card (#12) should be checked.

9. TRANSMITTER COMMUNICATION LINES (#39) should be

checked to determine the current level owing in the loop. The

method of measurement is to insert a multi-meter into the 4-20 mA

loop by disconnecting one of the mA signal wires, clipping one side

of meter to disconnected wire and connect other end of multimeter

to the lug or post from which the wire was removed. (mA wires are

red and green.)

If no water is owing through the meter, the current level should

be 4.0 mA. The purpose of the 4.0 mA at no ow, is to insure that

the loop is complete. If there is 4.0 mA in the loop when no water is

owing, then the loop is intact.

If water is owing through the meter, the current level should be

between 4-20 mA, depending on ow.

10. PRINTED CIRCUIT CARD (#12) should be checked to be sure

it is functioning properly. The circuit card (#12) may be checked as

follows:

WARNING: COVER TOP OF TRANSMITTER SO BRIGHT LIGHT OR

SUNLIGHT DOES NOT INTERFERE WITH NORMAL OPERATION

PRINCIPLES OF OPTIC SWITCH.

A. If the current level in the loop is 0.0 mA, check the voltage

between the mA terminals at the transmitter card. It should be at

the maximum power supply level (± 1.0 VDC).

If there is no voltage present, then check the loop voltage at its source.

If there is voltage at the voltage source then there is an opening in the

loop.

If there is no voltage at the power supply, disconnect loop and check

supply by itself. If the voltage level is still 0 VDC or very low (<10

VDC), replace power supply.

B. If the level of current is greater than 20 mA, there are two pos-

sibilities. The card may be starting to fail, but unless there has been

some major damage done to the card (physical impact or voltage

levels above 50 VDC applied), it should not exceed 25.00 mA.

High loop current can also be caused by a short in the trans-

mitter hookup cable. A zero ohm short will cause power supply fuse to blow. However, it is possible to have a shunt of

about 0.5Ω to 10Ω connecting transmission lines, which

will cause excessive loop current with transmitter in the

system (from 70.0 - 350 mA or more) but when the P. C.

30119-33 Rev. 1.8/04-14

8

meter (if it was necessary to remove it), see section IV - 10 and 11.

The totalizer assembly or indicator assembly must be reinstalled on

the transmitter base, see section X - 1 thru 3 for totalizer and section

X - 4 thru 6 for indicator.

1. BEFORE RETURNING TRANSMITTER TO FACTORY, please

notify McCrometer prior to shipment. Each unit must be properly

packaged to prevent damage to the product during shipment. Should

any of the unit’s parts, upon inspection, appear to be damaged or excessively worn, they must be replaced to assure proper operation and

prevent further damage. Cost for replacement parts not covered by

warranty are available from current parts and price lists. Should the

unit require further inspection, it must be reassembled and returned

to the factory.

XIV. PROCEDURES FOR CHECKING OUT INOPERATIVE INSTRUMENT

SYSTEMS.

NOTE: The 4-20 mA loop must be powered if the pulse output is used.

All instruments are factory tested with the transmitter that will be

operating it. When an instrument doesn’t operate and it is connected

to its proper transmitter, certain procedures need to be followed to

determine where and what the problem is. Most troubleshooting

procedures are part of each instrument and transmitter service

manual, but these suggestions may help.

1. CHECK ALL INSTRUMENTS AND TRANSMITTERS for obvious

visual damage.

2. CHECK YOUR INSTRUMENT to be sure it is operating properly

by following the instrument service manual. Check to be sure your

instrument is operating correctly when a simulated signal is put into

it. WARNING: Circuit to transmitter must be disconnected when

most testing equipment is used for checking your instrument. If

instrument checks out, proceed with checking transmitter and communication lines.

3. WHEN THE TRANSMISSION OR COMMUNICATION LINE is

suspected of being the reason the system is not functioning, it is

usually easier to check out the transmitter rst to be sure it is giving

proper output. There are some easy troubleshooting techniques to

be used. First, you must know what signal is expected from the

transmitter.

A. Standard Model TR15 & TR16 current transmit-

ters have an output of 4-20 mA at maximum scale of the

board is tested separately, it works ne. These shorts are dicult to

nd. They can be caused by incorrect wiring installation or damage

to present wiring. Damage can be caused by physical contact (back

hoe, etc.) or from environmental eects (water in the raceways).

