WB

L

I

S

T

E

D

®

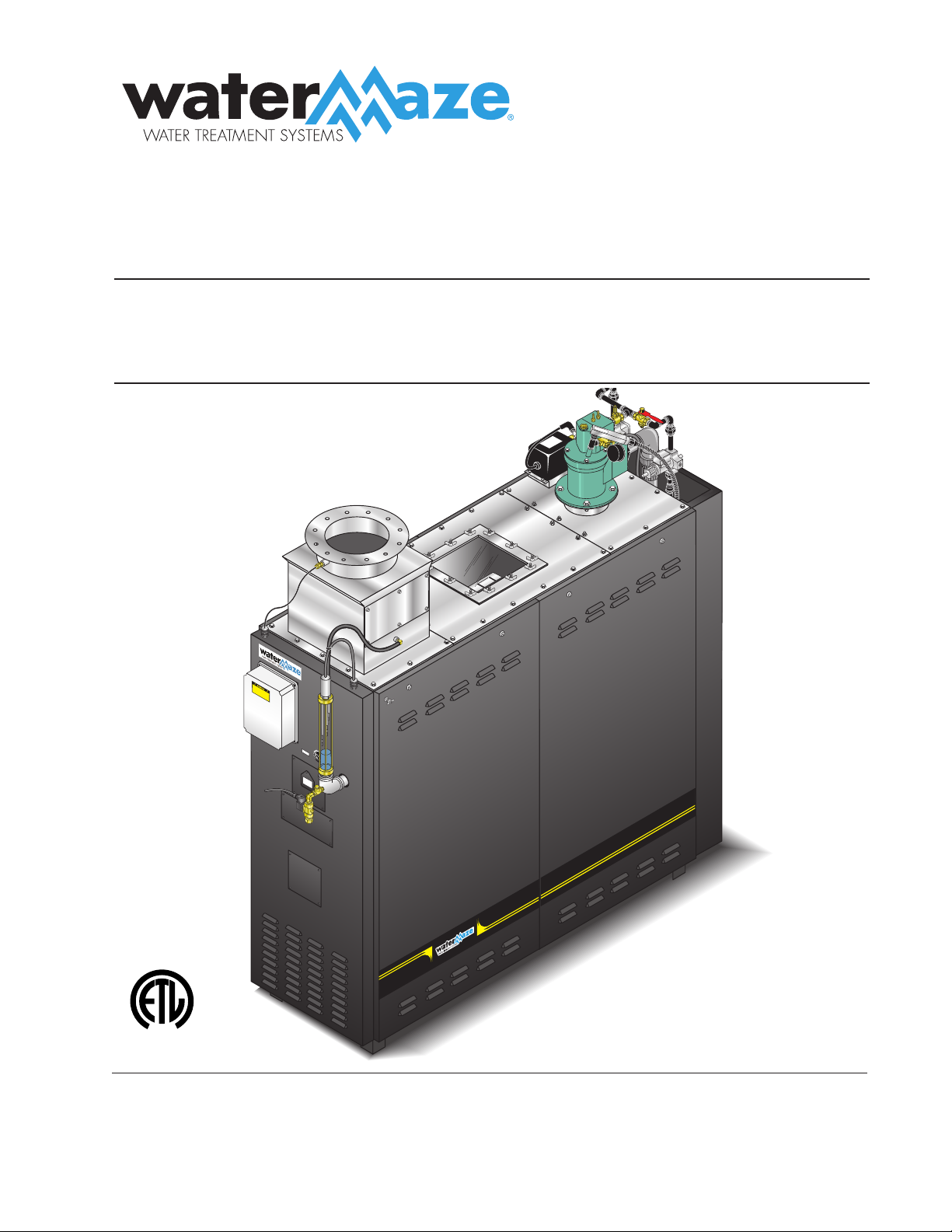

OPERATOR’S MANUAL

■ WB-50A ■ WB-120A

1.103-474.0 1.103-473.0

For technical assistance or the Water Maze Dealer nearest you consult our web page at

www.wmaze.com

07/11/19 8.913-984.0-L

CONTENTS

Introduction .................................................................................................................................... 4

Unpacking ...................................................................................................................................... 4

General Safety Instructions ....................................................................................................... 4, 5

Electrical Safety Information .......................................................................................................... 5

Wiring ........................................................................................................................................ 5, 6

Pump Safety .................................................................................................................................. 6

Standard Safety Features .......................................................................................................... 6, 7

Installation.................................................................................................................................. 7, 8

Pre-Startup Check List .................................................................................................................. 8

Operating Procedure ..................................................................................................................... 9

Principles of Operation .................................................................................................................. 9

Installation Drawings ............................................................................................................. 10 - 11

Storage Tank Configuration .........................................................................................................12

Exhaust Stacking Configuration ................................................................................................... 13

WB-50A Front View ...................................................................................................................... 14

WB-120A Front View .................................................................................................................... 15

Start-Up Procedures .................................................................................................................... 16

Shut Down Procedures ................................................................................................................ 16

Setting the Burner ........................................................................................................................ 17

Soft Start Ignition ......................................................................................................................... 17

Burner Adjustment Diagram ........................................................................................................ 18

Foaming ....................................................................................................................................... 19

Converting Natural Gas to L.P. Gas ............................................................................................. 19

Veri-Flame #7-8061 ..................................................................................................................... 20

3 Point Sensor Control ................................................................................................................. 20

Setting High Limit Control ............................................................................................................ 21

Maintenance ........................................................................................................................... 21-23

WB • #8.913-984.0-L

CONTENTS

Programming of Water Maze Cycle Timer .............................................................................. 24-26

Water Level Control Unit & Parts List .......................................................................................... 27

WB-50A Exploded View .......................................................................................................... 28-29

WB-50A Exploded View Parts List .......................................................................................... 30-32

WB Control Panel w/Parts list ................................................................................................. 33-35

WB-120A Exploded View ........................................................................................................ 36-37

WB-120A Exploded View Parts List ........................................................................................ 38-40

Water Maze w/Anti-Foam Metering Pump .................................................................................. 41

Air Line Assembly Exploded View and Parts List ...................................................................42-43

Gas Train Assembly WB-50 Exploded View and Parts List ..................................................... 44-45

3

Gas Train Assembly WB-120 Exploded View and Parts List ................................................... 46-47

Replacing Pump Head Tubing .................................................................................................... 48

Metering Pump and Parts List ..................................................................................................... 49

Peristaltic Metering Pump ............................................................................................................ 48

WB-50/120 Regenerative Blower #5-1503 ..................................................................................49

Troubleshooting ...................................................................................................................... 52-54

Specifications ............................................................................................................................... 55

Service Log .................................................................................................................................. 56

Warranty ......................................................................................................................................57

Model Number ______________________________

Serial Number ______________________________

Date of Purchase ____________________________

The model and serial numbers will be found on a decal attached

to the evaporator. You should record both serial number and date

of purchase and keep in a safe place for future reference.

WB • 8.913-984.0-L

WATERMAZE SERIES OPERATOR’S MANUAL

WARNING

WARNING

4

INTRODUCTION

Your owner's manual has been prepared to provide

you with a simple and understandable guide for equipment operations and maintenance based on the latest

product information available at the time of printing. To

keep your machine in top running condition, follow the

specific maintenance and trouble shooting procedures

given in this manual.

NOTE: WATER MAZE reserves the right to make chang-

es at any time without incurring any obligations

UNPACKING

1. WATER MAZE module with removable doors

2. 20 mesh filter screen in a plastic housing

3. Tube of caulk

4. Operator's manual

5. WATER MAZE tool kit and door removal tool

6. WATER MAZE 5600 Defoamer

7. Bulk head fitting and strain relief

NOTE: Report any damage to machine or components

for claim against the freight line.

Owner/User Responsibility:

The owner and/or user must have an understanding

of the manufacturer’s operating instructions and warnings before using this WATER MAZE machine. Warning

information should be emphasized and understood. If

the operator is not fluent in English, the manufacturer’s

instructions and warnings shall be read to and discussed

with the operator in the operator’s native language by

the purchaser/owner, making sure that the operator

comprehends its contents.

Owner and/or user must study and maintain for future

reference the manufacturers’ instructions.

SAVE THESE INSTRUCTIONS

This manual should be considered a permanent

part of the machine and should remain with it if

machine is resold.

When ordering parts, please specify model and serial number. Use only identical replacement parts.

This machine is to be used only by trained operators.

PLEASE NOTE: WATER MAZE is not responsible for

procurement of regulatory and/or operating permits that

may be required by city, county, state or federal agencies. It is the customer who is responsible for procurement of any hazardous or non-hazardous regulatory

and/or operating permits, compliance with codes or

other governmental requirements associated with the

installation, use, or disposal of waste associated with this

equipment. Submerged combustion can be classified as

WB • 8.913-984.0-L

incineration in specific jurisdictions. It is the customer's

responsibility for procurement of appropriate local and

state permits as needed.

The guidelines listed in the evaporator feasibility report

are specific only to the waste stream submitted for evaluation and estimated emissions. Moreover, WATER MAZE

is not reponsible for the operation or maintenance of

the evaporator unit. If the unit is subjected to any waste

stream other than that which has been tested by the

named laboratory, operation may cause adverse effects

on the equipment and will negate any warranty of parts

or equipment.

IMPORTANT SAFETY

INSTRUCTIONS

WARNING: To reduce the risk of

injury, read operating instructions carefully before using.

1. Read the owner's manual

thoroughly. Failure to follow

READ OPERATOR’S

MANUAL

THOROUGHLY

PRIOR TO USE.

2. The installation of the gas line must be done by a

licensed gas contractor and in accordance with local

and/or national codes.

DANGER

HAZARDOUS

VOLTAGE. CAN

SHOCK, BURN OR

CAUSE DEATH.

chine while it is in operation except those prescribed

in this manual.

4. Do not allow high concentrations of flammable fluids,

acids, caustic or abrasive fluids to pass through the

waste water pump into the combustion chamber.

5. Before servicing this machine, refer to all the MSDS

on the material identified in the waste stream. You

DANGEROUS FUMES:

INSTALL ONLY IN

WELL VENTILATED

AREA .

the instructions could cause a

malfunction of the machine and

result in death, serious injury

and/or property damage.

DANGER: The machine, when

installed, must be electrically

grounded in accordance with local and/or national codes. Do not

spray water near electrical components. Do not touch machine

with wet hands or while standing

in water.

3. Never make adjustments on ma-

must comply with all warnings and

wear all protective clothing stated

on the MSDS.

WARNING: Avoid installing machines in small confined areas.

Adequate oxygen is needed for

combustion or dangerous carbon

monoxide will result.

WATERMAZE SERIES OPERATOR’S MANUAL

WARNING

WARNING

5

6. Protect inlet hoses from traffic and sharp objects.

7. Be certain hoses and piping have been connected

before operating.

8. Turn the machine off before disconnecting hoses.

9. Inlet influent temperature must not exceed 150°F

(66°C).

10. When making repairs, disconnect the machine from

the electrical source.

11. The best insurance against an accident is precaution

and knowledge of the equipment.

12. WATER MAZE is not liable for any modifications or

the use of components not purchased from WATER

MAZE.

13. The WATER MAZE and components will freeze if

not in operation and must be located in a heated

enclosure in cold climates.

14. Running the system or the pump without water will

damage the pump and will void the warranty.

15. WATER MAZE should be installed and started up

by an authorized WATER MAZE dealer.

