Water Right ECLIPSE WRO-35 Installation, Operation & Service Manual

ECLIPSE

Reverse Osmosis

Drinking Water Sys tem

from Water-Right

Installation, Operation & Service Manual

WRO-35

R.O. Drinking

Water System

Sold and serviced

by authorized

Water-Right dealers.

Tested and Certifi ed by NSF International against

NSF/ANSI Standard 58 for the reduction of the claims

specifi ed on the Performance Data Sheet.

TABLE OF CONTENTS

Page

SECTION I. INTRODUCTION ...................................................................................3

SECTION II. SPECIFICATIONS ................................................................................4

SECTION III. PREPARATION......................................................................................5

A. Major System Components.............................................................5

B. Tools Recommended for Installation ...............................................7

C. Site Selection For Major System Components ...............................7

SECTION IV. INSTALLATION STEPS .........................................................................8

A. Faucet with Water Quality Monitor Installation ................................8

B. Feed Water Saddle Valve Installation............................................10

C. Drain Clamp Installation ................................................................10

D. R.O. Manifold Assembly Installation..............................................11

E. Position the Drinking Water Holding Tank

and Make the Final Hose Connections .........................................12

F. Start Up.........................................................................................13

SECTION V. OPERATION AND MAINTENTANCE ..................................................13

A. Normal Operation..........................................................................13

B. Changing Modules ........................................................................14

C. Changing the In-Line Activated Carbon Post Filter .......................14

SECTION VI. TECHNICAL DATA...............................................................................14

A. Water Quality ................................................................................14

B. Water Quantity ..............................................................................15

C. Net Pressure Differential ...............................................................15

D. Water Production Rate Chart ........................................................17

SECTION VII. TROUBLE SHOOTING GUIDE ...........................................................18

EXPLODED VIEW AND PARTS LIST ...................................................................................21

CAUTION:

The Centers for Disease Control and Prevention (CDC) and the Environmental Protection Agency (EPA) have issued guidance to people with severely

weakened immune systems who may want to take extra precautions to reduce the risk of infection with Cryptosporidium from drinking water. This

guidance pertains to people with HIV/AIDS, patients receiving treatment for cancer, recipients of organ or bone marrow transplants, transplant patients

taking immunosuppressive drugs, and persons who have congenital immunodefi ciencies.

The EPA has stated that they do not know the signifi cance of drinking water compared to other possible sources of Cryptosporidium to determine how

most people become infected. The CDC-EPA guidance suggests that immunosuppressed individuals discuss their risks with their health care provider.

This drinking water system is tested and Certifi ed by NSF International to NSF/ANSI Standard 58 for cyst reduction. It meets the NSF/ANSI standard of

reducing at least 99.95%* of cysts (including Cryptosporidium), however, because this is not 100%, immunosuppressed individuals should take the extra

precaution of boiling their drinking water. According to the CDC-EPA, bringing water to a rolling boil for one minute is the most certain approach for killing

Cryptosporidium.

All individuals should take adequate precautions when changing the fi lter cartridges, including wearing protective gloves, to avoid direct contact with the

exhausted cartridges.

*For complete specifi cations, refer to the Performance Data Sheet.

SECTION I. INTRODUCTION

Your new Reverse Osmosis (R.O.) Drinking Water

System uses a combination of fi ltration tech nol o gies

to reduce unwanted contaminants in a water supply.

The following steps combine to give you the best in

clear sparkling drinking water:

MECHANICAL FILTRATION/ACTIVATED

CARBON–The Sediment/Carbon Module will

remove the larger particles such as silt, rust

and scale. Its 5 micron (equal to 0.0002 inch)

nominal rating

R.O. Membrane.

helps to give maximum life to the

The activated carbon in the

Prefi lter will remove any chlo rine that may be

present in the feed water. This pre treat ment is

also necessary for membrane protection.

REVERSE OSMOSIS MEMBRANE–The R.O.

Membrane is the heart of the fi l tra tion system.

