Assembly and

Operating Instructions

Sand lter system SF 122 - 124

(Sand lter system small without pre-lter)

English

Illustrations are exemplary.

Sand lter system

Please read this manual carefully and

keep it for future reference.

2

> 3 m

selbst-ansaugend

132

4

D

UK

F

I

NL

S

CZ

SK

SI

HU

RO

D

UK

F

I

NL

S

CZ

SK

SI

HU

RO

D

UK

F

I

NL

S

CZ

SK

SI

HU

RO

D

UK

F

I

NL

S

CZ

SK

SI

HU

RO

Assembly and Operating Instructions Sand Filter System without Pre-lter

KURZANLEITUNG / QUICK START GUIDE / NOTICE SOMMAIRE / GUIDA RAPIDA BEKNOPTE HANDLEIDING / KORTFATTAD BRUKSANVISNING /

STRUČNÁ PŘÍRUČKAG / STRUČNÝ NÁVOD / KRATKA NAVODILAG / GYORS ÚTMUTATÓ ÎNDRUMĂTOR PE SCURT

Eigenschaft

der Pumpe: nicht-ansaugend

FI

Standort der Filteranlage wählen

Selecting the lter system location

Sélection du lieu d‘implantation de l‘installation de ltrage

Scegliere la collocazione del ltro

Positie van de lterinstallatie kiezen

Välj var ltret ska stå

Zvolte umístění lračního systému

Zvoľte miesto ltračného zariadenia

Izbira mesta postavitve ltrirne naprave

A szűrőberendezés felállítási helynek megválasztása

Selectarea locului de amplasare al instalaţiei de ltrare

Filteranlage montieren

Installing the lter system

Montage de l‘installation de ltrage

Montare il ltro

Filterinstallatie monteren

Montera lteranläggningen

Smontujte ltrační systém

Namontujte ltračné zariadenie

Montaža ltrirne naprave

A szűrőberendezés összeszerelése

Montarea instalaţiei de ltrare

Filteranlage muss unterhalb des Wasserspiegels stehen

Filter system must be positioned below water level

Le système de ltration doit être sous le niveau de l‘eau

Il ltro deve essere collocato sotto il livello dell‘acqua

Filtersysteem moet zich onder het waterniveau bevinden

Filteranordningen måste stå under vattenytan

Filtrační systém je nutno namontovat pod hladinou vody

Filtračné zariadenie musí stáť pod vodnou hladinou

Filter mora biti postavljen pod ravnijo vode

A szűrőberendezésnek a vízszint alatt kell elhelyezkednie

Instalaţia de ltrare trebuie să se găsească sub nivelul oglinzii apei

innenaußen

Entleerungsventil festschrauben

Fixing the drain valve

Fixation de la vanne de vidange

Avvitare la valvola di scarico

Aftapventiel vastschroeven

Skruva fast tömningsventilen

Přišroubujte výpustný ventil

Priskrutkujte výpustný ventil

Privitje ventila za izpraznitev

Az ürítőszelep rögzítése

Înşurubare fermă supapă de golire

Assembly and Operating Instructions Sand Filter System without Pre-lter

576

8

D

UK

F

I

NL

S

CZ

SK

SI

HU

RO

D

UK

F

I

NL

S

CZ

SK

SI

HU

RO

D

UK

F

I

NL

S

CZ

SK

SI

HU

RO

D

UK

F

I

NL

S

CZ

SK

SI

HU

RO

1

3

2

4

SteigrohrFilterstern

3

Steigrohr einsetzen (2 unterschiedliche Versionen)

Insert riser pipe (2 different versions)

Remplacer le tube montant (2 versions différentes)

Inserire il tubo montante (2 versioni diverse)

Stijgbuis toepassen (2 verschillende versies)

Sätt i stigröret (2 olika utföranden)

Nasazení stoupací trubky (2 různé verze)

Nasadiť stúpaciu rúru (2 rôzne verzie)

Vstavite dvižno cev (2 različni različici)

A felszállócső behelyezése (2 különböző változat)

Introducerea ţevii ascendente (2 versiuni diferite)

4

2

3

1

Ventil aufsetzen

Valve installation

Mise en place de la vanne à 6 voies

Applicare la valvola

Ventiel plaatsen

Sätt på ventilen

Nasaďte ventil

Nasaďte ventil

Namestitev ventila

A szelep felhelyezése

Amplasare supapă

Filtermaterial einfüllen

Filling the lter material in

Remplissage de la matière ltrante

Caricare il materiale ltrante

Filtermateriaal bijvullen

Häll i ltermediet

Naplňte ltrační materiál

Naplňte ltračný materiál

Polnjenje s ltrirnim materialom

A szűrőanyag betöltése

Umplere cu material de ltrare

Montage & Anschluss der Pumpe

Assembly and connection of the pump

Montage et raccordement de la pompe

Montaggio e collegamento della pompa

Montage & aansluiting van de pomp

Montering och tillkopplingen av pumpen

Namontujte a připojte čerpadlo

Montáž & Pripojenie čerpadla

Montaža in priklop črpalke

A szivattyú szerelése és csatlakoztatása

Montarea şi racordarea pompei

4

D

UK

F

I

NL

S

CZ

SK

SI

HU

RO

9

D

UK

F

I

NL

S

CZ

SK

SI

HU

RO

English

Assembly and Operating Instructions Sand Filter System without Pre-lter

(Please observe the labelling on the hose tting

of the 6-way valve to ensure a correct connection.)

