Water-Loo Portable Skid Toilet Operation Manual

Portable Skid Toilet

Patents Pending

Operations Manual

Revised 13 May 2005

STARTUP

Before using, turn on air compressor in the control

cabinet (shown on page 6) and fill water tank (page 3).

Flush a few times until water completely fills the system

(twice usually does the job). Flush by pushing and

momentarily holding the flush button at the rear of the

stool. Toilet is ready for use.

ABOUT THIS OPERATION MANUAL

The purpose of this manual is to familiarize you with how

FCM’s portable toilet system operates. This manual

contains information for the proper operation and

maintenance of the following:

Air Line Components

Microflush Air Operated Toilets

On-Board Sewage Treatment Systems

Chlorinators and Chlorine

Water Tank

Satellite “Blue Room”

To get familiar with this easy to use toilet system simply

page through this manual and read the instructions with

the accompanying photographs.

HOW THE MICROPHOR SYSTEM OPERATES

AIRLINE COMPONENTS FUNCTIONS

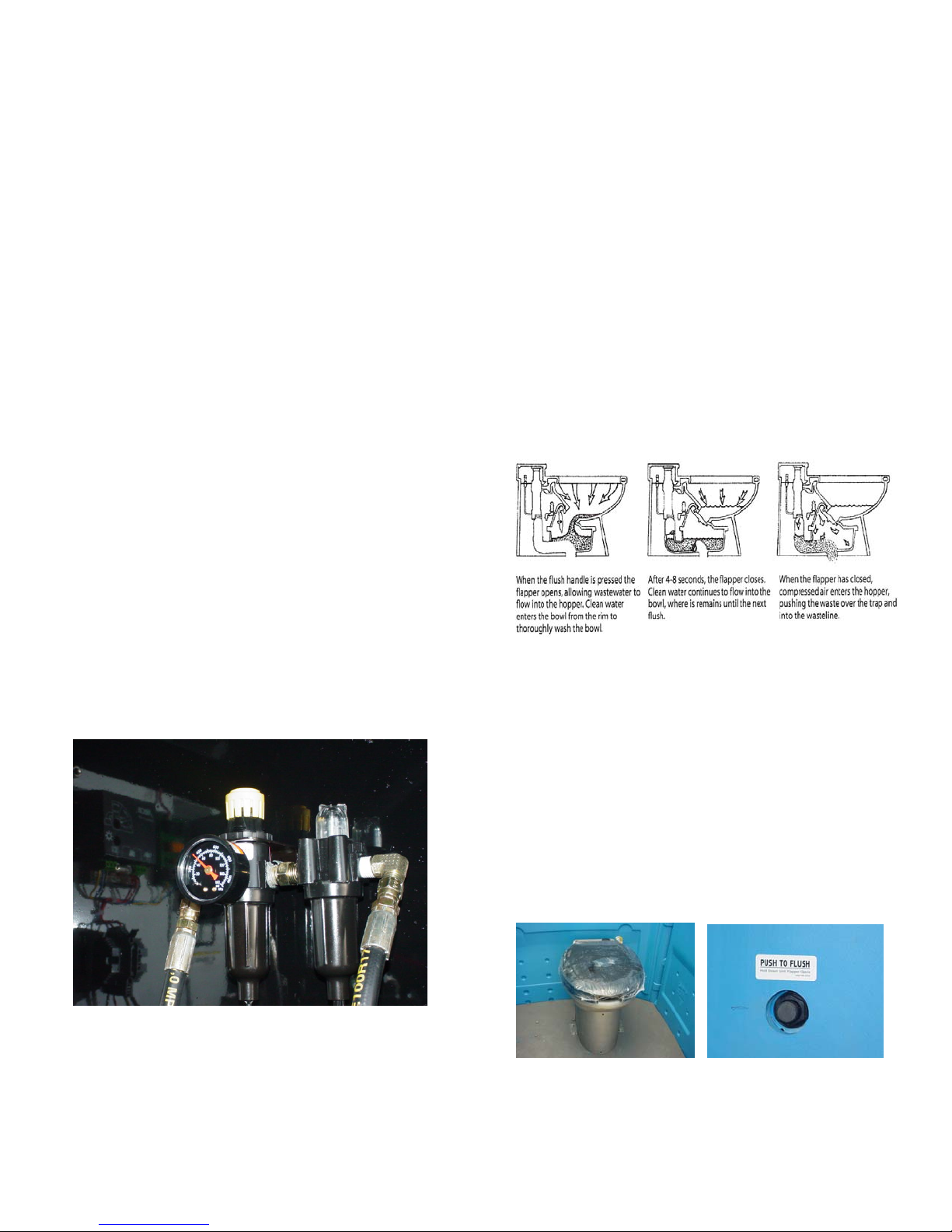

The Air Filter-Regulator (left bowl) removes moisture and

dirt from the air line to the toilet to prevent damage.