16. This machine can be used with natural gas or

propane. A conversion kit can be supplied by the

manufacturer to convert the machine to the alternate

fuel.

WARNING: If you smell gas, shut

off the gas supply valve, extinguish any open flame and test all

joints with a soap solution. If the

odor persists, call your gas sup-

RISK OF FIRE OR

EXPLOSION:

AVOID FLAMMABLE

LIQUIDS, VAPORS

OR SOLIDS.

plier immediately.

WARNING: Do not locate the machine in the vicinity of any flammable vapors, liquids or solids.

17. Only those liquid wastes that have been approved by

WATER MAZE and the proper regulatory agencies

should be placed in the WATER MAZE machine.

EPA test methods 8260 and 200.7 must be obtained.

NOTE: If any other liquids that have not been tested

are introduced into the WATER MAZE machine, the

warranty will be void.

18. WARNING: Do not attempt to evaporate flam-

mable wastes of any kind, i.e., do not process

solvents, pure oils, etc.

19. WATER MAZE requires a representative sample

of the waste stream analyzed for pH, metals, total

solids, total suspended solids, oil and grease, foam

and chlorides test.

20. High levels of chlorides and fluorides will cause corrosion especially when heated.

ELECTRICAL SAFETY

INFORMATION

WARNING: To reduce the risk of

injury, read electrical instructions

carefully before using.

WARNING: Do not bypass any

safety feature. You can cause

RISK OF FIRE OR

EXPLOSION:

OBEY SAFETY IN-

STRUCTIONS.

DANGER

fires and explosions. Obey the

safety precautions in safety

instructions.

DANGER: Hazardous voltage

can shock, burn or cause death.

Ground machine before connecting to power supply.

1. Ground the equipment before

HAZARDOUS

VOLTAGE. CAN

SHOCK, BURN OR

CAUSE DEATH.

connecting it to an electrical

power supply.

2. Failure to ground the equipment can cause a severe or

fatal electrical shock hazard.

3. Do not ground to a gas supply line.

4. To avoid dangerous or fatal electrical shock, turn

OFF the power to the equipment before working on

the electrical connections.

5. Supply voltage must be within ± 10% of the nameplate voltage. Incorrect voltage can cause a fire

or seriously damage the equipment and voids the

warranty. If in doubt, consult a licensed electrician.

6. Connect the equipment to a dedicated circuit with

no other equipment on it.

WIRING

1. Install a ground wire and maintain this equipment

in accordance with your local electrical code and all

other codes and ordinances that apply. Consult your

local building inspector for local code information.

2. Ground the equipment permanently using a wire

of size and type specified by local and/or National

Electrical Code.

3. Connect the ground wire first to the green grounding wire provided. Do not connect the equipment

to an electrical power supply until the machine is

permanently grounded, otherwise serious or fatal

electrical shock hazard may be caused.

4.

For the best ground connection, connect to a grounded lead in the service panel or to a metal underground

water pipe or well casing at least 10 feet long. If plastic

pipe or insulated fittings are used, run the ground

wire directly to the metal well casing or use ground

electrode furnished by the power company.

WB • 8.913-984.0-L

WATERMAZE SERIES OPERATOR’S MANUAL

WARNING

6

5.

If 208V single phase is the only available electrical

source, the step down transformer must be changed to

a 208/120V .500KVA transformer or a buck boost transformer must be installed to raise the voltage to 230V.

PUMP SAFETY

WARNING: Do not pump high

concentrations of flammable

liquids or explosives such as

gasoline, fuel oil, kerosene, etc.

Do not use in explosive atmo-

RISK OF FIRE OR

EXPLOSION:

OBEY SAFETY

INSTRUCTIONS.

warning could result in personal injury and/or property damage.

1. Know the pump application, limitations and potential

hazards.

2. Make certain that the power source conforms to the

requirements of your machine; 230V single phase

for all WATER MAZE machines. Always check the

serial plate for power requirements.

3. Release all pressure within the system before servicing any component.

4. Drain all liquids from the components before

servicing.

5. Check hoses for weak or worn condition before each

use, making certain all connections are secure.

6. Periodically inspect sparger tube, nozzle, filter and

other system components. Perform routine maintenance as required.

Personal Safety:

a. Keep work area clean, uncluttered and properly

lit. Replace all unused tools and equipment.

b. Keep visitors at a safe distance from the work

area.

c. Make the workshop safe with padlocks, master

switches and power lock out devices.

7. All wiring and electrical connections must be performed by a qualified electrician.

8. Protect the electrical cord by having the electrician

run all electrical wiring through conduit from the

power source to the machine.

9. Use wire of adequate size to minimize a voltage drop

at the motor.

10. Disconnect the power before servicing a motor or

other components. If the power disconnect is out-of-

sight, lock it in the open position and tag it to prevent

unexpected application of power.

spheres. The Water Maze should

only be used with liquids compatible with Water Maze component

materials. Failure to follow this

11. Do not touch an operating motor. Modern motors

are designed to operate at high temperatures.

STANDARD SAFETY FEATURES

The WATER MAZE uses electricity, gas and water to

operate. These can be fatal if not handled properly. For

this reason, the WATER MAZE has been designed with

safety in mind. The following are standard safety features

you will find on all WATER MAZE equipment.

Interlock System:

The WATER MAZE has an interlock system which must

be proven before the burner will ignite. All of these interlocks are proven through the Veri-Flame.

1. Pre-Ignition Interlocks:

a. High/low gas pressure switches

These switches insure that there is enough gas

pressure to operate the burner but not excessive

pressure (see page 20).

NOTE: The low pressure switch is set at 12 water

column inches (wci). The high pressure switch

is set at 60 water column inches (wci).

b. Air Pressure Switch

This switch insures there is at least 12 water

column inches of air pressure. NOTE: The High,

Low Gas and Air Pressure Switches have internal lights. If there is a failure, the light goes out.

See pages 43 & 45.

c. Gas Solenoid Valve

This valve must be closed during pre-ignition

checks. If open, the system will shut down.

NOTE: The WB-50 has three gas solenoid

valves. The WB-120 has six gas solenoid valves

(see pages 43-45).

d. 3 Point Sensor Control:

The evaporation tank must have a minimum

amount of water to prevent damage to internal

parts due to excessive heat. If the water level is

at the bottom rod on the 3 Point Sensor Control,

ignition of the burner is prevented (see item 3

page 27).

2. Post-Ignition Interlock:

UV Scanner

A UV scanner looks for the ignition of the burner.

Once the WATER MAZE has gone through the inter-

locks and the 15 second purge process, the burner

goes through an ignition sequence. If the burner fails

to ignite, the UV scanner shuts down the burner.

Filter:

A 20 mesh screen on the incoming waste water line

prevents solids from entering and damaging the pump.

WB • 8.913-984.0-L

WATERMAZE SERIES OPERATOR’S MANUAL

WARNING

7

Control Rod:

Automatic wastewater control set points on the 3 Point

Level Controller turns the wastewater air pump on and

off to control the water level inside the evaporator. The

controller also shuts burner off if water level gets to low.

Temperature Control:

Dual, manual reset, and high temperature controls

monitor the internal temperature of the evaporator. If the

exhaust or water temperatures become too high (225°F)

the system shuts down. The temperature is usually in

the 180° to 190° range.

Regulator Venting:

A pressure regulator gas vent is provided. The gas vent

needs to be plumbed to the atmosphere. If the gas

regulator fails, the gas is automatically vented outside, preventing a gas buildup in the location of the

WATER MAZE. This must be vented to comply with

local and/or national codes.

Demister Box:

The demister box contains screens inside that prevent

large water droplets from going up the stack (screen

hole size is 3/16").

INSTALLATION

Location:

Locate the WATER MAZE evaporator on a level con-

crete surface in a room that is well ventilated. Protect the

machine from damaging environment such as wind, rain

and freezing temperatures. Leveling feet are provided

with all evaporators.

CAUTION: For natural gas, air ventilation should

be located near the ceiling. For liquid propane, air

ventilation should be located near the floor.

Gas:

The WATER MAZE evaporator is available for operation

in natural gas or liquid propane.

CAUTION: There are major differences in the adjustments of the evaporators. Do not try to operate the

machine using the wrong gas.

The one inch (1") gas supply line on the WB-25, and

WB-50 and (one and one half inch (1-1/2") on the

WB-120) must have a minimum of 2 psig and a maximum of 10 psig and be of adequate size to supply the

necessary volume for proper burner operation. The high/

low gas switches require between 12-60 water column

inches. There must be a main gas shut-off valve (not provided) in the gas supply line located next to the WATER

MAZE which can be used as an emergency shut off for

repair or maintenance purposes.

WB • 8.913-984.0-L

WARNING: The gas line must be

installed by qualified personnel only. It must be checked for

leaks before installing the WATER

MAZE. All gas piping must comply with local and national fuel

GAS LINE MUST

BE INSTALLED BY

QUALIFIED

PERSONNEL ONLY.

“Natural Gas Only” or “L.P. Gas Only” depending on the

machine you purchase. Connect the vent line to the 1"

vent pipe on the rear panel of the WATER MAZE (see

figures 1-3).

CAUTION: This vent pipe must be vented to the atmosphere.

gas codes.

Connect the main gas line to the 1"

or 1-1/2" line on the rear panel of the

WATER MAZE. This will be labeled

Electrical:

The WATER MAZE requires 230 volts single phase. Re-

fer to the serial plate for proper voltage and amp requirements for your machine. All electrical lines must be tested

with a voltage meter for proper voltage before connecting to the WATER MAZE. NOTE: If 208V single phase

is the only electrical source available, the step down

transformer must be changed to a 208/120V transformer

(#6-60011) or a buck boost transformer must be used

to increase the voltage.

DANGER

HAZARDOUS

VOLTAGE. CAN

SHOCK, BURN OR

CAUSE DEATH.

rear panel conduit box using a 1/2" knock-out. Electrical

conduit must be run all the way to the connection point

in accordance with local codes.

DANGER: All electrical lines must

be installed by qualified personnel only. All installations must

be electrically grounded and

conform to all local and national

electrical codes. Water Maze is

ETL listed.

The electrical connection for the

WATER MAZE is located on the

Fresh Water:

During initial start up, we recommend using fresh water in

the wastewater tank. Fill to mark indicated on sight tube

and remove garden hose. Connect the garden hose to the

WATER MAZE at the female connector located on the 3

point level controller. Open valve partially so back pressure doesn't fill up sight glass tube.

Wastewater:

Wastewater is drawn directly into the evaporator using

the air pump supplied. A 20 mesh stainless steel filter

protects the pump from debris. The connection between

the above ground waste water tank and the machine is

made by using a 3/4" I.D. supply hose with common

WATERMAZE SERIES OPERATOR’S MANUAL

8

connectors supplied by the customer and is located on

the rear panel with the label, “Wastewater Inlet" (see

page 11). NOTE: The WATER MAZE is automatically

controlled by the 3 point level controller and will supply

wastewater as needed after startup.

CAUTION: Foaming detergents will affect the

evaporation process in the WATER MAZE. An

anti-foaming kit has been installed to control foam.

Venting:

Each evaporator must have its own vent stack. A 10"

vent pipe (WB-50) must be installed using the provided

exhaust stack adapter to the machine's exhaust stack

and be vented to the atmosphere. A 12" pipe must

be used for the WB-120 (see figure 4). The top of the

exhaust stack should be sufficiently above the roof to

allow for proper dispersion of the exhaust. It should be

unobstructed and in compliance with all local and federal

codes. Avoid bends if possible.

