Waterline Technology HFC-1000, SF-1000, SK-100 Installation And Operation Manual

DDrriinnkkiinngg WWaatteerr SSyysstteemmss

IInnssttaallllaattiioonn aanndd OOppeerraattiioonnss GGuuiiddee

Thank you for choosing AlwaysFresh™

Water the Way you Want It!™

Your AlwaysFresh Drinking Water System will provide delicious tasting,

crystal clear water directly from the selected tap… water that’s great for

drinking, cooking, hot or cold beverages, rinsing fruits and vegetables,

and conveniently connects to your ice maker, instant hot tap, chiller or

built in coffee maker.

The HFC-1000 is certified for 1.5 gpm flow and currently the only

point of use drinking water system NSF/ ANSI standard 42/53

certified for Volatile Organic Chemical, and MTBE at this flow rate.

Most systems have to reduce the flow to 1/2 gpm to achieve similar performance. Now you can enjoy high flow and chemical reduction with

one system!

High flow rates are convenient as well as efficient. Connecting the

system to the existing cold water supply to the sink eliminates the

need (most of the time) for a separate dispensing tap. When con-

nected to the existing cold water faucet in your kitchen or at your bathroom sink, your family members are using filtered water for the

benefits of a more healthy lifestyle. The amount of filtered water used

for other purposes in the kitchen ie, dishwashing, hand washing is minimal and the design allows you to use the water freely and still maintain an annual cartridge maintenance interval for most homes.

AlwaysFresh uses exclusive carbon block technology:

Superior Chemical reduction and fine filtration are combined to

produce high quality drinking water with high flow rates. With the

surface area for adsorption and filtration of up to 3x the carbon

filtration area (of comparable size units) Alwaysfresh combines high

capacity, 1/2 micron fine filtration carbon block wrapped with a

5 micron prefilter, and as well as an silver zeolite technology for filter

protection & optimizing efficacy and longevity. It also includes a hard

water scale control system* that protects your water using appliances

that heat, chill or freeze water. Scale control will extend the life of these

water using appliances and the exclusive carbon block technology will

produce a superior quality of drinking water for your family.

All AlwaysFresh Drinking Water Systems must be maintained according

to the manufacturer’s instructions, including timely replacement of the

filter cartridge.

Do not use with water that is microbiologically unsafe, or of unknown

quality, without adequate disinfection before or after the system.

Systems certified for cysts reduction may be used on disinfected waters

that may contain filterable cysts.

Check for compliance with state and local laws and regulations.

Note: Some states require installation by licensed installers, and some

states prohibit the use of saddle valves.

Note: Claims of capacity or rated service cycle are not applicable for

mechanical filtration units because of broad variations in quality and

quantity of particulate matter found in drinking water.

All of the contaminants and other substances reduced by your system are not necessarily

in your drinking water. However, the system can reduce chlorine taste and odors, as well

as cysts and other particulates 1/2 micron(1/50,000 of an inch) and larger.

HFC-1000 conforms to NSF/ANSI 53 FOR VOC reduction. See performance data sheet for

individual contaminant and reduction claims.

These systems must be maintained according to the manufacturer’s instructions, including replacement of cartridge.

*Claim not certified for scale control

The Owner’s Guide is Applicable for the

following Model Numbers:

HFC-1000............................DWS Rated capacity: 500 gallons

SF-1000................................DWS Rated capacity: 1000 gallons

SK-100..................................DWS Rated capacity: 100 gallons

For optimum performance cartridge replacement is required once

per year or sooner if the flow rate becomes too slow or if capacity

is reached whichever occurs first!

Replacement components:

RC HFC-1000 RC SF-1000

INSTALLATION OF YOUR SYSTEM

It is important that the installation be clean and sanitary. It is

recommended that all water contact parts, fittings, tubing, faucet,

etc. … be immersed in disinfectant (a capful of laundry bleach per

gallon of water), at the start of the installation.

Most systems have the mounting bracket attached to the filter head

assembly to insure that the inlet and outlet fittings are always in the

same position. Reversing this mounting bracket could result in system being installed backwards and thereby reduce its usable life.