Regulator is preset to 60-65 psi of pressure.

screw is located on the top of the oiler. Turning

clockwise decreases the amount of oil, and counterclockwise increases the amount of oil.

NOTE: Make sure the air supply is shut off before the

air line lubricator is opened to fill with oil.

TOILET FUNCTION

Human waste enters the Microphor Air Operated Toilet.

When the toilet is flushed, the flapper at the bottom of

the bowel opens allowing the effluent (waste water) to

enter the hopper below. At the same time fresh water

from the rim washes the bowl. After about six seconds

the flapper closes and fresh water fills the bowl. At the

same time compressed air enters the hopper and

pushes the influent through the waste line into the

Treatment Tank.

TOILET REQUIREMENTS

Air: Supply compressed air at 60-65 psi at the

toilet.

Water: Gravity fed

Flush Activator: Toilet mounted at the rear.

Some units may have an optional remote

mounted flush activator button.

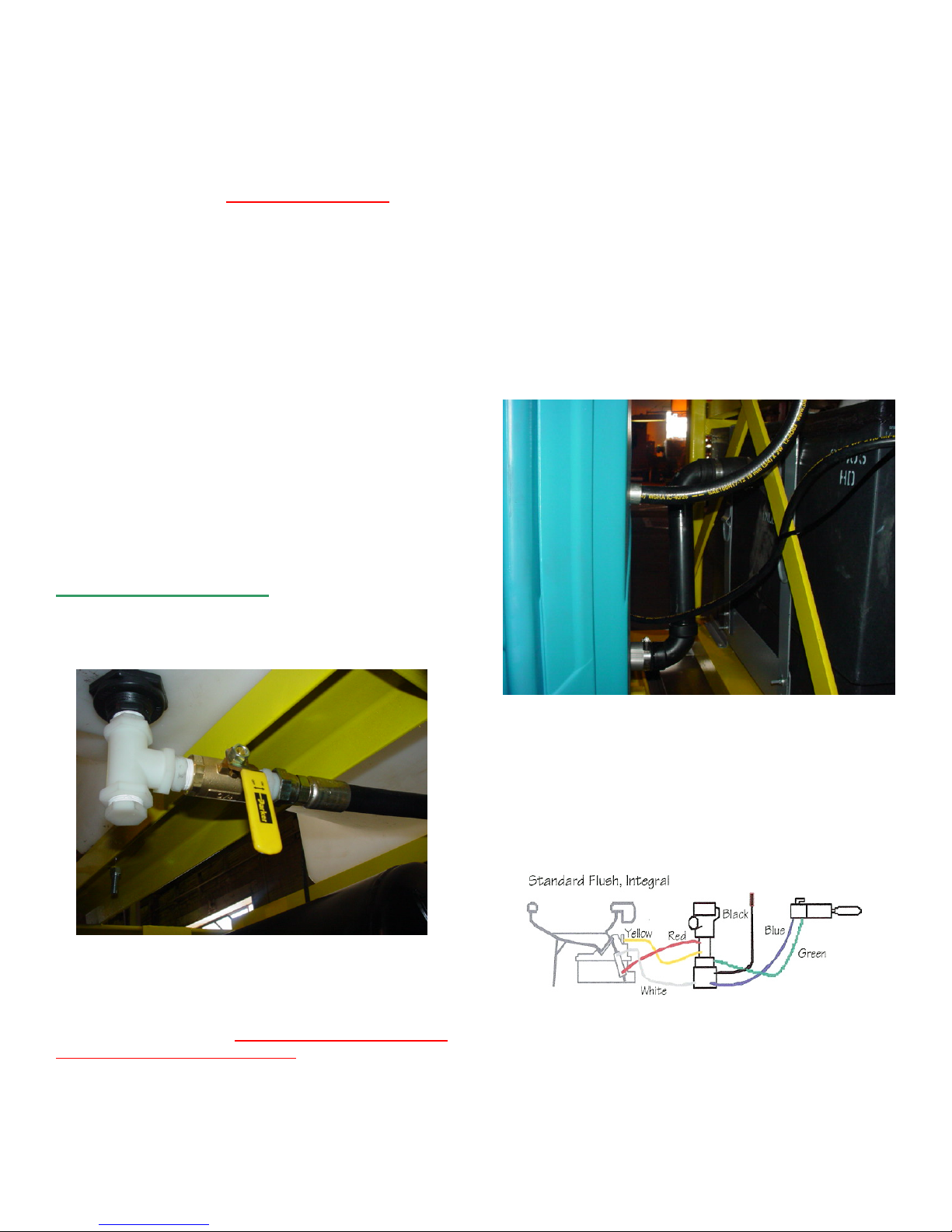

Air/Water Valve: The air and water (A/W)