NOTE: If possible, the stack should be a single piece.

CPVC is the recommended stack material. If it has

seams, the seams must be sealed with a duct sealant

to prevent moisture leaks since the exhaust is 100%

saturated air. All stacking must be installed by qualified

personnel only.

NOTE: Exhaust stacking must be water tight.

A straight stack is always the best. If you must have

bends, use 45° not 90° elbows. No more than two bends

should be used. A vertical discharge design is our ONLY

recommendation for a rain cover. A vertical rain cover is

an over-sized piece of stack material that is concentric

with the stack. The cover extends 6" down over the top

of the stack to allow flexibility in positioning fasteners.

Both rain protection and back pressure reduction are

achieved with this design. It works because rain never

falls straight down; it always falls at an angle. Therefore,

the cover is made long enough so that any rain will hit the

cover’s inside wall. Rain then runs down the inner wall

and out the angular opening at the top of the exhaust

stack (see page 13).

Air:

Connect air to regulator, adjust to 60-100 psi at 10 cfm

PRE-STARTUP CHECK LIST

Follow all pre-start procedures before attempting to start

the WATER MAZE.

1.

Level evaporator using leveling feet or anchor machine to floor. Anchoring to floor is the preferred

method.

2. Verify the voltage, then connect the electrical lines

to the machine. To be done by qualified personnel.

3. Leak test connected gas line.

WB • 8.913-984.0-L

4. Connect the wastewater line from the storage

tank.

NOTE: the pH of the wastewater should be kept

between 8 - 10 in the storage tank.

5. Attach (black) N/O float inside wastewater tank just

above outlet so fill pump doesn't suck air.

6. Attach a high heat hose (180°-190°F) to the 3/4"

stainless steel elbow located at the back side of

evaporator for the auto purge cycle. NOTE: Do not

send waste back to fill tank.

7. Attach the stack to the exhaust stack flange.

8. Remove the plugs from the brass orifices on the

gas and air line and install the test valves with the

brass hose barb fittings (not included). (See page

18.) Make sure the gas line is shut off.

NOTE: The valves, fittings, and manometers are

included in the WATER MAZE set-up kit, #7-8200,

which must be purchased separately.

9. Connect the high pressure port of the 0 to 50 manometer to the bottom gas orifice port and open the

gas line.

NOTE: Make sure the manometer is zeroed before

taking readings. Use the zero set screw at the bottom of the manometer. This will give you the static

gas pressure. For measuring the static gas pressure

on the WB-50/120, use the valve at the bottom of

the machine next to the high gas pressure switch

(see page 18). This pressure should be 45 water

column inches (wci). Close the valve and remove

the manometer. You must have between 12 and 60

wci before the high/low gas switches will allow the

burner to ignite.

10. Connect the 0 to 10 manometer to the hose barbs

on the gas line and open the valves with the low

pressure port of the manometer to the top port of

the orifice and the high pressure port to the bottom

port of the orifice. This will give you the pressure differential between the high side, before the orifice,

and the low side, after the orifice. This will be used

later to figure the evaporation rate and to balance

the burner. This reading will be taken after start up

.

when the burner is being used (see page 18).

NOTE: Items 8 through 10 have been set at the

factory but installation conditions change so adjustments need to be verified.

11. Open the valve on gas line and wastewater line.

12. Connect purge hose to bottom of combustion tank

and run to a separate holding tank. Do not connect

to feed tank.

13. Connect air.

14. Adjust anti-foam air to 2 psi and UV scanner air to

1/2 psi.

WATERMAZE SERIES OPERATOR’S MANUAL

9

OPERATING PROCEDURE

First, collect the waste stream. This can be accomplished

with the use of a catch basin, collection pit, sump or any

other process which collects the waste stream in one

location. The collection method should allow for oil and

solids separation. The waste stream must be stored in

an above ground tank to provide a gravity feed situation

to the waste stream pump of the evaporator. The WATER

MAZE air diaphragm pumps are self priming but we do

recommend a positive feed system (see figure 3).

1. A fresh water source is connected to the evaporator

for the initial fill. The evaporator must have a minimum amount of water before it will operate.

2. With the gas line, gas vent, exhaust vent and electrical connected and main disconnect turned on,

push the reset button F1/RST on the timer. NOTE:

Whenever the power to the evaporator goes out, the

reset button F1/RST on the timer must be pushed.

3. Turn the blower switch to the automatic position. This

will engage the blower which will push the water out

of the sparger tube. This causes the water level to

rise slightly in the liquid level float assembly. If the

low water light is still illuminated, attach a garden

hose to the back of the machine and fill the tank

until the light goes out. Now it is time to turn on the

burner.

4. Turn the burner switch to the on position. The system

now goes through the interlocks, 1) high/low gas

pressure; 2) air pressure; 3) closed gas solenoid,

4) low water, bottom setpoint on the 3 point level

control rod. Now a purge cycle will purge the sparger

tube with air for 15 seconds to insure that there is no

gas in the sparger tube. The burner then attempts

to ignite the soft start pilot flame. If there is not an

ignition, the UV scanner shuts the system down and

the start up sequence must be started over.

5. Once the burner ignites, the waste pump switch

can be turned on to introduce wastewater into the

evaporator. This will add wastewater to the system

through the back of the tank.

NOTE: The heat from the burner goes through the

sparger tube and out a slot in the bottom of the

sparger tube, and finally, into the surrounding water.

There are five stainless steel screens on a WB-50

and ten on the WB-120, that break down the size

of bubbles (from big to small) which increases the

surface area and transfers virtually 100% of their

heat to the water to increase saturation (screen hole

size is 1/16").

Auto Purge:

The unit will automatically purge the waste stream from

the combustion chamber at a set time depending on

your waste stream. This purged waste stream must

be sent to an appropriate discharge holding tank and

not back to the feed or inlet holding tank going to

WATER MAZE.

PRINCIPLES OF OPERATION

The WATER MAZE evaporator is designed to evaporate

wastewater. WATER MAZE uses a unique method of

introducing the wastewater directly into a 2000°F flame.

Using submerged combustion technology, the WATER

MAZE can obtain virtually a 100% heat transfer for a

more efficient and less costly method of evaporation.

In order to understand how this system works and why

it is superior to any other evaporator on the market, it is

important to understand a few aspects of relative humidity, submerged combustion and efficiency ratings of this

type of equipment.

First, relative humidity is called “relative” because the

amount of moisture a given amount of air can hold is

directly related to its temperature. For example, let's say

it's snowing. If you were to take a cubic foot of outside

air at 20° F, with a relative humidity of 100% and bring

this air inside and warm it up to 72°F; the same air would

have the same amount of moisture in it, but would have

a relative humidity of only 15%. The warmer the air is,

the more moisture it can hold. With regard to the WATER

MAZE, this "thirst" or affinity for moisture in hotter air is

especially dramatic at temperatures above 150°F.

Second, it will be of value for you to be familiar with some

basics of water heating and evaporation. All of this type

of equipment will be rated in terms of British thermal

units (BTU's) per hour.

A BTU is the amount of heat necessary to raise one

pound of water one degree Fahrenheit.

Let's say we want to evaporate one pound of water:

In order to get our pound of water from 60°F to 212°F,

we will have to add 152 BTU's to it (212°F minus 60°F).

This is called “sensible” heat.

Once this pound of water reaches 212°F, 970 BTU's must

then be applied to turn it into a pound of steam vapor still

at 212°F. We just want to change it from liquid water to

steam vapor and not raise the temperature at all. This

is called “latent” heat.

Therefore, to get our pound of 60°F water to 212°F

steam took 1122 BTU's.

A gallon of water weighs 8.34 pounds. In order to make

a gallon of water evaporate, we have to subject it to 8.34

lbs. x 1122 BTU's or, 9357 BTU's.

WB • 8.913-984.0-L

WATERMAZE SERIES OPERATOR’S MANUAL

10

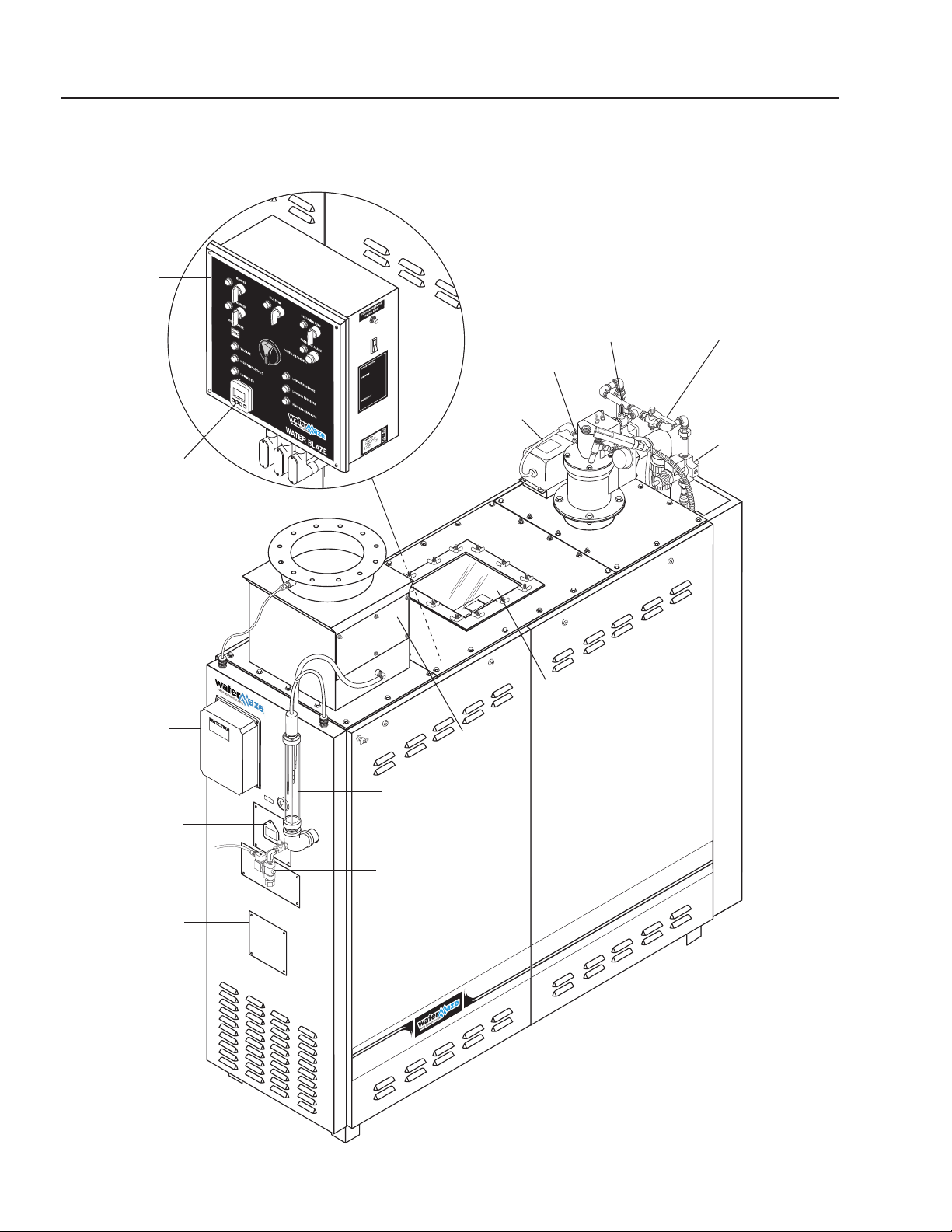

WB-50

INSTALLATION DRAWING

Figure 1

1" Inlet

Gas Line

Vent

Pipe

Wastewater

Inlet

WB • 8.913-984.0-L

WATERMAZE SERIES OPERATOR’S MANUAL

WB-120

INSTALLATION DRAWING

11

Auto Purge

Port

1-1/2"