C. If transmitter output remains at 4.0 mA even when the actuator

cup (#23) is rotating and the transmitter is away from direct sunlight

or other high energy light source, replace the circuit card (#12).

If the loop current is within a satisfactory range, 3.00 mA - 23.00 mA,

and varies with a varying ow rate, but is not within accuracy at any

given ow, then all that is needed is calibration. The 4-20 mA loop

current should only be adjusted as described under BENCH CALIBRATION.

D. BENCH CALIBRATION can be accomplished using the following

equipment:

Power supply - well regulated, 10-30 (24V STD).

Multimeter - must be better than 0.5% accuracy on 0-20 mA range.

Model CN09 - use test gears required for transmitter gearing.

1) Mount the transmitter on the CN09 calibration unit.

2) Hook-up the circuit as shown on the bench calibration wiring

diagram.

3) Adjust the zero potentiometer so that the multimeter reads 4.00,

±.02 mA.

4) Set CN09 to 75%, adjust the span potentiometer to 16.00 mA, ±

.02 mA.

5) Check the output at the 25% (8.00 mA) and 50% (12.00 mA) set-

tings on the CN09 to verify circuit linearity.

6) Reinstall the transmitter onto the meter after calibration is com-

plete.

11. REPLACING PRINTED CIRCUIT CARD (#12) can be accom-

plished in the following way: Turn the power for the transmitter o

at the instrument. Disconnect the communication wires from the

terminal strip on the circuit card (#12). Remove the three circuit card

mounting screws (#15) and washers (#16). Lift the circuit card (#12)

out of the transmitter base. If your transmitter is equipped with an

indicator-totalizer, then the A-drive gear (#8) set screw may have to

be loosened and the A-drive gear (#8) removed in order to remove the

circuit card (#12). Place the new circuit card (#12) in the same position

as the old circuit card and secure it to the support posts with the three

screws (#15) and washers (#16). Replace the indicator A-drive gear

(#8), if it was removed (see section VIII-3). The communication lines

should be attached to the terminals on the circuit card (#12) (see wiring

diagram). Be sure to route the communication lines connected to the

terminal strip away from the totalizer drive magnet (#9) or indicator

A-drive gear (#8). These rotating parts within the transmitter can

damage the wires.

XII. INSPECTION and eld testing has been accomplished at this point.

Should any of the parts, upon inspection, appear to be damaged or

excessively worn they must be replaced to assure proper operation

and prevent further damage. If the transmitter still does not work

then it should be returned to the factory for repair.

XIII. REASSEMBLY is necessary at this point. Before reassembling make

certain that the unit is cleaned of any dust or dirt. Cost for replace-

ment parts not covered by warranty are available from current parts

and price list. The transmitter base should be reinstalled on the

30119-33 Rev. 1.8/04-14

9

G. Pulse outputs from the transmitter can be checked by several

dierent types of digital counters. We will explain how our standard

Model IN16 remote totalizer can be used.

See the wiring diagram (see page 11) to hook up your wires correctly

by connecting the black wire clip to the pulse - (black outlet wire),

and the red clip to the pulse + (white outlet wire) inside the transmitter or on the same wires as they go into the instrument.

If there is no pulse output from the transmitter, check the power

supply voltage for transmitter (24 VDC). If the voltage is present at

the transmitter circuit board then the circuit board could be faulty.

If there is no voltage present, then the communication lines or

power supply could be bad. Check the power supply voltage at the

instrument. Check to see if the power supply is fuse protected before

replacing power supply. Also check for loose connections at the

terminals. Be sure transmitter is wired correctly to instrument. Be

aware power must be connected to the recorder so the 12 or 24 VDC

will then power the transmitter to operate the optic switch, which we

will be checking out.

After the IN16 is attached and you have your stop watch ready it is

very simple to reset the counter. Hold the button down and release

it at same time as you start the stop watch. When the stop watch is

approaching 60 seconds, be prepared to read the counter at exactly

when 60 is reached or disconnect one of the IN16 wires to stop it from

counting any more.

If the counted pulse rate matches with calculations done in Section

XIV # 4 - E and the instrument checks out per Section XIV - 1 and 2,

then the trouble is probably the communication line.

5. COMMUNICATION PROBLEMS can be so complex it is usually

recommended the instrument contractor or electrical contractor be

informed that our transmitters and indicators prove to be good units

and the trouble could be elsewhere. Sometimes it is necessary to

lay another line from the transmitter to instrument above ground to

help prove the lines are at fault prior to pulling and replacing existing

line. Communications lines should be kept from tangling up in high

voltage lines inside the panel or wiring cabinet. Communication lines

should be shielded cable and not run in same conduit as power lines.

