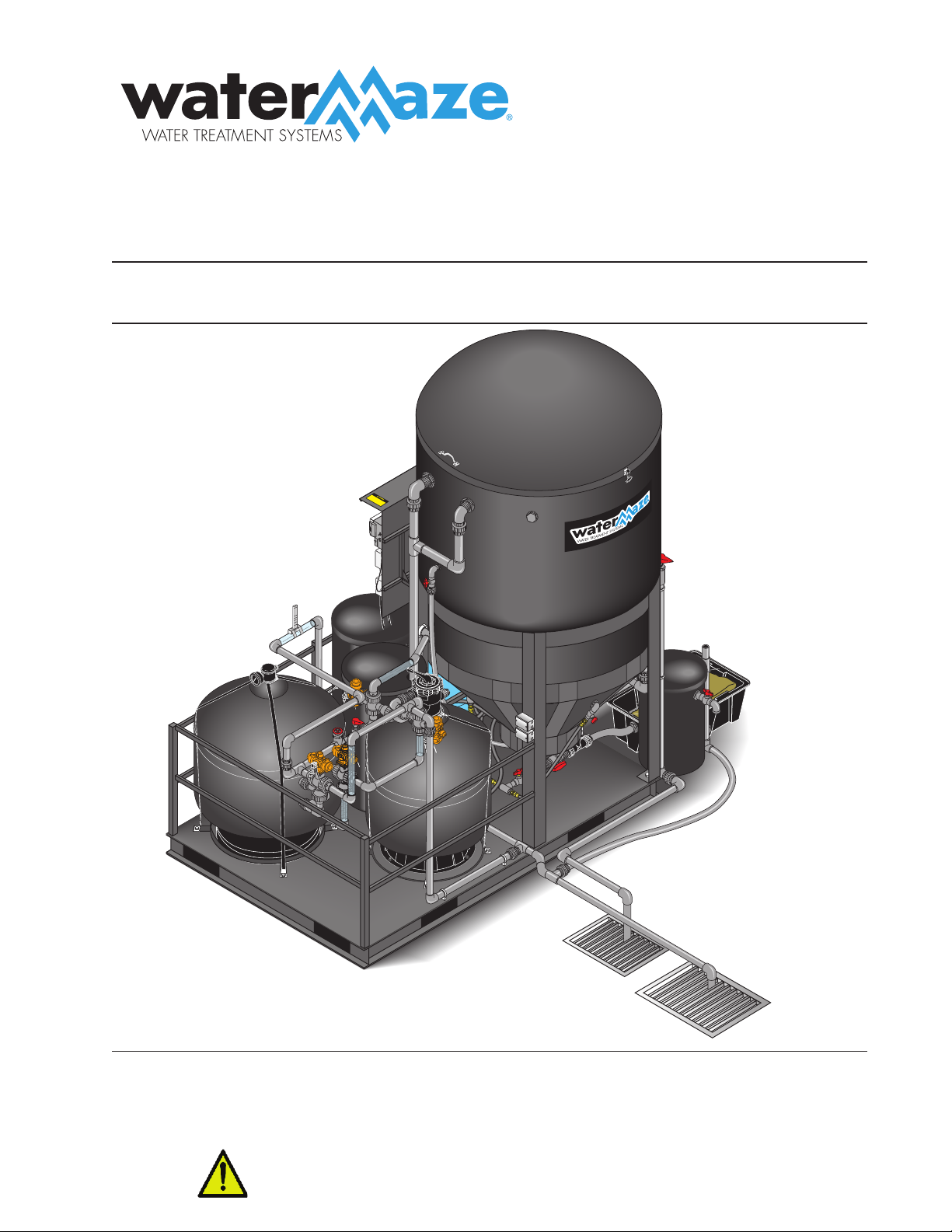

CLP

OPERATOR’S MANUAL

■ CLP-5024 ■ CLP-7034

89139700-14

For technical assistance or the WATER MAZE dealer nearest you, visit our website at

www.wmaze.com

WARNING:

This product and accessories may contain a chemical known to the State of

California to cause cancer and birth defects or other reproductive harm.

For more information about this regulation: www.P65Warnings.ca.gov

8.913-970.0 - L02/12/19

Introduction ..................................................................................................... 5

Unpacking ....................................................................................................... 5

Important Safety Information .......................................................................6-7

Installation Instructions .............................................................................. 7, 8

Check List Before Starting ..............................................................................8

Installation View .........................................................................................9-10

Start-up ......................................................................................................... 11

Operation CLP-5024/7034 .......................................................................11-12

Pressure Switch and Pressure Tank Operation ............................................ 13

Programming Instructions ........................................................................14-15

Valve Location & Function .......................................................................16-17

Operation Views .......................................................................................18-19

Water Panel Installation ................................................................................ 20

Standard ORP/pH Sensors ...........................................................................21

Sensor Maintenance ..................................................................................... 22

CONTENTS

Troubleshooting - Standard ORP/pH Sensors .............................................. 23

VSP20 Metering Pump ................................................................................. 24

General Maintenance & Service ...................................................................25

Ozone Generator .....................................................................................25-26

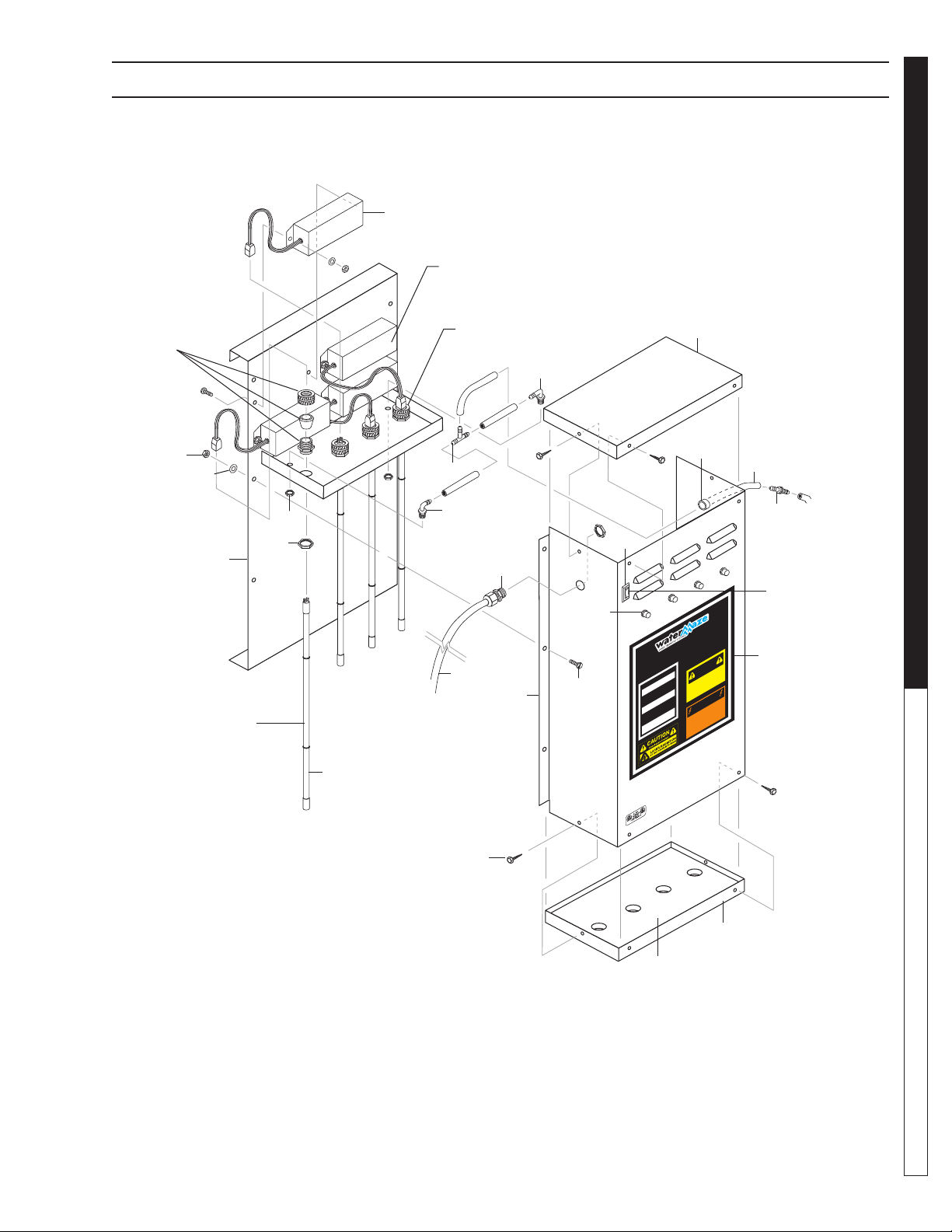

Ozone Generator Breakdown Exploded View & Parts List ......................27-28

Chemical Maintenance Program ..................................................................29

Daily Chemical Maintenance ........................................................................ 30

Centrifugal Pump Operation & Maintenance ................................................ 31

CLP-5024 Main Tank Plumbing Exploded View & Parts List ...................32-33

CLP-5024 & 7034 Electrical Box Exploded View & Parts List .................34-36

CLP-5024 Storage Tank Exploded View & Parts List .................................... 37

CLP-5024 Pumps Plumbing Exploded View & Parts List ........................38-39

CLP-5024 Plumbing Exploded View and Parts List .................................40-41

CLP-5024 Filter Plumbing Exploded View and Parts List ........................42-43

CLP-5024/7034 Water Panel Breakdown Exploded View & Parts List ....44-45

CLP-7034 Holding Tank Assemblies Exploded View & Parts List ............46-47

CLP-7034 Tank Drain & Oil Skimmer Exploded View & Parts List ...........48-49

CLP-7034 Main Tank Exploded View & Parts List ...................................50-51

CLP-7034 Transfer Pump Exploded View & Parts List .............................52-53

8.913-970.0 - L • WATERMAZE CLP 5024/7034

3

CONTENTS

CLP-7034 Carbon/Multi Media Filter Plumbing Expl. View & Parts List ...54-55

CLP-7034 Flow Meter Plumbing Exploded View & Parts List ..................56-57

CLP-7034 Ozone Pump Exploded View & Parts List ...............................58-59

CLP-7034 Filter Pump Exploded View & Parts List .................................60-61

CLP-7034 Surge Tank/Main Drain Exploded View & Parts List ...............62-63

CLP-7034 Manifold Exploded View & Parts List ......................................64-65

Metering Pump Exploded View & Parts List .................................................66

Transfer Pump Exploded View & Parts List ................................................... 67

Filter & Transfer Pumps Exploded View Parts List ...................................68-69

Ozone Pump Exploded View & Parts List .....................................................70

Ozone Pump Exploded View & Parts List .....................................................71

Submersible Sump Pumps Specifi cations .................................................... 72

Multi-Media/Carbasorb Filter Exploded View & Parts List ............................73

Carbasorb Filter Exploded View & Parts List ................................................ 74

Multi-Media Filter Exploded View & Parts List ..............................................75

6 Position Valve Exploded View & Parts List ................................................. 76

2" Multi-Port Valve Exploded View & Parts List .............................................77

Troubleshooting .......................................................................................78-83

Consumable Parts ........................................................................................ 84

CLP-7034 Maintenance Schedule ................................................................85

Warranty .......................................................................................................86

Model Number ____________________________________

Serial Number _____________________________________

Date of Purchase __________________________________

The model and serial numbers will be found on a decal attached

to the machine. You should record both serial number and date of

purchase and keep in a safe place for future reference.