It is designed to reduce the dis solved min er al

content of the water. Minerals picked up in the

environment by the water are measured as Total

Dissolved Solids (TDS). In the Reverse Os mo sis

process, dissolved minerals are sep a rat ed from

the incoming water (Feed Water) to produce

the product wa ter (the Permeate). The excess

minerals are rinsed to drain (the Reject Water).

The membrane is a specially con struct ed, fully

aromatic polyamide fi lm, and is classifi ed as a

Thin Film Composite (T.F.C.).

The spiral wound construction of the R.O.

Membrane provides maximum surface area

for water production and is less susceptible

to fouling by par tic u late matter, turbidity and

colloidal ma te ri als.

ACTIVATED CARBON–The Ac ti vat ed Carbon

Module contains carbon particles with a vast

network of pores. The tremendous surface

area of these pores (typically 800–1200 square

meters per gram of carbon) gives the carbon

very good adsorptive sites for sub stanc es that

contribute to tastes and odors.

IN–LINE ACTIVATED CARBON POST FILTER–

The In–Line Activated Carbon Post Filter is

located after the Holding Tank and reduces the

tastes and odors that may pass through the

system. It adds a fi nal polish to the water.

AUTOMATIC SHUTOFF VALVE–The ASO Valve

senses when the Holding Tank is full and closes

the feed water supply to prevent excess reject

water from going to drain when the unit is not

producing water.

WATER QUALITY MONITOR–The Water Quality

Monitor has been integrated into the faucet

base for instant monitoring at the touch of a

button. The monitor compares the level of the

Total Dissolved Solids in the incoming (feed)

water versus the product water and calculates

the percent rejection. The monitor is preset to

indicate a level of 75% rejection.

A green light indicates that the percent rejection

is at or above the set (desired) value and that

the system is producing quality water.

An amber light indicates that the product water

quality is less than acceptable. Because the

Water Quality Monitor was designed to operate

best while the system is making water, a false

reading may occur if tested when your R.O.

drinking water system is not

making water.

Please empty the Holding Tank, wait 15 minutes

for the system to begin making water, and test

your water quality again. If the Water Quality

Monitor light is still amber, please contact a

water treatment professional for service. The

Water Quality Monitor requires a 9 volt battery,

which is included.

IMPORTANT NOTICES:

This reverse osmosis system contains replaceable treatment components critical for effective performance. It is the user's

responsibility to, and the manufacturer strongly recommends that the user, periodically test the product water to verify the

system is performing satisfactorily. See the test kit(s) for sampling instructions.

This system is acceptable for treatment of infl uent concentrations of no more than 27 mg/l nitrate and 3 mg/l nitrite in

combination measured as N and is certifi ed for nitrate/nitrite reduction only for water supplies with a pressure of 40 psig

(280 kPa) or greater.

This system conforms to NSF/ANSI Standard 58 for pentavalent arsenic reduction. See the Performance Data Sheet and

Arsenic Facts section for an explanation of reduction performance.

DO NOT USE WITH WATER THAT IS MICROBIOLOGICALLY UNSAFE OR OF UNKNOWN QUALITY, WITHOUT

ADEQUATE DISINFECTION BEFORE OR AFTER THE SYSTEM. Systems certifi ed for cyst reduction may be used on

disinfected water that may contain fi lterable cysts.

3

SECTION II. SPECIFICATIONS

TABLE A – QUALIFIED SYSTEM PER FOR MANCE

Because the performance of an R.O. Mem brane is highly dependent upon pressure, temperature and TDS, the

following should be used for com par i son purposes only.

U.S. Metric

1

Membrane Production

Membrane TDS Reduction

35 ± 7 gpd (106–159 lpd)

1

95% minimum 95% minimum

System Production² 11 gpd 42 lpd

TDS Reduction² 90%+ typical 90%+ typical

Drain (reject water) Flow 3–5 x product fl ow 3–5 x product fl ow

Empty Storage Tank Precharge 5–7 psig air 35–48 kPa air

Storage Tank Capacity

1

Industry standards measure RO Mem branes performance with no backpressure on the product water, at 60 psig (414kPa) and

77°F (25°C). Further conditions on the above are 250 ppm TDS and a 15% recovery rate. Production rate and TDS reduction

fi gures are for a new Membrane that has been rinsed for 24 hours. The production rate of a new Membrane can decrease by

10% per year or more, depending upon the scaling and fouling ten den cies of the Feed Water.