Sometimes the 115 VAC line used for the instrument can be causing

the trouble. It is suggested the plug from the instrument be temporarily transferred to another AC outlet which is on another circuit. It

has been found a uorescent light circuit tied in with the instrument

power source, or faulty parking lot vapor lights can eect the instruments if AC wiring is done incorrectly to give a noisy AC circuit.

instrument it operates. They also have an optional 150 PPM pulse

output.

B. The original purchaser of the equipment should have invoices

or other paperwork to inform you what the 4-20 scale is. If these are

not available, you can phone the factory and furnish the meter serial

number and the transmitter record can be pulled to give you the full

scale information.

C. Let’s assume you found the meter was a 12” meter and the full

scale of the instrument is 3000 GPM.

4. FULL SCALE OUTPUT. Now we know what the output at full

scale is supposed to be from the transmitter, so now let’s nd out

what it actually is.

A. We need to nd out what the ow rate going through the meter

actually is.

B. Time the transmitter totalizer test or sweep hand with a stop

watch for 1 to 5 rotations, to give the best resolution or closest accuracy.

C. The example meter has a 1000 gallon totalizer and if you time

the sweep hand for three revolutions in 150 sec, proceed as follows:

150 sec ÷ 3 rev = 50 sec for 1000 gallons (1 rev)

D. To nd the true ow rate:

60 sec ÷ no sec per rev x totalizer dial

or as shown below

60 ÷ 50 x 1000 = 1200 GPM true ow rate

If the meter is furnished with a Model CN06 ow indicator, now is the

time to verify the indicator is accurate.

E. To determine what output the transmitter should be sending,

we must now nd what percent 1200 GPM is of the 3000 GPM scale

stated earlier.

1200 GPM ÷ 3000 GPM = 40%

1. Model TR15 & TR16 current output (4-20 mA).

Because 4 mA equals ZERO it must be subtracted from

20 mA.

Therefore, 20 - 4 = 16 mA usable output (SPAN)

40% x 16 mA = 6.4 mA then add 4 mA back to give 10.4

mA @ 1200 GPM.

2. 150 PPM at full scale, so 40% x 150 PPM = 60 PPM

@ 1200 GPM.

F. 4-20 mA current signal can be checked by using a digital

multimeter. Have the multimeter set to measure milliamps. With no

water owing through the meter the ammeter should measure 4.0

mA. If water is owing through the meter the current level should

be between 4-20 mA.

NOTE: Power should be removed from circuit before inserting the

multimeter. The multimeter must be connected in series with circuit

being tested.

30119-33 Rev. 1.8/04-14

TR15/16

BOARD

POWER

SUPPLY

> 12 VDC

mA

2 WIRE CIRCUIT CONNECTION

CUSTOMER SUPPLIED POWER SOURCE

(STANDARD TRANSMITTER SUPPLIED

WITHOUT PULSE OUTPUT)

TR15/16

BOARD

mA

GREEN

10

BENCH CALIBRATION

WIRING

NOTES

+ -

RED

GREEN

+ -

0.400

MULTIMETER

CUSTOMER

SUPPLIED POWER SUPPLY

> 12 VDC

+ -

RED

+ -

INSTRUMENT

4-20 mA

INPUT

6. SEPARATION OF SIGNAL AND POWER wiring in separate

conduits is the traditional precaution, however, other measures must

be taken to minimize the eects of electromagnetic interference

(EMI) and radio frequency interference (RFI) on the operation of the

instrument. Otherwise, if high level, short duration, noise spikes are

permitted to enter the digital equipment, the noise can be transferred

into the systems logic networks and can be misinterpreted as signal

data, resulting in erroneous system operation and other unpredictable responses. Potential noise sources: Relay coils, solenoids, AC

power wires, current carrying cables, or radio frequency transmissions.