4

8.913-970.0 - L • WATERMAZE CLP 5024/7034

INTRODUCTION & SAFETY INFORMATION

INTRODUCTION

Your owner’s manual has been prepared to provide you

with a simple and understandable guide for equipment

operation and maintenance, based on the latest product information available at the time of printing. To keep

your machine in top running condition follow the specifi c

maintenance and troubleshooting procedures given in

this manual. When ordering parts please specify model

and serial number.

NOTE: WATER MAZE reserves the right to make

changes at anytime without incurring any obligations.

Owner/User Responsibility:

The owner and/or user must have an understanding

of the manufacturer’s operating instructions and

warnings before using this WATER MAZE machine.

Warning information should be emphasized and

understood. If the operator is not fl uent in English, the

manufacturer’s instructions and warnings shall be read

to and discussed with the operator in the operator’s

native language by the purchaser/owner, making sure

that the operator comprehends its contents.

The owner and/or user must study and maintain the

manufacturers’ instructions for future reference.

WATER TREATMENT SYSTEM

OPERATOR’S MANUAL

SAVE THESE INSTRUCTIONS

This manual should be considered a permanent part

of the machine and should remain with it if machine

is resold.

When ordering parts, please specify model and

serial number. Use only identical replacement parts.

This machine is to be used only by trained operators.

UNPACKING

1. CLP Machine Assembly

2. Sludge Tub

3. Sludge Tub Bag Support

4. Accessory Box

6. Operator’s Manual

NOTE: Any damage to machine or components for

claims against the freight lines.

8.913-970.0 - L • WATERMAZE CLP 5024/7034

5

INTRODUCTION & SAFETY INFORMATION

WARNING

CAUTION

IMPORTANT

SAFETY

INFORMATION

CAUTION: To reduce the risk of

READ OPERATOR’S

MANUAL THOROUGHLY

PRIOR TO USE.

injury, read operating instructions carefully before

using.

WARNING

KEEP WATER SPRAY

OPERATOR’S MANUAL WATER TREATMENT SYSTEM

AWAY FROM

ELECTRICAL WIRING.

corder à la source d'alimentation.

WARNING

RISK OF EXPLOSION:

DO NOT SPRAY

FLAMMABLE LIQUIDS.

Code national de l'électricité et les codes locaux

pour tous les câblages.

WARNING: Follow the wiring instructions in this

manual when connecting the system to the power

lines.

AVERTISSEMENT: Suivre les instructions de câblage

dans le présent manuel au moment de

raccorder le système aux lignes de transport

d'électricité.

WARNING: All wiring must be performed by a qualifi ed electrician.

AVERTISSEMENT: Tout le câblage doit être effectué

par un électricien qualifi é.

2. Know the system application, limitations, and potential hazards.

WARNING: Do not use to pump

concentrations of flammable

6

injury, read operating instructions

carefully before using.

ATTENTION: To reduce the risk of

1. Read the owner’s manual thoroughly. Failure to follow the instructions will cause a malfunction of the

machine and result in death, serious

injury and/or property damage.

WARNING: Ground system before

connecting to the power supply.

AVERTISSEMENT: Mettre le système à la masse avant de le rac-

WARNING: Wire the system for

correct voltage. See “Electrical”

section of this manual and motor

nameplate.

WARNING: Meet the National

Electrical Code and local codes

for all wiring.

AVERTISSEMENT: Respecter le

8.913-970.0 - L • WATERMAZE CLP 5024/7034

or explosive fl uids such as gasoline, fuel oil, kerosene, etc. Do not use in explosive atmospheres.

Pumps should only be used with liquids compatible

with pump component materials. Failure to follow

this warning can result in personal injury and/or

property damage.

AVERTISSEMENT: Les pompes devraient être utilisées uniquement avec des liquides compatibles

avec les matériaux des composants des pompes. Le

non-respect des précautions peut mener à des lésions corporelles et/ou des dommages à la propriété.

3. WARNING: Risk of electric shock.

AVERTISSEMENT: Risque de choc électrique

All wiring should be performed by a qualified

electrician.

4. Never make adjustments on the machine while it

is in operation, except for those prescribed in this

manual.

5. The main power must be brought from the circuit

breaker and wired into the electrical box on the CLP.

This line must be run through conduit to protect it

from damage. A power disconnect should be located

next to the machine for maintenance purposes.

6. Before servicing the machine, refer to all the MSDS’s

on the material identifi ed in the wastestream. You

must comply with all warnings and wear all protective clothing as stated on the MSDS’s.

7. Protect all electrical cords from sharp objects, hot

surfaces, oil, sunlight, and chemicals. Avoid kinking

the cords. Replace or repair damaged or worn cords

immediately. All wiring should be run through conduit.

8. Inlet water temperature must not exceed 85°F.

9. Disconnect the power before servicing this machine.

If the power disconnect is out of sight, lock it in

the open position and tag it to prevent unexpected

application of power.

10. The best insurance against an accident is precaution

and knowledge of the equipment.

11. WATER MAZE is not liable for modifi cations or use

of components not purchased from WATER MAZE.

12. Personal Safety:

a. Wear safety glasses and other applicable

protective clothing at all times when working

on the CLP.

Refer to item #6 under Important Safety

Information.

b. Keep your work area clean, uncluttered and

properly lighted. Replace all unused tools and

equipment.

INSTALLATION INSTRUCTIONS

WATER TREATMENT SYSTEM

c. Keep visitors at a safe distance from work area.

d. Make the workshop safe with padlocks and

master switches.

13. Running the system without water will damage the

pumps and will void the warranty.

14. Release all pressure within the system before

servicing any component.

15. Drain all liquids from the component before

servicing.

16. Check hoses for weak or worn conditions before

each use, making certain that all connections are

secure.

17. Periodically inspect pump and system components.

Perform routine maintenance as required.

18. Do not touch an operating motor. Modern motors

are designed to operate at high temperatures.

19. Do not handle a pump or pump motor with wet hands,

when standing on a wet or damp surface, or in water.

20. The pump motors are equipped with an automatic

resetting thermal protector and may restart unexpectedly. Tripping is an indication of motor overloading as a result of operating the pumps at low heads

(low discharge restriction), excessively high or low

voltage, inadequate wiring, incorrect motor connections, or a defective motor or pump.

21. IMPORTANT NOTE: The sump pump is not a

trash pump and is subject to premature failure

unless sump pit baffl ing or additional protection is

provided.

22. Do not stand on the bracket that supports the

Electrical Box, Ozone Generator and the ORP/pH

Controller or on tanks 1 or 2. During installation and

maintenance obtain an OSHA approved ladder.

23. Keep machine from freezing.

24. Do not spray water directly at machine.

INSTALLATION INSTRUCTIONS

1. Because of the nature of the equipment, it is recommended these machines be installed indoors.

2. Locate the CLP on a containment pad to prevent

contamination.

3. Level machine by using shims that will provide ample

support and will not corrode or deteriorate over time.

4. Have a qualifi ed electrician connect the proper

power supply to the electrical control box. It is recommended that a ground fault circuit interrupter be

installed in the circuit breaker for the CLP.

NOTE: An electrician needs to locate where the

power supply will enter the electrical box and punch

a hole.

5. Install Orp/pH probes into cone bottom tank. Remove

cap and immerse probes into water. Don't let probes

dry. Save cap for future need.

6. Install the angle face dump valve on bottom of cone

bottom tank. Run air hose from angle face dump

valve to air valve assembly. Follow electrical wiring

diagram for air switch wires.

7. Plumb oil decanter barrel.

8. Run ORP/pH pump hoses from pumps to injectors.

9. Run air from air compressor to machine. Use at least

a 3 CFM air compressor with 60-100 psi.

10. Drill holes for 2" bulkheads and install bulkheads.

Connect the sludge tub assembly by placing the

sludge bag support into the sludge tub. Attach the

sludge bag onto the sludge inlet fi tting using the

screw clamp provided.

11. Attach the 2" fl ex hose to the sludge tub by screwing

the hose barbs into the bulkhead connectors, then

attach the 2" fl ex hose to the hose barb using a hose

clamp. The return line should gravity return to the

catch basin. The 2" inlet fl ex hose should connect

between the cone tank discharge valve and the

sludge bag inlet connector.

12. Build the inlet plumbing from the sump pump discharge port (min. 1-1/2" pipe) to the CLP 1-1/2" inlet

line. If the pipe is to be under the concrete, use 2"

pipe. Lower the sump pump into the sump pit.

13. Position the sump pump in the bottom of sump pit.

a. Elevate on a stand or cinder blocks, 6" off the

pit fl oor, to keep pump from sucking in rocks

or other heavy material that may plug pump or

plumbing.

b. Position the pump away from incoming water to

help prevent cavitation.

OPERATOR’S MANUAL

8.913-970.0 - L • WATERMAZE CLP 5024/7034

7

INSTALLATION INSTRUCTIONS

c. Tie a rope or chain to the pump handle and

bring out of the top of the pit for ease of pump

removal. Do not lift pump by power cords or

plumbing. Have a union installed on plumbing at

the top of the pit. Position union so it can easily

be reached and opened for pump removal.

14. The High Level Control Float FS1 (black, normally

open) is the upper fl oat which controls the upper

limits of the sump. It prevents the sump from fl ooding by opening SV1, the rain water solenoid valve.

Float tether length must be a minimum of 2" long.

Position the upper most point of fl oat a few inches

below top of pit. The Fresh Water Make-up Float FS2

(grey, normally closed) controls the lower limits of

the sump. It prevents the sump from running dry by

opening SV2, the fresh water solenoid valve. Turn-on

point for the Fresh Water Make-up Float must be at

least 8" above the suction inlet of sump pump. The

OPERATOR’S MANUAL WATER TREATMENT SYSTEM

further the water must travel before reaching the

sump, the higher the fl oat must be placed above the

suction intake. On three phase units, a third fl oat is

needed to protect the sump pump from the possibility

of running dry. Position the Low Water Protector Float

#7 (grey, normally closed) 6" above the suction inlet

of sump pump. Single phase sump pumps have a

fl oat built into them.

Floats must travel their complete arc without:

Water going over the top of the pit.

Touching sidewalls or bottom.

The pit running out of water.

Interfering with electrical wiring, plumbing, bottom

or sidewalls of sump, or any object. Attach the

fl oats to the PVC line on the sump pump.

Check to assure the fl oats can operate freely.

(See Installation View.)

15. Run the electrical cords from the sump pump and

fl oats to the electrical junction boxes near the inlet

line and attach wires. If the sump pump and fl oats

are located farther then 20 feet from the electrical

junction boxes, then have an electrician install water

tight junction boxes with conduit and proper sized

wire to extend the electrical connections.

