Waterloo F1878 User Manual [en, de, es, fr]

OPERATOR’S MANUAL

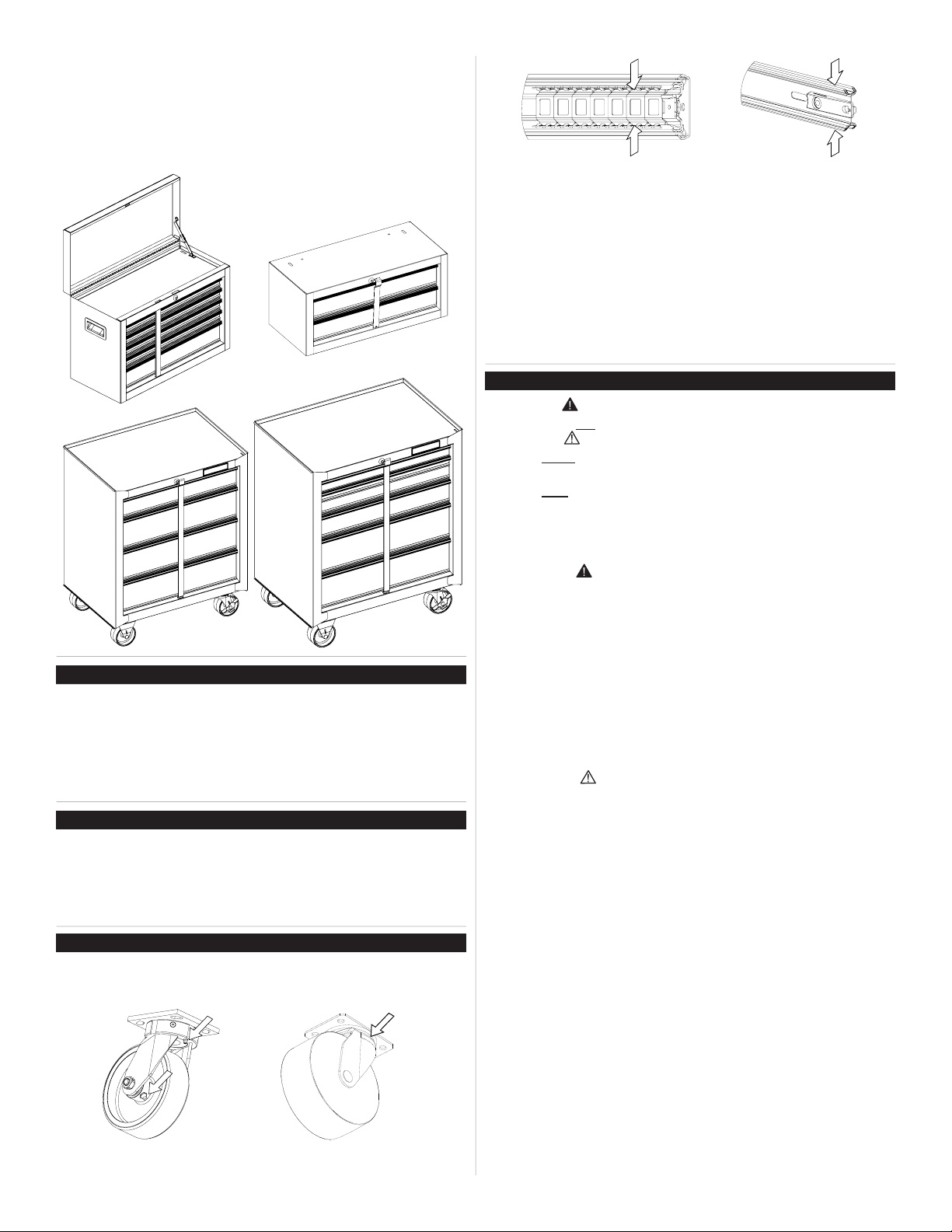

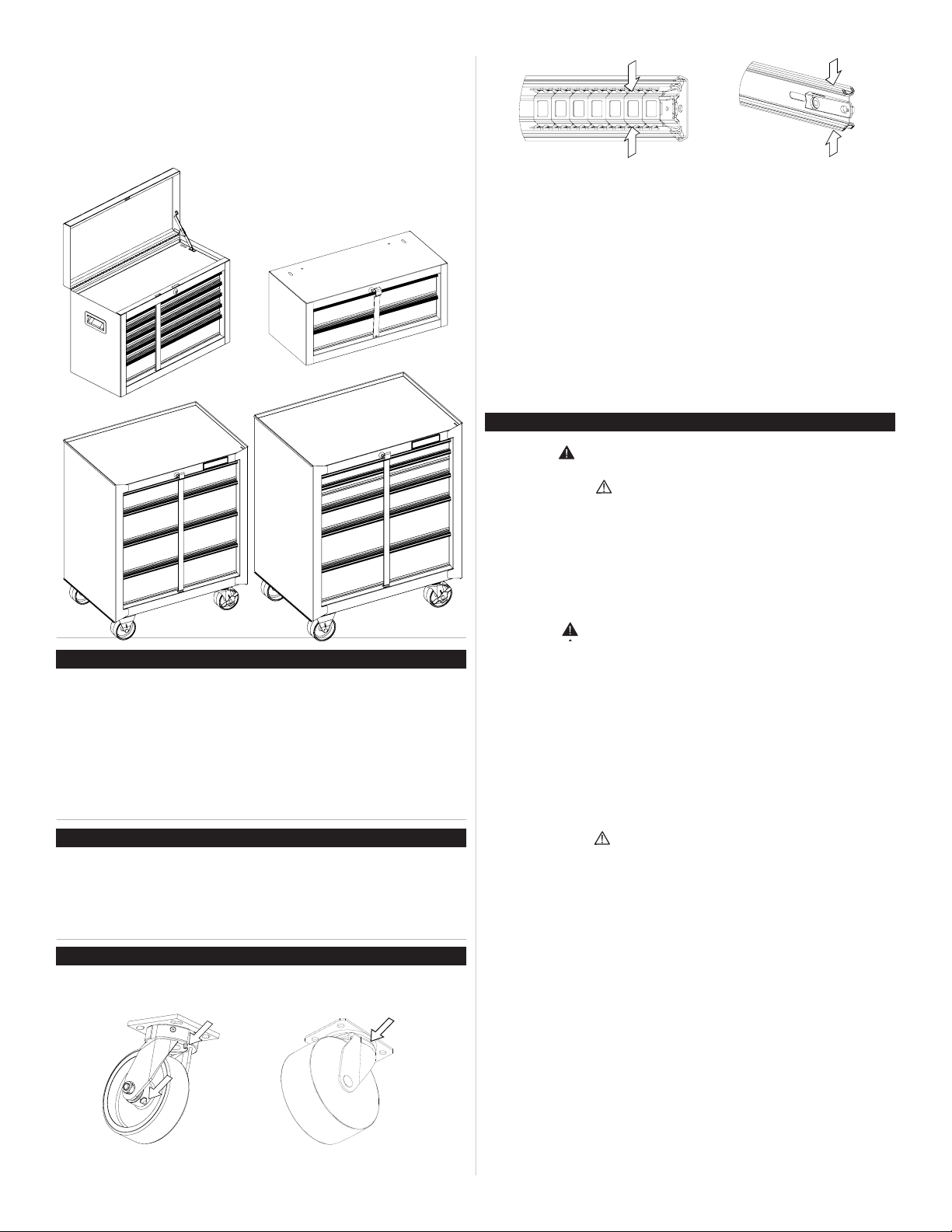

BASIC FRICTION OR BALL BEARING

CHESTS AND CABINETS

Some instructions and drawings may not apply

to your specic unit.

SERVICE PARTS

CALL 1-800-833-4405 FOR SERVICE PARTS. Refer to Service

Parts Drawing for full listing of Service Parts. Please have model

number ready at time of call.

