Waterite FUSION2 Owner's Manual

Advanced Water Conditioners

featuring the Custom Control F2CC Valve

OWNER’S MANUAL

FOR ALL FUSION² F SERIES AND FCA SERIES WATER CONDITIONERS

THIS MANUAL IS TO BE LEFT WITH THE OWNER OF THE EQUIPMENT FOR

REFERENCE PURPOSES AND TECHNICAL GUIDANCE. IT IS STRONGLY

RECOMMENDED THAT QUALIFIED DEALER SERVICE PERSONNEL BE

CONTACTED IN THE EVENT OF AN UNKNOWN INTERRUPTION OF SERVICE OR

APPARENT PRODUCT MALFUNCTION. AN ANNUAL PREVENTATIVE

MAINTENANCE INSPECTION BY A WATER PROFESSIONAL IS RECOMMENDED

TO ENSURE TROUBLE-FREE AND CONTINUOUS OPERATION.

Waterite Technologies, Inc. ■ 1-885 Keewatin Street, Winnipeg, MB Canada ■ R2X 2S7

www.waterite.com

TABLE OF CONTENTS

Preinstallation Instructions for Dealer.......................inside front cover

Specifications.................................................................................1

Cycle Sequence Settings................................................................2

Softener System Setup (programming)...........................................3-5

Bypass Valve Description & Diagrams..............................................6

Installation...................................................................................7-8

Installer Settings....

Hardness, Override, Regen Time & Time of Day..................

Normal Operating & Error Displays, Power Loss..................10

Low Salt Warning & Resetting It

Start Up Instructions......................................................................12

Replacement Parts & Valve Repair

Front Cover, Drive Assembly and Piston..............................13

Injector Assembly & Refill Port Assembly............................14

Drain Line 3/4" Assembly & Flow Controls

Drain Line 1" Assembly & Flow Controls

Water Meter & Bypass Valve..............................................17

Installation Fitting Assemblies & Service Wrench.................18

Control Valve Servicing..............................................................19-23

Troubleshooting Procedures

.......................................................24-25

.........................................11

..........................15

.............................16

....9

PREINSTALLATION INSTRUCTIONS

This unit has a control valve which enables the setting of not only the length of each regeneration cycle but also the

order in which cycles (steps of regeneration) occur. The following pages instruct how to set the treatment unit’s

sequence of cycles, cycle times, salt dose, exchange capacity, and gallon capacity/regeneration time. A salt

warning option may also be included.

THE DEALER...

1. Read this page, GENERAL INSTRUCTIONS, INSTALLER SETTINGS, NORMAL OPERATING

DISPLAYS, and LOW SALT WARNING.

2. Complete the CYCLE SEQUENCE SETTINGS.

3. Complete the SOFTENER SYSTEM SETUP.

a. Cycle Times

b. Choose Softener or Filter

c. Set Salt Dose

d. Set Capacity

e. Set How Gallon Capacity Will be Calculated

f. Set Regeneration Time Option

g. Select or Turn Off Low Salt Warning

THE INSTALLER...

1. Read Bypass Valve page.

2. Read GENERAL INSTRUCTIONS, NORMAL OPERATING DISPLAYS, and RESETTING LOW SALT

WARNING (if applicable).

3. Be sure CYCLE SEQUENCE SETTINGS and SOFTENER SYSTEM SETUP are done before leaving for

installation.

4. Follow INSTALLATION INSTRUCTIONS, INSTALLER SETTINGS, TIME OF DAY, and RESETTING

SALT AMOUNT (if applicable).

5. Follow START UP INSTRUCTIONS.

page 1

CONTROL VALVE SPECIFICATIONS

SERVICE FLOW RATE & PRESSURE LOSS

27 gpm (102.2 lpm) @ 15 psi (103 kPa)

(valve only, including bypass valve, but not

including mineral, etc.)

BACKWASH FLOW RATE & PRESSURE LOSS

27 gpm (102.2 lpm) @ 25 psi (172 kPa) ∆∆∆∆P

(whole conditioner...including bypass valve)

MINIMUM & MAXIMUM OPERATING

20 psi (138 kPa) - 125 psi ( 862 kPa)

PRESSURE

MINIMUM & MAXIMUM OPERATING

40∞F (4∞C) -110∞F (38∞C)

TEMPERATURE

CURRENT DRAW & VOLTAGE 0.5 amperes 110 volts

REGENERANT TANK REFILL RATE 0.5 gpm (1.9 lpm)

INLET / OUTLET FITTING TYPES (a) 1" NPT elbow

(b) 3/4" & 1" PVC solvent weld socket

(c) 1" straight brass sweat fitting

(d) 3/4" straight brass sweat fitting

∆∆∆∆P

DISTRIBUTOR TUBE 1.05" O.D. (3/4" U.S. PVC Pipe Size)