2

Measured at 50 psig, 77°±2°F, and 717 mg/l TDS per NSF/ANSI Standard 58.

2

1.8 gallons 6.8 liters

TABLE B – RECOMMENDED OPERATING LIMITS FOR FEED WATER

Specifi cations T.F.C. Membrane

Water Pressure 40–100 psig (280–690 kPa)

TDS 2000 ppm (also mg/l) max.

Temperature 40–100°F (4–38°C)

pH 3–11

Hardness Less than 10 gpg (170 mg/l) or soften

Iron Less than 0.1 ppm (also mg/l)

Manganese Less than 0.05 ppm (also mg/l)

Hydrogen Sulfi de None

Chlorine See note

Bacteria Must be potable**

NOTE: Chlorine will damage a T.F.C. Membrane. The Sediment/Carbon Module will remove chlorine from the incoming water.

Change fi lter every 6 months, more often if the water contains more than 1 ppm chlorine.

**DO NOT USE WITH WATER THAT IS MI CRO BI O LOG I CAL LY UN SAFE OR OF UNKNOWN QUALITY, WITHOUT AD E QUATE DIS IN FEC TION BEFORE OR AFTER THE SYSTEM.

4

SECTION III. PREPARATION

A. Major System Components

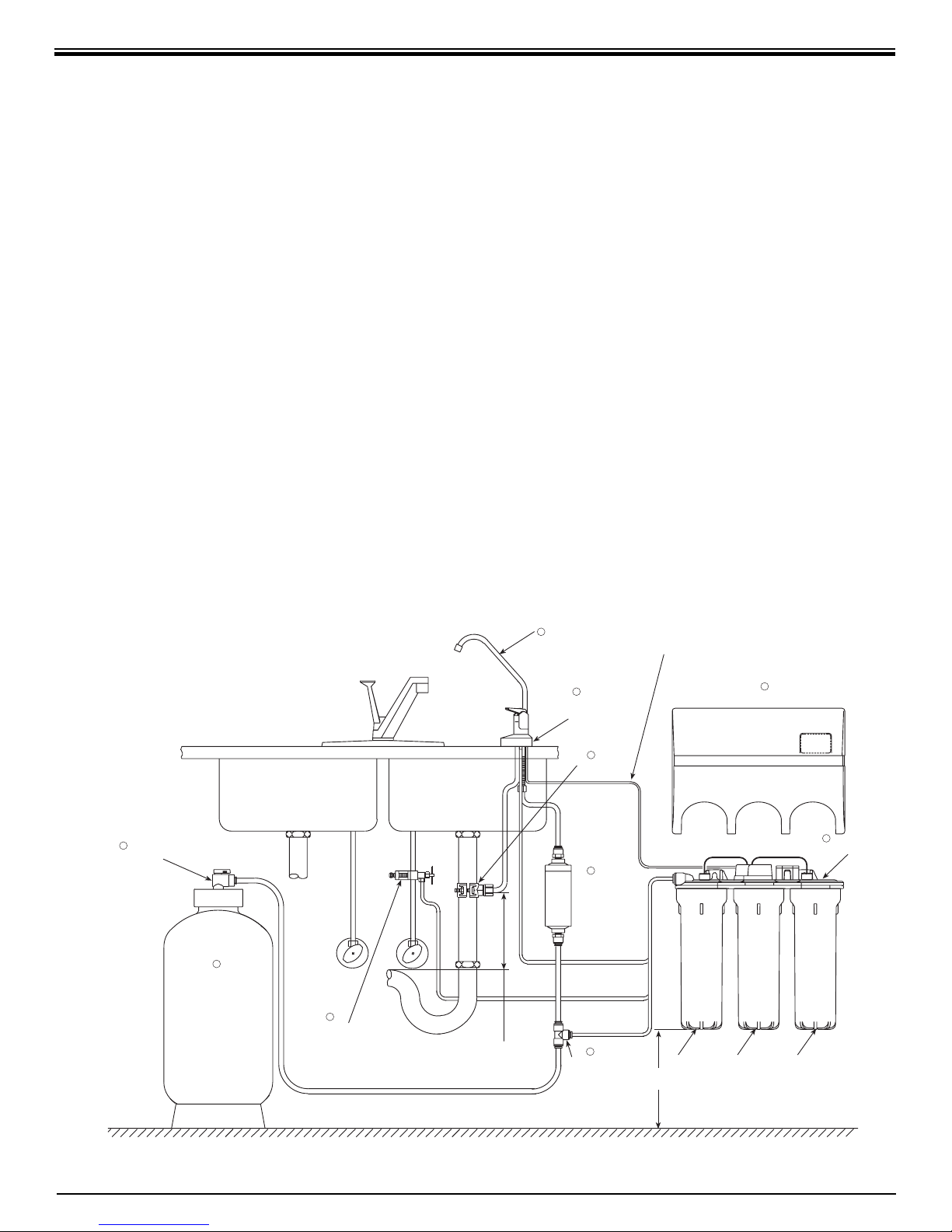

The following components comprise the R.O.

Drinking Water System. (Refer to Fig. 1, below

for general system layout.)

• A Sediment/Carbon Module, shrink wrapped.

• An Activated Carbon Module, shrink

wrapped.