Inlet Gas

Line

Vent

Pipe

Wastewater

Inlet

Figure 2

WB • 8.913-984.0-L

WATERMAZE SERIES OPERATOR’S MANUAL

12

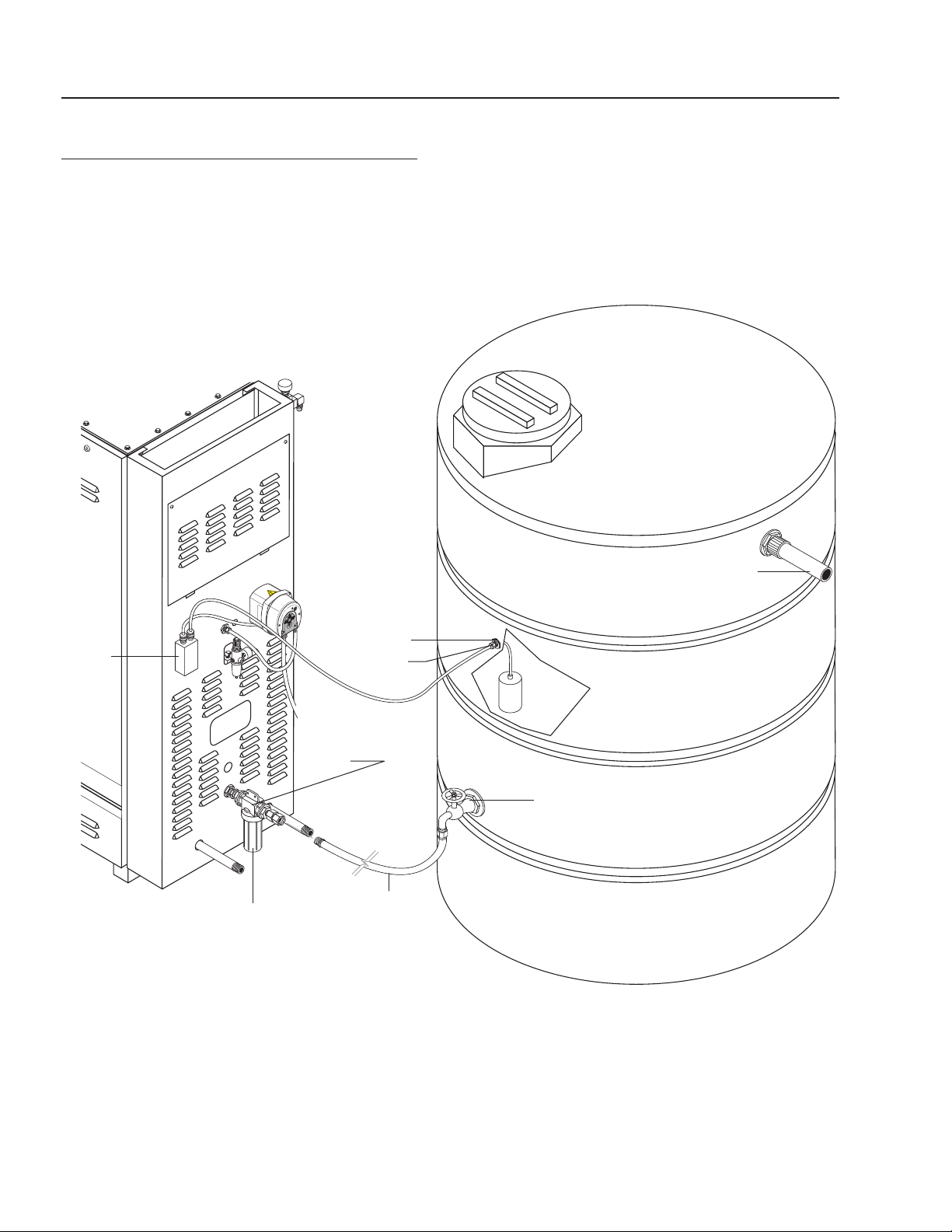

STORAGE TANK CONFIGURATION

Wastewater

Storage Tank

Junction

Box

Filter

Housing

Wastewater Inlet

Bulkhead

Strain

Relief

Float

Switch

Inline

Filter

Wastewater

Shut-Off Valve

(Customer Supplied)

Wastewater

Inlet Connection

(Customer Supplied)

Figure 3

WB • 8.913-984.0-L

WATERMAZE SERIES OPERATOR’S MANUAL

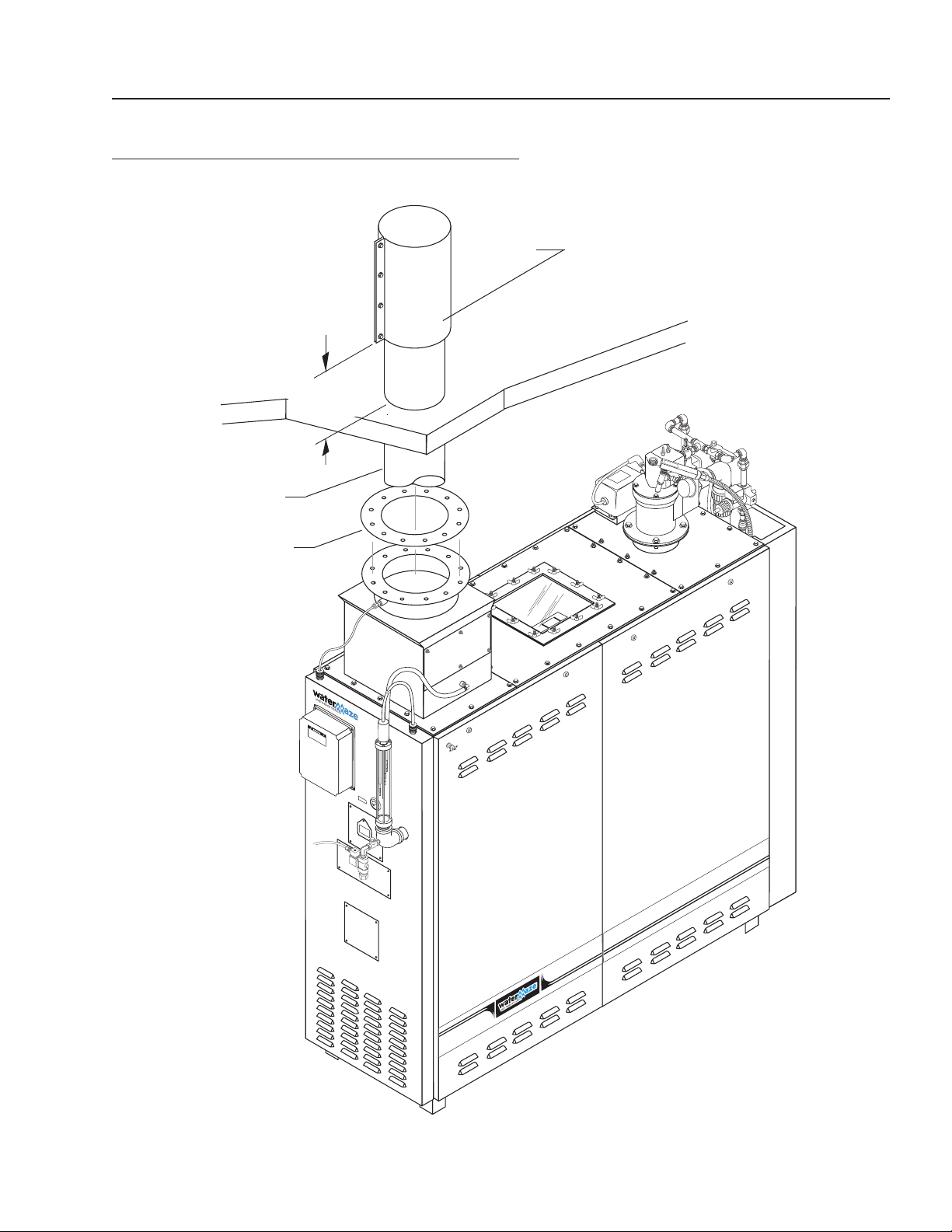

EXHAUST STACKING CONFIGURATION

Flue Raincap

Roof

2'

Minimum

10" Flue

Exhaust

Pipe

13

Stack

Flange

Figure 4

WB • 8.913-984.0-L

WATERMAZE SERIES OPERATOR’S MANUAL

14

WB-50

FRONT VIEW

Electrical

Box

Spark Plug

Main Gas Valve

Adjuster

Soft Start Gas

Valve Adjuster

(WB-50)

Burner Cycle

Level Controls

NEMA Box

Flame

View

Port

Timer

3 Point Level

Control Rods

Transformer

Demister

Screens

Soft Start

Solenoid

(WB-50)

Glass View

Port

Photohelic

Gauge

(Option)