• This is where the hose that is used to return the cleaned

water back into the pool is connected, i.e. the hose

running to the inlet nozzle.

• This is where the short black hose is connected, which

PUMP

2

3

RETURN

3

WASTE

2

runs to the lter pump.

1

• This is where you can connect a 3rd hose, which runs to

the sewer.

Anschluss an den Pool

Connection to pool

Connexion à la piscine

Collegamento alla piscina

Aansluiting op de pool

Anslut till bassängen

Please observe the detailed instructions

on the following pages.

Připojení k bazénu

Pripojenie na bazén

Priklop na bazenu

Csatlakoztatás a medencénél

Racordare la bazin

Eine ausführliche Anleitung in Ihrer Sprache steht im Internet

unter http://download.waterman-pool.com für Sie bereit.

A detailed manual in your language is available on the Internet

at http://download.waterman-pool.com.

Une notice d‘utilisation détaillée dans votre langue est disponible

sur le site Internet http://download.waterman-pool.com

Potete trovare la descrizione dettagliata nella vostra lingua in

Internet all‘indirizzo http://download.waterman-pool.com

Een uitgebreide handleiding in uw taal staat op internet

onder http://download.waterman-pool.com voor u klaar.

En utförlig anvisning på ditt språk nns att ladda ner på Internet

under adressen http://download.waterman-pool.com

Podrobné pokyny ve vašem jazyce jsou k dispozici na internetu

jsou pro vás připraveny pod http://download.waterman-pool.com

Podrobný návod vo vašom jazyku nájdete na internete

na stránke http://download.waterman-pool.com

Celotna navodila v Vašem jeziku najdete na spletni strani

http://download.waterman-pool.com

Részletes útmutató az Ön beszélt nyelvén az interneten

a következő címen http://download.waterman-pool.com áll rendelkezésére.