16. Connect the fresh water line (3/4" GHM garden hose

not provided) to the “Fresh Water Inlet” port on the

water panel (see Water Panel Illustration).

17. Connect the “Outlet to Pressure Washers” to your

pressure washer by using a 5/8" garden hose (not

provided). Valve #7 behind the water panel should

remain closed until start-up. You may need a 1" line to

obtain a higher fl ow. If you are going a great distance

or using a lot of elbows, you may not get full fl ow.

18. Connect the “Rain Water Overfl ow” to the sewer or

storage (line not provided). Valve #8 behind the water

panel should remain halfway open.

CAUTION: Discharge Permits are required and

must be obtained before any treated water is

discharged.

ATTENTION: Des permis de déversement sont

requis et doivent être obtenus avant de procéder

au déchargement de toute eau traitée.

19. Connect a hose to “Rinse Water” outlet if it is to be

used. Make sure valve #6 behind the water panel

stays closed until rinse water is needed (hose not

provided).

NOTE: The use of rinse water in a closed loop

system will overfi ll the system and will lead to an

overfl ow situation causing the rainwater overfl ow

valve to open.

20. Run the "Return/Backwash" line back to the collection pit or fi rst pit where the water will be collected.

This is very important so that there is no stagnant

water when recycling and also to give more setting for the backwash water. If not done properly, it

could void warranty. Run at least a 2" line if above

ground and 3" if below ground. The sludge tub and

oil decanter barrel are plumbed together and run to

the return line. Any back pressure could overfl ow

the sludge tub and/or oil decanter barrel. A separate

return line for the sludge tub and oil decanter barrel

may be needed , the sludge tub can be elevated or

a check valve can be installed.

CHECK LIST

BEFORE STARTING:

Yes No

1. Is inlet line connected from

the sump pump to the inlet

of the machine? ___ ___

2. Is the voltage correct? ___ ___

3. Is the return line connected? ___ ___

4. Is the Fresh Water Make-up

hose connected? ___ ___

5. Is the Outlet to Pressure

Washer hose connected. ___ ___

6. Is the Rainwater Overfl ow

connected? ___ ___

START-UP:

8

8.913-970.0 - L • WATERMAZE CLP 5024/7034

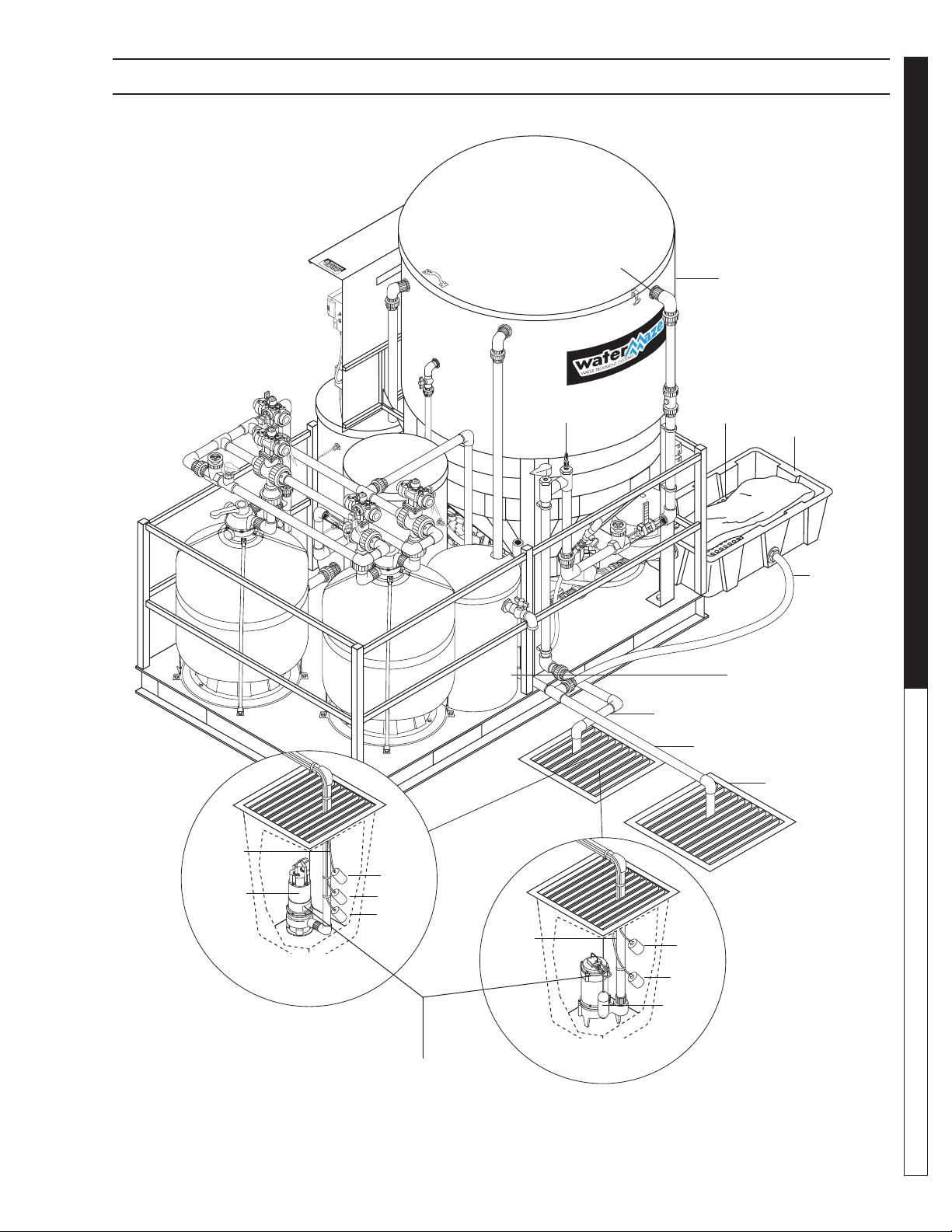

CLP-5024 INSTALLATION VIEW

Inlet

pH Injector

Cone

Bottom Tank

Bag

Support

Sludge

Tub

WATER TREATMENT SYSTEM

OPERATOR’S MANUAL

Inlet

Line

Sump

Pump

Sump Pump

Installation

(3 Phase)

Sump

Pit

FS1

FS2

FS7

Inlet

Line

2" Flex

Hose

Oil Decanter

Barrel

Inlet

Line

Return

Backwash Line

Catch

Basin

Sump

Pit

FS1

FS2

Sump

Pump

Sump Pump

Sump Pump Not Supplied

with Machine. See

Specifi cation on Page 70.

8.913-970.0 - L • WATERMAZE CLP 5024/7034

Installation

89139700-3

9

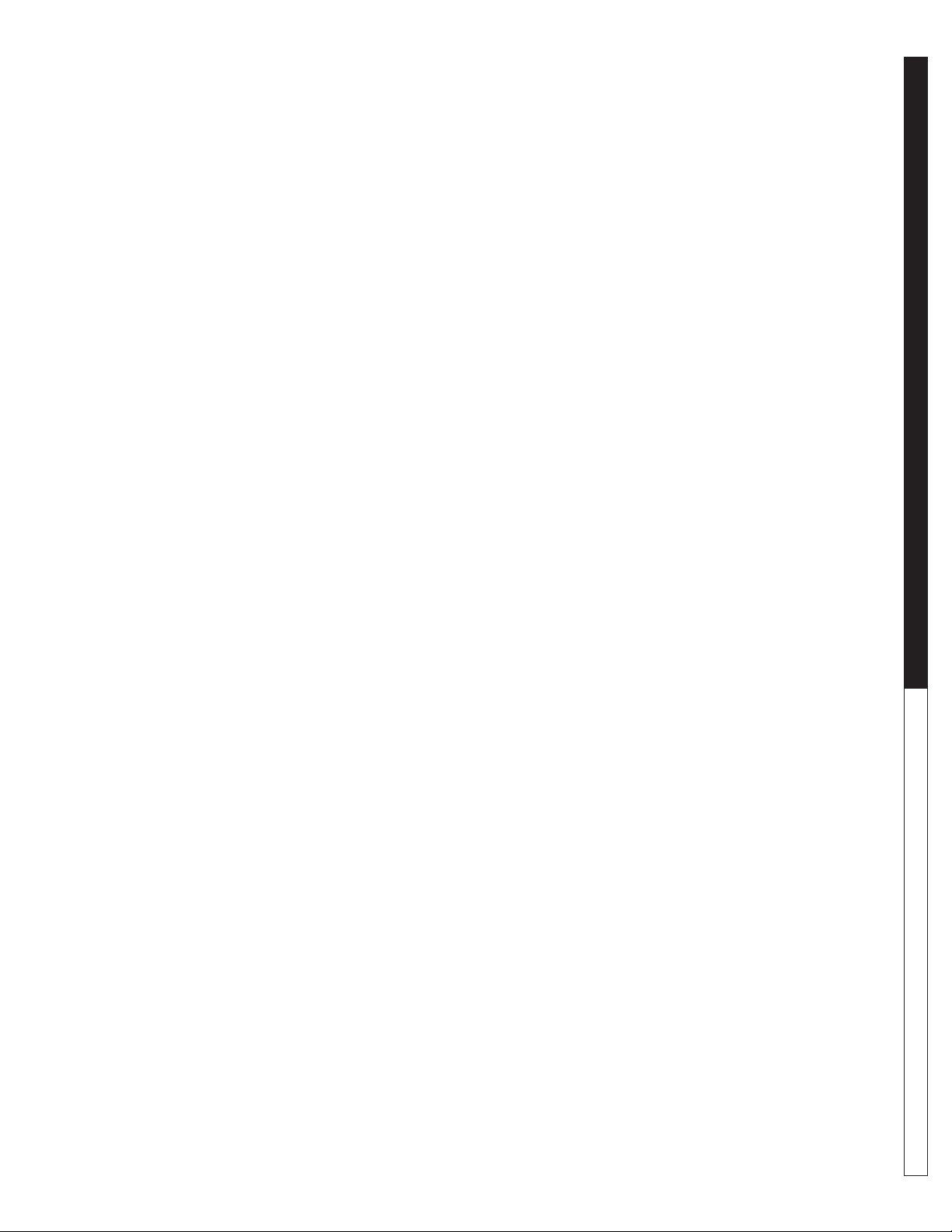

CLP-7034 INSTALLATION VIEW

Cone Bottom Tank

Flow Meter

Inlet

Sludge Tub

OPERATOR’S MANUAL WATER TREATMENT SYSTEM

3 Way

Ball Valve

Assembly

Inlet

Line

Sump

Pump

Sump Pit

Sump

Pump

Installation

FS1

FS2

Inlet

Line

Sump Pit

Installation

(3 Phase)

Sump

Pump

FS1

Oil

Decanter

Barrel

2" Flex Hose

Inlet Line

Return/Backwash

Line

Catch Basin

10

Sump Pump Not Supplied

with Machine. See

Specifi cation on Page 70.