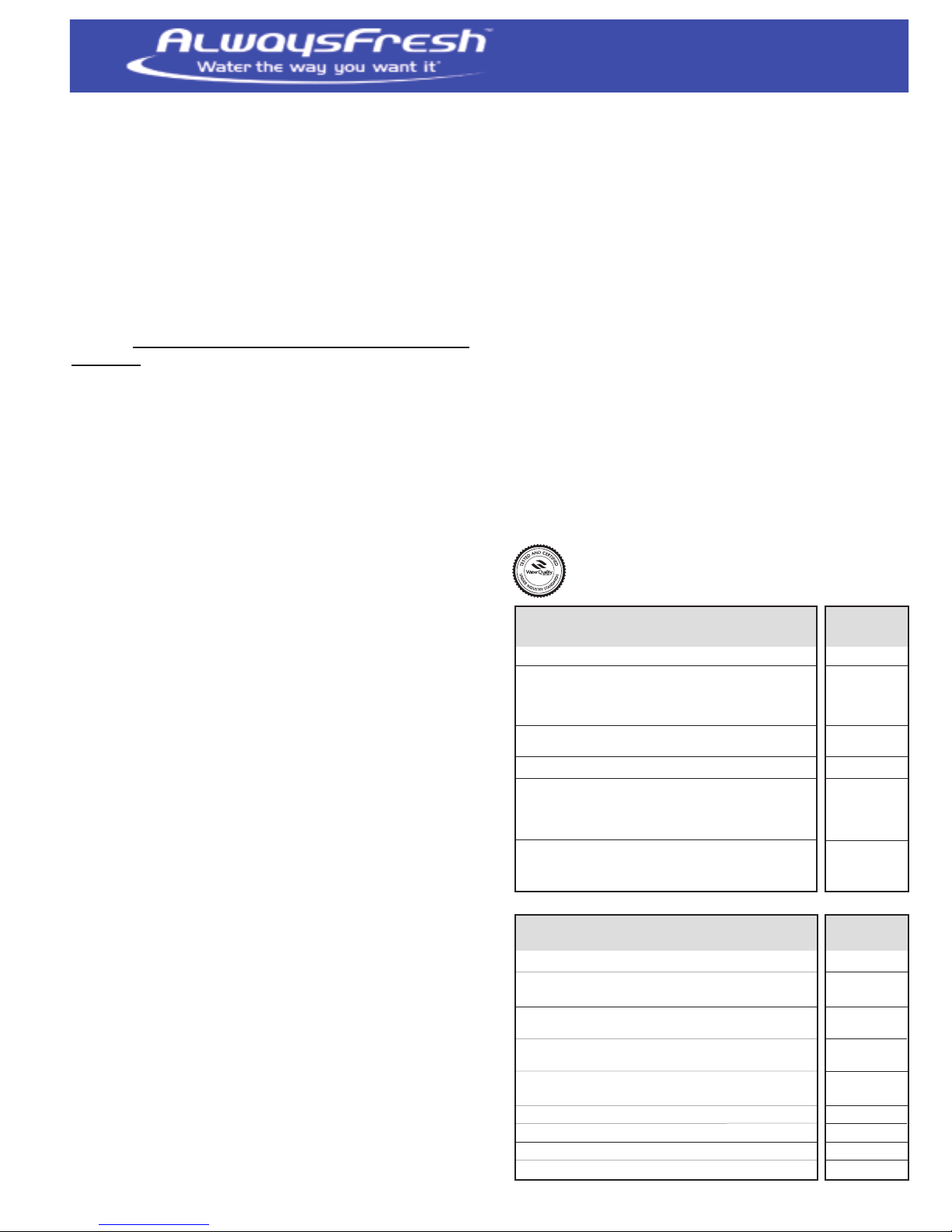

These systems conform to NSF/ANSI 42

and 53 for specific performance as

verified and substantiated by test data:

Model Number and HFC-1000 SF-1000

replacement cartridges RC-HFC 1000 RC-SF-1000

Standard 42: Aesthetic Effects

Chemical Reduction

• Taste & Odor yes yes

• Asethetic Chlorine Taste & Odor yes yes

• Asethetic Chloramine Taste & Odor yes

Mechanical Filtration

• Particulate Class 1 yes yes

Standard 53: Health Effects

Chemical Reduction

• Lead yes yes

• MTBE yes

• TTHM’s & VOC’s yes

Mechanical Filtration

• Turbidity yes yes

• Cyst yes yes

Specifications: Cold Water Only

Capacity in gallons 500 1000

Temperature

• (35-100° F) 2-38° C yes yes

Min-Max Pressure

• 10-125 psi (.7-8.6 bar) yes yes

Service Flow rate 1.5 gpm .75 gpm

Dimensions: (W x D x H)

5˝x 5˝x (including 2.5˝ clearance) 23˝ 18˝

Filter Protection-Silver Zeolite yes yes

Scale Control* yes yes

.5 micron filtration yes yes

5 micron prefiltration built-in yes yes

“Commonwealth of MA Plumbing Code 248 CMR shall be adhered to. The use

of saddle valves are not permitted. Please consult your local plumber.”

(5.7 lpm) (2.85lpm)

INSTALLATION INSTRUCTIONS

AlwaysFresh System mounting/location details:

The systems are designed for under the sink installation. Optional

basement or utility area is OK, however additional 3/8˝ tubing and

fittings will be required.

1) Install filter cartridge into the head assembly using cartridge

installation instructions.

a. Using a water proof marker write the date installed on the

cartridge label.

b. Install filter inlet/outlet Swivel fittings on head assembly

c. Apply 3-4 wraps of Teflon tape onto 3/8˝ NPT Male threads

6) Mark the supply line previously connecting the cold water to the

faucet 3/4˝ from the bottom as a guide for inserting into the

union fitting.