TANK THREAD 2Ω" - 8 NPSM

PC BOARD MEMORY Nonvolatile EEPROM

(electrically erasable programmable read only

memory)

COMPATIBLE REGENERANTS

COMPATIBLE CHEMICALS

sodium chloride, potassium chloride, potassium

permanganate, sodium hydroxide, hydrochloric acid

sodium bisulfite, sodium hydrosulfite, chlorine,

chloramines

GENERAL INSTRUCTIONS

During operation, the normal user displays such as time of day, gallons or days remaining before regeneration

(optional), and salt warning (optional), are shown. Each of these can be viewed by pressing NEXT to scroll through

them. When moving through any displays or programming, if no buttons are pressed within five minutes, the display

returns to normal operating displays. Any changes made prior to the five minute time out are incorporated.

To quickly exit any Programming, Installer Settings, etc., press SET CLOCK. Any changes made prior to the exit

are incorporated.

If desired, two regenerations within 24 hours are possible with a return to the preset program. To do a double

regeneration if the control valve is factory set to “NORMAL” or “NORMAL + on 0” (see Step 9S under SOFTENER

SYSTEM SETUP):

1. Press the “REGEN” button once. REGEN TODAY will flash on the display.

2. Press and hold the “REGEN” button for three seconds until a regeneration begins.

Once the valve has completed the immediate regeneration, the valve will regenerate one more time at the preset

regeneration time.