• An R.O. Manifold assembly.

• Housings and Housing O–rings.

• A Drinking Water Holding Tank.

• A Dispensing Faucet with Water Quality

Monitor Assembly.

• A Feed Water Saddle Valve.

• A Drain Clamp.

• Plastic Tubing and tube connectors.

• A Reverse Osmosis Mem brane sealed in a

plastic bag.

TYPICAL WRO-35 UNDER SINK INSTALLATION DIAGRAM

11

NITRATE/NITRITE

TEST KIT

• An In–Line Activated Carbon Post Filter,

shrink wrapped.

• Other items necessary for installation may

include wood screws or machine screws and

nuts for mounting the manifold, or concrete

anchors for hanging on basement wall.

Additional tubing or tube connectors. Plastic

wire ties for organizing tubing.

1

DISPENSING

FAUCET WITH

AIR GAP

2

WATER QUALITY

MONITOR

FAUCET BASE

WATER QUALITY

MONITOR CABLE

4

COVER

10

HOLDING TANK

SHUTOFF VALVE

(Open Position)

9

DRINKING

WATER

HOLDING

TANK

SADDLE VALVE

(COLD WATER LINE ONLY)

3

DRAIN

CLAMP

DRAIN

(3/8" Black)

8

LOCATE DRAIN CLAMP ABOVE

"P" TRAP

TANK

(3/8" Yellow)

PRODUCT

(3/8" Blue)

6

IN-LINE

ACTIVATED

CARBON

POST FILTER

(1/4" Black)

(1/4" Red)

(1/4" Yellow)

7

POLYTUBE

TEE

DRAIN

INLET

4" MIN.

