WATERKOTTE EcoTouch DS 5050T Planning And Installation

WATERKOTTE GmbH, Gewerkenstraße 15, D-44628 Herne

Tel.: 0049/(0)2323/9376-0, Service: 0049/(0)2323/9376-350

Fax: 0049/(0)2323/9376-99, E-Mail: info@waterkotte.de

Internet: http://www.waterkotte.de

Planning and installation

EcoTouch DS 5050T

2-power levels (0 % - 50 % - 100 %)

04.12..2015 / Z21974

04.12.2015

2 / 48

Copyright 2014 by: WATERKOTTE GmbH. Subject to changes.

Copyright 2014 by:

WATERKOTTE GmbH

Gewerkenstraße 15, 44628 Herne, Germany

All rights reserved. Reproduction, duplication as well as translation of

this publication, or excerpts therefrom, require prior written approval by

WATERKOTTE GmbH.

Illustrations and diagrams serve as explanatory description and shall not

be used as drawings for construction, offers or installation.

All specifications comply with the state of technology at time of

printing; we reserve the right to make changes that serve technical pro-

gress.

This publication has been prepared with all reasonable care.

WATERKOTTE GmbH does not assume any liability for remaining errors

or omissions, or for possible damages.

04.12.2015

3 / 48

Copyright 2014 by: WATERKOTTE GmbH. Subject to changes.

Content

1 Safety ......................................................................................................................................... 6

1.1 Intended use ..................................................................................................................... 6

1.2 Basic safety precautions ................................................................................................... 6

1.2.1 Keep information available .................................................................................. 6

1.2.2 Before initial use .................................................................................................. 6

1.2.3 Environmental protection ..................................................................................... 7

1.2.4 Modifications and repairs on the heat pump ....................................................... 7

1.3 Hazards ............................................................................................................................ 7

1.4 Specific types of hazards .................................................................................................. 9

1.5 Operator's duty of care ..................................................................................................... 9

1.6 Other applicable documents ............................................................................................. 9

2 Functional principle of heat pump ........................................................................................ 10

3 Product description ................................................................................................................ 11

3.1 Overview ......................................................................................................................... 11

3.2 Overview (unit opened) .................................................................................................. 12

4 Components and installation ................................................................................................ 13

4.1 Heating system EcoTouch DS 5050T ............................................................................ 13

4.2 Installation....................................................................................................................... 13

4.2.1 Heat pump system series EcoTouch DS 5050T ............................................... 13

4.2.2 Heat pump module ............................................................................................ 13

4.3 Electrical equipment ....................................................................................................... 14

4.3.1 Electronic heat pump control ............................................................................. 14

4.3.2 Sensors .............................................................................................................. 14

4.3.3 COP counter ...................................................................................................... 14

4.4 Options ........................................................................................................................... 14

5 Transport ................................................................................................................................. 15

5.1 Transport to installation site ............................................................................................ 15

6 Installation ............................................................................................................................... 16

6.1 Environmental conditions for installation ........................................................................ 16

6.2 Creating the foundation and installing heat pump .......................................................... 17

6.2.1 Laying a foundation for acoustic heat pump ...................................................... 17

6.3 Installation of the housing ............................................................................................... 18

6.3.1 Removing the housing ....................................................................................... 18

7 Installation and connection ................................................................................................... 19

7.1 Connections EcoTouch DS 5050T (rear side) ................................................................ 19

7.2 Connection to heating system ........................................................................................ 19

7.2.1 Heat pump with underfloor heating .................................................................... 20

7.2.2 Heat pump with radiators (no cooling mode) ..................................................... 20

7.2.3 Heat pump with swimming pool ......................................................................... 21

7.3 Connection to heat source .............................................................................................. 21

7.3.1 Water glycol systems ......................................................................................... 21

7.3.2 Groundwater heat source .................................................................................. 21

7.3.3 Flow monitoring ................................................................................................. 23

7.3.4 Groundwater installation: Separating heat exchanger ...................................... 24

04.12.2015

4 / 48

Copyright 2014 by: WATERKOTTE GmbH. Subject to changes.