Un manual cu instrucţiuni detaliate vă stă la dispoziţie pe internet pregătit în

limba dumneavoastră la http://download.waterman-pool.com

Assembly and Operating Instructions Sand Filter System without Pre-lter

D

UK

F

I

NL

S

CZ

SK

SI

HU

RO

Beschreibung des 6-Wege-Ventils

Description of the 6-way valve

Description de la vanne à 6 voies

Descrizione della valvola a 6 vie

Beschrijving van het 6-weg ventiel

Beskrivning av 6-vägsventilen

Popis 6-cestného- ventilu

Popis 6-cestného ventilu

Opis 6-potnega ventila

A 6 utú szelep leírása

Descrierea supapei cu 6 căi

Return

5

English

Waste

Pump

FILTER

FILTRATION

FILTRACION

FILTRAZIONE

FILTERN

FILTRACAO

FILTRARE

SZŰRÉS

FILTRIRANJE

BACKWASH

LAVAGE

LAVADO

LAVAGGIO

SPÜLEN

LAVAGEM

SPĂLARE

ÖBLÍTÉS

IZPIRANJE

RINSE

RINÇAGE

ENJUAGUE

RISCIACOUO

NACHSPÜLEN

ENXAGUAMENTO

CLĂTIRE

UTÓÖBLÍTÉS

NAKNADNO IZPIRANJE

CLOSED

FERMÉ

CERRADO

CHIUSO

GESCHLOSSEN

FECHADO

ÎNCHIS

ZÁRT

ZAPRTO

RECIRCULATE

RECIRCULATION

RECIRCULACION

RICIRCOLO

ZIRKULIEREN

RECIRCULACAO

RECIRCULARE

KERINGTETÉS

OBTOK

WASTE

VIDANGE

VACIADO

SCARICO

ENTLEEREN

ESVAZIAMENTO

GOLIRE

ÜRÍTÉS

IZPRAZNITEV

6

Assembly and Operating Instructions Sand Filter System without Pre-lter

English

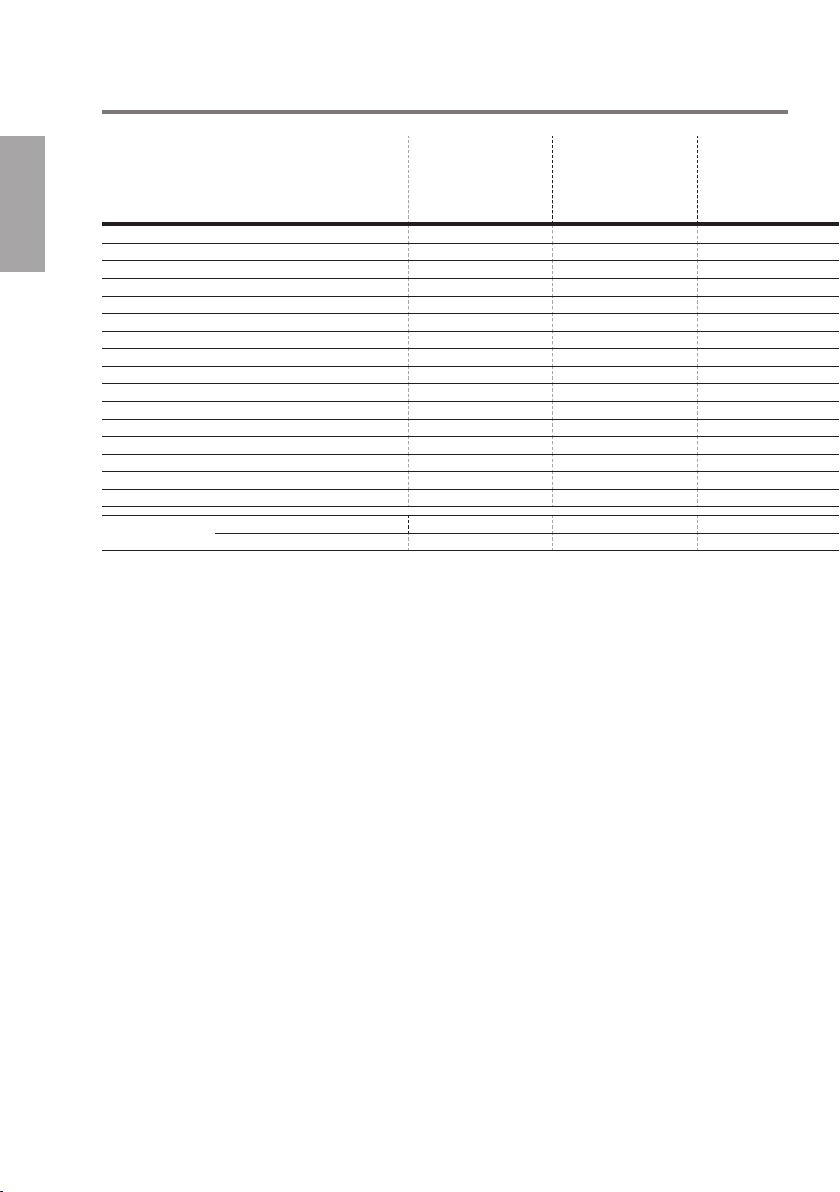

STÜCKLISTE

No. Article no. Description

1 2260130 Filter pu mp Aqua Mini 3 X X X

1 2260140 Filter pu mp Aqua Small 4 - XKP 202E-1

1 2260148 Filter pu mp Aqua Small 4 Alternative model Alternative model Alternative model Alternative model Alternative model

2 2260101 Filter tank Ø 25 0mm grey X

2 2260106 Filter tank Ø 250mm grey X

2 2260105 Filter tank Ø 300 mm blue X

2 2260150 Filter tank Ø 330 mm grey

3 590000014 Drain valve 27mm ro und hole X X X X X X X X

4 2260115 Filter pa llet 545x325 mm X X X X X X X X

5 22600 96 6-way valve with clamping ring X X X X X

5 2260100N 6-way valve with c lamping ring + seal X X X

6 2260120 Hose Ø 38 mm, length 0.33 m X X

6 2260121 Hose Ø 38 mm, length 0.37m

6 2260122 Hose Ø 38 mm, length 0.38 m X

2600020 Pressure gauge

592260113 Accessories bag X X X

Sand quantity

approx. 10 - 15 kg X X

approx. 2 0 - 25 kg X

Sand l ter system

SF 122

Art . no.: 502010476

Sand l ter system

3 m³/h

Art . no.: 2260011

Sand l ter system

CP2503, 3m³/ h

Art . no.: CP2503

Assembly and Operating Instructions Sand Filter System without Pre-lter

7

Sand l ter system

SF 124 Ar t. no.:

2260006 + 2260006CH

X X X X X

X X X X X

X X X X X

X X X X X

X X X X X

Sand l ter system FH 4m ³,

tank 33 0mm

Art . no.: 45116000

Sand l ter system

SF 124

Art . no.: 50201048 0

Sand l ter system SF 124

Konifera

Art . no.: 50201049 0

Sand l ter system

SF 124, OB I

Art . no.: 502010497

English

8

Assembly and Operating Instructions Sand Filter System without Pre-lter

English

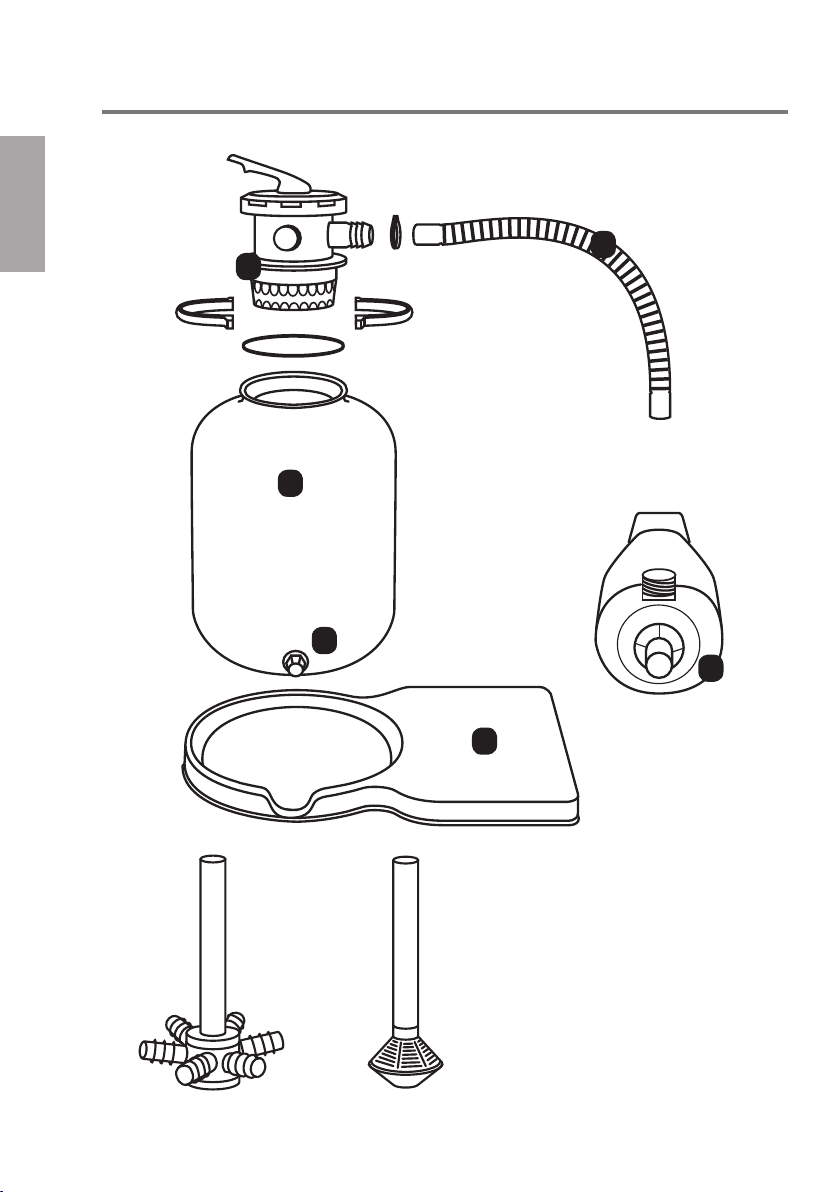

6

5

2

3

1

4

Riser pipe model 1

OR*

Riser pipe model 2

COMPONENTS OF THE FILTER SYSTEM

1. Pump

2. Filter tank

3. Drain valve

4. Filter pallet

5. Multiway valve

6. Connecting hose pump - valve

* Each delivery includes one riser

pipe model only.

Assembly and Operating Instructions Sand Filter System without Pre-lter

Important instructions

9

• The use of lter systems for swimming pools

and their protected areas is only permitted if

they are designed and constructed in accordance with VDE 0100-49D. It is mandatory to

protect the power connection via an residual

leakage circuit breaker.

• In order to maintain the required protected

area (removal of electronic equipment from

water), the lter system must be positioned

outside the water with a minimum distance

of 3 m. (Protected area 2 according to VDE

0100-702.)

• Further safety instructions can be found in

the enclosed operating instructions for the

pump. These must be observed! (The CE

label is also included).

TABLE OF CONTENTS

1. Filter system – Description

1.1 Description of 6-way valve

1.2 Description of circulation pump

1.3 Description of lter tank

2. Commissioning

2.1 Assembly Instructions - Assembly

2.2 Filling the quartz sand lter

2.3 Filling water in - Commissioning

2.4 Flushing the quartz sand

2.5 Filter – Operation

2.6 Setting the ltration time

2.7 Connection of sand lter system

3. Regular backwash

3.1 Backwash

3.2 Rinse

4 Maintenance works

4.1 Maintenance of lter tank

4.2 Maintenance of circulation pump

4.3 General maintenance

To avoid damage:

English

• Never let the pump run dry (the lter system

must be installed and the suction hose

lled with water before commissioning).

The connection to the pool skimmer and to

the inlet nozzle must be completed before

commissioning.

• Actuate the 6-way valve only when the pump

is switched off!

• Filter systems with non-self-priming pump

must be installed below the water level.

5 Taking out of operation

6. Troubleshooting

6.1 Pump not priming

6.2 Insufcient performance of circulation pump

6.3 Circulation pump is too noisy

6.4 Circulation pump does not start automatically

6.5 Circulation pump leaks

6.6 Sand in the pool

6.7 Filter pressure is not correct

6.8 Water is not clear

6.9 Pool loses water

7. Water treatment –

General Information

7.1 pH value

7.2 Algae control

7.3 Error/fault

7.4 Continuous disinfection

7.5 Turbidity

7.6 Causes of unsatisfactory condition of water

10

Assembly and Operating Instructions Sand Filter System without Pre-lter

1. FILTER SYSTEM – DESCRIPTION

English

The sand lter system you have

purchased is a high-quality quality

product. We hope you will enjoy your

swimming pool and the lter system.

We recommend that you read these assembly

instructions and the enclosed operating instructions

for the pump carefully. Keep them in a safe place

1.1 DESCRIPTION OF 6-WAY VALVE

The individual functions/positions of the plastic

valve are clearly marked on the upper side so that

there is no risk of confusion. Please also observe

the drawings and explanations in our Quick

Start Guide on page 5.

1.1.1 FI LTER:

Filtration (operating state)

In this position, the swimming pool water is

pumped through the lter tank and quartz sand

and then back to the pool. The dirt is ltered

out via the quartz sand.

1.1.2 Closed:

Servicing

All functions are disabled in this position. The

circulation pump must not be switched on. This

position is used when maintenance works are

carried out in the lter tank.

1.1.3 Backwash:

CLEANING THE Filter system

In this position, the swimming pool water

is pumped through the lter in the opposite

direction (from bottom to top) to clean it. The

waste water is drained sideways out of the

valve (hose outlet = waste).

and familiarize yourself with the special features

and possible uses of this system. The lter system

ensures a mechanical treatment of swimming pool

water. However, an impeccable water quality can

only be guaranteed if the water is treated chemically

in addition (see information on reverse side).

