Page 1

Model HP-RO-1000 Undersink Reverse Osmosis System

WARNING:

User Manual

OPERATING SPECIFICATIONS

Before installing the system, make certain

your water supply complies with the

to do so may reduce the effectiveness

of the system and will void the warranty.

Consult your local water treatment utility

the quality for your water and use the table

below to record your results for future

reference.

HP-RO-1000 Specifications

Pressure Range: 40–100 psi

Temperature Range: 40–100°F

Total Dissolved Solids < 2000 ppm

Maximum Hardness*

Chlorine in Water Supply: < 2 ppm

Water Supply pH Limits: 3-11

Turbidity: 5 NTU Max.

Date of Purchase:

*

If the hardness of your water is above 10 gpg (171 mg/L), lime scale will build

up rapidly on the membrane inside of the RO membrane cartridge. Scale

buildup will plug the RO membrane cartridge and make the system ineffective.

We do not recommend the HP-RO-1000 to be used with water in excess of 10 gpg

(171 mg/L) hardness, unless the water is softened prior to the reverse osmosis

system.

†

See your local dealer or water treatment specialist to reduce these substances

in your water.

†

: 10 gpg

(2.8–6.9 bar)

(4.4-37.8°C)

(171 mg/L)

†

: < 0.1

Your Water

HP-RO-1000 Dimensions:

System Dimensions 13" H x 15" W x 4.75" Dia

(330 x 381 x 120.6 mm)

Tank Dimensions 14.5" H x 11" Dia

(368 x 279 mm)

System Weight 23 lbs (10.4 kg)

Tank Capacity 3.2 gal (12.1 L)

Tools Required

• Hand or Electric Drill • Phillips Screwdrivers

• 2 Adjustable Wrenches • Drill Bits: 1/8", 1/4" and 3/8"

• File • Towel

• Pencil • Safety Glasses

• Needle-nose Pliers • Tape Measure

• Utility Knife or Tube Cutter

(for plastic tubing)

Optional Materials

(For sinks without extra hole for faucet)

• Hand or Electric Drill • Center punch

• Drill Bits: 1/4" and 3/4" • Respirator

®

•

Tape • 1-3/8" Bi-metal or Carbide

Tipped Hole-saw

NOTE: All tools listed will not be necessary for installation.

Read installation procedures before starting to

determine required tools.

Parts Included

• Head Assembly • Drain Saddle Valve

• Screws for mounting • Water Supply Adapter

• Lead-free air gap drinking

• Quick-connect Fitting

water faucet

• Silicone grease • Storage Tank

• Tank Valve • Faucet Adapter

®

•

• 3/8" Plastic Tubing

Tape • Change Indication Sticker

• 1/4" Plastic Tubing

(red and blue)

(white, red and green)

• TDS Test Kit

• Filter Cartridges:

Filter Kit (to be changed annually)

PART # WI-HP-RO-1000-FILTER-KIT

Filter Kit Includes:

PW-S2500R Cartridge (Yellow)

PW-C5000R Cartridge (Blue)

PW-C2500R Cartridge (Violet)

Membrane (to be changed every 3-5 years)

PART # WI-HP-RO-1000-MEMBRANE:

PW-RO75R Cartridge (Green)

HP-RO-1000-Manual Rev. 2-14

Page 2

GENERAL PRECAUTIONS

WARNING:

WARNING:

WARNING:

WARNING:

CAUTION

CAUTION

Do not use with water that is

microbiologically unsafe or of unknown

quality without adequate disinfection before

cyst reduction may be used on disinfected

The HP-RO-1000 contains a replaceable RO

membrane cartridge that is critical to the

NOTE: If the HP-RO-1000 stands for more than 2 to 3 days

without being used, the storage tank should be

emptied.

to seal joints. Do not use pipe compound (“pipe

dope”), sticks, or similar compounds with this

unit; they contain petroleum derivatives which can

cause crazing and cracking of the plastic in the

®

tape without adhesive backing

RO membrane cartridge should be with one

and contaminant reduction performance.

The HP-RO-1000 contains a replaceable RO

membrane cartridge, critical for the effective

reduction of total dissolved solids. Product

water should be tested periodically to verify

that the system is working properly.

The HP-RO-1000 is acceptable for treatment

than 27 mg/L nitrate and 3 mg/L nitrite in

for nitrate/nitrite reduction only for water

supplies with a pressure of 40 psig (280 kPa)

or greater.

WARNING:

WARNING:

CAUTION

NOTE: Substances listed as reduced are not necessarily

NOTE: Your water must be within required limits for

NOTE: Install on cold water line only.

NOTE: Do not install where system will be exposed to

NOTE: Make certain that installation complies with all state

NOTE: During extended periods of non-use (such as

The HP-RO-1000 shall only be used for arsenic

reduction on chlorinated water supplies

containing detectable residual free chlorine

at the system inlet. Water systems using an

in-line chlorinator should provide a oneminute chlorine contact time before the unit.

The HP-RO-1000 will not protect against

disease-causing bacteria or remove naturallyoccurring harmless bacteria.

The HP-RO-1000 must be protected against freezing

resulting in water leakage.

Turn off water supply to head without cartridge if

it must be left unattended for an extended period

of time.

Do not use electrical heating tape on this unit.

in your water. System must be maintained

according to manufacturer's instructions, including

satisfactory operation. If not, the RO membrane

cartridge’s life may be shortened and your warranty

direct sunlight.

and local laws and regulations.

included with the system have limited service lives.

water indicate that the cartridges and/or membrane

should be replaced.

during a vacation), remove the membrane cartridge

them in a sealed plastic bag. Store the cartridges

in the refrigerator for future use. When re-starting

NOTE: Use only soap and water to clean components.

NOTE: Do not use aerosol sprays (bug spray, cleaning

fluids, etc.) near the HP-RO-1000. They contain organic

solvents which will cause crazing and cracking of

NOTE: After prolonged periods of non-use, such as a

vacation, it is recommended that the system be

before using.

NOTE: Do not use a torch near the unit.

HOW REVERSE OSMOSIS (RO) WORKS

The HP-RO-1000 uses a semi-permeable membrane to reduce

dissolved salts, improving the taste and odor of your water. The

RO membrane cartridge contains multiple layers of micron-thin

pass through the cartridge, while dissolved salts are rejected.

chlorine that may foul the membrane. The RO membrane

WATER and REJECT WATER. Your household water pressure

forces water through the membrane within the RO membrane

cartridge, and into the storage tank. This is product water.

Dissolved salts cannot pass through the membrane and are

sent to the drain as reject water. When you open the faucet,

product water (permeate) is drawn from the storage tank

any remaining taste or odor in the water and provides you and

your family with cleaner, great-tasting water.

The HP-RO-1000 also features an auto shut-off valve, which shuts

off the system once the pressure in the storage tank reaches

2/3 of the incoming water pressure (your household water

pressure). When you open the faucet to draw water from

the storage tank, the pressure inside the tank drops and

the auto shut-off valve opens. The system then begins to

operate, replenishing the water you took from the storage tank.

produced, up to 7 gallons are discharged as reject water. The

storage tank can hold up to 3.2 gallons (12.1 L) of water at a

time, more than enough for the average family’s drinking and

cooking needs.

on page 1 of this manual, the RO membrane

cartridge of the HP-RO-1000 should last 12–24 months.

The precise life span of the HP-RO-1000's RO membrane

cartridge will depend on the quality of the water

entering the system, and the frequency with which

you use it. Frequent use prevents the dissolved

salts from building up on the membrane as scale.

The more water the system is required to produce,

the longer the membrane will last. You may wish

to find a variety of uses for your HP-RO-1000 system in

order to prolong the life of the membrane.

instructions.

2 • HP-RO-1000 Undersink Reverse Osmosis System

Page 3

INSTALLATION

WARNING:

WARNING:

WARNING:

WARNING:

precautions before installing and using your

HP-RO-1000 system.

NOTE: The HP-RO-1000 may be installed under a sink or

NOTE: The HP-RO-1000 is installed vertically.