8 Electrical work ........................................................................................................................ 25

8.1 Electrical installation ....................................................................................................... 25

8.2 Installation instructions for external sensor .................................................................... 26

8.3 Cabeling .......................................................................................................................... 26

8.4 Electrical connections ..................................................................................................... 27

8.5 Controller WWPR 2 ........................................................................................................ 28

8.6 Connectors ..................................................................................................................... 29

9 Pipe & instrumentation / measurement & control technology .......................................... 30

10 Commissioning ....................................................................................................................... 31

10.1 Pre-startup checks .......................................................................................................... 31

10.2 Initial start-up of machine ............................................................................................... 32

10.3 Control of entire operation .............................................................................................. 33

10.4 Turning heat pump off .................................................................................................... 34

10.5 Taking heat pump out of operation for extended period ................................................ 34

11 Troubleshooting ..................................................................................................................... 35

11.1 Possible faults and solutions .......................................................................................... 35

11.1.1 Fault at input side (LP fault) ............................................................................... 35

11.1.2 Fault at output side (HP fault) ............................................................................ 35

11.1.3 Fault in circulation pumps .................................................................................. 35

11.1.4 Fault in compressor motor ................................................................................. 35

12 Safety measures ..................................................................................................................... 36

12.1 Pressure limits of compressor ........................................................................................ 36

12.2 Motor protection against excessive temperature............................................................ 36

12.3 Refrigerator oil ................................................................................................................ 36

13 Maintenance and care ............................................................................................................ 37

14 Connection diagrams ............................................................................................................. 38

14.1 Heat pump EcoTouch DS5050T with underfloor heating system, without single

room control .................................................................................................................... 38

14.2 Heat pump EcoTouch DS5050T with underfloor heating system and single room

control ............................................................................................................................. 39

14.3 Heat pump EcoTouch DS5050T with underfloor heating system, without single

room control, with hygienic hot water heating ................................................................ 40

14.4 Heat pump EcoTouch DS5050T ground water or ground – with connection

accessory F10815 (option) ............................................................................................. 41

14.5 Heat pump EcoTouch DS5050T ground water or ground – with connection

accessory F10815 (option) ............................................................................................. 42

14.6 Description of the parts in the connection diagram ........................................................ 43

15 Technical data ......................................................................................................................... 45

04.12.2015

5 / 48

Copyright 2014 by: WATERKOTTE GmbH. Subject to changes.

Note: This symbol mark applies only to countries within the European Union

(EU).

This symbol mark is in compliance with Directive 2002/96/EG, Article 10.

The product has been designed and manufactured with high-quality materials and components which are suitable for recycling.

This symbol means that electrical and electronic equipment, at the end of

its useful life, shall be disposed of separately from household waste. Please

dispose of this equipment at your designated collection point or local recycling centre.

In the European Union, different collection systems are available for used

electrical and electronic equipment. Please help us to conserve the environment we live in!

Do not release R410A into the atmosphere:

R410A is a fluorinated greenhouse gas according to Kyoto Protocol and

has a global warming potential (GWP) of 1600.

Safety

04.12.2015

6 / 48

Copyright 2014 by: WATERKOTTE GmbH. Subject to changes.

1 Safety

1.1 Intended use

Your WATERKOTTE heat pump is used for space heating and cooling, and

heating of domestic water.

Project planning of the heat source system must be performed in compliance with the technical information provided by WATERKOTTE for layout of

heat source systems.

Heat pump shall only be turned on after the refrigerant connections are

completely filled, and the other hydraulic circuits are completely filled and

vented, and all electrical connections are properly completed.

Commissioning may only be carried out by trained professionals. Damages

caused by non-compliance with above mentioned items are not covered by

the warranty (see enclosed Exclusion of Warranty).