30119-33 Rev. 1.8/04-14

3

4

5

12

13

14

15

16

17

18

ANALOG OUT

INPUT

RESET INPUT

GROUND

12 VOLT OUT

DC POWER IN

ISOLATE -12 V

ISOLATE +12 V

A.C. IN

A.C. IN

mA

VOLT

METER

-

TR15/TR16

CIRCUIT CARD

TERMINAL STRIP

PROCEDURES FOR CHECKING INOPERATIVE INSTRUMENT SYSTEMS

WITH mA AND PULSE OUTPUT TRANSMITTERS

INPUT

RESET INPUT

GROUND (DC)

12 VOLT OUT

DC POWER IN

ISOLATE -12V

ISOLATE +12V

A.C. IN

A.C. IN

4

5

12

13

14

15

16

17

18

-

TR15/TR16

CIRCUIT CARD

TERMINAL STRIP

NOTE: Connections for checking power supply

voltage at the instrument. (24 VDC)

110 VAC / 60 HZ

TO INSTRUMENT

IN62

TERMINAL STRIP

+

WHITE

(24 VDC)

VOLT

METER

GREEN

RED

mA

- +

PULSE

BLACK

WHITE

IN16

COUNTER

NOTE: Connections for checking

pulse output at transmitter. Black

and white wires must be disconnected from transmitter terminal

strip for this test. Power must be

removed from instrument before

disconnecting wires.

BLACK

TESTING TRANSMITTER PULSE OUTPUT AND INSTRUMENT POWER SUPPLY

TR15/TR16 TRANSMITTER (150 PPM AND 600 PPM PULSE OUTPUT)

WIRED TO A MODEL IN62

TESTING TRANSMITTER OUTPUT AND POWER SUPPLY VOLTAGE

TR15/TR16 TRANSMITTER (4-20 mA OUTPUT)

WIRED TO A MODEL IN60

NOTE: Connections for measuring

the amount of current owing in

the 4-20 mA loop. There should

be 4.0 mA with no water owing

through meter and 20.0 mA at full

scale. Connect ammeter in series

with circuit.

+

AMMETER

-

4-20 mA

GREEN

RED

+

110 VAC / 60 HZ

TO INSTRUMENT

NOTE: Connections for

checking power supply

voltage for the transmitter.

(24 VDC) connect voltmeter

in parallel with circuit.

(24 VDC)

IN60

TERMINAL STRIP

11

30119-33 Rev. 1.8/04-14

TRANS

+

4-20 mA.

mA

AMMETER

AMMETER

NOTE: Connections for

checking transmitter

power supply voltage (24

VDC). Connect voltmeter

in parallel with circuit.

NOTE: Shield on transmitter

cable can be connected to

the ground screw on the

IN36-1.

115 VAC

PULSE

mA

4-20 mA. INPUT

J-10

RED

JUMPER

GREEN

IN48 TERMINAL STRIP

IN36-1 (24 V) POWER SUPPLY

INST.

+

GND

L2

L1

-

115 AC

-

N

G

TB-2

R

-

+

L1

L2

L

GREEN

WHITE

BLACK

GRAY

ORANGE

+

-

RED

GREEN

+

-

+

-

BLACK

PULSE OUTPUT

(OPTIONAL)

WHITE

NOTE: Connections for measuring the

amount of current owing in the 4-20 mA

loop. There should be 4.0 mA with no water

owing through meter and 20.0 mA at full

scale. Connect ammeter in series with circuit.

MAIN PCB

PEN 1

VOLT METER

TESTING TRANSMITTER OUTPUT AND POWER SUPPLY VOLTAGE

TR15/TR16 TRANSMITTER (4-20 mA OUTPUT)

WIRED TO A MODEL IN48 10” CHART RECORDER SOLD BEFORE 5/93

NOTE: Connections for checking

transmitter power supply voltage (24 VDC) Connect voltmeter in parallel with circuit.

VOLT

METER

+

-

TRANSMITTER

POWER (24 VDC)

+

-

J-6

-

+

250 OHM RESISTOR

+

-

+

-

TR15/TR16 CIRCUIT CARD TERMI-

NAL STRIP

NOTE: Connections for measuring the amount of current owing

in the 4-20 mA loop. There should be 4.0 mA with no water owing through meter and 20.0 mA at full scale. Connect ammeter

in series with circuit. If there is no current in the loop and the

power supply voltage is there, then the problem is possibly in

the communication lines or the transmitter circuit board.