1.1.4 Recirculate:

Circulate without ltration

(increased circulation)

In this position, the swimming pool water ows

right into the swimming pool, the lter tank is

bypassed. This setting is used after adding

pool chemicals (e.g. after a shock chlorinati-

on).

1.1.5 RINSE:

Filtration into the sewer

In this position, the lines of the lter system are

cleaned from residual dirt after backwashing.

1.1.6 Waste:

Emptying/Sewer

In this position, the swimming pool water is

pumped directly into the sewer (valve outlet

‚Waste‘).

Assembly and Operating Instructions Sand Filter System without Pre-lter

1.2 DESCRIPTION OF CIRCULATION PUMP

The circulation pump is used to pump the water from the swimming pool through the lter tank and back into

the swimming pool (see also enclosed separate pump manual).

1.2.2 SHAFT SEAL

The pump is equipped with a mechanical seal between the pump housing and the motor to seal the

motor shaft. This seal is a wearing part/no warranty

(see pump 4.2.3).

1.3 DESCRIPTION OF FILTER TANK

11

English

The lter tank is used to mechanically remove

suspended particles such as hair, skin akes, pollen

and other impurities from the swimming pool water

by means of a special quartz sand for swimming

pools (0.4 - 0.8 mm or other lter medium, e.g. lter

glass or lter balls). This is done at a pressure of

0.4 - 0.8 bar. When the pressure increases (loud

pumping noise) the lter must be backwashed (see

section 2.4). This is by no means a defect of the

pump, it is a normal process, as the pump has to

work against a higher resistance if the lter tank/

lter sand is too dirty. To measure the lter pressure

in the tank, there is an optional pressure gauge

(item no.: 2600020) available (not included in delivery), which is xed at the top of the valve (bleeder

screw). The pressure gauge allows you to read

the lter pressure at any time and thus determine

whether a backwashing is required. If you do not

have or use a pressure gauge, we recommend

backwashing once a week.

12

English

Assembly and Operating Instructions Sand Filter System without Pre-lter

2. INSTALLATION OF SAND FILTER SYSTEM

Step 1:

The following tools are required for this: Phillips

screwdriver, Teon tape, 7 mm wrench, possibly

drill, possibly cordless screwdriver, rubber hammer.

Step 2:

Insert the drain valve into the pre-drilled hole on the

lter tank, i.e. from the inside to the outside. While

doing so, please mount a rubber seal each from the

inside and from the outside and then x the drain

valve with the lock nut from the outside.

Step 3: (Instructions for model with riser pipe 1)

At rst, screw only 2 of the lter cartridges into the

riser pipe.

Step 4: (Instructions for model with riser pipe 1)

The other lter cartridges are inserted in the tank,

as otherwise the assembled riser pipe would not t

through the tank opening.

Step 5: (Instructions for model with riser pipe 2)

If you use our alternative tank with xed (glued) lter

basket, it is simply inserted into the lter tank.

Assembly and Operating Instructions Sand Filter System without Pre-lter

Step 6:

Before lling the quartz sand in, close the top of the

riser pipe with a plastic bag to prevent sand from

entering the riser pipe.

Step 7:

Please select the correct quartz sand grain size (0.4

- 0.8 mm) for your lter system, as otherwise there

may be problems during the lter operation.

Step 8:

Carefully ll the correct amount of quartz sand (see

table) in from the top into the lter tank, and ensure

that the riser pipe remains in the correct central

position. About two-thirds of the lter tank should be

lled with quartz sand.

13

English

Step 9:

Next place the O-ring on the valve from below.

Step 10:

Please ensure that the clamping ring and the screws

are mounted/assembled correctly, i.e. in the right

direction. You can see the correct way on the photo:

The nut of the screw also

grips into the groove of

the clamping ring to hold

the nut in place.

14

English

Assembly and Operating Instructions Sand Filter System without Pre-lter

Step 11:

If necessary, loosen the clamping ring carefully

using a rubber hammer to achieve a better sealing

and a uniform tensioning of the clamping ring.

Step 12: Only with 2260140 and 2260148 pump

Insert the rubber hose tting (only included with

2260140 and 2260148 pump) into the connecting

hose and insert in on the upper pump connection

(as far as possible). Then x it rmly with a hose

clip.

Step 13:

Fasten the hose to the middle hose connection

(labeled ‚Pump‘) on the top of the valve.

Step 14:

Fix the lter pump on the lter pallet using the

self-tapping screws.

Step 15:

If the hose connections do not seal well, you can

use Teon tape for additional sealing. To do this,

wrap at least 15 times.

Assembly and Operating Instructions Sand Filter System without Pre-lter

Step 16:

The hose is attached to the suction side of the

pump, which runs to the swimming pool skimmer.

Step 17:

The return hose to the inlet nozzle is connected to

the ‚Return‘ hose connection via the valve.

Step 18:

On the right-hand side of the valve, you can nd the

hose connection for backwashing (dirty water into

the drains). This is labeled ‚Waste‘.

15

English

2.3 FILLING WATER IN - COMMISSIONING THE FILTER

2.3.1 INSTALLATION WITH BUILT-IN SKIMMER

After the swimming pool has been lled with

water up to at least the middle of the surface

skimmer, the water automatically runs into

the pump. If necessary, we recommend the

installation of a gate valve in addition. It can

be used to interrupt the water ow of the lter

system.

2.3.2 SYSTEM WITH SUSPENSION SKIMMER

Before the suction hose is connected to the

skimmer, it must rst be completely lled with

water.