1.2 Basic safety precautions

1.2.1 Keep information available

1.2.2 Before initial use

In addition to the operating manual, also furnish operating instructions in

terms of Labour Protection Law and Work Equipment ordinance.

Keep all safety and operating signs on the heat pump in fully legible condition at all times. Replace damaged or illegible signs immediately.

Before initial use of your WATERKOTTE heat pump, familiarise yourself with:

Operating and control elements of your WATERKOTTE heat pump

Equipment of heat pump

Operation of heat pump

Immediate surroundings of heat pump

Safety devices of heat pump

Before initial start, perform the following work:

Ensure that all safety devices are installed and function as intended.

Check heat pump for visible damage. Remedy any detected defects

immediately.

Heat pump must be in perfect condition during operation!

Ensure that only authorised personnel is in the work area of the heat

pump and that no other persons are endangered when heat pump is

started.

Remove all objects and other materials that are not required for opera-

tion of the heat pump from the work area of the heat pump.

Safety

04.12.2015

7 / 48

Copyright 2014 by: WATERKOTTE GmbH. Subject to changes.

1.2.3 Environmental protection

Observe the regulations regarding waste avoidance and proper waste

recycling or disposal when performing any kind of work on and with the

heat pump.

Ensure that particularly during installation and maintenance work, as well

as when placing out of operation, pollutants such as grease, oil, refrigerant, solvent- containing cleaning fluids, etc. do not contaminate the

ground or enter the sewer system!

These materials must be collected, stored, transported and disposed of

in appropriate containers.

1.2.4 Modifications and repairs on the heat pump

For safety reasons, no unauthorised modifications shall be performed on

the heat pump.

Thus, all intended modifications are subject to written approval by

WATERKOTTE.

1.3 Hazards

Use only original spare parts from WATERKOTTE.

Original spare parts are specially designed for your heat pump. Externally

procured parts provide no guarantee that they are designed and manufactured in compliance with relevant usage and safety requirements.

Parts and special equipment not delivered by WATERKOTTE are not approved for use on the heat pump.

Observe the following points to avoid life-threatening injuries and damages

to the heat pump during operation:

Warning! Risk of electric shock!

Do not use water or other liquids to clean the unit!

Keep all electrical supply units locked at all times!

Any work on the electrical equipment of the heat pump shall only be performed by professional electricians!

Discharging refrigerant can cause severe personal injury (suffocation or hypothermia)!

Avoid contact with refrigerant!

Note the minimum volume of the installation room and consider the type of

the refrigerant (EN 378-1).

Warning! Risk of suffocation!

The packaging is not a toy! The packaging must be disposed of environmentally acceptable.

Safety

04.12.2015

8 / 48

Copyright 2014 by: WATERKOTTE GmbH. Subject to changes.

Risk of burns!

During operation, surface temperatures (compressor and pressure line) can

climb above 100 °C or drop below 0 °C.

Do not remove housing cover during operation!

Allow heat pump to cool down before removing cover.

Risk of injury!

Risk of chemical burns: when skin has a direct contact with lubricant leak.

Wear suitable clothing when performing maintenance work on the heat

pump!

Risk of injury in case of leakage in cooling circuit!

Skin contact with refrigerant may cause freezing of tissue and frostbites.

High vapour concentrations can cause headaches, dizziness, fatigue, nausea and even unconsciousness. Irregular heartbeat (arrhythmia).

Avoid contact with refrigerant! Do not expose to heat, sparks, naked light or

other ignition sources!

Electrostatic charge!

Electronic components can be damaged by electrostatic processes.

Ground yourself before touching electronic components.

Risk of total loss!

Repeated restart of heat pump can result in total loss!

In case of heat pump failure, before restart an inspection by qualified

and authorised personnel must be performed.

Due to test bench operation, the heat pump can have ethylene glycol residues.

Safety

04.12.2015

9 / 48

Copyright 2014 by: WATERKOTTE GmbH. Subject to changes.

1.4 Specific types of hazards

To avoid damage to machine or life-threatening injuries during installation of

machine, the following points must be observed:

Machine parts that are improperly placed or incorrectly attached can fall

down or overturn.