LOCATING MODEL # INFORMATION

Model number and other information required for service parts is

on a label located on the back of the unit.

CAPACITIES

• The maximum weight for each drawer should be no more than

25 pounds.

• The maximum product weight, including contents, should be no

more than 500 pounds for cabinets; maximum including contents, 300 pounds for tool centers.

MAINTENANCE

• For casters, use high quality bearing grease (yearly).

• Lubricate the slides with grease or equivalent (twice yearly.)

Ball bearing slides

• Periodically the drawer fronts, drawer trim, and other surfaces

should be cleaned with a mild detergent and water.

• Auto wax will preserve the unit’s luster nish. Apply the wax as to

a car. The wax will also help protect the unit against scratches.

• Grease and oil can be removed with most standard cleaning

uids. For safety, use a nonammable cleaning uid.

• If drawer liners are supplied, it is recommended they are used

to protect the nish inside the drawers and to make the drawers

easier to clean. The drawer liners may be cleaned with soap and

water.

Friction slides

SAFETY

DANGER is used to indicate a hazardous situation which,

if not avoided, will result in serious injury or death.

WARNING indicates a hazardous situation which, if not

avoided, could result in serious injury or death.

CAUTION is used to indicate a hazardous situation which, if not

avoided, may result in minor injury, moderate injury, or property

damage.

CAUTION: Read and follow all Safety Rules and Operating

Instructions before rst use of this product.

DANGER

• DO NOT stand on this product. You may fall or cause product to

tip.

• DO NOT open more than one drawer at a time. The product may

become unstable and tip.

• DO NOT step in the drawers. You may fall or cause product to

tip.

• DO NOT mount this product on a truck bed or any other moving

object.

• DO NOT move the product prior to closing and locking all the

drawers. The drawers could come open and make the product

unstable and tip.

WARNING

• WEAR SAFETY GLASSES when removing or repositioning the

slides.

• DO NOT pull this product when moving it. Push the product to

prevent personal injury.

• USE THE BRAKES when not moving this product. This will

prevent the product from rolling.

• DO NOT alter this product in any manner. For example, do not

weld external lockbars or attach electrical equipment.

• Keep the product on level surfaces. The product may become

unstable and tip if stored or moved on an uneven surface.

• BE CAREFUL when closing the cover. Remove hands before

the cover closes completely.

• Lubricate lock with graphite (yearly).

Waterloo Industries, 139 West Forest Hill Avenue, Oak Creek, WI 53154, USA

CAUTION

• This product is not designed to be directly lifted with a fork lift, or

to be towed with any mechanical devices.

• The maximum weight for each drawer should never be exceeded.

• Only transport this product empty. Properly secure when transporting.

• DO NOT exceed maximum product weight, including contents.

See Capacities section for load rating.

F1878

HARDWARE

Tools Required:

3/8 inch wrench Screwdriver

7/16-in wrench 5/16-inch drill bit

CHEST HARDWARE INCLUDED:

1/4 - 20 x 5/8" Screw (Qty: 4)

CARTON CONTENTS

Hardware bag

Caster Pack

Literature

ASSEMBLY

NOTE: Not all assembly instructions will apply to your

model.

WARNING

Remove wooden work surface or rubber mat, if any,

before attaching chest(s) to the cabinet.

1/4 - 20 Nut (Qty: 4)

INTERMEDIATE CHEST HARDWARE INCLUDED:

1/4 - 20 x 5/8" Screw (Qty: 4)

1/4 - 20 Nut (Qty: 4)

CABINET HARDWARE INCLUDED:

1/4 - 20 x 5/8" Screw (Qty: 16)

1/4 - 20 Nut (Qty: 16)

TO ATTACH CHEST

Process:

· Remove enough drawers to access the top and bottom

mounting surfaces of the units. Refer to drawer removal

instructions.

· Place the chest in the desired location on top of the cabi-

net or intermediate chest and mark the mounting hole

locations onto the cabinet top.