2.3.3 FRAME POOL OR QUICK UP POOL

Please connect the suction hose and also the

return hose to the two hose ttings of the pool.

We recommend to install a suitable skimmer

offered by the pool manufacturer in addition.

This is usually connected with a separate

hose from the inside of the pool.

In no case should the 2 hoses simply hang

into the water and the lter system be installed

without a skimmer. This can and will not work

and there is a risk of irreparable damage to the

lter system/pump.

16

Assembly and Operating Instructions Sand Filter System without Pre-lter

English

2.4 RINSING THE QUARTZ SAND

(BEFORE COMMISSIONING)

Set the hand lever of the 6-way valve to the RINSE

position, switch the lter system on electrically. In

case of very long suction lines, it can take up to 2-3

minutes until the swimming pool water is pumped.

After water starts to be pumped, drain the water into

the sewage system for about 1 minute to prevent an

abrasion of quartz sand from entering the swimming

pool via the inlet nozzle. Then set the valve to

“Rinse” for 30 seconds (see also section 3.2).

Warning! Please operate the 6-way

valve only when the lter pump is

switched off.

Otherwise there is a danger of destroying

the 6-way valve!

2.5 FILTER – OPERATION

Set the hand lever of the 6-way valve to FILTER.

The quartz sand lter for a mechanical water

treatment of your swimming pool is now ready for

operation. Switch the lter system on.

2.6 SETTING THE FILTRATION TIME

The operating time of the quartz sand lter depends

on swimming pool size (water volume), bather load,

weather and the used chemicals.

Example: It is recommended to recirculate the

pool volume 1 to 1.5 times in 24 hours.

If a pool volume of 10 m³ is circulated 1.5 times, a

total of 15 m³ must be circulated. If the pump has

an output of 6 m³ per hour, the operating time of the

lter is approx. 2.5 hours. To achieve an optimal

mechanical cleaning, the lter should be running

without interruption during this time.

Attention: On hot days, the lter time must be

increased to ensure a sufcient disinfection.

(Example: 2 hours in the morning and 2 hours in the

afternoon.) The lter system must also be switched

on on rainy days, as organic impurities get into the

swimming pool via the rainwater, which promotes

algae growth!

2.7 CONNECTING THE SAND FILTER

SYSTEM TO THE POOL

A connecting hose to the skimmer of your pool

(where the dirty water is drawn in) is laid on the suc-

tion side of the pump (horizontal hose connection).

The cleaned water is fed back into the pool via a

connecting hose between the valve of your lter system (the valve has 3 black hose adapters which are

labeled as follows: Return, Waste and Pump) and

the hose adapter labeled ‘Return’.

3

RETURN

2

PUMP

WASTE

3

1

2

Assembly and Operating Instructions Sand Filter System without Pre-lter

17

3. REGULAR BACKWASHING

Clean the lter (backwashing) once a week.

To be able to determine when to carry out a lter

cleaning (BACKWAHING), we recommend to use a

pressure gauge. Systems with pressure gauge allow

reading the pressure off the gauge. If the pressure

increases by 0.3 bar (max. 0.6 bar), a backwashing

must be carried out. A weekly backwashing of

the lter is recommended, even if this value is not

reached. This ensures that the lter sand remains

loose and does not stick together. Pressure gauges

for our lter system are available separately (article

no.: 2600020). Please contact your dealer, if

required.

Attention: Rell the missing water

level in the pool with fresh water after

backwashing!

3.1 BACKWASHING

Set the 6-way valve to BACKWASH.

Switch the lter system on. When the pumped water

is clean, the backwashing process is completed,

which should take 3 minutes at the most.

Set the 6-way valve to FILTER or RINSE (switch the

power supply off rst).

3.2 RINSE

The 6-way valve optionally also allows draining

parts of the residual dirt after backwashing into the

sewer system instead of the swimming pool.

4. MAINTENANCE WORKS

4.1 MAINTENANCE OF FILTER TANK

The gate valves must be closed during mainte-

nance works and be reopened after completion of

these works.

The ll level and condition of the quartz sand must

be checked once a year. The sand must ow loosely

through the hand! If lumps are formed, the quartz

sand must be replaced completely. See Section 2.2

‘Filling’.

4.2 MAINTENANCE OF CIRCULATION PUMP

Switch the pump off, set the 6-way valve to

CLOSED. Observe point 1.1.2! In the winter, empty

the pump completely and store it in a frost-free

place; turn the motor shaft occasionally to prevent

the shaft from becoming encrusted by limescale

deposits.

4.2.1 MOUNTINGS

The two engine mounts are self-lubricating

and do not require maintenance.

4.2.2 SHAFT SEAL

The shaft is equipped with a mechanical seal

which may leak after prolonged operation. We

recommend purchasing a new pump when

this happens.

4.2.3 MOTOR

No special maintenance required.

English

To do this, set the 6-way valve to RINSE. Switch the

lter system on for a maximum of 30 seconds, then

reset the 6-way valve to FILTER.

4.2.5 MAINTENANCE OF 6-WAY VALVE

This valve is maintenance-free. It is important, however, that the pump is always rst

switched off before changing the position.

18

Assembly and Operating Instructions Sand Filter System without Pre-lter

English

4.3 GENERAL MAINTENANCE

• The swimming pool must be maintained and

serviced in accordance with the manufacturer’s

instructions.