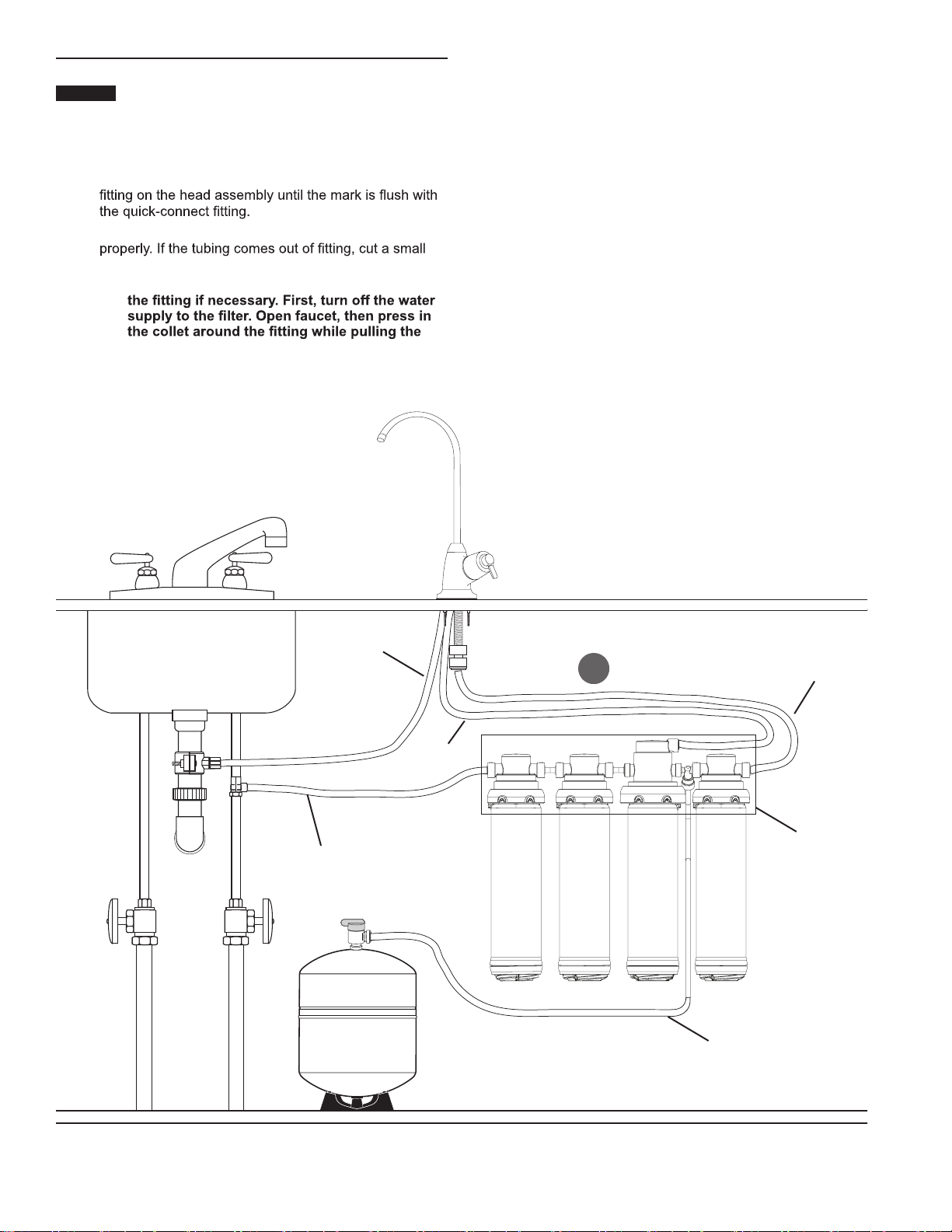

NOTE: Numbered diagrams correspond with numbered

NOTE: For standard installation on 1/2" 14 NPS threads

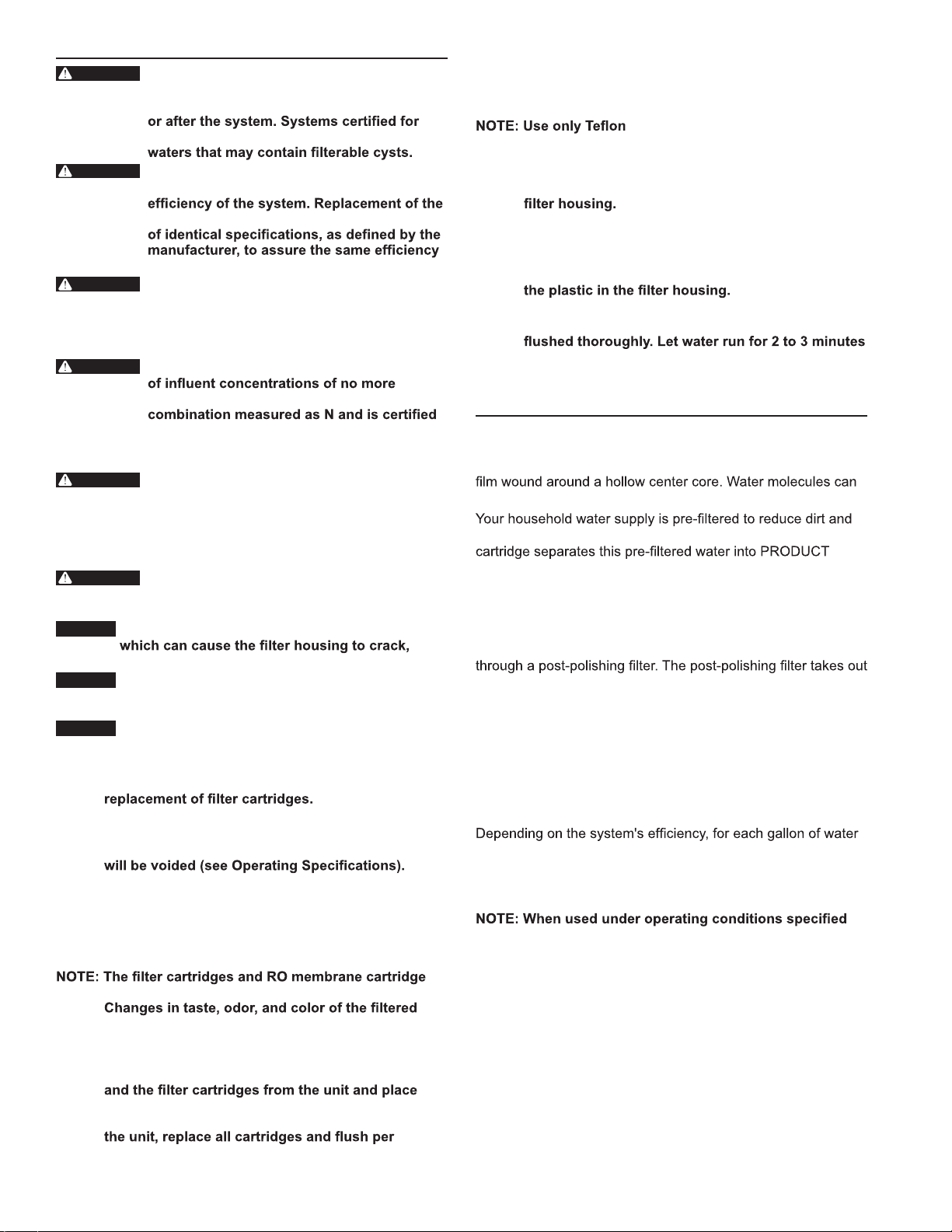

1. Installing the Water Supply Adapter

in the basement.

steps.

(most common thread on kitchen faucets) cold

water line.

to the cold water supply line. If local codes do not permit

the use of the supply adapter, alternate connectors can be

obtained from your local retailer.

A. Turn off cold water supply line. If cold water line does

not have a shut-off valve under the sink, one should be

installed.

B. Turn on the cold water faucet and allow all water to

drain from line.

C. Disconnect cold water line from 1/2" 14 NPS threaded

stub on bottom of main faucet.

D. Screw the water supply adapter to the threaded faucet

stub as shown.