· Remove the chest and drill two 5/16" (8mm) holes

through the top of the cabinet or intermediate chest.

· Secure the units together using two 1/4 - 20 x 5/8"

screws and nuts at each joint. The hardware is provided

in the bag located in the top tray of the chest.

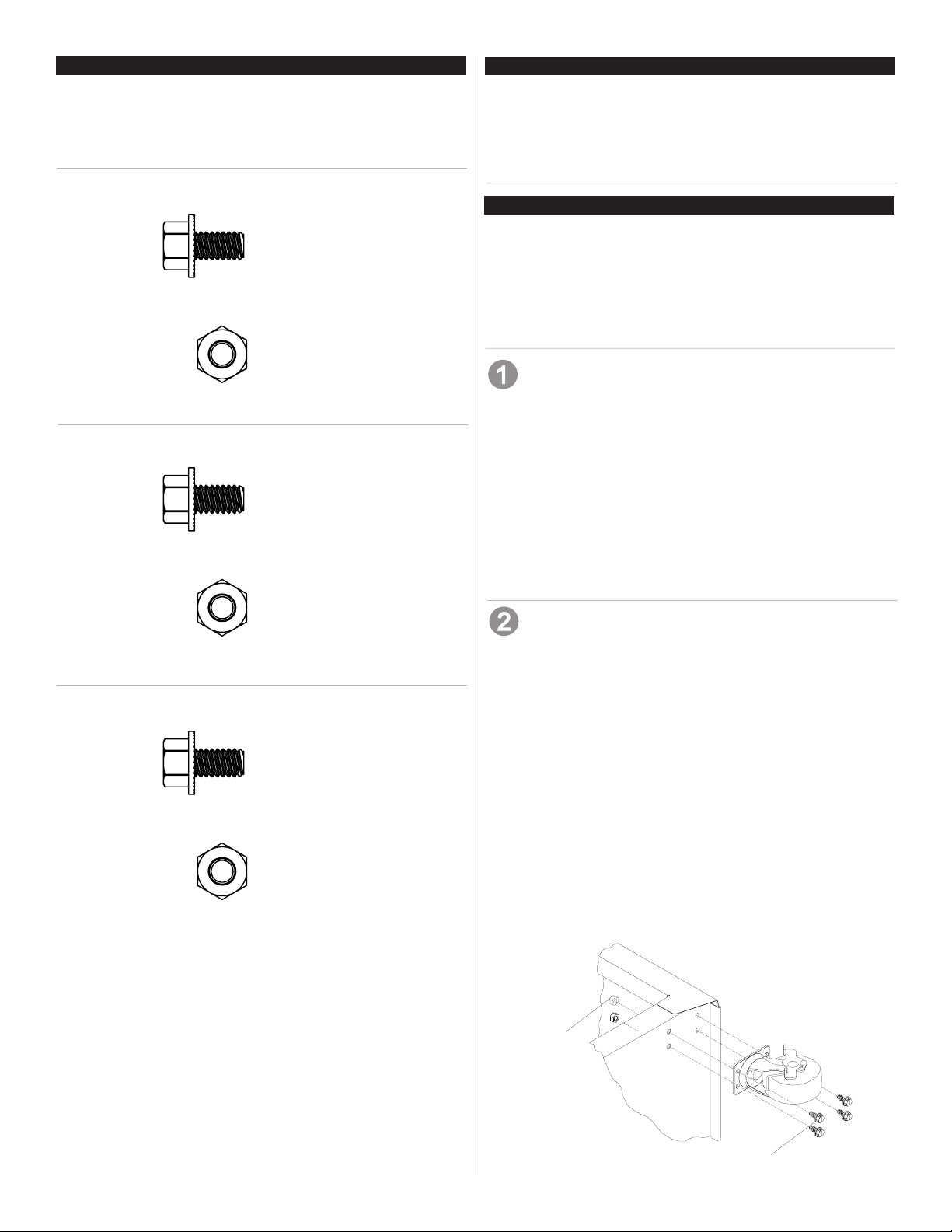

CASTER INSTALLATION

Items Needed:

1/4 - 20 x 5/8" Screw (Qty: 16)

1/4 - 20 Nut (Qty: 16)

7/16-in Wrench

3/8-in Wrench

Process:

• Remove bottom drawers. (See Operation Section, Part

B.)