TR15/TR16 CIRCUIT CARD TERMINAL

STRIP

PROCEDURES FOR CHECKING INOPERATIVE INSTRUMENT SYSTEMS

HAVING A TRANSMITTER WITH 4-20 mA

TESTING TRANSMITTER OUTPUT AND POWER SUPPLY VOLTAGE

TR15/TR16 TRANSMITTER (4-20 mA OUTPUT)

WIRED TO A MODEL IN41 10” CHART RECORDER

12

30119-33 Rev. 1.8/04-14

mA

TR15/TR16

4-20 mA

TRANSMITTER POWER

(24 VDC)

+

-

-

+

TRANS INST.

+

-

-

+

mA

WHITE

PULSE OUTPUT

(OPTIONAL)

-

+

ORANGE

GRAY

115 VAC

R

RECORDER

MAIN PCB

NOTE: SHIELD TO GROUND

4-20 mA.

13

WIRING DIAGRAM FOR TR15/16 TO IN41

TR15/TR16 TRANSMITTER (4-20 mA OUTPUT)

WIRED TO A MODEL IN41 10” CHART RECORDER

IN36-1

POWER SUPPLY

OUTPUT

24 VDC

INPUT

115 VAC

+

-

L1

N

BLACK

G

N

TB-2

L1

WHITE

GRN.

RED

TERM.

STRIP

+

-

PULSE

BLACK

TR15/TR16

4-20 mA

WIRING DIAGRAM FOR TR15/16 TO IN48

FOR RECORDERS SOLD AFTER 5/93

FROM TRANSMITTER RECEIVING POWER FROM RECORDER

J2 PLUG

+

-

-

+

+

-

WHITE

BLACK

J11 PLUG

JUMPER

GRN.

RED

NOTE: Terminal screws must be tight

to insure a good connection.

Shield to ground .

PULSE OUTPUT

(OPTIONAL)

30119-33 Rev. 1.8/04-14

14

MODEL TR15 and TR16

TRANSMITTER

SOLID STATE CONSTRUCTION

CURRENT OUTPUT - PULSE RATE OUTPUT

(TWO) 2-WIRE CIRCUITS

NOTES:

Maximum current consumption of transmitter is 20 mA. Units which are provided

with only 2 output wires may be rewired for 150 ppm pulse output by stripping

back the insulation on both ends of the output cables and wiring as shown above.

Wire Size Information:

The distance of the communication line from transmitter to the device the 4-20mA

will operate depends on the loop resistance, the wire size, and the power supply.

Based on a 24V DC power supply and 22 gauge wire, we recommend a maximum

loop of 5,250 feet.

Power Power supply Maximum

Supply voltage resistance of

for loop instruments in loop

Variable 12.0VDC 175Ω

Variable 15.0VDC 325Ω

Variable 18.0VDC 475Ω

Variable 21.0VDC 675Ω

IN36-1(24V) 24.0VDC 775Ω

Variable 27.0VDC 925Ω

Variable 30.0VDC 1075Ω

2 WIRE CIRCUIT CONNECTION

(STANDARD TRANSMITTER SUPPLIED WITHOUT PULSE OUTPUT)

(AVAILABLE SEPARATELY)

115 VAC

60

Hz

CURRENT OUTPUT

(4-20 mA SOURCING TYPE

NOTE: MAXIMUM CURRENT CONSUMPTION OF TRANSMITTER IS 20 mA.

4 WIRE CIRCUIT CONNECTION (WITH PULSE OUTPUT)

(AVAILABLE SEPARATELY)

115 VAC

60 Hz

(-)

CURRENT OUTPUT

(4-20 mA SOURCING TYPE

(+)

(+)

P

1

(-)

P

2

PULSE OUTPUT

SHIELD TO GROUND

SHIELD TO GROUND

(+)

(-)