• The skimmer strainer in the surface skimmer

must be cleaned regularly at short intervals.

• It is important to ensure that the water level in the

pool never falls below the middle of the skimmer

at least (minimum lling level).

5. TAKING OUT OF OPERATION

• The swimming pool must be winterized in accord-

ance with the relevant instructions of the pool

manufacturer.

• The lter system must be winterized if there is a

risk of frost. The following should be observed:

Drain the water from the lter tank through the

drain plug at the bottom of the lter tank.

• The pipes from and to the swimming pool must

be emptied completely.

• Switch off the power supply (set to 0), unplug the

earthed plug (Schuko).

• Remove the quartz sand from the lter tank and

store the entire lter system in a frost-protected

area (e.g. in the basement). Do not push or

transport the lled tank, otherwise there is a risk

of breakage.

6. TROUBLESHOOTING

6.1 PUMP DOES NOT DRAW IN WATER

AUTOMATICALLY OR THE PRIMING

TAKES VERY LONG

1. Check the suction line for leaks, as air is drawn in

if the line is leaking.

2. Check the water level in the pool. If the water

level in the skimmer is too low, the pump also

draws in air. Fill water in (increase water level) up

to the middle of the skimmer port.

3. Check whether the skimmer ap can be moved

easily and does no jam. Otherwise, the pump pri-

ming will be poor or the water column will always

break down. This can damage the pump.

4. Check whether the strainer basket in the skimmer

is clean, if necessary clean the strainer basket.

5. Check whether the gate valves in the suction and

pressures pipes are open.

6.2 INSUFFICIENT PERFORMANCE OF

CIRCULATION PUMP

1. Filter is dirty; it must be backwashed.

2. Gate valves in the system are not fully open.

3. Skimmer basket in skimmer dirty? Cleaning required.

4. Suction line leaking, pump draws air in.

Assembly and Operating Instructions Sand Filter System without Pre-lter

19

6.3 CIRCULATION PUMP IS TOO NOISY

1. Filter is dirty; it must be backwashed.

2. Remove foreign particles from the pump, unscrew

pump housing, clean housing and impeller.

3. Motor bearings are too noisy, replace the entire

motor complete with impeller.

4. The pump is standing on a bare wood oor or

concrete oor, resulting in a sound transmission

to the building (structure-borne sound). Place the

pump on a noise-damping insulating base (rubber,

cork, etc.).

6.4 CIRCULATION PUMP

DOES NOT START AUTOMATICALLY

1. Check whether the power line is live.

2. Check if the fuse is defective.

3. For AC pumps, check whether the capacitor is in

proper working order.

4. Check that the motor is in proper working order;

have the winding checked by an electrician.

5. Check whether the pump has got stuck (motor

shaft can be turned easily with a screwdriver, otherwise see 6.4). Attention: Carry out only after the

mains plug has been disconnected! Risk of injury!

Check whether the motor-protective circuit-breaker has been tripped; if so see point 6.2.

6.5 WATER DRIPPING FROM CIRCULATI-

ON PUMP BETWEEN PUMP HOUSING

AND MOTOR

1. During commissioning, it is possible that water

escapes in drops at intervals of approx. 2 minutes.

After a few hours of operation, when the seal has

run in, the dripping stops automatically.

2. If water is constantly leaking from this point, the

mechanical seal is defective.

6.6 QUARTZ SAND IS FLUSHED OUT OF

THE FILTER INTO THE POOL

1. Incorrect grain size (too ne). Special quartz

sand granulation 0.4 - 0.8 mm required.

2. Filter base in lter container damaged - replace

lter base.

3. 6-way valve damaged or dirty - replace/clean.

6.7 FILTER PRESSURE AT THE PRESSURE GAUGE DOES NOT DROP BACK

TO INITIAL PRESSURE AFTER BACKWASHING, OR INITIAL PRESSURE IS

TOO HIGH

1. Pressure gauge defective - replace.

2. Quartz sand hardened and/or clumped - lter sand

must be replaced.

3. Suction or pressure line too small or valve closed.

6.8 WATER IS NOT CLEAR

1. Insufcient disinfection (chlorination), which cau-

ses an overload of the lter; check and adjust

chlorine and pH value in respect of specied

values.

2. Filter is too small.

3. Circulation time is too short.

4. If necessary, use occulant for quartz sand lters.

5. Insufcient lter backwashing operations cause

short lter run times.

6.9 SWIMMING POOL LOSES WATER VIA

THE FILTER SYSTEM

1. Gaskets in 6-way valve damaged - replace.

2. Feed pipe from swimming pool is leaking.

English

20

Assembly and Operating Instructions Sand Filter System without Pre-lter

WHAT TO DO IF...?

Tips for troubleshooting in case of problems that may occur during setup:

English

Problem Description of problem Possible causes Possible remedial measures

Filter systems / Pumps Insufcient or no lter

performance

Pump does

not star t

Engine noise

but no lter

performance

Pump leaking Mechanical seal is defective Pump must be returned for repair

Sand in pool Used lter sand has

Filter tank/

pipes leaking

No water ow from pool to

lter system and back.

Air intake via suction pipe Check connection piece and seals

Mechanical seal is defective Pump must be replaced

Excessive suction lift Correct pump height or use a check

Pre-lter or skimmer without water

(level)

Filter is clogged Backwash in case of sand lter.