8.913-970.0 - L • WATERMAZE CLP 5024/7034

FS2

FS7

89139700-21

Sump

Pump

START-UP INSTRUCTIONS

WATER TREATMENT SYSTEM

• Make sure that the CLP is level.

• Turn on the Fresh Water Makeup hose.

• After checking for proper power supply voltage,

turn on the circuit breaker to the CLP Machine.

NOTE: Make sure all switches are turned ”OFF”.

• Fill the sump pit with water, and check that the water

level does not drop, which would indicate the pit is

not sealed.

• Turn the sump pump switch to the ON position. The

sump pump lamp will illuminate if sump pump is

operating. (NOTE: the pump has an internally operated fl oat for low water on single phase only. The

sump pump should fi ll the cone bottom tank with

water. FS3 in tank 1 will shut off the sump in the up

position).

• Adjust the fl ow of water into the CLP using valve

#1 by reading the indicator marks on the inlet fl ow

meter. Set fl ow 2-4 GPM above demand.

• The ozone genertor is programmed to run from 11:00

p.m. to 4:00 a.m. every night. If more ozone is needed

during the day time hours, program Ozone 2 and

Ozone 3 on the PLC to the desired times needed.

• Turn the fi lter pump switch to the ON position. Tank

#2 should fi ll and FS5 will turn off the fi lter pump

when in the up position. The fi lter pump lamp will

illuminate when pump is in operation.

• Adjust valve #10 so that the fi lter fl ow meter has the

same or 2 GPM lower fl ow rate than the inlet GPM

fl ow rate.

• Turn the transfer pump switch to the ON position.

The pump should pressurize and shut off. NOTE:

When the pump is put into operation the pressure

switch may need to be adjusted. See inside cover

of pressure switch for adjustment instructions. The

2 HP pump is set at 20 PSI ON and 40 PSI OFF.

The transfer pump lamp will illuminate when pump

is operating.

• Turn the ozone pump switch to the ON position.

• Check to ensure the oil skimmer is adjusted properly.

Adjust if needed by screwing the funnel up or down,

or angling the pipe to allow a small amount of water

to free fl ow. If oil starts to build up on top of the cone

tank, adjust the skimmer to allow increased fl ow.

NOTE: Only adjust the oil skimmer when the sump

pump is running.

• Place the ORP/pH probes in the bracket inside the

CLP tank. Remove the liquid fi lled cap on the end of

the probes and place them in the bracket. Make sure

the tank is full of water and the probes are kept wet.

Run the connector through the hole in the tank wall

near the bracket and attach the connectors to the

controller. The connector with the white tag near it

is the ORP and is connected to the top stud on the

controller. The other is the pH and is connected to

the bottom stud on the controller.

• Look over entire machine for leaks. The machine

was hydrostatically tested at the factory but may

have been damaged in shipment.

• Program the AMC controller (CLP-7034).

• Turn the ozone generator ON/OFF switch ON.

• Set ozone generator for proper air fl ow.

• Turn ORP/pH controller switch ON.

• Turn ORP/pH feed pumps ON.

• Adjust valves per instructions (See Standard Orp/

pH Controller pages).

OPERATION: CLP-5024/7034

The CLP-5024/7034 are a fully automatic, self-contained

wash water recycling system suitable for treating wastewater generated from cleaning machinery and equipment. They are designed to separate free oil/greases

and dirt.

At the heart of the automated system is an automatic

maintenance controller (AMC). The AMC provides the

benefi ts of reliability and versatility to control numerous

functions. The AMC controls pump operations, machine

mode light display, fi lter status, backwash requirements,

recirculation, ozone injection, and sludge dumping.

Filter Mode

In a typical operation, wastewater is gravity fed from a

wash pad catch basin to a sump pit (preventing large

solids from entering the sump pump). Water resides in

the sump pump pit until Tank #1 requires water. On Tank

#1's demand, wastewater is pumped into the cone bottom tank. In the cone bottom tank the following occurs:

• Wastewater exits the tank by passing through

a series of corrugated coalescing cones. These

cones slow the fl ow of water (velocity drop) allowing the separation and settling of solids. Solids

settle to the bottom of the tank and are later automatically removed (see automatic sludge dump).

The coalescing cones oil attracting properties,

combined with the 55° incline angle, maximizes

free oil/water separation. Free oils are skimmed

from the surface and discharged to a 26 gallon

oil decanter for further separation.

• To control odor and kill bacteria, an ozone pump

recirculates ozonated water through the upper

section of the cone bottom tank.

OPERATOR’S MANUAL

8.913-970.0 - L • WATERMAZE CLP 5024/7034

11

OPERATING INSTRUCTIONS

Water is gravity fed from the 600 gallon tank to Tank #1

and remains there until Tank #2 requires water. When

water is consumed from Tank #2 (by pressure washer,

recirculation or sewer discharge) the fi lter pump circulates water from Tank #1 through the fi lters to Tank #2.

Flow rates through the fi lters can be adjusted up to 30

gallons per minute (GPM). For best results the fl ow rate

should be set to the lowest GPM that still allows the

entire system to operate correctly (the lower fl ow rate

increases wastewater/fi lter contact time and reduces the

fi lters solids loading).

Water remains in Tank #2 until it is either discharged

to the sewer (check your local regulations for limits in

your area), reused by the pressure washer or used for

recirculation of the pits and fi lters (see recirculation

mode). In the event an excess amount of water enters

the system (through rinse water or rain water) water is

automatically discharged from Tank #2 through the rain

water overfl ow solenoid valve to either the sewer or to

a holding tank. If the system's water level becomes too

low (i.e. evaporation, vehicle carry off), a fresh water

OPERATOR’S MANUAL WATER TREATMENT SYSTEM

make-up solenoid valve feeds fresh water to Tank #2

until proper levels are maintained.

Filters

To ensure optimum filter performance and life, the

multi-media and carbon fi lters must periodically be

backwashed (see automatic backwash mode).

• The multi-media fi lter consists of a blend of sand,

garnet, gravel and anthracite. The media blend is

effi cient in screening out solids to 25-30 microns.

During the recirculation mode, the constant fl ow

through the media fi lter provides a fi nal polish to

the water.

• The carbon fi lter consists of degassed, virgin activated carbon. Carbon removes, through absorption, pesticides, solvents, benzene, diesel fuels,

acetone and other hydrocarbons as well as low

levels of heavy metals.

Automatic Backwash Mode

Backwashing the media fi lters is required to rejuvenate

the fi lter media. Backwashing removes collected materials and disperses the media to eliminate any channeling.

During normal operation of the CLP-5024/7034, the

multi-media fi lter, carbon fi lter or both may become

impacted with fi ltered solids, resulting in pressure head

loss through the fi lters and in poor overall performance.

The CLP-5024/7034 will backwash everyday if it needs

to or not. The multi-media will start backwashing at

midnight for 30 minutes. The CLP will then recover the

water level in Tank #1 and then backwash the carbon

fi lter. The operator cannot use the pressure washer at

that time, so it is important that the program imitates

your schedule. If it doesn't, call factory for assistance in

reprogramming your controller.

To backwash, the affected fi lter is isolated and the fl ow is

reversed via air actuated three way valves. A slip stream

solenoid is activated to allow proper water fl ow (30 GPM

for multi-media valve 20, 15-20 GPM for carbon valve

21) and water is pumped from Tank #1 through the fi lter

by the fi lter pump. This process continues for 30 minutes

and the resulting backwash outfl ow is returned to the

wash pad catch basin.

Once backwashing of the fi rst fi lter is completed the

second fi lter will then be backwashed. At no time will

both fi lters be backwashed at the same time.

Recirculation Mode

The purpose for recirculating the water through the pit

system and the fi lters is to minimize odor, kill bacteria

and provide high quality polished water.

Once each day the CLP will enter a recirculation mode.

This mode consists of two separate stages.

Stage 1: The transfer pump sends water from Tank #2

through the return line to the wash pad catch

basin. To prevent odor and kill bacteria, the

return water is ozonated via a mazzi injector.

Stage 2: Water is recirculated through the fi lter pack.

The transfer pump circulates water from

Tank #2 through a mazzi injector to Tank #1.

From Tank #1 the fi lter pump circulates water

through the fi lters to Tank #2.

Automatic Sludge Dump

During normal operation, the settling properties of the

solids will result in sludge build-up inside the cone bottom

tank cone. This sludge must be periodically removed.

This is accomplished once each day by an automated

sludge dump system.

To dump sludge, an air activated dump valve opens while

simultaneously a water solenoid activates (to stir-up any

impacted material in the bottom of the cone bottom tank)

to allow sludge to fl ow to the sludge collection bag. To

reduce excess water in the sludge bag, the water solenoid is only activated for a few seconds. Once the dump

valve closes, the sludge bag is allowed to de-water and

excess water is returned, via gravity feed, to the wash

pad catch basin.

If at any time, the user needs an additional sludge dump, a

manual switch enables the automatic sludge dump cycle.

AUTOMATIC MAINTENANCE

CONTROLLER; 5024, 7034

12

8.913-970.0 - L • WATERMAZE CLP 5024/7034

PRESSURE SWITCH AND PRESSURE TANK OPERATION

WATER TREATMENT SYSTEM

WARNING

WARNING: Live electrical

contacts are exposed, so disconnect power fi rst and have

work performed by a qualifi ed

electrician.

RISK OF

ELECTRIC SHOCK: USE

CAUTION

WHEN HANDLING.

AVERTISSEMENT: Les contacts électriques sous tension sont exposés, il faut

donc d'abord débrancher

l'alimentation électrique et confi er le travail à un

électricien qualifi é.