MODEL IN36-1

POWER SUPPLY

MODEL IN36-1

POWER SUPPLY

30119-33 Rev. 1.8/04-14

15

NOTES

30119-33 Rev. 1.8/04-14

16

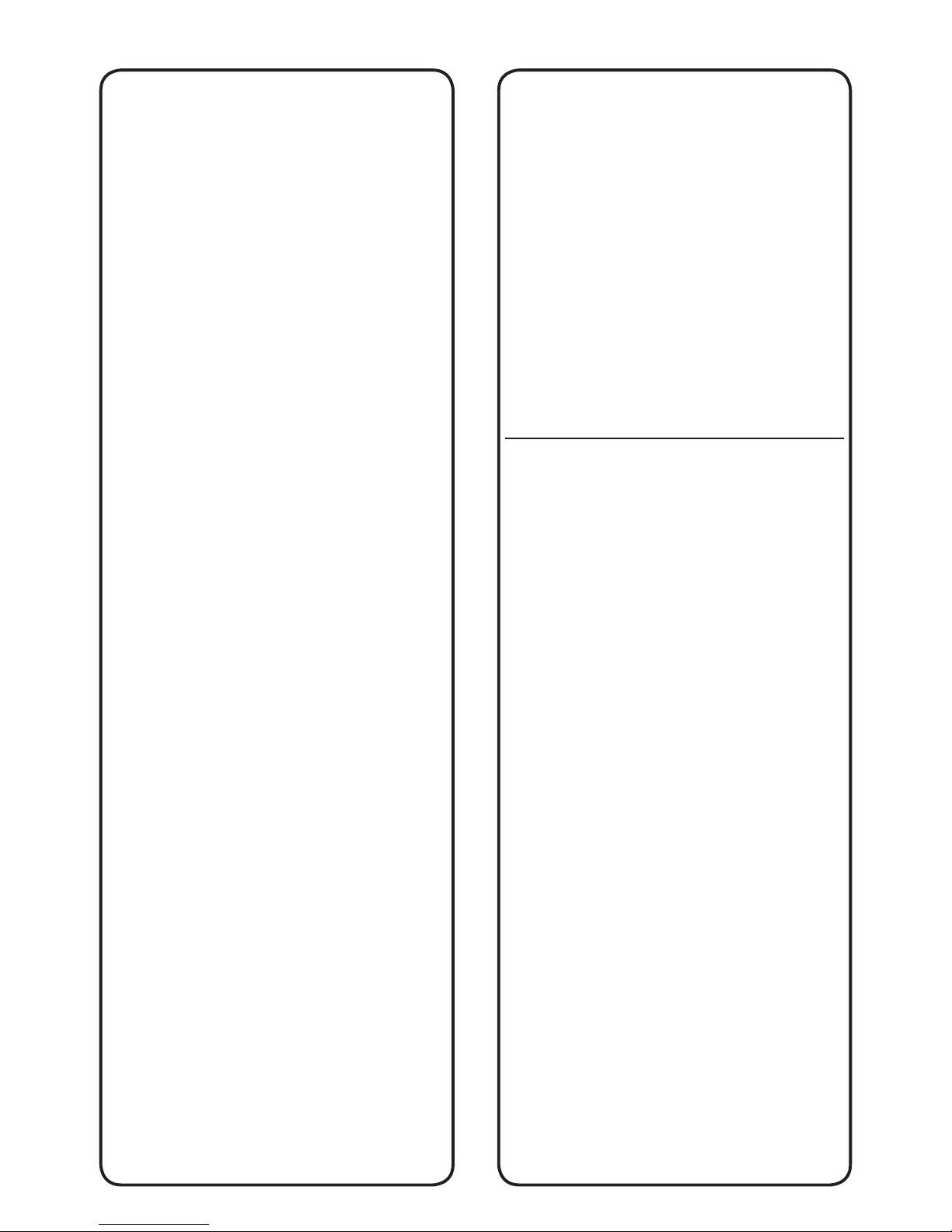

TOTALIZER-TRANSMITTER

MODEL TR15

PARTS LIST

‡ CONSULT FACTORY TO COMPLETE PART NUMBER

CONSULT FACTORY FOR PRICES

No.

none

none

none

1

none

2

3

4

none

none

none

5

6

7

8

9

10

12

15

18

19

20

23

23

24

26

27

28

29

30

31

32

33

35

36

37

38

39

none

QTY

1

1

1

1

1

1

4

1

1

2

1

1

1

1

1

1

1

1

3

1

1

3

1

1

1

1

1

1

2

1

1

1

1

4

1

1

1

Part Number

7-TR15-150/600

6-4260

7-4260

5-4316

1-4317-2

1-1551-38

1-1115-10-10B

5-4260

‡-2310-‡

1-1118-3-3

1-4276

1-4318

1-1551-17

3-4045-‡

3-4045-‡

3-2324

4-4141-1

5-4140-5

1-1118-4-4

5-4142-R

1-4142

1-1118-4-4

1-4158

2-4158-8

1-1118-4-6

2-4148-1

2-4149

2-4150

3-4045-‡

1-1303-1

1-1503-13

3-4045-‡

1-4143

2-4152

1-4153

1-1115-10-10B

1-1551-38

3-1701-4

1-1607-5

Description

Model TR15 Totalizer Transmitter (Specify Pulse Rate)