Auto Flush

89139840-27

Figure 5

WB • 8.913-984.0-L

WATERMAZE SERIES OPERATOR’S MANUAL

89139840-26

15

WB-120A

FRONT VIEW

Burner

Cycle

Timer

Electrical

Box

Glass

View

Port

Transformer

Main Gas Valve

Adjuster Burner 1

Soft Start Gas

Valve Adjuster

Burner 1

Soft Start Solenoid

Burner 1

UV Scanner

Burner 2

Level Controls

NEMA Box

Flame View

Port

Demister

Screens

Auto Flush

Glass View

Port

3 Point Level

Control Rods

Figure 6

WB • 8.913-984.0-L

WATERMAZE SERIES OPERATOR’S MANUAL

89139840-24

89139840-25

16

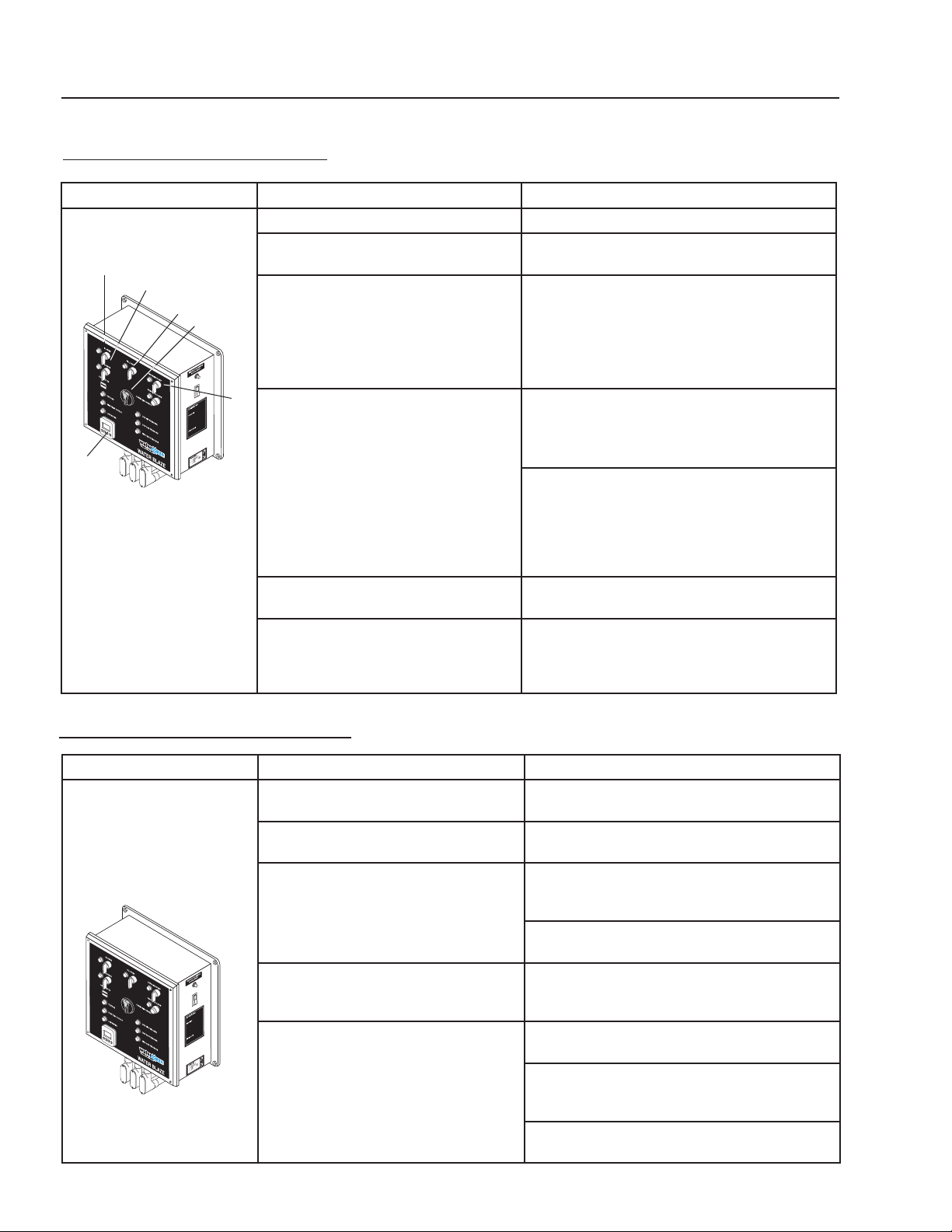

START-UP PROCEDURES

PANEL PROCEDURE RESULT

Turn on the main disconnect switch #1. Timer (LED screen) lights up.

Press F1/RST (reset button)

3

4

5

1

#2 on cycle timer.

Turn on the blower switch #3 to

desired position (manual or auto-matic).

“Manual” will bypass the liquid level float

in the customer's holding tank. “Automatic” will allow the float to control the

on/off operation of the blower.

6

Turn on the burner switch #4. The interlocks are checked and a green light will

2

Turn on the pump switch #5. As water is evaporated, the wastewater

Turn defoamer switch #6 to auto mode. Anti-foam will be added when fill pump is on.

Powers up the timer (LED screen).

Voltage light comes on.

Blower light turns on. Water

level in the sight tube will rise

as the water is evacuated

from the sparger tube.

WATER MAZE

be seen on the Veri-Flame. If there is a red light

on the Veri-Flame, there is a problem with one of

the interlocks that must be corrected.

After the interlocks are proven, the blower

will purge the sparger tube for 15 seconds,

then the burner will ignite. If the burner does

not ignite within eight seconds, the “UV scanner”

will shut the system down. At full burner

ignition, burner light turns on.

pump will automatically refill the tank.

If more defoamer is needed, turn the feed

adjustment (See page 48, figure 16) clockwise

to increase the speed of defoamer pump.

SHUT DOWN PROCEDURES

PANEL PROCEDURE RESULT

(To locate individual items,

please see above.)

Turn defoamer switch

#6 to middle off position.

Turn the pump

switch #5 off.

Turn the burner

switch #4 off.

Turn the blower

switch #3 off.

Turn the main

disconnect switch #1 off.

The defoamer

light goes out.

The pump light goes out. The waste stream

pump shuts down and the solenoid valve closes.

The burner light goes out. The burner shuts

down. The gas solenoid closes and the power

is cut to the transformer preventing a spark.

After turning the burner off, let the blower

run for at least one minute before turning it off.

The blower light goes out. At this point, the

blower shuts down and water from the tank

enters into the sparger tube.

The voltage light goes out. All power to the

evaporator is disconnected except to timer.

The water in the evaporator is still HOT at this

point. Allow the water to cool before any

maintenance is done, i.e., sludge removal.

If the evaporator is to be left off overnight or

longer, shut off the gas supply to the evaporator.

WB • 8.913-984.0-L

WATERMAZE SERIES OPERATOR’S MANUAL

17

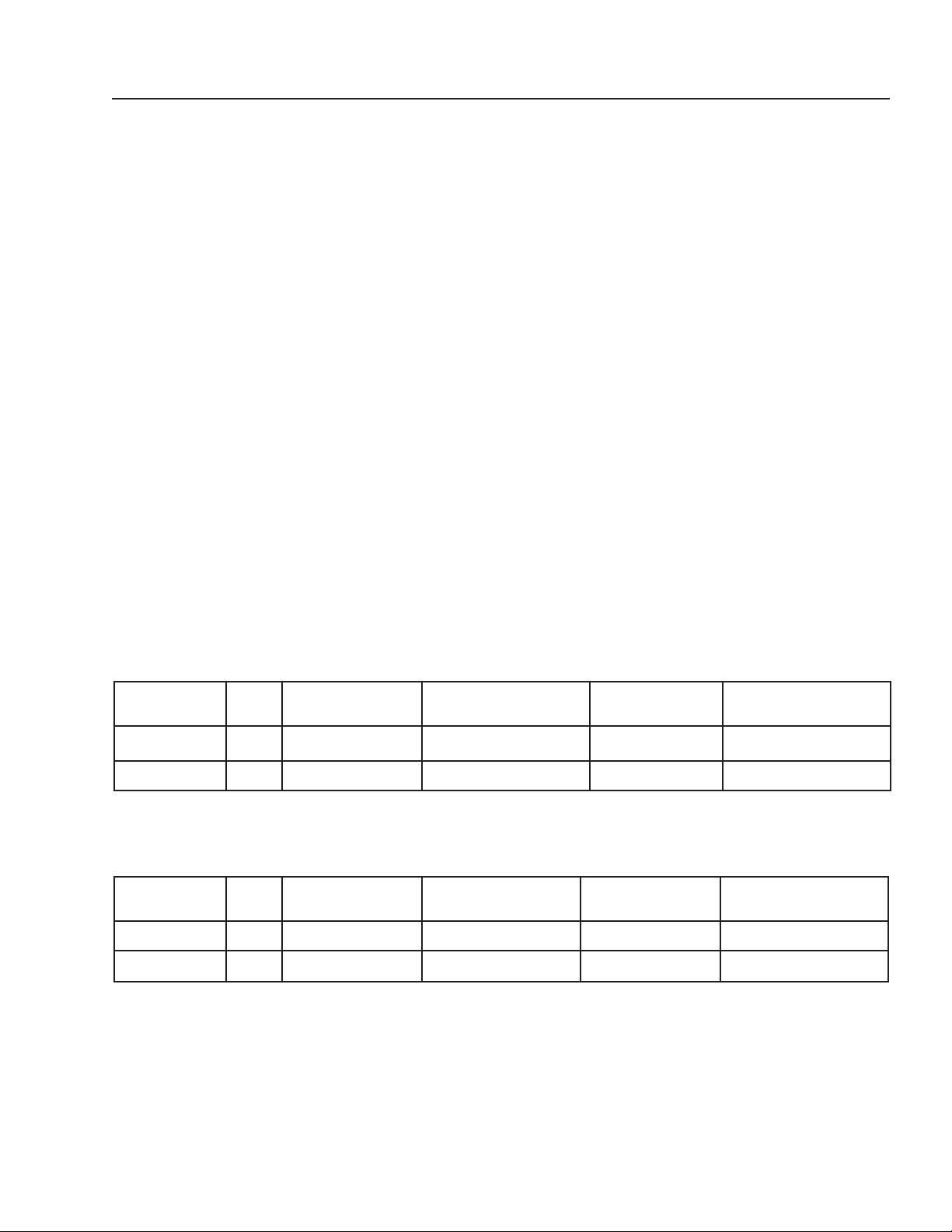

SETTING THE BURNER

The quickest and easiest way to adjust the air and gas

differential to the appropriate settings listed below is to

purchase the WATER MAZE set up kit (#7-8200). Refer

to figure 7 for locations on setting the burner. Shut main

gas valve off. With 7/16" wrench remove brass plugs

from all metering orifices on back side of machine. Install

brass valves included in set up kit into each position

and close. Turn gas main valve back on. To set static

pressure, use 0 - 50 manometer on (D or E). To adjust

setting to desired 45 wci, remove cap on gas regulator

(F) and turn inside adjustment screw clockwise for higher

pressure, counterclockwise for lower pressure. Replace

cap. Start machine by turning the blower switch to the

“auto” position and burner switch to the “on” position.

Once the burner lights, use the 0 - 10 manometer to set

the air differential at (B). Note: lower port is high pressure and upper port is low pressure. With hoses in position, open brass valves. Set air differential as per chart

below. Note: needle will shake; pinch both hoses lightly

together to read number. Adjust by opening or closing

main air butterfly and secondary air butterfly (located

on left side of burner, up top). Close brass valves. Set

the gas differential the same way as the air. Note: read

chart for proper gas used. Attach 0 - 10 manometer at

(C) and set as per chart. The adjustment valve is located

to the right of the burner up top. Remove the brass cap

and adjust with a standard screwdriver. You will have to

set one burner at a time on a WB-120. Once adjusted,

shut off burner and blower. Shut off main gas line. Now

remove the brass valves used with the manometers and

replace plugs into the air and gas orifices. Turn the main

gas back on and follow the procedures for start up. Your

evaporator is now in service.

SOFT START IGNITION

To provide a smooth ignition and meet all gas train

standards, the WB-50 and WB-120 come standard with

the soft start ignition system. Before trial of ignition the

Veri-Flame will make sure the top gas solenoid is closed

(proof of closure). Once closed, the Veri-Flame will try for

a pilot flame. After approximately 8 seconds, the proof

of closure solenoid will close and allow the main gas

solenoid to open slowly.

Soft start settings: The gas metering orifice SBO-A-1

(A) for the soft start needs to be set on 7 wci for the gas

differential. Follow (Setting The Burner) instructions for

setting the soft start gas differential.