page 2

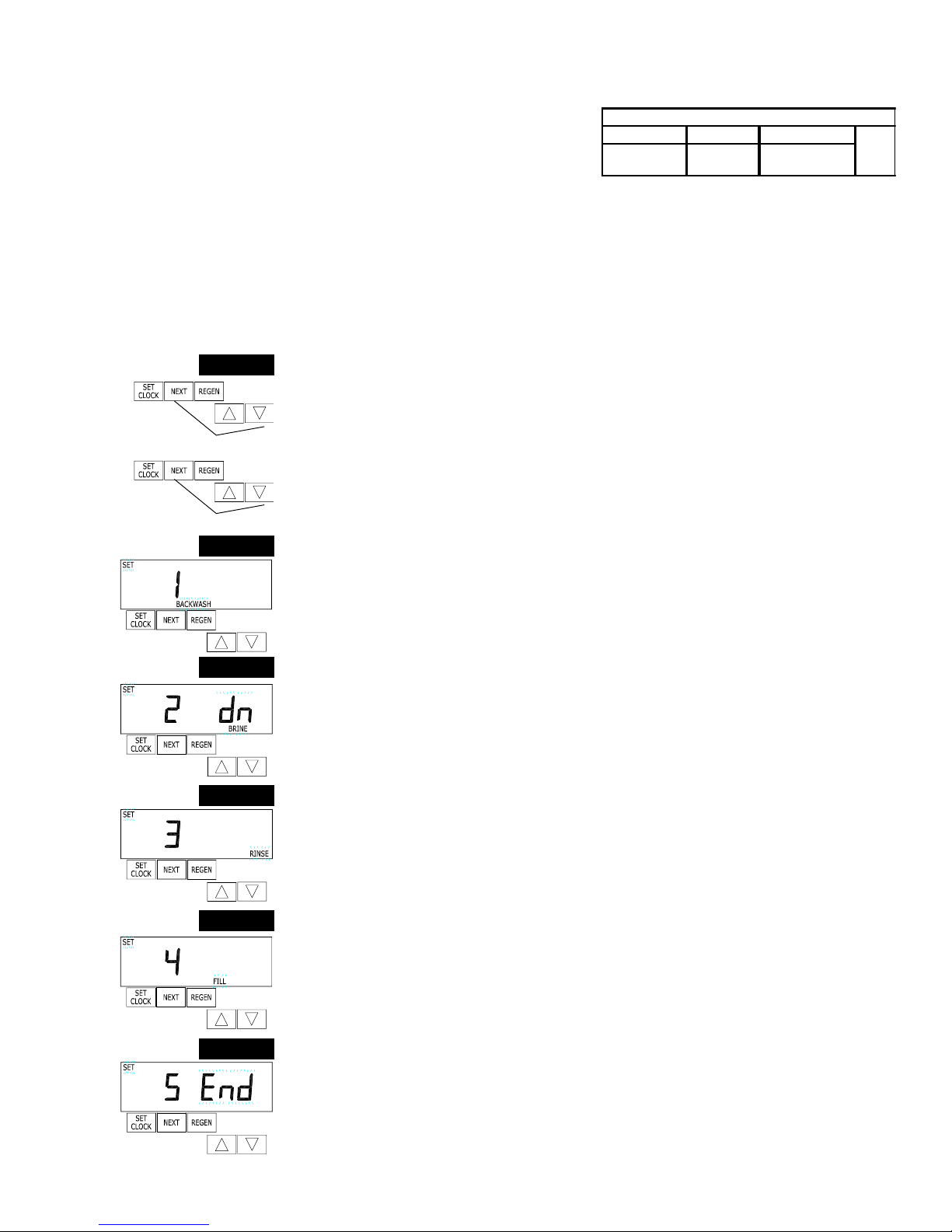

CYCLE SEQUENCE

CYCLE SEQUENCE instructions allows the setting of the order of the

cycle. There are 9 cycles which can be arranged in any order.

Later in this book the INSTALLER SETTINGS allow the setting of how

long cycles will last.

BACKWASH DN BRINE FILL

RINSE UP BRINE

CYCLE OPTIONS

SOFTENING

OR FILTERING

END

END must be used as the last cycle option. The SERVICE cycle should only be used in brine prefill applications.

If using upflow brine verify that the valve is configured as follows:

1. upflow piston is installed; and

2. injector is located in up hole and injector plug is in down hole.

The following is an example of how to set a valve so that when regeneration is initiated BACKWASH occurs first, dn

BRINE occurs second, RINSE occurs third, and FILL occurs fourth.

ß

ß

STEP 1CS

ß

ß

STEP 2CS

STEP 3CS

STEP 4CS

Step 1CS – Press NEXT and simultaneously for 3 seconds until SOFTENING or

FILTERING appears on the display and release. If SOFTENING doesn’t appear, use the

or ∆ button to display it. Then press NEXT and again for 3 seconds and release. If

screen in Step 2CS does not appear in 5 seconds the lock on the valve is activated. To

unlock press , NEXT, ∆, and SET CLOCK in sequence, then press NEXT and simulta-

neously for 3 seconds and release.

Then press NEXT and again for 3 seconds and release.

Step 2CS – Press the or ∆, buttons until BACKWASH appears.

Press NEXT to go to Step 3CS.

Press REGEN if you need to return to the previous step.

Step 3CS - Press the or ∆ buttons until dn BRINE appears.

Press NEXT to go to Step 4CS.

Press REGEN if you need to return to the previous step.

Step 4CS - Press the or ∆ buttons until RINSE appears.

Press NEXT to go to Step 5CS.

Press REGEN if you need to return to the previous step.

ß

STEP 5CS

Step 5CS - Press the or ∆ buttons until FILL appears.

Press NEXT to go to Step 6CS.

Press REGEN if you need to return to the previous step.

ß

STEP 6CS

Step 6CS - Press the or ∆ buttons until END appears.

Press NEXT to exit CYCLE SEQUENCE.

Press REGEN if you need to return to the previous step.