Totalizer & Bonnet Complete (Items 1 thru 6)

Totalizer & Bonnet Complete (Items 1 thru 8)

Totalizer Bonnet Assembly

Totalizer Bonnet Lid with pin

O-ring, Totalizer Bonnet

Screw, Bonnet Mounting

Totalizer Sub-Assembly Less Gears (Specify dial)

Dial (as specied)

Screw, Dial Mounting

Sweep Hand

Totalizer Base Cup

O-ring, Base Cup

A Gear Assembly (Specify # of teeth)

B Gear Assembly (Specify # of teeth)

Totalizer Drive Magnet Assembly

Transmitter Base Sub-Assembly

TR15 mA/Pulse Rate Card

Screw, Card Mounting

Transmitter Gear Train Assembly (Items 19-33)

Transmitter Top Plate

Screw, Bottom Plate Mounting

Actuator Transmitter Cup (4 slot)

Actuator Transmitter Cup (8 slot)

Screw, Top Plate Mounting

Actuator Cup Shaft

Idler Shaft

Driven Clevis Shaft

Transmitter Drive Gear Assembly

Thrust Washer

Thrust Bearing

Transmitter Idler Gear Assembly (Specify # of Teeth)

Transmitter Bottom Plate

Drive Clevis

Drive Clevis Coupling

Screw, Transmitter Base Mounting

O-ring, Transmitter Base

Cable Assembly

Desiccant Capsule

30119-33 Rev. 1.8/04-14

17

TOTALIZER-TRANSMITTER

MODEL TR15

30119-33 Rev. 1.8/04-14

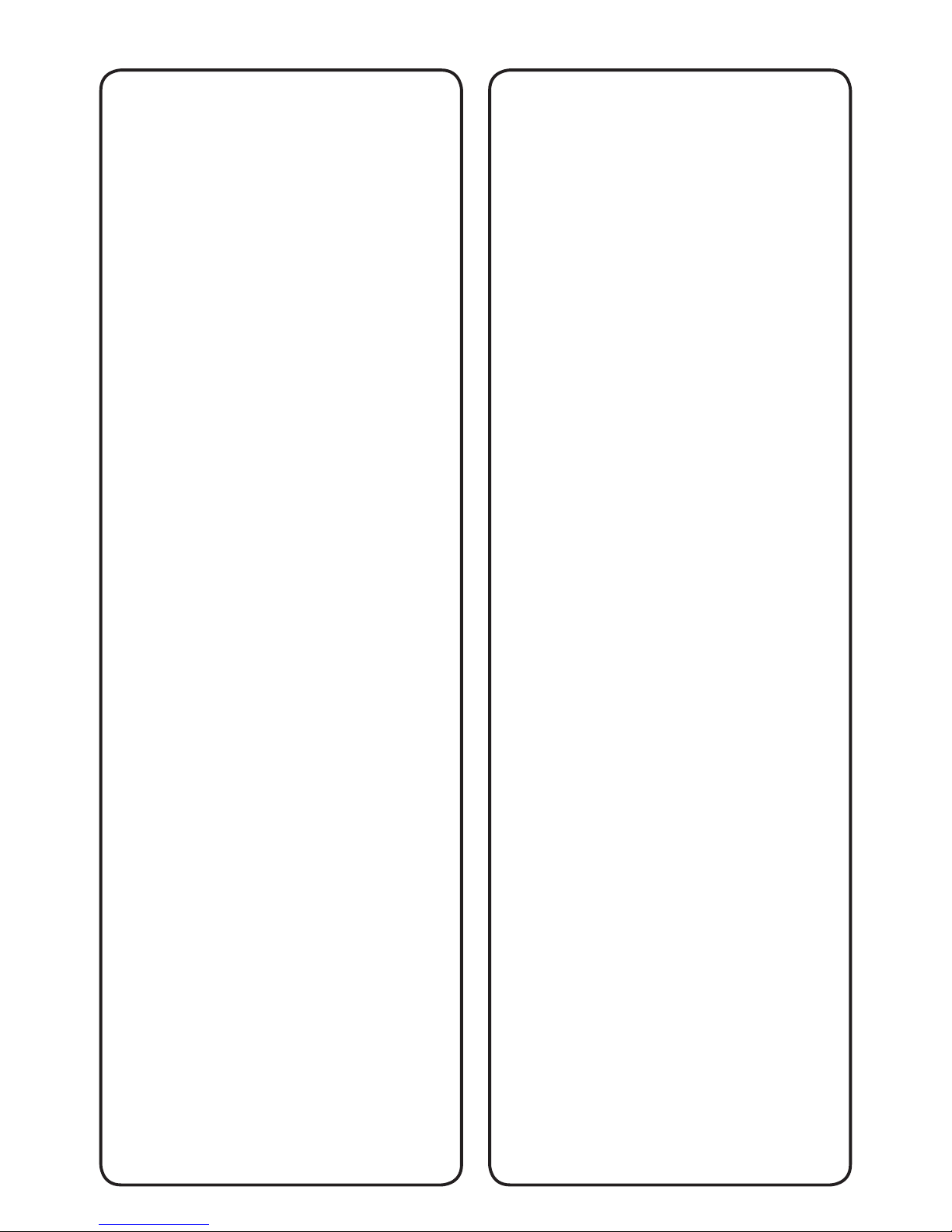

INDICATOR-TOTALIZER-TRANSMITTER

MODEL TR16

PARTS LIST

18

‡ CONSULT FACTORY TO COMPLETE PART NUMBER

CONSULT FACTORY FOR PRICES

No.

none

none

none

2

3

4

5

none

none

none

6

7

8

8

9

10

12

15

18

19

20

23

23

24

26

27

28

29

30

31

32

33

35

36

37

38

39

none

QTY

1

1

1

4

4

1

1

1

1

1

2

2

1

1

1

1

1

3

1

1

3

1

1

3

1

1

1

2

1

1

1

1

4

1

1

1

Part Number

7-TR16-150/600

5-4337

1-4338

1-1115-10-56H

1-1551-6

1-1551-49

5-CN06-2-R

‡-4013-‡

1-4321

1-4326

1-1113-10-6