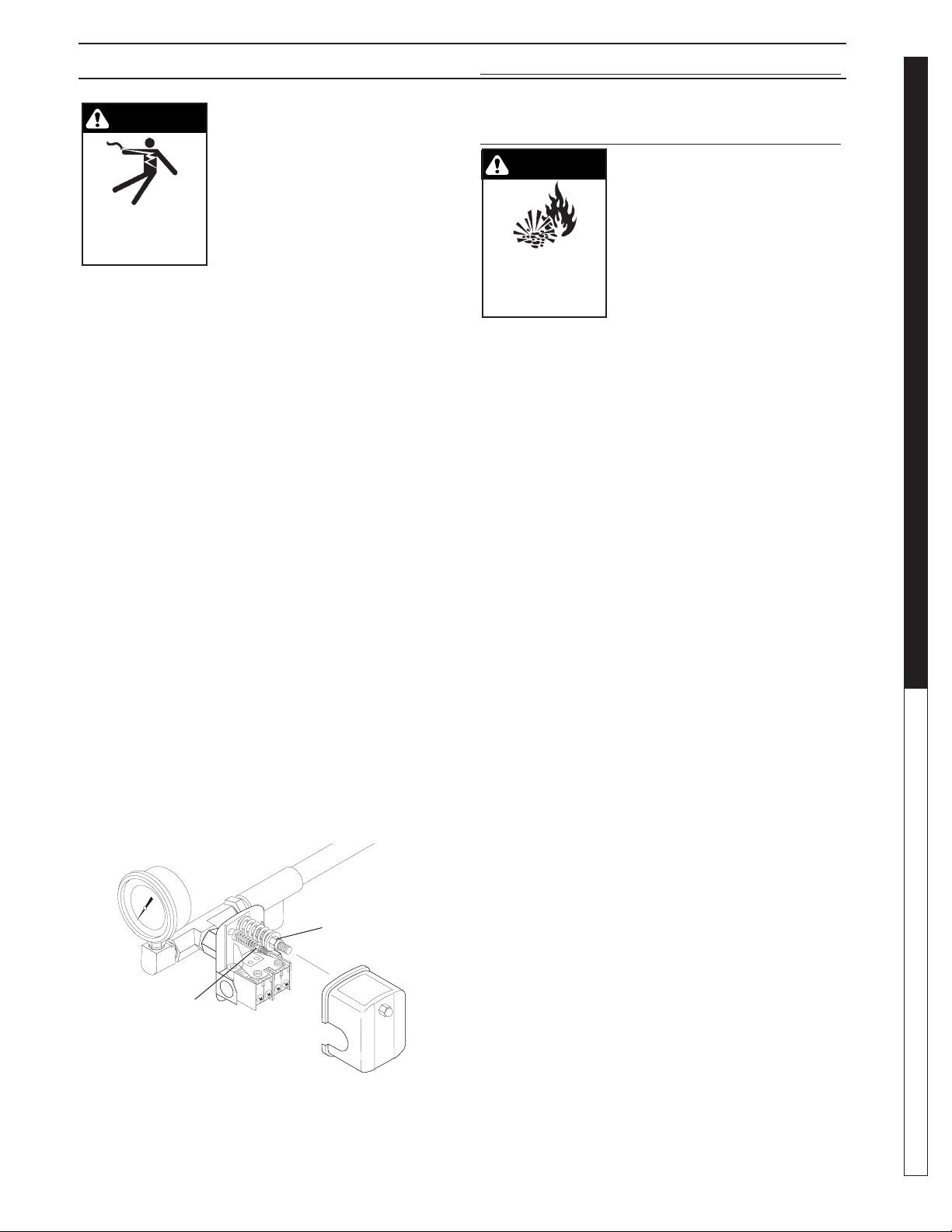

Remove cover of the pump pressure control switch to

allow access to the two nuts used to adjust the pump

operating pressure. The pressure switch on Water

Maze equipment is set at the factory and should not

have to be adjusted at start-up, but will need to be

verifi ed at start up and maintained regularly at least

monthly.

1. The nut on the larger spring in the pump pressure

switch, adjusts the pump cut in (cut on) and pump

cut out (cut off) pressures simultaneously.

2. The nut atop the smaller spring in the pump pres-

sure switch only controls the cut out range and

is used to narrow or widen the gap between the

pump cut in and cut out pressures.

3. To cycle the pump less frequently, the gap should

be as wide as possible while still allowing the

pump to shut off quickly when all outlets are

closed. Adjust the smaller spring to widen the

gap between pump in and out (on and off). 4045 PSI (CLP, Rec2-20) or 30 PSI (EC1-300A) is

desirable. Adjusting the larger spring should not

be necessary.

4. When making pressure switch adjustments, make

sure all pump outlets are off or closed, except for

the one outlet valve used to relieve and build pressure while making pressure switch adjustments.

Controls

Cut in/Cut out

Controls

Cut out Range

8913970-39

8.913-970.0 - L • WATERMAZE CLP 5024/7034

PRESSURE TANK

OPERATION

WARNING

RISK OF

EXPLOSION:

INSTRUCTIONS WHEN

CHANGING PRESSURE

FOLLOW

AVERTISSEMENT: Après avoir effectué l'entretien

du réservoir, il est nécessaire de passer à une

pression de précharge supérieure en raison d'un

changement requis du paramètre du pressostat;

le non-respect des directives ci-dessous peut

causer une rupture ou une explosion, et pourrait

causer des lésions corporelles graves ou fatales

et/ou des dommages à la propriété.

• Do not adjust or add pressure if there has been a

loss of air.

• Do not adjust the pre-charge pressure if there is

visible exterior corrosion.

• Do not adjust the pre-charge pressure if there has

been a reduction of the pump cycle time or the

pre-charge pressure compared to its initial setting.

A reduction in pump cycle time can result from

loss of tank corrosion and any re-pressurization

or additional pressure could result in rupture or

explosion.

• Pressure tank pressure is factory set but will have

to be checked regularly (at least monthly). Use

an air pressure (tire) gauge. Before checking air

pressure on the pressure tank, purge all water out

of the tank by turning the pump on and pumping

all water out of the pressure tank.

1. Our transfer pump water systems use a water

pressure tank and water pump with these two

pressure operation ranges:

Cut in (start pumping): 20 PSI

Cut out (stop pumping): 30 PSI (EC1-300A)

Cut out (stop pumping): 40-45 PSI (CLP, REC2-20)

2. Typical factory set air pressure on bladder-type

residential water pressure tanks are shipped from

the factory with a standard pre-charge of:

18 psig for models WX-101 and WX-102

18 psig for models WX-103 and WX-203

18 psig for models WX-205 and WX-350

3. Set the well tank air pressure to 2 PSI below the

pump pressure switch cut-in pressure. This is

usually 18 PSI.

WARNING! When the tank has

been in service and a change

to a higher pre-charge pressure

is necessary because of a required change in the pressure

switch setting, failure to follow

instructions below can cause a

rupture or explosion and could

cause serious or fatal personal

injury and/or property damage.

OPERATOR’S MANUAL

13

PROGRAMMING INSTRUCTIONS

The heart of the CLP Automatic Maintenance System,

the AMC Controller, has been pre programmed at the factory with Maintenance Modes described in the Program

Schedule shown below. In order for the CLP wastewater

system to function properly, the controller clock must be

set with the correct time-of-day and date.

Setting the Clock

After the time-of-day and date are set, the Automatic

Maintenance System will automatically control the operation of your CLP and provide daily scheduled maintenance in accordance with the Program Schedule below.

If electrical power is cut from the CLP, the AMC Controller will retain its program for 7 days. If electrical power

is not reconnected within 7 days, then the time-of-day,

month and year must be reset.

1. Press the ESC key located next to the display win-

dow and under the arrow key pad (see fi gure below).

Pressing the ESC key will access the Parameter

OPERATOR’S MANUAL WATER TREATMENT SYSTEM

Assignment Menu.

2. Using the up/down arrow keys ▲ or ▼, move the

cursor to highlight ‘Setup’ and press OK to accept.

3. Move the cursor to highlight ‘Clock’ and press OK to

accept.

Program CardParameter Assignment Menu

Mo 10:15

2006-10-13

4. Move the cursor to highlight ‘Set Clock’ and press

OK to accept.

ESC OK

Arrow

Key Pad

NOTE: When setting time on clock, use only military time.

NTP

Set Clock

S/W Time

5. Move the cursor to the value wanting to be changed

using the left/right arrow keys or , and change

the value by using the up/down arrow keys ▲ or ▼.

Set Clock

Mon. 10:15

YYYY-MM-DD

When you are done setting the time and date press

OK to accept your changes.

6. Press ESC three times to exit to the main menu.

Program Schedule

The Automatic Maintenance Controller has been preprogrammed to the Program Schedule on the next page

with Mode #1 starting at 12:00 midnight and continuing

through all 6 maintenance modes to 4:16 a.m. If needed,

the Mode start time and run times may be changed to

suit a specifi c application. We suggest that you consult

a factory representative prior to making any changes to

the Program Schedule.

14

Stop

Program

Setup

Network

Diagnostics

Msg Cong

Start Screen

Clock

LCD

Menu Language

Switch to OP

VALVE LOCATION &

8.913-970.0 - L • WATERMAZE CLP 5024/7034

PROGRAMMING INSTRUCTIONS

Maintenance

Mode Description Start Time Run Time Program Name

1 Media Filter Backwash 12:10 a.m. 30 minutes MMB Time 1

2 Carbon Filter Backwash 12:45 a.m. 30 minutes CRB Time 1

3 System Recirculation 1:30 a.m. 1.5 hours SR Time 1

4 Filter Recirculation 3:15 a.m. 1 hour FR Time 1

5 Automatic Sludge Dump 4:16 a.m. 1 minute P Time 1

6 Ozone Circulation 11:00 p.m. 5 hours Oz Time 1

WATER TREATMENT SYSTEM

Manual Start/Run:

Overriding the automatic maintenance schedule and

manually starting any of the Modes above can be done

in two ways:

1. To manually start and run any of the six maintenance

modes as shown in the Program Schedule above,

reset the AMC time-of-day clock to the start time as

shown in the schedule. For example, to manually

start the Media Filter Backwash cycle, temporarily

reset the AMC clock to 12:00 midnight. Don't forget

to set the clock back to its true time of day.

2. Maintenance Modes 1 through 4 are used by

WaterMaze personnel to test each CLP before it

leaves the factory, these four modes can be manually

started and run by following these instructions.

a. From the date and time screen hit the

left arrow and you'll see "ESC + C" displayed.

b. From the " ESC + C" screen follow the chart

below for the mode you want to test. For example to

start the Media Filter Backwash fi rst hit the "ESC"

button followed by the up arrow (

second delay between the two. Each mode will run

for 2 minutes to give time to check for proper operation,

set fl ows and etc.

▲), about a 1/2

OPERATOR’S MANUAL

Maintenance Mode

1

2

3

4 Filter Recirculation ESC FR Time 1

Description Button Button Program Name

Media Filter Backwash ESC MM TIme 1

Carbon Filter Backwash ESC CRB Time 1

System Recirculation ESC SR Time 1

8.913-970.0 - L • WATERMAZE CLP 5024/7034

▲

▲

▲

▲

15

VALVE INSTRUCTIONS

FUNCTION:

It is extremely important to know the location and function of the valves on the CLP. Improper positioning of

the valves can cause overfl ow or damage which could

result in time consuming clean-up and repairs. Study the

section on “Valve Location and Function.”

• Valve 1 - Flow Control Valve

This valve controls the amount of water allowed

into the CLP from the sump pump. Adjust 2-4 gpm

above your demand on the system (See Pages

13, 58).

• Valves 2 & 3 - Ozone Pump

Should be open at all times (See pages 19, 42,

44).

NOTE: Only to be closed when removing or re-

placing the ozone pump.

OPERATOR’S MANUAL WATER TREATMENT SYSTEM

• Valve 4 - Oil Skimming Bucket

Valve should be closed except when draining

off oil (See pages 13-14).

• Valve 5 - Tank Valve

This valve should be open at all times except when

removing air valve for repair (see pages 13-14).

• Valve 6 - Rinse Water Control Valve

This valve is opened only when rinse water is

needed (See page 44).

• Valve 7 - Outlet to Pressure Washer Valve

After start-up, this valve is left fully open all of

the time. Controls water to the pressure washer

(See page 44).

• Valve 8 - Rain Water Overfl ow Valve

Left open partially. When SV#1 opens, water is

allowed to discharge while still providing water for

the pressure washer (See page 44).