Diameter of suction line

too small

Pump not properly mounted Fix pump correctly

Foreign particles in the pump Clean pump

Pump impeller or

shaft is defective

Incorrect voltage Compare pump voltage with mains

Foreign particles in the pump Clean pump

Thermal protection relay has

responded

No voltage Reset the fuse

Motor is blocked Pump must be returned for repair

Foreign particles in the pump Clean pump

Motor is blocked Pump must be replaced

incorrect granulation

Multi-way valve defective Replace multiway valve

Riser pipe/lter base defective Pump must be returned for repair

Screw connections not

properly tightened (too loose)

No sealing Seal with Teon tape

Mechanical damage Replace defective parts.

Hoses on pump and valve are not

mounted/connected correctly.

on the suction side Teon tape may

possibly be missing

valve

Fill up water in pool

Clean/change system or cartridge

Convert to piping system or use larger

diameter

Pump must be replaced

voltage

Reset thermal circuit breaker and

determine cause

Observe manufacturer's instructions/

use only original lter sand

Retighten/retension screw connections

Please check again if all hoses have

been mounted correctly on valve

or pump (see pages 4 and 5 of this

manual).

Assembly and Operating Instructions Sand Filter System without Pre-lter

WARRANTY

Please note the following in case you want to assert a warranty claim:

21

• We offer a 2-year warranty for our products,

starting from the purchase of the product. During

this period, we warrant that the products delivered

by us are free from manufacturing and/or material

defects.

• Our warranty obligation shall not extend to

defects, errors or damage that are the result of

improper or violent use by the customer or third

parties who are not responsible. Furthermore, the

warranty is excluded in case of force majeure.

• In case of transport of the defective product

within the warranty period, we will bear the costs.

Outside the warranty period, the customer has to

bear the costs.

• In case of a free replacement delivery, this

does not lead to an interruption of the period of

limitation in accordance with §212 BGB (German

Civil Code).

• Furthermore, we assume no guarantee for

wearing parts, for cases of poor maintenance

and for consequential damages due to the use of

impermissible supplies.

• The same applies to non-compliance with opera-

ting or maintenance instructions, overuse/over-

To ensure a prompt, trouble-free and uncomplicated processing of your complaint, it is

important that the registration form is completely lled out in block letters and submitted

together with all required documents (proof of purchase or sales receipt/photos). A proof of

purchase like a sales receipt is a mandatory prerequisite for all warranty claims. Without proof of

purchase, it is unfortunately not possible for us to acknowledge/process a complaint. Relevant photos

regarding your complaint will help us to evaluate the facts more quickly. This will save both you and us

unnecessary costs and waiting times/delays.

straining or other interventions in the delivered

goods, in cases where modications are made

to the delivered goods, parts are replaced or

consumables are used for these products that do

not meet the original specications.

• Customer claims for damages, e.g. for non-performance, culpa in contrahendo, violation of

secondary contractual obligations, consequential

damages caused by a defect, unlawful acts and

other legal grounds are excluded. This does not

apply to the liability for lack of a guaranteed property, intent or gross negligence. In particular, no

damages are paid for water and chemicals that

had to be drained due to a leakage in your pool.

English

By post to: Waterman Customer Service

Bahnhofstr. 68, 73240 Wendlingen/Germany

By fax to: + 49 (0) 7024/4048-667

By E-mail to: service@waterman-pool.com

You can download the registration form here:

http://waterman-pool.com/#downloads

Place* Date* Signature*

I want to submit the following complaint

(Please include a precise description):

the product (model) with article number

I bought from (company) at (Postcode/Town)

*Required information/documents

processed faster and unnecessary costs and waiting times

are avoided for all involved.

It is mandatory that you attach a proof of purchase*

to your claim! (A proof of purchase like a sales receipt is

a mandatory prerequisite for all warranty claims. Without

proof of purchase, it is unfortunately not possible for us to

acknowledge/process a complaint).

Please attach relevant photos* of the damage to

your complaint! (Photos of defective item.) These allow us

to better evaluate the facts. In addition, the complaint can be

Waterman Customer Service

Bahnhofstr. 68

73240 Wendlingen/Germany

Tel.: + 49 (0) 7024/4048-666

Fax: + 49 (0) 7024/4048-667

E-mail: service@waterman-pool.com

Registration of complaint

regarding sand filter system

E-mail*

Fax

Mobile

Phone*

Postcode/City*

Address*

Name*

Your contact data

The sand lter system alone cannot ensure and provide clear swimming pool water.

The sand lter retains smallest dirt particles and removes

them from the water circulation during backwashing.

An additional treatment of the water plus disinfection, e.g. based on chlorine or oxygen,

is always required. For further information about water treatment, see here:

http://www.planet-pool.de http://www.summer-fun.info

CUSTOMER SERVICE

Thank you for purchasing one of our products.

Our products are subject to stringent nal quality

checks. It can nevertheless not be excluded that

malfunctions or defects may occur. If, contrary to

expectations, the purchased product should not

function properly or should otherwise not be in good

order, please contact our customer service directly.

As a matter of course, our customer service is

available for you also after the warranty period.

PLEASE DO

NOT RETURN TO

THE STORE!

Questions? Problems? Missing parts?

Please contact our customer hotline if you

need any help.

Waterman Customer Service

Bahnhofstr. 68, 73240 Wendlingen/Germany

Tel.: +49 (0) 7024/4048666

Fax: +49 (0) 7024/4048667

E-mail: service@waterman-pool.com

Loading...

Loading...