• Lay the cabinet on its back. Use packaging material to

protect the nish.

• Mount both swivel casters on the same side of the unit

as the side handle.

• Attach the casters using (4) 1/4 - 20 x 5/8" screws and

(4) 1/4 - 20 nuts per caster.

• Wrench tighten all screws. It is recommended not to

exceed 80 inch pounds of torque.

• Return the unit to its upright position.

• Reinstall bottom drawers.

Nut

Screw

2

OPERATION

NOTE: Not all operation instructions will relate to your

model.

TO LOCK CHEST

Process:

▪ Make sure drawers are fully closed.

▪ Insert the lockbar (which stores in the top tray), tabbed

end up, into the slot in the top tray and down into the slot

in the base.

▪ Close the cover and lock with the key.

TO UNLOCK CHEST

• Reverse above procedure.

TO LOCK INTERMEDIATE CHEST

The lockbar for the intermediate chest is stored in the

top drawer.

Process:

▪ Insert the lockbar into the slot in the base.

▪ Move the lockbar toward the unit until the bent end ts

into the slot near the lock.

▪ Lock with the key.

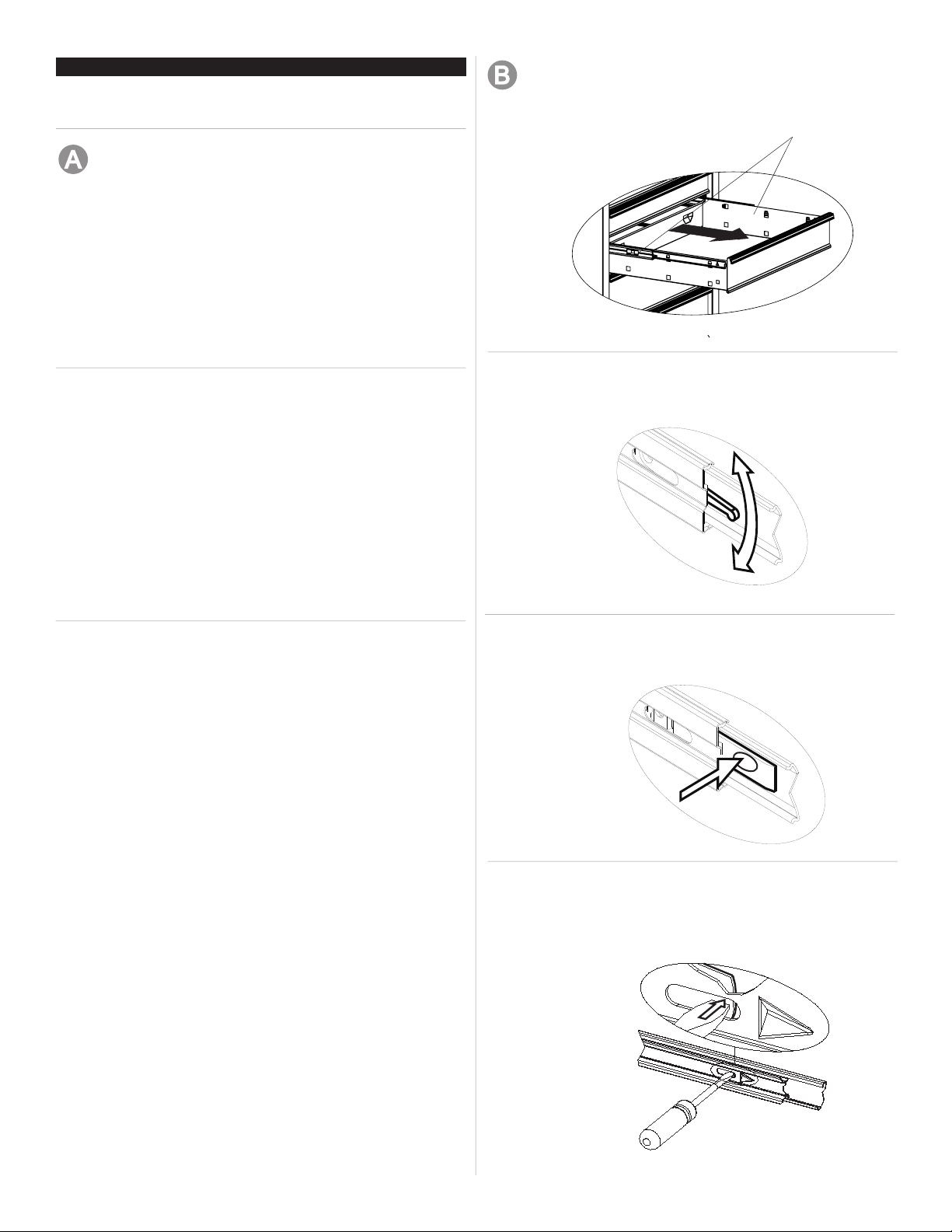

REMOVING DRAWERS

• Empty the drawer.

• Fully extend the drawer.

Release

Lever Style - Lift or lower (depending on the slide) the

release lever on both sides, (this allows the slides to ride

over the stops.) Pull out to remove.

TO UNLOCK INTERMEDIATE CHEST

▪ Reverse above procedure.

THE LOCKBAR FOR THE ROLLER CABINET IS

STORED IN A SLOT IN THE TOP FRONT CORNER OF

THE UNIT.

TO LOCK ROLLER CABINET

Process:

▪ Insert the straight end of the lockbar into the slot in the

base.

▪ Move the lockbar toward the unit until the bent end ts

into the slot near the lock.

▪ Lock with the key.

TO UNLOCK ROLLER CABINET

▪ Reverse above procedure.

NOTE: If your unit is equipped with a storage compartment

with a panel at the bottom, pull panel out, lift up and push

panel back into unit to gain access to compartment.

Tab Style - Depress the release tabs on both sides,

(this allows the slides to ride over the stops.)

Pull out to remove.

Friction Style - Fully extend the drawer. Insert screwdriver

into the slot in the side and push in on the stop until it

clears the lance. Pull drawer just past lance before

releasing stop. Repeat the process for the other slide.