• Valve 9 - Recycle Flow Control Valve

This valve is used to control the volume of

water going back to the collection pit for recycling

through the system when the PLC or AMC activates the solenoid, SV3, for recycling the system.

Open partially to match fi lter fl ow meter allowing

a smooth fl ow without cycling transfer pump as

much as possible (See pages 46, 66).

• Valve 10 - Filter Flow Control Valve

This valve controls the amount of water allowed

to fl ow through the fi lters. Adjust to the same or

2 gpm below valve #1 (See pages 36, 62).

• Valve 11 & 12 - Filter Control Valve

When set on Filter, this valve allows water to pass

through the fi lter. When set on Backwash, the

water passes through the fi lter in reverse, then

passes back to the catch basin. The air valves

control these valves (See pages 13-14).

• Valve 13

Should be open at all times. Allows pressur-

ized water to fl ush sediment from the cone tank

(See pages 13-14).

• Valve 14

16

8.913-970.0 - L • WATERMAZE CLP 5024/7034

This valve should be open at all times to allow

pressurized water to fl ush out the sludge hose

(See pages 14, 38, 66).

Valve 16

Should be open at all times. Allows fresh water

into tank 2 when SV#2 opens. Valve should be

fully open (See page 44).

Valve 17

In the recirculation mode, this valve is used to

control the volume of water going to tank #1 when

the PLC or AMC opens SV#4. Open partially to

match fi lter fl ow meter allowing a smooth fl ow

without cycling transfer pump as much as possible

(See pages 38, 66).

Valve 20

Should be open partially to control the amount

of water fl ow to backwash the multi-media fi lter

when the PLC or AMC opens SV#7. Set for 30

gpm (See pages 36, 62).

Valve 21

Should be open partially to control the amount of

water fl ow to the backwash carbon fi lter when the

PLC or AMC opens air solenoid valves. Set for

15 gpm (See pages 40, 56).

WATER TREATMENT SYSTEM

OPERATOR’S MANUAL

8.913-970.0 - L • WATERMAZE CLP 5024/7034

17

OPERATOR’S MANUAL WATER TREATMENT SYSTEM

Tank #1

Control Panel

CLP-5024 OPERATION VIEW

Orp/pH

Probes

STEP

R

ON THIS PLATFORM

PRECAUTION/ATTENTION

DO NOT STAND O

WARNING

WARNING

DO NOT STAN

PRECAUTION/ATT

ON THIS PLATF

D

ENTI

OR STEP

ON

OR

M

Valve

2

300 Gallon Cone

Bottom Tank

Junction Box

Valve 1

Tank #2

Valve 11

Multi Media

Filter

Valve 21

Carbon

Filter

Inlet

Line

Sump

Pump

Sump Pump

Installation

(3 Phase)

Valve 12

Sump

Pit

FS1

FS2

FS7

Oil

Decanter

Barrel

Inlet

Line

Sump

Pump

Sludge Tub

Flow

Meter

Valve 13

Valve 5

Valve 4

Sump

Pit

FS1

FS2

18

Sump Pump Not Supplied

with Machine. See

Specifi cation on Page 70.

Sump Pump

Installation

8.913-970.0 - L • WATERMAZE CLP 5024/7034

89139700-5

CLP-7034 OPERATION VIEW

WATER TREATMENT SYSTEM

Flow Meter

Orp/pH Probe

Control

Tank #2

Tank #1

Panel

Valve 12

Valve 5

Valve

14

600 Gallon

Cone Bottom

Tank

Sludge

Tub

Valve 4

Oil

Decanter

Barrel

OPERATOR’S MANUAL

Multi-Media

Filter

Carbon Filter

3-Way Ball Valve

Assembly

8.913-970.0 - L • WATERMAZE CLP 5024/7034

Junction Box

Valve 13

89139700-25

19

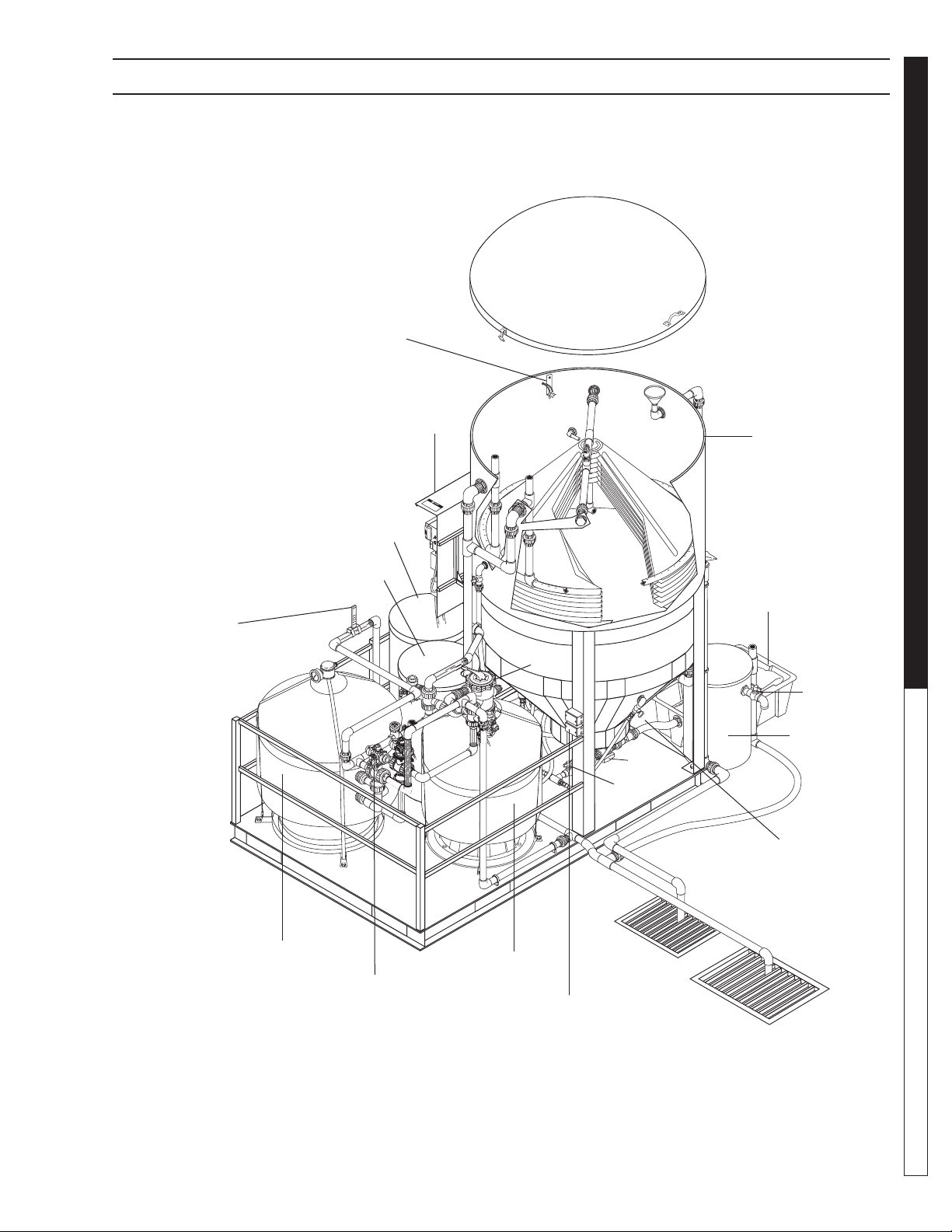

OPERATOR’S MANUAL WATER TREATMENT SYSTEM

WATER PANEL INSTALLATION

SV1

SV2

To Fresh Water Line

To Sewer or Storage

To Pressure Washer

89139700-31

20

8.913-970.0 - L • WATERMAZE CLP 5024/7034

STANDARD ORP/PH CONTROLLER

WATER TREATMENT SYSTEM

STANDARD ORP/PH DIGITAL

CONTROLLER - MODEL 250

Operation

The Oxidation Reduction Potential (ORP) and pH of the

water stream are controlled automatically by the digital

controller. The controller receives input from the ORP

sensor on the activity of the sanitizer and input from the

pH sensor on the pH level of the waste stream. The level

of ORP and pH being sensed, and the requested levels

programmed in the controller will determine if outputs

from the controller are sent to the feed pumps. If sanitizer or pH adjust are needed, the output will turn the

corresponding feed pump on. This will inject the required

sanitizer or pH until programmed levels are reached and

feed pump will stop.

If ORP or pH adjustment is needed the ozone pump will

also turn on. The chemical is injected at the outlet of the

ozone pump. If ORP is needed the controller also turns

on the ozone generator. All will run until setpoint levels

are reached.

Acid/Base Switching

Because most systems are dealing with a high pH situation, the controller is factory set for acid feed. If you

require a base feed, open plastic door on controller and

ORP Control Setpoint

The ORP setpoint is factory set at 550 mV, which is

recommended to maintain water quality by killing germs

and bacteria. There is no need for ORP calibration.

The sanitizing concentration required to generate a

desired ORP value varies with pH and overall water

quality, particularly Total Dissolved Solids (TDS) concentration and organic load.

To change the ORP control setpoint:

• Press [SETPOINT],

• Press [ORP]: the display fl ashes,

• Use the [UP] and [DOWN] arrows to adjust the

ORP value,

• Press [SETPOINT] again to save the new value.

pH Calibration

To calibrate the pH, use a reliable, fresh test kit (Phenol

Red). Note the value of the pH and compare it to the

display value.

To change the pH calibration:

• Press [CALIBRATION],

• Press [pH]: the display fl ashes,

• Use the [UP] and [DOWN] arrows to adjust the

pH value,

• Press the [CALIBRATION] again to save the new

value.

OPERATOR’S MANUAL

WATER MAZE ® 250

FEED

ALARM

PROPORTIONAL

CONTROL

MANUFACTURED BY SANTA BARBARA CONTROL SYSTEMS - SANTA BARBARA CALIFORNIA 93111 USA

ORP

OFF MANUAL AUTO

SAFETY

TIMER

SETPOINT

CALIBRATION

24V 50/60Hz 5A

pH

ORP / pH

DIGITAL CONTROLLER

pH

OFF MANUAL AUTO

LOW LIMIT HIGH LIMIT

FEED

ALARM

push the up and down arrows at the same time and let

go. To toggle between acid (Ac) or base (bA) push the

up arrow once then let the controller go though its start

up procedure. Close plastic door.

Feed Mode

The feed mode for the pH and sanitizer can be set to

"OFF", Manual or Automatic. Set to Automatic. To select

the desired feed mode, press [ORP] or [pH] until the

corresponding LED indicator light is illuminated. There

is a short delay before activation. NOTE: Holding the

switch for more than 5 seconds resets the setpoint and

calibration for [ORP] or [pH] to original factory values.

pH Control Setpoint

The pH setpoint is preset at 6.8. To change the pH

control setpoint:

• Press [SETPOINT],

• Press [pH]: the display fl ashes,

• Use the [UP] and [DOWN] arrows to adjust the

pH value,

• Press [SETPOINT] again to save the new value.