ß

RETURN TO NORMAL MODE

page 3

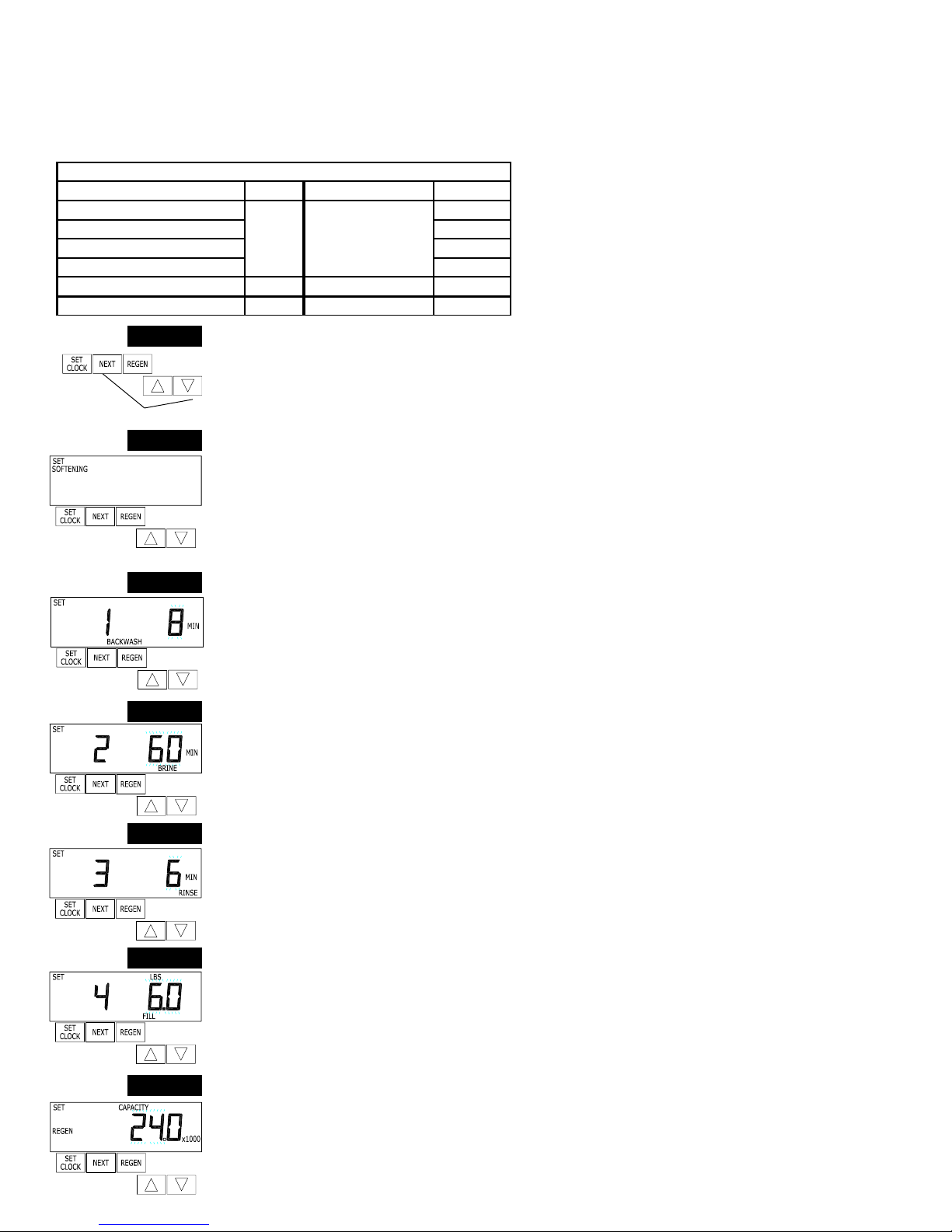

SOFTENER SYSTEM SETUP

In SOFTENER SYSTEM SETUP you choose the duration for the cycles selected in CYCLE SEQUENCE and specify

other other operating parameters for the system. The upper and lower limits of the allowable values for the cycles are

as follows:

CYCLE SETTING LIMITS

CYCLE OPTIONS UNITS LOWER/UPPER LIMIT DEFAULT

Backwash

Rinse (fast rinse) 6

dn Brine (brine and slow rinse) 6 0

UP Brine (brine and slow rinse) 6 0

Fill (regenerant tank refill) Lbs. 0.1 to 120.0 6.0

Service minutes 1 to 1200 24 0

minutes 1 to 1200

8

Since no time is associated with the END

cycle, the END cycle will not appear in the

SOFTENER SYSTEM SETUP sequence.

Note: Fill is in pounds of salt.

STEP 1S

Step 1S – Press NEXT and simultaneously for 3 seconds and release. If screen in

Step 2S does not appear in 5 seconds the lock on the valve is activated. To unlock press

, NEXT, ∆, and SET CLOCK in sequence, then press NEXT and ∆ simultaneously for 3

ß

STEP 2S

ß

STEP 3S

ß ßß

STEP 4S

STEP 5S

seconds and release.

Step 2S – Choose SOFTENING using the or ∆ button.

Press NEXT to go to Step 3S.

Press REGEN if you want to exit SOFTENER SYSTEM SETUP.

Step 3S – Select the time for the first cycle (which in this example is BACKWASH) using

the or ∆ button.

Press NEXT to go to Step 4S.

Press REGEN if you need to return to previous step.

Step 4S – Select the time for the second cycle (which in this example is dn BRINE) using

the or ∆ button.

Press NEXT to go to Step 5S.

Press REGEN if you need to return to previous step.

NOTE: The display will flash between cycle number and time, and brine direction (dn or

UP).

Step 5S – Select the time for the third cycle (which in this example is RINSE) using the

or ∆ button.

Press NEXT to go to Step 6S.

Press REGEN if you need to return to the previous step.

Step 6S – Select the Lbs. for the fourth cycle (which in this example is FILL) using the

or ∆ button. Press NEXT to go to Step 7S. Press REGEN if you need to return to the

previous step.

STEP 6S

Step 7S – Set Grains Capacity using the or ∆ button. The ion exchange capacity is in

grains of hardness as calcium carbonate for the system based on the pounds of salt that

will be used. Calculate the pounds of salt using the fill time previously selected. The

allowable grains capacity range varies from 5000 to 200,000 grains. The increment in-

ß

crease is 500 for the range from 5000 to 30,000, 1000 for the range of 30,000 to 100,000,

and 2000 for the range of 100,000 to 200,000. Grains capacity is affected by the fill time.