E. Using the nut that previously connected the cold water

line to the faucet, screw the cold water line to the male

supply adapter threads.

E

B

C

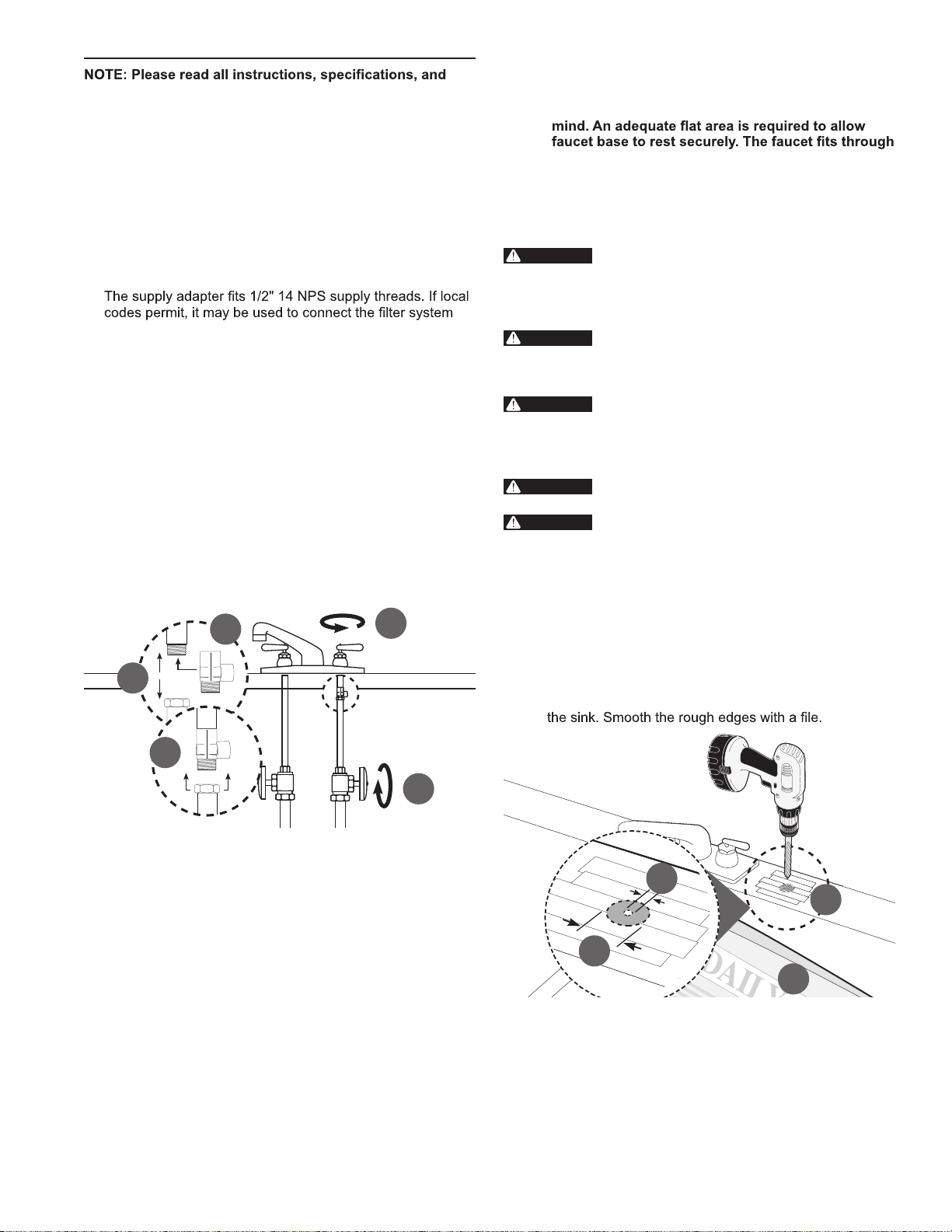

2. Selecting the Faucet Location

NOTE: The drinking water faucet should be positioned

with function, convenience, and appearance in

a 1-3/8" hole. Most sinks have pre-drilled 1-3/8" or

1-1⁄2" diameter holes that may be used for faucet

installation. If these pre-drilled holes cannot be

used or are in an inconvenient location, it will

be necessary to drill a 1-3/8" hole in the sink to

accommodate the faucet.

This procedure may generate dust which

can cause severe irritation if inhaled or come

in contact with the eyes. The use of safety

glasses and respirator for this procedure is

recommended.

Do not attempt to drill through an all-

porcelain sink. If you have an all-porcelain

sink, mount the faucet in pre-drilled sprayer

hole or drill through countertop next to sink.

When drilling through a countertop, make

sure the area below the drilled area is free

of wiring and piping. Make certain that

you have ample room to make the proper

connections to the bottom of the faucet.

Do not drill through a countertop that is

more than 1" thick.

WARNING:

A. Line bottom of sink with newspaper to prevent metal

B. Place masking tape over the area to be drilled to help

C. Mark hole with center punch. Use a 1/4" drill bit for a

D. Using a 1-3/8" hole saw, drill a hole completely through

Do not attempt to drill through a tiled,

marble, granite or similar countertop.

Consult a plumber or the countertop

manufacturer for advice or assistance.

shavings, parts, or tools from falling down drain.

prevent scratches if drill bit slips.

pilot hole.

F

D

A

Figure 1

C

C

1

4”

D

11⁄4”