ACTIVATED

CARBON

MODULE

REVERSE

OSMOSIS

MEMBRANE

HOUSING

5

RO MANIFOLD

SEDIMENT/

CARBON

MODULE

Figure 1

5

FLOOR

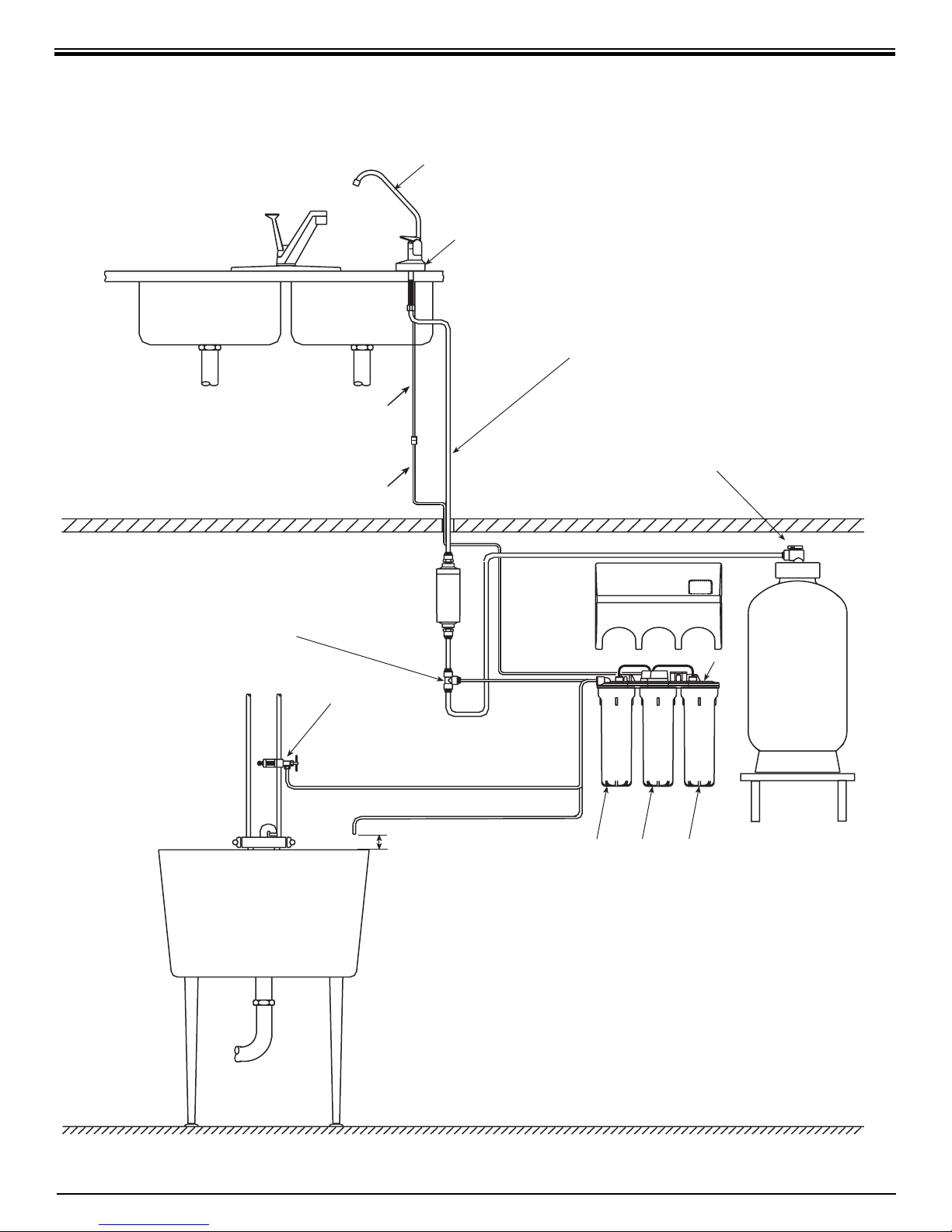

OPTIONAL WRO-35 BASEMENT INSTALLATION DIAGRAM

DISPENSING

FAUCET

WATER QUALITY

MONITOR

FAUCET BASE

NOTE: FOR REFRIGERATOR

WATER DISPENSER OR ICE

MAKER HOOKUP, TEE INTO

WATER QUALITY

MONITOR CABLE

OPTIONAL 25 FT. EXTENSION

CABLE FOR WATER QUALITY

MONITOR

PRODUCT

(3/8" Blue)

3/8" BLUE TUBING TO

DISPENSING FAUCET

HOLDING TANK

SHUTOFF VALVE

(Open Position)

POLYTUBE

TEE

IN-LINE

ACTIVATED

CARBON

POST FILTER

FEED WATER

SADDLE VALVE

(COLD WATER

LINE ONLY)

1" AIR GAP

REQUIRED

INLET

(1/4" Red)

DRAIN

(1/4" Black)

TANK

(3/8" Yellow)

(1/4" Yellow)