The grains capacity for the selected fill time should be confirmed by testing. The capacity

STEP 7S

and hardness levels entered are used to automatically calculate reserve capacity when

gallon capacity is set to AUTO. Press NEXT to go to Step 8S.

Press REGEN if you need to to return to previous step.

ß

page 4

w

a

c

c

w

g

a

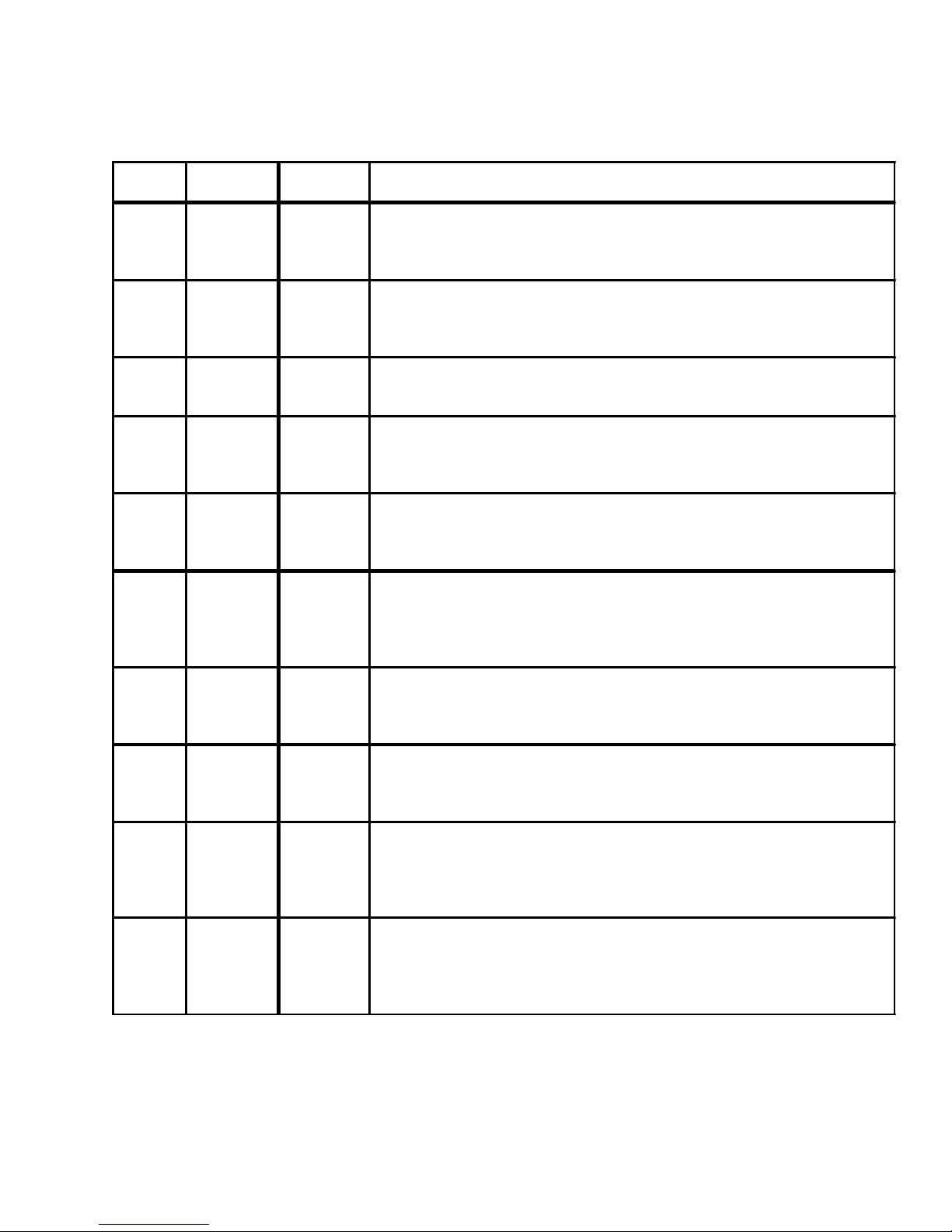

SOFTENER SETUP DETAIL TABLE

This table is to be used as a guide or shortcut to the settings made in Step 3I, 8S, and 9S. For quick programming

use the recommended settings shown in row 3 below in bold italic type.