Sharp-edged machine parts that are still exposed and accessible can

result in injury.

Incorrectly installed lines (e.g. insufficient bending radius) can cause

smouldering and cable fires.

Risk of chemical burns when skin comes in direct contact with lubricant

leak.

Electronic components can be damaged by electrostatic processes.

During operation, surface temperatures (compressor and pressure line)

can climb above 100 °C or drop below 0 °C.

Serious burns/frostbites can occur. Before working on the compressor:

Switch off unit and allow to cool down.

1.5 Operator's duty of care

Your WATERKOTTE heat pump has been designed and built on the basis

of a risk analysis and after careful selection of standards to be observed.

Thus, your heat pump is state-of-the-art and provides for maximum safety.

In practice, however, this safety can only be ensured by taking all necessary

measures. As operator of the heat pump it is your responsibility to plan

these measures and oversee their implementation.

You must ensure that:

The heat pump is only used as intended (see also chapter 1.1,

The heat pump is only operated in perfect, fully functional condition and

The operating manual is available in perfect condition at the heat pump

The heat pump is operated, maintained and repaired only by adequately

„Intended use“).

safety devices are checked regularly to ensure that they are working

properly.

at all times.

qualified and authorised personnel.

None of the safety and warning notices on the heat pump are removed

or damaged.

1.6 Other applicable documents

Operating manual: WWPR WATERKOTTE heat pump controller.

Functional principle of heat pump

04.12.2015

10 / 48

Copyright 2014 by: WATERKOTTE GmbH. Subject to changes.