8.913-970.0 - L • WATERMAZE CLP 5024/7034

21

SENSOR MAINTENANCE

Out-of-Range Alarms

The out-of-range alarms are factory set at 450 to 650

mV for ORP and 6.5 to 7.5 for pH. If the ORP is below

the low limit, the red LED alarm fl ashes but the sanitizer

feed continues.

If the pH limits are exceeded, the red LED alarm fl ashes

and the pH feeder continues.

To change an alarm limit:

• Press [LOW LIMIT] or [HIGH LIMIT],

• Press [ORP] or [pH]; the display fl ashes,

• Use the [UP] and [DOWN] arrows to adjust the value,

• press [LOW LIMIT] or [HIGH LIMIT] again.

CAUTION: Increasing the out-of-range limits may

cause overfeeding of chemicals.

ORP AND PH SENSOR

OPERATOR’S MANUAL WATER TREATMENT SYSTEM

The controller is virtually maintenance free. The enclosure and front panel can be cleaned with a soft cloth

moistened with a mild soap and water solution or a glass

cleaner. Do not use abrasives or harsh chemicals.

Sensor Cleaning/Testing

The sensor tips must be kept clean and free from

chemical deposits and contamination to function properly.

After saturation in the waste

stream, the sensors may need

to be cleaned on a weekly or

monthly basis depending on

the water quality and other

facility-specifi c characteristics.

Slow response and inconsistent readings are indications

that the sensors are in need

of cleaning.

To clean a sensor, carefully

remove it from the compression fi tting or holding bracket.

Clean the tip of the sensor with a mild liquid detergent

(Joy®, etc) solution. Rinse with fresh water and soak the

sensor in a mild acid solution for fi ve minutes. Rinse with

fresh water and reinstall the sensor.

MAINTENANCE

66-123 66-122

To check sensor for proper operation place a small

amount of white vinegar, muriatic or hydrochloric acid

into a cup and place sensor probe into solution. For the

pH sensor, the needle should drop. For the ORP sensor,

the needle should rise.

NOTE: Only clean one sensor at a time. Sensors must

stay in some kind of liquid at all times.

Sensor Replacement

For preventative maintenance it is also recommended

to replace the sensors on an annual basis or as performance diminishes.

Sensor Storage

Extended exposure to atmospheric conditions will cause

the sensor tips to dry out. Always remove and properly

store the sensors if they are to be winterized or inactive.

Store the sensors with the original cap provided, making

sure that each cap is fi lled with clean water. If the storage containers have been misplaced, store the sensors

individually in small glasses or plastic containers with

clean water covering the sensor tips.

Terminal Block Wiring

B W G

B W G

B W G

ORP R W B Power pH

Rotary

Flowswitch

B=black, W=white, G=green, R=red

Dry-Contact

Alarm

22

8.913-970.0 - L • WATERMAZE CLP 5024/7034

TROUBLESHOOTING - ORP/PH SENSORS

All controllers are manufactured to the highest quality standards and thoroughly tested before leaving the factory.

State-of-the-art designs and fabrication technology should ensure years for trouble-free operation.

PROBLEM SOLUTION

WATER TREATMENT SYSTEM

NO LIGHTS ARE

ON WITH

POWER ON

ILLOGICAL pH AND

ORP VALUE DISPLAYS

ORP FEEDER

DOES NOT

ACTIVATE

pH FEEDER

DOES NOT

ACTIVATE

pH REQUIRES

FREQUENT

CALIBRATION

Check for power going to controller.

Check for damaged power connector.

Check internal fuse (1A slow blo) marked F3 on control board.

The sensor cable connections may be reversed. Verify that the sensor

cables are properly connected to their respective BNC connectors

on the controller unit.

Make sure the AUTO feed light for ORP is on.

Check the ORP setpoint.

Check ORP relay fuse (5A slow blow) marked F2 on control board.

Verify that the acid/base feed jumper JP14 on the control board is properly set.

Make sure the AUTO feed light for pH is on.

Check the pH relay fuse (5A slow blow) marked F2 on control board.

Clean or replace the sensor as outlined in the maintenance section.

OPERATOR’S MANUAL

INCONSISTANT

OR SLOW pH OR ORP

READINGS

CHEMICAL FEEDER

RUNS CONTINUOUSLY

Verify that the sensor cables are properly connected to their

respective BNC connectors and the controller unit.

Clean or replace the sensor as outlined in the maintenance section.

Replace the sensors if needed.

Make sure the AUTO feed mode is selected.

Verify that the chemical feeders are properly connected to their

respective connectors or controller unit.

8.913-970.0 - L • WATERMAZE CLP 5024/7034

23

METERING PUMP

VSP20 METERING PUMP

#5-2359

(Variable Speed Peristaltic)

TECHNICAL INFORMATION

Materials:

Pump Head .................................. Polycarbonate

Pump Head Tubing .....Special Synthetic Rubber

Strainer and Injection Point Fitting ...............PVC

Feed Rate: 2.6 - 20 GPD

Tubing Size: 7/16" O.D. x 1/4" I.D.

Dimensions: Hgt. = 5", Wdt. = 6-1/4", Dpt. = 7"

Standard Accessories Provided with Pump:

Head Tubing

Injecting Fitting with Check Valve

Strainer

OPERATOR’S MANUAL WATER TREATMENT SYSTEM

Polyethylene Tubing (1/4" O.D. x 15')

Tubing Sleeve (for strainer connection)

Electrical Rating:

24V

.3 Amps

50/60 Hz

Maximum System Pressure: 25 PSI

(maximum allowable at injection fi tting)

24

8.913-970.0 - L • WATERMAZE CLP 5024/7034

GENERAL MAINTENANCE & SERVICE

GENERAL MAINTENANCE

AND SERVICE

Periodic Maintenance:

• Oil Skimmer Collection Drum

• Monitor the level of oil in the collection drum.

Empty it as required.

• Check the electrical cords to ensure they are safe,

no damage or cracking.

• Check inlet / outlet pipes for leaks or damage.

Winterizing

If a heated area is not provided in areas where freezing

temperatures can be expected, the entire machine must

be drained.

Testing Carbon

Remove the valve from the Carbasorb Filter and extract a

carbon sample. Place carbon sample in the 4 oz. plastic

bottle. (Fill the bottle 1/4 full of carbon, about 2 inches).

Fill the 2 oz. bottle with water and add 1 drop chlorine.

Dip the chlorine test paper into the solution to ensure

you have at least 100 parts per million of chlorine in the

mixture. Add this solution to the carbon in the 4 oz. bottle.

Cap and shake it periodically over a period of three minutes. After three minutes, dip a new piece of chlorine test

paper into the solution. Compare the color with the color

chart that comes with the test paper. If the color matches

the color on test paper, order new carbon. There may

be some dark discoloration from the carbon. Do not

confuse this with the color caused by the chlorine.

OZONE GENERATOR

Ozone...Nature’s Purifi cation Agent

Ozone is produced in nature or artifi cially by man. In

the earth’s atmosphere, ozone is formed when oxygen

is exposed to ultraviolet light or an electrical charge as

during thunderstorms. Ozone’s primary function in nature

is to purify the air we breathe and screen us from harmful

rays of the sun. In a similar fashion, the CLP system uses

ozone to disinfect water because

of characteristics that make it ideal for water treatment.

Ozone’s Characteristics

Ozone is well suited for water treatment, and it’s unique

characteristics are described below:

Ozone has a number

•

Ozone works up to 3,000 times faster than chlorine

to kill bacteria and destroy harmful microorganisms.

• Ozone is a more powerful oxidizing agent than

chlorine and bromine, having a better ability to

remove water contamination.

• Ozone will not form harmful by-products, like

THM’s (a problem in drinking water), or chloramines, (by-products of chlorine that are responsible for odors, skin irritations and burning eyes.)

• Ozone will not alter the water’s pH, reducing pH

fl uctuations.

• Ozone coagulates small particles in water so

clarity is dramatically improved.

• Ozone acts as a deodorizer removing unpleasant

odors from water.

How the CLP Ozone System Works

Because ozone is unstable, it cannot be packaged and

used at a later date. For this reason, ozone is always

produced where it is utilized.

Point-of-use ozone generation is simple. This powerful

disinfectant is produced from ambient air surrounding the

generator using special ultraviolet lamps located inside

the system’s cabinet. To generate the ozone, air movement is created through the use of an air compressor or

water venturi. As air passes over these unique lamps,

the oxygen contained in the air is converted. The resulting ozone gas is subsequently introduced to the water

in the inlet pipeline, where oxidation and disinfection

immediately takes place.

Ozone Generator Maintenance

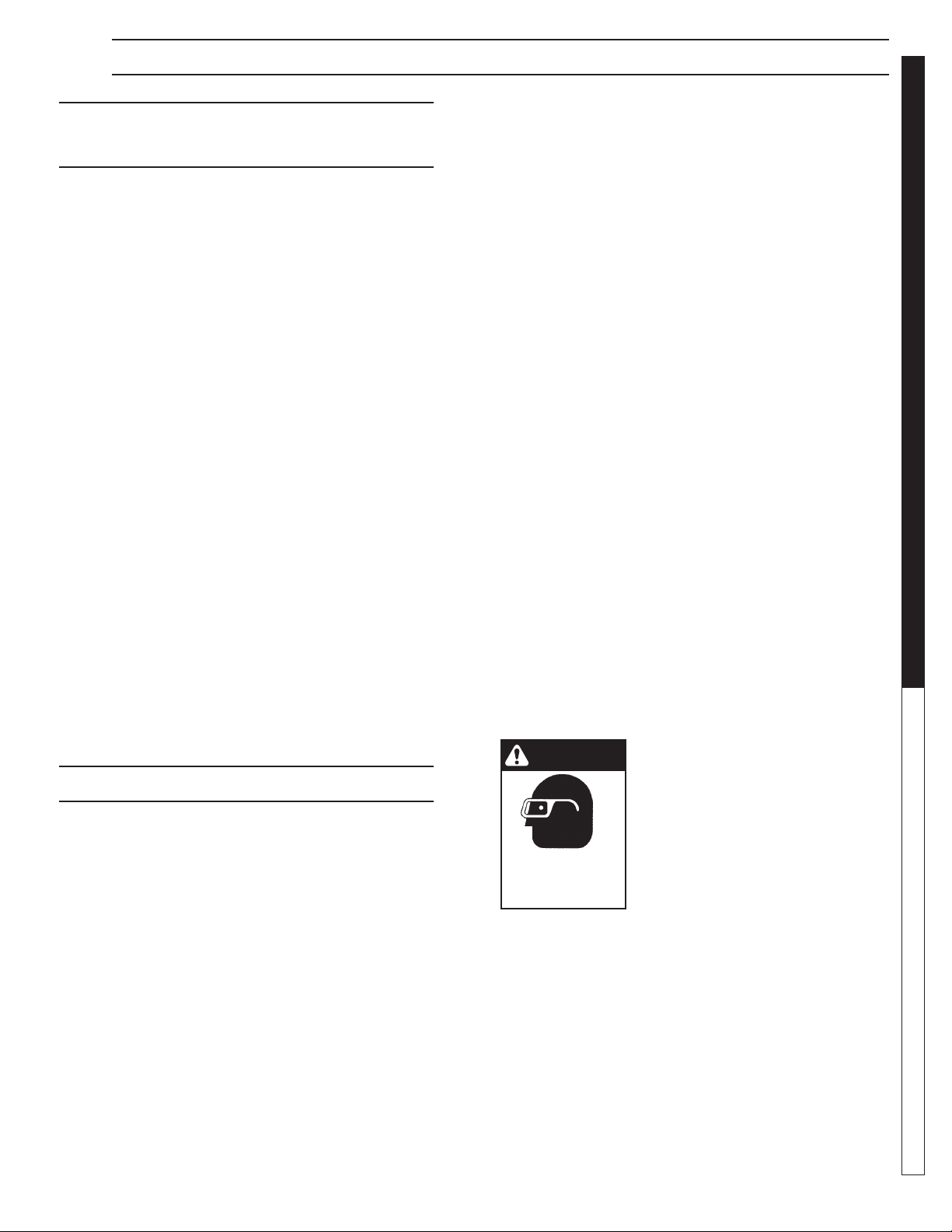

WARNING: Never look at an un-

WARNING

EYE HAZARD:

NEVER LOOK

AT UNSHIELDED

OZONE LAMP

Lamp: The light has a 9,000 hour life expectancy.

shielded ozone lamp while operating the unit. This lamp will cause

severe eye and skin damage.