Gallons

Capacity

AUTO NORMAL oFF

AUTO NORMAL

Any

number

oFF NORMAL Any number

Any

number

AUTO On O oFF

Any

number

Regeneration

Time Option

NORMAL oF F

NORMAL Any number

On O oF F

Day Override

Any number

or 14 day

default

Result

Reserve capacity automatically estimated.

Regeneration occurs when gallons capacity falls below the reserve capacity at the

Time.

Reserve capacity automatically estimated.

Regeneration occurs at the next Regen Set Time when gallons capacity falls belo

capacity...

or the specified number of days between regenerations is reached.

Reserve capacity not automatically estimated. Regeneration occurs at the next Re

when gallons capacity reaches 0

Reserve capacity not automatically estimated.

Regeneration occurs at the next Regen Set Time when the specified number of d

regenerations is reached.

Reserve capacity not automatically estimated.

Regeneration occurs at the next Regen Set Time when gallons capacity reaches 0

number of days between regenerations is reached.

Reserve capacity automatically estimated.

Regeneration occurs immediately when gallons capacity reaches 0.

Time of regeneration is not allowed to be set because regeneration will always oc

gallons capacity reaches 0.

Reserve capacity not automatically estimated.

Regeneration occurs immediately when gallons capacity reaches 0.

Time of regeneration is not allowed to be set because regeneration will always oc

AUTO NORMAL on 0 oFF

AUTO NORMAL on 0 Any number

Any

number

NORMAL on 0 Any number

Reserve capacity automatically estimated.

Regeneration occurs when gallons capacity falls below the reserve capacity at the

Time or regeneration occurs immediately after 10 minutes of no water usage whe

reaches 0.

Reserve capacity automatically estimated.

Regeneration occurs at the next Regen Set Time when gallons capacity falls belo

capacity or the specified number of days between regenerations is reached, or re

immediately after 10 minutes of no water usage when gallon capacity reaches 0.

Reserve capacity not automatically estimated.

Regeneration occurs at the next Regen Set Time when the specified number of d

regenerations is reached, or regeneration occurs immediately after 10 minutes of

when gallon capacity reaches 0.

page 5

SOFTENER SYSTEM SETUP

STEP 8S

ß

STEP 9S

ß

ß

RETURN TO

NORMAL MODE

STEP 10S

Step 8S – Set Gallons Capacity using the or ∆ button. If value is set to:

• “AUTO” ...the gallon capacity will be automatically calculated and reserve capacity will be

automatically estimated.

• “oFF”...the regeneration will be based on the day override set

(see Installer Settings Step 3I).

• a specific number (allowable range 20 to 50,000)...the regeneration initiation will be based

on the value specified. The settable increment is 20 for the range 20 to 1000, 50 for the

range of 1000 to 10,000 and 100 for the range of 10,000 to 50,000.

If “oFF” or a specific number is used, hardness display will not be allowed to be set in

Installer Displays Step 2I. Press NEXT to go to Step 9S.

Press REGEN if you need to return to the previous step.

Step 9S – Set Regeneration Time Options using the or ∆ button. If value is set to:

• “NORMAL”...the regeneration will occur at the preset time.

• “on O”...the regeneration will occur immediately when the gallons capacity reaches 0

(zero).

• “NORMAL + on 0”...the regeneration will occur at one of the following:

— the preset time when the gallons capacity falls below the reserve or the specified

number of days between regenerations is reached whichever comes first; or,

— immediately after 10 minutes of no water usage when the gallon capacity reaches 0

(zero).

Press NEXT to go to Step 10S. Press REGEN if you need to return to the previous step.