ACTIVATED

CARBON

MODULE

COVER

R.O. MANIFOLD

REVERSE

OSMOSIS

MEMBRANE

HOUSING

SEDIMENT/

CARBON

MODULE

DRINKING

WATER

HOLDING

TANK

MOUNT HOLDING

TANK ON SHELF OR

STRAP BETWEEN

FLOOR JOISTS

(Shelf Or Straps Not

Included)

BASEMENT

FLOOR

PLEASE NOTE: IF AIR GAP ON FAUCET IS NOT USED IN BASEMENT

INSTALLATIONS, A PROPER AIR GAP MUST BE CREATED. PLEASE

CHECK WITH LOCAL PLUMBING CODES. SEE EXAMPLE ABOVE.

6

B. Tools Recommended for Installation

The following tools will cover most of the

in stal la tion sites encountered:

3

1.

/8" variable speed electric drill.

2. Extension work light with outlet.

3. Safety glasses.

4. 1¼" porcelain hole cutter kit.

5. 1¼" Greenlee hole punch and

1

/8" and

½" metal drill bits for pilot hole.

6. Center punch and hammer.

7. 1¼" wood bit.

8. Concrete drill bits.

9. Assorted wood and metal drill bits in clud ing

7

/32" metal drill bit.

10.Phillips head and fl at blade screwdrivers.

11.½",

9

/16" and 5/8" open end wrenches.

12.10" Crescent wrench with jaws taped to hold

faucet.

13.Basin wrench or 10" pipe wrench.

14.Tefl on tape.

15.Wide masking tape or duct tape.

16.Plastic tubing cutter.

17.Extra plastic tubing.

18.Low range air pressure gauge.

19.Bicycle hand air pump.

20.Small bottle of liquid chlo rine bleach.

21.Graduated measuring cyl in der.

22.Paper towels, wisk broom and assorted clean

up materials.

1. Dispensing Faucet–The faucet should be

placed near the sink where drinking water

is normally obtained. Convenience of use

(fi lling of water pitchers and glasses), and an

open area beneath the faucet under the sink

for attaching product and drain tubing are

considerations. A 2" diameter fl at surface is

required above and below the installation site.

The thickness of the mount ing surface should

not exceed 1¼". Watch for strengthening

web bing on the underside of cast iron sinks.

2. Drinking Water Holding Tank–The Holding

Tank may be placed where it is convenient

within 10 feet of the faucet; under the sink or

in an ad ja cent cabinet are best the choices.

If a longer run of tubing is required, the

tubing should be the

3

/8" diameter OD size

to prevent a high pres sure drop. Re mem ber,

these tanks can weigh up to 30 pounds when

full of water; a fi rm, level area is required.

3. R.O. Manifold Assembly–The manifold can

be installed on either the right or left side

of the under–sink area or a cabinet. The

right side is recommended because all the

tubing will be to the back of the cabinet and

out of the way. Installation in the basement

is also an option; one location is near the

laundry/utility sink where cold potable water

and drain access are handy. The mounting

location should allow adequate clear ance

and accessibility for cartridge chang es.

4. Feed Water Connection–The Feed Water

Saddle Valve should be located as close to

the manifold assembly as possible. USE A

POTABLE COLD WATER SUPPLY ONLY.

Softened water is preferred as it will extend

the life of the R.O. Membrane.

C. Site Selection for Major System Components

The R.O. System was designed to fi t under a

sink, however, because of space limitations

or other reasons, the system’s fl exible design

allows for other lo ca tions. When determining the

location re mem ber that access to a cold water

tap line, the household drain, and ease of fi lter

re place ment are important considerations.

All components and tubing should be located in

an area not exposed to freezing temperatures. If

winter temperatures are severe, the area should

be above the minimum temperature listed in

Table B, page 4 for proper performance. Do not

expose unit or tubing to direct sunlight.

5. Drain Connection–The waste water must

go to drain through an anti–siphon air gap.

The air gap is pro vid ed for in the base of

the faucet. If discharging into a utility sink

or standpipe, an air gap of greater than 1"

above the fl ood rim must be provided.