D

HP-RO-1000 Undersink Reverse Osmosis System • 3

⁄

Figure 2

B

A

Page 4

INSTALLATION continued

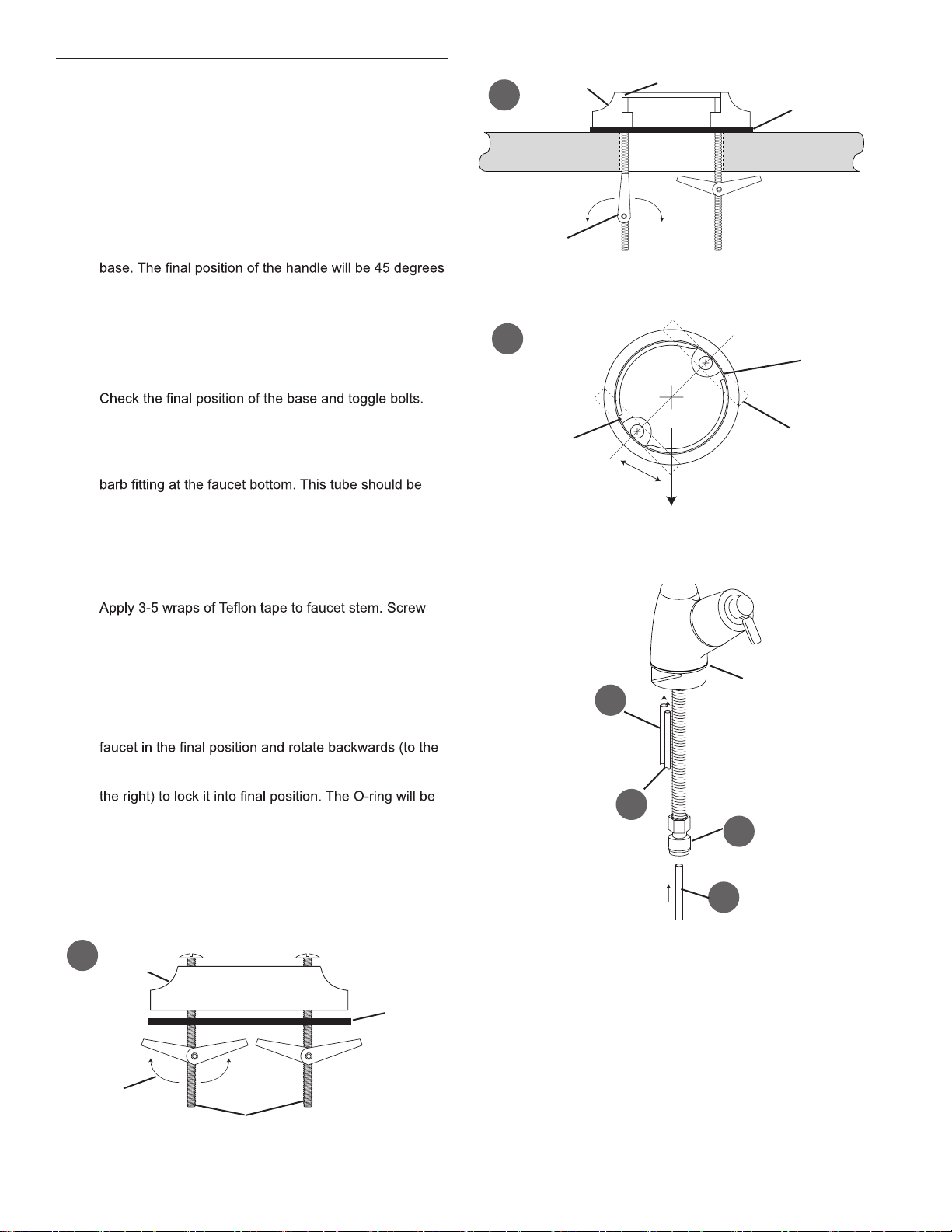

3. Mounting the Faucet

A. Pre-assemble the base. The rubber washer should be

in place below the base. The two toggle bolts should be

inserted through the base and the rubber washer. The

bolts are screwed into the spring-loaded toggle.

B. Place the base assembly over the hole in the sink. The

two toggles should pass through the hole far enough to

spring fully open. If they are not open, unscrew the bolt

until the toggle moves down to clear the sink.

C. Look down through the base for this step. Before

tightening the bolts, determine the correct rotation of the

Base

B

Will Spring Open

O-ring Seat

Black Rubber

Washer

off from the bolt heads. Use Figure 5 to help determine

the best position for your installation.

Through the hole in the base, hold the toggle in position

while tightening the bolt. The spring loaded toggle

will contact the bottom of the counter top and hold in

position. Do not fully tighten. Repeat for second toggle

bolt.

Tighten the two bolts evenly. DO NOT OVERTIGHTEN.

Tighten only far enough to prevent the base from

rotating when the faucet is rotated in place.

D. Attach large diameter 3/8" (red) drain tube to the larger

long enough to reach the drain clamp in Step 7.

E. Locate the 1/4" red brine tube from the right side of the

system head assembly. Route the tube through the

faucet base and connect to small barb on the faucet.

Make certain that the tube is not kinked or stressed

once the head assembly is mounted.

F.

quick connector onto end of threads.

G. Wet end of 3/8" blue tube. Push into bottom of

connector. Tug gently to be sure connection is

complete. This tube should be long enough to reach the

top right side of the RO Assembly.

H. Check that the O-ring is in place on the faucet. Feed

the remaining 3/8" tubes through the base. Hold the

C

Notch For Faucet

Handle Faces This Direction

Figure 4

Notch For Faucet

Blades Must Be Held

When Tightening

45°

Figure 5

O-ring

D

left) while pushing down. The faucet will drop into the

base. Push down on the faucet and rotate forward (to

seated and the faucet held securely in position.

I. Insert the spout into the top opening. Hold in position

and screw the collar onto the base.

NOTE: If the faucet handle is not in the correct

A

Folds Upward

4 • HP-RO-1000 Undersink Reverse Osmosis System

position, remove the faucet, loosen the toggle

bolts and reposition the base. Tighten the

toggle bolts. Then reinstall the faucet.

Base

Black Rubber

Washer

Figure 3

E

F

G

Figure 6

Page 5

CAUTION

INSTALLATION continued

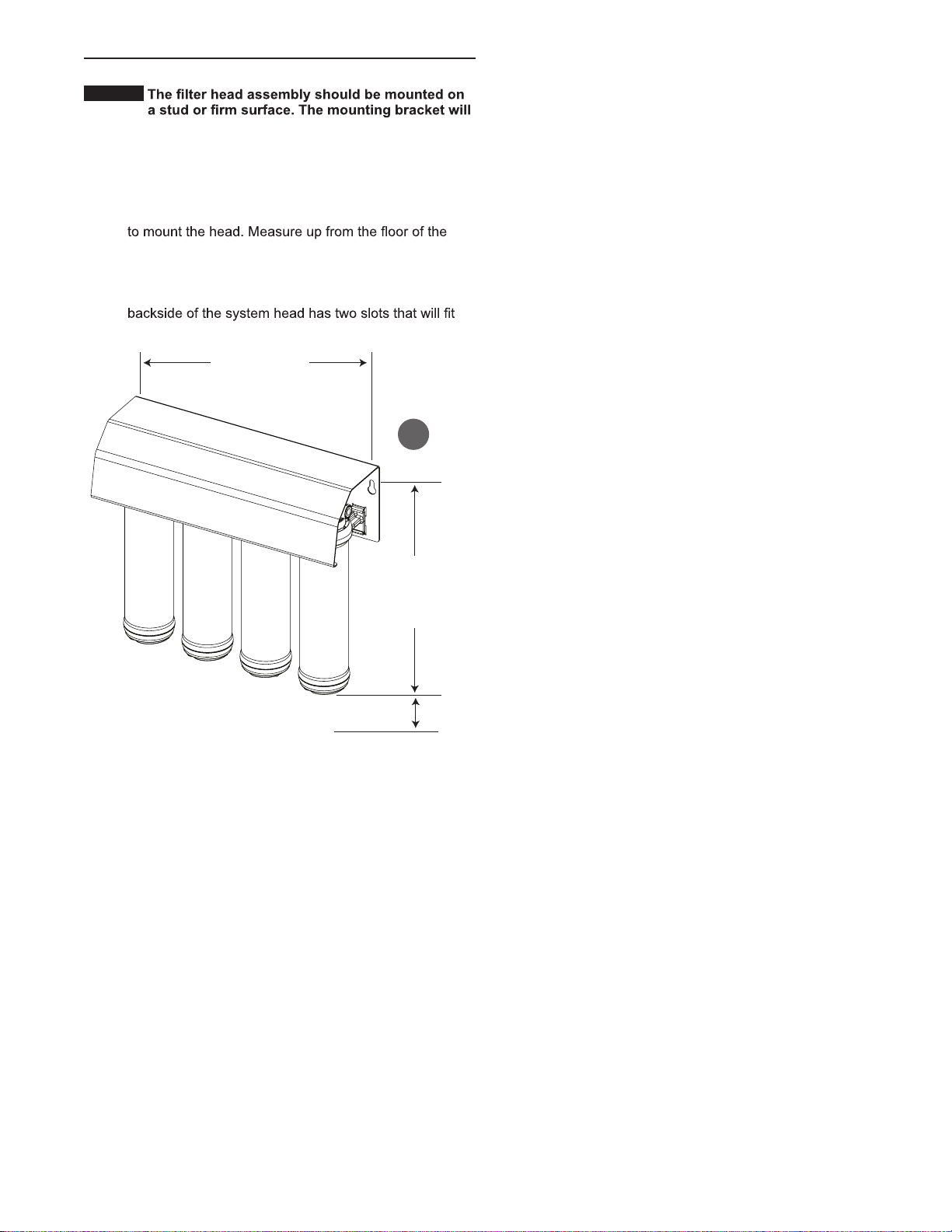

4. Mounting the System

support the weight of the cartridges and help

prevent strain on the water lines.

A. Select location under sink or in basement where unit

is to be mounted. The head assembly is mounted in a

vertical position.

B. When mounting the HP-RO-1000 two screws are supplied

cabinet 14-1/2". This will provide clearance to change

the cartridges. The two screws will be 14" apart and

level. Screw the two screws into the wall. Leave a

gap between the screw head and the wall of 1/8". The

over the screw heads and slide down to lock.

14 Inches

Between Holes

B

From Mounting

Hole to Bottom

of Cartridge

2-1/2 Inches Clearance Below Cartridges

Figure 7

12 Inches

HP-RO-1000 Undersink Reverse Osmosis System • 5

Page 6

CAUTION

INSTALLATION continued

5. Connecting the Faucet

Water supply to the tee should have a separate

shut-off valve. If it does not, a separate shut-off

should be installed.