sequence valve is the air controlled valve that

operates the toilet. The valve is mounted at the

rear of the toilet stool where the water line

enters the stool.

The Air Line Lubricator (right bowl) adds a small amount

of lubricant to the air system to help lubricate the moving

components of the toilet. Use a silicone based air tool

oil for best protection. A check should be made

periodically to determine if there is enough oil to

lubricate the toilet parts. The oiler should be adjusted to

add one drop of oil per flush. The slotted adjustment

Stainless Steel Stool Remote mounted flush activator

2

CLEANING the TOILET

Use Microphor’s Micro-Clean Organic Spray

Cleaner, P/N 24542 or equivalent.

NOTE: Sanitizers like Lysol, Pine-Sol, Hezol or

Ammonia base products

sanitizers when flushed into the treatment tank can stop

the biological action. Never use any anti-bacterial

product in the Microphor System.

WINTERIZING the TOILET

If the toilet system is taken out of service during freezing

conditions and propylene glycol has not be added to the

water supply, turn off water line to toilet, drain water

tank, flush toilet until no more water flows into bowl.

Flush once more to clear ejection chamber under toilet.

To reactivate: fill water tank, turn on water line and flush

toilet. When outside temperatures are consistently

above freezing use water only without any additives.

USING the TOILET in FREEZING CONDITIONS

For freeze protection during freezing conditions add

food grade propylene glycol to water supply. A 30%

mix protects to about 12˚F and a 60% mix protects to

about minus 40˚F. Food grade propylene glycol is

available through chemical dealers everywhere.

should never be used. These

UNPLUGGING the TOILET

The system can only decompose human waste and

tissue. Heavy paper towels will not decompose and will

eventually clog the passages in the treatment tank. If

the toilet becomes plugged, a standard plunger can be

used to help unplug the unit. If the toilet is plugged, shut

off the water supply and disconnect the air supply.

Press the flush button several times to bleed off the air

pressure. When air pressure is out of the valve, the

flapper in the bottom of the toilet can be pushed open.

Use the plunger as with any standard toilet. If this does

not clear the toilet the waste line to the treatment tank

may be plugged. To clear the waste line remove flexible

junction just outside toilet cabana and clear with a wire

or flush with a stream of water.

Water shut-off valve and tank drain

Note: Never use ethylene glycol based products in

place of the propylene glycol. The alcohol based

products will shut down the bacteria action when flushed

into the treatment tank.

RV water systems cannot be used.

Products advertised to protect

Waste line and water supply line

TOILET AIR LINE COLOR CODE

TROUBLESHOOTING the A/W SEQUENCE VALVE

3

(Microphor #39014 bare or #95008 valve w/fittings)

If the A/W sequence valve becomes erratic the following

trouble shooting action can be taken:

A. Flush Button Sticks: If the flush button becomes

sticky and does not press down and return

freely, apply silicone lubricant directly onto the

shaft, press up and down until free.

B. Flapper Stays Open and Will Not Close: clean or

replace Bleed-Off Plug, Lubricate Air Cylinder

Rod.

C. Flapper will open and close rapidly, not allowing

unit to go through full cycle:

1. Check for air leaks

2. Hole in Bleed Plug could be oversized

due to wear or damage, replace plug.

3. Check valve in bottom cap of A/W is

malfunctioning:

a. Remove hoses attached to bottom of

valve (#1 & #2).

b. Unscrew bottom (#6) from valve.

c. Using a 7/16 nut driver, remove spring

retainer nut (#3) from inside of bottom

cap. Do not lose spring (#4) when

removing small check valve with rubber

O-ring (#5).

d. Clean all parts – blow out air passages

in bottom cap and needle before

reassembly.

e. Re-assemble in reverse order of above.