NATURAL GAS:

UNIT GPH METERING

WB-50A

WB-120A

60 SBO-D-7 6.5 SBO-677 8

120 SBO-D-7 6.5 SBO-677 8

LIQUID PROPANE GAS:

UNIT GPH METERING

WB-50A

WB-120A

60 SBO-C-3 6 SBO-677 9

120 SBO-C-3 6 SBO-677 9

ORIFICE

ORIFICE

GAS DIFFERENTIAL METERING

ORIFICE

GAS

DIFFERENTIAL

METERING

ORIFICE

AIR DIFFERENTIAL

AIR

DIFFERENTIAL

WB • 8.913-984.0-L

WATERMAZE SERIES OPERATOR’S MANUAL

18

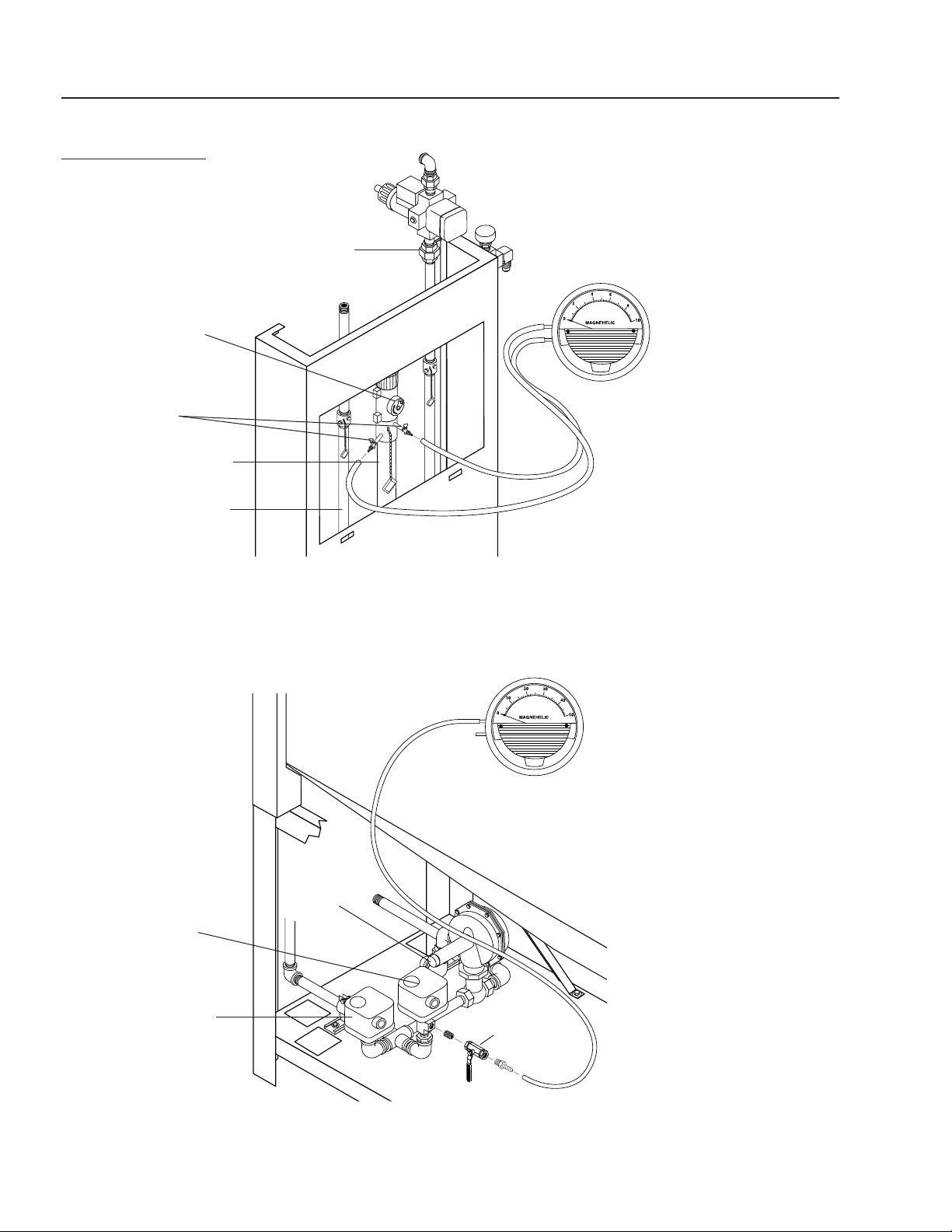

WATER MAZE

BURNER ADJUSTMENT

Main Gas Pipe

(All Models)

Main Air

Valve

Test Valves

Main Air Pipe

(All Models)

High

Air/Gas

Differential

Low

Soft Start

Gas Pipe

WB-50/120 Models

High

Low

High Switch

Low

Switch

Static Gas

Gas

Regulator

Cap

Static Gas

Check Port

WB-50/120 Models

Figure 7

WB • 8.913-984.0-L

WATERMAZE SERIES OPERATOR’S MANUAL

WARNING

19

FOAMING

The WATER MAZE uses a high volume of air to operate

the burner, which pushes the heat out of the sparger

tube and into the evaporation tank. There, the air goes

through baffle screens to break the air bubbles down

into smaller sizes. This process can cause excessive

foaming from the detergent used in the washing process

if it has any kind of foaming agents. This foam interferes

with the evaporation process of the WATER MAZE and

the foam will go up the stack causing problems with the

venting of the WATER MAZE.

The best solution is not to use detergents or cleaning

compounds that cause foaming. An anti-foam pump is

a standard feature on this machine. WATER BLAZE has

defoamer chemicals available, developed for use in the

evaporator.

CONVERTING NATURAL GAS

TO L.P. GAS

WARNING: Before converting

from natural gas to L.P. gas, be

certain that the evaporator is shut

down, the water has been cooled,

the gas line is shut off and the

RISK OF FIRE,

EXPLOSION OR

SERIOUS BURNS:

SHUT DOWN UNIT,

SHUT OFF GAS LINE

AND DISCONNECT

POWER BEFORE

CONVERTING.

power is disconnected.

The WATER MAZE can be ordered

from the factory in natural gas or

L.P. gas. Once they are in the field,

you must order a conversion kit to

change from natural gas to L.P. gas

or from L.P. gas to natural gas.

NOTE: Be certain that the orifice is installed right side

up or the system will not work properly. The orifice has

an arrow indicating the flow. If there is not an arrow, look

on the side of the orifice where the plugs are located.

One has green paint around it, the other has red paint.

The plug with green paint goes on the top.

Change the regulator orifice in the gas regulator from

1/2" for natural gas to 3/8" for L.P. gas. Remove the

regulator at the unions. The orifice sits in the tee below

the regulator unions. Use a 1" socket with an extension

to remove the orifice. Put the new 3/8" orifice in. Replace

the regulator.

Replace the “Natural Gas Only” label with the “L.P.

Gas Only” label.

Conversion Kits:

8.906-066.0 Factory Conversion from Natural Gas

to L.P. WB-50/120, Qty 2 for WB-120

8.906-072.0 Field Conversion Kit from Natural Gas

to L.P. WB-50/120, Qty 2 for WB-120

8.906-069.0 Field Conversion Kit from L.P. to Natural

Gas WB-50/120, Qty 2 for WB-120

Standard WATER MAZE machines are natural gas fired

and are so constructed. When propane fuel is specified

please add the appropriate conversion part number to

the order. Thank you.

WB-50/120:

The conversion kit for the WB-50/120, natural gas to

L.P, is # 7-8112.

Remove the SBO-D-7 and replace it with SBO-C-3.

(See items 19 and 21 on pages 42 & 43.) Change the

regulator orifice. Remove the 5/8" orifice and replace

with the 1/2" orifice.

To replace the orifice, disconnect the 3/4" gas line at the

unions above and below the metering orifice. Remove

the section of pipe by unscrewing it from the orifice and

then remove the orifice by unscrewing it from the pipe

above it.

Install the new orifice by applying pipe sealant to the

pipe coming from the gas solenoid valve and screw the

orifice to the pipe. Apply pipe sealant to the section of

pipe that was removed and screw it into the bottom of

the orifice. Reconnect at the unions.

WB • 8.913-984.0-L

WATERMAZE SERIES OPERATOR’S MANUAL

20

VERI-FLAME

#7-8061

Dipp Switches

"Flame Signal" – should be red

"Interlocks Closed" – should be green

"System Error" – These are your

interlocks, this light shouldn't be

illuminated, if it is check interlocks.

"Flame Failure" – UV Scanner

Figure 8

The Veri-Flame is the controller which proves all of the

interlocks. It provides for a purge cycle to insure that

there are no combustibles in the sparger tube before

the trial for ignition (TFI). The length of the purge cycle

is determined by the settings on the Veri-Flame. It is

preset at the factory for 15 seconds.

If you need to check the settings on your Veri-Flame

or if you replace a Veri Flame and it needs to be set,

remove the screws holding the cover on and unplug the

cover from the back. Dipp switches are located on the

reverse side. Set the eight switches as follows: switch 1

ON, switch 2 OFF, switch 3 ON, switch 4 ON, switches

5, 6, 7 and 8 OFF.

If switch 1 is ON, the burner will recycle once after an

air or main flame failure. Otherwise, the system will shut

down.

A pilot light is not used so switch 2 is set to OFF. Switch

3 controls the amount of time the machine has for TFI.

With this switch set to ON, the machine has 10 seconds

for TFI. Switches 4 through 8 control the amount of

purge time before TFI. Switch 4 gives the machine a 15

second purge before TFI.

A Veri-Flame and U.V. scanner tester is available

(#7-8063).

WB • 8.913-984.0-L

"Air Failure" – Blower

Button in "Out" position

3 POINT SENSOR CONTROL

The 3 point sensor control is part of the safety interlock

system and also controls the wastewater air diaphragm

pump.

The bottom rod is the low water safety position. If the

wastewater level is too low, this rod, working through the

Veri-Flame, will not allow the burner to ignite. When the

wastewater level drops to the position of the middle rod,

there is a demand for water and the wastewater pump

turns on. The air diaphragm pump continues to run until

the top rod is reached by the wastewater. At this point

the pump shuts off. When the level drops to the middle

rod, the wastewater pump restarts again.

WATERMAZE SERIES OPERATOR’S MANUAL

WARNING

WARNING

21

SETTING LIMIT CONTROL

Adjust the high limit control temperature accordiningly.

230° for the WB-50/WB-120

MAINTENANCE

WARNING: Use protective gloves,

goggles and any other protective

clothing according to the MSDS

reports of chemicals mixed with

WEAR PROTECTIVE

EYEWEAR, GLOVES

AND CLOTHING.

require consistent maintenance. The frequency of maintenance will vary depending on what is in the water that

is being evaporated.

TURN OFF MACHINE

AND ALLOW TO

COOL BEFORE

SERVICING.

tube, cleaning the UV scanner and the ignition plug.

Daily Maintenance Procedures:

1. Turn WATER MAZE wastewater pump, burner and

blower to the off position.

2. Turn WATER MAZE main power disconnect to the

off position before initiating maintenance.

3. Connect garden hose to garden hose fitting at the

elbow of the liquid level control sight glass. Turn on

water, set timer in electrical box for 10 seconds to

flush elbow and nipple.31

Weekly Maintenance Procedures:

1. Turn the WATER MAZE wastewater pump, burner

and blower to the off position.

2. Turn the WATER MAZE main power disconnect to

the off position before initiating maintenance.

the waste stream.

The WATER MAZE does not require

a lot of maintenance, but it does

WARNING: Shut down the WATER

MAZE and allow it to cool before

performing maintenance.

General maintenance will consist

of removal of any floating oil in the

evaporation tank, removal of sludge

from the evaporation tank and the

sparger tube, removal and cleaning

of the liquid level switch and sight

3. If oil removal is necessary, you can remove the oil

by removing the access window on the top of the

machine and using a shop vacuum to remove the

oil.

4. With a sludge catch container in place, open the

1-1/2" sludge ball valve to remove accumulated

sludge and concentrated liquid from the WATER

MAZE tank.