3

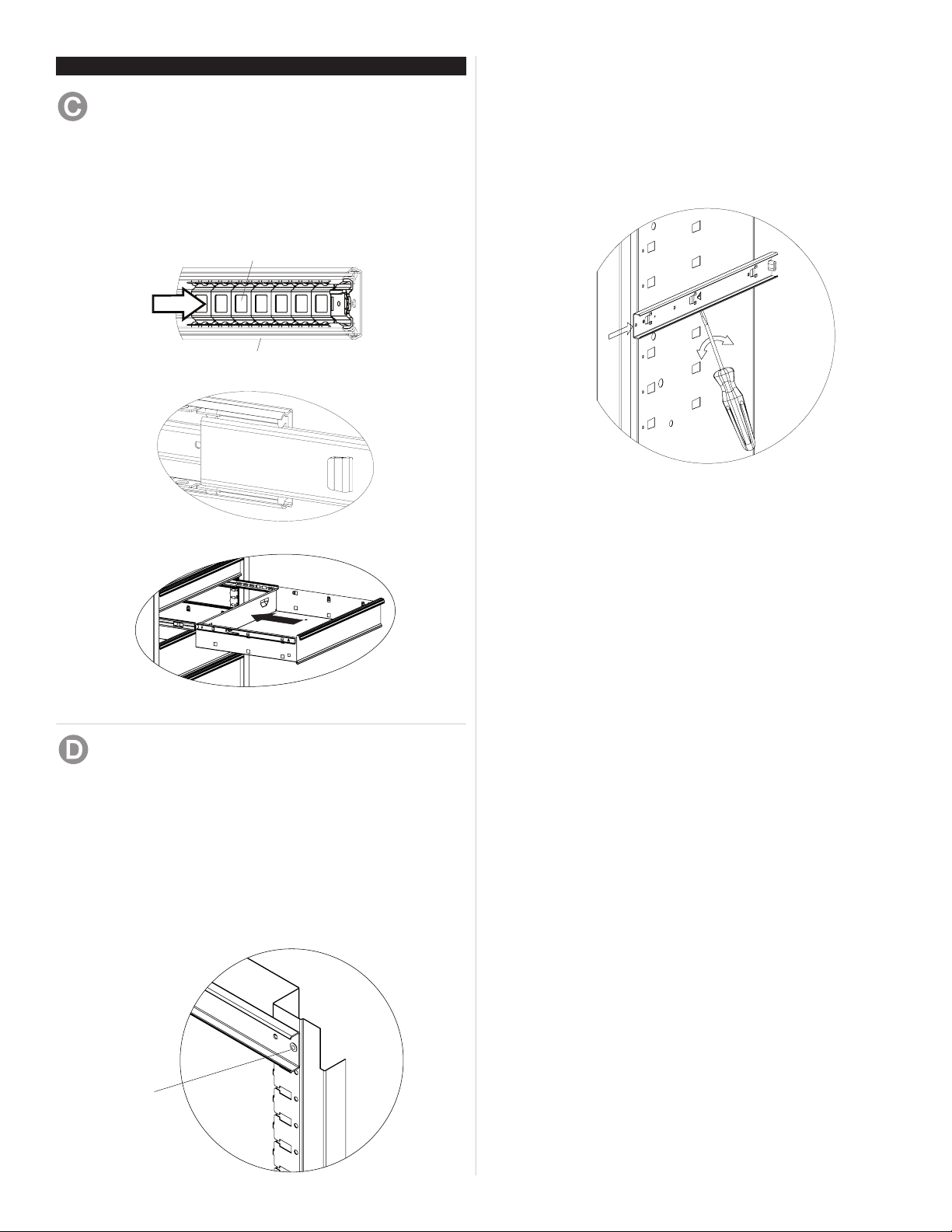

OPERATION

INSTALLING DRAWERS

Ball bearing slide - Pull slides and slide carrier out to fully

extended position (see illustration.) Hold the slide on the

cabinet while aligning it with the slide on drawer. Slightly

insert one side and repeat for the other side. Slowly push

drawer to its fully closed position to engage slide. Open

drawer and reclose to ensure proper operation.

slide carrier

slide

Snap-In Style -

• First remove the drawer. (See section B.)

To remove the slide:

• Insert at tip screw driver between slide and unit, behind

rear rectangular cutout.(See illustration.)

• Rotate screw driver ¼ turn to force slide away from unit.

• Push on front of slide pushing it towards back of the unit.

To attach the slide:

• Locate lances within respective cutout in carrier.

• Pull slide forward until slide locks back into place.

• Reinstall drawer following drawer installation procedure.

(See section C.)

REMOVING AND INSTALLING SLIDES

Rivet Style -

• To remove the slide from the unit, rst remove the

drawer.

• After removing the drawers drill out the rivets, use a

5/32-in drill bit. The rivets will need to be replaced.

• To reinstall the slide, place the slide in the appropriate

position in the unit and pull toward the front of the unit.

Replace rivets to secure slide to the unit.

• For smooth operation, make sure the drawers are

matched with their original slides.

Drill out rivet

4

MANUAL DE USUARIO

COFRES Y GABINETES DE FRICCIÓN BÁSICA O CON

COJINETES DE BOLA

Algunas instrucciones y dibujos pueden no aplicarse

a tu unidad especíca.

Cojinetes de bolas

• Lubrique la cerradura con grato (anualmente).

• Limpie con detergente suave y agua los frontales y los bordes laterales

de los cajones y las demás supercies.