A. Locate the 3/8" blue tubing from the faucet and place a

mark 5/8" from the end of the tubing. Moisten the end of

the tubing with water and insert into the quick-connect

B. Gently pull back on the tubing to ensure it is connected

section off of the tubing and reconnect.

NOTE: Tubing may be quickly and easily removed from

tubing with your other hand.

Step 8

3/8" Red

1/4" White

Step 6

Step 9

Yellow

A

Blue

1/4" Green

1/4" Red

Green

3/8" Blue

Violet

Step 11

Step 5

Cover Not Shown

Figure 8

6 • HP-RO-1000 Undersink Reverse Osmosis System

Page 7

INSTALLATION continued

6. Connecting the Water Supply Adapter

A. Determine the length of 1/4" white plastic tubing needed

to connect the inlet (white collet) on the left side of the

enough tubing to prevent kinking and cut the tubing

squarely. Place a mark 5/8" from the end of the tubing.

B. Wet tubing with water and insert into water supply

inserting other end of tubing into inlet of the head

assembly.

D

E

7. Installing the Drain Clamp

NOTE: If you have a single-basin sink with a disposal

unit, call Technical support at 1-800-322-9283 for

options.

NOTE: Before installing the drain clamp, check the

drainpipes under the sink for corrosion. Corroded

pipes should be replaced before continuing with

installation.

A. Attach the drain clamp to a vertical section of the

drainpipe, about 6" above the trap. Make sure the

opening on the drain clamp is facing towards the

drinking water faucet.

B.

a 1/4" hole through one side of the drainpipe.

C. Remove the drain clamp from the drainpipe and enlarge

edges from the drilled hole.

D. Make sure the black rubber gasket is adhered to the

inside of the drain clamp and place the drain clamp

assembly over the drilled hole. Look through the hole

and position the clamp so that the center of the clamp

hole is slightly higher (about 1/16") than the center

of the drilled hole, see Figure 11. Tighten the clamp

securely.

E. Screw the plastic compression nut onto the drain clamp

until hand-tight.

Figure 11

8. Connecting the Faucet to the Drain

NOTE: This is a gravity drain line. Any loops, kinks or

sharp bends must be eliminated before proceeding.

Failure to create a straight line to the drain may

result in reject water leaking through the air gap

in the faucet onto the counter top and below the

faucet.

A. Align the 3/8" red tubing from the faucet with the

compression nut on the drain clamp. Create as straight

a path as possible with the tubing. Cut the tubing

squarely below the nut and remove the internal and

external burrs.

B. Loosen the compression nut two complete turns. Insert

then tighten 1 to 2 turns with a wrench.

A

B

B

A

Figure 12

6"

Figure 9

C

Figure 10

HP-RO-1000 Undersink Reverse Osmosis System • 7

Page 8

INSTALLATION continued

CAUTION

CAUTION

9. Installing the Cartridges

11. Putting the System Into Operation

the model number.

Cartridge #1 = PW-S2500R, Yellow

Cartridge #2 = PW-C5000R, Blue

Cartridge #3 = PW-RO75R, Green

Cartridge #4 = PW-C2500R, Violet

Install the cartridges in order. If the cartridges are installed

A. Slide the cartridge into the head until it stops.

B. Twist the cartridge 1/4 turn clockwise until it snaps into

place. Gently pull out on the cartridge to ensure the

cartridge is locked into place.

5

0

0

C

0

W

P

Quick Change

Sediment Cartridge

CAPACITY:

Replace every 12 months

TEMPERATURE RANGE:

40-100°F (4.4-37.8°C)

PRESSURE RANGE:

30-125°F (2.4-8.6 Bar)

For use with Pentair Water models:

PB4RO-75, PP4RO-75 and PB5RO-75

2

5

S

-

-

0

0

R

W

P

Quick Change

EP Cartridge

CAPACITY:

Replace every 12 months

TEMPERATURE RANGE:

40-100°F (4.4-37.8°C)

PRESSURE RANGE:

30-125°F (2.4-8.6 Bar)

For use with Pentair Water models:

PB4RO-75, PP4RO-75 and PB5RO-75

R

quality without adequate disinfection

before or after the systems. Systems

on disinfected waters that may contain

Warning: Do not use with water that is

microbiologically unsafe or of unknown

0

LLC

,

n

o

ltrati

i

F

l

a

denti

i

es

R

ir

WI, USA

a

t

,

e

n

ke

u

0 Pe

a

1

0

lw

2

i

©

M

0

0

MR1

5

2

v A

e

C

R

-

W

7144

4

P

H2

S

ina

h

bled in C

m

Asse

1

R

Milwaukee, WI, USA

Assembled in China SH247143 Rev A MR10

3

on disinfected waters that may contain

2

R

0

0

5

2

C

-

W

P

Figure 13

NOTE:

Installing the green reverse osmosis cartridge PW-RO75R

requires additional force than the other cartridges to rotate

into the proper position. Improper installation of the cartridge

may prevent water from flowing through the system.

To ensure proper installation, rotate the cartridge in the port

until the cartridge label faces directly forward and the side tab

on the cartridge aligns with the side port on the filter body.

10. Connecting the Storage Tank to the System

CAUTION

When tank is full, it weighs approximately 35

pounds. Provide ample support under the tank.

A.

B. Thread the tank valve onto the top of the tank opening

by turning it clockwise until snug.

C. Locate the green tubing and a mark 3/4" from the end.

Moisten one end of the green tubing with water and

insert with a twisting motion into the free port of the tank

NOTE: Do not cut green tube. This line should be left at

the pre-cut length for future service.

NOTE: The pressurized storage tank has capacity of

3.2 gallons. The tank's air pressure is factory

set at 5 to 7 psi when tank is empty

.

to wall to prevent it from falling and possibly

becoming damaged.

NOTE: Use caution not to bend or pinch the tubing behind

the system while attaching to mounting screws.

may make the water appear gray in color. The

NOTE: The HP-RO-1000 system does not produce a high

does. Water is produced at a slow, drop-by-drop

storage tank. As water is taken from the tank, the

system automatically starts the cycle of replacing

the water and then stops water production when

the tank is full.

A. Make sure cold water faucet is “off” (Figure 14).

B. Make sure tank valve is in the open position.

C. Slowly turn on cold water supply.

D.

for 12 hours, then close it.

E.

check the installation for leaks. After the storage tank

minutes for all of the water to drain from the tank. Close

Visually check the entire system for leaks. If a leak is

present, see TROUBLESHOOTING.

F. Repeat Step E four times.

NOTE: Initially, the water may appear cloudy. This is a

It is not harmful and will disappear in a matter

of minutes. It may take up to a week after

trapped air to dissipate.

The system is ready for operation. You can now enjoy quality

water from the HP-RO-1000.

Closed

Tank Valve

B

Open

Tank Valve

A

Figure 14

8 • HP-RO-1000 Undersink Reverse Osmosis System

Page 9

OPTIONAL INSTALLATION

CAUTION

CAUTION

CONNECTING THE HP-RO-1000 TO

REFRIGERATOR ICEMAKER/WATER

DISPENSER

If you are connecting the HP-RO-1000 to your

refrigerator/icemaker with initial system

installation, wait to turn on the icemaker until

the Post- Filter Cartridge (on the right side of the

Step 11.

NOTE: For optimum performance, it is recommended

that the distance between the HP-RO-1000 and the

refrigerator icemaker/water dispenser be no greater

than 10 feet (3 m). At distances greater than 10 feet,

the water pressure from the system may not be

adequate to deliver water to the refrigerator.

Materials Required

(available from Water, Inc.)