Heat source

Low temperature

Driving energy

Energy output

Heat pump

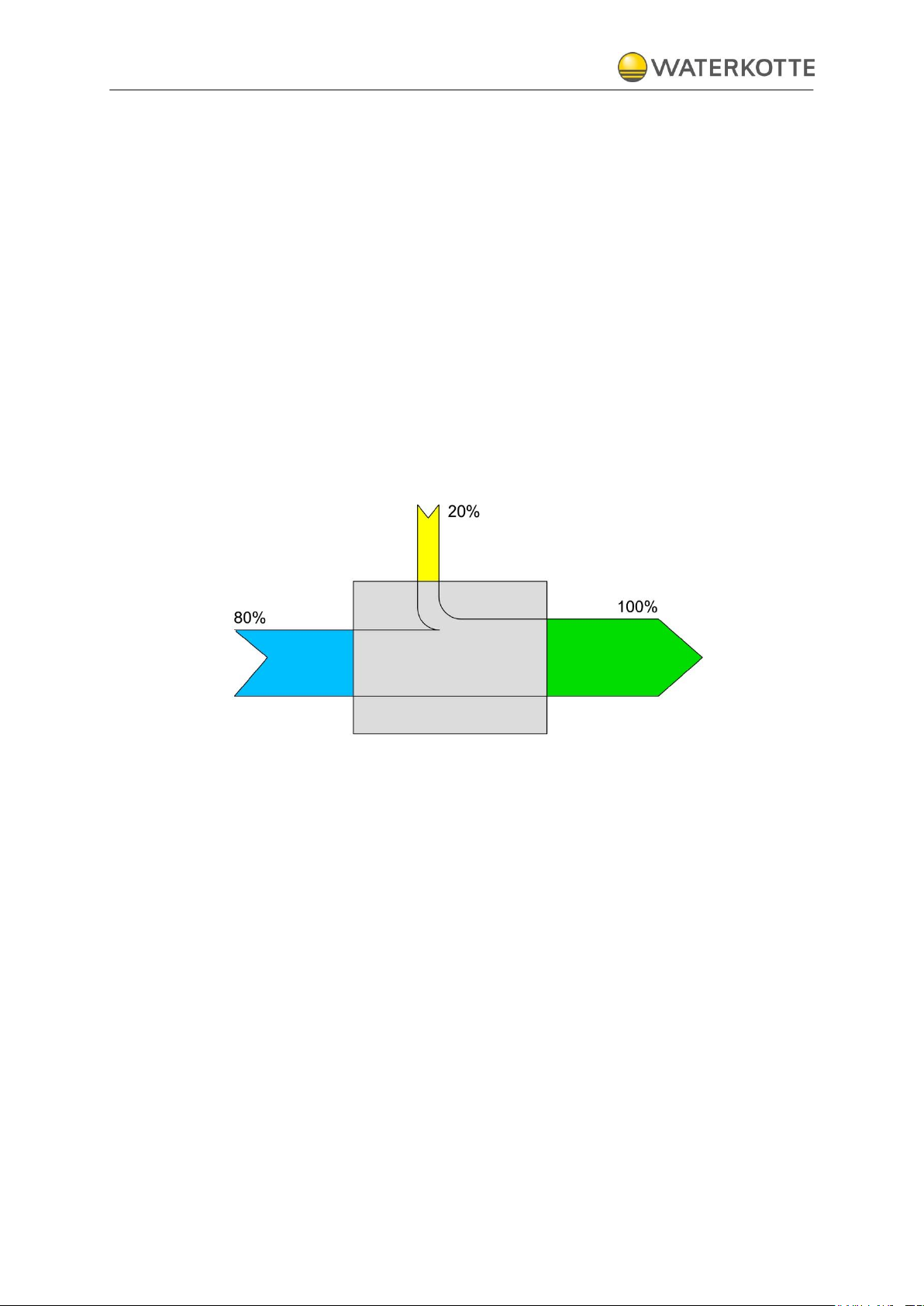

2 Functional principle of heat pump

The heat pump is used to produce thermal energy for space heating and, if

required, domestic water heating. The medium used as heat source (WQ) is

the ground.

It is also possible to cool a building.

To utilise ground as thermal energy, for domestic water heating and cooling

in your home, you need the following:

a heat source (borehole with geothermal energy probes or groundwater

extraction / discharge)

heating system EcoTouch DS 5050T

domestic hot water tank

Figure 1: Energy share when using a geothermal energy pump

Product description

04.12.2015

11 / 48

Copyright 2014 by: WATERKOTTE GmbH. Subject to changes.