• La cera para automóviles preservará el acabado brilloso de la unidad.

Aplique la cera como lo haría al carro. La cera también ayudará a proteger la unidad contra raspones.

• La grasa y el aceite pueden retirarse con la mayoría de los líquidos

estándar para limpieza. Por razones de seguridad, utilice un líquido

incombustible para limpieza.

• Si se suministran forros para las gavetas, se recomienda que se utilicen

para proteger el acabado interno de las mismas y para facilitar la limpieza. Los forros para gavetas pueden limpiarse con agua y jabón.

Correderas de friccion

SEGURIDAD

PELIGRO se utiliza para indicar una situación peligrosa que, de

no evitarse, resultará en lesiones graves o la muerte.

ADVERTENCIA indica una situación peligrosa que, de no

evitarse, podría producir lesiones graves o la muerte.

PRECAUCIÓN se utiliza para indicar una situación peligrosa que, de

no evitarse, puede derivar en lesiones leves o moderadas, o en daño a la

propiedad.

PIEZAS DE SERVICIO

EN ESTADOS UNIDOS LLAME AL 1-800-833-4405 PARA

PIEZAS DE REPUESTO. FUERA DE ESTADOS UNIDOS

LLAME A SU DISTRIBUIDOR LOCAL. Suministre el número de

modelo al comunicarse.

UBICACIÓN DE INFORMACIÓN DEL NO. DE MODELO

Los número de modelo y la otra información necesaria para obtener partes de repuesto, se encuentran al dorso del gabinete.

CAPACIDAD

• El peso máximo en cada gaveta no debe ser mayor de 11,4 kg. (25

pounds)

• El peso máximo del producto, incluyendo el contenido, no debe ser más

de 500 lb para los gabinetes; como máximo incluyendo el contenido, de

300 libras para los centros de herramientas.

MANTENIMIENTO

• Para las ruedas, utilice grasa para rodamientos de alta calidad (anualmente).

ATENCIÓN: Lea y siga todas las Normas de Seguridad y las Instruccio-

nes de Funcionamiento antes de utilizar por primera vez este producto.

PELIGRO

• NO se ponga de pie sobre esta unidad. Puede caerse u ocasionar que

el producto se vuelque.

• NO abrir más de un cajón a la vez. El producto podría quedar inestable

y volcarse.

• NO utilice las gavetas como peldaños. Puede caerse u ocasionar que

el producto se vuelque.

• NO monte este producto en una cama de carro o ninguÌn otro objeto

móvil.

• NO mueva la unidad antes de cerrar y asegurar todas las gavetas. Las

gavetas podrían abrirse y hacer que la unidad se vuelva inestable y se

vuelque.

ADVERTENCIA

• USE GAFAS DE SEGURIDAD al quitar o volver a poner las corred-

eras.

• NO hale la unidad, empújela cuando la mueva.

• UTILICE LOS FRENOS cuando el producto no esté en movimiento. Esto

impedirá que se deslice.

• NO altere la unidad en modo alguno. Por ejemplo, no suelde las barras

de sujeción externas ni le incorpore equipos eléctricos.

• Mantenga la unidad en supercies niveladas. La unidad puede tornarse

inestable y volcarse si se almacena o se moviliza en una supercie no

nivelada.

• TENGA cuidado cuando cierre la tapa. Quite las manos antes de que la

tapa cierre completamente.

• Lubrique las guías con grasa o equivalente (dos veces por año).

Waterloo Industries, 139 West Forest Hill Avenue, Oak Creek, WI 53154, USA

PRECAUCIÓN

• Este producto no está diseñado para ser levantado directamente con un

montacargas, ni para ser remolcado con unidades mecanizadas.

• Nunca debe exceder el peso máximo de cada gaveta.

• Sólo transporte esta unidad cuando esté vacía. Asegúrela adecuadamente cuando la transporte.

• NO exceda el peso máximo del producto, incluyendo el contenido. Ver la

Sección de Capacidades para capacidad de carga.

F1878

Loading...

Loading...