5. When you are sure the water level is below the sparger tube, remove the panel that covers the clean out

flange and open the sparger tube clean out access

flange. With the supplied tool kit, remove any solids

from the inner diameter of the tube and sparger

slot. Place the removed solids in a holding container in accordance with disposal regulations. When

cleaning of the sparger tube is completed, inspect

the inside of it for any deterioration. Reassemble the

sparger tube, clean out flange and cover panel.

6. Inspect the inside of the WATER MAZE tank, screens

and outside of the sparger tube for any build up of

solids. This can be done by removing the glass access window on the top of the machine. Remove

solids build up if necessary. Replace window and

bezel when completed.

7. Remove the demister box access door and inspect

screens. If the screens have a build up of solids,

remove the screens and clean the inside of the

demister box and screens. Reassemble the screens

in the demister box and reattach the access door.

8. Remove the 3 point level controller rods by removing

the three 3/8" nuts on top of the upper body sight

glass holder and slide straight upward. Clean rods

with rag. Use a Scotch Brite pad for bottom end of

rods.

9. Remove sightglass and clean out hole in lower

sightglass holder. If plugged, remove lower sight

glass holder from elbow and flush with freshwater.

10. Shut off the wastewater inlet valve (not supplied)

located near the wastewater inlet. Unscrew the filter

housing and remove the 20 mesh filter screen. Clean

and replace the screen. Screw the filter housing back

into place and open the wastewater valve.

Monthly Maintenance Procedures:

1. Turn the WATER MAZE wastewater pump, burner

and blower to the off position.

2. Turn WATER MAZE main power disconnect to the

off position before initiating maintenance.

WB • 8.913-984.0-L

WATERMAZE SERIES OPERATOR’S MANUAL

22

3. Turn waste source off. Drain tank after evaporating

until low water shut off.

4. Remove top lid of the WATER MAZE and thoroughly

inspect the interior of the tank and sparger tube.

Remove any solids that may have built up on the

interior of the tank, sparger tube and air distributor.

Rinse the interior of the tank.

5. Remove the ignition plug wire from the ignition plug.

Remove the ignition plug from the burner and clean.

Inspect the ignition plug for any cracks in the insulation. If cracks are found, replace the ignition plug.

6. Remove the U.V. scanner from the burner, inspect

and clean the lens.

7. Refill the WATER MAZE tank with water to the

minimum restart liquid level. Restart the blower and

burner and verify the air/gas ratios with manometers

for proper operation of the burner.

8. Thoroughly clean the following: 3 point level controller rods, glass tube, demister screens, wastewater

filter and housing.

Semi-Annual Maintenance Procedures:

1. Turn the WATER MAZE water pump, burner and

blower to the off position.

2. Turn the WATER MAZE main power disconnect to

the off position before initiating maintenance.

3. Turn waste source off. Drain tank after evaporating

until low water shut down.

4. Remove top lid of the WATER MAZE and thoroughly

inspect the interior of the tank and sparger tube. Remove any solids that may have built up on the interior

of the tank and sparger tube. Rinse the interior of

the tank.

5. Inspect the blower for proper operation. Check the

amp draw, bearing noise and inlet screen.

6. Inspect the wastewater pump for proper operation.

Also check for possible leaks in the housing.

7. Inspect hoses for any deterioration.

8. Loosen the air/gas line unions and remove the

burner from the mounting flange. Clean the nozzle

inside the burner with a small steel brush removing

any build up that is obstructing the mixing of the air

and gas through the nozzle. Replace the burner

mounting gaskets with new gaskets each time the

burner is removed.

9. Refill the WATER MAZE tank with water to the

minimum restart liquid level. Restart the blower and

burner and verify air/gas ratios with manometer for

proper operation of the burner.

Chlorides/Fluorides

Water evaporation tends to concentrate non-volatile

solids in a waste stream. Thus chlorides, fluorides and

related corrosion increase as the volume of the waste

stream decreases. In order to obtain the maximum life

from the WATER MAZE, it is important to monitor the

chloride and fluoride content of the liquid in the evaporation tank, so the waste can be purged prior to damage

by chloride or fluoride corrosion.

Clean Screen:

Shut off the wastewater valve (not included) located near

the “wastewater inlet” on the back end panel. Unscrew

the filter housing and remove the 20 mesh filter. Clean

and replace the screen. Screw the filter housing back

into place and open the wastewater valve (See figure 3).

Clean U.V. Scanner & Ignition Plug:

Once a month, the UV scanner needs to be removed and

cleaned, usually by wiping the scanner off with a cotton

swab and replacing it. Also every month remove the ignition plug and clean it. Check for damage or wear.

Demister Box Screens:

Remove the screens from the demister box and clean

them off. Replace them in the demister box. Make sure

that the door is secure and the gasket is good so that

there are no leaks.

Anti-Foam Maintenance:

CAUTION: Do not attempt to feed chemicals without

consulting your chemical feeder dealer or chemical

supplier.

1. Filling the Chemical Tank

To avoid running out of chemical, follow a regular

schedule of monitoring the chemical supply. Also

inspect and clean the strainer by flushing with a

compatible liquid, as needed.

2. Tubing Inspection

Inspect all tubing regularly and replace it if deteriorat-

ing. Follow the instructions with figure 10 to replace

the pump head tubing.

3. Feeding Adjustment

The feed adjustment is under the front cover. Re-

move the cover and turn the screw clockwise to

increase the feed or counterclockwise to decrease

the feed. Replace the enclosure cap after making

the adjustment. NOTE: Always start with the lowest

feed rate. (See figure 10). Lower feed rate pumps

are available.

WB • 8.913-984.0-L

WATERMAZE SERIES OPERATOR’S MANUAL

23

4. On/Off/ Full Speed Switch

Now that the system is adjusted, turn the pump on.

The pump will come on and inject “anti-foam” into the

waste stream when the wastewater pump comes on.

The Full Speed setting can be used to fill the feed

lines more quickly.

Sludge Removal:

Remove the doors on the right side of the WATER MAZE.

At the bottom of the evaporation tank you will find a

1-1/2" ball valve. Connect a hose to the valve and place

the other end into a container. Open the valve and flush

out the sludge. If nothing comes out, you may need to

run a wire into the valve to break loose the sludge that

has collected in the evaporation tank. Once the sludge

has been drained, close the valve.

NOTE: Drain water level below the sparger tube before

removing item E (See figure on page 23).

Sparger Tube Cleaning:

The tool kit, (8.903-719.0), consists of four items. Check

to ensure that the kit is complete (refer to the drawing).

A. Tool handle (2 pc.)

B. Probe/scraper

C. Trough assembly

Remove the panel that covers the flange assembly (this

cover is not shown in this drawing). Use a 3/4" socket to

remove the nuts holding the front of the flange assembly

(E) from the rear flange assembly (D). Also remove the

gasket and check it for damage or wear.

Next, place the trough assembly (C) onto the bottom

two studs of the rear flange (D) and replace the nuts to

hold it securely in place. Assemble the tool by screwing

the tool handle (A) into the probe/scraper (B). Place the

probe/ scraper tool as far back into the sparger tube as

possible. While pulling the scraper forward, scrape out all

of the buildup that has accumulated inside of the sparger

tube (H) and direct it into the slot of the sparger tube.

Continue until the sparger is clean. Clean out the slot (F)

inside the sparger tube. Remove sludge from the bottom

of the tank monthly.

Once this is completed, remove the probe/scraper and

the trough assembly (C). Make sure the gasket is clean

along with the surface area between the front flange (E)

and the rear flange assembly (D). Place the gasket over

the studs on the rear flange assembly and then do the

same with the front flange assembly (E). Use the 1/2"

nuts to secure the flange assembly. Refill the evaporator

tank and check the flange assembly for leaks. Replace

the panel that covers the flange assembly.

A

Bucket

(Not Included)

H

D

B

C

E

F

Figure 9

WB • 8.913-984.0-L

WATERMAZE SERIES OPERATOR’S MANUAL

24

PROGRAMMING OF

WATER MAZE CYCLE TIMER

Function Settings

Reset Button. Push to restart machine after

batch cycle completed.

Scroll Button. Push to select the different pro-

gramming modes. Also saves program values.

Vertical Scroll changes programming values.

▲

Horizontal Scroll for multiple values. Also

changes programming values.

Programming

1. Press and hold button for 2 seconds. (Entry)

will appear in red. (Auto Sc) will appear in green.

No change is necessary.

2. Press button once, (trAngE) will appear in red.

Press ▲ button until (h.n.O) appears in green.

3. Press button, (OPEr) will appear in red. Press

▲ button until (31) appears in green.

4. Press button, (rSt.P.uP) will appear in red. (no)

will appear in green. No change is necessary.

5. Press button, (Ac Pr S) will appear in red. (-N-

N) will appear in green. Press button until far left

(-y) is blinking. Press ▲ button until (-n) appears.

Press button once more and the right (-y) will

blink. Press ▲ button until (-n) is showing.

6. Press button, (PrESEt) will appear in red. The

value to set is predetermined from the wastewater

analysis. This value is known as PRS1(Preset 1).

Press the ▲ or buttons until the burner time is

achieved.

7. Press button, (PrESEt) will appear in red. This

value,PRS2(Preset 2) must be set with the same

value as (Preset 1). Press the ▲ or buttons to

set value.

8. Press button, (PltrAc) will appear in red. (no)

will appear in green. No change is necessary.

9. Press button, (Ac Out) will appear in red. (-L-L)

will appear in green. Press button until the far left

(-L) value is blinking. Press the ▲ button until

(-n) appears. Press the once more and the right

(-L) will blink. Press the ▲ button until (-n) is show-

ing.

10. Press button, (OutrES) will appear in red. Press

the ▲ button until (0.1 SEC) appears in green.

11. Press button, (OutPut) will appear in red. This

value is the autopurge valve #1. For WB-25 or WB50, this value needs to be set at (300) seconds. For

WB-120 the value is (999) seconds. Press the ▲ button until the correct value for your machine appears.

WB • 8.913-984.0-L

12. Press button, (OutPut) will appear in red. This

value, auto purge valve #2, must be set with the

same value as autopurge valve #1. Press ▲ or

buttons to set value.

13. Press button, (rEUOut ) will appear in red.

(-n-n) will appear in green. Press the until the

far left (-n) blinks. Press the ▲ button once and the

(-y) appears.

14. Press button, (rEUAnu) will appear in red.

(-n-n) will appear in green. No change is necessary.

15. Press button, (OutP.uP) will appear in red.

(-F-F) will appear in green. No change is necessary.

16. Press button, (USr In 1) will appear in red.

(rst -L) will appear in green. Press ▲ button until

(Pro.diS) appears.

17. Press button, (USr In 2) will appear in red.

(rSt -L) will appear in green. No change is neces-

sary.

18. Press button, (USr In 3) will appear in red.

(rSt -L) will appear in green. No change is necessary.

19. Press button, (USr FI) will appear in red.

(rSt -L) will appear in green. Press ▲ button until

(rStOut) appears.

20. Press button, (CodE) will appear in red.

(0) will appear in green. No change is necessary.

21. Press button, (ScroLL) will appear in red.

(no) will appear in green. No change is necessary.

22. Press button, (FAcSEt) will appear in red.

(no) will appear in green. No change is necessary.

23. Press and hold button for 2 seconds. (Prog)

will appear in red and (SAVE) will appear in green.