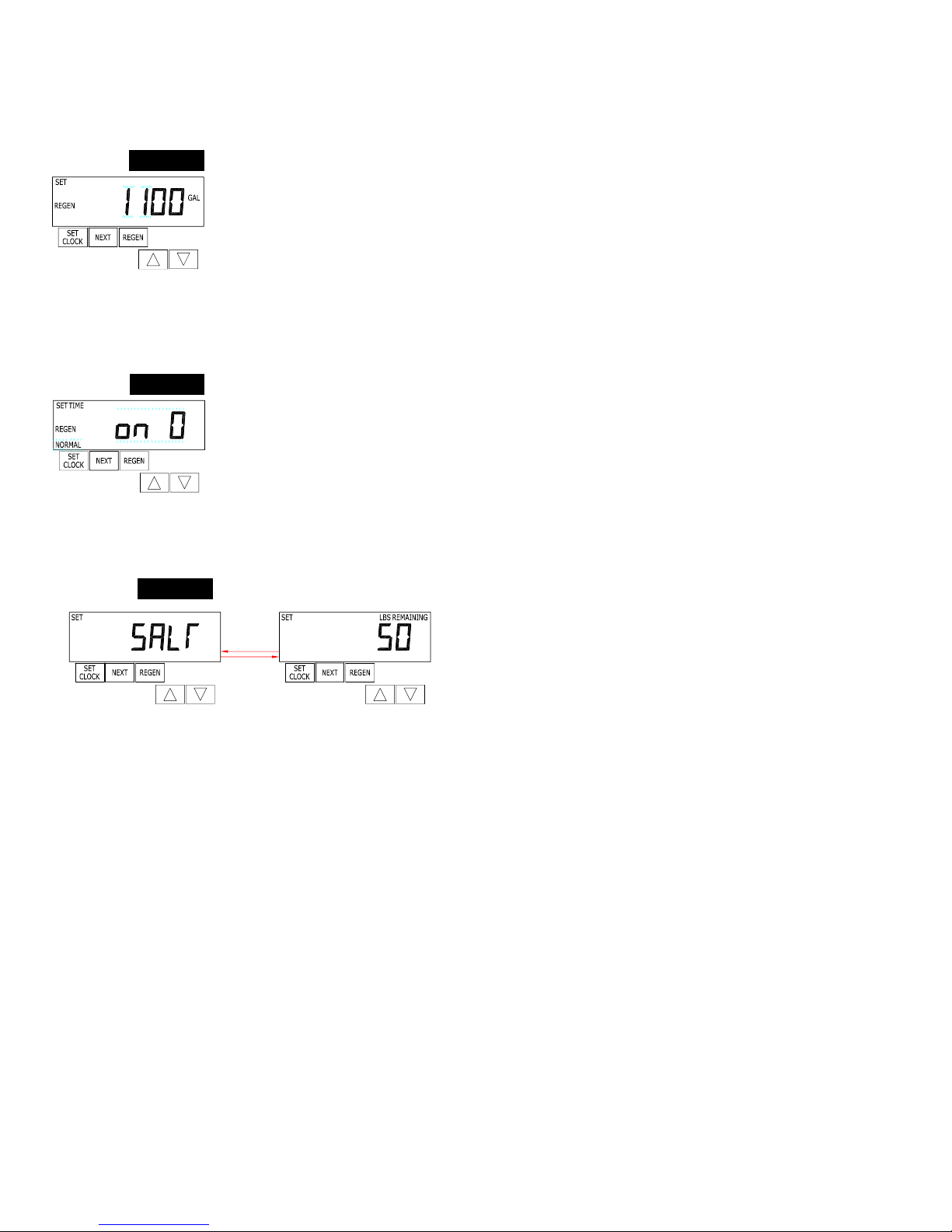

Step 10S – Set Low Salt Warning using the or ∆ button. If the value is set to:

• “oFF”...no low salt level warning will appear for the user.

• a specific value...“FILL SALT” will flash on the display when

the calculated remaining pounds of salt falls below that level.

Allowable values range form 10 to 400 pounds in 10 pound

increments.

Press NEXT to exit SOFTENER SYSTEM SETUP.

Press REGEN if you ned to return to the previous step.