Note: these are Microphor part numbers

TREATMENT TANK FUNCTION

In the treatment tank, solid waste and toilet paper is

broken down by bacteria into liquid and gas. The gas

escapes out the tank vent. The liquid then flows through

the filters to the bottom of the treatment tank, then into

the chlorinator. Microphor recommends adding a cup of

Micro Culture monthly to insure proper operation.

TOILET HOPPER and COMPONENTS

Shown left to right to left are the following components:

Top Row:

1. Hopper Top w/Flapper, P/N 90040

2. Hopper, bottom only, P/N 90041

3. Hopper, complete, P/N 90039 (does not include

air cylinder)

4. Crank Assembly only, P/N 90042

5. Air Cylinder, P/N 94560

6. Flapper Assembly only, P/N 90048

7. Hopper O-Ring Seal, P/N 27270

TREATMENT TANK VENT

The vent in the treatment tank is a key part of the

Microphor treatment process. The vent allows oxygen

into the tank and also allows co

2

gas out of the tank.

This exchange is critical to the decomposition process.

Treatment Tank Vent

4

CHLORINATOR

In the Microphor process, the effluent from the treatment

tank flows through the chlorinator which is to be kept full

of chlorine slugs. The chlorinator is located on the side

of the treatment tank.

Chlorinator

The chlorinator should be filled as full as possible with

chlorine slugs while making a tight seal. Consumption of

chlorine is dependent upon frequency of use of the

system. Use product similar or equal to Microphor

Chlorinating Slugs (P/N 94135). Lubricate chlorinator lid

O-Ring before replacement.

CHLORINATOR FILLING INSTRUCTIONS –

Maintenance and Safety Procedure

1. Microphor recommends using rubber gloves and

goggles or a face shield. High ambient heat can

cause higher levels of chlorine vapor and may

require the use of a respirator, depending on

ventilation at chlorinator. (Refer to Material

Safety Data Sheet [MSDS] )

2. Inspect chlorinator for chlorine slugs by pressing

downward on cap while turning counter-

clockwise ¼ turn and then lift cap off very slowly.

If water is seen coming out around the cap,

replace cap immediately. Rectify blockage in

outlet of system.

3. If chlorinator is full of slugs, replace cap by

placing on the chlorinator body and, while

pressing down, turn clockwise until locking lugs

on cap engage chlorinator and it is sealed.

4. If slugs must be added, make sure any residual

chlorine at bottom is not blocking opening on

lower portion of chlorinator. If residual chlorine

is caked, carefully probe with a screwdriver or

similar tool to break up.

5. Add slugs until chlorinator is full. Lay slugs flat,

one on top of another, not on their edges. Refill

as much as possible with slugs, but do not

overfill, as this will put undue pressure on cap

and possibly cause damage or packing of slugs.

6. The chlorinator unit is designed to hold slugs

and seal off chlorine odors. Inspect the unit

carefully to make sure rubber cap seal or o-ring

on chlorinator body is in place and is lubricated

with silicone lubricant only. Inspect hoses,

clamps, etc. to make sure they are tight and in

good condition.

7. Chlorine is highly corrosive, causes skin and eye

damage, is irritating to nose and throat and may

be fatal if swallowed. Avoid breathing dust or

vapor.

8. ENVIRONMENTAL HAZARDS: Chlorine is toxic

to fish. Do Not dispose into lakes, ponds,

streams, estuaries, oceans or public waters

unless this product is identified and addressed in

a NPDES Permit. For guidance, contact the

regional office of the EPA.

9. PHYSICAL and CHEMICAL HAZARDS: Strong

oxidizing agent! Mix only with water. Do Not add

this product to any dispensing device containing

remnants of any other product. Such use may

cause violent reaction leading to fire or

explosion.

10. STORAGE and DISPOSAL: Keep this product

dry in a tightly closed container when not in use.

Store in a cool, dry, well ventilated area away

from heat or open flame. Shelf life is one year

from manufacturing date. Refer to MSDS for

disposal.

11. PRACTICAL TREATMENT (First Aid):

Eye/Skin Contact – Flush with plenty of water

for at least 15 minutes, while removing

contaminated clothing and shoes. For eye

contact seek immediate medical attention. If skin

irritation occurs, seek medical attention.

Inhalation – Relocate to fresh air. If signs of

irritation or discomfort occur, take immediately to

a hospital or physician. Swallowing – If

conscious, drink large quantities of water. Do

Not induce vomiting. Take immediately to a

hospital or physician. If vomiting occurs,

administer additional water. If unconscious or in

convulsions, take immediately to a hospital.

5

Loading...

Loading...