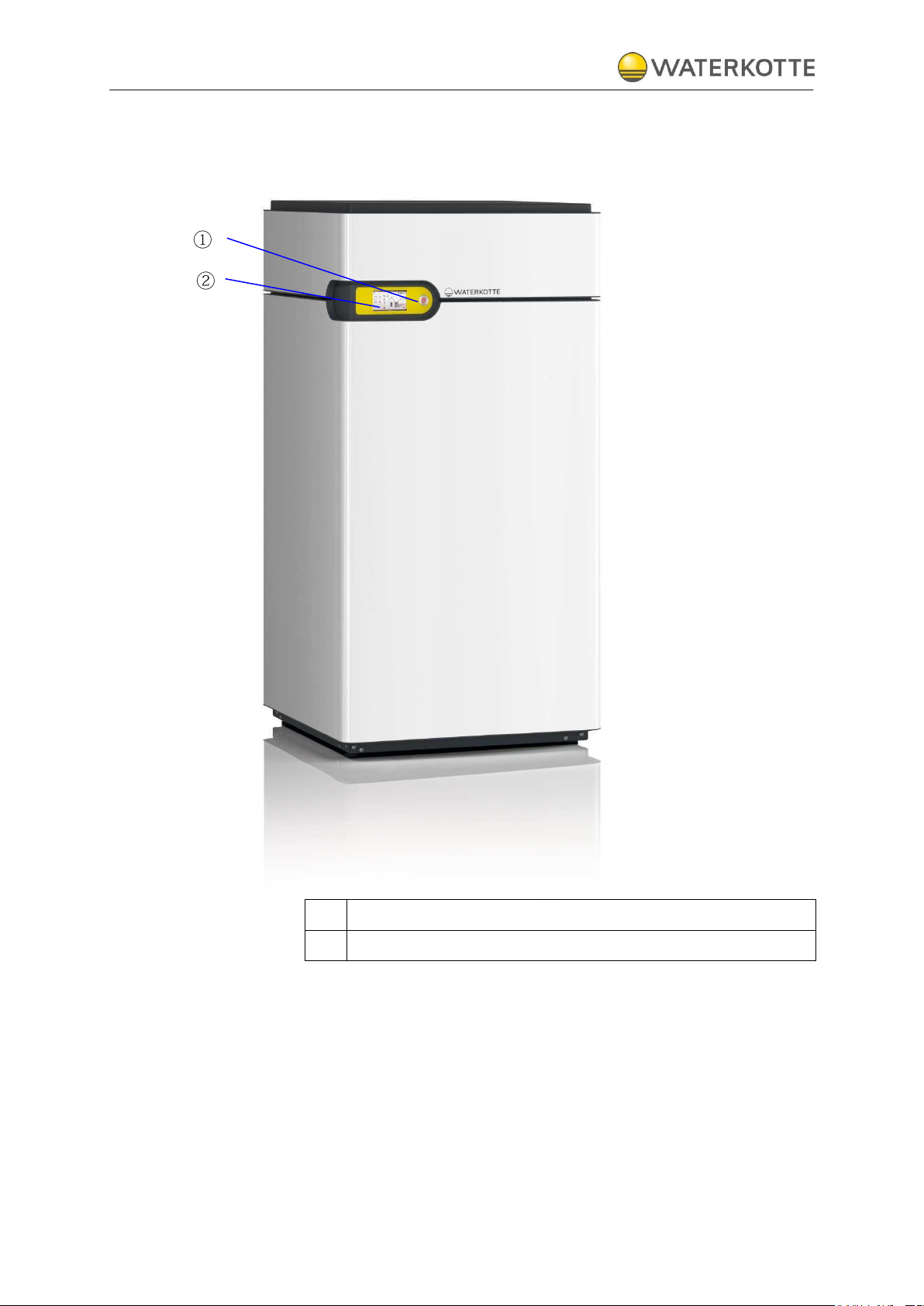

1

ON / OFF switch

2

Control panel (electronic heat pump controller)

3 Product description

3.1 Overview

Figure 2: Heating system EcoTouch DS 5050T

Product description

04.12.2015

12 / 48

Copyright 2014 by: WATERKOTTE GmbH. Subject to changes.

1

Safety group with manometer: relief valve, bleeder

2

Connection terminal

3.2 Overview (unit opened)

Illustration 3: EcoTouch DS 5050T (top view, opened

Components and installation

04.12.2015

13 / 48

Copyright 2014 by: WATERKOTTE GmbH. Subject to changes.

4 Components and installation

4.1 Heating system EcoTouch DS 5050T

All components of the heating system are mounted in a protective steel

plate housing which is intended for installation inside. The base frame consists of a bent, thick-walled sheet steel. Together with the rear panel frame,

which also consists of a thick-walled sheet steel, it forms a unit. Side panels, cover, front and the tilt-mounted, ergonomic control panel can be removed.

All enclosure components are reliably and permanently protected by powder-coating and a stove enamel finish. A sound insulation ensures low noise

emissions.

4.2 Installation

4.2.1 Heat pump system series EcoTouch DS 5050T

The heat pump is designed as complete operational unit for thermodynamic

space heating, expandable to domestic hot water production.

4.2.2 Heat pump module

Functions: Heat pump, domestic hot water heating system, natural cooling

(option), regulation and electrical control.

All dynamic components are located on an internal chassis (dual chassis

construction), separated from the external housing. The pipe joints between

internal and external chassis are flexibly mounted to prevent structure-born

noise transmission within the unit.