To complete setting the timer, first pull the face plate

of the timer out of its holder with your fingers. This will

expose the internal circuit boards. Along the left side

(wall) you will see two (blue) jumpers. Pull upward on

the blue jumper not touching the side wall and move

it forward one position on the pins. This is the lock out

mode for the timer.

Slide the timer back into its holder. Initial programming

of the timer is complete. Once power is supplied to

the timer via the main disconnect on the Water Maze,

the button must be pushed to set the timer in

run mode.

NOTE: Reprogramming can not be preformed with the

blue disable jumper in the forward position. Remember,

if reprogramming is to be done, always place the disable

jumper in the most forward position when done.

NOTE: Original cycle timer has been preset at

factory.

WATERMAZE SERIES OPERATOR’S MANUAL

SETTINGS CHART

MODE VALUE SETTING

Entry Auto Sc

trAngE h.n.O

OPEr 31

rSt.P.uP no

Ac PrS -n-n

PrESEt Customer run time value #1

PrESEt Customer run time value #2

PltrAc no

Ac Out -n-n

OutrES 0.1 SEC

25

OutPut Auto purge run time value #1

OutPut Auto purge run time value #2

rEUOut -y-n

rEUAnu -n-n

OutP.uP -F-F

USr In 1 Pro.diS

USr In 2 rSt -L

USr In 3 rSt -L

USr F1 rStOut

CodE O

ScroLL no

FAcSEt no

WB • 8.913-984.0-L

WATERMAZE SERIES OPERATOR’S MANUAL

26

WATER MAZE CYCLE TIMER

QUICK REPROGRAMMING

INSTRUCTIONS

Function Settings

Reset Button. Push to restart after power

outage.

Scroll Button. Push to select the different pro-

gramming modes. Also saves program values.

Vertical Scroll changes programming values.

▲

Horizontal Scroll for multiple values. Also

changes programming values.

Programming

1. Pull face plate of timer out of its holder in electrical

box with your fingers. Along the left side (wall) of

the circuit board, the blue disable jumper needs to

be pulled upward and moved back one pin position.

This will allow for reprogramming. Slide timer back

into its holder.

2. Press button until LED screen in green shows

PRS #02

(

). Push the ▲ or button until the new run

time appears in green Then press the button

once to save the setting for preset 1.

3. Press button once more. The LED screen will

4. Remove timer once again from its holder in the elec-

PRS #02

show (

is the same value as preset 1. Press button to

save setting for preset 2.

trical box. Change the blue disable jumper back to

the most forward pin position. Slide the timer back

into its holder in the electrical box.

). Push the ▲ or until the value in green

Program Disable Plug Jumper

The program disable plug jumper is used to enable and

disable front panel programming. The plug jumper is

located on the CPU board.

Program Disable Jumper Settings

FIGURE 10

User Input and Program

Disable Jumper Locations

User Input and Program Disable Jumper Locations

WB • 8.913-984.0-L

WATERMAZE SERIES OPERATOR’S MANUAL

WATER MAZE

WATER LEVEL CONTROL UNIT

1

27

1

4

11

12

10

6

ITEM PART NO. DESCRIPTION QTY

1 8.755-211.0 Controller, Level,

Z-Tron IV, LL/HL 3

2 9.802-064.0 Grommet 1

3 8.716-300.0 Sensor, Capacitance,

3 Point 1

4 8.716-290.0 Box, Plastic, 9.8 x 6.8 x 5.61 1

8.716-291.0 ▲ Plate, Back 1

9.802-515.0 ▲ Strain Relief, Strt,

LQ Tite 1

8.913-230.0 ▲ Bracket, Controller

Mount 1

2

3

8

5

7

9

ITEM PART NO. DESCRIPTION QTY

5 8.706-051.0 Nipple, 1/2" Close, 316L SS 1

6 9.802-146.0 Swivel, 1/2" MP x 3/4" GHF

w/Strainer 1

7 8.751-320.0 Swing Check Valve, 316 SS 1

8 8.706-208.0 Street Elbow, 1/2" MPT x 1/2"

FPT 1

9 8.706-790.0 Nipple, 1/2" Close 1

10 8.713-149.0 Solenoid Valve/ 1/2" 1

11 9.802-422.0 Cord Service, SEO 16/2 7 ft.

12 9.802-514.0 Strain Relief, LT, 1/2" 1

▲ Not Shown

WB • 8.913-984.0-L

WATERMAZE SERIES OPERATOR’S MANUAL

28

WB-50A

EXPLODED VIEW LEFT SIDE

72

113

144

142

71

72

143

84

13

104

17,125,126

103

105

83

1

15

80

14

82

81

41

16

92

148

125

149

126

125

126

79

98

124

36

33

31

35

37

41

40

8

3

91

11

112

122

106

10

4

5

7

6

121

129

34,124,125

32

123

53

116

90

137

21

136

2

135

WB • 8.913-984.0-L

89

29

130

131

52

For

Detail

See Air

Line Assy.

Illus.

128

127

20

19

18

WATERMAZE SERIES OPERATOR’S MANUAL

WB-50A

EXPLODED VIEW RIGHT SIDE

29

22

55

117

108

64

138

140

59

114

77

73

100

85

107

69

138

47

140

57

67

68

66

61

58

39

93

87

63

62

60

48

For

Detail

See Gas

Plumbing

Assy. Illus.

For

Detail See

Electrical

Box Illus.

78

9

55

23

111

46

120

132

138

86

110

45

43

95

54

25

102

101

73

96

139

119

51

50

109

97

65

64

88

Detail See

Air Line

Assy.

99

76

115

108

49

55

25

For

Illus.

131

133

#30-844

Option

56

67

74

26

67

12

24

109

73

WB • 8.913-984.0-L

25

27

97

73

75

69

For Detail

See Gas

Plumbing

Assy.

Illus.

69

38

53

44

134

44

118

30

145, 146, 147

WATERMAZE SERIES OPERATOR’S MANUAL

30

WB-50A

EXPLODED VIEW PARTS LIST

ITEM PART NO. DESCRIPTION QTY

1 8.913-019.0 Baffle, Screen 5

2 8.912-987.0 Panel, Control End 1

9.802-791.0 ▲ Nut, Cage, 10/32" x 16 GA 8

3 8.724-680.0 Label, WATER MAZE

Wastewater Evaporators 3

4 8.716-300.0 Sensor, Capacitance, 3 Point 1

8.707-383.0 ▲ Gasket, Sight Glass Tube 2

8.706-757.0 Tube, Sight Glass 1

8.900-583.0 ▲ Label, Level Control 1

5 8.719-976.0 Body, Sight Glass, Upper,

Brass 1

8.719-977.0 Body Sight Glass, Upper,

304L 1

6 8.719-972.0 Body, Sight Glass, Lower,

Brass 1

8.719-973.0 Body, Sight Glass, Lower,

304L 1

7 8.719-974.0 Rod, Sight Tube, Brass,

1/4" x 12.5" 3

8 8.716-571.0 Strain Relief, 1/2" LQ Tite 2

9.802-524.0 ▲ Locknut, 1/2" Conduit 1

9 8.712-157.0 Gauge, Thermometer 1

8.706-806.0 ▲ Nipple, 1/4" x 2-1/2", 316L 1

8.706-813.0 ▲ Coupling, 1/4" Hex, 316L 1

10 8.913-025.0 Plate, Observation 1

9.802-759.0 ▲ Screw, 10/32" x 1/2"

BHSOC Black 5

9.804-567.0 ▲ Nut, 10/32", ESNA 1

11 8.913-010.0 Cover, View Port 1

9.800-028.0 Label, Pilot Light Hole 1

12 8.706-958.0 Hose Barb, 90°, 1/4" Barb

x 1/4" Pipe 3

13 8.913-033.0 Box, Demister Assy, 316L 1

8.913-034.0 Box, Demister Assy, AL-6XN 1

14 8.913-015.0 Lid, Center Plate, 316L 1

8.913-016.0 Lid, Center Plate 1

15 8.912-972.0 Bezel 1

8.707-382.0 ▲ Gasket, Bezel, All, Buna-n 2

16 8.706-758.0 Cover, Tempered Glass 1

17 8.718-906.0 Nut, 3/8" Wing, SS 8

18 8.913-027.0 Cover Plate w/Viewer 1

19 8.707-397.0 Gasket, Cover Plate, Silicone 1

20 8.718-201.0 Glass, Site, Observation 1

ITEM PART NO. DESCRIPTION QTY

21 8.715-190.0 Blower, Regenerative, 2.5 HP

R-6125 1

8.709-083.0 ▲ Clamp 1

9.802-066.0 ▲ Pad, Soft Rubber 4

9.802-819.0 ▲ Washer, 7/16" x 2-1/2",

Zinc 4

22 8.913-000.0 Tank, Assy, SS 316L 1

8.913-001.0 Tank, Assy, AL-6XN 1

8.913-002.0 Tank, Assy, Duplex 1

8.707-385.0 ▲ Gasket, Tank Cover 1

23 8.912-976.0 Base, Assy 1

8.913-005.0 ▲ Raceway, Electrical 1

8.913-006.0 ▲ Raceway, Cover 2

24 8.716-689.0 Valve, Solenoid, 120V 1

25 9.802-533.0 Solenoid, Coil, 120V 3

26 8.716-690.0 Solenoid, Coil, 120V 1

27 8.716-691.0 Valve Solenoid, 120V 3

28 8.706-475.0 Union, CPVC 80, 1-1/4" 1

29 8.706-474.0 Union, CPVC 80, 2" 2

30 8.717-748.0 Regulator, Rockwell, 3/4" 1

8.718-172.0 ▲ Orifice, Regulator, 1/2", LP 1

30 8.718-173.0 ▲ Orifice, Regulator, 5/8", NG 1

31 8.912-005.0 Burner, Sparger Tube

Assy, 316L 3

8.912-006.0 Burner, Sparger Tube Assy,

AL-6XN 1

32 8.912-008.0 Distributor, Air, 316L 1

8.912-009.0 Distributor, Air, AL-6XN 1

33 8.912-014.0 Bracket, WB Distributor

Mnt. Ring, 316L 2

8.912-015.0 Bracket, WB Distributor

Mnt. Ring, AL-6XN 2

34 9.802-715.0 Bolt, 3/8" x 1" HH NC, 316L 4

9.802-808.0 ▲ Washer, 3/8" SS, Flat 4

8.719-024.0 ▲ Washer, 3/8" SS, Lock 4

8.719-089.0 ▲ Nut, 3/8" Hex, NC, 316L 4

35 8.906-087.0 Single, Ignition Wire 1

36 8.718-177.0 Transformer, Ignition, 120V 1

37 8.718-185.0 Ignition Plug, 16946-5,

Eclipse 1

38 8.718-182.0 Valve, Gas Solenoid, 3/4" 1

▲ Not Shown

WB • 8.913-984.0-L

WATERMAZE SERIES OPERATOR’S MANUAL

WB-50A

EXPLODED VIEW PARTS LIST CONTINUED

31

ITEM PART NO. DESCRIPTION QTY

39 8.716-321.0 Box, Junction 3 Hole, 1/2" 2

8.716-324.0 Box, Junction 4 Hole, 1/2" 1

9.802-483.0 Cover Plate, Junction Box,

2" x 4" 3

8.670-187.0 ▲ Switch, Float, N/O 1

40 8.718-159.0 Burner, Eclipse 1

41 8.718-174.0 Scanner, UV, All 1

42 8.718-166.0 Tube, Combustion 1