There is a green indicator light

which will dim when the unit is

operating properly and will turn

bright green if there is a malfunction. See product description for

location of the indicator light.

ULTRAVIOLET LIGHT

COMPLIANCE

Ultraviolet Light Safety Requirements

The device used in this product is a Class 1 certifi ed

ozone generator product. Operating this product outside

specifi cations or altering its original design may result

WATER TREATMENT SYSTEM

Troubleshooting Guide

8.913-970.0 - L • WATERMAZE CLP 5024/7034

25

OZONE SPECIFICATIONS

in hazardous radiation exposure, and may be considered

an act of modifying or new manufacturing of a laser

product under U.S. regulations contained in 21CFR

Chapter 1, subchapter J.

CAUTION: Avoid exposure to direct or strongly

refl ected germicidal ultraviolet rays.

DO NOT STARE INTO BEAM.

ATTENTION: Éviter l'exposition aux rayons ultra-

violets germicides fortement réfl échis.

NE PAS REGARDER DIRECTEMENT LE FAISCEAU.

DANGER: Ultraviolet radiation. Disconnect

OPERATOR’S MANUAL WATER TREATMENT SYSTEM

Power Before Replacing Lamp.

ATTENTION: Radiation ultraviolette. Débrancher

l'alimentation avant de remplacer la lampe.

DANGER: Connect only to a circuit that is protected by Ground Fault Circuit Interrupt (GFCI).

DANGER: Raccorder uniquement à un circuit qui

est protégé par un disjoncteur différentiel de fuite

à la terre (DDFT).

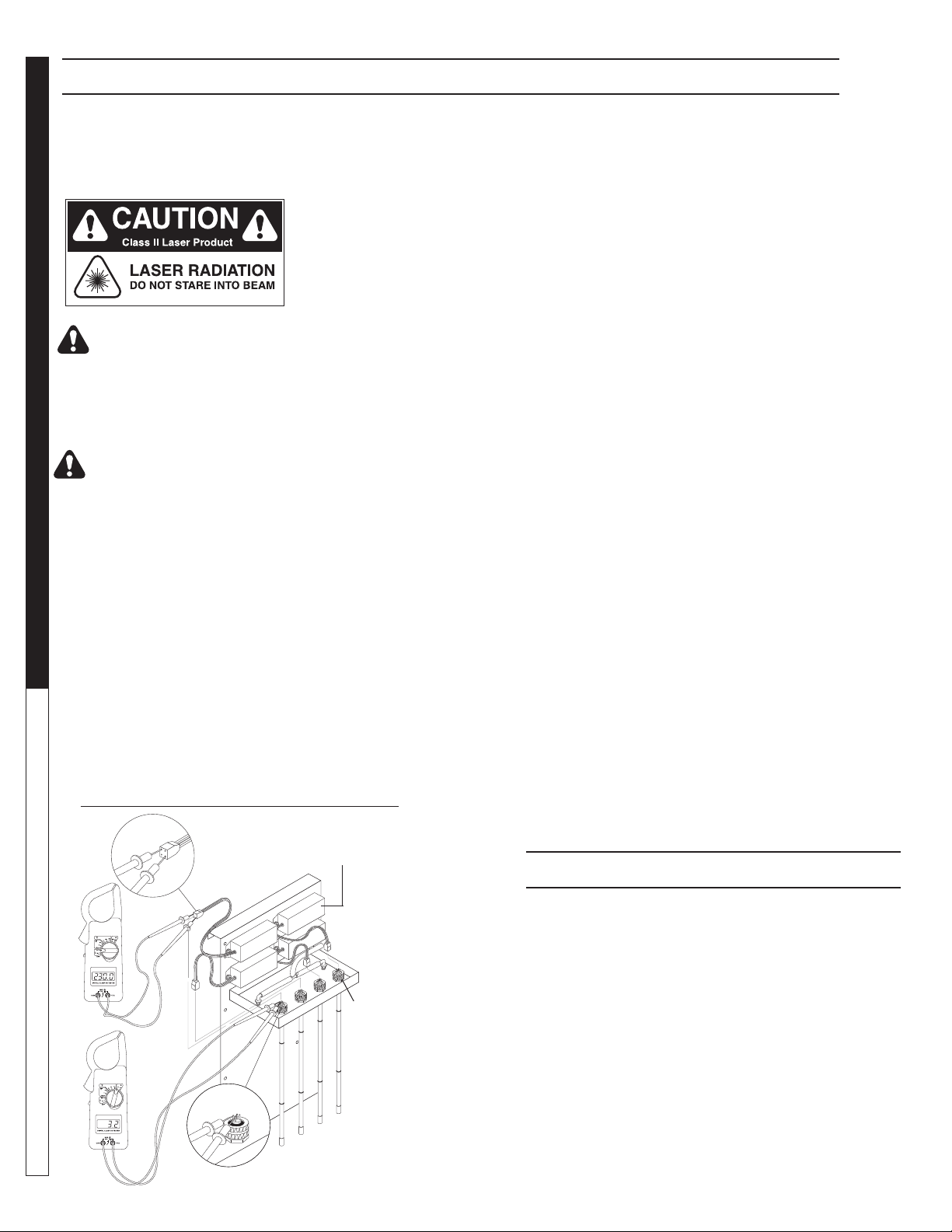

Testing the Lamp:

(See Ozone Generator Testing Illus.)

To test the ozone lamp, use a voltmeter set on ohms.

First remove the ozone cover and unplug the lamp plug

from the ozone lamp.

OZONE GENERATOR TESTING

Four Pin

Connector

Ballast

NOTE: There are two fi laments - an upper and a lower -

inside the lamp. Place one of the voltmeter leads on one

of the lamp prongs and, with the other lead, touch all of

the three remaining prongs. If continuity is not achieved

on both upper and lower fi laments, replace the ozone

lamp (Part #6-0534)

To test the power pack, use a voltmeter set on the correct voltage (120V or 240V). Place one of the voltmeter

leads into the lamp plug where the white wire goes into

it and plug the other voltmeter lead into the lamp plug

where the blue wire goes into it. If no voltage is present

replace the ozone ballast (Part #6-05231 - 120V, Part

#6-05232 - 240V). When ordering an ozone ballast, you

also need the 4-pin connector (Part #6-05233).

Replacing the lamp:

(See Ozone Generator Breakdown)

Lamp replacements are available from your WATER

MAZE Dealer should they need to be replaced. Simply

turn off the power to the CLP at the breaker, remove the

screws on the power pack cover and remove the cover.

Disconnect the plug on the end of the ozone lamp. Now,

loosen the lamp holder locking ring from around the end

of the lamp by turning it counterclockwise and remove

it. Remove the lamp by grabbing the rubber bushing

around the end of the lamp and pulling it straight out.

Remove the rubber bushing from the lamp and install

it on your new lamp, making sure the outer edge of the

bushing is fl ush with the outer edge of the silver end cap

on the lamp. Now, slide the lamp back into the reaction

chamber. The lamp holder may now be reinstalled and

tightened. Reinstall the plug onto the lamp and replace

the power pack cover.

CAUTION: Keep the lamp free of fi ngerprints and

dust particles by only handling the metal end caps

on the lamp. You can clean the lamp with rubbing

alcohol and a soft cloth. A dirty lamp will not allow

maximum ozone output.

SPECIFICATIONS

26

Energy required 110V:

105VAC MIN., 125VAC MAX., .800 AMP/Ballast

Energy required 220V:

210VAC MIN., 230V MAX., .450AMP/Ballast

Ozone

Lamp

Prongs

Power Consumption: 20 Watts

Average Lamp Life: 9,000 Hours

Lamp Wave length: 185 nm

89139700-34

8.913-970.0 - L • WATERMAZE CLP 5024/7034

OZONE GENERATOR BREAKDOWN EXPLODED VIEW

21

Ballast

WATER TREATMENT SYSTEM

5

Prongs

Ozone Lamp

19

OPERATOR’S MANUAL

11

9

23

10

4

1

12

11

16

17

13

14

6

On/Off

Switch

8

Ozone

Lamp

15

3

UCION

N

AUTION

A

C

PREC

IGHT OPERATIO

L

.

e

v

uous light indicates UV

ecti

f

mador está def

r

o

f

TEUR

A

o

f

rans

ATTENTION

OT!

H

!

UD!

ALIENTE!

A

C

H

C

.

o

ectuos

mateur est

r

ENT

TT

A

/

!

ARNING!

W

ION

VICING.

VICING.

R

R

!

ENC

OM ELECTRICAL

OM ELECTRICAL

R

T

R

A

VICI

VICI

R

Y BEFORE SE

Y BEFORE SE

L

L

AR SE

AR SER

D

AR

D

PAR

DISCONNECT F

P

DISCONNECT F

TION ÉLECTRI

TION ÉLECTRI

SUPP

SUPP

TA

TA

ANTES DE

ANTES DE

L’ALIMEN

L’ALIMEN

AIRE UNE RÉ

AIRE UNE RÉ

DESCONECTE LA CORRIENTE ELECTRICA

DESCONECTE LA CORRIENTE ELECTRICA

F

F

COUPER

COUPER

ANT DE

ANT DE

AV

AV

ON!

I

.

.

UE

UE

O

O

Q

Q

TION.

TION.

A

A

8.900-455.0

OZONE GENERATOR

INDICATOR

ight contin

2

22

r

A b

light or ballast de

INDICADORA

OPERACION DE LA LUZ

ans

r

Una luz luminosa indica que la luz ultravioleta o t

INDIC

OPÉRATION DE LE LAMPE

Une lumière claire indique que la lumière

aviolette ou le t

r

ult

défectueux.

7

24

8.913-970.0 - L • WATERMAZE CLP 5024/7034

18

20

89139700-26

27

Loading...

Loading...