1-1302-10

3-2176-‡

3-2157-‡

3-2163-‡

4-4141-1

5-4140-5

1-1118-4-4

5-4142-R

1-4142

1-1118-4-4

1-4158

2-4158-8

1-1118-4-6

2-4148-1

2-4149

2-4150

3-4045-‡

1-1303-1

1-1503-13

3-4045-‡

1-4143

2-4152

1-4153

1-1115-10-10B

1-1551-38

3-1701-4

1-1607-6

Description

Model TR15 Totalizer Transmitter (Specify Pulse Rate)

Indicator Totalizer Bonnet Assembly

Indicator Totalizer Bonnet Lid with Pin

Screw, Bonnet Mounting

Screw, Bonnet Mounting O-ring

O-ring, Bonnet

Indicator Totalizer Mechanism

(Including Dial Specied and Gears)

Dial (as specied)

Indicator Hand

Test Hand

Screw, Indicator Totalizer Mounting

Shakeproof Washer

A Gear Assembly (Specify # of teeth)

A Gear Assembly (Specify # of teeth)

B Gear Assembly (Specify # of teeth)

Transmitter Base Sub-Assembly

TR16 mA/Pulse Rate Card

Screw, Card Mounting

Transmitter Gear Train Assembly (Items 19-33)

Transmitter Top Plate

Screw, Bottom Plate Mounting

Actuator Transmitter Cup (4 slot)

Actuator Transmitter Cup (8 slot)

Screw, Top Plate Mounting

Actuator Cup Shaft

Idler Shaft

Driven Clevis Shaft

Transmitter Drive Gear Assembly

Thrust Washer

Thrust Bearing

Transmitter Idler Gear Assembly (Specify # of Teeth)

Transmitter Bottom Plate

Drive Clevis

Drive Clevis Coupling

Screw, Transmitter Base Mounting

O-ring, Transmitter Base

Cable Assembly

Desiccant Bag

30119-33 Rev. 1.8/04-14

19

INDICATOR-TOTALIZER-TRANSMITTER

MODEL TR16

30119-33 Rev. 1.8/04-14

SPECIFICATIONS INDEX

A/B

RATIO

CHANGE GEARS

METER SIZE &

MODEL NO.

REGISTRATION

INDICATOR DIAL

GEARING

REPAIR RECORD

SERIAL NUMBER

PURCHASE DATE

ODOMETER READING

NOTES:

DATE REPAIR METER LOCATION COMMENTS

20

Loading...

Loading...