The series 5050T is provided with two compressors (power level:

50 % or 100 %). The compressors feature a fully hermetic design in approved leading scroll technology (fig. left). Evaporator and condenser are

designed as soldered stainless steel plate packs with reverse flow circuits,

according to state-of-the-art development, tailored to the new nonflammable safety refrigerants that will be required by law in the future. In

combination with ester oil (biodegradable), this guarantees optimum lubrication conditions, low friction losses and therefore the highest possible life expectancy for the compressor according to the latest industrial research

findings.

The cooling circuit is designed in accordance with the relevant safety regulations. Manufacturing quality is carried out based on ISO 9000ff, supplemented by an automated computer-monitored quality test (pressure stress

and helium leak test) in addition to inspection of all parameters in a subsequent trial run.

Components and installation

04.12.2015

14 / 48

Copyright 2014 by: WATERKOTTE GmbH. Subject to changes.

4.3 Electrical equipment

The electrical connections are made via the internal terminal (on the construction profile). The implementation of the electrical cable is carried by the

rear wall (with the strain relief).

The internal terminal connects the entire sensor, all queries, all relay outputs, digital circuit, the compressor and the electrical heating element. The

WATERKOTTE WWPR-controller is supplied with a control panel mounted

on the 24 V AC transformer.

4.3.1 Electronic heat pump control

The heat pump control (control panel is pictured) is included in the scope of

delivery of the WATERKOTTE heat pump.

Use in other than WATERKOTTE heat pumps will void any warranty claim.

The control is used to control and monitor heating systems that are operated with WATERKOTTE compact heat pumps according to technical guidelines of WATERKOTTE Wärmepumpen GmbH.

4.3.2 Sensors

4.3.3 COP counter

The following tasks are performed: everything to do with regulation (depending on the external temperature with pilot room guidance), control,

monitoring, self-diagnosis, saving of data in cases of breakdown.

WATERKOTTE explicitly states that function warranty will become void if

used on systems not approved by WATERKOTTE. Any liability for consequential damages due to incorrect function within these systems shall be

explicitly excluded.

Info: Technical details, operation and warning messages (see

manual for Heat pump control)

.

Operating

The control's sensor system consists of: Pressure transmitter for evaporation and condensation pressure/temperature, 5 sensors for temperature

detection in all circuits. External wall sensor (accessories kit). Pilot room

sensor and hot water sensor: optional.

A WATERKOTTE COP counter is already integrated in the heat pump control. For additional information, please refer to

Operating manual for Heat

pump control.

4.4 Options

Domestic hot water production (heating-side vertical tank, hot

water heater, temperature sensor, three way valve), pilot room sensor,

natural cooling, WEB interface: for control and parameterization of the heat

pump via internet.

Transport

04.12.2015

15 / 48

Copyright 2014 by: WATERKOTTE GmbH. Subject to changes.

5 Transport

Exercise particular caution when transporting the units. Since the unit

weighs 232 kg or more, at least two people are required for transport.

Do not use the packaging straps to carry the unit. Wear protective

gloves for unpacking and transporting the unit to prevent hand injuries

from cooling fins or other parts.

Observe the transport information on the packaging.

Observe the specified storage requirements.

The units may not be stacked.

Machine may only be lifted at the provided attachment points.

Machine may only be transported in upright position.

Ensure proper disposal of packaging materials. Packaging materials,

such as nails or other metal or wooden parts, may cause injuries.

Please also read chapter "General safety information“.

5.1 Transport to installation site

Units of the EcoTouch DS 5050T series are delivered ready-to-connect with

separate metal cladding. For transport purposes, the metal cladding and

the heat pump are delivered in one carton on a palette. During transport it

must be ensured that appropriate means of transport are used (lift truck,

transport rollers, handcart).

Unit must be transported upright!

Transport in tilted position (45°) is permitted only temporarily during insertion.

Horizontal transport results in oil displacement in compressor and can

cause damage during start-up.

After packaging is removed or opened it is not permitted to tilt the unit by

applying pressure to the pipelines or housing enclosure; this could result in

bent housing parts and pipelines.

Loading...

Loading...