7) Insert this tube into one end of union connecter fitting to the

insertion line.

8) For Flexible hose installation from step 2.

9) Disconnect cold water line from existing 3/8˝ NPS stop valve

10) Apply 3-4 wraps of Teflon tape onto Male threads of the existing

3/8˝ NPS Stop valve male fitting.

2) Screw fittings into female 3/8˝ NPT fittings (inlet & outlet) on

head assembly until finger tight (approximately one-two turns).

a. Caution: Models HFC-1000 and SK-100 use white swivel fitting

for inlet and black swivel fitting for outlet. Model SF-1000 use

black swivel fitting with white collets for outlet.

3) To insure seal continue one to two more turns past finger tight.

4) Total number of turns from start to finish need not exceed five

turns. Do not over tighten.

5) Position system with cartridge, head assembly (with fittings) and

mounting bracket to desired location. It is recommended to

mount top of bracket 23˝ off floor to accept our longest replacement cartridge (HFC-1000)

a. Allow a clearance of 2-1/2˝ minimum below cartridge for

removing and replacement.

b. Allow sufficient clearance on each side for inlet/outlet fittings

to swivel freely 180 degrees.

c. Use a dark colored marker to mark positions of screw

eyelets (mounting bracket) on mounting wall.

d. Insert screws into wall at marks, which will hold the filter

leaving enough screw head to insert mounting bracket into

eyelets. (note wood screws provided)

NOTE: Unit can weigh up to 10 lbs. with water so be sure the wall is

strong enough to hold the weight.

11) Connect Faucet adapter female fitting to existing stop valve. Do

not over tighten.

12) Push tube end of Faucet Adapter female fitting into bottom of

new supply valve

13) Apply 3-4 wraps of Teflon tape onto male threads of the flexible

hose fitting currently connected to the cold sink faucet.

14) Connecting this hose to the 3/8˝ Faucet male adapter. Do not

over tighten.

15) Push tube end of Faucet adapter into union connector.

B: Connecting the water supply and existing sink faucet to Filter.

IINNLLEETT FFiittttiinngg::

1) Determine the length of plastic tubing (3/8˝ tubing 5´ supplied

with system) needed to connect the inlet (left side) of the filter

with the supply valve.

a. Be sure to allow enough tubing to prevent kinking and cut the

tubing squarely and remove all burrs. Place a mark 3/4˝ from

end of tubing.

b. Wet tubing with water and insert into outlet of supply valve

(3/4˝) until mark is flush with fitting.

c. Place a mark on the other end 3/4˝ from end of tubing.

d. Insert tubing into inlet of system fitting to insertion mark.

e. Secure complete system by tightening the mounting bracket

screws.

Select the installation choice below for using: Existing

cold water sink faucet or Separate dispensing tap !

INSTALLATION USING EXISTING COLD WATER

SINK FAUCET

A: Installing the water supply fittings: Turn off cold water supply

line. If cold water line does not have a shut-off valve under the sink,

you should install one.

1) Open the cold water faucet and allow all the water to drain from

line.

2) For cold water lines that use tubing (plastic or soft copper)follow

these instructions. For flexible hose installation that uses 3/8˝

NPS compression connection, go to step 8. Do not complete steps

3-7.

3) Cut tubing a minimum of 2˝ above the existing cold water stop

valve and removes any burrs.

4) Mark this length of tubing 3/4˝ from top as a guide for inserting

into the new supply valve elbow’s quick connect fitting.

5) Insert tubing into bottom of the new supply valve elbow to

insertion line. “Commonwealth of MA Plumbing Code 248 CMR

shall be adhered to.The use of saddle valves are not permitted.

Please consult your local plumber.”

OOUUTTLLEETT FFiittttiinngg::

2) Determine the length of tubing (3/8˝ tubing supplied) with

system to make the connection from the outlet fitting of filter to

3/8˝x 3/8˝ union fitting. A 3´ minimum length is suggested to

connect accessories into this line.

a. Place a mark 3/4˝ from end of tubing.

b. Wet tubing with water and insert into union until mark (3/4˝)

is flush with union fitting connected to tube/hose.

3) Double check that the water supply is directed to the filter inlet

and the outlet is directed to the sink cold faucet line.

Go to Placing Filter in Operation section

INSTALLATIONS USING SEPARATE

DISPENSING TAP

A: Installing the Water supply fittings: Turn off cold water supply

line. If cold water line does not have a shut-off valve under the sink,

you should install one.

1) Turn on the cold water faucet and allow all the water to drain

from line.

2) For cold water lines that use tubing (plastic or soft copper follow

these instructions. For flexible hose installation that use 3/8˝

NPS compression connection go to step 6. Do not complete

steps 3-5.

2

Loading...

Loading...