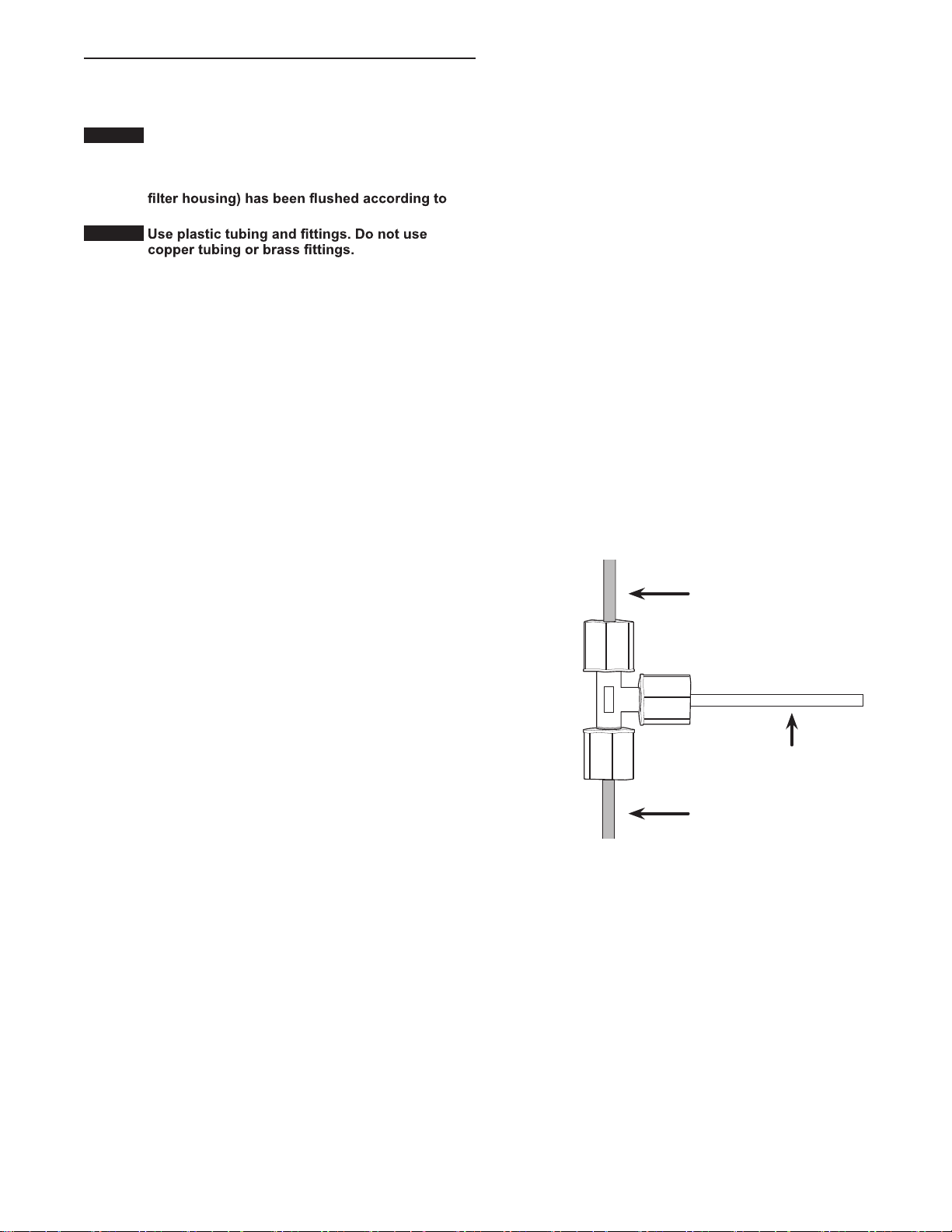

• 3/8" x 3/8" x 3/8" (9.5 x 9.5 x 9.5 mm) compression or

quick-connect tee.

• 3/8" (9.5 mm) polyethylene tubing (maximum length of

10 feet [3 m] recommended)

• Shut-off valve

A. Turn off icemaker and refrigerator water supply. Consult

manufacturer’s guidelines.

B. Close tank valve (on top of storage tank).

C. Turn off water to the system at the cold water supply.

D. Open drinking water faucet to relieve pressure.

E. Locate blue tubing leading to your drinking water faucet.

Cut and insert the 3/8" x 3/8" x 3/8" (9.5 x 9.5 x 9.5 mm)

compression or quick-connect tee into the blue tubing

(Figure 15). Consult manufacturer’s guidelines before

installing the tee connection.

NOTE: When cutting the blue tubing, you may

experience some water leakage.

F. Using a length of 3/8" polyethylene tubing, connect

the icemaker/dispenser line with the free port on the

compression tee.

G. The shut-off valve should be installed as close to this

port of the tee as possible. Shut-off valve should be

installed in the OFF position. Consult manufacturer’s

guidelines before installing the shut-off valve.

H. Completely open cold water supply (until it comes to a

stop).

I. Open tank valve.

J. Turn off the drinking water faucet.

K. Open shut-off valve at the tee connection.

L. Turn on ice maker. Consult manufacturer’s instructions.

M. Check for leaks and tighten connections if necessary.

Figure 15

Tubing to drinking

water faucet

Tubing to

refrigerator

Tubing from

system outlet

HP-RO-1000 Undersink Reverse Osmosis System • 9

Page 10

TESTING YOUR REVERSE OSMOSIS

CAUTION

CHANGING THE CARTRIDGES

SYSTEM

Total Dissolved Solids (TDS) Test

NOTE: Under NSF/ANSI Standard 58, it is highly

recommended that you (the consumer) have your

water tested at least every 6 months to verify that

your system is performing satisfactorily.

Sampling Instructions:

Sampling instructions are included with the Total Dissolved

Solids (TDS) Test Kit. If the TDS Test Kit is missing from your

unit, please call Customer Support at 1-800-322-9283 for a

replacement.

Total Dissolved

Solids Test Kit

Figure 16

WHEN TO CHANGE THE CARTRIDGES

The life of the cartridge depends on the water volume used and

the substances in the water. Normally, cartridges should be

changed at intervals of 6 months. Replace the cartridge sooner

if the water pressure at the faucet begins to drop noticeably or

water.

Materials Needed

• Replacement Cartridges (color coded):

PW-S2500R Cartridge Yellow

PW-C5000R Cartridge Blue

PW-RO75R Cartridge Green

PW-C2500R Cartridge Violet

when the water pressure at the faucet begins to drop

time. The cartridges are color coded to indicate which location

they are installed into.

1. Changing the Cartridges

NOTE: Only the replacement cartridges listed can be used

with this system. Failure to use recommended

replacement cartridges will void your warranty.

A. Place a small pan or towel under the HP-RO-1000 to catch

any water that may drip.

B.

housing) counter-clockwise for a 1/4 of a turn, and pull

the cartridge out of the system. If the system has any

C. Push the new cartridge into the head until it can go no

further.

D. Twist the cartridge 1/4 turn clockwise until it snaps into

place.

E. Gently pull the cartridge straight out to ensure the

cartridge is locked into place.

F. Repeat for all other cartridges.

G. Turn on water and check for leaks. If leaks are found,

see Troubleshooting.

H.

2. Flushing the RO membrane

NOTE: The HP-RO-1000 system does not produce a high

does. Water is produced at a slow, drop-by-drop

storage tank. As water is taken from the tank, the

system automatically starts the cycle of replacing

the water and then stops water production when

the tank is full.

A. Make sure cold water faucet is “off” (Figure 14).

B. Make sure tank valve is in the open position.

C. Slowly turn on cold water supply.

D.

for 12 hours, then close it.

E.

check the installation for leaks. After the storage tank

minutes for all of the water to drain from the tank. Close

Visually check the entire system for leaks. If a leak is

present, see TROUBLESHOOTING.

F. Repeat Step E four times.

10 • HP-RO-1000 Undersink Reverse Osmosis System

Page 11

TROUBLESHOOTING

CAUTION

Leaks on Supply Adapter Connection

1. Turn off water supply valve and turn on drinking water

faucet to release pressure in system.

2.

out leaking tubing by pressing collar surrounding tubing

while pulling the tubing with your other hand.

3. Inspect to see if plastic tubing is scratched and supply

adapter was properly attached.

4. If tubing is scratched, cut off 1/2" to 5/8" and reinstall.

Leaks on Faucet/Tubing Connection

1. Turn off water supply valve and turn on drinking water

faucet to release pressure.