page 6

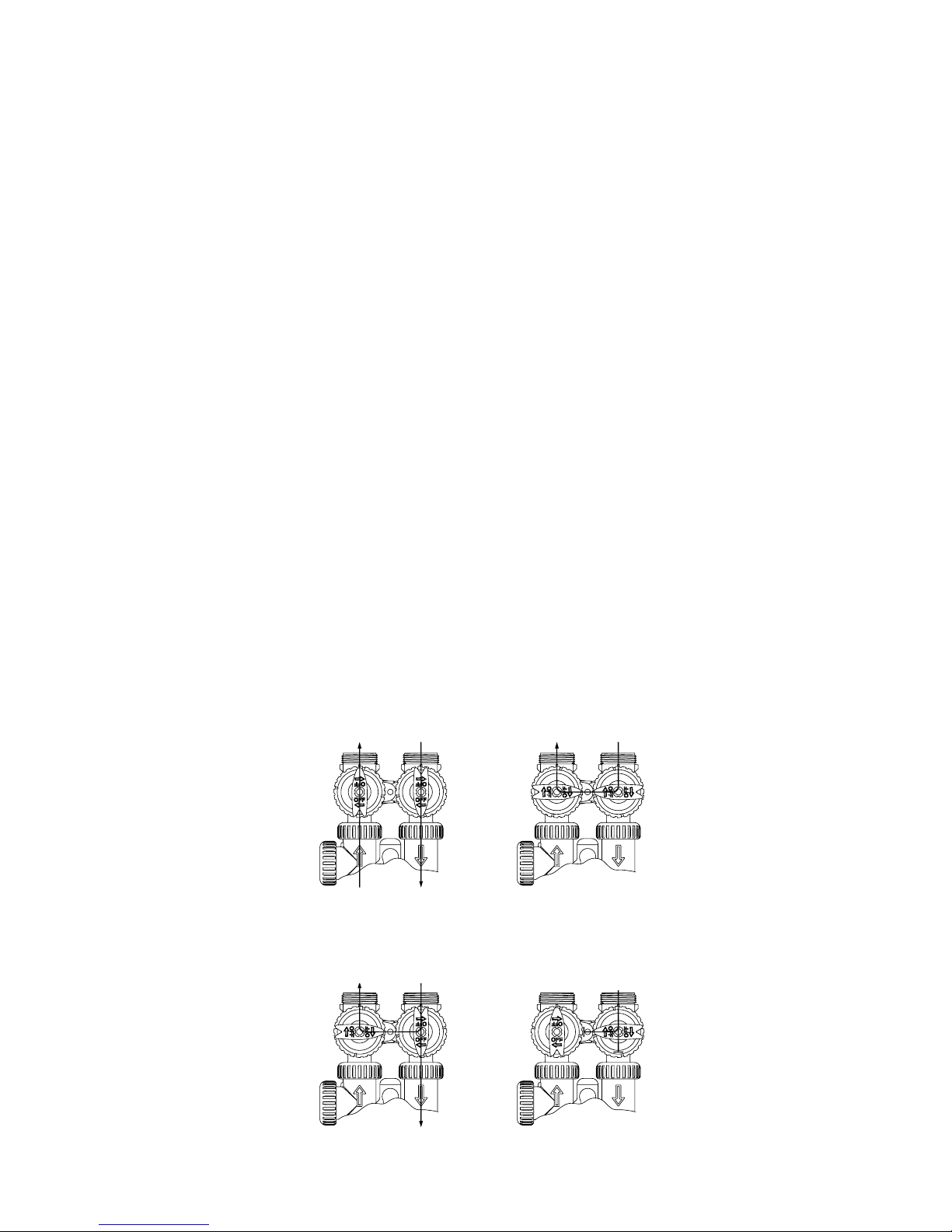

BYPASS VALVE

The bypass valve is typically used to isolate the control valve from the plumbing system’s water pressure in order to perform control valve

repairs or maintenance. The 1" full flow bypass valve incorporates four positions including a diagnostic position that allows a service

technician to have pressure to test a system while providing untreated bypass water to the building.

The bypass body and rotors are glass filled Noryl and the nuts and caps are glass filled polypropylene. All seals are self-lubricating EPDM

to help prevent valve seizing after long periods of non-use. Internal o-rings can easily be replaced if service is required.

The bypass consists of two interchangeable plug valves that are operated independently by red arrow shaped handles.

The handles identify the direction of flow. The plug valves enable the bypass valve to operate in four positions.

1. Normal Operation Position: The inlet and outlet handles point in the direction of flow indicated by the engraved arrows on the

control valve. Water flows through the control valve for normal operation of a water softener or filter. During the regeneration

cycle this position provides regeneration water to the unit, while also providing untreated water to the distribution system.

(See Figure 1)

2. Bypass Position: The inlet and outlet handles point to the center of the bypass.

The system is isolated from the water pressure in the plumbing system.

Untreated water is supplied to the building. (See Figure 2)

3. Diagnostic Position: The inlet handle points toward the control valve and the outlet handle points to the center of bypass valve.

Untreated supply water is allowed to flow to the system and to the building, while not allowing water to exit from the system to

the building (See Figure 3).

This allows the service technician to draw brine and perform other tests without the test water going to the building.

NOTE: The system must be rinsed before returning the bypass valve to the normal position.

4. Shut Off Position: The inlet handle points to the center of the bypass valve and the outlet handle points away from the control

valve. The water is shut off to the building.

The water treatment system will depressurize upon opening a tap in the building. A negative pressure in the building combined

with the softener being in regeneration could cause a siphoning of brine into the building.

If water is available on the outlet side of the softener or filter it is an indication of water bypassing the system (i.e. a plumbing

cross-connection somewhere in the building). (See Figure 4)

Figure 1

Figure 3

NORMAL OPERATION BYPASS OPERATION

“TREATED” WATER

EXITS

DIAGNOSTIC MODE

SUPPLY WATER

EXITS

SUPPLY WATER

ENTERS

SUPPLY WATER

ENTERS

SUPPLY WATER

EXITS

SHUT OFF MODE

NO WATER

EXITS

SUPPLY WATER

ENTERS

SUPPLY WATER IS SHUT OFF

FROM THE HOUSE AND THE VALVE

Figure 2

Figure 4

page 7

Loading...

Loading...