Do NOT connect the system drain line to

the dishwasher drain or near the garbage

dis pos al. Backpressure from these units may

cause the air gap to overfl ow.

7

SECTION IV. INSTALLATION STEPS

All plumbing should be done in accordance with

state and local plumbing codes.

NOTE: Some codes may require installation by a

licensed plumber; check with the local plumbing

authority prior to installation.

In restricted under–sink areas, it may be easier to

install the faucet fi rst. Allow ad e quate tubing lengths

for any fi nal component position.

A. Faucet With Water Quality Monitor Installation

The faucet contains an anti–siphon air gap.

–

While the system is producing water, the drain

water fl ows from the R.O., through the air gap

and then to the household drain. The purpose of

the air gap is to prevent water in the drain from

backing up into the R.O. Drinking Water System.

NOTE: For proper installation the Air Gap Faucet

has a critical level line “CL” marked on its body

and should be mounted so that the “CL” line is at

least one (1) inch (26mm) above the fl ood level

rim of the sink.

The easiest installation is to use an existing

spray attachment hole. If the spray faucet hole is

not available, then the sink top must be drilled.

Choose a convenient location as described in

Sec. III, C.1, page 7.

1. Mark the location of the center of the faucet

base.

2a.Drilling a stainless steel sink:

•Center punch the hole to provide a starting

point for the drill.

•Start with a smaller drill as a pilot, and then

drill a ½" diameter hole to accept the bolt of

a 1¼" Greenlee Hole Punch (1¼" chassis

punch).

•Clean away any chips.

•Install the punch and tighten the nut to cut

the hole.

•Deburr any sharp edges.

2b.Drilling a porcelain sink:

It is best to use a special 1¼" diameter cutter

designed for porcelain. A carbide tipped

masonry bit is a second choice.

•Place a piece of tape over the area to be

drilled to help prevent chip ping.

•Drill a pilot hole for the porcelain cutter.

Use the pilot drill supplied with the kit or a

car bide tipped drill.

•When drilling the 1¼" hole, drill slowly and

carefully; the porcelain chips easily.

•After drilling, clean the area well. Iron fi lings,

if left in place, can cause rust stains.

2c. Drilling a counter top:

NOTE: The counter top must be less than

1¼" thick. Treat ceramic tile as por ce lain until

the tile is pen e trat ed, then use the carbide

tipped metal cutter.

Formica counter tops may be drilled with a

good 1¼" wood bit; drilling a

3

/32" pilot hole

will help keep the bit going straight.

3. Assemble and attach the Faucet, Water

Quality Monitor Faucet Base and tubing (refer

to Fig. 2A & 2B, page 9.)

•Assemble the Body and Spout by removing

the plastic ship ping plug from the Body and

then fi rmly pressing in the Spout.

Locate the ¼" Black Drain Tubing which

is shipped loose in the box. Connect the

Black Drain Tubing to the ¼" Hose Barb on

the Dispensing Faucet by fi rmly pressing

over the barb. Allow the tubing to relax,

then press fi rmly again to insure proper

seating. The end of the Black Drain Tubing

that should be inserted into the "Drain" port

on the R.O. Manifold will have a blue drain

restrictor in it. DO NOT attach this end to

the Dispensing Faucet.

Locate the

3

/8" Black Drain Tubing which is

shipped loose in the box. Firmly press one

3

end of the tubing over the

/8" drain outlet

hose barb on the Dispensing Faucet. Allow

tubing to relax, then press fi rmly again to

insure proper seating. No connectors are

required when attaching tubing to Hose

Barbs.

Slide Water Quality Monitor Faucet Base

over ¼" Black Drain Tubing, 3/8" Black Drain

7

Tubing and

/16" stud screw and seat with

Amber/Green LED's aligned under Air Gap

Window on Dispensing Faucet. (See Figure

2A, page 9.)

Assemble the Plastic Spacer (with open

end upwards and facing tubing), the

7

Washer and the

/16" Hex Nut onto the 7/16"

7

/16"

stud screw. Do Not tighten at this point.

8

Loading...

Loading...