2. Unscrew tubing nut at bottom of faucet. Inspect the tubing.

The insert, plastic ring and tubing should not be damaged.

3. Check if insert is in place and tubing is cut squarely and

not scratched, cut tubing if necessary to get square smooth

end.

4. If the tubing is smooth and square, reconnect tubing by

inserting into faucet and tightening nut. The plastic ring

should be held tight to the faucet system when the nut is

tight.

5. Turn on water supply valve, then close faucet and check for

leaks.

NOTE: If leaks persist, or if there are other leaks on

system, turn off water supply and call Technical

Support 1-800-322-9283.

Leaks Between Cartridge and Filter Housing

1. Turn off cold water supply to system at saddle valve. Close

tank valve. Open drinking water faucet to relieve water

pressure.

2. Remove the cartridge, inspecting it for damage. Inspect

O-rings to make sure they are seated and clean.

3.

4. Turn on water supply at saddle valve. Open tank valve.

leaks persist, call Technical Support.

Leaks at Quick-Connect Fittings

The 1/4" red tubing connected to the top of the

The system will not operate correctly if the

restrictor is removed.

1. Close tank valve, close saddle valve, and open drinking

water faucet.

2.

the tubing with your other hand.

3. Cut off 1" of tubing. Tubing should be cut squarely. Internal

and external burs should be removed. Place a mark on

tubing 5/8" from end on 1/4" tubing or 3/4" from end on 3/8"

tubing.

4.

5. Open the saddle valve until it comes to a stop. Open the

tank valve and close drinking water faucet. If leaks persist,

call Technical Support.

Leaks from Faucet

1. Check to make sure white tubing leading from the drinking

water faucet to the drain is as straight as possible (it is

usually necessary to cut this line during installation). Any

to the drain.

2. Check to make sure the drain clamp and the drain hole are

properly aligned, refer to Figure 7 on page 7).

1. Check to make sure there is no foreign matter clogging the

drain line or at the drain clamp hole. If leaks persist, call

Technical Support.

No Flow or Slow Flow from the Brine (Reject) Line (Less

the unit is producing water by turning the valve on

the storage tank off and opening the drinking water

faucet. Water should drip from faucet.

1.

Leak Between Tank Valve and Storage Tank

1. Turn off water supply to system at the saddle valve. Open

faucet to drain storage tank. Let faucet run for 3–5 minutes

until it drips.

2. Remove green tubing from tank valve by pressing the collar

hand.

3. Unscrew the tank valve from the storage tank.

®

4.

storage tank.

5. Thread the tank valve onto the top of the tank opening by

turning it clockwise until snug.

6. Cut off 1" of tubing. Tubing should be cut squarely. Internal

and external burrs should be removed. Place a mark on

tubing 3/4" from end of tubing.

7.

8. Turn water supply on at the saddle valve and close drinking

water faucet.

9. Allow system to pressurize for several hours and check for

leaks.

10. Check for leaks after tank is fully pressurized (1–3 hours). If

leak persists, call Technical Support .

tape on the threads of the

2.

High TDS in Product Water

1. If high TDS (Total Dissolved Solids) is detected in the

product water, the RO Cartridge may need to be replaced

new installation, call Technical Support.

2. Otherwise, draw 1 gallon of water from the unit. After

10 minutes, then run water from the faucet and test the

water again.

3. Determine when you last changed the RO Filter Cartridge

and call Technical Support.

HP-RO-1000 Undersink Reverse Osmosis System • 11

Page 12

TROUBLESHOOTING continued

Limited Flow at Drinking Water Faucet

1. Turn off water supply to system at saddle valve.

2.

3. Unscrew the blue cap at the base of the storage tank to

expose air valve. Use a small air compressor or bicycle

pump to add air to the storage tank. This will force the

water out of the storage tank through the faucet. Continue

to add air until no more water comes out of the faucet.

4. Turn off the drinking water faucet.

5. Using an air pressure gauge, adjust the pressure in the

storage tank to 5–7 psi.

6. Replace the blue cap.

7. Open the saddle valve until it comes to a stop. Let the

approximately 33 pounds. If performance has not improved,

call Technical Support.

Sudden Return of Taste and Odor

If shortly after complete servicing, noticeable taste and odors

return, contact Technical Support.

If you are experiencing a problem not listed in this manual,

shut off the water supply at the saddle valve and close the tank

valve. Call Technical Support at 800-322-9283.

12 • HP-RO-1000 Undersink Reverse Osmosis System

Page 13

WARNING:

Do not use with water that is

microbiologically unsafe or of unknown

quality without adequate disinfection before

cyst reduction may be used on disinfected

REPLACEMENT PARTS

For replacement parts contact your local retailer or call

Customer Service at 1-800-322-9283.

Item #Part Number Description QTY

NOTE: Substances that may be reduced are not

necessarily in your water. Filter must be maintained

according to manufacturer’s instructions, including

MAINTENANCE

For replacement cartridges, you can:

• go to waterinc.com

• find a local dealer at dealer.waterinc.com

• or call 800-322-9283

REPLACEMENT CARTRIDGES:

Filter Kit (to be changed annually)

PART # WI-HP-RO-1000-FILTER-KIT

Filter Kit Includes:

PW-S2500R Cartridge (Yellow)

PW-C5000R Cartridge (Blue)

PW-C2500R Cartridge (Violet)

Membrane (to be changed every 3-5 years)

PART # WI-HP-RO-1000-MEMBRANE:

PW-RO75R Cartridge (Green)

1 244877 Storage Tank 3.2 Gal 1

2 555612-96 Cartridge, Sediment PW-S2500R,

Yellow

3 555586-96 Cartridge, Carbon Block PW-C5000R,

Blue

4 555676-96 Cartridge, RO Element, 75 GPD

PW-RO75R, Green

5 555585-96 Cartridge, GAC PW-C2500R, Violet 1

6 244876 Kit, Faucet 1

244857 Faucet, Air Gap - Paragon

(includes Toggles)

244783 Valve, RO Tank 1/4" NPT x 1/4" QC 1

247117 Label, Water Change Reminder 2

1-459-00 Mounting Screw 2

143495 Lubricant, Silicone Packet 1

244796 Drain Clamp, 3/8" QC 1

244797 Inlet Adaptor, 1/2" FIPS x 1/2" MIPS x

1/4" QC

244880 Faucet Adaptor, 1/4" NPT x 3/8" QC 1

150646 TDS Test Kit 1

7 244849 Tube, 3/8" OD Red - Faucet Drain 1

8 244848 Tube, 3/8" OD Blue - Permeate 1

9 244794 Tube, 1/4" OD White PE 1

10 244850 Tube, 1/4" OD Green 1

11 244875 Tube, 1/4" OD Red 1

12 357484 Head Assembly Includes Bracket,

Screws, Manifold Assembly and

Plastic Tee

HP-RO-1000-Manual

Rev. 2-14

HP-RO-1000 Manualt (Not Shown) 1

1

1

1

1

1

1

1

6

IT’S TIME TO CHANGE YOUR

Place this half of the label on your

IT’S TIME TO CHANGE YOUR

calendar, date book or refrigerator.

Bend and Peel Here

Place this half of the label on your

calendar, date book or refrigerator.

cartridge on:

month day year

For more info: 1-800-279-9404

month day year

For more info: 1-800-279-9404

12

T

N

A

C

I

R

LUB

Bend and Peel Here

SILICONE

cartridge on:

SH247117 JA10

SH247117 JA10

10

HP-RO-1000 Undersink Reverse Osmosis System • 13

5432

987

11

Page 14

Arsenic Fact Sheet

Arsenic (abbreviated As) is found naturally in some well

water. Arsenic in water has no color, taste or odor. It must

be measured by a lab test. Public water utilities must have

their water tested for arsenic. You can get the results from

your water utility. If you have your own well, you can have

the water tested. The local health department or state

labs. The cost is typically $15 to $30. Information about

arsenic in water can be found on the Internet at the US

Environmental Protection Agency web site: www.epa.gov/

safewater/arsenic.html.

There are two forms of arsenic: pentavalent arsenic [also

called As(V), As(+5), and arsenate] and trivalent arsenic

[also called As(III), As(+3) and arsenite]. In well water,

arsenic may be pentavalent, trivalent, or a combination

of both. Special sampling procedures are needed for a

lab to determine what type and how much of each type of

arsenic is in the water. Check with the labs in your area to

see if they can provide this type of service.

Reverse osmosis (RO) water treatment systems do not

remove trivalent arsenic from water very well. RO systems

are very effective at removing pentavalent arsenic. A free

chlorine residual will rapidly convert trivalent arsenic to

pentavalent arsenic. Other water treatment chemicals

such as ozone and potassium permanganate will also

change trivalent arsenic to pentavalent arsenic. A

combined chlorine residual (also called chloramine) may

not convert all the trivalent arsenic. If you get your water

free chlorine or combined chlorine is used in the water

system.

HP-RO-1000 system is designed to remove pentavalent

The

arsenic. It will not convert trivalent arsenic to pentavalent

arsenic. The system was tested in a lab. Under those

conditions, the system reduced 0.30 mg/L (ppm)

pentavalent arsenic to 0.010 mg/L (ppm) (the USEPA

standard for drinking water) or less. The performance of

the system may be different at your installation. Have the

treated water tested for arsenic to check if the system is

working properly.

The RO component of the HP-RO-1000 system must be

replaced every 12-24 months to ensure the system will

continue to remove pentavalent arsenic. The component

component are listed in the installation/operation manual.

14 • HP-RO-1000 Undersink Reverse Osmosis System

Page 15

Performance Data

Important Notice: Read this performance data and compare

the capabilities of this system with your actual water treatment

needs. It is recommended that before installing a water

treatment system, you have your water supply tested to

determine your actual water treatment needs.

This system has been tested according to NSF/ANSI 58 for the

reduction of the substances listed below. The concentration

for the indicated substances in water entering the system

was reduced to a concentration less than or equal to the

NSF/ANSI 58.

NOTE: Substances that may be reduced are not

necessarily in your water. Filter must be maintained

according to manufacturer’s instructions, including

to the system that is available to the user as reverse osmosis

treated water under operating conditions that approximate

typical daily usage. The tested recovery rating is 27.40%.

to the membrane portion of the system that is available to the

user as reverse osmosis treated water when the system is

operated without a storage tank or when the storage tank is

bypassed.

HousePure HP-RO-1000

Maximum

Permissible

Substance

Standard 58

Arsenic V 0.050 mg/L ± 10% 0.010 mg/L 97.6%

Barium 10.0 mg/L ± 10% 2.0 mg/L 96.7%

Cadmium 0.03 mg/L ± 10% 0.005 mg/L 98.2%

Chromium III 0.3 mg/L ± 10% 0.1 mg/L 97.6%

Chromium VI 0.3 mg/L ± 10% 0.1 mg/L 97.0%

Copper 3.0 mg/L ± 10% 1.3 mg/L 98.8%

Cysts Minimum 50,000/mL 99.95% 99.99%

Fluoride 8.0 mg/L ± 10% 1.5 mg/L 96.2%

Lead 0.15 mg/L ± 10% 0.010 mg/L 99.0%

Radium

226/228

Selenium 0.10 mg/L ± 10% 0.05 mg/L 98.0%

Total Dissolved

Solids

Turbidity 11 mg/L ± 1 NTU 0.5 NTU 99.1%

Standard 42

Chlorine 2 mg/L >=50% 93.0%

Production Rate: 24.83 gpd

Concentration

27pCi/L ± 10% 5pCi/L 80%

750 mg/L ± 40 mg/L 187 mg/L 94.9%

The HP-RO-1000 is Tested and Certified by NSF International

against NSF/ANSI Standard 42 and 58 for the reduction of

substances listed in the table above.

Product Water

Concentration

Testing was performed under standard laboratory conditions,

actual performance may vary.

Reduction

Requirements

Average

Reduction

State of California

Department of Public Health

Water Treatment Device

Certicate Number

209711-

Date Issued: October 24, 2011

Trademark/Model Designation

HousePure HP-RO-1000

Manufacturer:

The water treatment device(s) listed on this certificate have met the testing requirements pursuant to Section

116830 of the Health and Safety Code for the following health related contaminants:

Microbiological Contaminants and Turbidity

Cysts

Turbidity

Organic Contaminants

None

Pentair Residential Filtration, LLC

Replacement Elements

PW-RO75R (RO Membrane)

PW-

S2500R (Pre Filters)

PW-C5000R (Pre Filters)

PW-C2500R (Post Filter)

Inorganic/Radiological Contaminants

Arsenic (pentavalent)

Barium

Cadmium

Chromium (hexalent)

Chromium (trivalent)

Copper

Fluoride

Lead

Radium 226/228

Selenium

1

Rated Service Capacity:

Do not use where water is microbiologically unsafe or with water of unknown quality, except that systems certied

for cyst reduction may be used on disinfected waters that may contain lterable cysts.

1

Claims for arsenic reduction shall only be made on water supplies maintaining detectable residual free chlorine at the

reverse osmosis (RO) system inlet. Water systems using an in-line chlorinator should provide a minimum of 1 minute

chlorine contact time before the RO system.

1250 gal service cycle

Conditions of Certification:

Rated Service Flow:

24.8 gpd

HP-RO-1000 Undersink Reverse Osmosis System • 15

Page 16

HP-RO-1000

Water, Inc. LIMITED WARRANTY

Water, Inc. warrants to the original owner (under normal use): Reverse Osmosis System to be free from defects in material and/or

workmanship one (1) year from the date of purchase. Any replacement products furnished will be free from defects in material and/or workmanship for the

remainder of the original warranty period. This warranty does not cover: (1) pre and post filter cartridges, or reverse osmosis membrane (2) defects not reported

within the above time period, (3) items manufactured by other companies, (4) problems arising from failure to comply with Water, Inc.

instructions, (5) problems and/or damage arising from acts of nature, abuse, misuse, negligence or accident by any party other than Water, Inc.,

(6) problems and/or damage resulting in whole or in part from alteration, modification, repair or attempted alteration, modification or repair by any party other

than Water, Inc., (7) noncompliance with applicable codes/ordinances.

If a defect in workmanship and/or material in a product or part covered by the warranty should arise, Water, Inc., at its sole discretion, will

repair or replace the defective product or part (Water, Inc. may consider, in good faith, the customer’s preference).

All claimed defective product must: (1) be authorized for return by Water, Inc. with an RGA number (2) include proof of the purchase date of

the product or part (3) returned to Water, Inc. prior to the expiration of the warranty date, at the customer’s expense, shipment pre-paid, (4) be

accompanied by a letter detailing the Model Number, Serial Number (if any), and a brief description of the problem.

TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, WATER, INC. DISCLAIMS ALL OTHER WARRANTIES, WHETHER

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, WITH

REGARD TO THE PRODUCTS, PARTS AND ANY ACCOMPANYING WRITTEN MATERIALS.

To the maximum extent permitted by applicable law, Water, Inc. shall not be liable for any damages whatsoever (including, but not limited

to, loss of time, inconvenience, expenses, labor or material charges incurred in connection with the removal or replacement of the system, special, incidental,

consequential, or indirect damages for personal injury, loss of business profits, business interruption, loss of business information, or any other pecuniary loss)

arising out of the use of or inability to use the defective products or parts, even if Water, Inc. has been advised of the possibility of such

damages.

Water, Inc. maximum liability under any provision of this Limited Warranty shall be limited to the amount actually paid for the system.

NOTE: Because some states do not allow the exclusion or limitation of incidental or consequential damages, the above limitations or exclusions may not apply.

THIS WARRANTY GRANTS SPECIFIC LEGAL RIGHTS, AND OTHER RIGHTS MAY APPLY. SUCH RIGHTS VARY FROM STATE TO STATE.

Buyer Seller Date

Water Inc

1044 E. Del Amo Blvd.

Carson, CA 90746

800.322.WATER(9283)

waterinc.com

©2014 Water, Inc. HP-RO-1000-Manual Rev. 2-14

Loading...

Loading...